Submitted:

29 October 2024

Posted:

30 October 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Method and Modelling

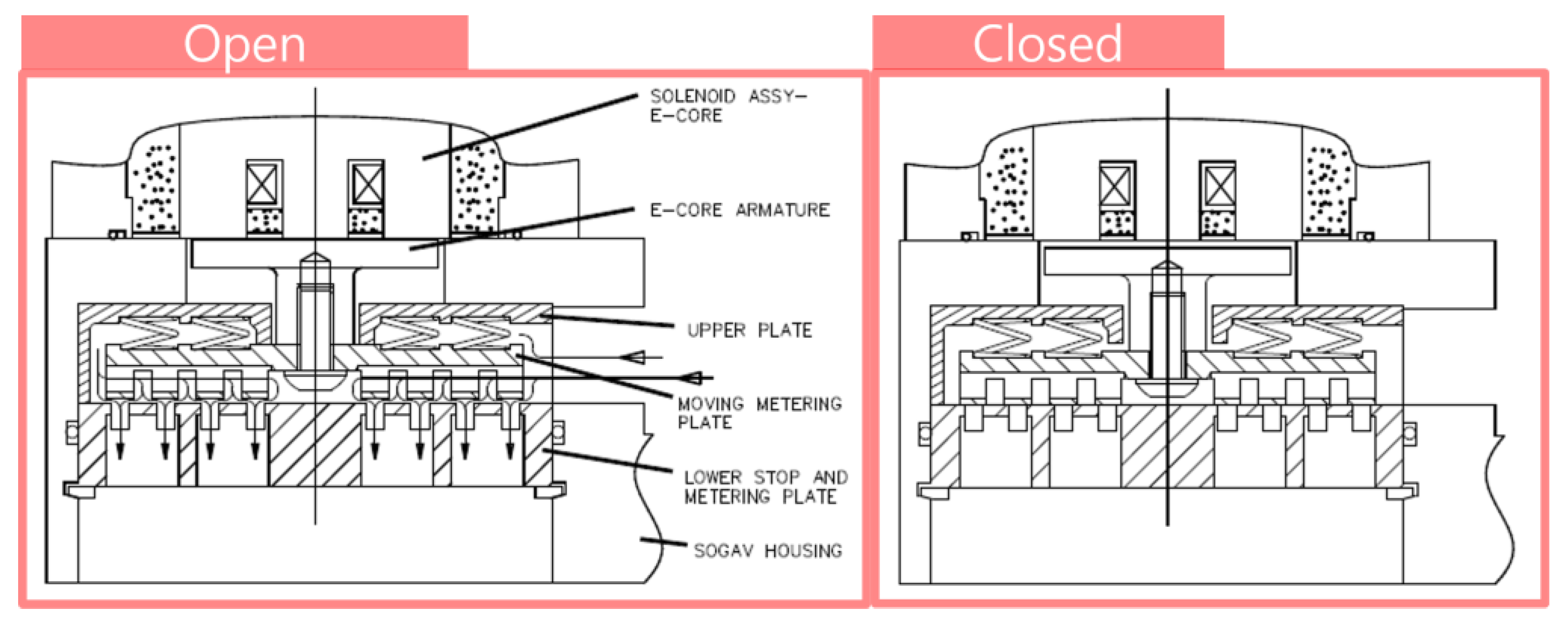

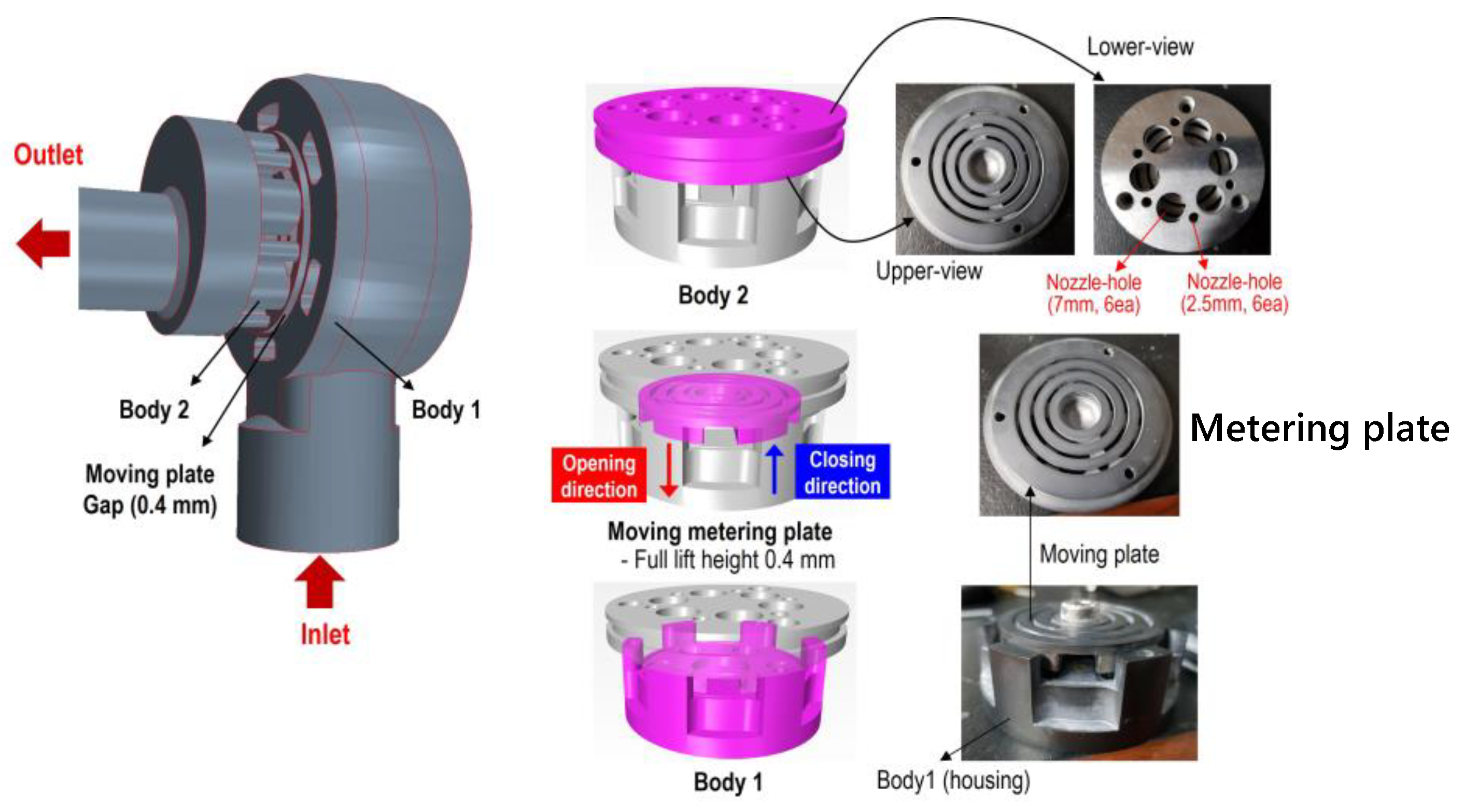

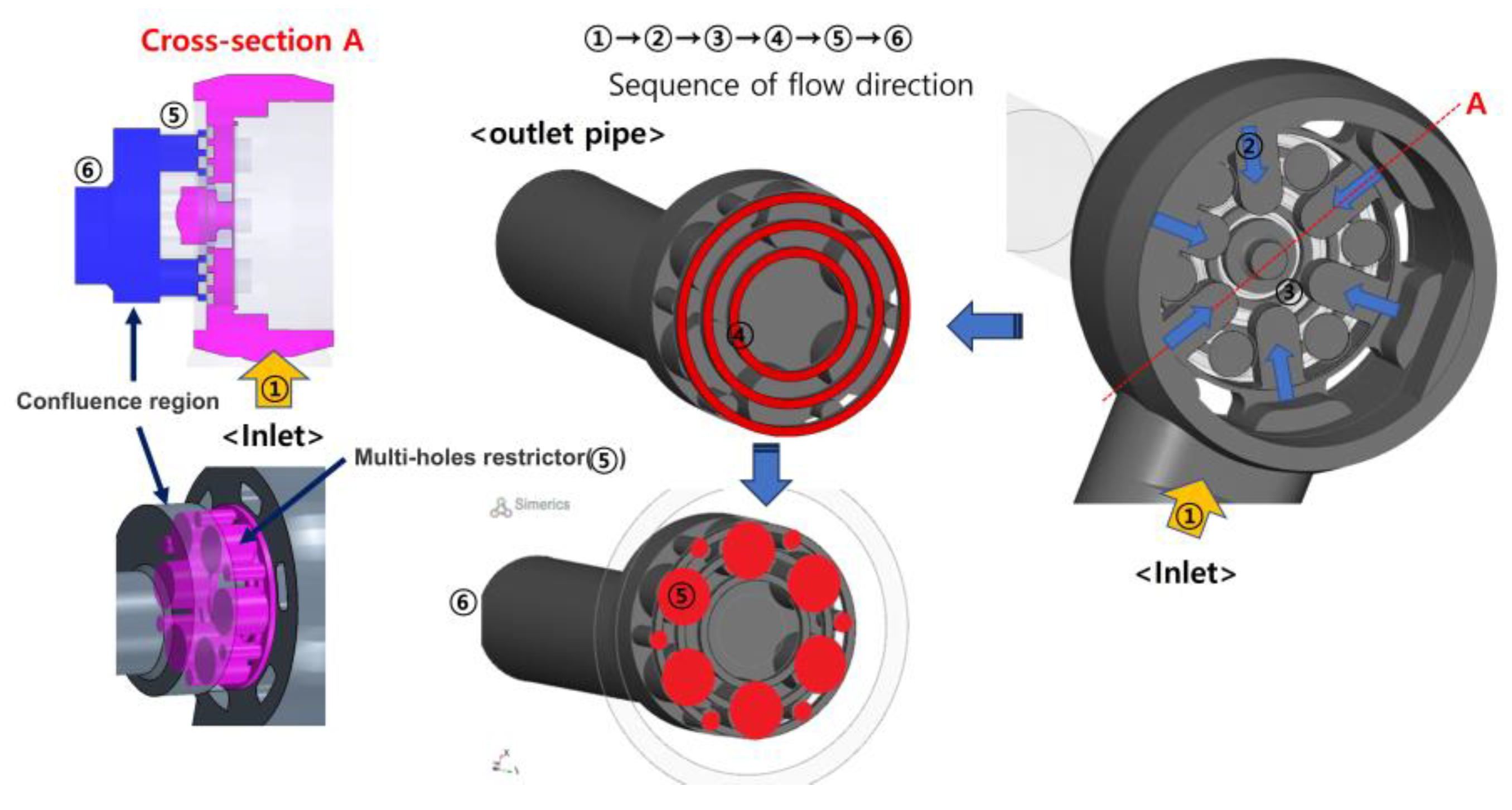

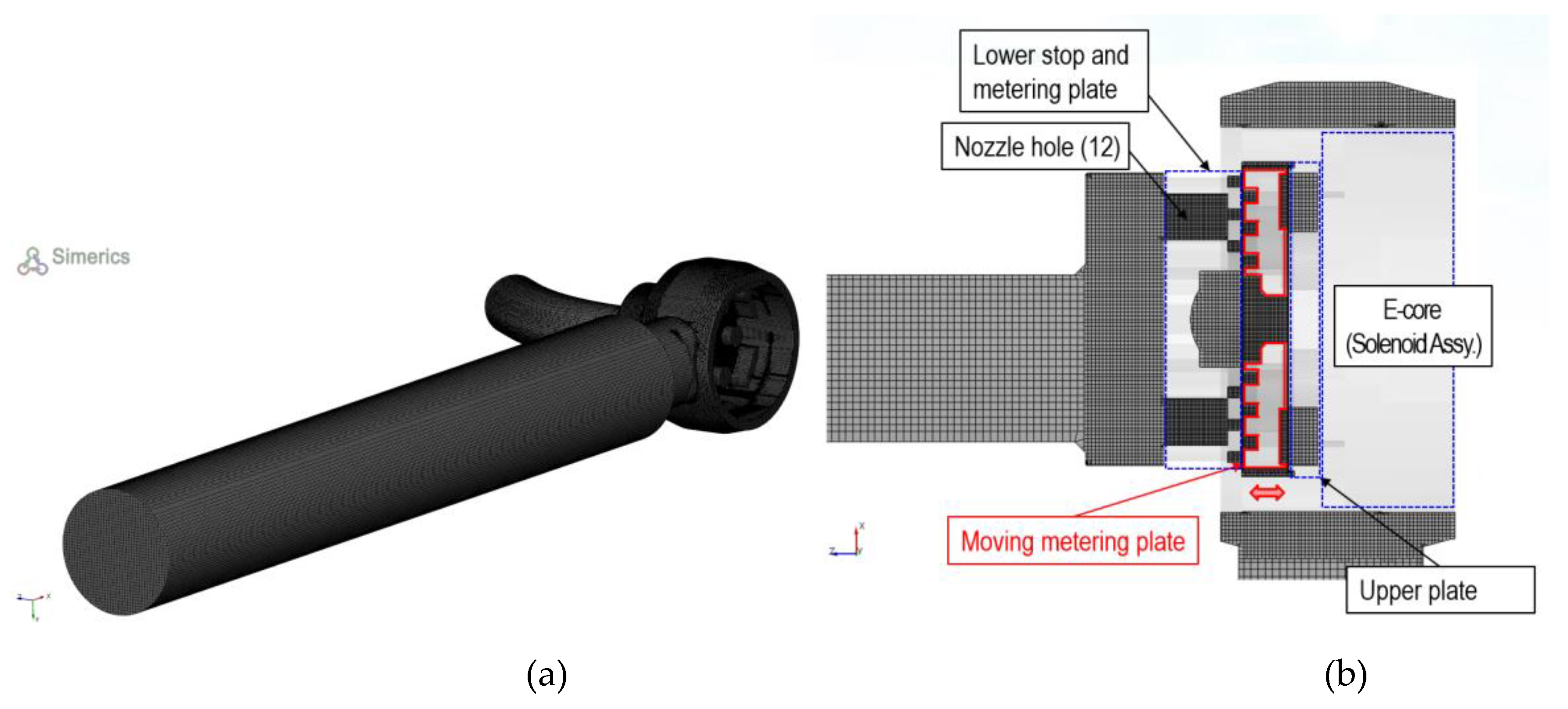

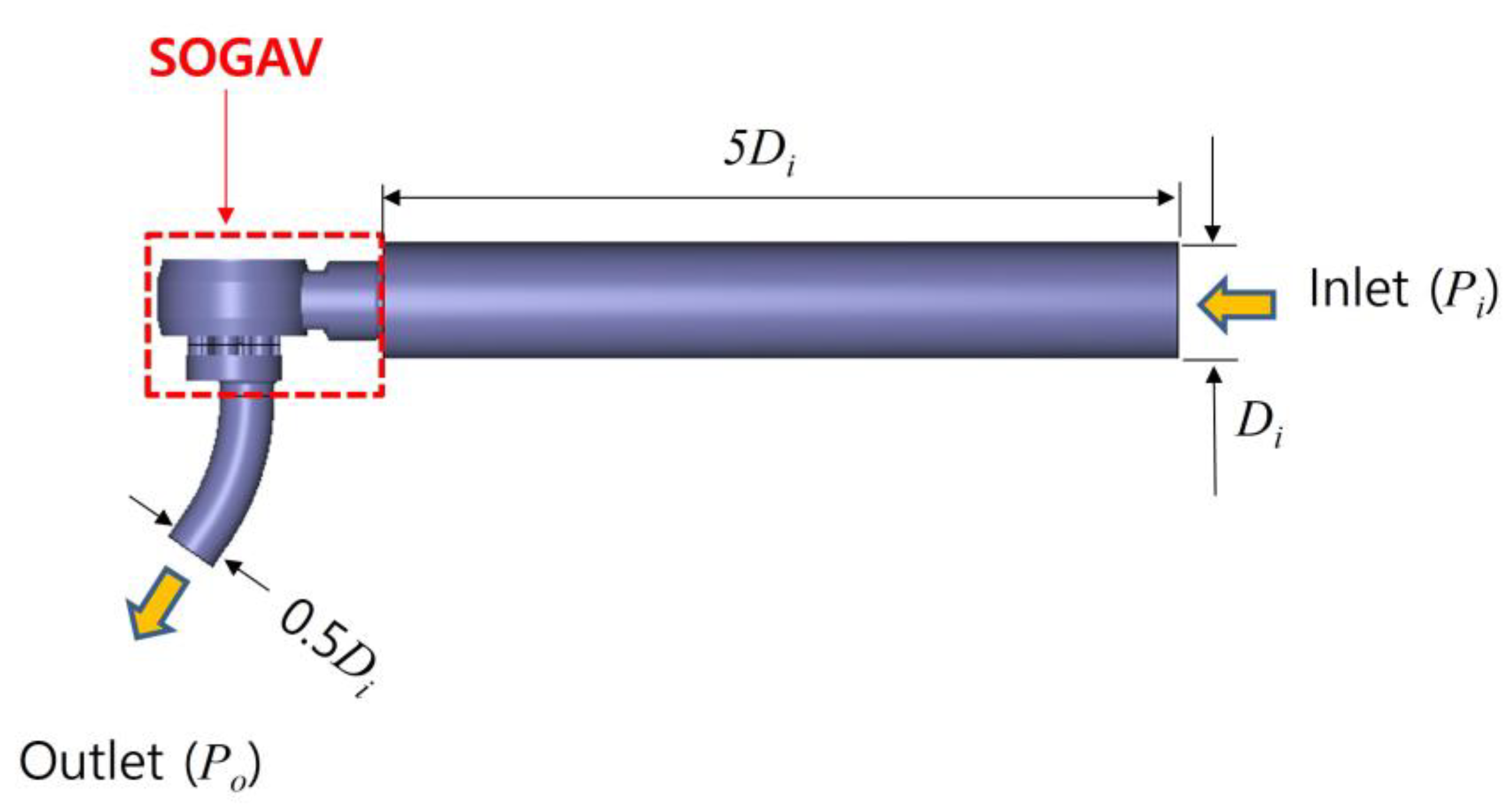

2.1. Physical Model

2.2. Mathematical Model

2.3. Dynamic Mesch Technique, Initial and Boundary Condition Setting

- -

- is the force exerted on node i by node j.

- -

- is the spring stiffness (inversely proportional to edge length)

- -

- and are displacements of nodes i and j

2.4. Solver Setting

3. Results and Discussion

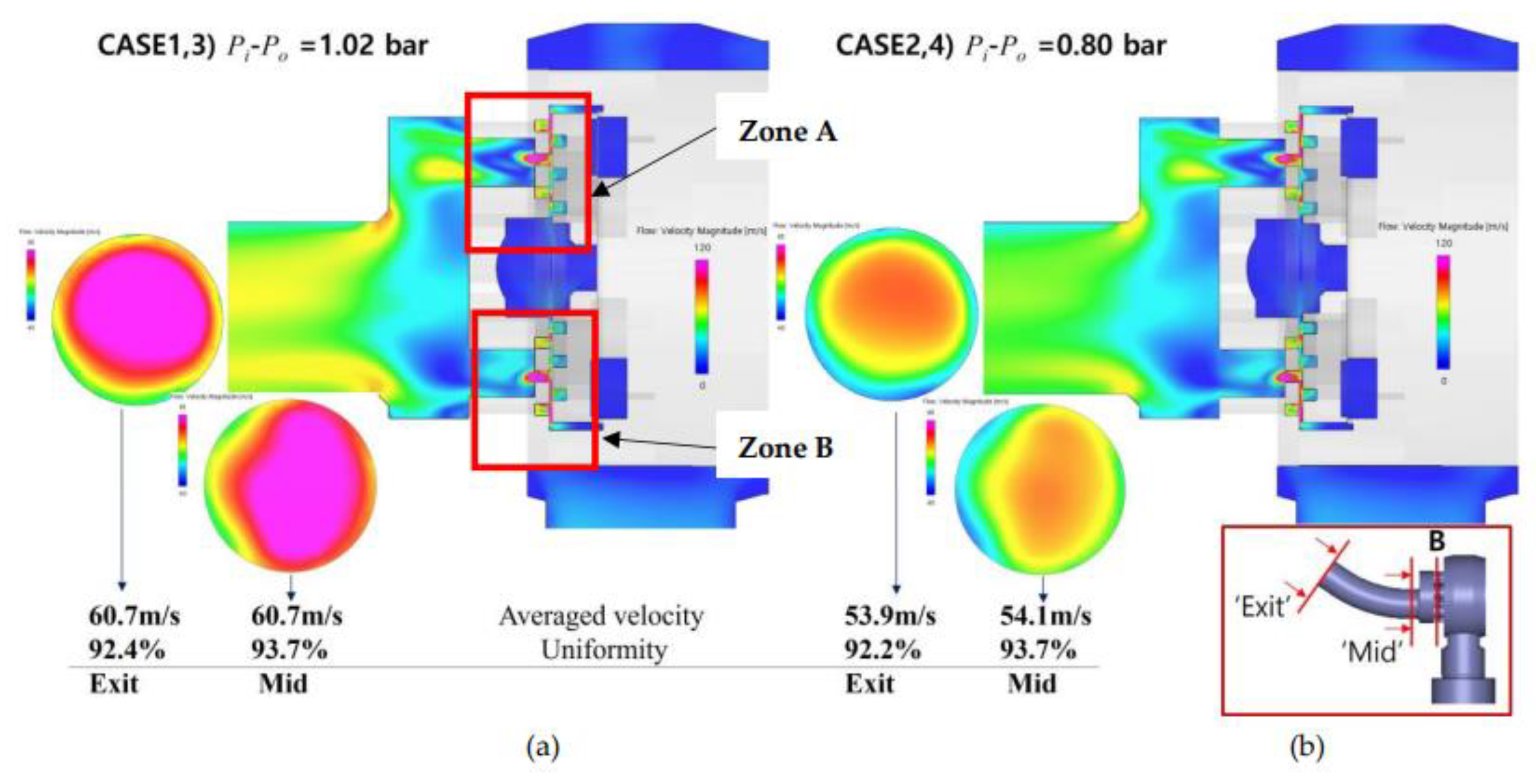

3.1. Effects of Different Pressure Differences Between the Inlet and Outlet on Staedy-State CFD Simulation Results

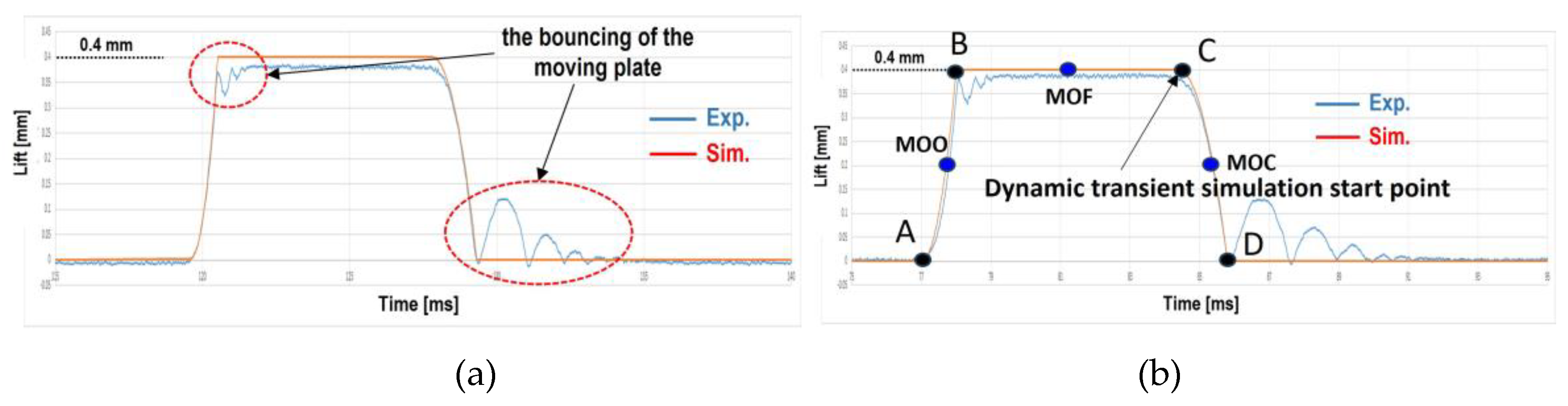

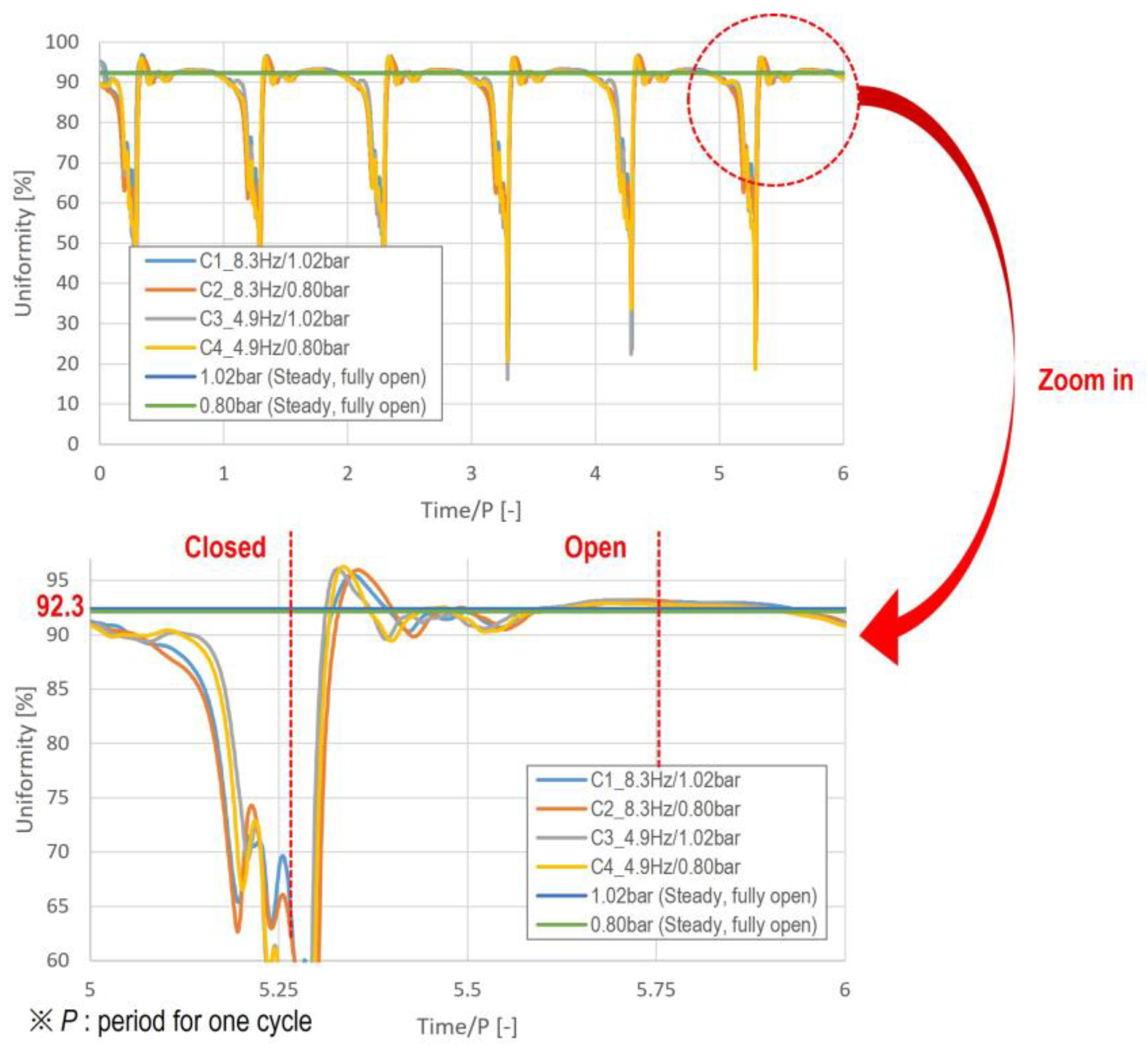

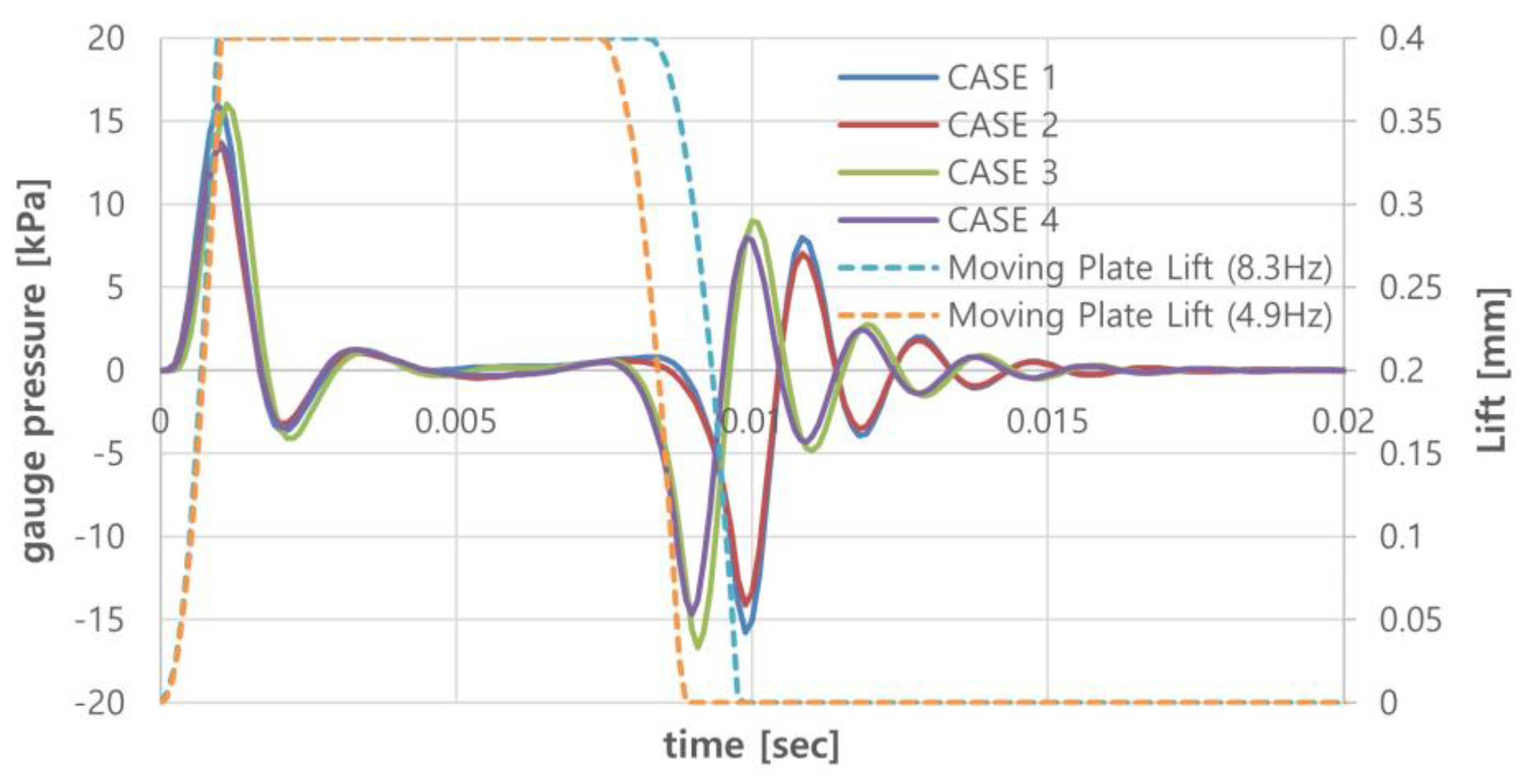

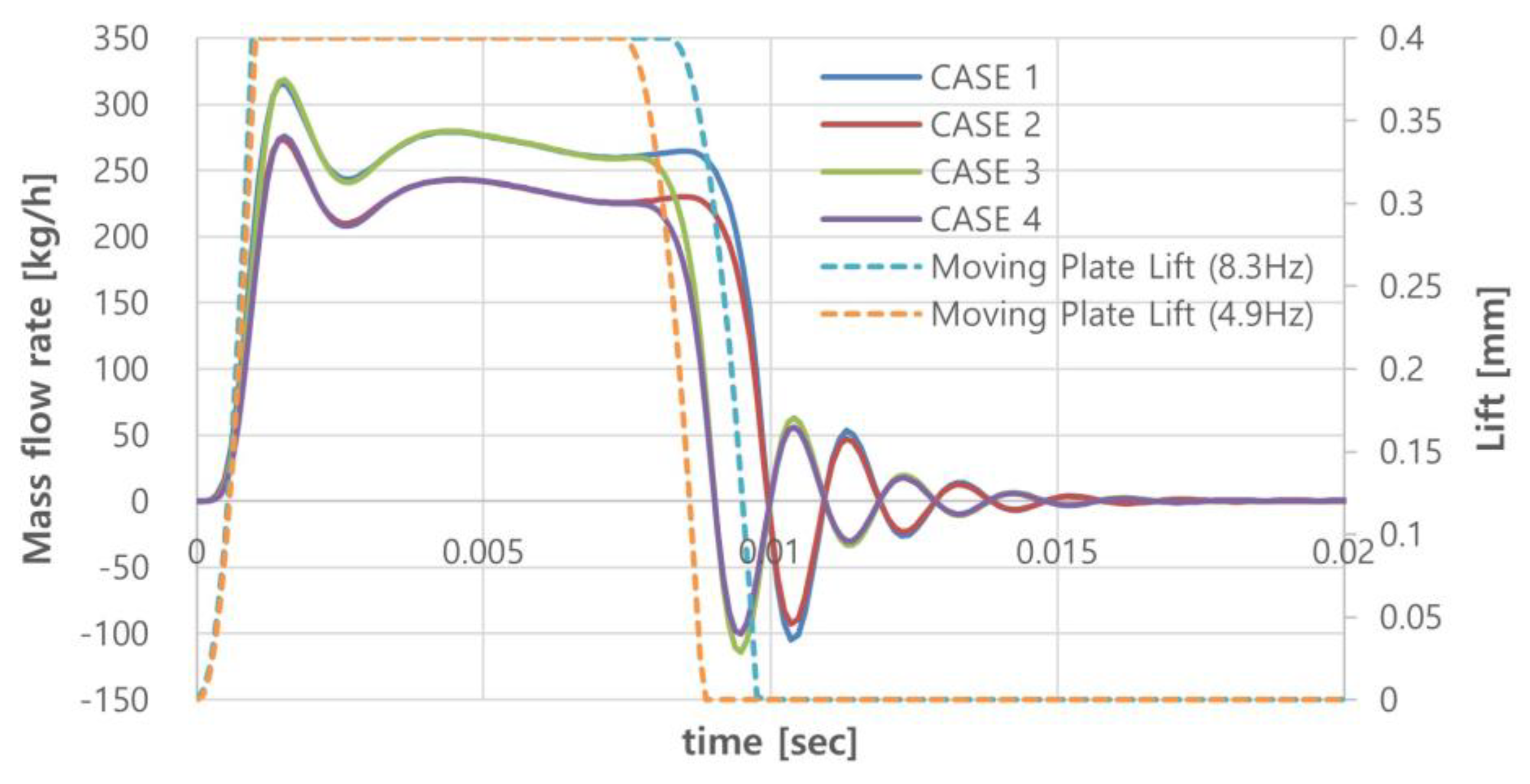

3.2. Dynamic Transient Flow Characteristics of a SOGAV Under Various Operating Conditions

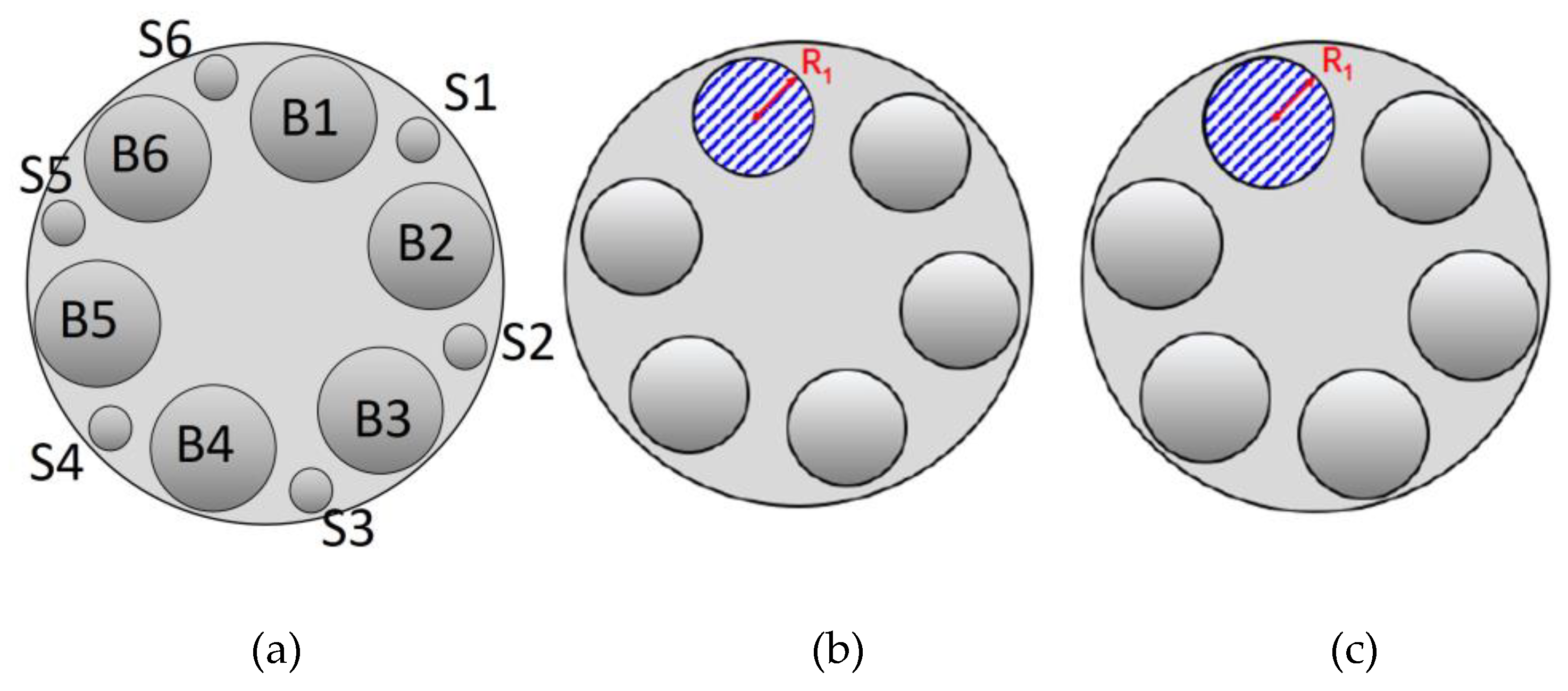

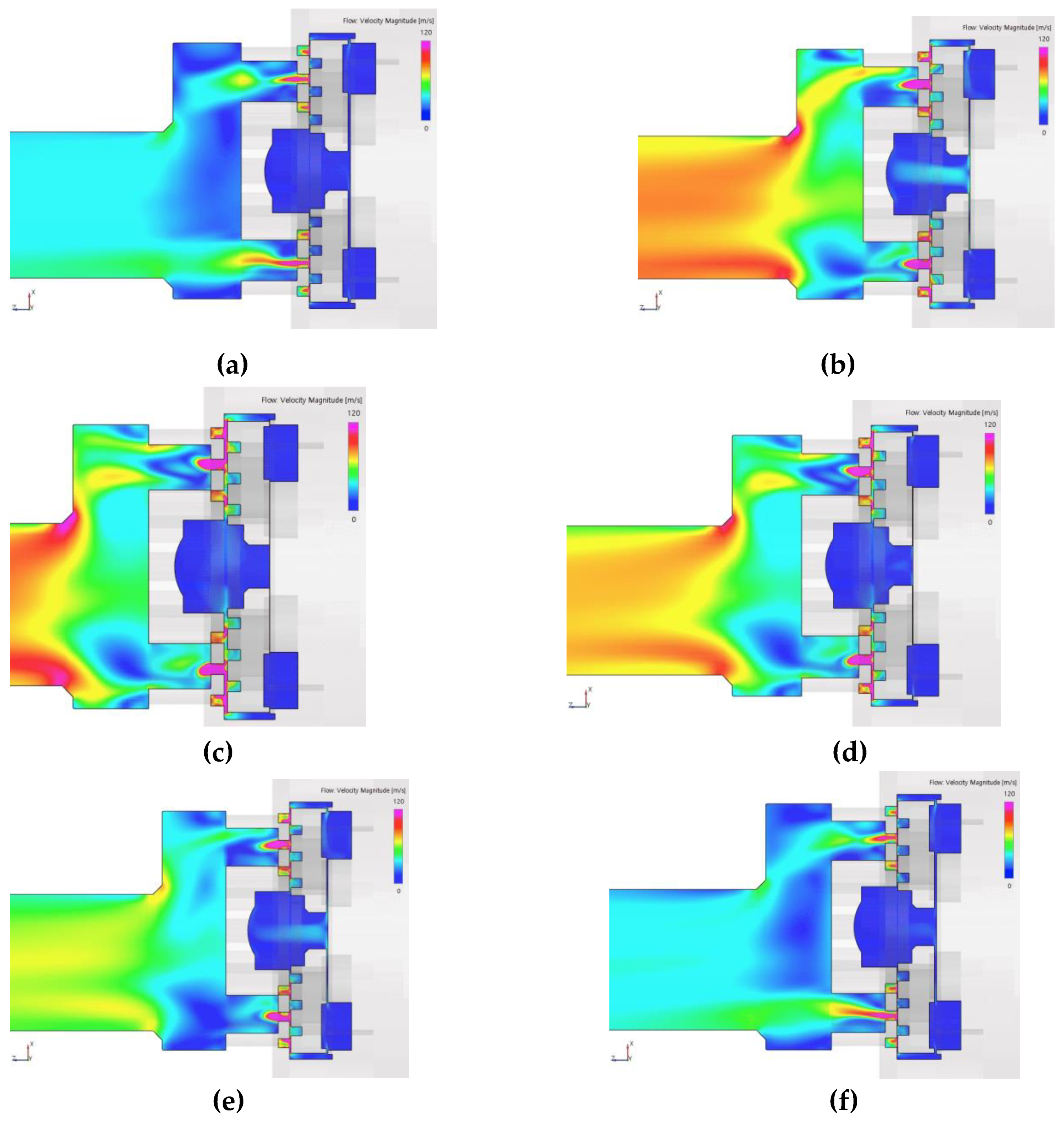

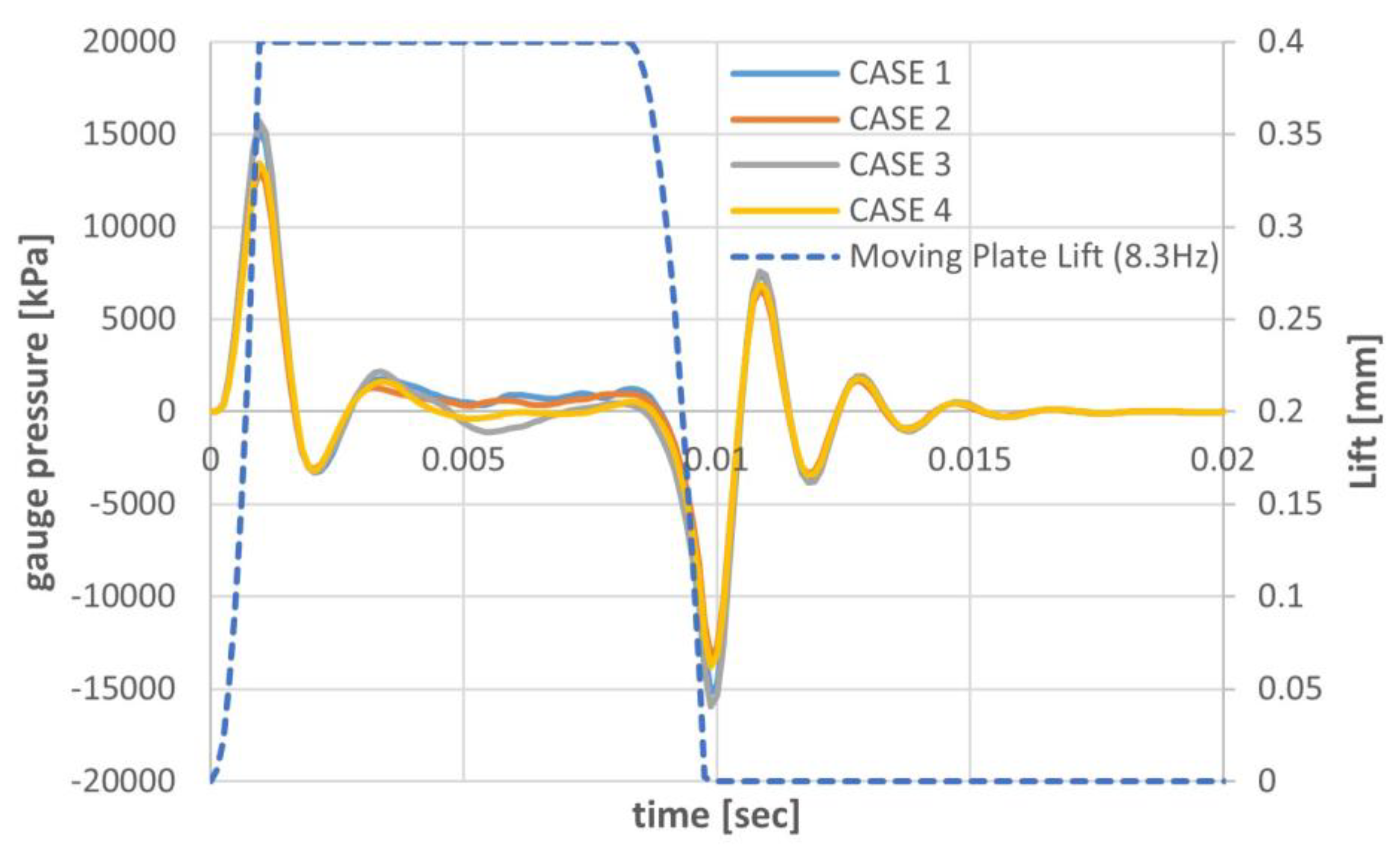

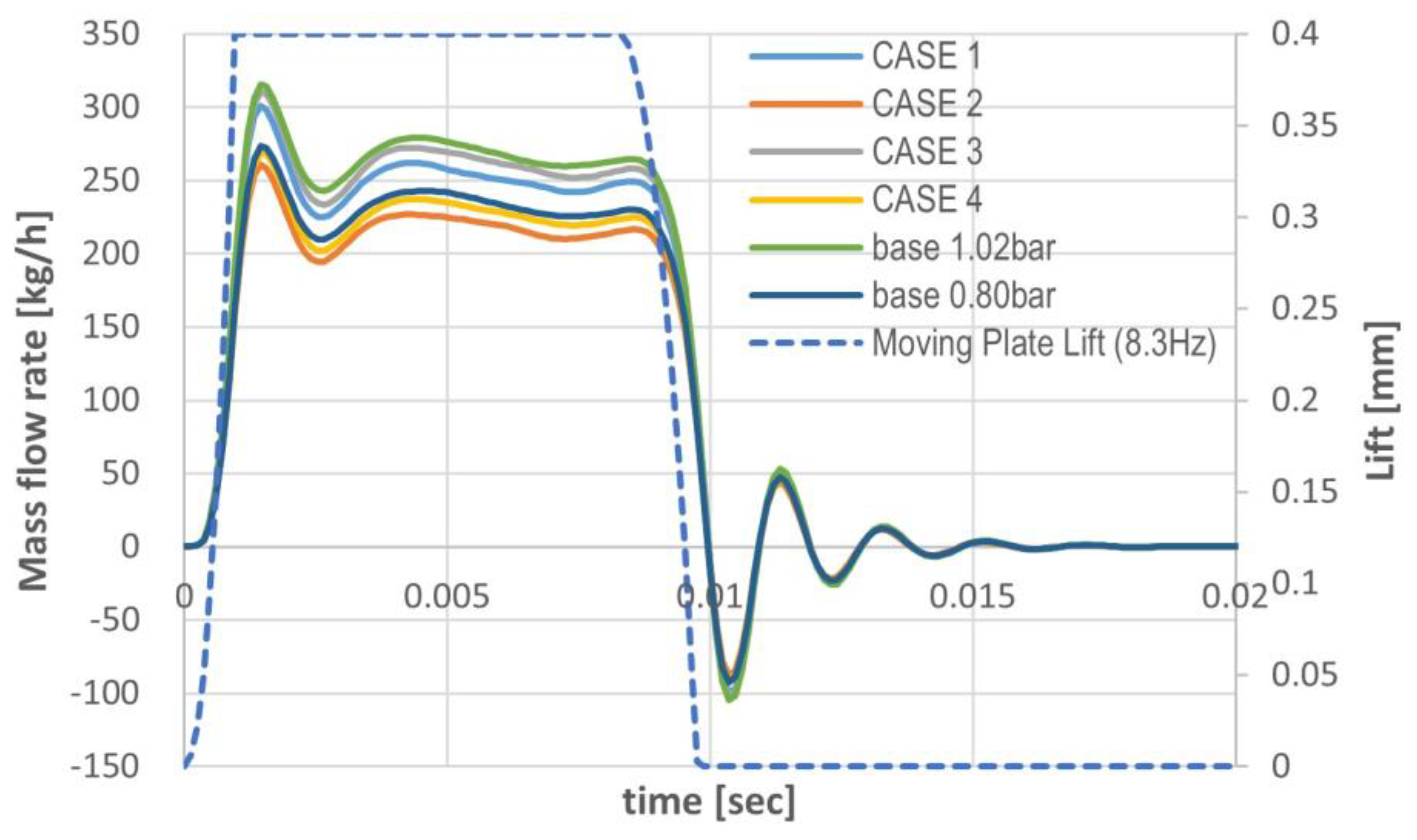

3.3. Dynamic Transient CFD Simulation for the Shape Optimization of a Moving Plate

4. Conclusions

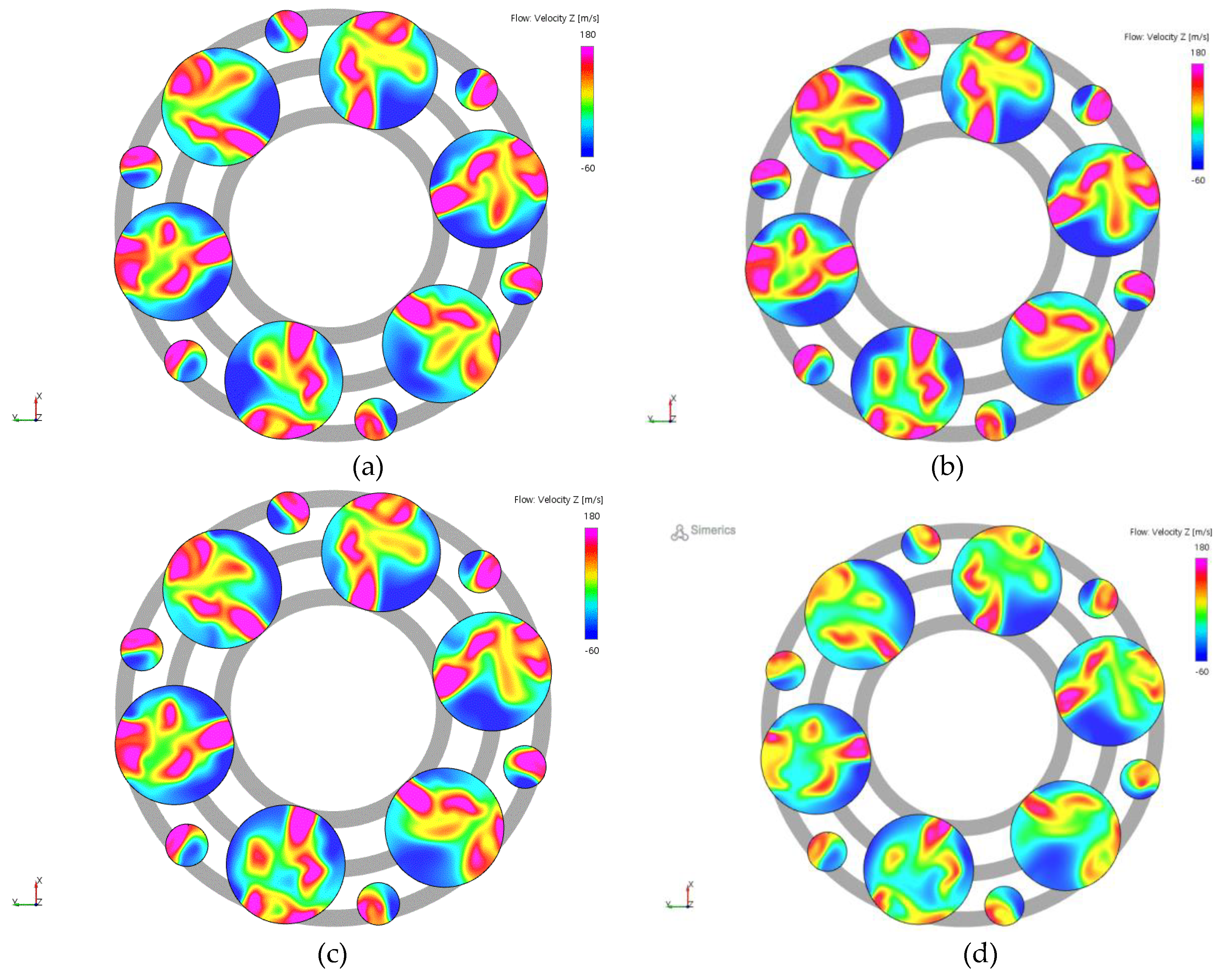

- This study demonstrated that orifice configurations with different-sized holes promote more uniform flow distribution and help reduce fluid velocity, thereby minimizing flow resistance. This geometry also disrupts large coherent turbulent structures, which are known sources of aerodynamic noise and flow inefficiencies.

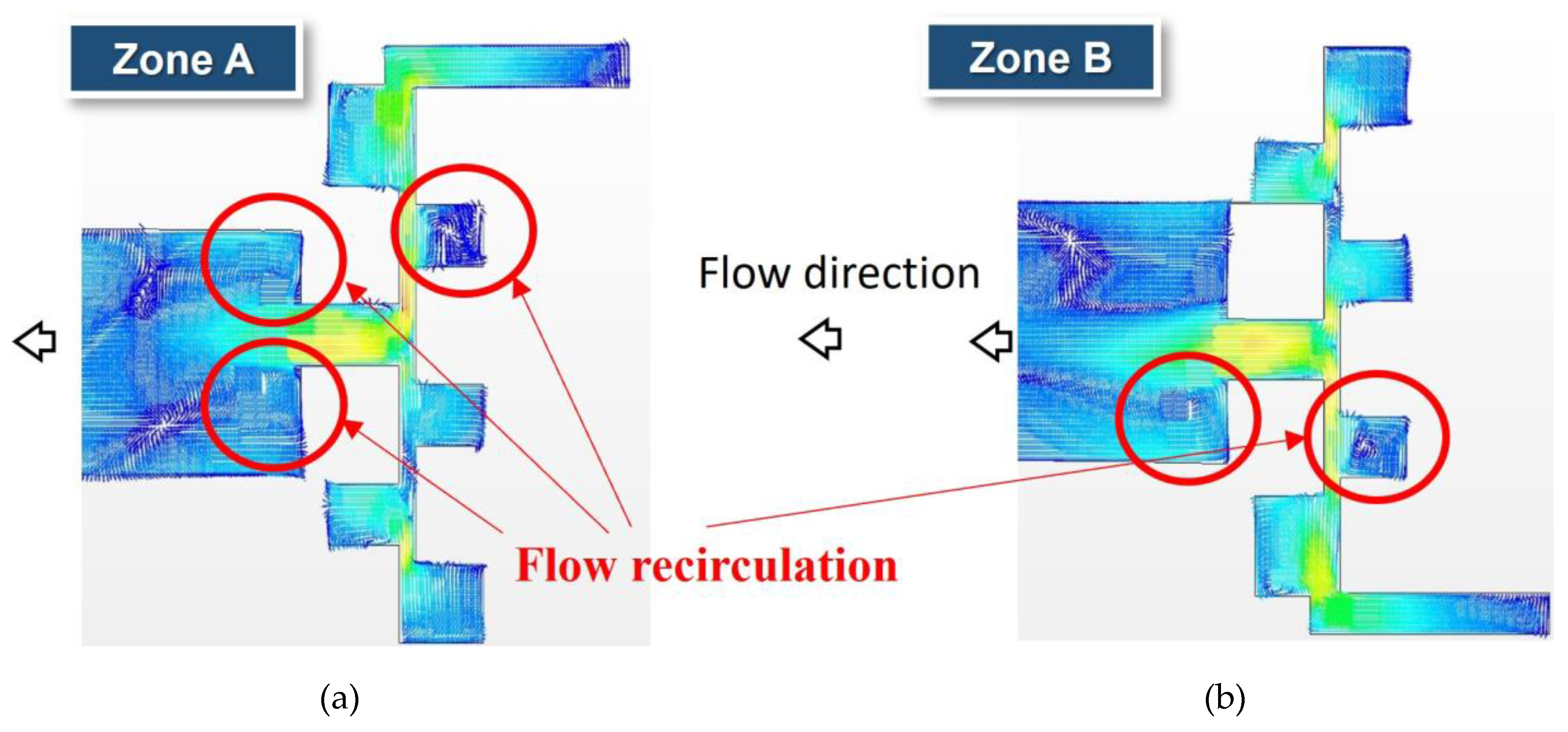

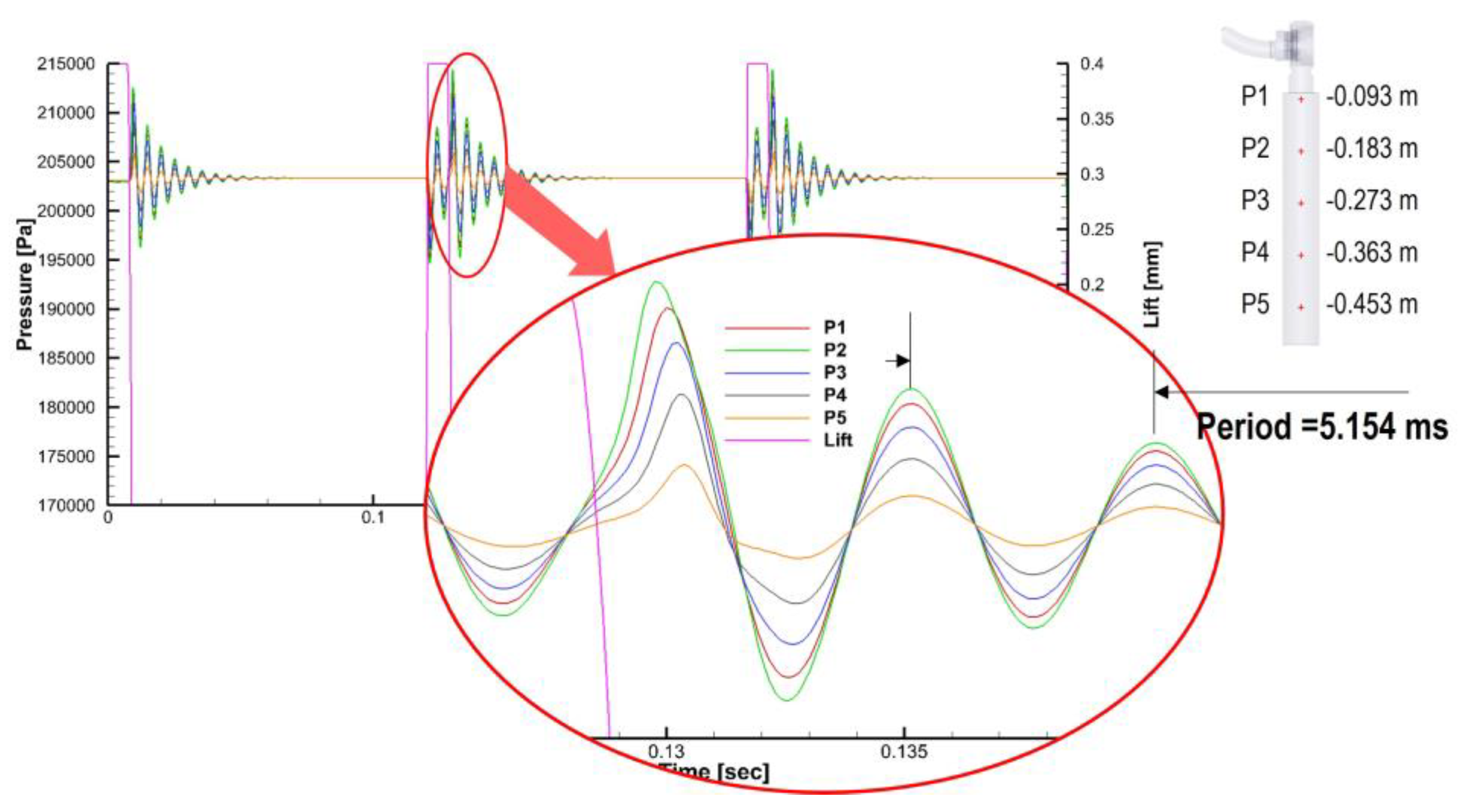

- The transient analysis of this study revealed that rapid motion of the moving plate induces significant inertial effects, leading to pressure wave generation and backflow patterns. Such dynamic behaviors are difficult to capture using steady-state analysis alone, underscoring the importance of employing dynamic simulations to model real-world valve operations accurately.

- It was confirmed that standing wave patterns form within the intake pipe due to the constructive and destructive interference of incident and reflected waves. The alignment of simulation results with the theoretical predictions for standing waves validated the accuracy of the CFD model.

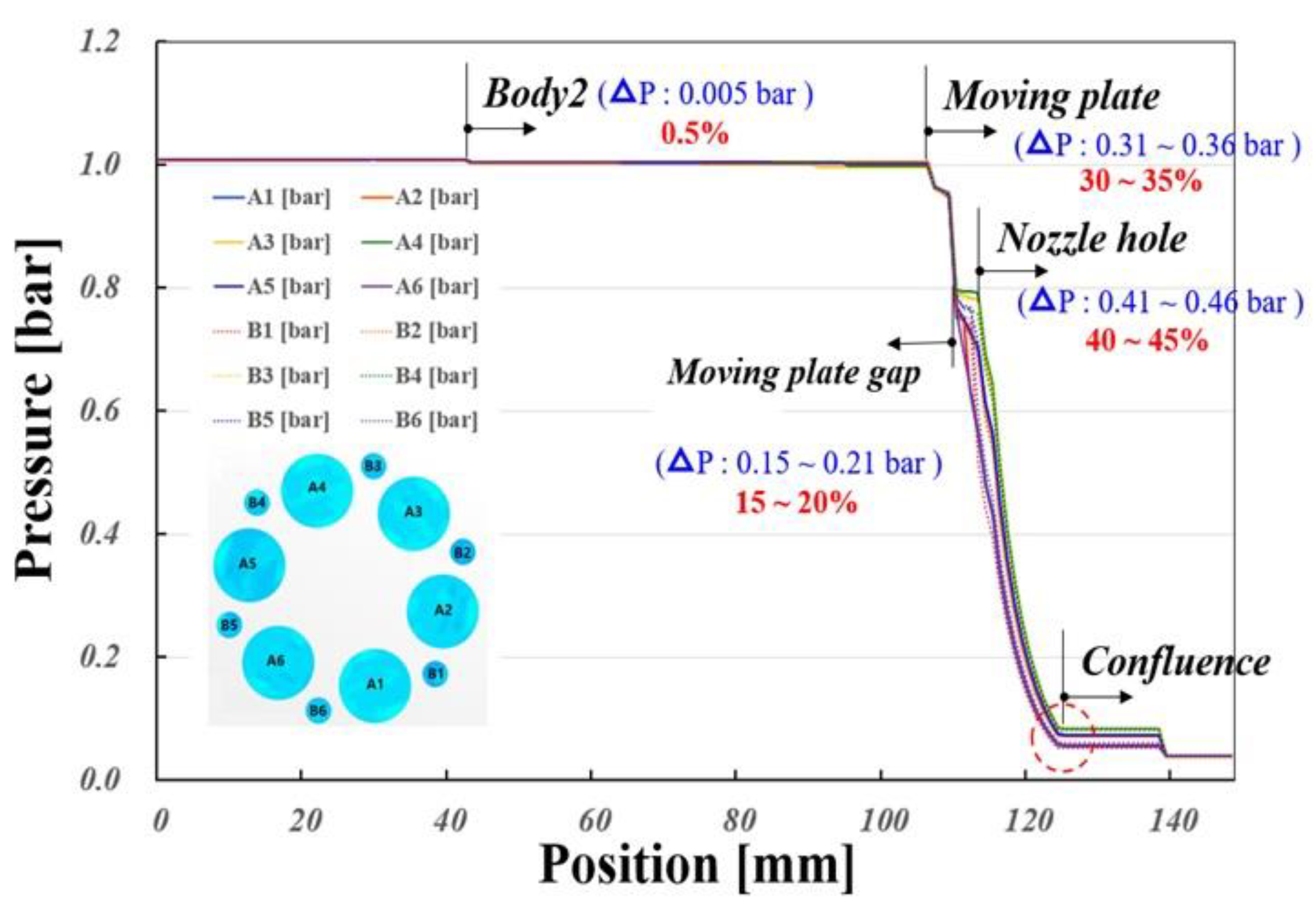

- This study explored the effect of varying pressure differentials and valve lift profiles on mass flow rate and pressure wave patterns. It was observed that orifice geometries with reduced cross-sectional areas exhibited lower mass flow rates, highlighting the importance of geometric optimization for performance enhancement.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Peurala, J. Model-based Design, Modelling and Simulation of Digital Hydraulic Gas Admission Valve. Master of Science Thesis, Tampere University of Technology, Finland, 6 March 2014. [Google Scholar]

- Woodward's Innovative SOGAV Gas Admission Valve for Marine Engines Awarded IGF Code Compliance. Available online: https://www.marinebusinessworld.com/news/258925/SOGAV-gas-valve-awarded-IGF-Code-compliance (accessed on 3 October 3, 2024).

- Woodward’s Gas Admission Valve for Marine Engines Awarded IGF Code. Compliance. Available online: https://www.powertransmission.com/articles/9113-woodwards-gas-admission-valve-for-marine-engines-awarded-igf-code-compliance (accessed on 1 February 2024).

- Gas Admission Valve for Large Engines. Available online: https://www.bosch-mobility.com/en/solutions/valves/gas-injector-valve/ (accessed on 3 October 3, 2024).

- Christiner, P.; Gasselsdorfer, C.; Schmitzberger, M. Development of gas valves for multi-point admission. MTZ Industrial 2017, 7, 27–35. [Google Scholar] [CrossRef]

- SOGAV™ 43 and SOGAV 105. Available online: https://www.pmcontrol.com/attachments/PMControl/products/46/SOGAV%2043%20&%20105.pdf (accessed on 31 July 2024).

- R. Amirante; P.G. Moscatelli; L.A. Catalano, Evaluation of the flow forces on a direct (single stage) proportional valve by means of a computational fluid dynamic analysis. Conversion and Management 2007, 48, 942–953. [Google Scholar] [CrossRef]

- Wu, G.; Li, S.; Wu, P. CFD Simulation of Flow-Pressure Characteristics of a Pressure Control Valve for Automotive Fuel Supply System. Energy Conversion and Management 2015, 48, 658–665. [Google Scholar] [CrossRef]

- Kang, H-L. ; Park, H.-J.; Han, S-H. Investigation of the Flow Characteristics for Cylinder-in-Ball Valve Due to a Change in the Opening Rate. Appl. Sci. 2022, 12, 8930–8941. [Google Scholar] [CrossRef]

- Srikanth, C.; Bhasker, C. Flow Analysis in Valve with Moving Grids through CFD Techniques. Advances in Engineering Software 2009, 40, 193–201. [Google Scholar] [CrossRef]

- Li, S.; Wu, P.; Cao, L.; Wua, D.; She, Y. CFD Simulation of Dynamic Characteristics of a Solenoid Valve for Exhaust Gas Turbocharger System. Applied Thermal Engineering 2017, 213–222. [Google Scholar] [CrossRef]

- Qian, J.-y.; Wei, L.; Jin, Z.-j.; Wang, J.-k.; Zhang, H.; Lu, A-l. CFD Analysis on the Dynamic Flow Characteristics of the Pilot-Control Globe Valve. Energy Conversion and Management 2014, 87, 220–226. [Google Scholar] [CrossRef]

- Zhang, P.; Tao, Y.; Yang, C.; Ma, W.; Zhang, Z. Transient Characteristics Simulation and Flow-Field Analysis of High-Pressure Pneumatic Pilot-Driven On/Off Valve via CFD Method. Flow Measurement and Instrumentation 2024, 97, 102620–102637. [Google Scholar] [CrossRef]

- Shu, Z.; Liang, W.; Qin, B.; Lei, G.; Wang, T.; Huang, L.; Che, B.; Zheng, X.; Qian, H. Transient Flow Dynamics Behaviors During Quick Shut-Off of Ball Valves in Liquid Hydrogen Pipelines and Storage Systems. Journal of Energy Storage 2023, 73, 109049. [Google Scholar] [CrossRef]

- Hou, J.; Li, S.; Pan, W.; Yang, L. Co-Simulation Modeling and Multi-Objective Optimization of Dynamic Characteristics of Flow Balancing Valve. Machines 2023, 11, 337–351. [Google Scholar] [CrossRef]

- Jeong, S.-J.; Kang, J.-h.; Moon, S.-J.; Lee, G.-s. Transient and Dynamic Simulation of the Fluid Flow through Five-Way Electric Coolant Control Valve of a 100 kW Fuel Cell Vehicle by CFD with Moving Grid Technique. Actuators 2024, 13, 110–131. [Google Scholar] [CrossRef]

- Simerics-MP+, Simerics, ver. 5.2.15. Available online: https://www.simerics.com (accessed on 3 February 2024).

- Zhao, L.; Chang, Z.; Mai, C.; Ran, H.; Jiang, J. Experimental and numerical investigation on dynamic characteristic of.

- nozzle check valve and fluid-valve transient interaction. Nuclear Engineering and Design 2024, 416, 112737–112751. [CrossRef]

- Kim, N.-S.; Jeong, Y.-H. An investigation of pressure build-up effects due to check valve’s closing characteristics using dynamic mesh techniques of CFD. Annals of Nuclear Energy 2021, 107996–108007. [Google Scholar] [CrossRef]

- Sami, N.A.; Turzo, Z. Computational Fluid Dynamic (CFD) Simulation of Pilot Operated Intermittent Gas Lift Valve. Petroleum Research 2020, 5, 254–264. [Google Scholar] [CrossRef]

- Koutsourakis, N.; John, G. B.; Markatos, N.C. Evaluation of Reynolds stress, k-ε and RNG k-ε turbulence models in street canyon flows using various experimental datasets. Environmental Fluid Mechanics 2012, 12, 379–403. [Google Scholar] [CrossRef]

- Perini, F.; Zha, K.; Busch, S.; Reitz, R. Comparison of Linear, Non-Linear and Generalized RNG-Based k-epsilon Models for Turbulent Diesel Engine Flows; SAE Technical Paper 2017-01-0561; SAE International: Warrendale, PA, USA, 2017. [Google Scholar]

- Versteeg, H.K.; Malalasekera, W. An Introduction to Computational Fluid Dynamics, 2nd ed.; Citeseer: Harlow, UK, 2007; pp. 77–176. [Google Scholar]

- Chen, C.-J.; Jaw, S.-Y. Fundamentals of Turbulence Modeling; Taylor & Francis: New York, NY, USA, 1998; ISBN 1-56032-405-8. [Google Scholar]

- Yakhot, V.; Orszag, S.A.; Thangam, S.; Gatski, T.B.; Speziale, C.G. Development of turbulence models for shear flows by a double expansion technique. Phys. Fluids A 1992, 4, 1510–1520. [Google Scholar] [CrossRef]

- Chen, C.-J.; Jaw, S.-Y. Fundamentals of Turbulence Modeling; Taylor & Francis: New York, NY, USA, 1998; ISBN 1-56032-405-8. [Google Scholar]

- Davidson, L. Fluid Mechanics, Turbulent Flow and Turbulence Modeling; Chalmers University of Technology: Goteborg, Sweden, 2024. [Google Scholar]

- Yin, F.; Zhang, Y.; Nie, S.; Ji, H.; Ma, Z. A system-level CFD simulation model for investigating the energy dissipation mechanism of seawater pump and rotary energy recovery device in SWRO desalination system 2024, 587, 117947–117964.

- Samii, D.R.; Hashemabadi, S.H.; Margan, P. CFD based design gas rotameters: Dynamic mesh transient simulation. Flow Measurement and Instrumentation 2024, 95, 102513–102522. [Google Scholar] [CrossRef]

- Schmidt, J.; Stoevesandt, B. Dynamic mesh optimization based on the spring analogy. In Proceedings of the ITM Web of Conferences, 2, 2014. [CrossRef]

- Lin, T.J.; Guan, Z.Q.; Chang, J.H.; Lo, S.H. Vertex-Ball Spring Smoothing: An efficient method for unstructured dynamic hybrid meshes. Computers and Structures 2014, 136, 24–33. [Google Scholar] [CrossRef]

- Karlsso, J. Implementing Anisotropic Adaptive Mesh Refinement in OpenFOAM. Mater’s Thesis, Chalmers university of technology, Göteborg, Sweden, December, 2012.

| Parameter | Case 1 | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|

| Frequency [Hz] | 8.3 | 8.3 | 4.9 | 4.9 |

| Pi – P0 [bar] | 1.02 | 0.8 | 1.02 | 0.8 |

| Title 1 | Case 1 | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|

| Pi-Po (Bar) | 1.02 | 0.8 | 1.02 | 0.8 |

| Radius of hole(mm) | 7(6*)+2.5(6*) | 7(6*) | 7.4(6*) | 7.4(6*) |

| Operating Frequency (Hz) |

8.3 | |||

| Model name | Option | |

|---|---|---|

| Turbulence model | RNG k-ε | |

| Discretization for Convective terms | Upwind scheme | |

| Time integration method | Implicit | |

| Time Discretization method | Upwind Scheme | |

| Working Fluid Properties | Name | CH4 |

| Density(25℃) | the ideal-gas state equation | |

| Viscosity(25℃) | 11.23×106(Pa∙sec) | |

| Dynamic Mesh | Remeshing Smoothing |

a CAB algorithm a spring-based algorithm |

| Boundary conditions | Inlet | Constant Pressure |

| Outlet | Constant Pressure | |

| Wall | No-slip, Wall function | |

| Timestep size | 1,000 step/cycle | |

| Convergence Criteria | 10-6 | |

| Total number of computational volumes | 2,378,698 | |

| Computing number of cycles | 6 | |

| Computing Resources | 12 cores intel i7-8700/3.2 GHz | |

| Computing time/case | 96.6 hrs | |

| Time averaged | Case 1 | Case 2 | Case 3 | Case 4 | |

|---|---|---|---|---|---|

| Velocity(m/s) | 52.93 | 45.58 | 50.52 | 43.39 | |

| Uniformity (%) | 88.18 | 87.62 | 88.26 | 87.71 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).