Submitted:

26 October 2024

Posted:

28 October 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

- the drafting of an explanatory and operational reference contribution, in the absence of cognitive and instrumental supports (within the international scientific and academic literature) capable of exposing the typological, functional and constructive configuration of the systems under examination on the basis of the investigation around the experimental applications towards new buildings;

- the use of the executive re-elaboration of the systems as a technical tool for understanding and knowledge of the functional modes and sustainable procedures;

- the drafting of a technical guide to understanding the construction and functional modes, focusing the analysis on the design and construction aspects;

- the definition of the main functional typologies, established on the basis of the analysis conducted on the experimental case studies, with the aim of achieving at a categorization of the performance and executive potentialities;

- the possibilities of technology transfer towards common construction, with the aim of increasing environmental and energy sustainability also through applications on the external perimeter enclosures of the existing buildings;

2. Materials and Methods

2.1. Scientific Framework: Environmental Constitution of the Multi-Layer Façade Systems

- the criteria aimed at realizing built spaces in a stable and balanced manner, with the possibility of transmitting, modifying or rejecting the climatic stresses;

- the development of an interchange tool for the ability to respond to the external loads through the different functional levels and the use of means of regulation to manipulate the interactions with the environment (Figure 2).

2.2. Scientific Analysis: Functional Constitution of the Multi-Layer Façade Systems

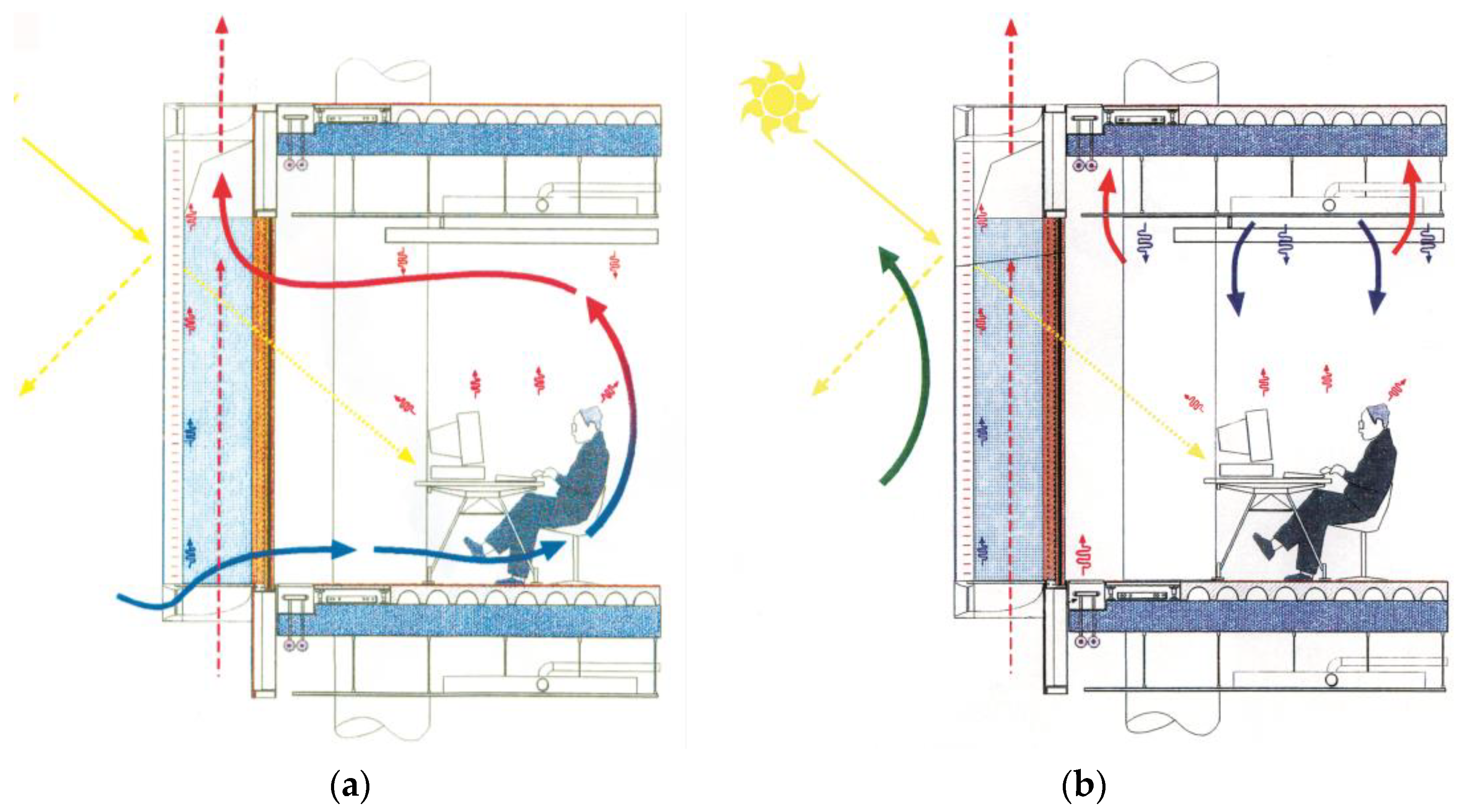

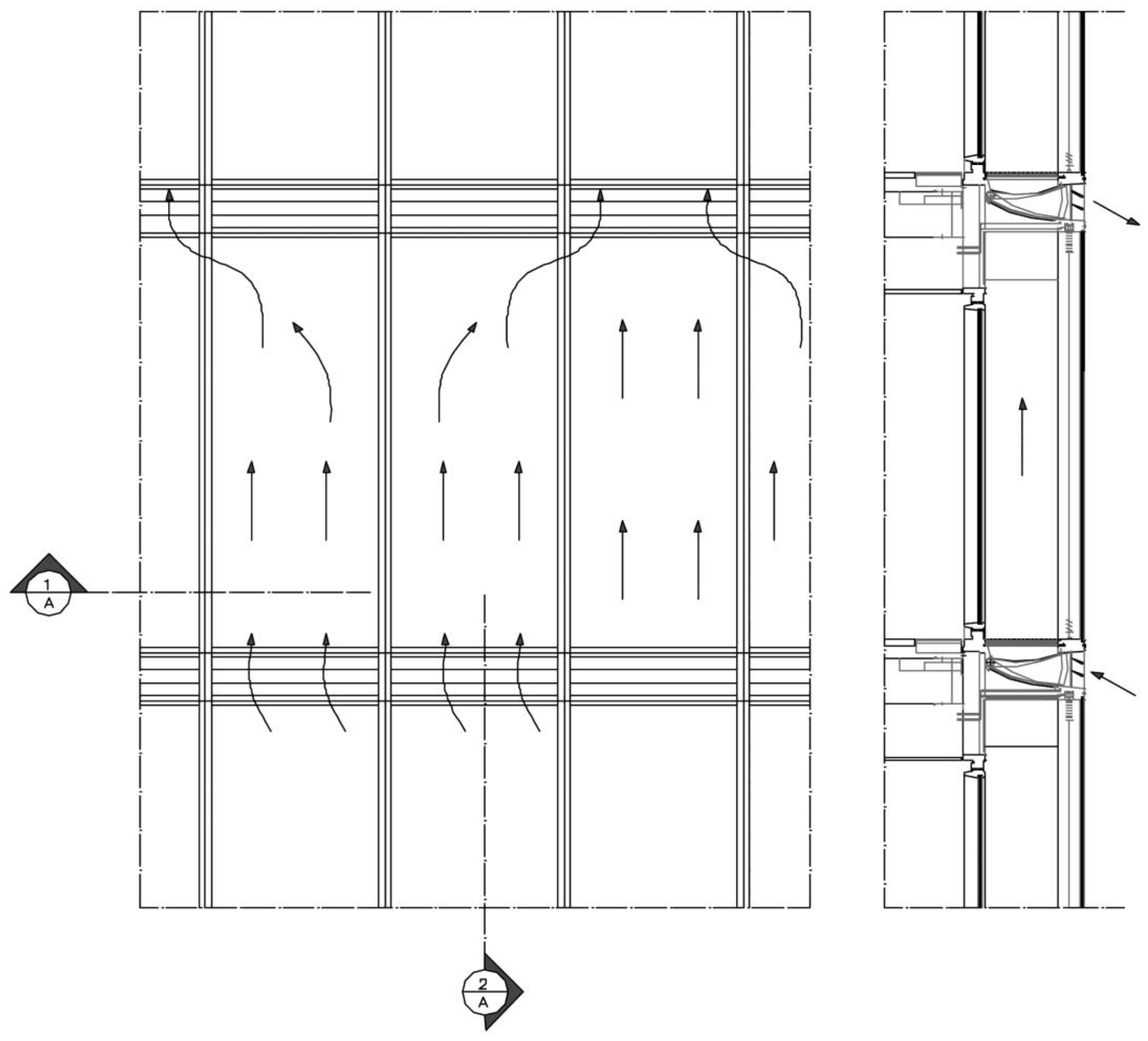

- during the summer season, by the day, the vertical passive ventilation conducts upwards the heat generated in the external cavity, recalling (through the opening of the window related to the external curtain) the flow of air consequent to the opening of the window in the opposite and parallel curtain;

- during the summer season, by the night, the vertical passive ventilation recalls the flow of air resulting from the opening of the window in the opposite and parallel curtain and conducts it up to the cavity, cooling the internal spaces;

2.3. Scientific Analysis: Typological and Construction Classification of the Multi-Layer Façade Systems

2.3.1. Methodology of Identification and Analytical Classification

- the analysis of the experimental and in prototype form applications, often realized according to customized solutions;

- the examination of the components, technical elements and interfaces between the systems and the environmental loads;

- the opening and closing elements of the ventilation devices, which allow the regulation of the temperature and speed of the air inside the cavity;

- the transversal partitions, placed horizontally or vertically, which functionally delimit the contiguous components that make up the multiple-skin façades systems;

- the aerodynamic control for the input, conduction and output of the airflows;

- the separation between the component units, in order to prevent the outflow of air from one unit from being reintroduced into the ventilation duct of the contiguous unit, assuring the inflow of air from the outside without the risk of it being affected by the air expelled from the interior spaces [23,24].

- the sustainable methods in the form of the box-windows systems (2.3.2);

- the sustainable methods in the form of the multistory systems (2.3.3);

- the sustainable methods in the form of the shaft-box systems (2.3.4);

- the sustainable methods in the form of the corridor systems (2.3.5).

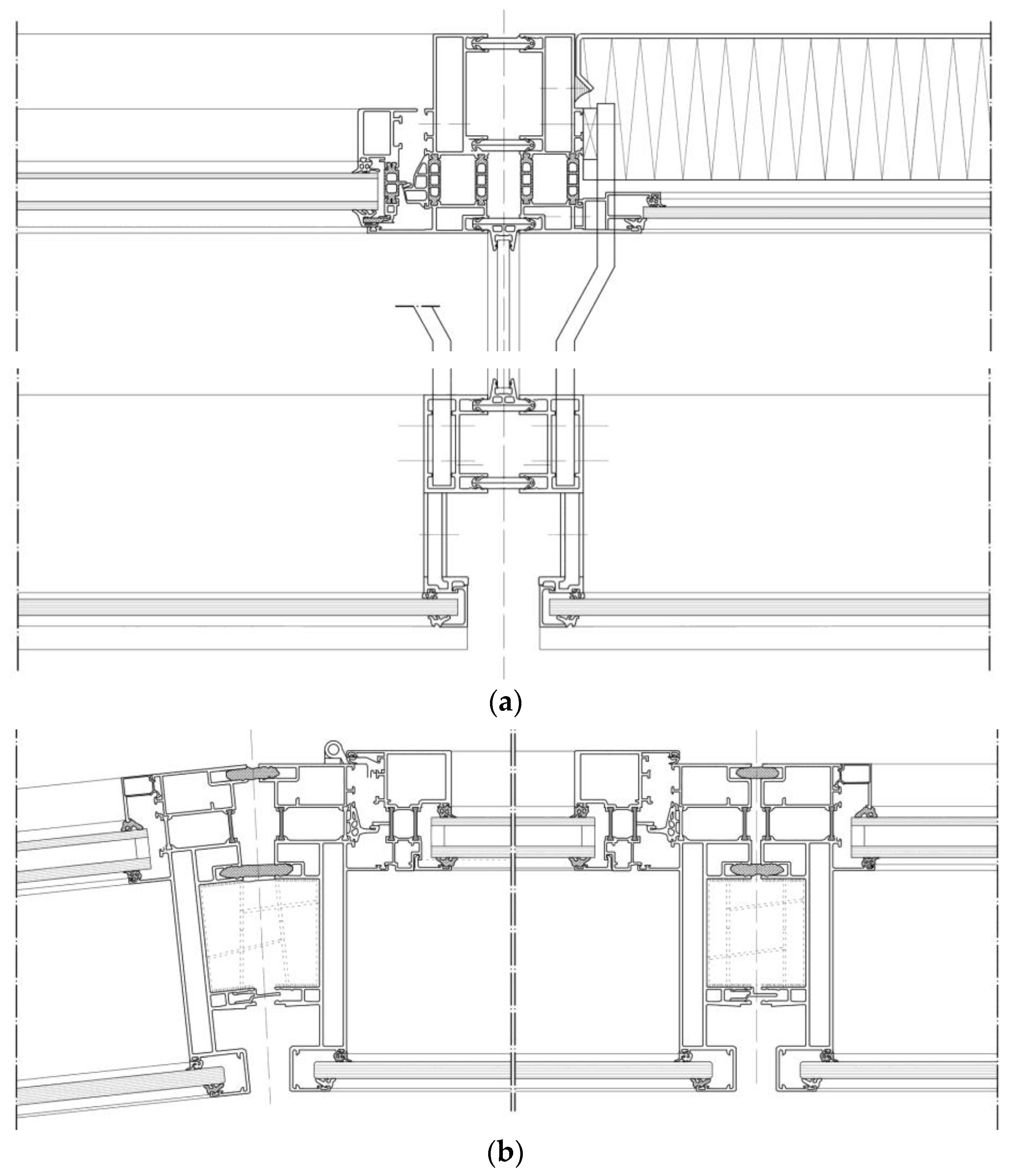

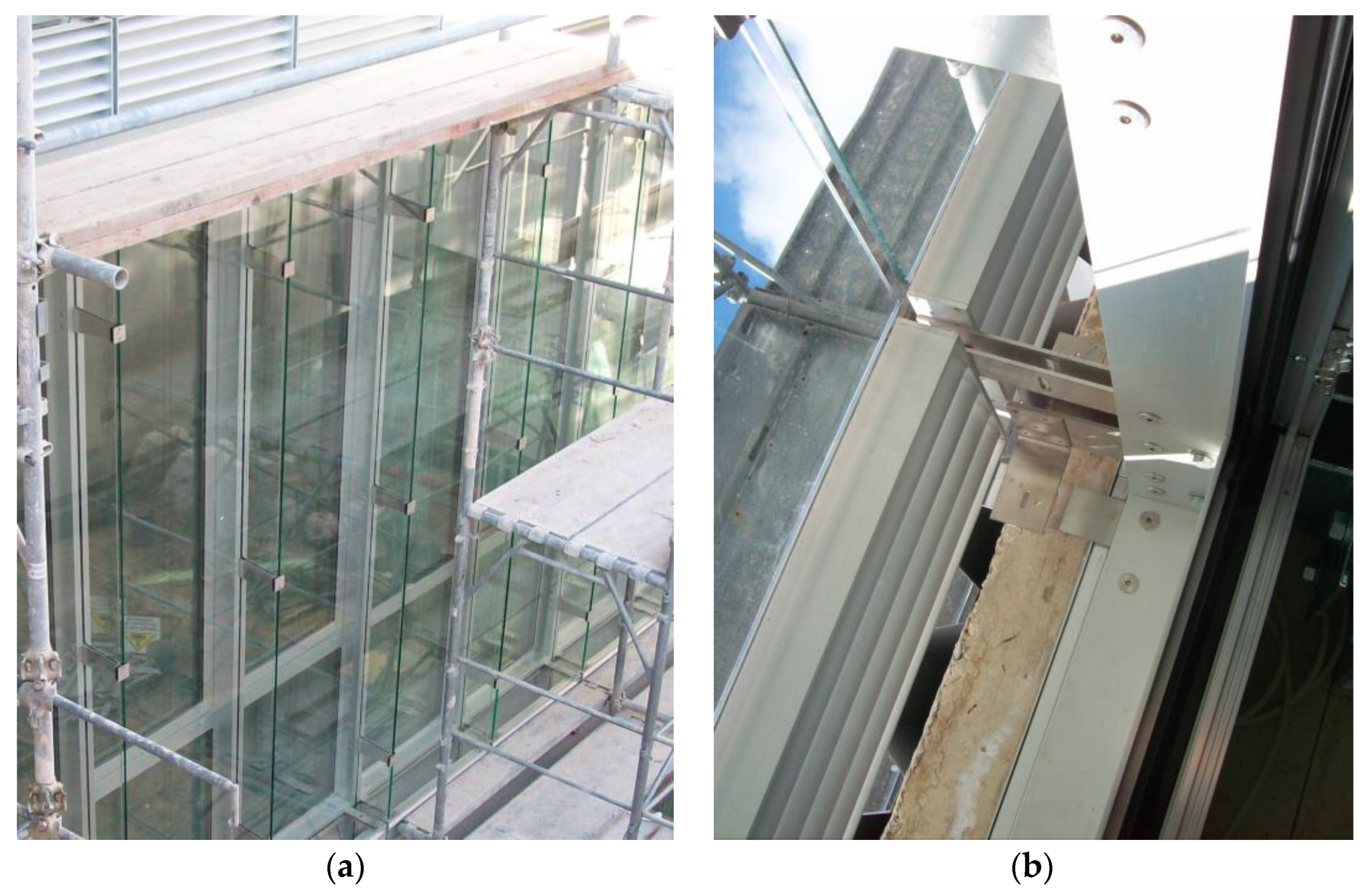

2.3.2. Sustainable Methods in the Form of the Box-Windows Systems

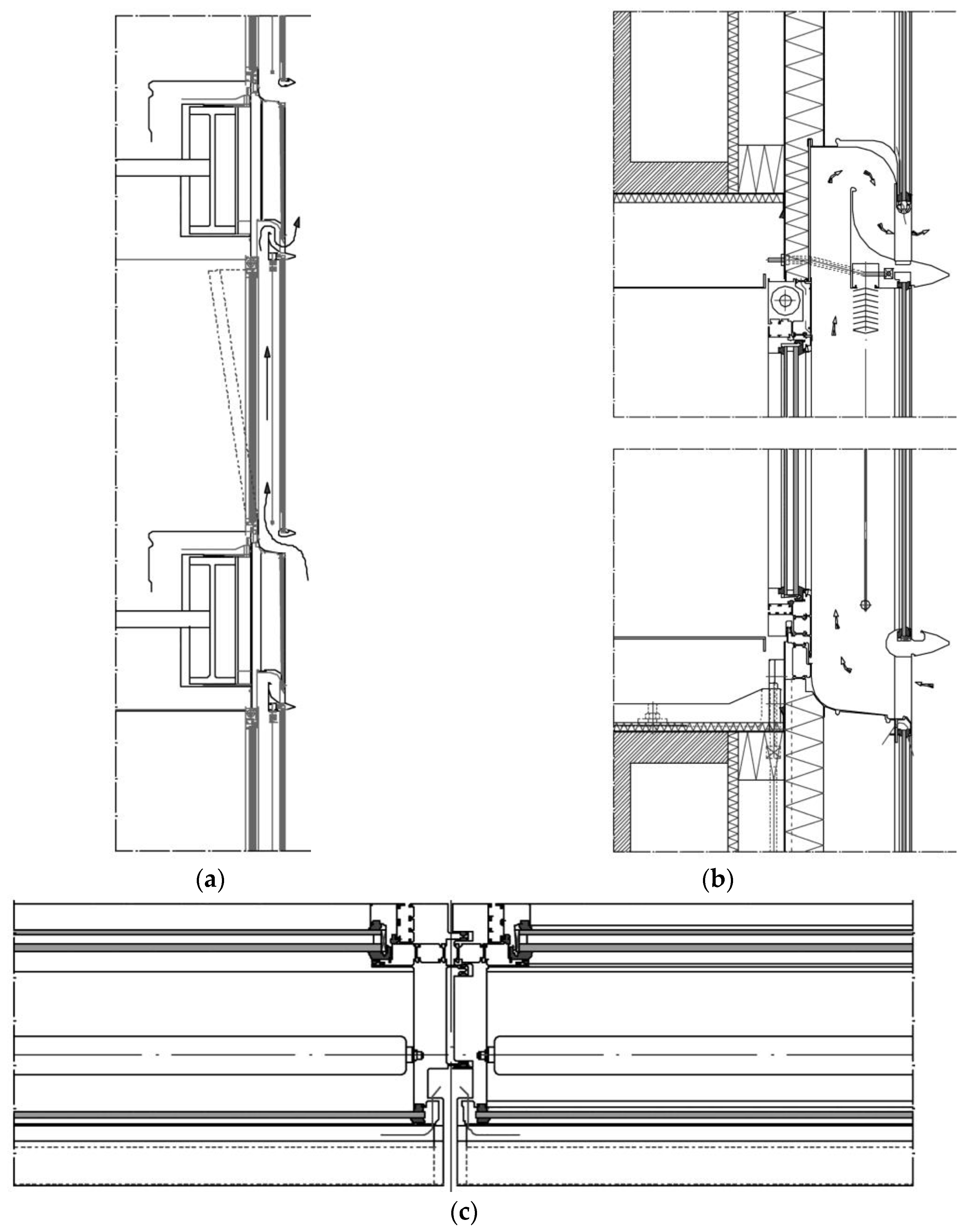

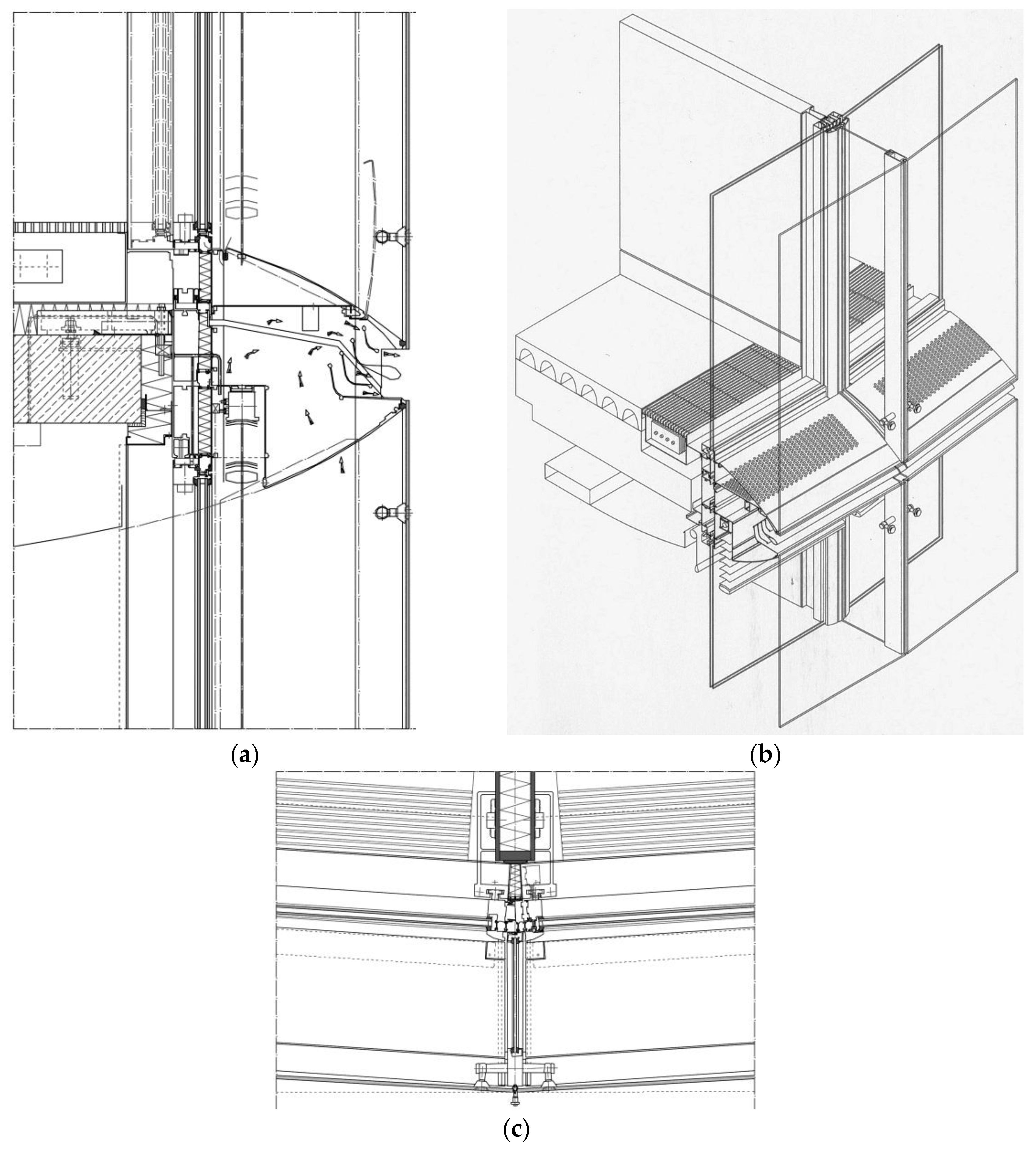

- the application of the internal façade curtain, the external glazing screen and the interposed cavity;

- the location of the lower and upper openings for each module, which allow the entry of external airflows and the exit of the exhausted airflows, providing the ventilation both inside the cavity and in the internal spaces;

- the horizontal division of the cavity between the internal façade curtain and the external glass screen;

- the vertical division both between two contiguous modules and with respect to the vertical development (where the continuous divisions provide to avoid the acoustic transmission).

- part of the radiation is reflected and diverted by the sunshade foils;

- the upward rotational flow is sucked in and conveyed outside through the opening at the top of the window frame [25].

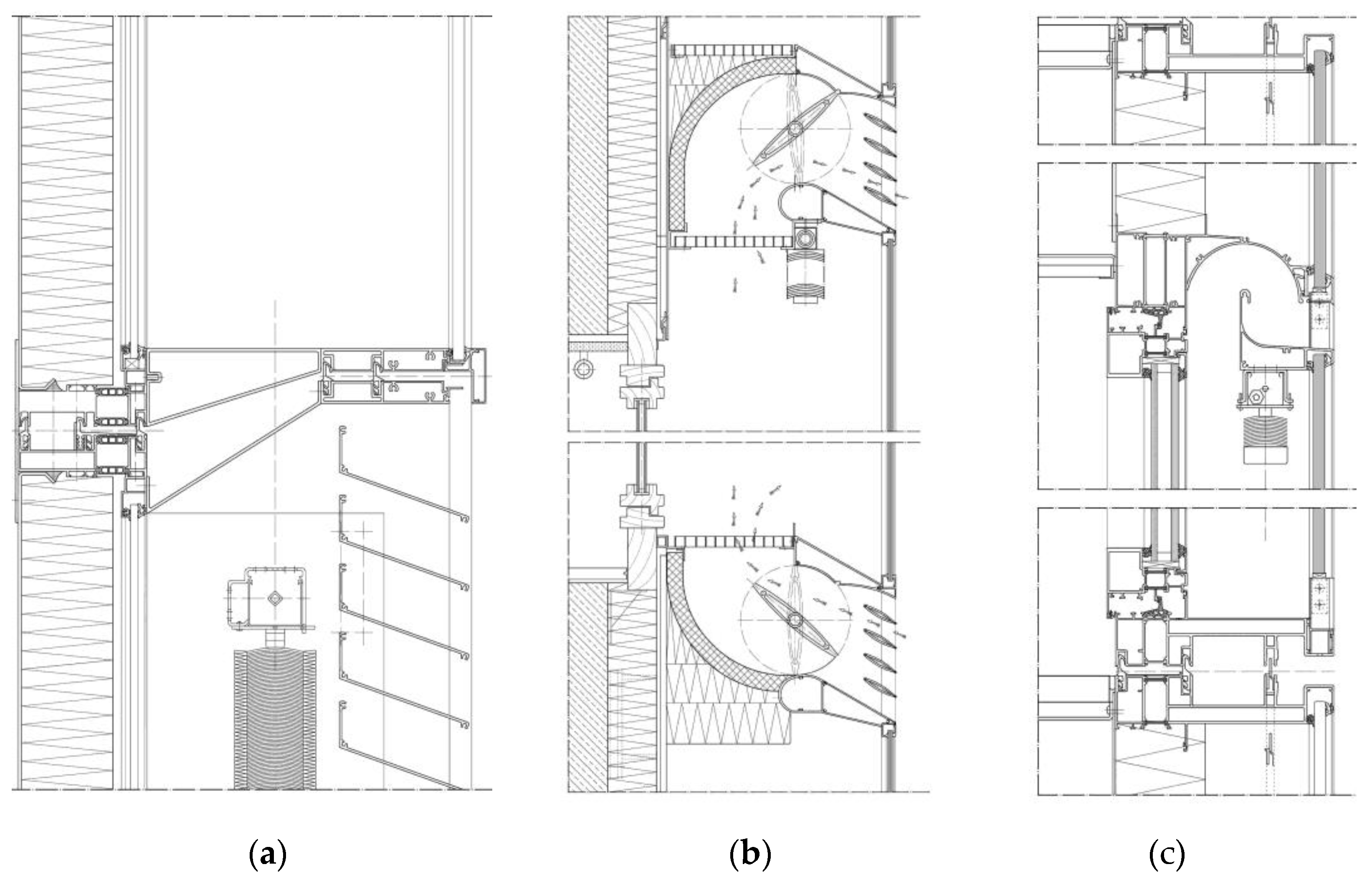

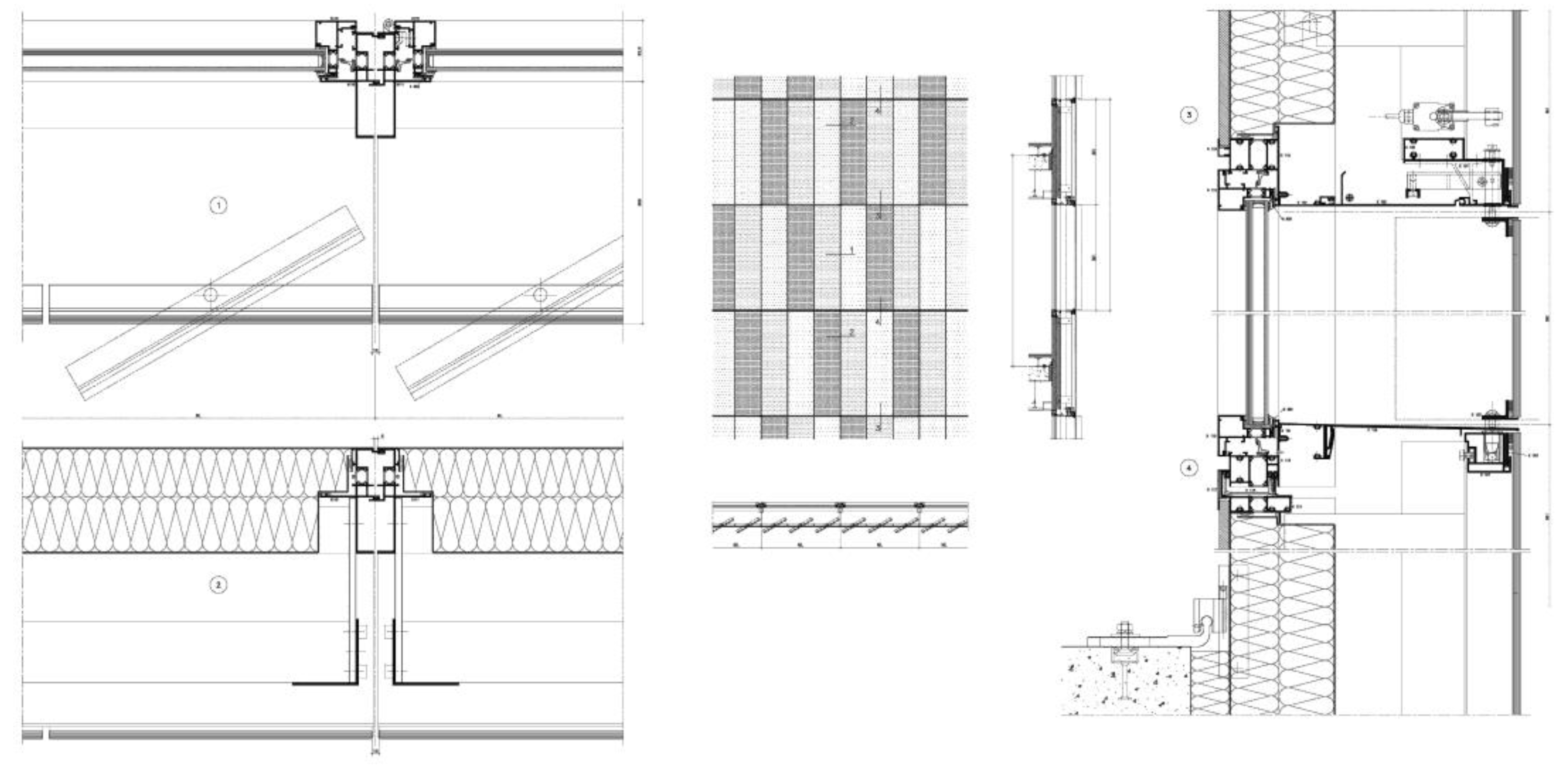

- the internal façade curtain, realized by the steel sheet (acting as a vapour barrier and fire barrier element), the thermal insulation layer and the aluminium sheet cladding, together with the window with aluminium frame and double-glazing, which can be opened with a tilt and turn mechanism;

- the external screen (supported by the aluminium brackets), made from the individual glass modules with the open joints for the ventilation of the cavity (Figure 9).

- for the capture of the convective flows (in the lower position) from outside the façade towards the inside of the ventilated cavity;

- for outflow (in the upper position) from inside the façade towards the outside [26].

- the internal panel defined by the opaque section (in front of the horizontal structures) with the thermal insulation layer and the tilt-and-turn window with double-glazing;

- the external screen in tempered glass (minimum thickness = 6 mm);

- the two extruded aluminium wing profiles for capturing the convective airflows (in the lower position) from the outside towards the inside of the ventilated cavity and, subsequently, for the outflow (in the upper position) towards the outside [27].

- the internal façade made up of two opaque sections, a lower one (on which the aluminium frame of the tilt and turn window, with double glazing, is grafted) and an upper one (interfacing with the external profile of the horizontal structure and with the ventilation device), contained internally by an (aluminium) layer and covered externally by a glass panel;

- the external shading composed of the single panel of toughened glass, supported by the double perforated profile mullions (in aluminium) and connected to the façade plane including, at each inter-floor level, the ventilation devices (Figure 12).

- the inflow of air through the circular holes (60 mm in diameter) located on both profiles of the external mullions;

- the outflow of the air through the ventilation devices (at least 450 mm high), which are characterized by two deflecting wings (inclined, functional with respect to the weather protection) that guide the ventilation inside the cavity towards the outside.

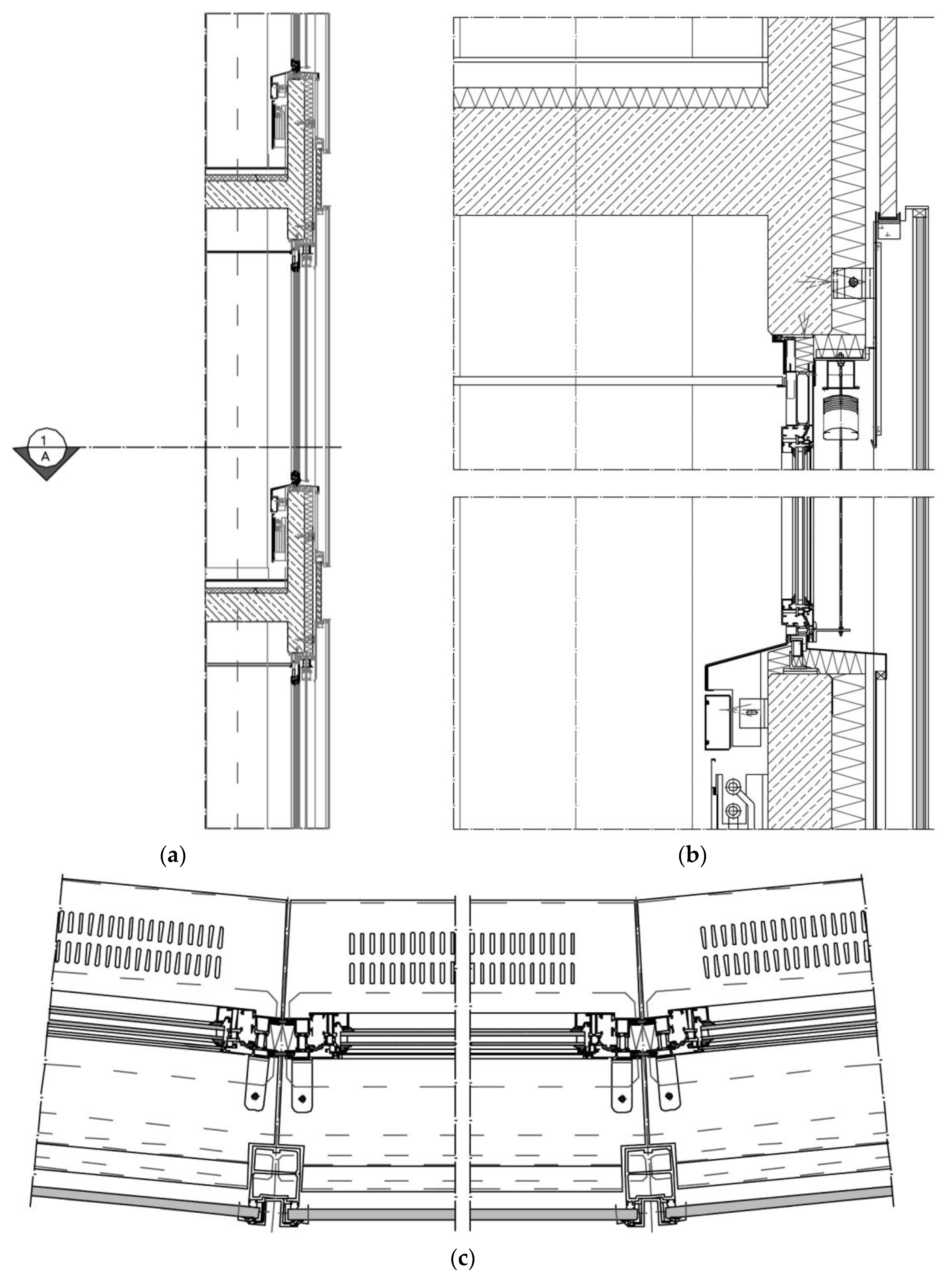

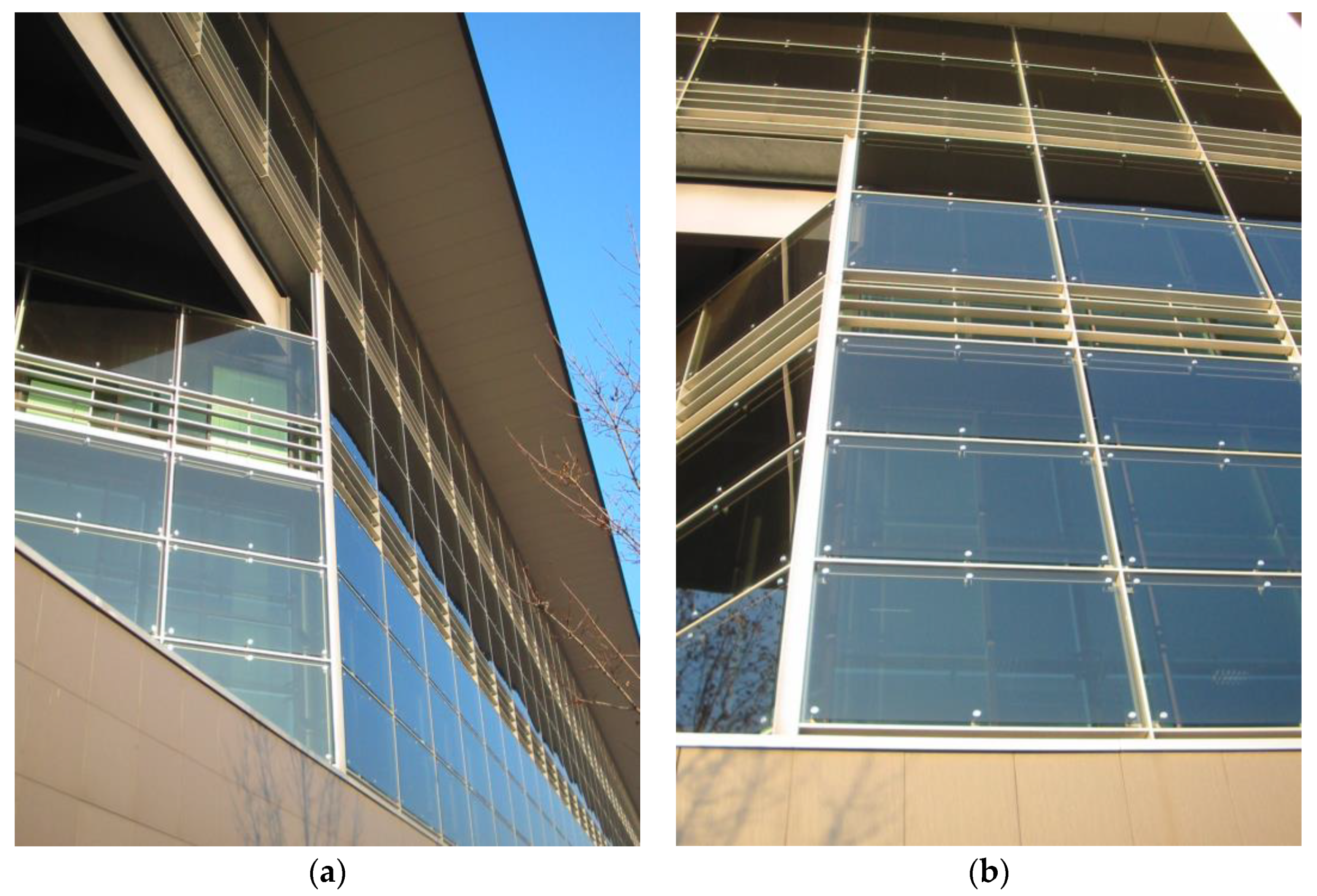

2.3.3. Sustainable Methods in the Form of the Multistory Systems

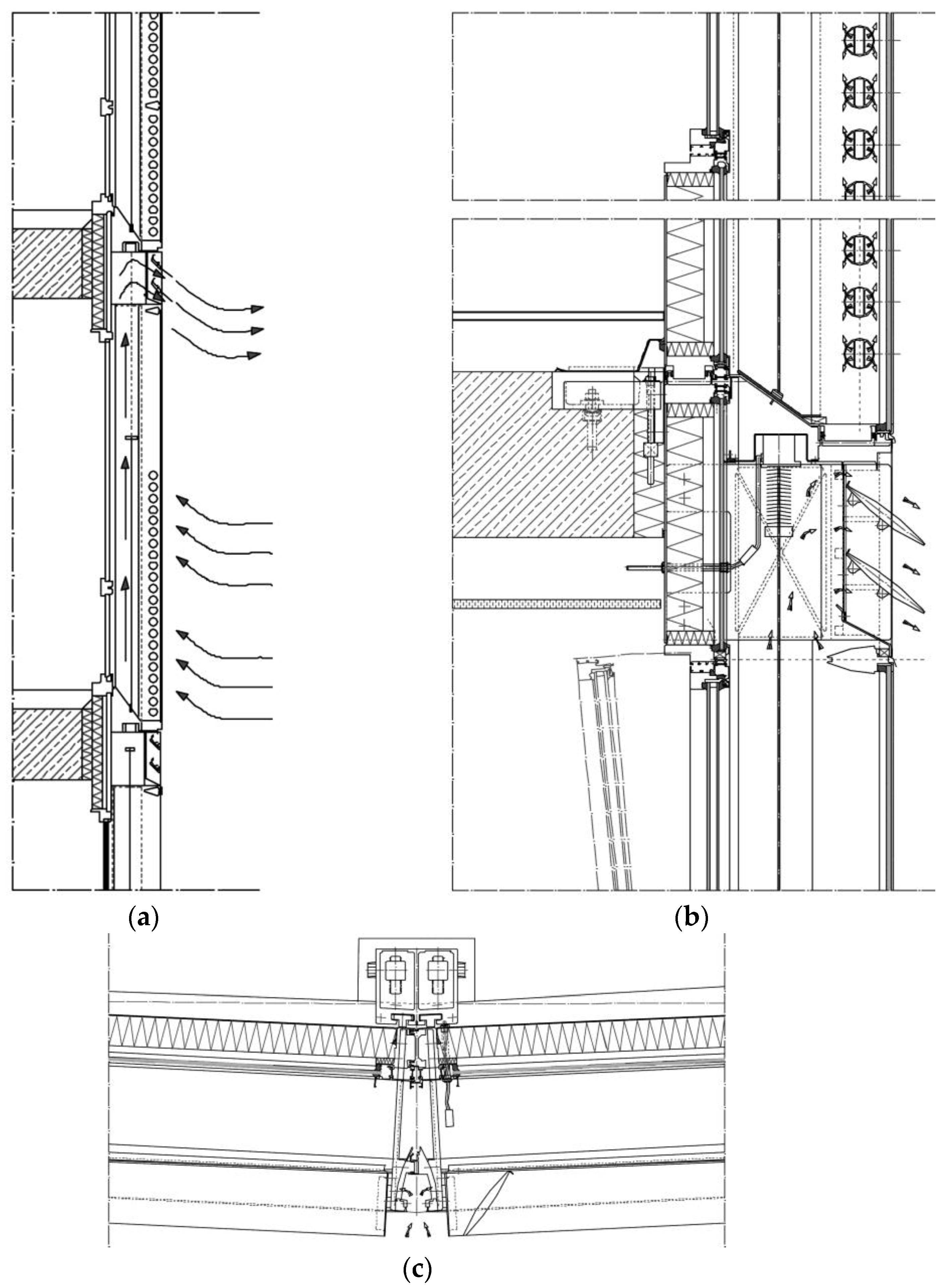

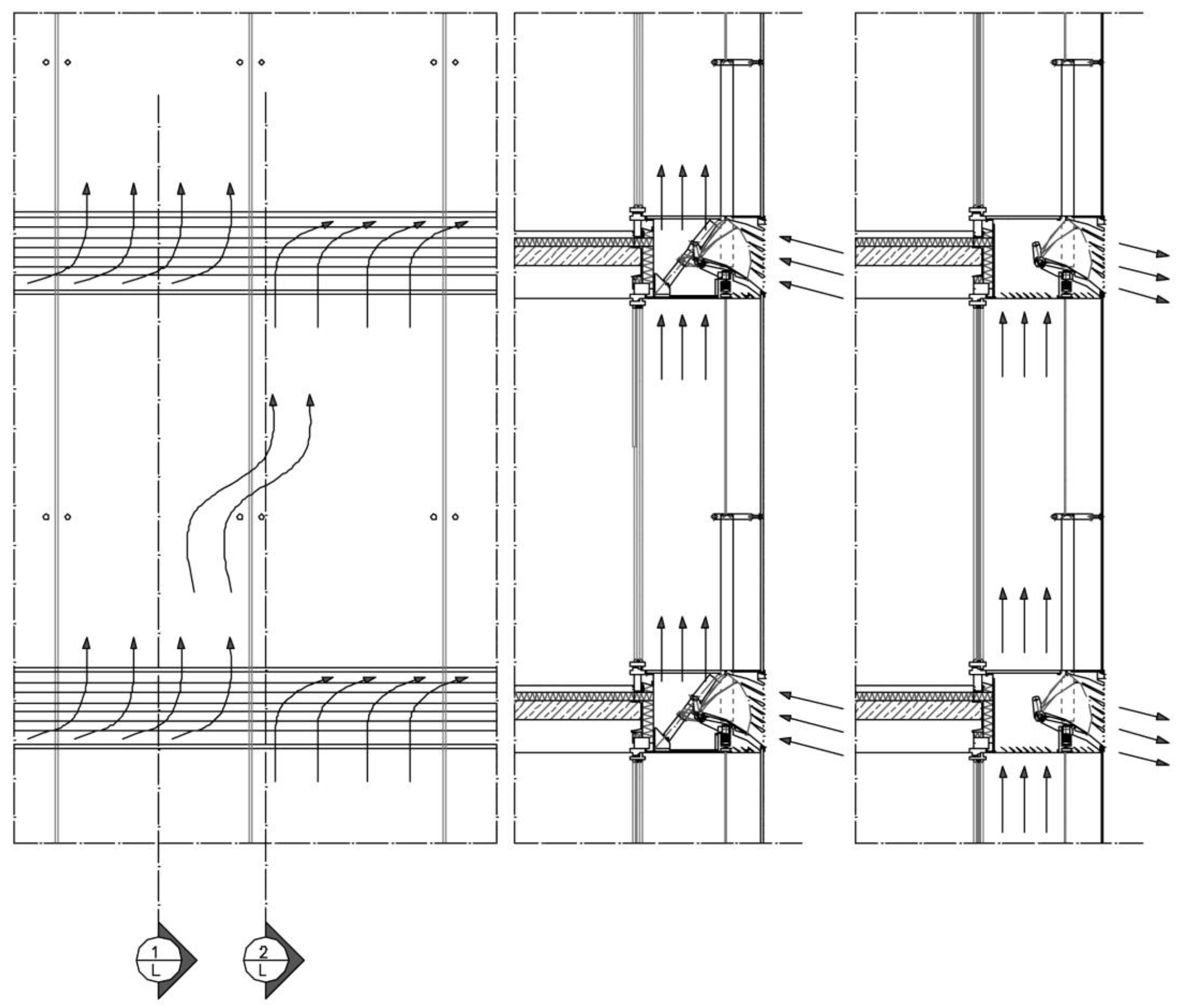

- the application of the intermediate space between the inner and outer layers that is adjoined vertically and horizontally, where the cavity may extend around the entire envelope without any intermediate divisions;

- the ventilation (air-intake and extract) of the intermediate space that occurs via large openings near the ground floor and the roof;

- the possibility to close the cavity at the top and bottom, during the heating periods, to exploit the conservatory effect and optimize the solar-energy gains;

- the arrangement of the casement opening light that depends on the ventilation and cleaning concept chosen for the façade;

- the application of the external skin that is set independently in front of the inner façade, where the cavity can be ventilated in all the directions [28].

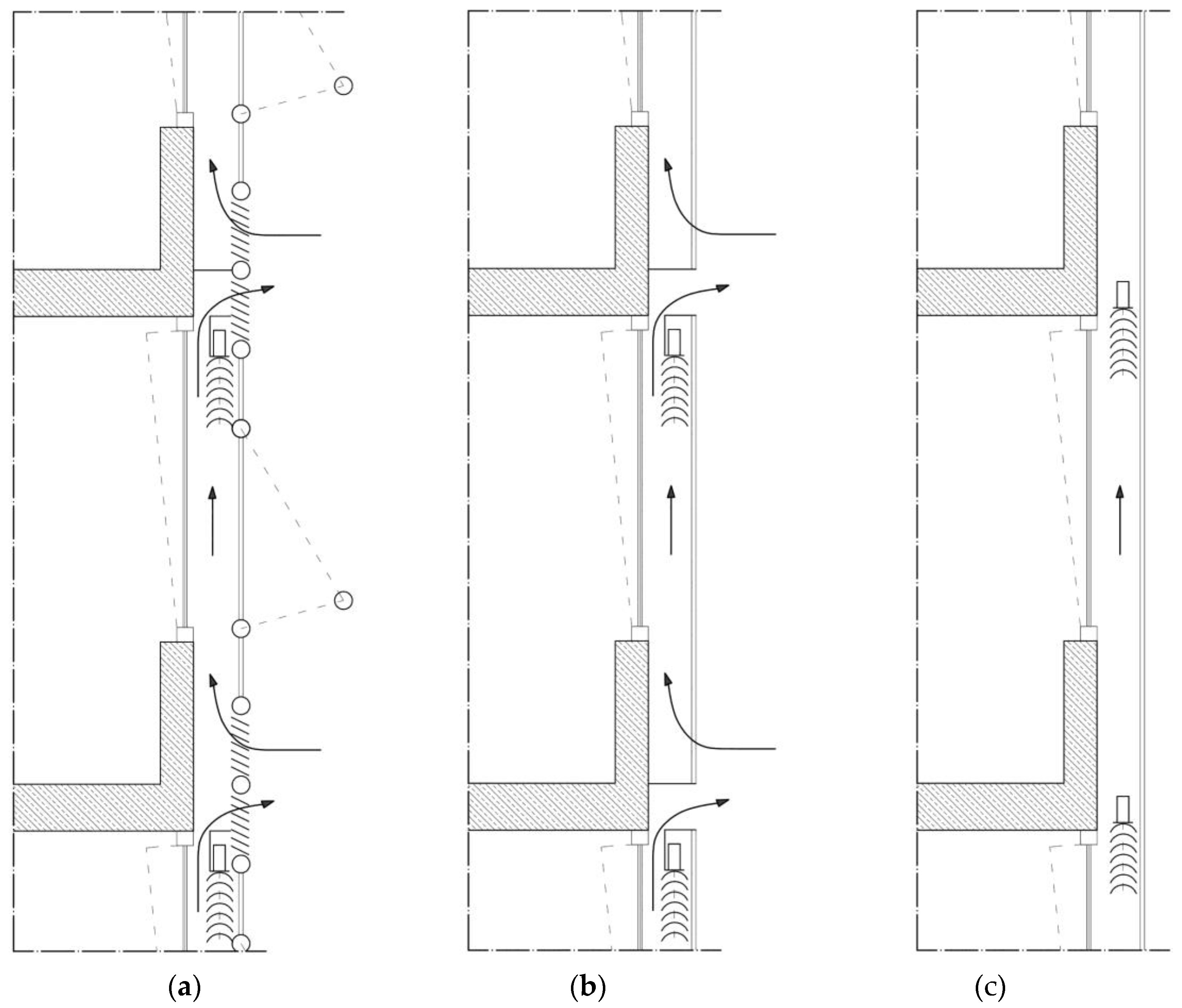

- during the winter period, the glass blades are closed (resulting in a sound-absorbing cavity): solar radiation, by heating the air in the cavity, generates a heat-insulating layer (due to the greenhouse effect) that contributes to maintaining heat in the interior spaces and reducing energy consumption for heating;

- during the summer period and depending on the outside temperature level, the glass blades are open, allowing the ventilation of the cavity and the night cooling of the buildings, acting in combination with the opening of the windows [29].

- the winter functioning, with the aim of exploiting the heating of the air mass present in the cavity to transfer the heat to the interior spaces; that is, with the objective of directly distributing the accumulated heat, through the natural thermo-circulation established by the vertical convective flows;

- the summer functioning, with the aim of avoiding the overheating of the indoor air by removing the heat and transferring it outside.

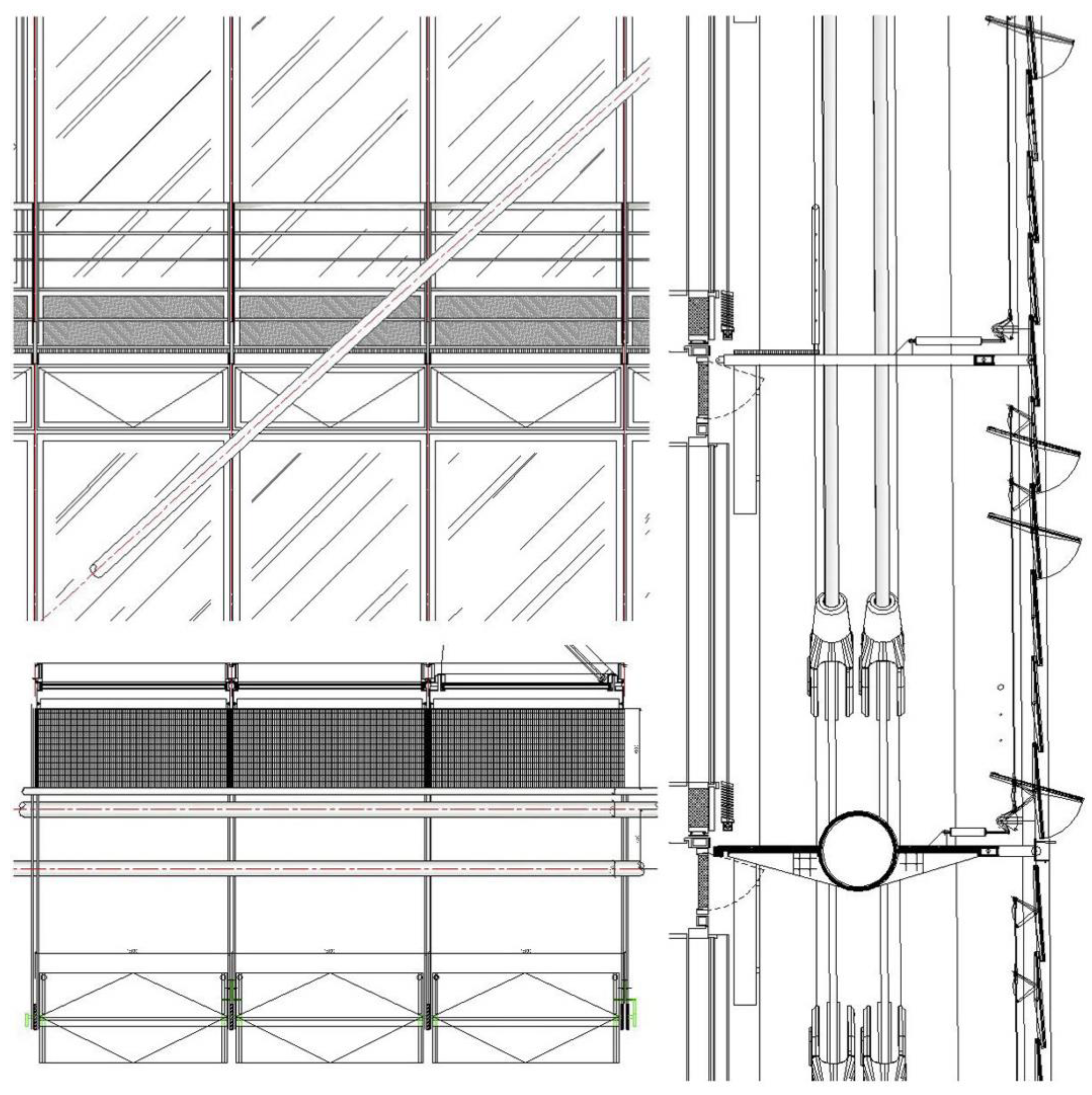

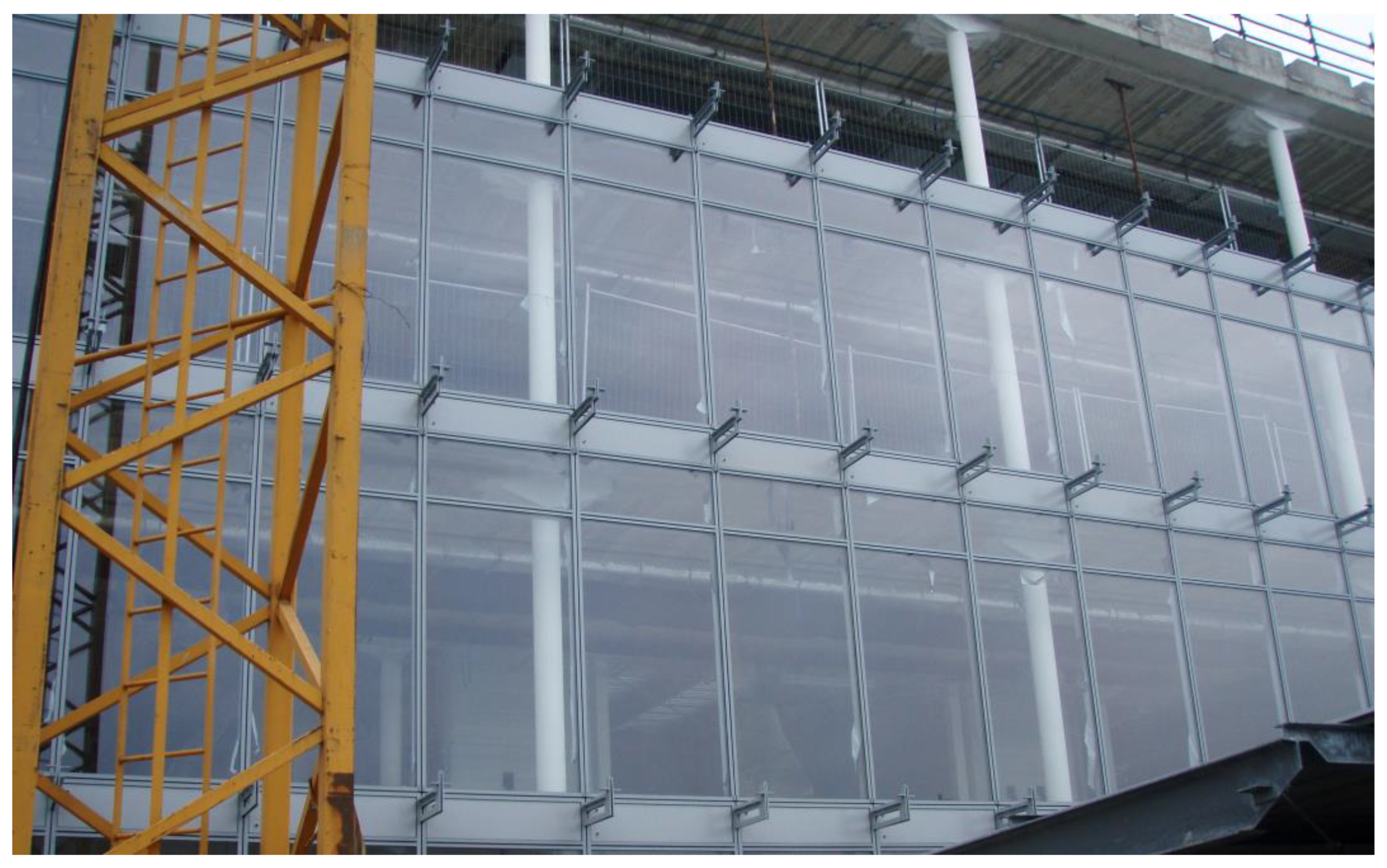

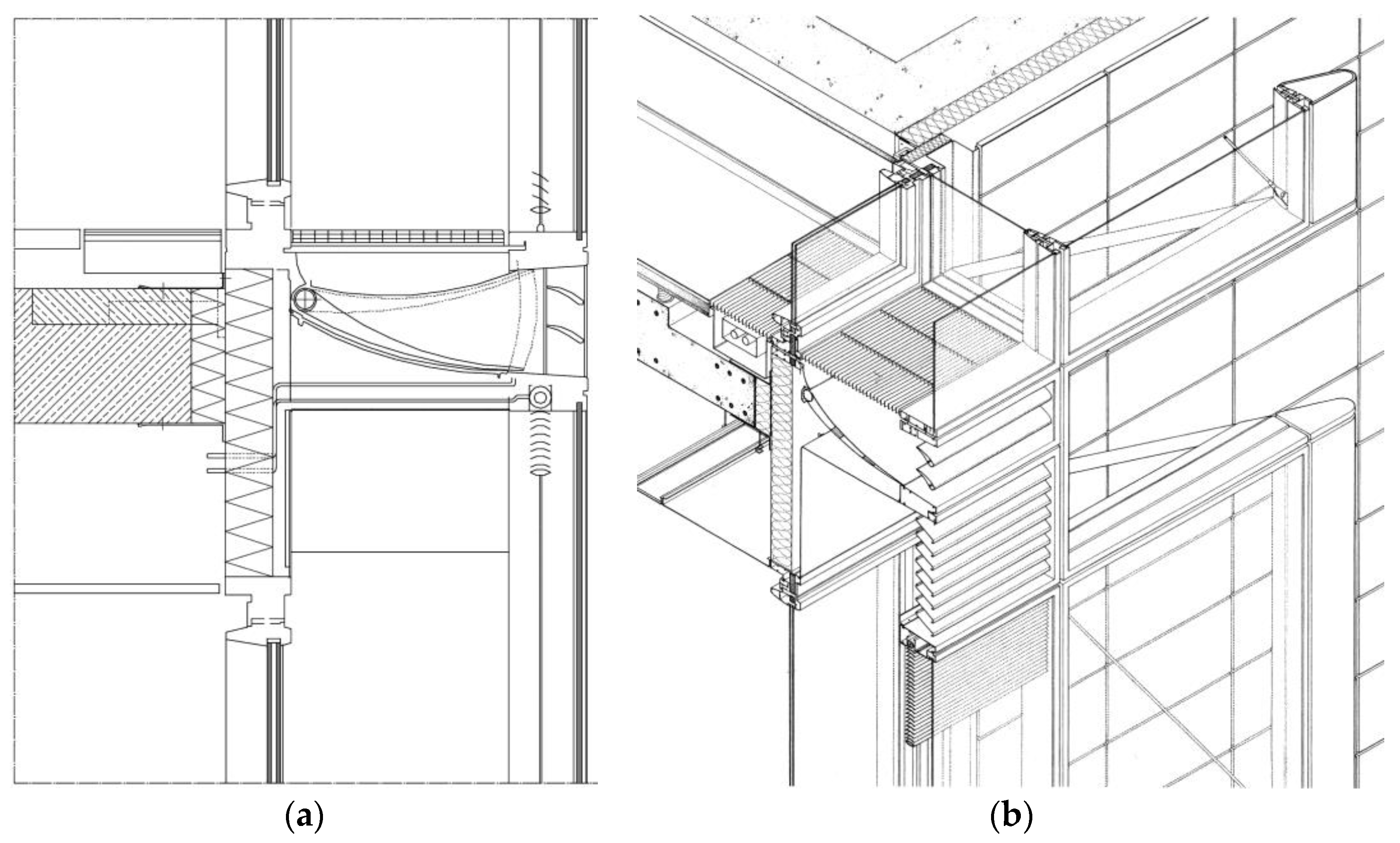

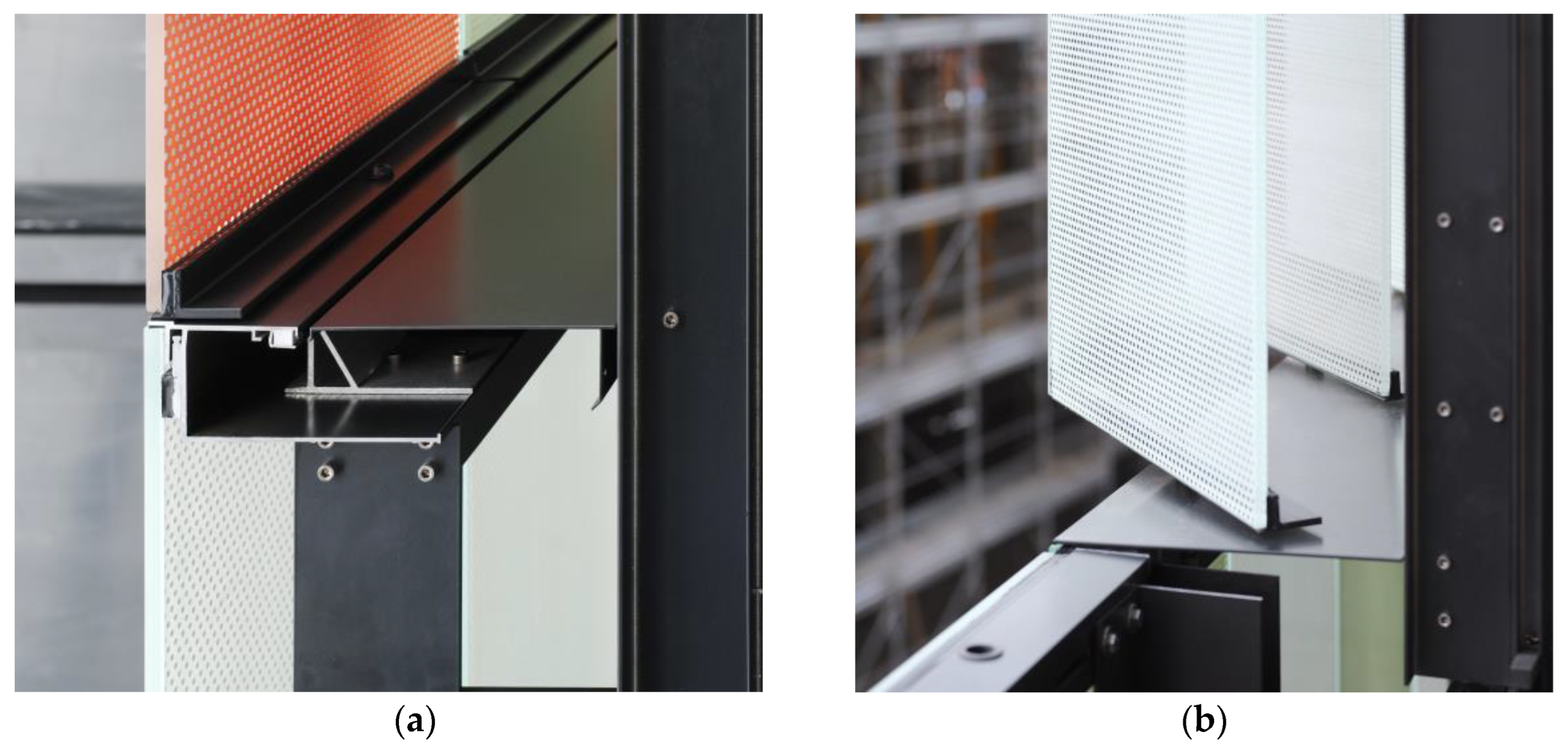

- the constitution of the internal curtain wall in the unit system typology, detecting the composition of the fixed modules alternating with the modules that can be opened both for wasistas (for the climatic regulation of the internal spaces) and for maintenance requirements. The façade components in the unit system typology are provided with the bracket elements for the connection to the rods aimed at supporting the external shading and grid;

- the positioning, contiguous to the floor perimeter sections, of the mechanically adjustable elements capable of raising (up to a height of 90°) to enhance the natural ventilation conditions of the cavity;

- the constitution of the external shading realized by the mechanically adjustable glazing blades, applied with respect to the vertical profiles. In particular, the functioning of the louvres is connected to the needs relating to both bioclimatic and fire prevention formulation, opening up to favour the passage of ventilation into the interior spaces in the event of fire [30].

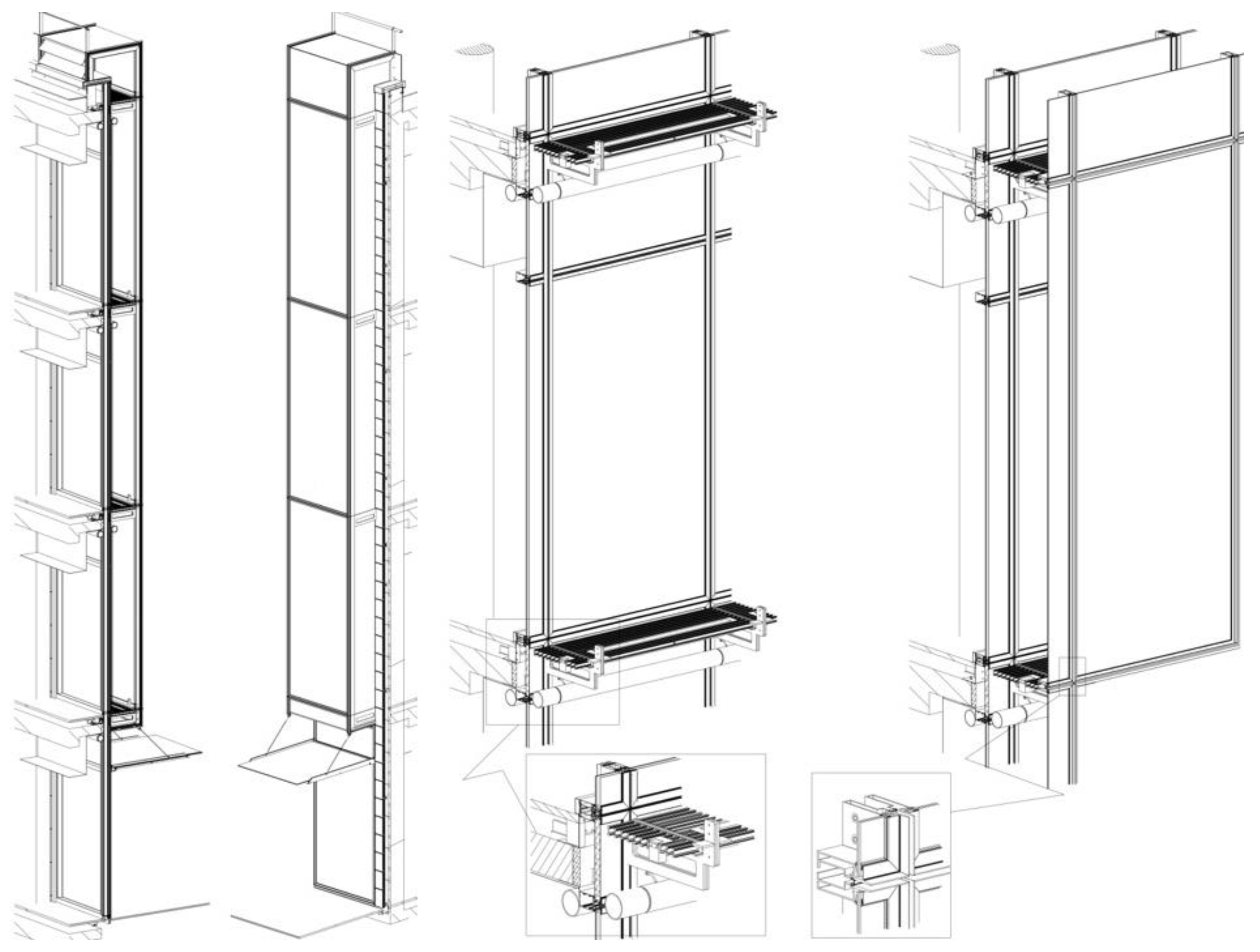

- the longitudinal tubular section, between the two open cavities for the interface with the gaskets;

- the front chamber, for the aggregation of the couple of polyamide thermal break profiles in connection with the outer chamber;

- the outer chamber, articulated by the ribs aimed at supporting the central sealing gasket couple;

- the glazing bead, fitted with the housing for the external grip gasket on the double-glazing enclosures and the spandrel panel;

- the external front section, fitted with the housing for the external gripping gasket on the double-glazing fasteners and the spandrel stringer panel [31].

- the execution of the fan coils at the perimeter interface towards the stringcourse sections, with the inclusion of the thermal and sound-insulating layers enclosed by the aluminium sheets directed towards the internal vertical partitions of the transoms;

- an increase in visual comfort and savings in consumption for the artificial lighting;

- the exploitation, during the winter season, of the heat inputs due to solar radiation, in the case of situations that exclude an excessive increase in internal temperature and visual interference (Figure 20).

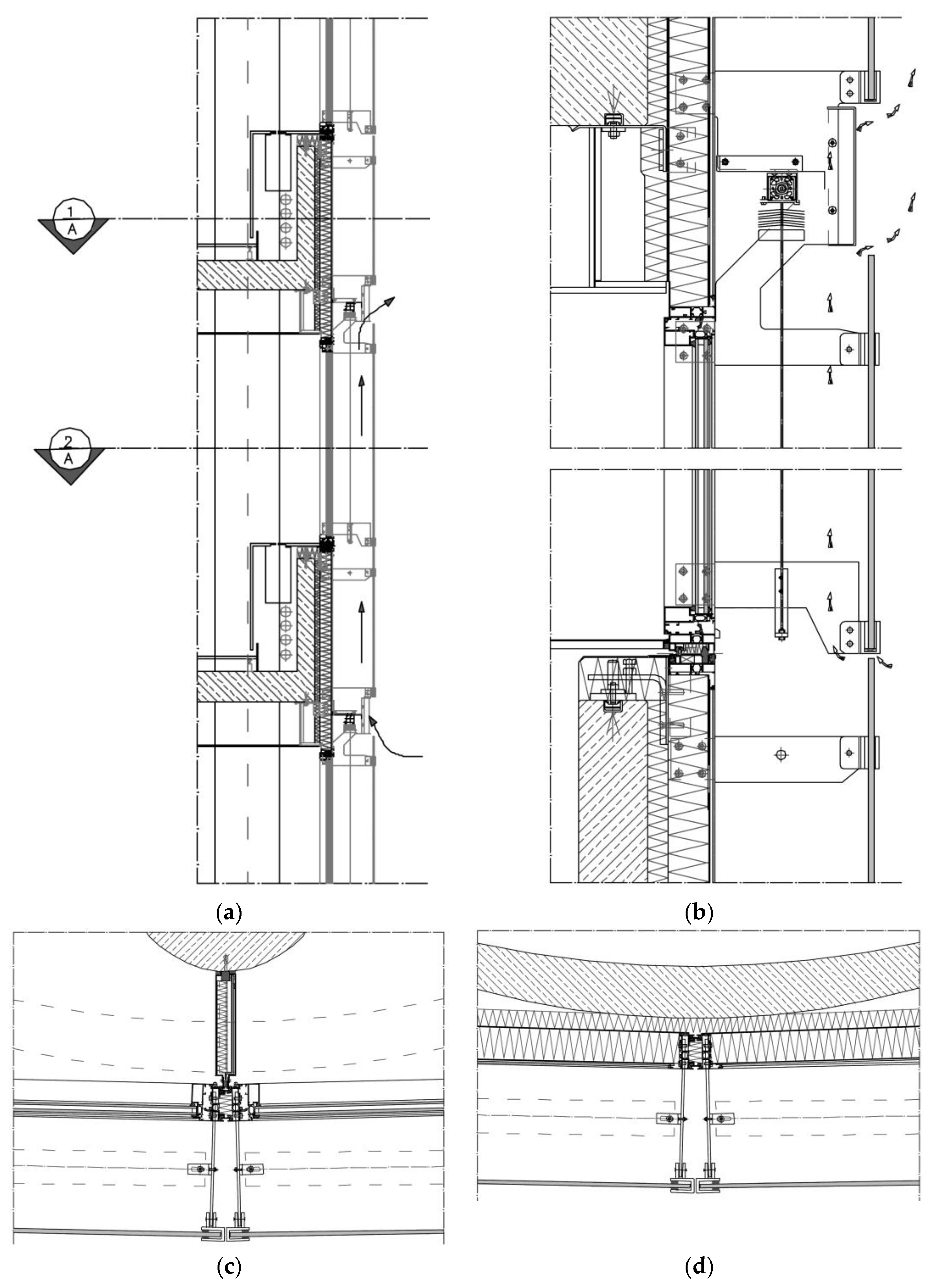

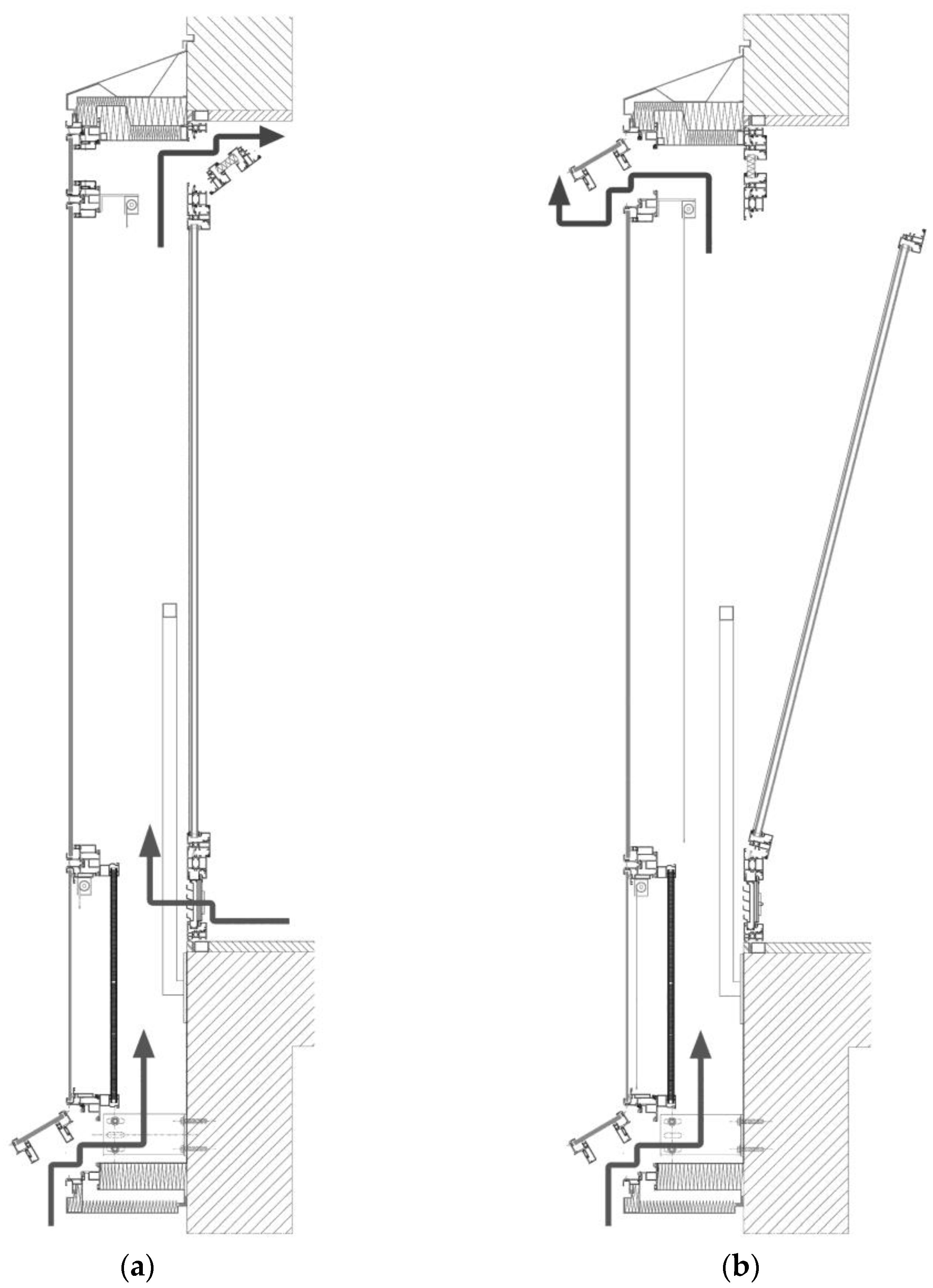

2.3.4. Sustainable Methods in the Form of the Shaft-Box Systems

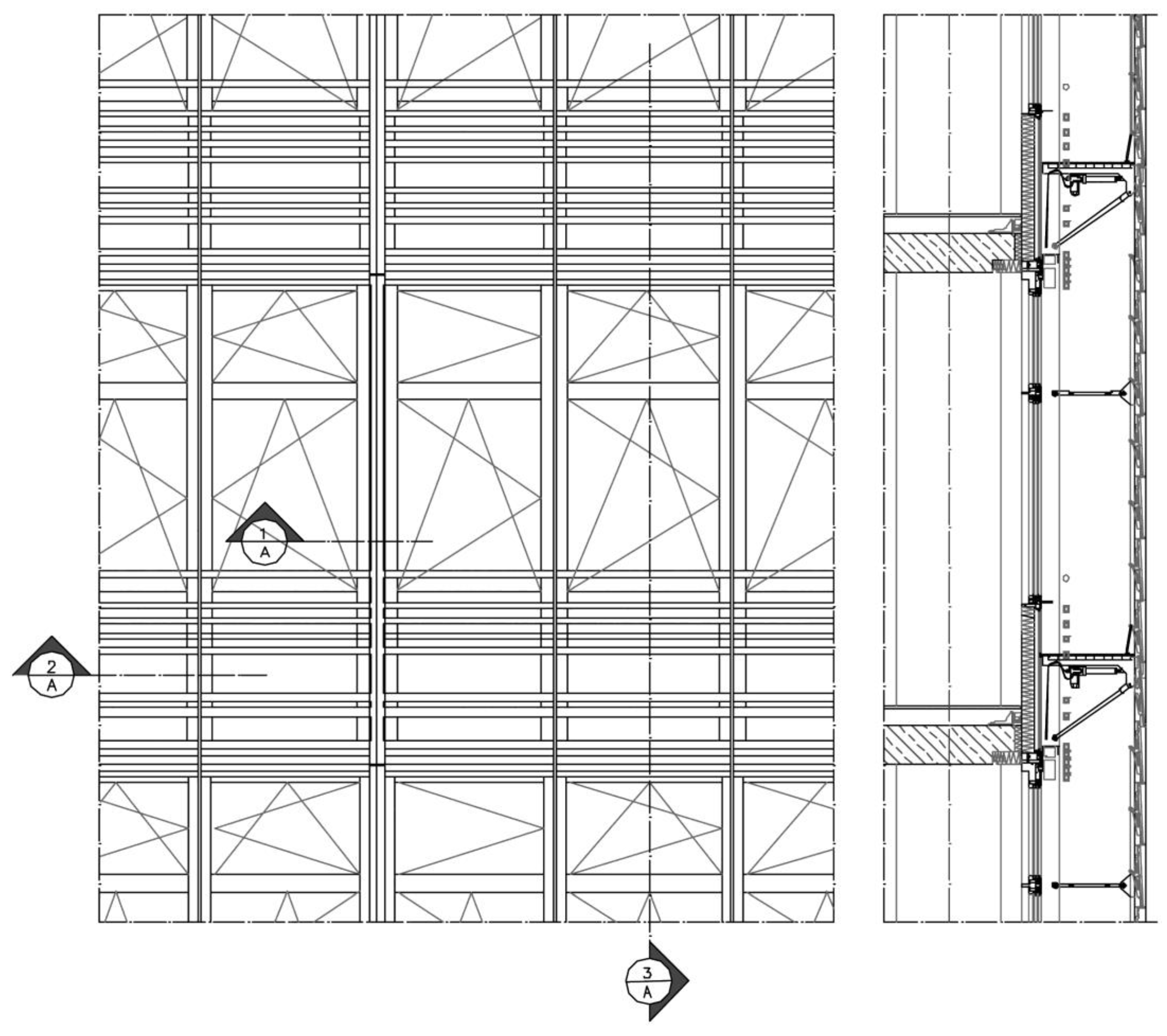

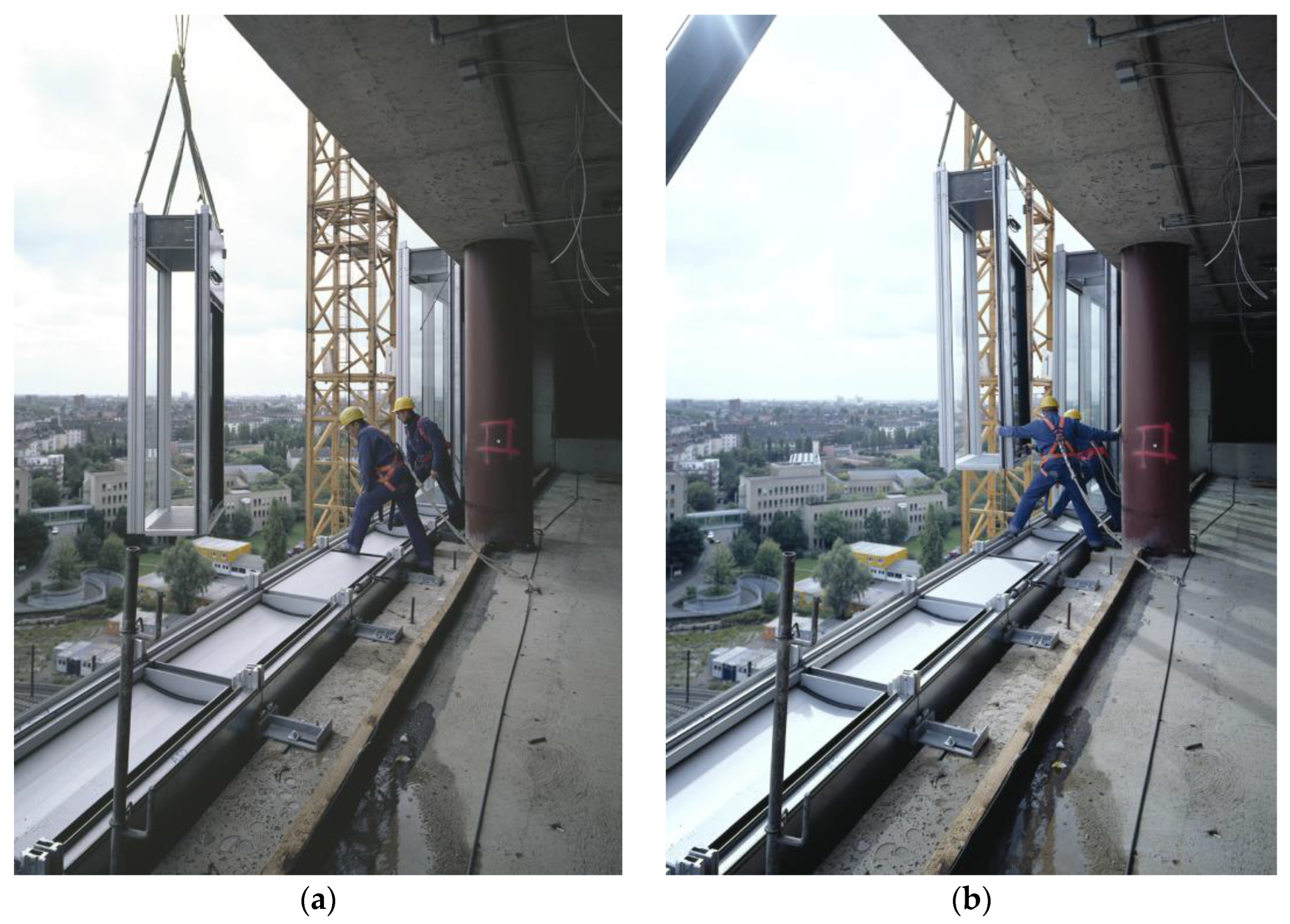

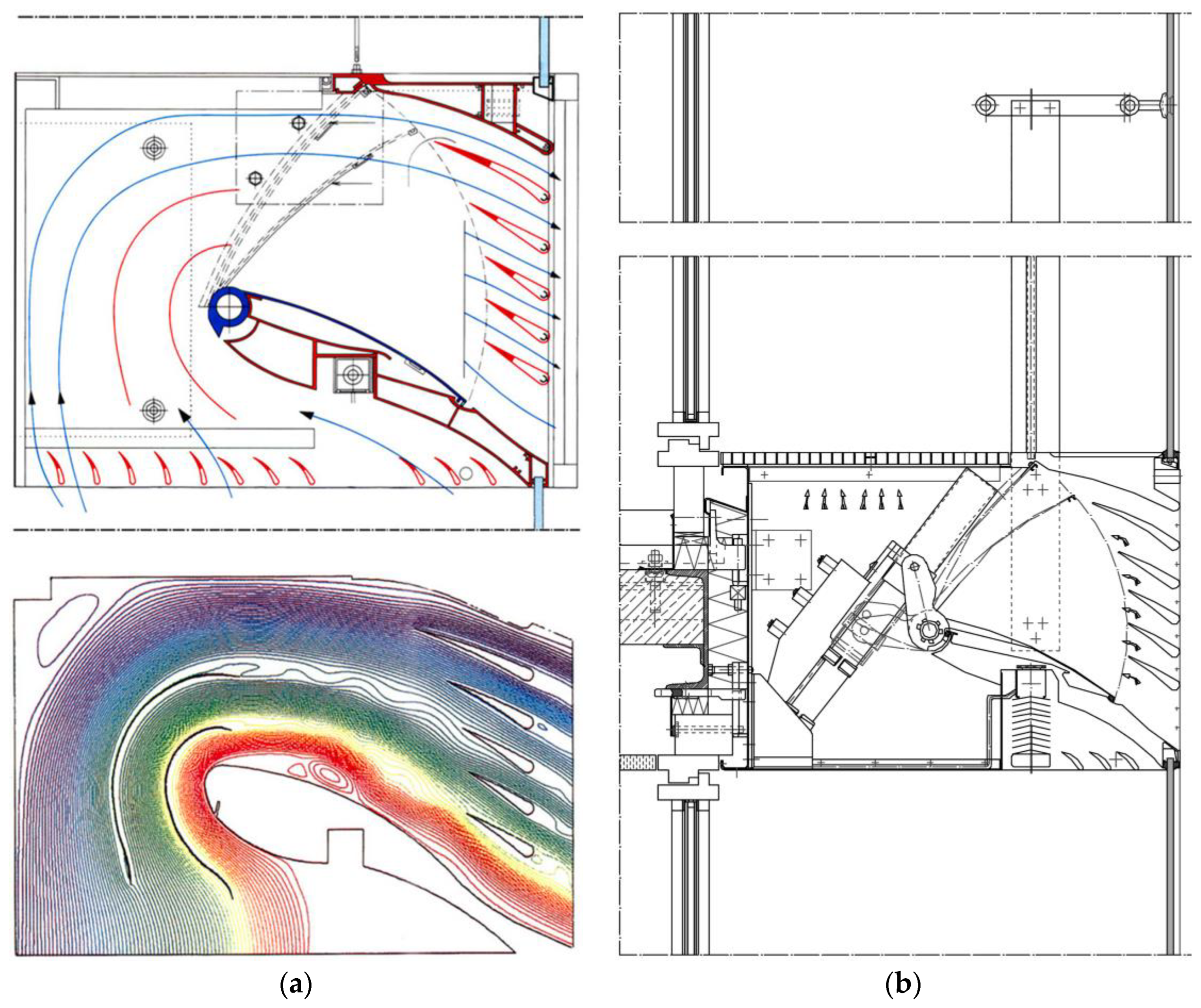

- the application of the box-window components with continuous vertical shafts that extend over a number of stories to generate a stack effect (as an alternation of the box-window components and vertical shafts segments);

- the connection of the vertical shafts, on every storey, to the adjoining box-windows by means of a bypass opening: the stack effects draws the airflows from the box-windows into the vertical shafts and from there up to the top, where it is emitted. As a means of supporting the thermal uplift, the airflows can also be sucked out mechanically via the vertical shafts;

- the require of few openings in the external skins, since it is possible to exploit the stronger thermal uplift within the stack (by contributing to the insulation against the external noise). Since the height of the stacks is limited, this type of envelope is suited to lower-rise buildings [32].

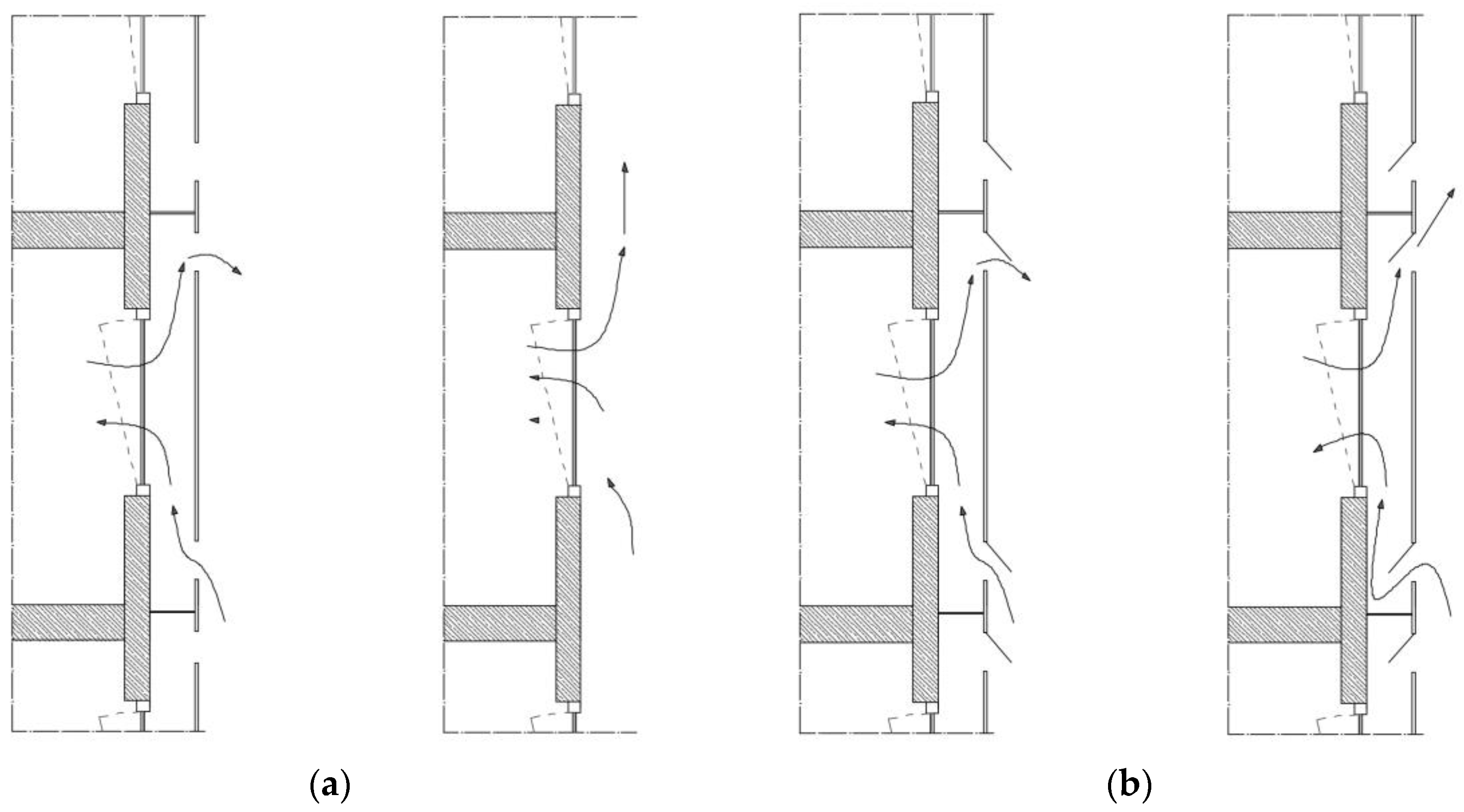

- the first and third box-window components (integrated, laterally, by the vertical separation panel) provide for the ventilation devices to be in the open condition towards the outside, by means of the downward rotation of the concave wing element;

- the intermediate component is open to the reception of the airflows extracted from the internal spaces (by means of the opening of the windows related to the two lateral components), by diagonal conduction and through the bypass openings arranged at the top of the vertical separation panels. It provides for the ventilation devices to be in the closed condition, by means of the upward rotation of the concave wing element, so that the inflow of the external air is prevented and the outflow of the internal air into the cavity (coming from the diagonal conduction from the two side components) is prevented.

- in the case of the opening of the wing devices (in the down position) and of the frames of the lateral components, the introduction of the airflows, conducted in a circle and capable of conveying the internal air upwards to the ascending convective airflows in the cavity of the intermediate components;

- in the case of closing both the wing devices (in the up position, which is also necessary for safety reasons for wind loads with a speed greater than 8 m/s) and the internal window frames, a ventilated façade is obtained.

- the internal enclosure, realized by an opening frame at floor height. The frames related to the central band (equipped with the components in which the airflows intake take place) can only be opened for maintenance operations;

- the external screen, assembled to the mullions and transoms framing of the unit, made of a single sheet of laminated glass at floor height.

- the internal façade executed by the openable window frame at the floor height, with the aluminium frame and the double-glazing enclosures; the window frame related to the central layer (corresponding to the ventilated façade with continuous intake of airflows) can only be opened for maintenance operations;

- the external screen executed by the laminated glass pane at the floor height.

- the two wing flaps, which guide the external convective airflows towards the regulating equipment;

- the regulation equipment, electrically operated with a control system and based on the rotation of the devices, which guide the closing and opening of the cavities;

- the ventilation grid (walkable for maintenance and repair work inside the cavity).

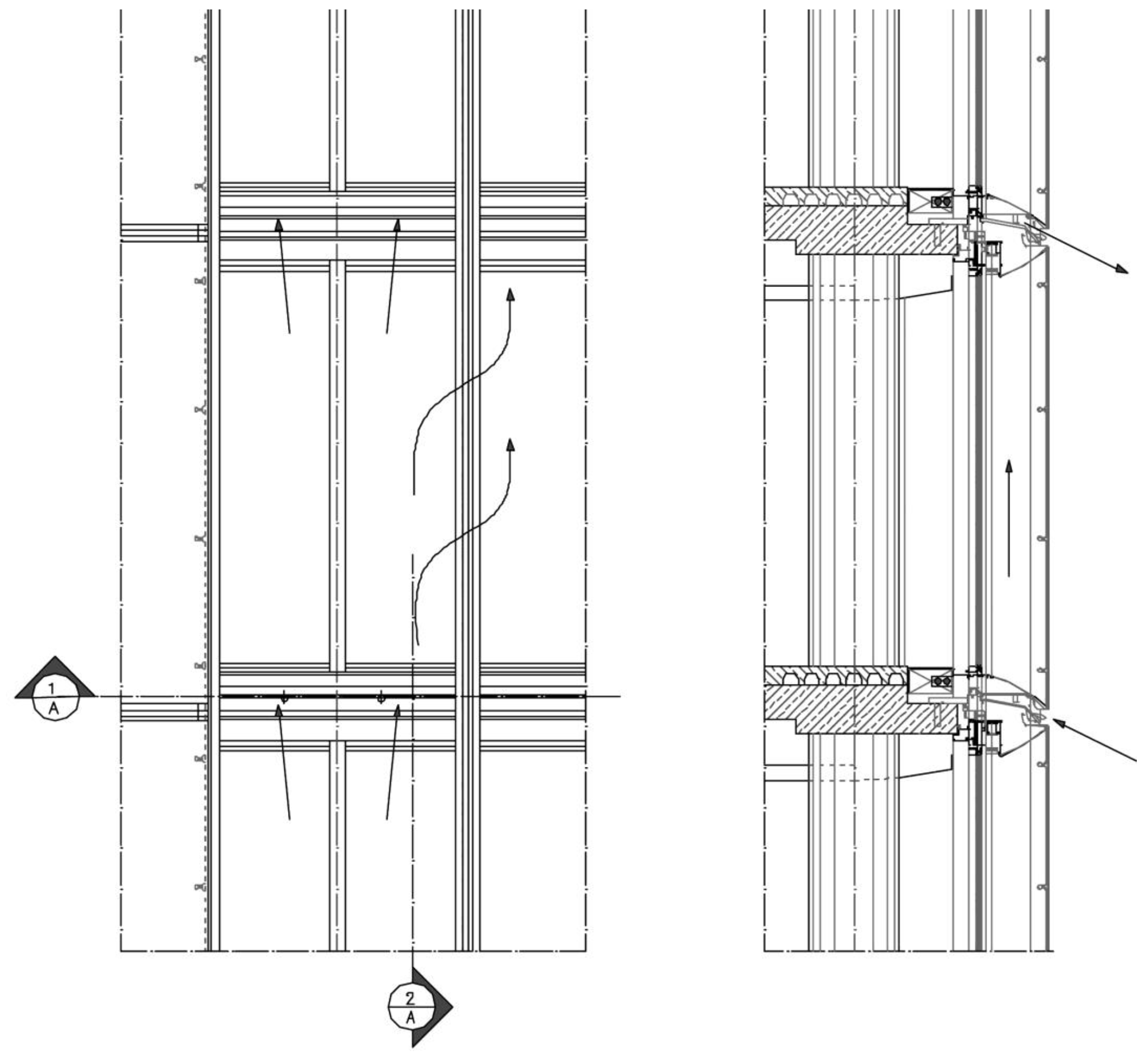

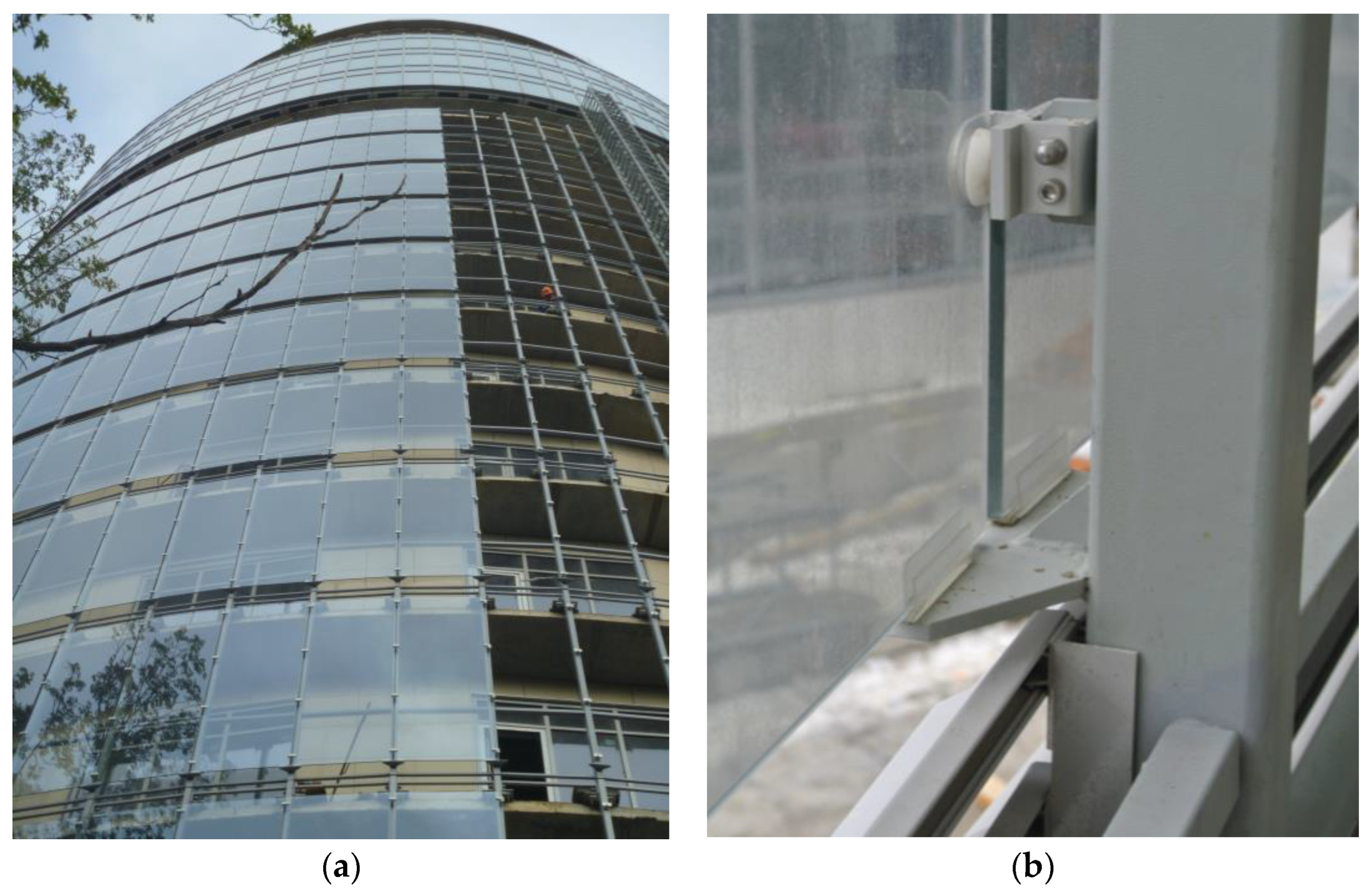

2.3.5. Sustainable Methods in the Form of the Corridor Systems

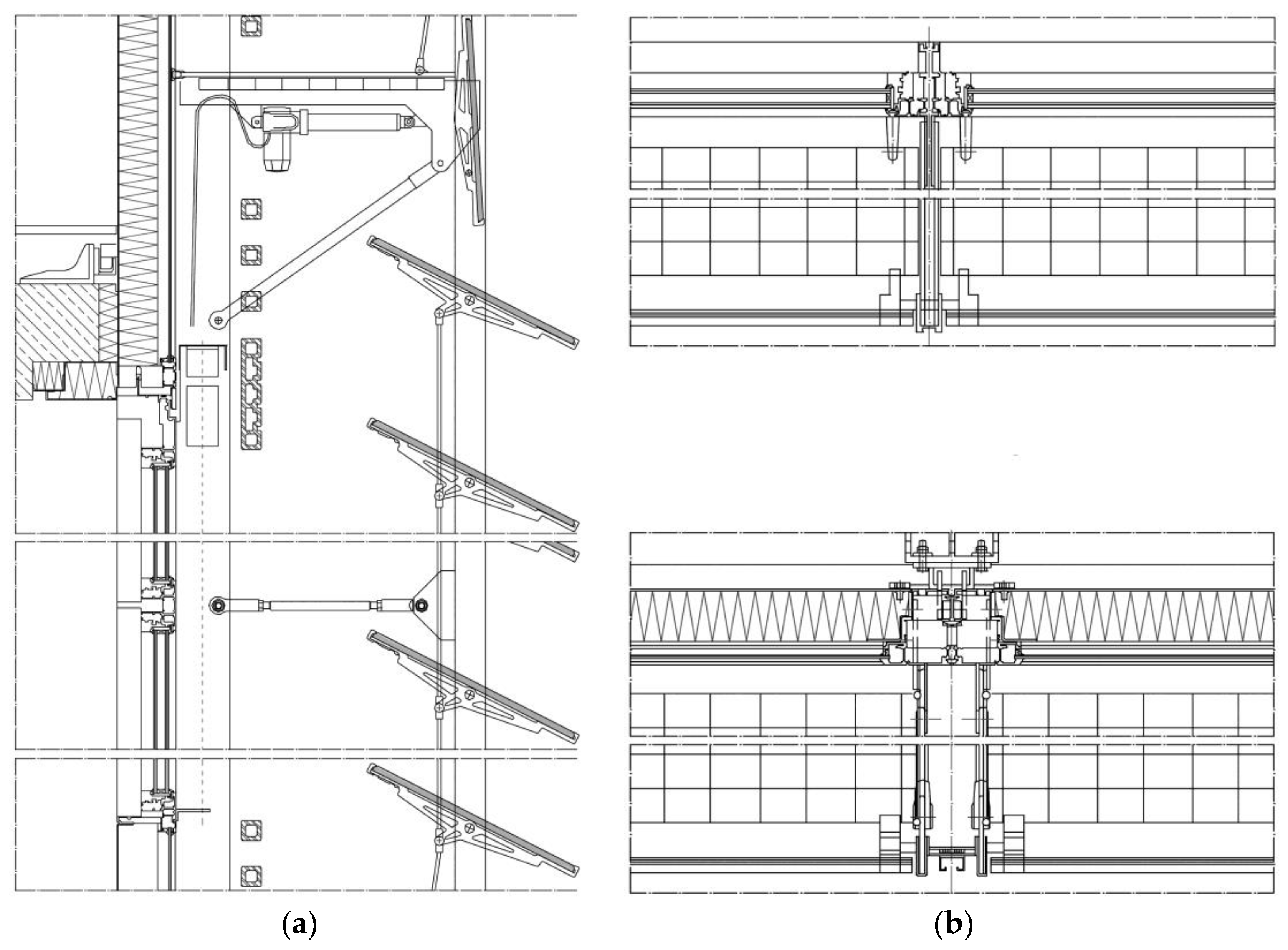

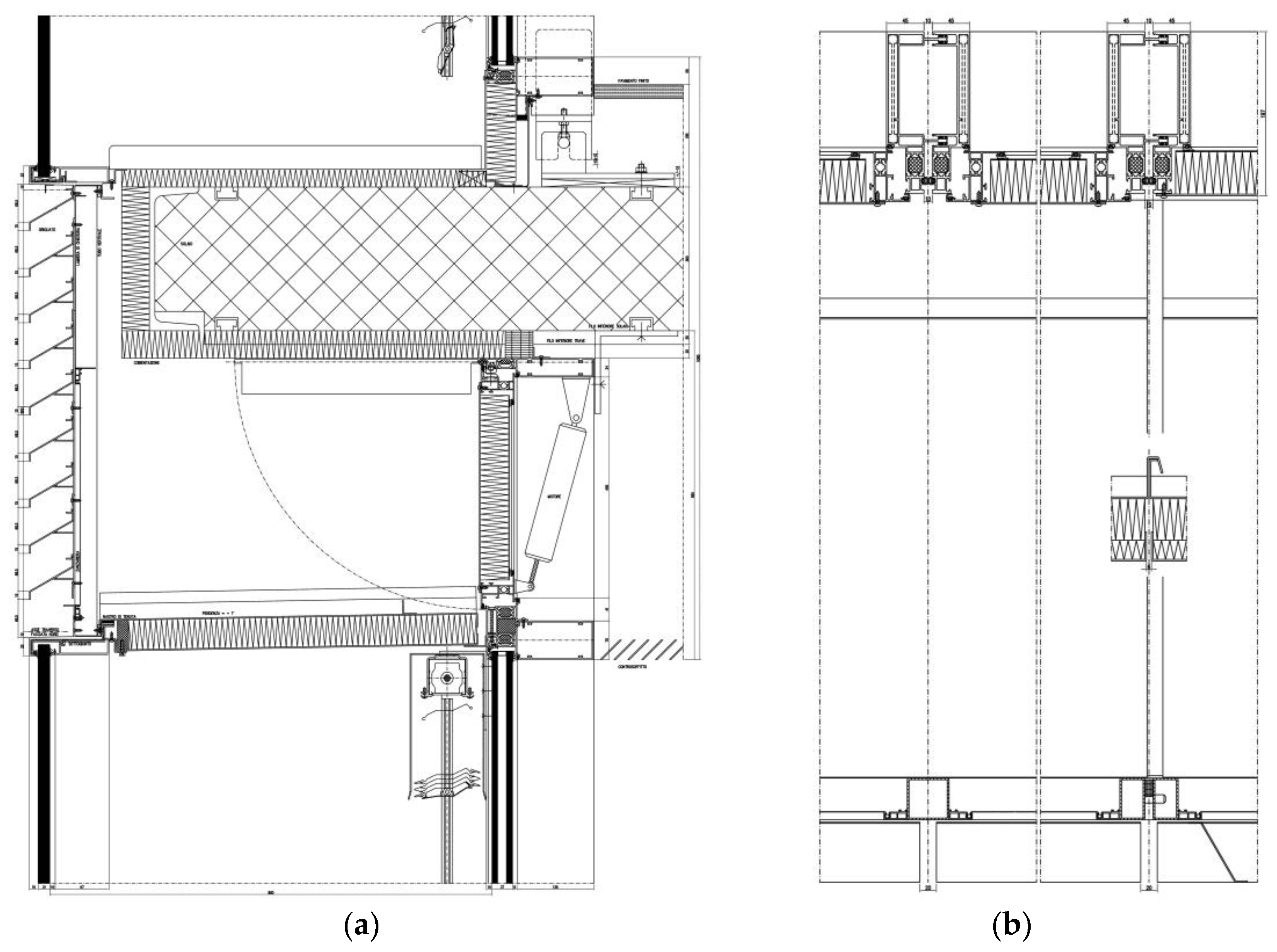

- the application of the intermediate space between two contiguous components closed at the level of each floor. The divisions are foreseen along the horizontal length of the corridor where it is necessary for acoustic, fire-protection or ventilation needs;

- the application of the air-intake and extract openings in the screen placed near the floor and the ceiling: they are usually laid out in staggered form from bay to bay to prevent vitiated air extracted on one floor entering the space on the floor above.

- the internal enclosure realized by a double-glazed frame at floor height, with sections that can be opened outwards;

- the external screen realized by a single tempered glass panel, connected, at each inter-floor level, to the apparatus including the external ventilation devices [34].

- a series of deflecting wings, facing outside the façade, which guide the external convective airflows towards the regulating equipment;

- the regulation apparatus, electrically operated with centralized control;

- a series of deflecting wings inside the devices, located in the lower section, necessary to direct the airflows, in a vertical direction, inside the cavity (Figure 27).

- the left component provides for the inflow of the convective airflows, by lowering the regulating element, and the airflows, first vertical and then diagonal, towards the cavity; the lower and upper sections of the ventilation device are open;

- the right component provides for the outflow of the air from the cavity to the outside, by lifting the regulation element; the lower section is open and has deflecting wings that guide the airflows in the cavity to the outside, and the upper section is closed.

- the effectiveness against the direct and reflected solar radiation, with the opportunity to direct the incident sun rays towards the internal ceiling surfaces increasing the diffusion conditions of the natural light;

- the supply of the heat depending on the external temperature and solar radiation conditions, being particularly effective when the external temperature is lower than the temperature of the internal spaces and for low overall radiation values;

- the conditions of easy management (through automatic regulation), as the devices are protected from the wind loads and external climatic conditions (Figure 28).

3. Results

3.1. Scientific and Executive Perspectives: Potential and Criticality of Development and Application

- the detection of the sustainable methods directed towards the formulation of the physical and passive procedures of natural ventilation, light radiation calibration and thermal storage;

- the detection of the specific methods of activation, transformation and acquisition of the environmental loads;

- the detection of the opportunities and criticalities of replication, diffusion and technology transfer to the buildings of common character of new construction or subject to technological requalification [35].

-

the development of the potential of sustainable methods in the form of the box-windows systems (2.3.2), through:

- -

- the constitution of systems and components of reduced geometries, dimensions and functionality, understood as system evolution and in the form of technical hybridization with respect to the reference typologies (3.2);

- -

- the constitution of systems and components aimed at the technological requalification of the pre-existing buildings (with frame structure and vertical development), through the replacement of the vertical enclosures with interactive systems with respect to the external and internal environmental loads (3.3);

- -

- the constitution of systems and components through the use of standard, mass and non-customized products, in the form of technology transfer (3.4);

-

the development of the potential of sustainable methods in the form of the multistory (2.3.3) and of the corridor systems (2.3.5), through:

- -

- the constitution of systems and components of calibrated geometries, dimensions and functionalities with respect to the vertical and horizontal elevation structures of new and pre-existing buildings;

- -

- the detection of multiple applications, for specific sectors or for complete envelope extensions for the activation of upward convective airflows by the chimney effect;

- -

- the possibility of establishing calibrated applications with respect to the performance-enhancing functions at thermo-hygrometric, lighting and acoustic levels in combined or specific form, even with respect to the façade sections with openings;

- -

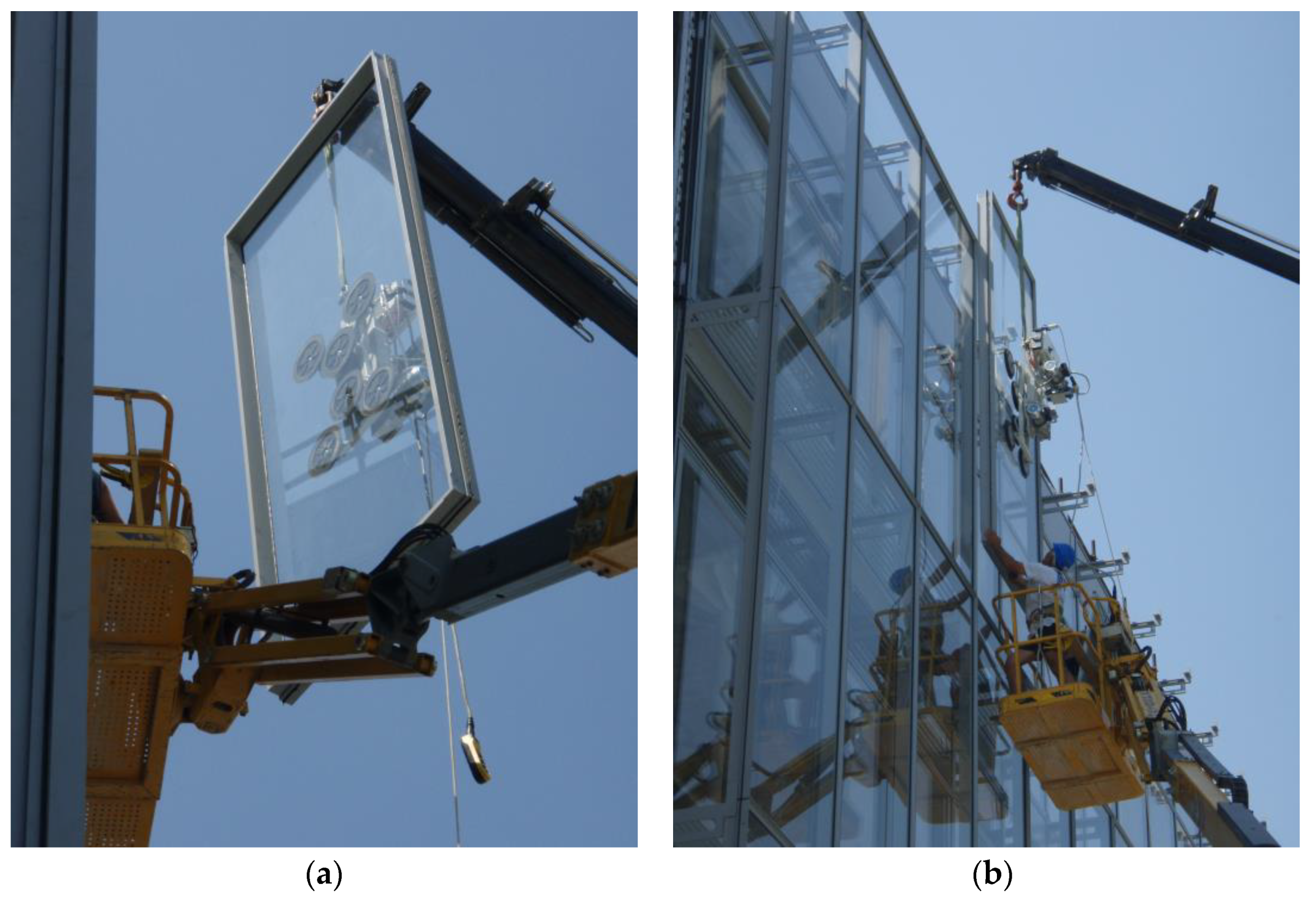

- the possibility of applying the screen components in the form of modules or in the form of prefabricated unit systems;

- -

- the adaptability of the shading solutions either by means of customized or standard and non-customized types of framing, or by means of different layering of glass surfaces or other cladding components (3.5);

-

the criticality related to the development of the sustainable methods in the form of the shaft-box systems (2.3.4), as it determines:

- -

- the need for a vertical extension of the façade such as to allow the combined aggregation of two types of components with different functioning and according to three types of execution (i.e., the series of central modules for the convection of the airflows relative to the exhaust air and the side modules both for the acquisition of the external airflows and for the conduction towards the central modules)

- -

- the need for complex design and production of the devices for acquiring external airflows, which require specific aerodynamic calibration against the environmental conditions of the context [36].

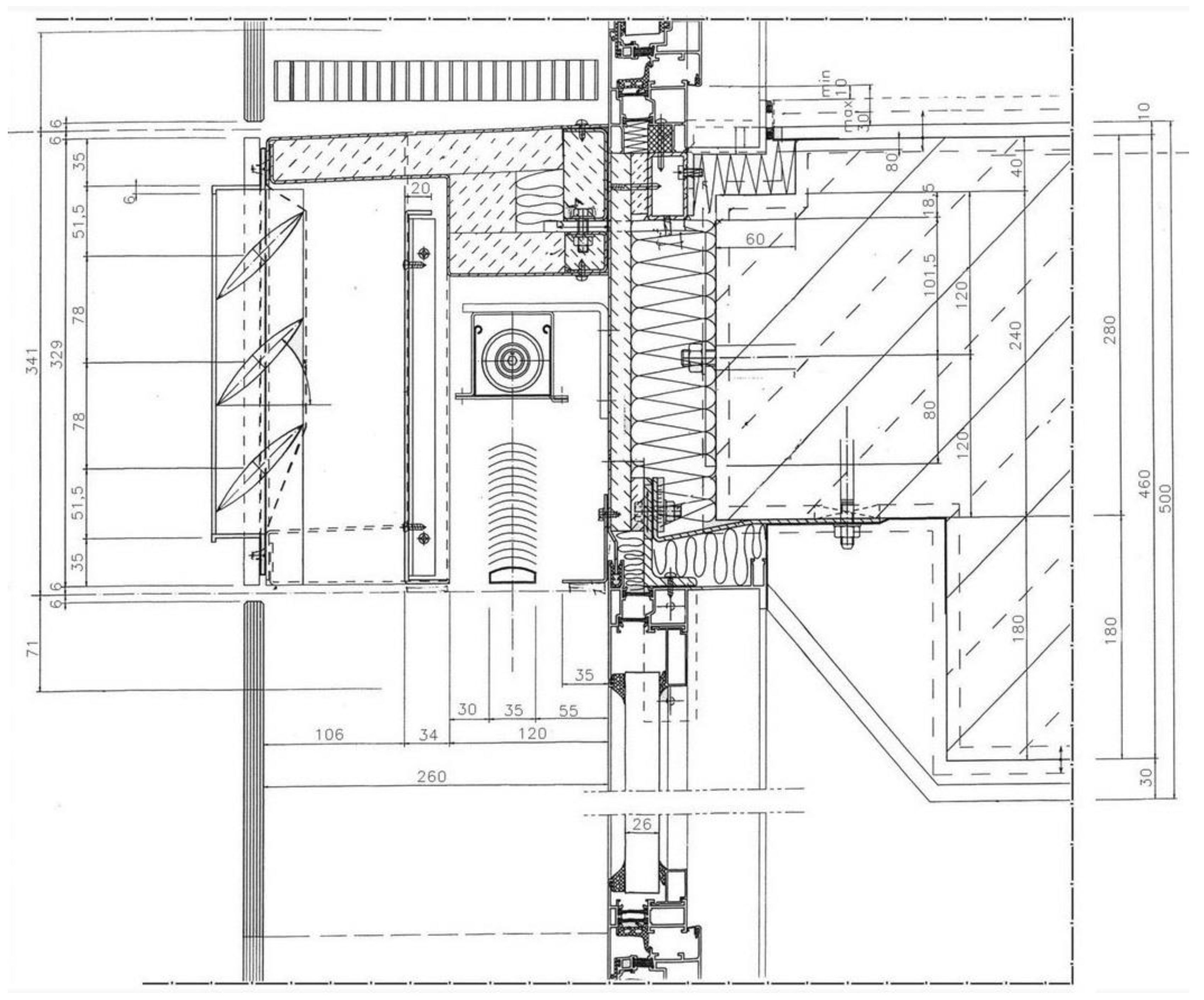

3.2. Technical Hybridization: Sustainable Methods Through System Calibration

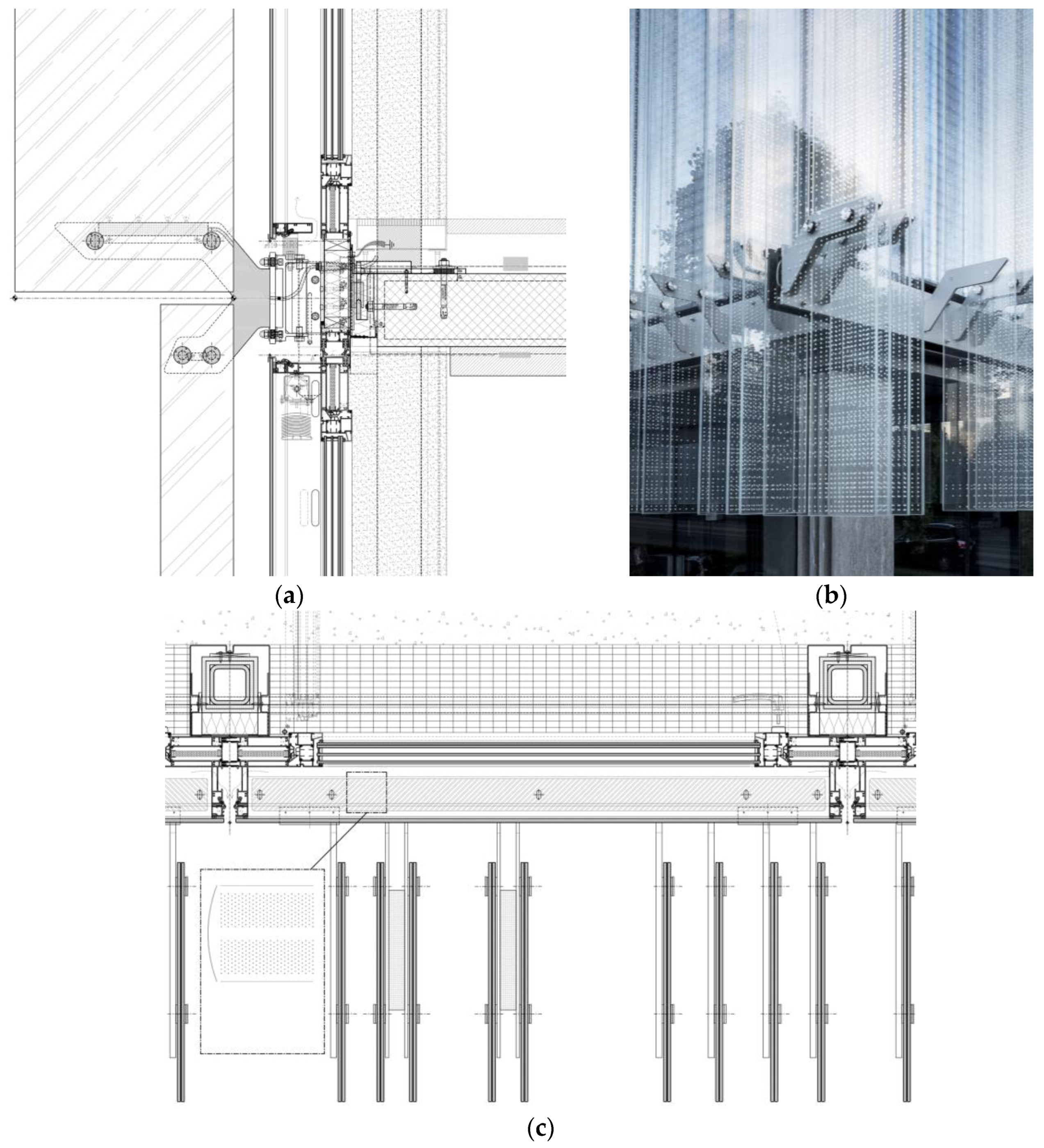

- for the internal façade, the double-glazing panels (with thickness = 6+6 mm and with air gap thickness = 18 mm), HST-tempered and transparent, of low-emissivity type (with the thermal transmittance coefficient UW = 1,40 W/m².K);

- for the external sunshades, the screen-printed single-glazing panels (thickness = 12 mm), adjustable around the vertical axis (Figure 31).

- the internal enclosure composed of the triple glazing with two chambers of the Guardian Extraclear Tempered float type (according to the values expressed by FS = 50%; RL = 16%; TL = 67%; thermal transmittance coefficient UW = 0,60 W/m2.k);

- the interposed ventilated cavity containing the micro-perforated venetian blind device for the regulation of the light radiation (for the overall width of 130 mm);

- the simple extra-clear tempered HST glass (thickness = 10 mm) of the external screen, defined by the selective section of type SunGuard Solar SiverLite 70 HD (according to the values expressed by FS = 69,5%; RL = 26,9%; TL = 69,6%; Rw = 33 db; thermal transmittance coefficient UW = 0,60 W/m2.k).

- the combination of the extended triple tubular section profiles, provided with the double specular cavities for the insertion of the internal gaskets, on the assembly axis, and the perimeter frame profiles, for the rebate of the opening sashes;

- the projection, perpendicular to the triple tubular profiles, of the frame with the first extended tubular cavity and the external tubular cavity to support the frame profiles for the connection (by means of structural silicone) of the external shading glass panels beyond the ventilated cavity;

- the insertion, in the air gap, of the venetian blind devices made of micro-perforated aluminium louvres (Figure 32).

3.3. Technological Requalification: Replacement of Previous Curtains with Sustainable Systems

- the concept and application of the multiple-skin façade in accordance with the different solar exposure situations in order to optimize the energy behaviour;

- the dynamic interaction with the thermo-hygrometric, light and air loads, with the possibility of regulating their flows and conducting them in the overall functioning: in this way, the requalification procedures consider the fine-tuning of the cell components as mediating devices towards the climatic stresses [38,39].

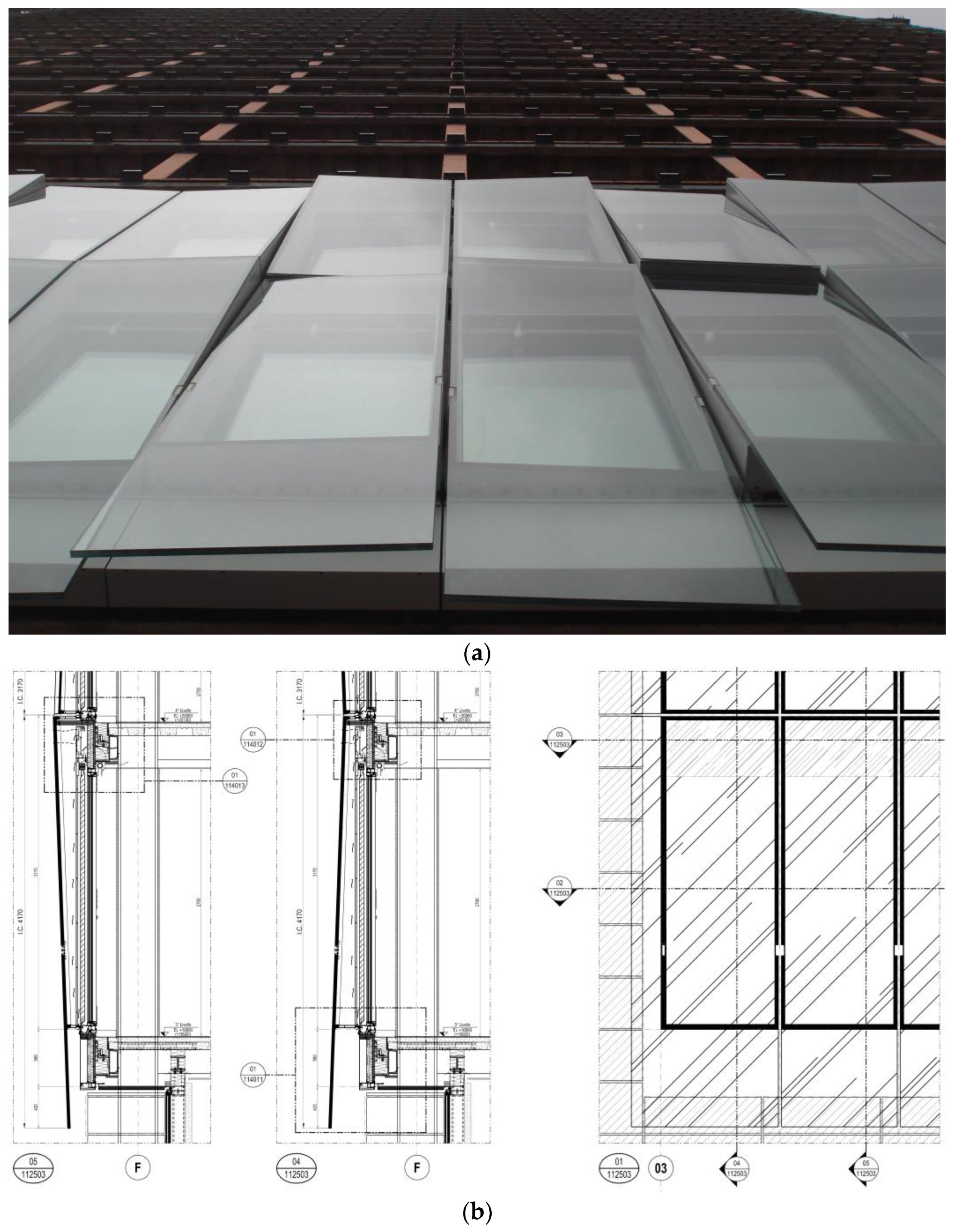

- the lower and upper interfaces, configured by the profile geometries of the transoms being laid in accordance with the interposition of the wing elements, ribs and gaskets;

- the (fixed) profile sections supporting the double-glazing enclosures;

- the pronounced portion on the outside, of box-shaped composition and of variable dimensions with respect to the curtain at inter-floor level, to support the laminated glass screen, in accordance with the geometry of the cavity thickness.

3.4. Technology Transfer: Sustainable Methods Through Mass Production Components

3.5. Technology Transfer: Potential for Sustainable Methods by Means of External Screens

4. Discussion

- the analysis of the main functional and construction modes of the multiple-skin façades, proposing their classification with respect to the executive constitution and control of the airflows within the cavities;

- the analysis of the opportunities and criticalities with respect to their diffusion also by means of non-customized components, technical elements and devices [42].

- the detection of a series of construction and functional methods that can be the object of diffusion, technology transfer and improvement for their serial production;

- the constitution of a document in which the graphic diagrams, the executive models (also with the support of clear, selected and focused illustrations of real cases) and applications of technology transfer, system evolution and technical hybridization can constitute a reference for the interaction between expert skills in the design, production and construction fields and expert skills in the physical field, in the modelling and simulation of the actual functional criteria: this is in order to calibrate the dimensions of the cavities, to optimize the types of transparent surfaces related to the internal façades and external shading, to proceed with the component design of the devices directed to the capture and conduction of the airflows;

- the constitution of a basic document for learning, observing and subsequently setting up the technical interfaces between the building structures (new or pre-existing) and sustainable applications of the multiple-skin façades;

- the formulation of methodological knowledge aimed at creating the cognitive and applicative basis for the theoretical and professional training of the façade designer or façade manager (often performed by structural engineers or technical-professionals within the production and construction companies) [43,44].

References

- Banham, R. Megastructure. In Urban futures of the recent past; Thames & Hudson: London, 1976. [Google Scholar]

- Daniels, K. The Technology of Ecological Building; Birkhäuser: Basel-Boston-Berlin, 1994. [Google Scholar]

- Slessor, C. Eco-Tech. In Sustainable Architecture and High Technology; Thames & Hudson: London, 1997. [Google Scholar]

- Herzog, T.; Krippner, R.; Lang, W. Fassaden Atlas; Institut für Internationale Architektur–Documentation: Munich, 2004. [Google Scholar]

- Altomonte, S. L’involucro architettonico come interfaccia dinamica; Alinea: Florence, 2004. [Google Scholar]

- Paoletti, I.; Nastri, M. Executive Design of the Façade Systems. In Typologies and Technologies of the Advanced Building Envelopes; Springer: Cham, 2023. [Google Scholar]

- Paoletti, I.; Nastri, M. Construction of the Façade Systems. In Production and Assembly Procedures of the Advanced Building Envelopes; Springer: Cham, 2023. [Google Scholar]

- Schittich, C. (Ed.) Building Skins; Birkhäuser: Basel-Boston-Berlin, 2001. [Google Scholar]

- Eren, Ö.; Erturan, B. Sustainable Buildings with Their Sustainable Facades. IACSIT International Journal of Engineering and Technology 2013, 5, 725–730. [Google Scholar]

- Lovell, J. Building Envelopes. An Integrated Approach (Architecture Briefs); Princeton Architectural Press: New York, 2010. [Google Scholar]

- Schmid, F.; Cseh, X.; Rohrer, E.; Teich, M. Double-Skin Façades: Boundary Conditions, Challenging Examples and Developments. Glass in Architecture and Structural Engineering 2018, 2, 103–112. [Google Scholar] [CrossRef]

- Hausladen, G.; de Saldanha, M.; Liedl, P. ClimateSkin. In Building-skin Concepts that Can Do More with Less Energy; Birkhäuser: Basel, 2008. [Google Scholar]

- Aksamija, A. Sustainable façades: Design methods for high-performance building envelopes; John Wiley & Sons: Hoboken, NJ, 2013. [Google Scholar]

- Nastri, M. Future Façade Systems. Technological Culture and Experimental Perspectives. In Material Balance. A Design Equation; Paoletti, I., Nastri, M., Eds.; Springer: Cham, 2021; pp. 83–103. [Google Scholar] [CrossRef]

- Yonghuort, L.; Mohd, R.I. Aptitudes of Double Skin Façade Toward Green Building within Built Environment. Journal of Advanced Research in Fluid Mechanics and Thermal Sciences 2022, 100, 146–170. [Google Scholar] [CrossRef]

- Boswell, K. Exterior Building Enclosures. Design Process and Composition for Innovative Facades; Wiley & Sons: Hoboken, NJ, 2013. [Google Scholar]

- Daniels, K. Advanced Building Systems. A Technical Guide for Architects and Engineers; Birkhäuser: Basel, 2003. [Google Scholar]

- Wasiska, I.; Surjamanto, W.; Aswin, I. Natural Airflow Performances of Double-Skin Facade Types. Journal of Architecture and Built Environment 2014, 41, 65–72. [Google Scholar] [CrossRef]

- Omrani, H.; Ghaffarianhoseini, A.; Ghaffarianhoseini, A.; Raahemifar, K.; Tookey, J. Application of passive wall systems for improving the energy efficiency in buildings. Renewable and Sustainable Energy Reviews 2016, 62, 1252–1269. [Google Scholar] [CrossRef]

- Oesterle, E.; Lieb, R.-D.; Lutz, M.; Heusler, W. Double-Skin Facades; Prestel: Munich, 2001. [Google Scholar]

- Gelesz, A.; Reith, A. Classification and re-evaluation of double-skin facades. International Review of Applied Sciences and Engineering 2011, 2, 129–136. [Google Scholar] [CrossRef]

- Bostancioglu, E.; Onder, N.P. Applying analytic hierarchy process to the evaluation of double skin façades. Architectural Engineering and Design Management 2019, 5, 66–82. [Google Scholar] [CrossRef]

- Al-awag, E.A.N.; Wahab, I.A. Perspectives in double-skin façade (DSF) advantages and disadvantages. In Proceedings of the IOP Conference Series: Earth and Environmental Science, 6th International Conference on Civil and Environmental Engineering for Sustainability (IConCEES 2021), Online, 15 November 2021; pp. 1–9. [Google Scholar] [CrossRef]

- Shameri, M.A.; Alghoul, M.A.; Sopian, K.; Fauzi, M.; Zain, M.; Elayeb, O. Perspectives of double skin façades systems in buildings and energy saving. Renewable and Sustainable Energy Reviews 2011, 15, 1468–1475. [Google Scholar] [CrossRef]

- Ding, W.; Hasemi, Y.; Yamada, T. Natural ventilation performance of a double-skin façade with a solar chimney. Energy and Buildings 2005, 37, 411–418. [Google Scholar] [CrossRef]

- Khoshbakht, M.; Gou, Z.; Dupre, K.; Altan, H. Thermal environments of an office building with double skin façade. Journal of Greenbuilding 2017, 12, 3–22. [Google Scholar] [CrossRef]

- Chou, S.K.; Chua, K.J.; Ho, J.C. A study on the effects of double skin façades on the energy management in buildings. Energy Conversion and Management 2009, 50, 2275–2281. [Google Scholar] [CrossRef]

- Ahmed, M.M.S.; Abel-Rahman, A.K.; Ali, A.H.H.; Suzuki, M. Double Skin Façade: The State of Art on Building Energy Efficiency. Journal of Clean Energy Technologies 2016, 4, 84–89. [Google Scholar] [CrossRef]

- Safer, N.; Woloszyn, M.; Roux, J.J.; Kuznik, F. Modeling of the double-skin facades for building energy simulations: Radiative and convective heat transfer. Building Simulation 2005, 1067–1074. [Google Scholar]

- Feng, X.; Yang, H.; Feng, X.Y.; Jin, F.Y.; Xia, G.Q. A Review of Research Development of Ventilated Double-Skin Façade. Applied Mechanics and Materials 2014, 587–589. [Google Scholar] [CrossRef]

- Hensen, J.; Bartak, M.; Drkal, F. Modeling and simulation of a double-skin façade system. ASHRAE Transactions 2002, 108, 1251–1259. [Google Scholar]

- Roth, K.; Lawrence, T.; Brodrick, J. Double-skin facades. ASHRAE Journal 2007, 49. [Google Scholar]

- Baldinelli, G. Double skin façades for warm climate regions: Analysis of a solution with an integrated movable shading system. Building and Environment 2009, 44, 1107–1118. [Google Scholar] [CrossRef]

- Aksamija, A. Sustainable façades: Design methods for high-performance building envelopes. Journal of Façade Design & Engineering 2018, 6, 1–39. [Google Scholar] [CrossRef]

- Musa, B.T.; Alibaba, H.Z. Evaluating the Use of Double Skin Facade Systems for Sustainable Development. Journal of Medical and Applied Biosciences 2017, 9, 55–72. [Google Scholar]

- Høseggen, R.; Wachenfeldt, B.J.; Hanssen, S.O. Building simulation as an assisting tool in decision making: Case study: With or without a double-skin façade? Energy and Buildings 2008, 40, 821–827. [Google Scholar] [CrossRef]

- Syed, A. Advanced Building Technologies for Sustainability; Wiley & Sons: Hoboken, NJ, 2012. [Google Scholar]

- Hamid, A.A. Design and Retrofit of Building Envelope; Bookbaby: Pennsauken, NJ, 2012. [Google Scholar]

- Kim, G.; Schaefer, L.; Kim, J.T. Development of a Double-Skin Façade for Sustainable Renovation of Old Residential Buildings. Indoor and Built Environment 2012, 22, 180–190. [Google Scholar] [CrossRef]

- Mohsen, A. Design to Manufacture of Complex Building Envelopes; Springer: Cham, 2020. [Google Scholar]

- Knaack, U.; Klein, T.; Bilow, M.; Auer, T. Façades. In Principles of Construction; Birkhäuser: Basel, 2007. [Google Scholar]

- Stazi, F. Advanced Building Envelope Components; Elsevier: Amsterdam, 2019. [Google Scholar]

- Abrantes, V.; Rangel, B.; Amorim Faria, J.M. (Eds.) The Pre-Fabrication of Building Facades; Springer: Cham, 2017. [Google Scholar]

- Gunawardena, T.; Mendis, P. Prefabricated Building Systems. Design and Construction. Encyclopedia 2022, 2, 70–95. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).