Submitted:

11 October 2024

Posted:

11 October 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

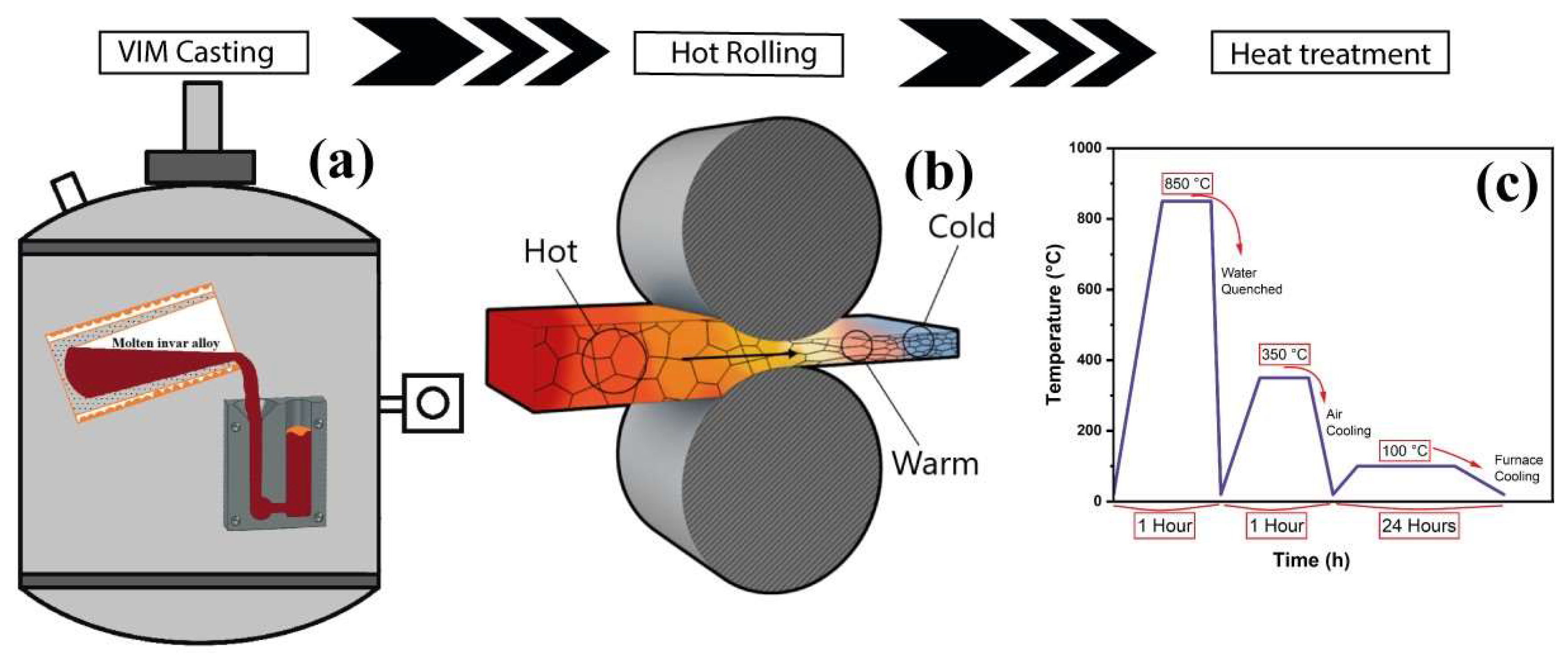

2. Materials and Methods

2.2. Characterization

3. Results and Discussion

4. Conclusions

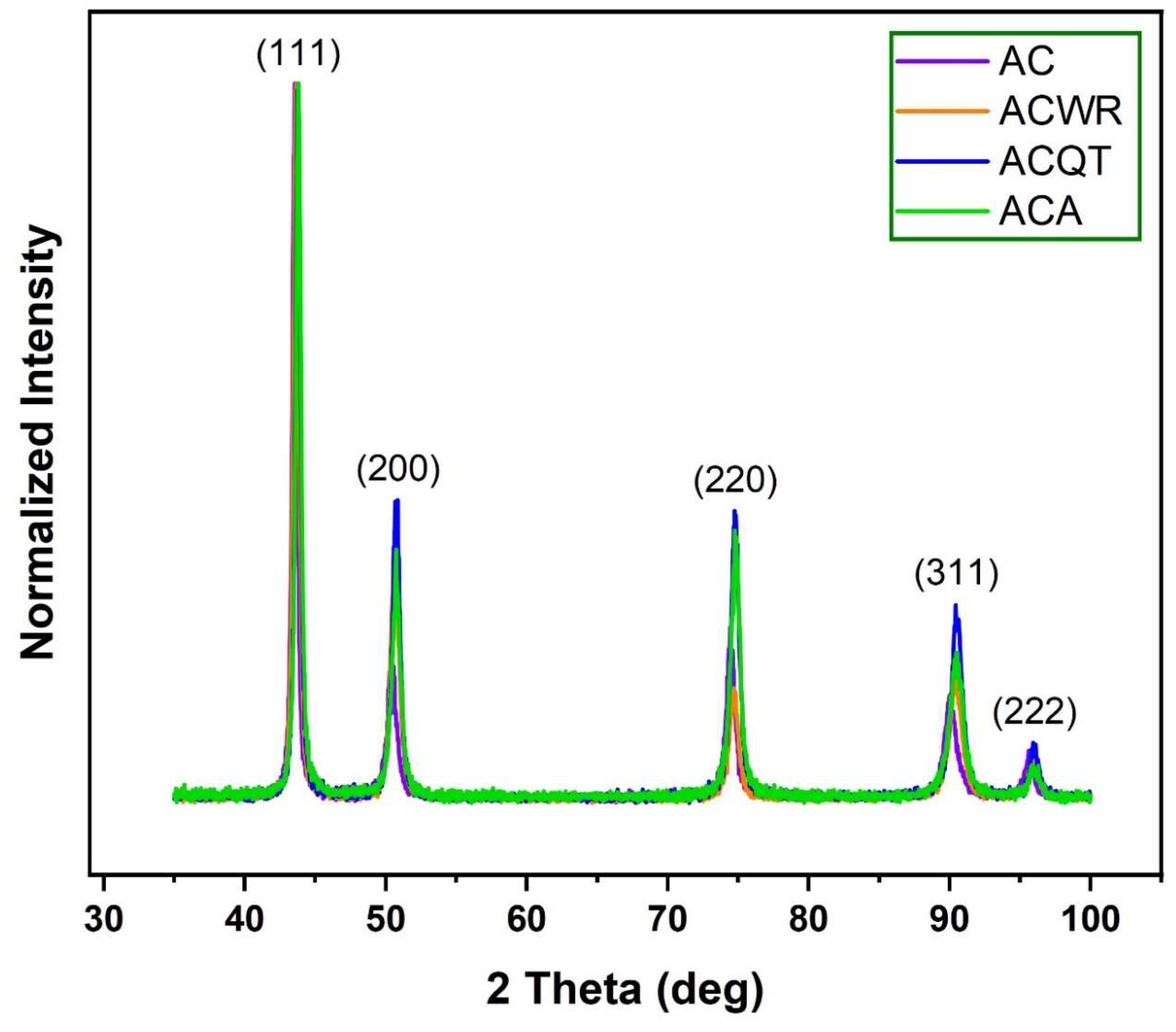

- All samples exhibited classical austenite (γ-Fe) XRD peaks, with the strongest diffraction peaks being primarily γ(111), γ(200), γ(220), γ(311) and γ(222). The relative intensities of thermodynamically stable planes, such as (111), were observed to be higher in all samples. It is noteworthy that the intensity of peak (200) increased significantly, while the intensity of peak (220) decreased and the intensity of the other peaks remained relatively unchanged during the warm rolling process.

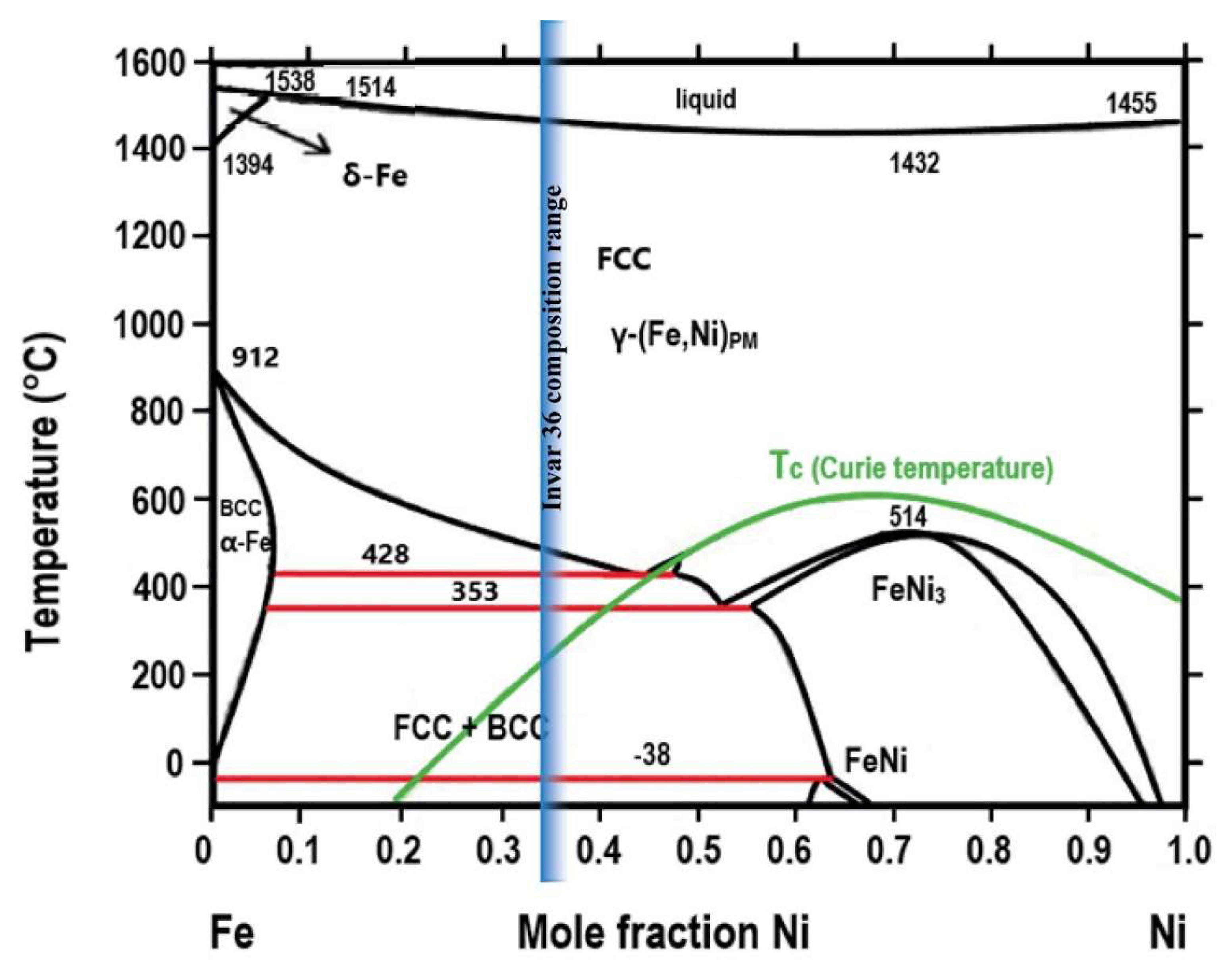

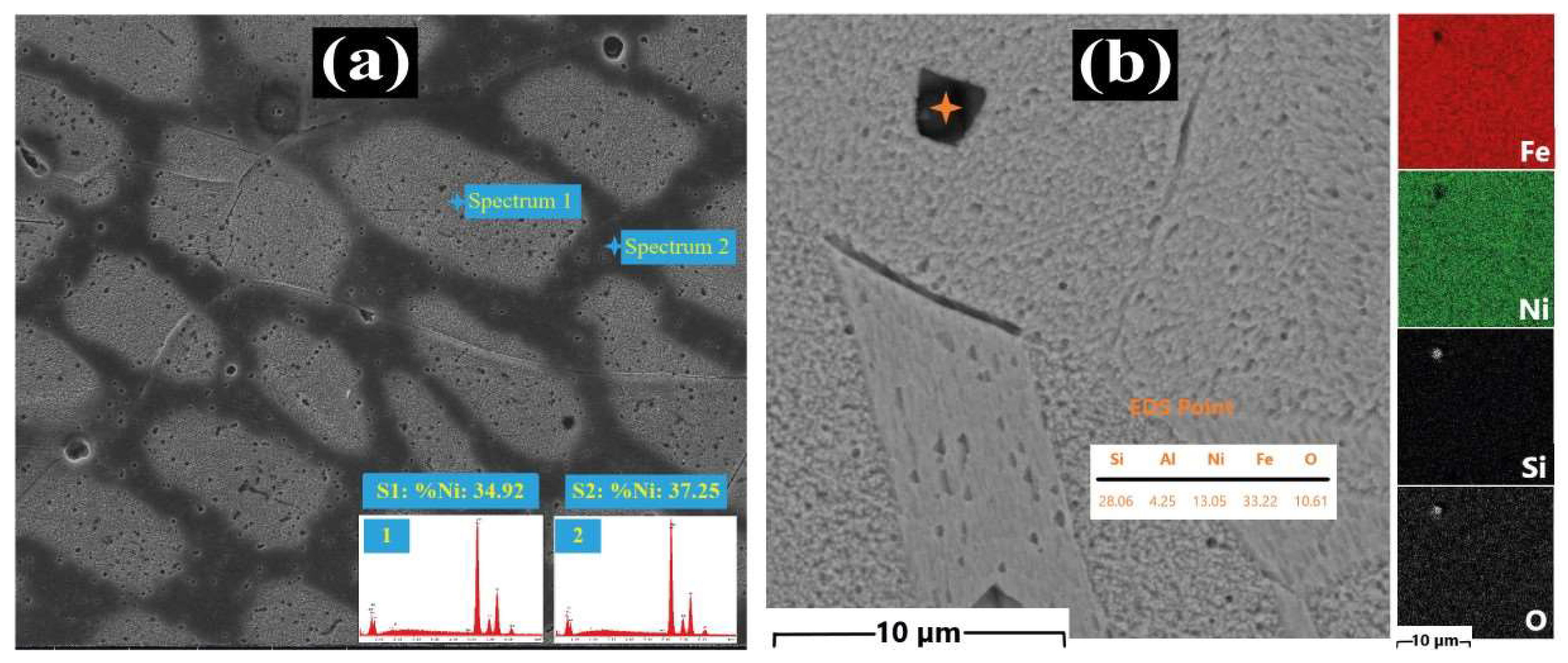

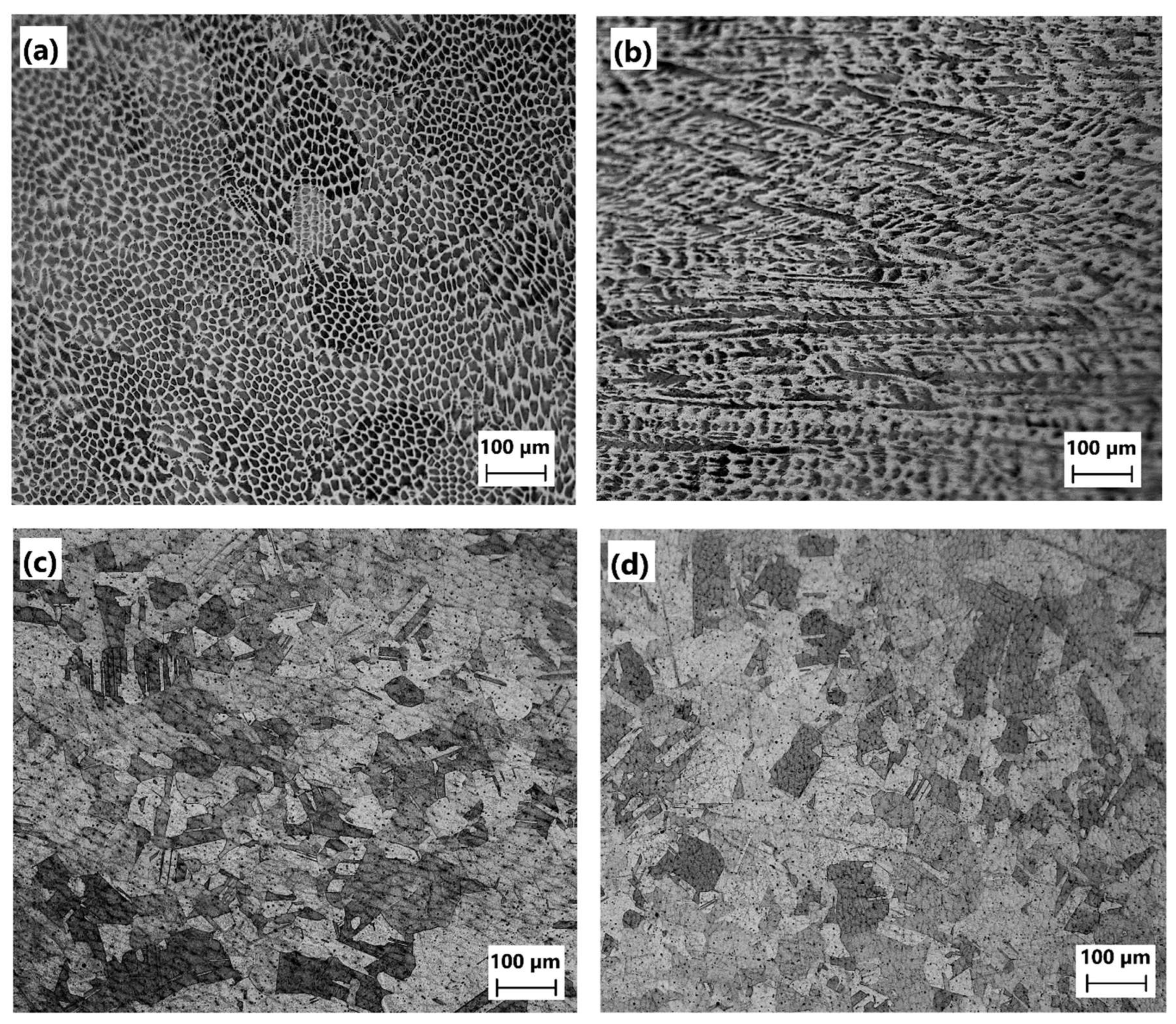

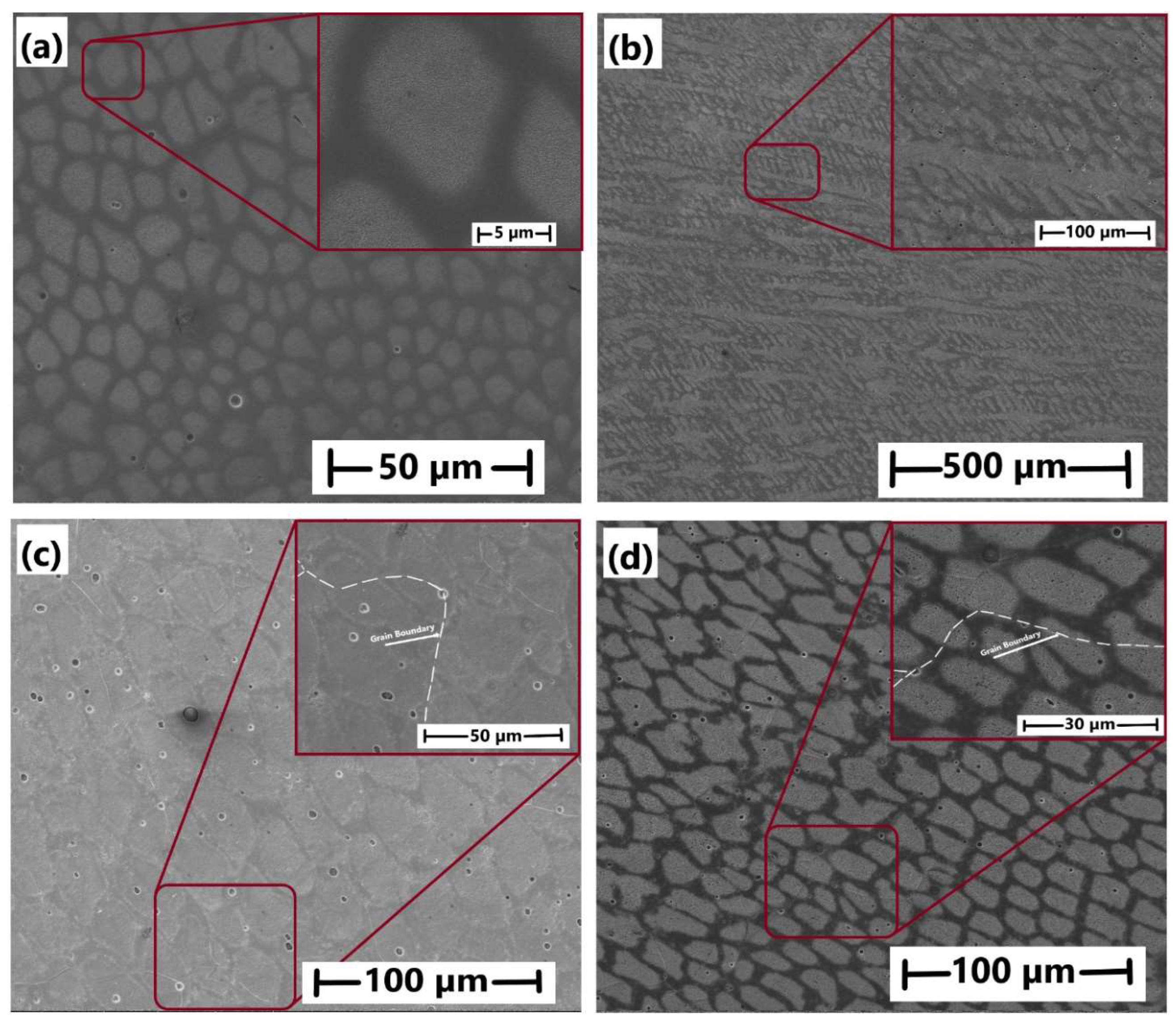

- The casting process resulted in the formation of microcellular structures that exhibited a resemblance to sub-grain structures. The formation of microcellular structures can be facilitated by the influence of relatively rapid solidification. The microcellular regions in which Ni segregation occurs are distinguished by the presence of Ni-poor regions and encompass the diverse morphological states of microcellular structures that resemble "cobblestones" embedded in austenite grains.

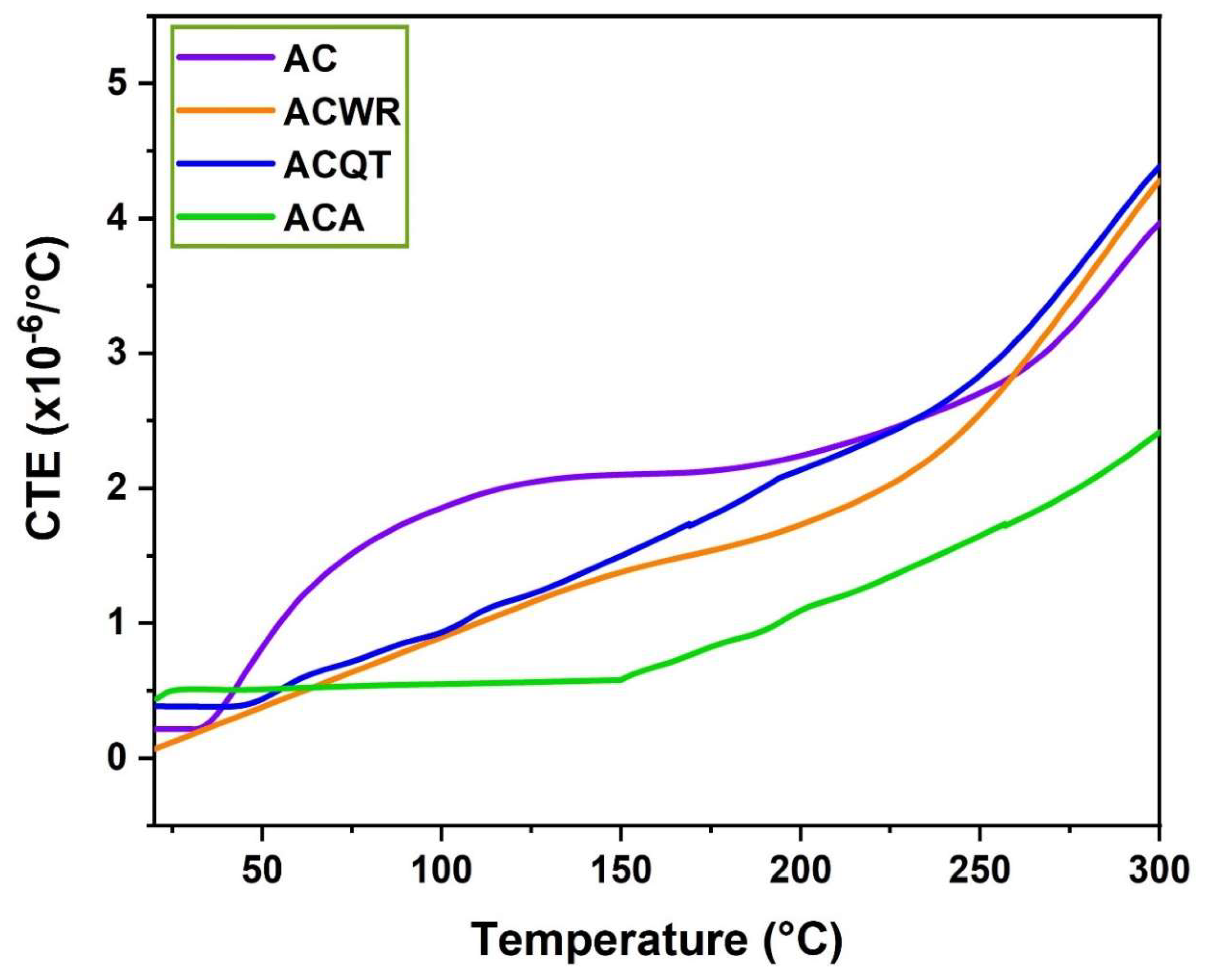

- The most favorable result that could be expected from Invar 36, which displays both minimal thermal expansion and thermally stable properties up to ~150 °C, was observed in the sample that underwent a three-step heat treatment. The material displays remarkable consistency in its dimensional stability of thermally, exhibiting minimal fluctuations in its coefficient of thermal expansion (CTE) value between 0.5 and 0.6 x10-6/°C up to 150 °C.

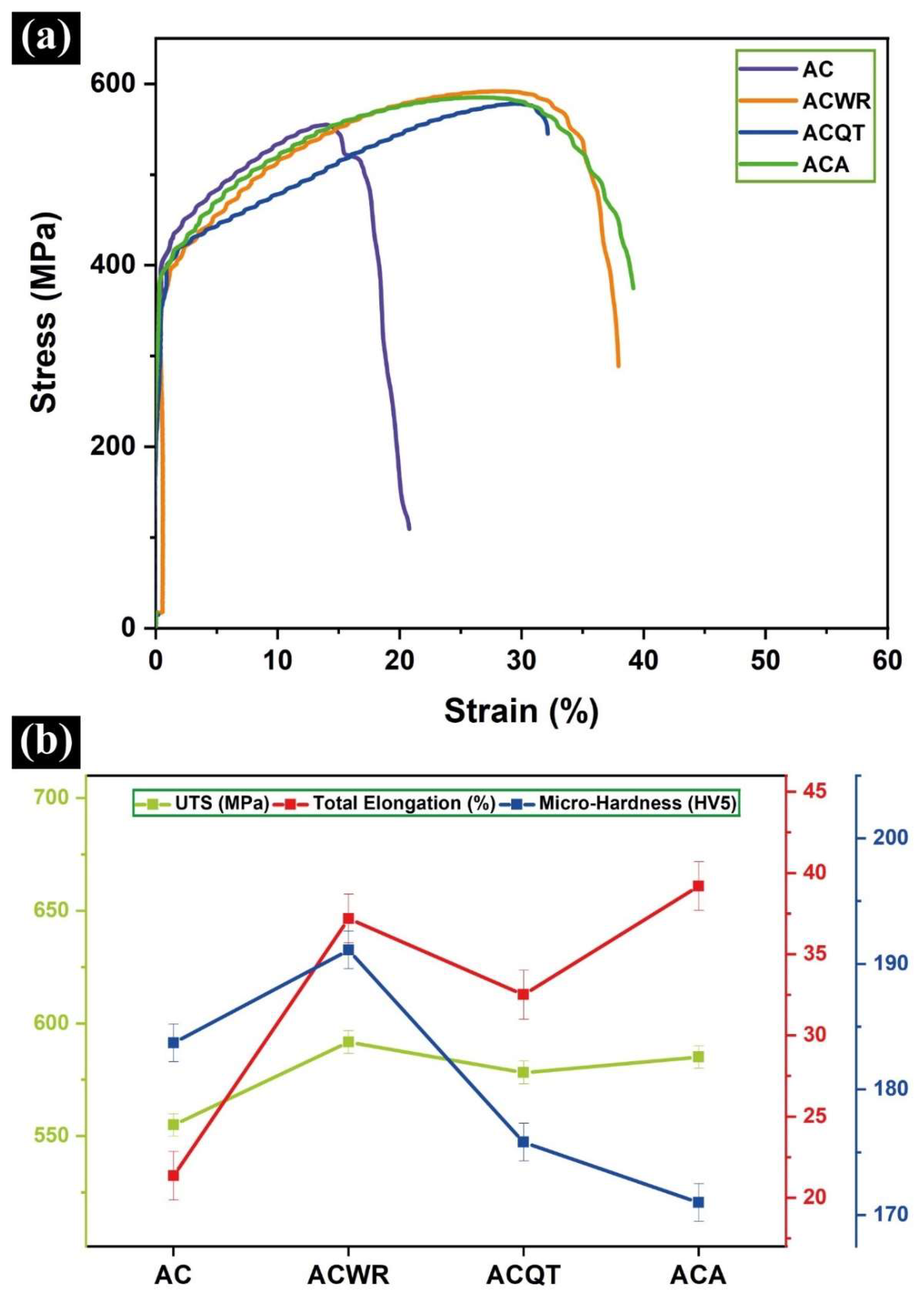

- Following the application of warm rolling at 900 °C, an increase of approximately 40 MPa in tensile strength was observed. The warm-rolled specimen exhibited the highest tensile strength, reaching 592 MPa. The total elongation value after casting was relatively low at 21%, which is likely due to the presence of micro voids after casting, which have had a detrimental impact on the total elongation. The conclusion of the warm rolling and three-step heat treatment resulted in a notable enhancement in total elongation, reaching 40%, which can be attributed to the combined influence of reduced dislocation densities and residual stresses, in addition to recrystallisation within the structure.

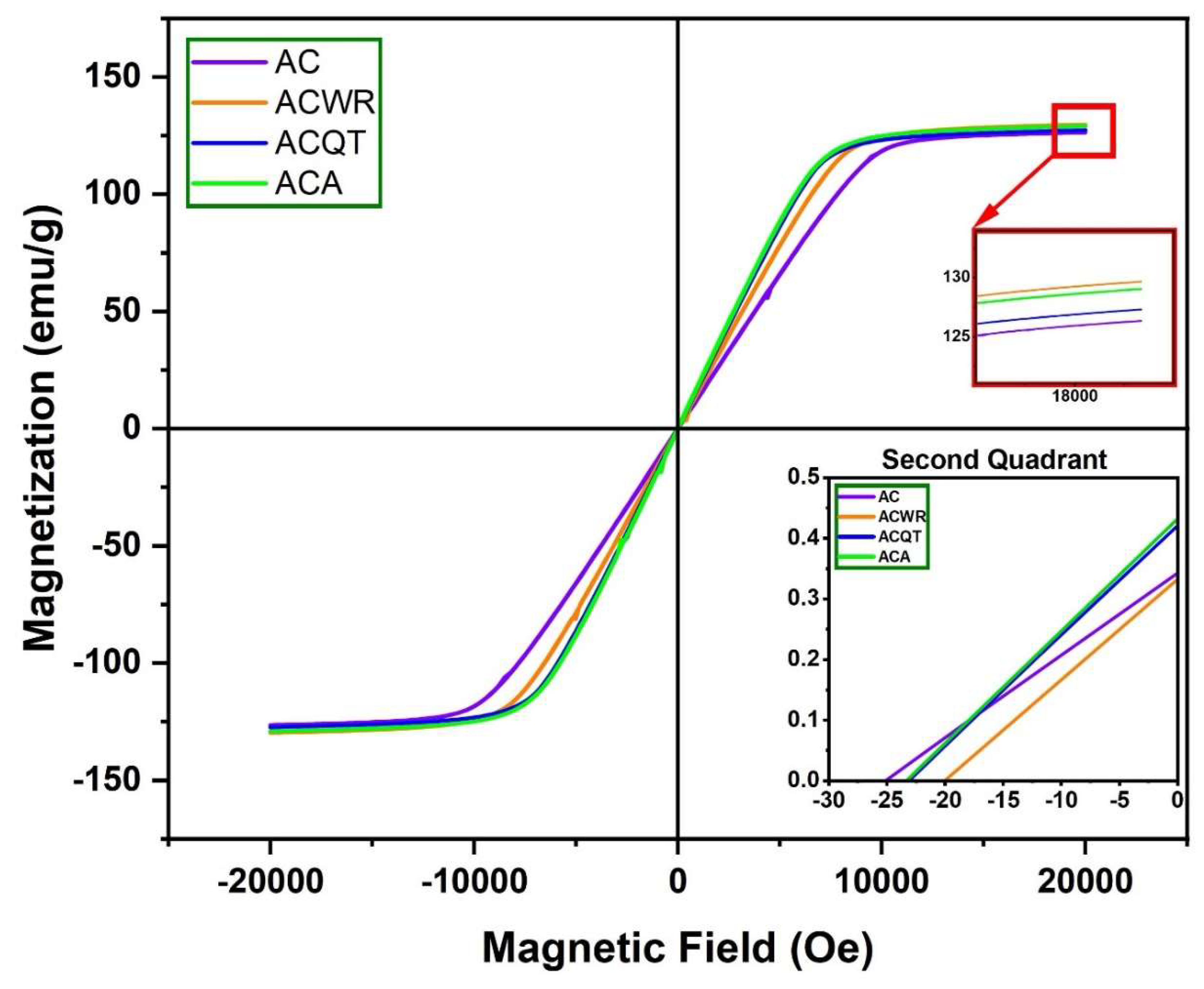

- All samples exhibited soft magnetic properties. The saturation magnetization (Ms) was observed to increase from 126 emu/g to 130 emu/g as a consequence of the warm rolling and three-step heat treatment processes. The coercivity values of the samples were found to vary between 20 and 25 Oe.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nie, Q.; Chen, G.; Wang, B.; Yang, L.; Zhang, J.; Tang, W. Effect of Invar Particle Size on Microstructures and Properties of the Cu/Invar Bi-Metal Matrix Composites Fabricated by SPS. J. Alloys Compd. 2022, 891, 162055. [CrossRef]

- Nyanor, P.; El-Kady, O.; Yehia, H.M.; Hamada, A.S.; Hassan, M.A. Effect of Bimodal-Sized Hybrid TiC–CNT Reinforcement on the Mechanical Properties and Coefficient of Thermal Expansion of Aluminium Matrix Composites. Met. Mater. Int. 2021, 27, 753–766. [CrossRef]

- Guillaume, C.E. Recherches Sur Les Aciers Au Nickel. Dilatations Aux Temperatures Elevees; Resistance Electrique. C. R. Acad. Sci. Paris 1897, 125, 235–238.

- Guillaume, C.-É. Invar and Elinvar. Nobel Lect. Phys. 1901-1921, 1920.

- Van Schilfgaarde, M.; Abrikosov, I.A.; Johansson, B. Origin of the Invar Effect in Iron-Nickel Alloys. Nature 1999. [CrossRef]

- Roy, D.M.; Pettifor, D.G. Stoner Theory Support for the Two-State Hypothesis for γ Iron. J. Phys. F Met. Phys. 1977. [CrossRef]

- Weiss, R.J. The Origin of the “invar” Effect. Proc. Phys. Soc. 1963. [CrossRef]

- Kul, M.; Akgül, B.; Karabay, Y.Z.; Pehlivanoğlu, K.; Türkyaman, B. A Study of the Effect of Ti-Al-V Microalloying on the Mechanical and Physical Properties of Invar 36. Mater. Today Commun. 2024, 39, 109050. [CrossRef]

- Konovalov, S.F.; Mayorov, D. V.; Semenov, A.E.; Ponomarev, Y.A.; Chulkov, V.E.; Malykhin, A.A.; Kharlamov, M.S.; Malykhin, D.A. Temperature Drift and Instability of a Zero Signal of Pendulum Compensating Q-Flex Accelerometer. 27th Saint Petersbg. Int. Conf. Integr. Navig. Syst. ICINS 2020 - Proc. 2020. [CrossRef]

- Kim, D.S.; Pyo, C.; Kim, J.; Kim, J.; Lee, H.K. A Study on Cross-Shaped Structure of Invar Material Using Cold Wire Laser Fillet Welding (PART I: Feasibility Study for Weldability). Met. 2020, Vol. 10, Page 1385 2020, 10, 1385. [CrossRef]

- Sokolowski, W.M.; Jacobs, S.F.; Lane, M.S.; O’Donnell, T.P.; Hsieh, C. Dimensional Stability of High-Purity Invar 36. In Proceedings of the Quality and Reliability for Optical Systems; Bilbro, J.W., Parks, R.E., Eds.; December 7 1993; pp. 115–126.

- NASA Turbopump Systems for Liquid Rocket Engines. NASA Sp. Veh. Des. Criteria (Chemical Propulsion) 1974.

- Wang, C.-S.; Wang, Y.-M. DURABLE TOOL FORMOLDING OF POLYMER COMPOSITES 2008, 1–5.

- Vinogradov, A.; Hashimoto, S.; Kopylov, V.I. Enhanced Strength and Fatigue Life of Ultra-Fine Grain Fe-36Ni Invar Alloy. Mater. Sci. Eng. A 2003. [CrossRef]

- Chen, C.; Huang, Y.L.; Yao, Y.F.; Fu, X.K.; Li, W.; Hou, Y.H. Effects of Thermal Annealing on Improved Magnetic Properties and Microstructure for SmFe11Ti Alloy. J. Magn. Magn. Mater. 2021, 530, 9–13. [CrossRef]

- Wegener, T.; Brenne, F.; Fischer, A.; Möller, T.; Hauck, C.; Auernhammer, S.; Niendorf, T. On the Structural Integrity of Fe-36Ni Invar Alloy Processed by Selective Laser Melting. Addit. Manuf. 2021. [CrossRef]

- Liu, H.; Sun, Z.; Wang, G.; Sun, X.; Li, J.; Xue, F.; Peng, H.; Zhang, Y. Effect of Aging on Microstructures and Properties of Mo-Alloyed Fe–36Ni Invar Alloy. Mater. Sci. Eng. A 2016, 654, 107–112. [CrossRef]

- Sui, Q.S.; Li, J.X.; Zhai, Y.Z.; Sun, Z.H.; Wu, Y.F.; Zhao, H.T.; Feng, J.H.; Sun, M.C.; Yang, C.L.; Chen, B.A.; et al. Effect of Alloying with V and Ti on Microstructures and Properties in Fe–Ni–Mo–C Invar Alloys. Materialia 2019. [CrossRef]

- Ha, T.K.; Min, S.H. Effect of C Content on the Microstructure and Physical Properties of Fe-36Ni Invar Alloy. Mater. Sci. Forum 2014, 804, 293–296. [CrossRef]

- Bitkulov, I.K.; Burkhanov, A.M.; Kazantsev, V.A.; Mulyukov, R.R.; Mulyukov, K.Y.; Safarov, I.M. Effect of Severe Plastic Deformation on the Properties of the Fe-36% Ni Invar Alloy. Phys. Met. Metallogr. 2006, 102, 91–96. [CrossRef]

- Manufacturingguide Hot Rolling of Sheets Available online: https://www.manufacturingguide.com/en/hot-rolling-sheets (accessed on 9 September 2024).

- Alloyeau, D.; Dachraoui, W.; Javed, Y.; Belkahla, H.; Wang, G.; Lecoq, H.; Ammar, S.; Ersen, O.; Wisnet, A.; Gazeau, F.; et al. Unravelling Kinetic and Thermodynamic Effects on the Growth of Gold Nanoplates by Liquid Transmission Electron Microscopy. Nano Lett. 2015, 15, 2574–2581. [CrossRef]

- Wen, Y.-N.; Zhang, J.-M. Surface Energy Calculation of the Fcc Metals by Using the MAEAM. Solid State Commun. 2007, 144, 163–167. [CrossRef]

- Fu, B.; Liu, W.; Li, Z. Calculation of the Surface Energy of Fcc-Metals with the Empirical Electron Surface Model. Appl. Surf. Sci. 2010, 256, 6899–6907. [CrossRef]

- Berns, H.; Fischer, A.; Kleff, J. Scratch Tests on Iron-, Nickel- and Cobalt-Based Alloys at Elevated Temperatures. Wear 1993, 162–164, 585–589. [CrossRef]

- Walter, M.; Mujica Roncery, L.; Weber, S.; Leich, L.; Theisen, W. XRD Measurement of Stacking Fault Energy of Cr–Ni Austenitic Steels: Influence of Temperature and Alloying Elements. J. Mater. Sci. 2020, 55, 13424–13437. [CrossRef]

- Wang, P.; Xiao, N.; Lu, S.; Li, D.; Li, Y. Investigation of the Mechanical Stability of Reversed Austenite in 13%Cr-4%Ni Martensitic Stainless Steel during the Uniaxial Tensile Test. Mater. Sci. Eng. A 2013, 586, 292–300. [CrossRef]

- Zhang, W.X.; Chen, Y.Z.; Cong, Y.B.; Liu, Y.H.; Liu, F. On the Austenite Stability of Cryogenic Ni Steels: Microstructural Effects: A Review. J. Mater. Sci. 2021, 56, 12539–12558.

- Park, S.J.; Jo, S.-H.; Oh, S.; Oh, Y.-S.; Kim, S.-J.; Lee, H.W.; Kang, S.-H.; Hoon Moon, Y.; Jung, J. Microstructure-Dependent Etching Behavior of a Partially Recrystallized Invar Alloy. Mater. Des. 2022, 217, 110631. [CrossRef]

- Zhang, M.; Gourgues-Lorenzon, A.F.; Busso, E.P.; Luo, H.; Huang, M. Recrystallisation-Assisted Creep of an Austenitic Fe-Ni Alloy under Low Stresses after Hot Deformation. Acta Mater. 2018, 153, 23–34. [CrossRef]

- Opěla, P.; Kawulok, P.; Schindler, I.; Kawulok, R.; Rusz, S.; Navrátil, H. On the Zener–Hollomon Parameter, Multi-Layer Perceptron and Multivariate Polynomials in the Struggle for the Peak and Steady-State Description. Metals (Basel). 2020, 10, 1413. [CrossRef]

- Huang, K.; Logé, R.E. A Review of Dynamic Recrystallization Phenomena in Metallic Materials. Mater. Des. 2016, 111, 548–574. [CrossRef]

- Montheillet, F.; Lépinoux, J.; Weygand, D.; Rauch, E. Dynamic and Static Recrystallization. Adv. Eng. Mater. 2001, 3, 587. [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Dynamic and Post-Dynamic Recrystallization under Hot, Cold and Severe Plastic Deformation Conditions. Prog. Mater. Sci. 2014, 60, 130–207.

- ASTM, F.-06 Standard Specification for Iron-Nickel and Iron-Nickel-Cobalt Alloys for Low Thermal Expansion Applications; West Conshohocken, 2016;

- Han, J.; Li, H.; Zhu, Z.; Jiang, L.; Xu, H.; Ma, L. Effects of Processing Optimisation on Microstructure, Texture, Grain Boundary and Mechanical Properties of Fe–17Cr Ferritic Stainless Steel Thick Plates. Mater. Sci. Eng. A 2014, 616, 20–28. [CrossRef]

- Chen, C.; Ma, B.; Liu, B.; He, J.; Xue, H.; Zuo, Y.; Li, X. Refinement Mechanism and Physical Properties of Arc Melted Invar Alloy with Different Modifiers. Mater. Chem. Phys. 2019. [CrossRef]

- Akgul, B.; Kul, M.; Erden, F. The Puzzling Thermal Expansion Behavior of Invar Alloys: A Review on Process-Structure-Property Relationship. Crit. Rev. Solid State Mater. Sci. 2023, 1–54. [CrossRef]

- Zheng, Y.; Wang, F.; Li, C.; Yang, Z.; He, Y. Effects of B on the Hot Ductility of Fe-36Ni Invar Alloy. High Temp. Mater. Process. 2019. [CrossRef]

- He, Y.; Wang, F.; Li, C.; Yang, Z.; Zhang, J.; Li, Y. Effect of Mg Content on the Hot Ductility of Wrought Fe-36Ni Alloy with Ti Addition. Mater. Sci. Eng. A 2016. [CrossRef]

- Zhang, C.; Liu, Z.; Wang, G. Effects of Hot Rolled Shear Bands on Formability and Surface Ridging of an Ultra Purified 21%Cr Ferritic Stainless Steel. J. Mater. Process. Technol. 2011, 211, 1051–1059. [CrossRef]

- Hitzler, L.; Sert, E.; Öchsner, A.; Werner, E. Microstructure and Mechanical Property Correlation for Additively Manufactured Aluminum-Silicon Alloys. Qual. Anal. Addit. Manuf. Met. Simul. Approaches, Process. Microstruct. Prop. 2023, 355–387. [CrossRef]

- Çelebi, M.; Çanakçi, A.; Güler, O.; Akgül, B.; Karabacak, A.H. Study on Effect of Milling Time on the Mechanical and Wear Properties of the ZA40-B4C-Graphene Hybrid Nanocomposites Fabricated by Vacuum Hot-Pressing. JOM 2023, 75, 3935–3950. [CrossRef]

- Kim, B.-S.; Yoo, K.-J.; Kim, B.-G.; Lee, H.-W. Effect of Carbon on the Coefficient of Thermal Expansion of As-Cast Fe−30wt.%Ni−12.5wt.%Co−×C Invar Alloys. Met. Mater. Int. 2002, 8, 247–252. [CrossRef]

- Mokhena, T.C.; Mochane, M.J.; Sefadi, J.S.; Motloung, S.V.; Andala, D.M. Thermal Conductivity of Graphite-Based Polymer Composites. In Impact of Thermal Conductivity on Energy Technologies; IntechOpen, 2018 ISBN 978-1-78923-673-6.

- Burzo, M.G.; Komarov, P.L.; Raad, P.E. Thermal Transport Properties of Gold-Covered Thin-Film Silicon Dioxide. IEEE Trans. Components Packag. Technol. 2003, 26, 80–88. [CrossRef]

- Kul, M.; Akgul, B.; Karabay, Y.Z. The Relationship of Hot and Cold Rolling Processes with the Structure and Properties of Invar 36. Mater. Chem. Phys. 2023, 295, 127215. [CrossRef]

- Nadutov, V.M.; Vashchuk, D.L.; Svystunov, Y.O.; Beloshenko, V.A.; Spuskanyuk, V.Z.; Davidenko, A.A. Magnetic and Invar Properties of Fe-35 %Ni Alloy after Grinding of Structure by Hydroextrusion. Funct. Mater. 2012, 19, 334–342.

- Nadutov, V.M.; Kosintsev, S.G.; Svystunov, E.O.; Zaporozhets, O.I. Interatomic Interaction and Magnetostriction in Invar FeNi-C-Based Alloys. Metallofiz. i Noveishie Tekhnologii 2009, 31, 1021–1034.

- Balikci, E.; Raman, A.; Mirshams, R.A. Microstructure and Texture Effect on the Thermal Expansion of a Variously Aged Polycrystalline Superalloy IN738LC. Metall. Mater. Trans. A 1999, 30, 2803–2808. [CrossRef]

- Hansen, L.N.; Zimmerman, M.E.; Kohlstedt, D.L. Grain Boundary Sliding in San Carlos Olivine: Flow Law Parameters and Crystallographic-Preferred Orientation. J. Geophys. Res. 2011, 116, B08201. [CrossRef]

- Wang, Q.; Dong, Y.; Jiang, Z.; Zou, T.; Liu, Y.; Wu, Y.; Qing, H. Effects of Ce Addition on Mechanical Properties and Thermal Expansion Behavior of Fe-36Ni Invar Alloy. Mater. Charact. 2024, 207, 113584. [CrossRef]

- Wang, Q.; Dong, Y.; Jiang, Z.; Huang, J. Enhancing Low Thermal Expansion Behavior and Strength via Induced Zr-Rich Intermetallic Phase in Fe-36Ni Invar Alloy. Mater. Des. 2023, 226, 111644. [CrossRef]

- Hong-Guang, Z.; Li-Jiang, Y.; Heng, X. Effect of Two Kinds of Refiners on the Solidification Structure and Property of Invar Alloy. High Temp. Mater. Process. 2013. [CrossRef]

- Erden, F.; Akgul, B.; Danaci, I.; Oner, M.R. Thermoelectric and Thermomechanical Properties of Invar 36: Comparison with Common Thermoelectric Materials. J. Alloys Compd. 2023, 932, 167690. [CrossRef]

- Bac, L.H.; Kim, J.S.; Kim, J.C. Synthesis of Fe–Ni Invar Alloy Nanopowder by the Electrical Explosion of Wire in the Liquid. Res. Chem. Intermed. 2010, 36, 795–800. [CrossRef]

- Ahmad, S.; Ziya, A.B.; Ashiq, M.N.; Ibrahim, A.; Atiq, S.; Ahmad, N.; Shakeel, M.; Khan, M.A. Improved Magnetic and Electrical Properties of Cu Doped Fe–Ni Invar Alloys Synthesized by Chemical Reduction Technique. J. Magn. Magn. Mater. 2016, 419, 125–130. [CrossRef]

- Huang, L.; Zhou, Y.; Guo, T.; Han, D.; Gu, Y.; Song, C.; Pan, F. Investigation of Temperature-Dependent Magnetic Properties and Coefficient of Thermal Expansion in Invar Alloys. Materials (Basel). 2022, 15, 1504. [CrossRef]

- Rao, Z.; Ponge, D.; Körmann, F.; Ikeda, Y.; Schneeweiss, O.; Friák, M.; Neugebauer, J.; Raabe, D.; Li, Z. Invar Effects in FeNiCo Medium Entropy Alloys: From an Invar Treasure Map to Alloy Design. Intermetallics 2019. [CrossRef]

- Inoue, A.; Kong, F. Soft Magnetic Materials. In Encyclopedia of Smart Materials; Elsevier, 2022; pp. 10–23.

- Azuma, D. Magnetic Materials. In Wide Bandgap Power Semiconductor Packaging; Elsevier, 2018; pp. 97–107.

| Chemical Composition | ||||||||

| Alloying elements | Fe | Ni | Mn | Si | Cr | Cu | Co | C |

| Amounts | 63.28 | 36.22 | 0.17 | 0.11 | 0.07 | 0.05 | 0.06 | 0.04 |

| Sample Codes | ||||||||

| AC | As-cast in VIM | |||||||

| ACWR | Warm rolled at 900 °C | |||||||

| ACQT | Quenched from 850 °C and tempered at 350 °C for 1 hour | |||||||

| ACA | Aged at 100 °C for 24 hours | |||||||

| Strongest Peak | (111) | (200) | (220) | (311) | (222) |

| AC | 100 | 20.38 | 24.37 | 15.10 | 7.24 |

| ACWR | 100 | 35.52 | 15.90 | 17.62 | 6.39 |

| ACQT | 100 | 42.05 | 40.56 | 27.44 | 8.37 |

| ACA | 100 | 35.18 | 37.82 | 20.79 | 5.27 |

| Condition | 20–50 °C | 20–100 °C | 20–150 °C | 20–200 °C | 20–250 °C | Reference |

| Water quenching after holding at 850 °C for 1 h, followed by tempering at 350 °C for 1 h and finally kept at 100 °C for 24 hours. | 0.511 | 0.549 | 0.581 | 1.095 | 1.648 | This study |

| Water quenching after holding at 840 °C for 1 h, followed by tempering at 315 °C for 1 h. | – | 1.400 | – | 2.430 | – | [52] |

| Water quenching after holding at 840 °C for 1 h, followed by tempering at 315 °C for 1 h. | – | 1.400 | – | 2.420 | – | [53] |

| Water quenching after holding at 840 °C for 1 h, followed by tempering at 315 °C for 1 h. | – | 0.915 | – | 2.750 | – | [54] |

| Water quenching after holding at 843 °C for 1 h, followed by tempering at 315 °C for 1 h and finally kept at 93 °C for 24 hours. | – | 0.800 | 1.500 | 2.300 | 4.000 | [35] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).