Submitted:

26 September 2024

Posted:

29 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

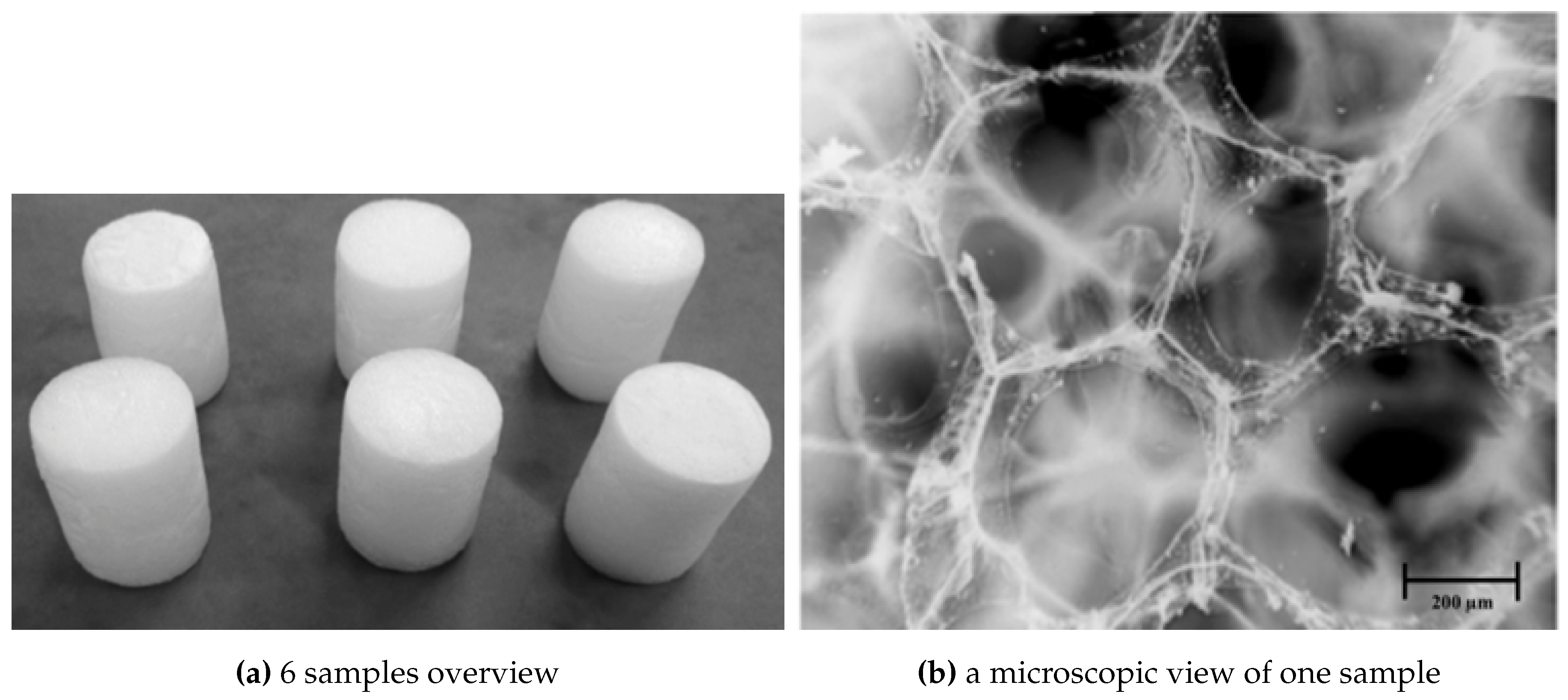

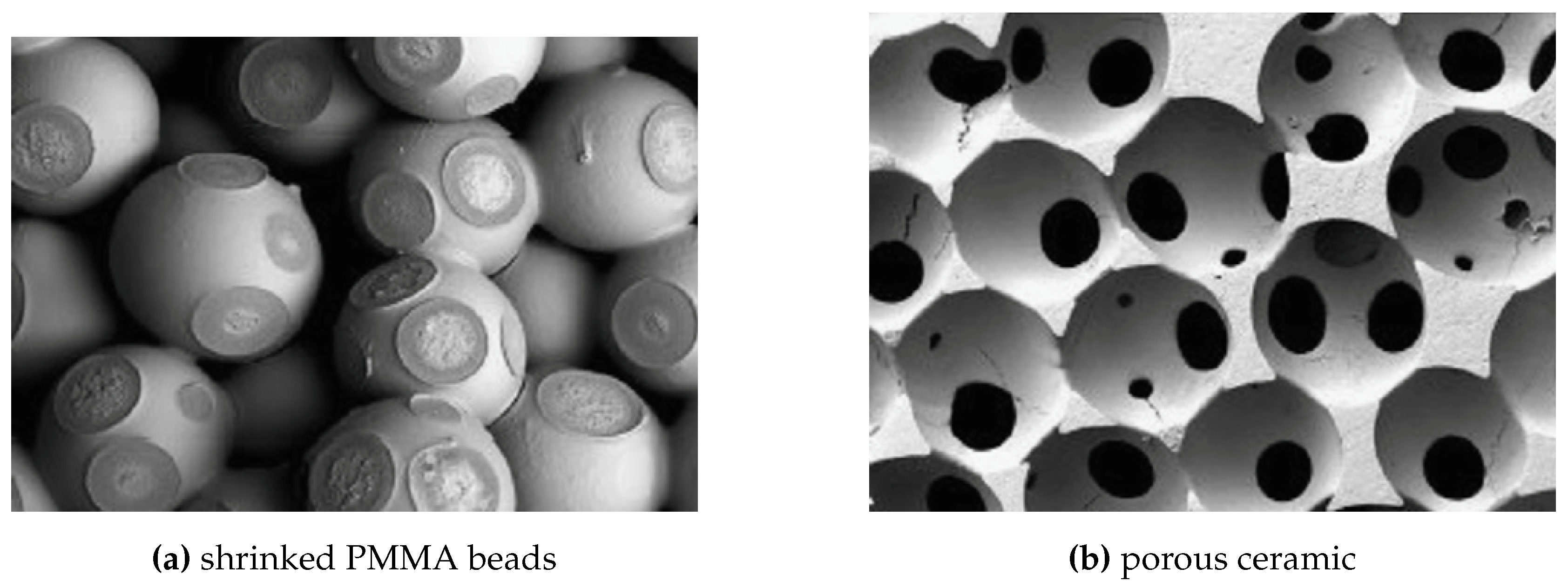

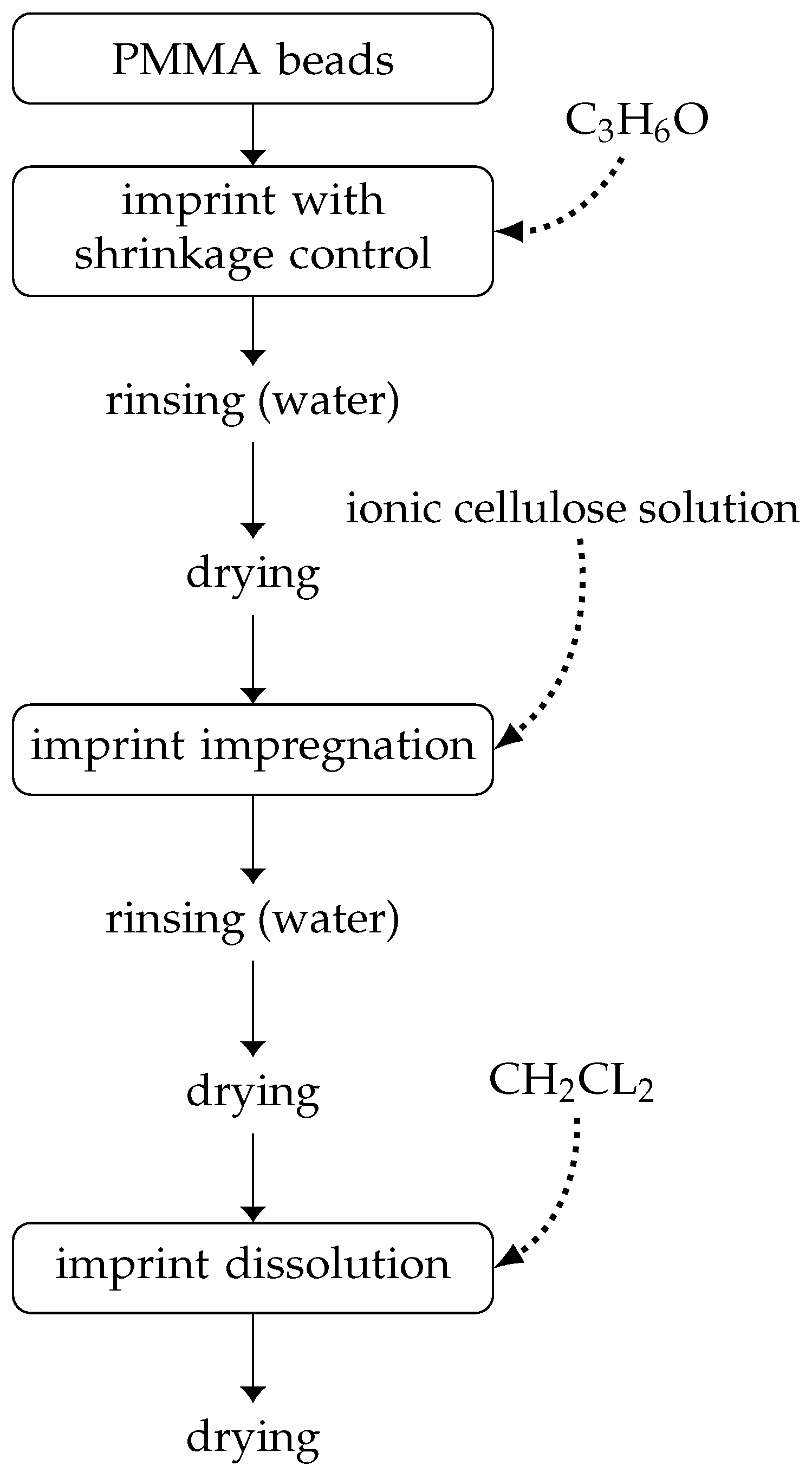

2. Fabrication Process

3. Macro-Controlled Properties

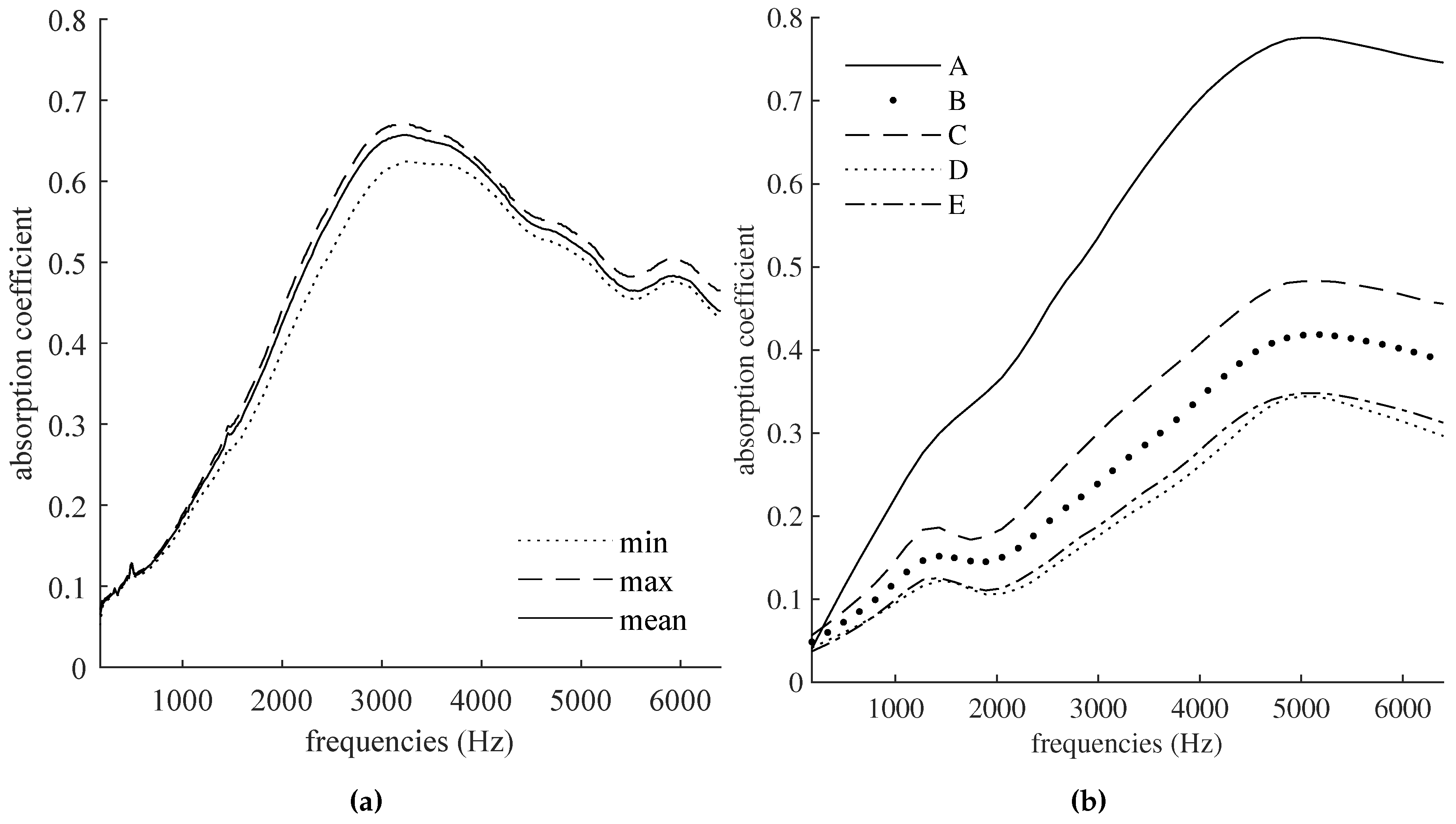

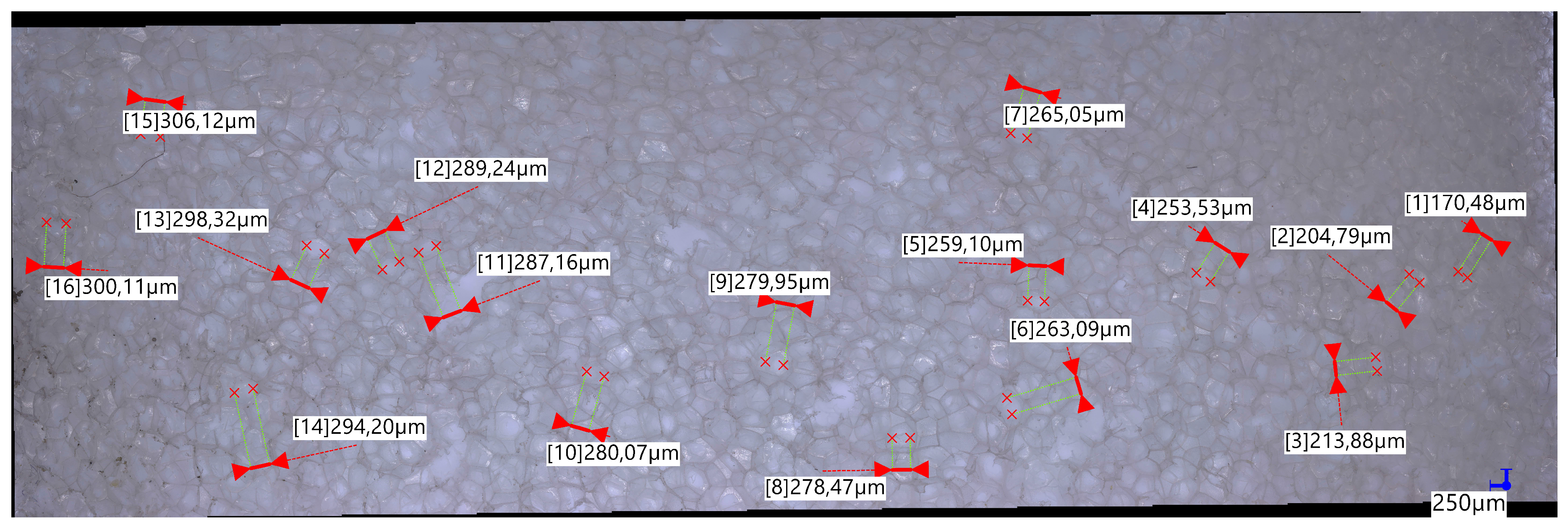

3.1. Basic Control of Skeletal Structure

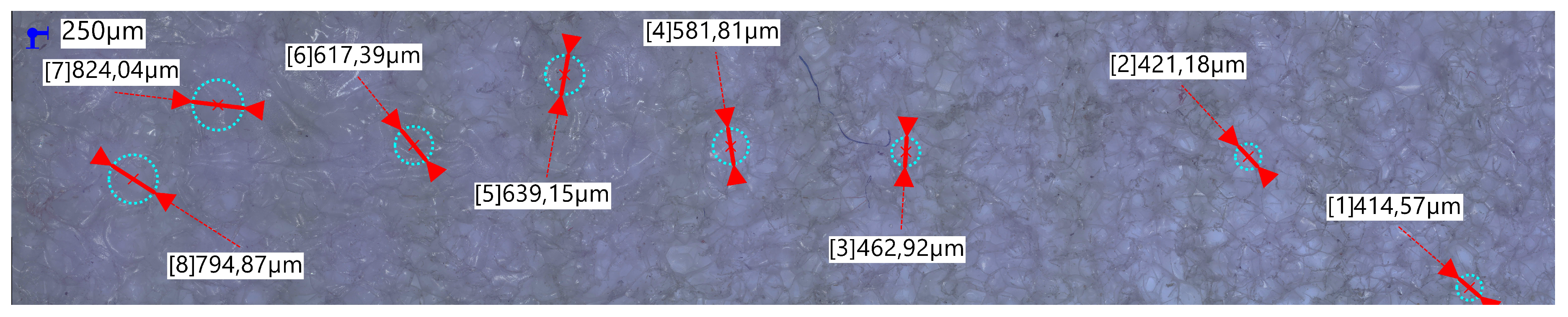

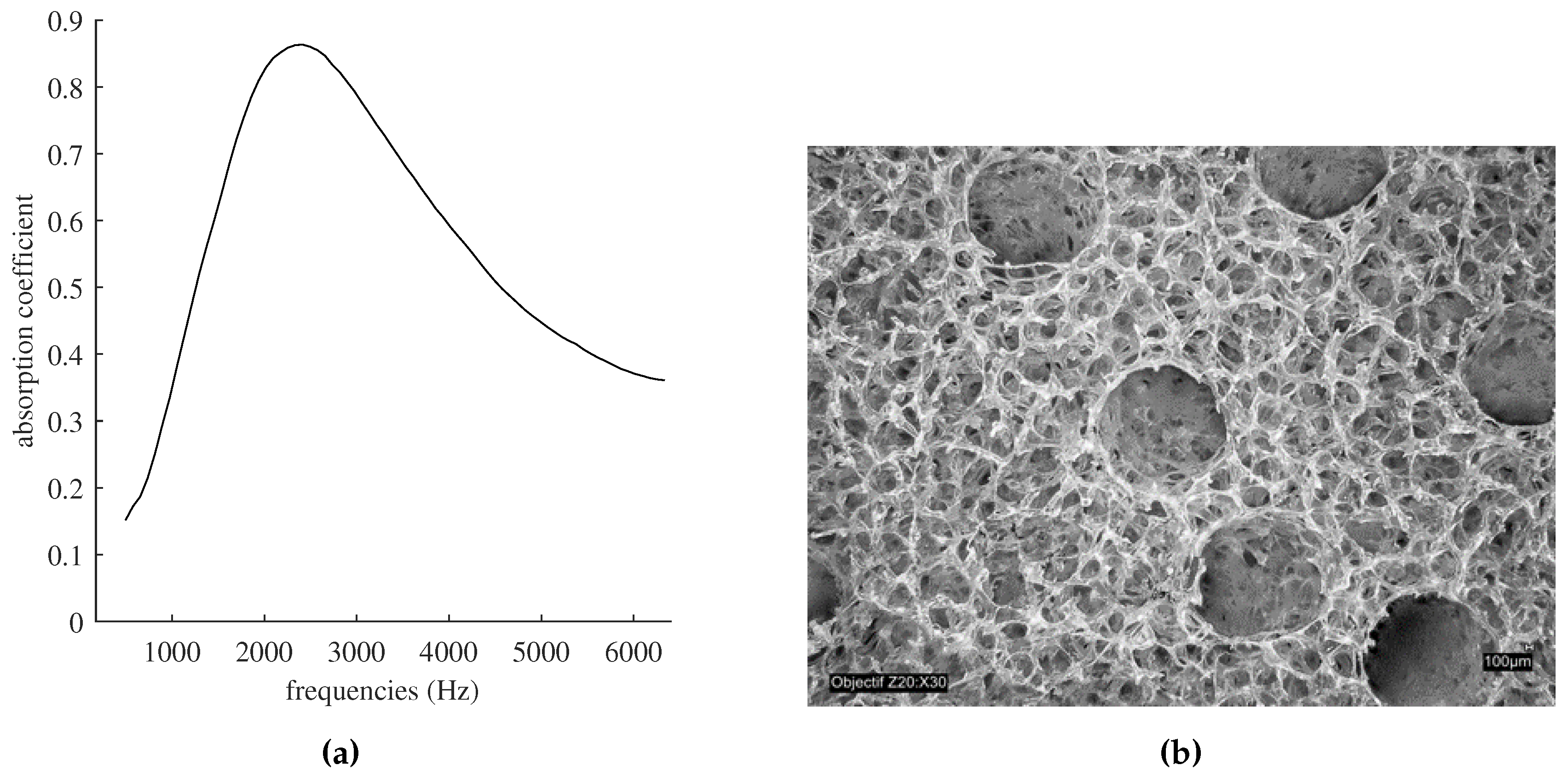

3.2. Double Porosity

3.3. Gradient Porous Biomaterials

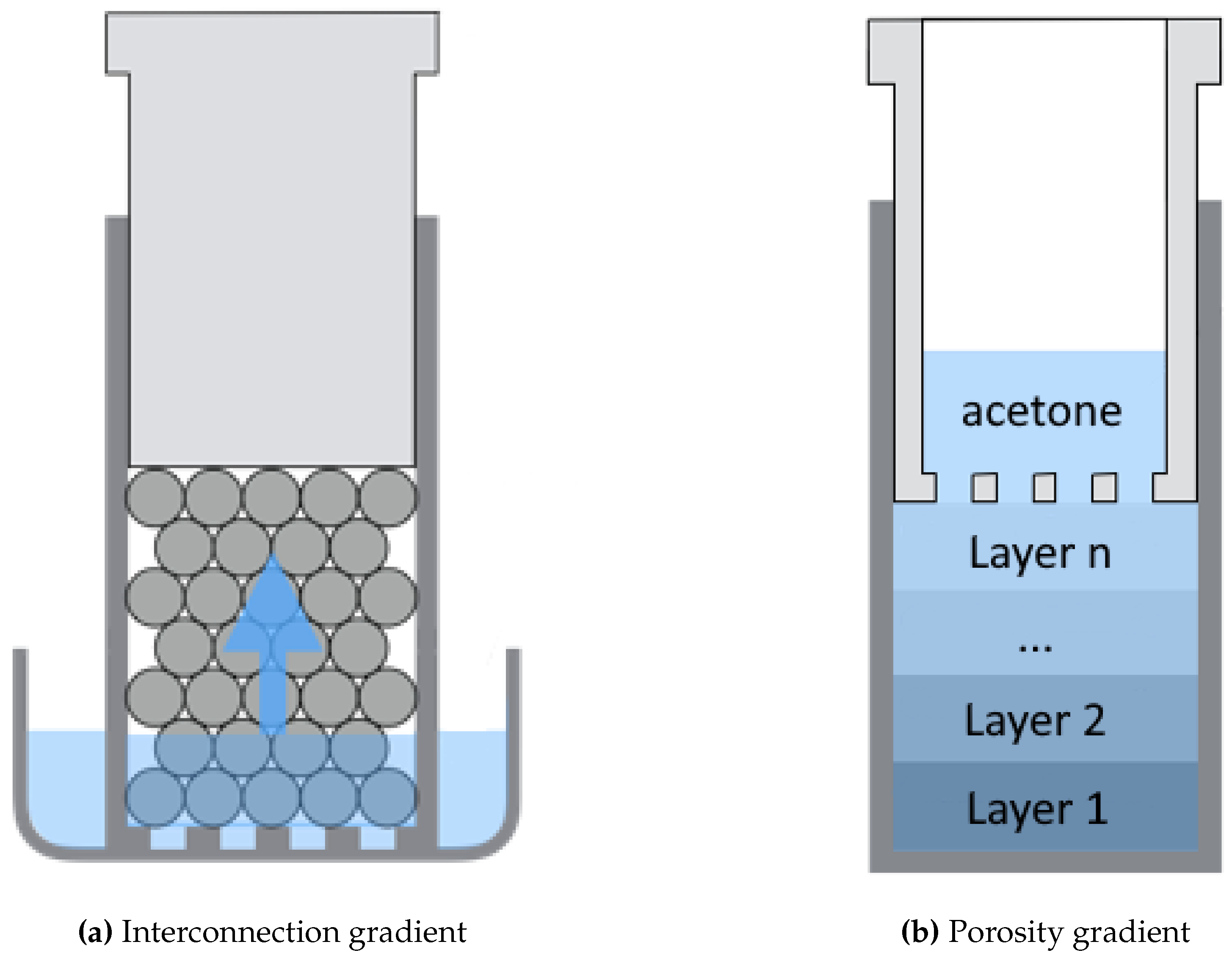

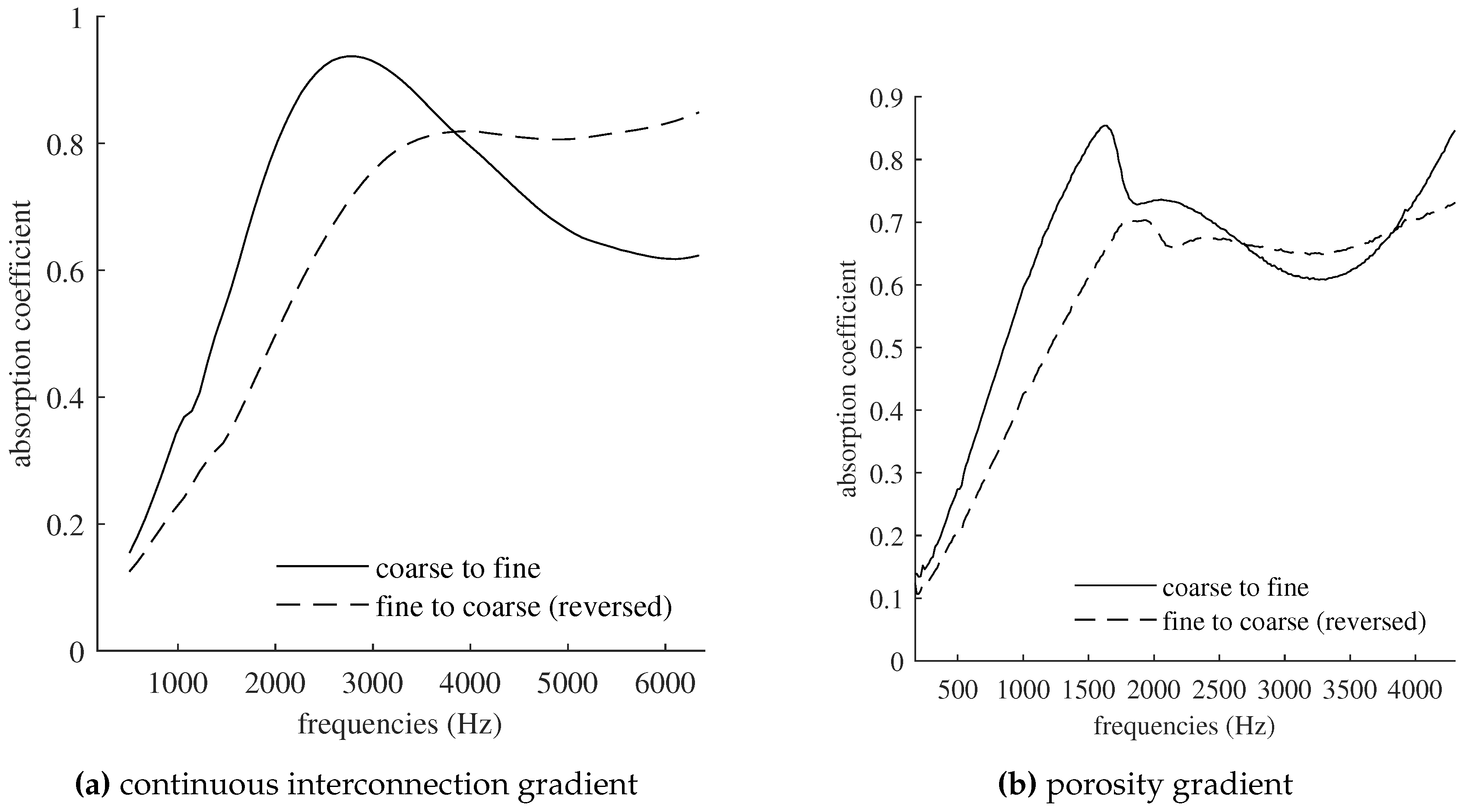

3.3.1. Continuous Interconnection Gradient

3.3.2. Porosity Gradient

4. Conclusions

References

- Al-Qararah, A.M.; Ekman, A.; Hjelt, T.; Ketoja, J.A.; Kiiskinen, H.; Koponen, A.; Timonen, J. A unique microstructure of the fiber networks deposited from foam–fiber suspensions. Colloids and Surfaces A: Physicochemical and Engineering Aspects 2015, 482, 544–553. [CrossRef]

- Ferreira, F.V.; Otoni, C.G.; Kevin, J.; Barud, H.S.; Lona, L.M.; Cranston, E.D.; Rojas, O.J. Porous nanocellulose gels and foams: Breakthrough status in the development of scaffolds for tissue engineering. Materials Today 2020, 37, 126–141. [CrossRef]

- Zieliński, T.G.; Dauchez, N.; Boutin, T.; Leturia, M.; Wilkinson, A.; Chevillotte, F.; Bécot, F.X.; Venegas, R. Taking advantage of a 3D printing imperfection in the development of sound-absorbing materials. Applied Acoustics 2022, 197, 108941. [CrossRef]

- Xue, Y.; Nobles, L.P.; Sharma, B.; Bolton, J.S. Designing hybrid aerogel-3D printed absorbers for simultaneous low frequency and broadband noise control. Materials & Design 2024, 242, 113026. [CrossRef]

- Arjunan, A.; Baroutaji, A.; Robinson, J.; Vance, A.; Arafat, A. Acoustic metamaterials for sound absorption and insulation in buildings. Building and Environment 2024, p. 111250. [CrossRef]

- Godbold, O.; Soar, R.; Buswell, R. Implications of solid freeform fabrication on acoustic absorbers. Rapid Prototyping Journal 2007, 13, 298–303. [CrossRef]

- Setaki, F.; Tian, F.; Turrin, M.; Tenpierik, M.; Nijs, L.; Van Timmeren, A. 3D-printed sound absorbers: Compact and customisable at broadband frequencies. Architecture, Structures and Construction 2023, 3, 205–215. [CrossRef]

- Zheng, Z.; Li, Y.; Yang, W. Absorption properties of natural fiber-reinforced sandwich structures based on the fabric structures. Journal of Reinforced Plastics and Composites 2013, 32, 1561–1568. [CrossRef]

- Tiuc, A.E.; Vermeşan, H.; Gabor, T.; Vasile, O. Improved sound absorption properties of polyurethane foam mixed with textile waste. Energy Procedia 2016, 85, 559–565. [CrossRef]

- Zhu, X.; Kim, B.J.; Wang, Q.; Wu, Q. Recent Advances in the Sound Insulation Properties of Bio-based Materials. BioResources 2014, 9. [CrossRef]

- Oldham, D.J.; Egan, C.A.; Cookson, R.D. Sustainable acoustic absorbers from the biomass. Applied Acoustics 2011, 72, 350–363. [CrossRef]

- Del Rey, R.; Alba, J.; Arenas, J.P.; Sanchis, V.J. An empirical modelling of porous sound absorbing materials made of recycled foam. Applied Acoustics 2012, 73, 604–609. [CrossRef]

- Trematerra, A.; Lombardi, I. Acoustic Properties of Cellulose. IOP Conference Series: Materials Science and Engineering. IOP Publishing, 2017, Vol. 225, p. 012082. [CrossRef]

- Arenas, J.P.; Rebolledo, J.; Rey Tormos, R.M.d.; Alba Fernández, J. Sound absorption properties of unbleached cellulose loose-fill insulation material. BioResources 2014, 9, 6227–6240. [CrossRef]

- Seciureanu, M.; Nastac, S.M.; Guiman, M.V.; Nechita, P. Cellulose Fibers-Based Porous Lightweight Foams for Noise Insulation. Polymers 2023, 15, 3796. [CrossRef]

- Nastac, S.M.; Nechita, P.; Guiman, M.V.; Roman, M.; Rosca, I.C. Applications of Xylan Derivatives to Improve the Functional Properties of Cellulose Foams for Noise Insulation. Polymers 2023, 15, 4648. [CrossRef]

- Muchlisinalahuddin, M.; Dahlan, H.; Mahardika, M.; Rusli, M. Cellulose-based Material for Sound Absorption And Its Application–A Short Review. BIO Web of Conferences. EDP Sciences, 2023, Vol. 77, p. 01003. [CrossRef]

- Miranda-Valdez, I.Y.; Coffeng, S.; Zhou, Y.; Viitanen, L.; Hu, X.; Jannuzzi, L.; Puisto, A.; Kostiainen, M.A.; Mäkinen, T.; Koivisto, J.; others. Foam-formed biocomposites based on cellulose products and lignin. Cellulose 2023, 30, 2253–2266. [CrossRef]

- Taiwo, E.M.; Yahya, K.; Haron, Z. Potential of using natural fiber for building acoustic absorber: A review. Journal of Physics: Conference Series. IOP Publishing, 2019, Vol. 1262, p. 012017. [CrossRef]

- Mahasaranon, S.; Horoshenkov, K.V.; Khan, A.; Benkreira, H. The effect of continuous pore stratification on the acoustic absorption in open cell foams. Journal of applied physics 2012, 111. [CrossRef]

- Geslain, A.; Groby, J.P.; Dazel, O.; Mahasaranon, S.; Horoshenkov, K.; Khan, A. An application of the Peano series expansion to predict sound propagation in materials with continuous pore stratification. The Journal of the Acoustical Society of America 2012, 132, 208–215. [CrossRef]

- Descamps, M.; Duhoo, T.; Monchau, F.; Lu, J.; Hardouin, P.; Hornez, J.; Leriche, A. Manufacture of macroporous β-tricalcium phosphate bioceramics. Journal of the European Ceramic Society 2008, 28, 149–157. [CrossRef]

- Joly, N.; Granet, R.; Krausz, P. Crosslinking of cellulose by olefin metathesis. Journal of Carbohydrate Chemistry 2003, 22, 47–55. [CrossRef]

- Panneton, R.; Gros, E. A missing mass method to measure the open porosity of porous solids. ACTA Acustica united with Acustica 2005, 91, 342–348.

- Atalla, Y.; Panneton, R. Inverse acoustical characterization of open cell porous media using impedance tube measurements. Canadian acoustics 2005, 33, 11–24.

- Allard, J.; Allard, J. Sound propagation in cylindrical tubes and porous materials having cylindrical pores. Propagation of Sound in Porous Media: Modelling Sound Absorbing Materials 1993, pp. 48–78. [CrossRef]

- Liu, X.; Ma, X.; Yu, C.; Xin, F. Sound absorption of porous materials perforated with holes having gradually varying radii. Aerospace Science and Technology 2022, 120, 107229. [CrossRef]

- Doutres, O.; Atalla, N. Sound absorption properties of functionally graded polyurethane foam. INTER-NOISE and NOISE-CON Congress and Conference Proceedings. Institute of Noise Control Engineering, 2012, Vol. 2012, pp. 679–688.

- Sacristan, C.; Dupont, T.; Sicot, O.; Leclaire, P.; Verdière, K.; Panneton, R.; Gong, X.L. A mixture approach to the acoustic properties of a macroscopically inhomogeneous porous aluminum in the equivalent fluid approximation. The Journal of the Acoustical Society of America 2016, 140, 2847–2855. [CrossRef]

| Sample | m (g) | h (mm) | d (mm) | () | () | (%) |

| 1 | 0.5492 | 35.57 | 28.09 | 22.04 | 0.38 | 0.983 |

| 2 | 0.5720 | 35.25 | 28.13 | 21.91 | 0.39 | 0.982 |

| 3 | 0.5894 | 34.86 | 27.65 | 20.93 | 0.41 | 0.981 |

| 4 | 0.4612 | 35.12 | 25.79 | 18.35 | 0.32 | 0.983 |

| 5 | 0.5479 | 34.83 | 27.62 | 20.87 | 0.38 | 0.982 |

| 6 | 0.5792 | 35.78 | 27.57 | 21.36 | 0.40 | 0.981 |

| Sample | D (mm) | m (g) | h (mm) | d (mm) | (%) |

| A | 0.2-0.4 | 0.17 | 18.1 | 22.04 | 9 |

| B | 0.5-0.6 | 0.22 | 20.3 | 21.91 | 5 |

| C | 0.5-0.6 | 0.21 | 19.1 | 20.93 | 11 |

| D | 0.6-0.7 | 0.23 | 20.9 | 18.35 | 5 |

| E | 0.7-0.8 | 0.21 | 19.1 | 20.87 | 5.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).