Experimental measurements were performed continuously in a measurement and evaluation step of 25 cm. The accuracy of the KRAB measuring device is reliable ±1 mm of the average height determination error due to the deflection of the LHD rails R/L, which is also documented by the graphic outputs in individual stages; the same waves are recorded everywhere and, what is essential, the curves of the graphs are transformed gradually (also confirmed from previous research measurements). Each new stage of measurement on the transition zone as part of the monitoring confirmed the curve of the last measurements and certain new developments of the deflection of the deformation of the heights of the LHD rails over time.

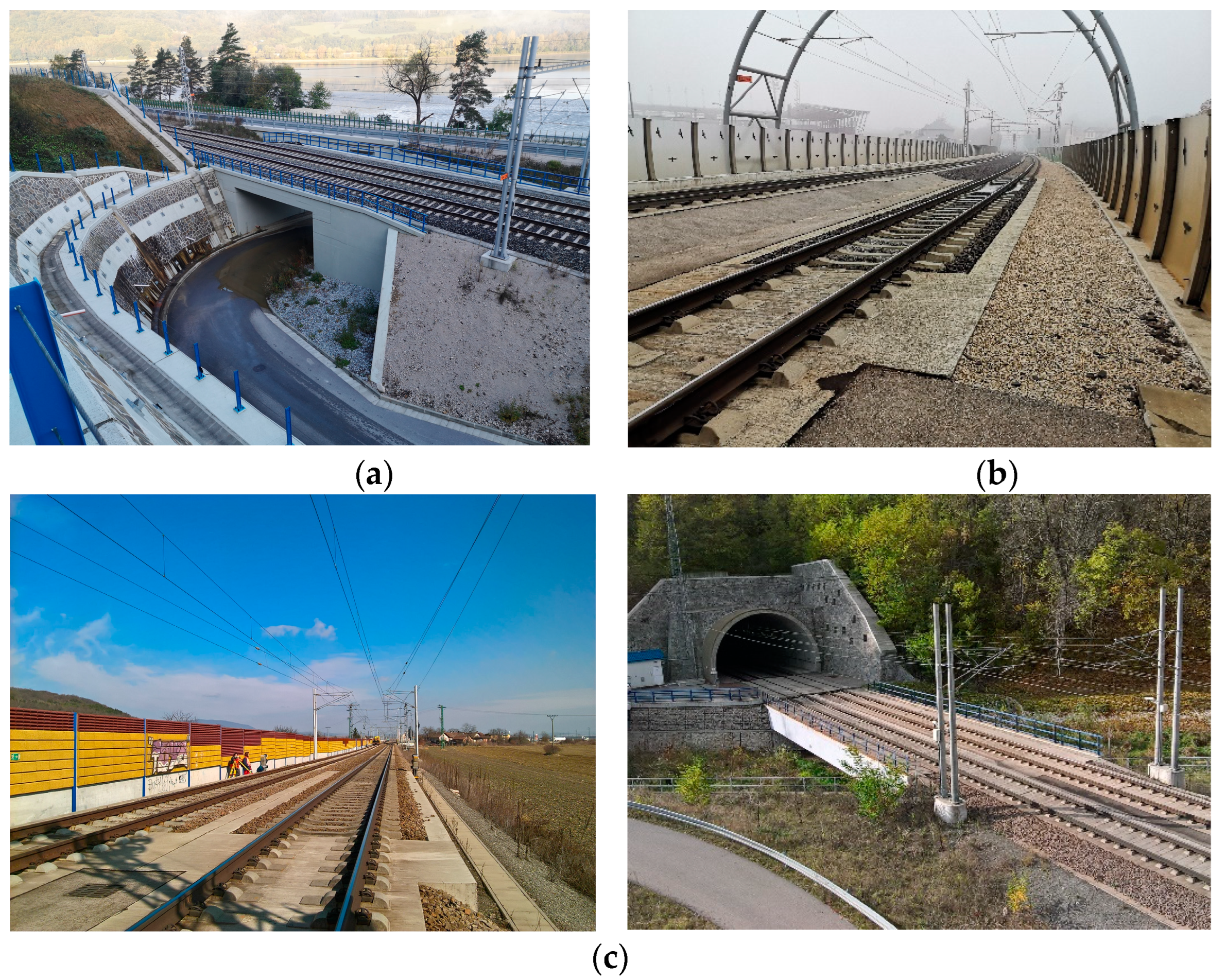

3.1. Bridge Objects and Transition Zones

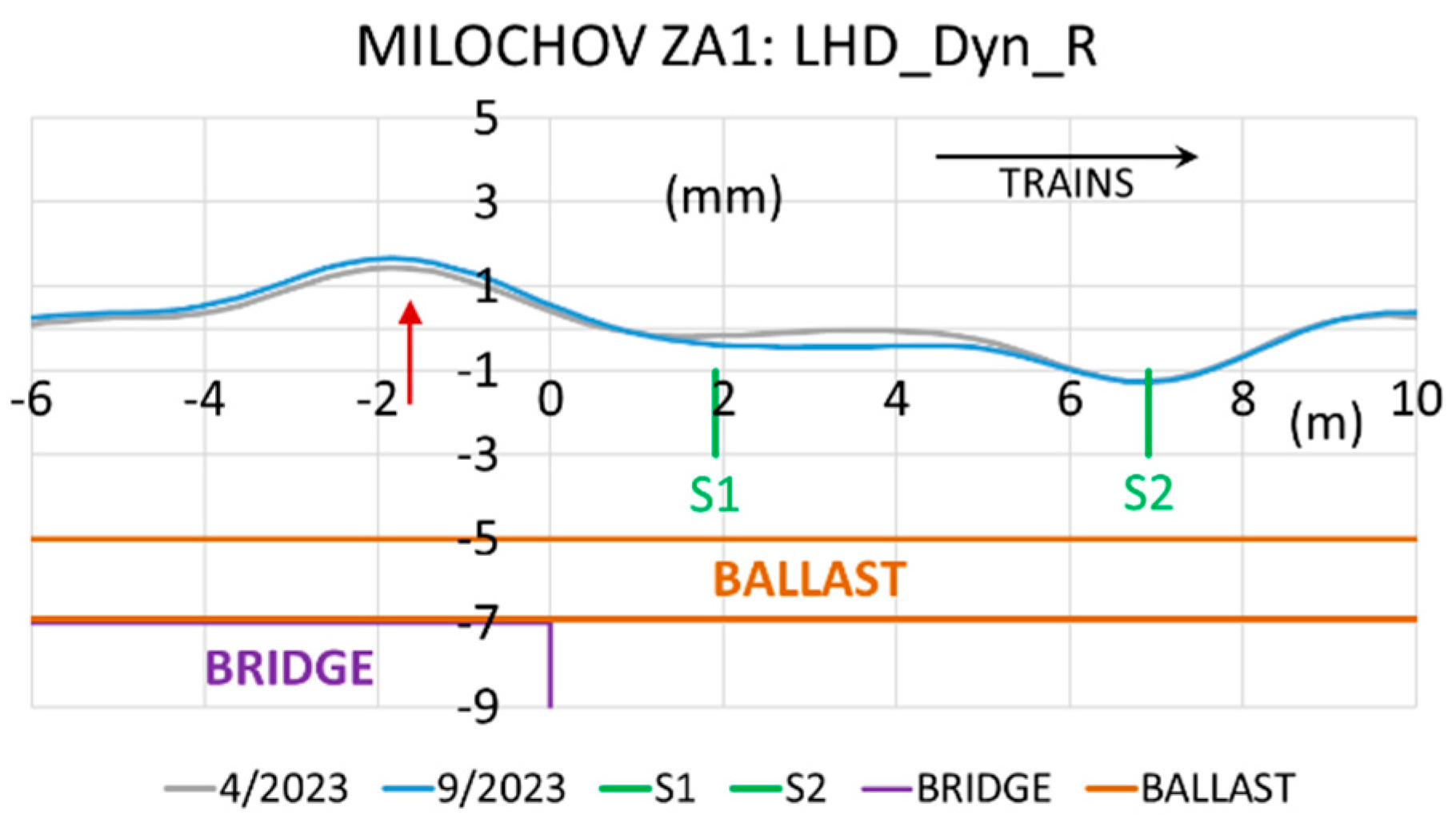

First, we point out the bridge object with adjacent parts of track sections, whose measured values of LHD rails R/L are shown in

Figure 1. Markings "ZA1", "ZA2", "BA1", and "BA2" are marked directions of the location of measured transit zones near objects (bridge, tunnel), for example, ZA - towards the city of Zilina, BA - towards the city of Bratislava, 1 and 2 are track numbers. In the figure, the transition zone is in the railway substructure (bridge), where the railway's upper structure forms a classic ballast bed. The “arrows” represent the prevailing direction of trains (approx. 80 %). We can conclude that the results show characteristic deflections of the track geometry after the train sets pass through the track. The figure shows the bridge object and the positions of the sensors for measuring forces S1 to S4 (they are not the subject of this text and are prepared for subsequent physical measurements in the track, not only monitoring using the KRAB trolley).

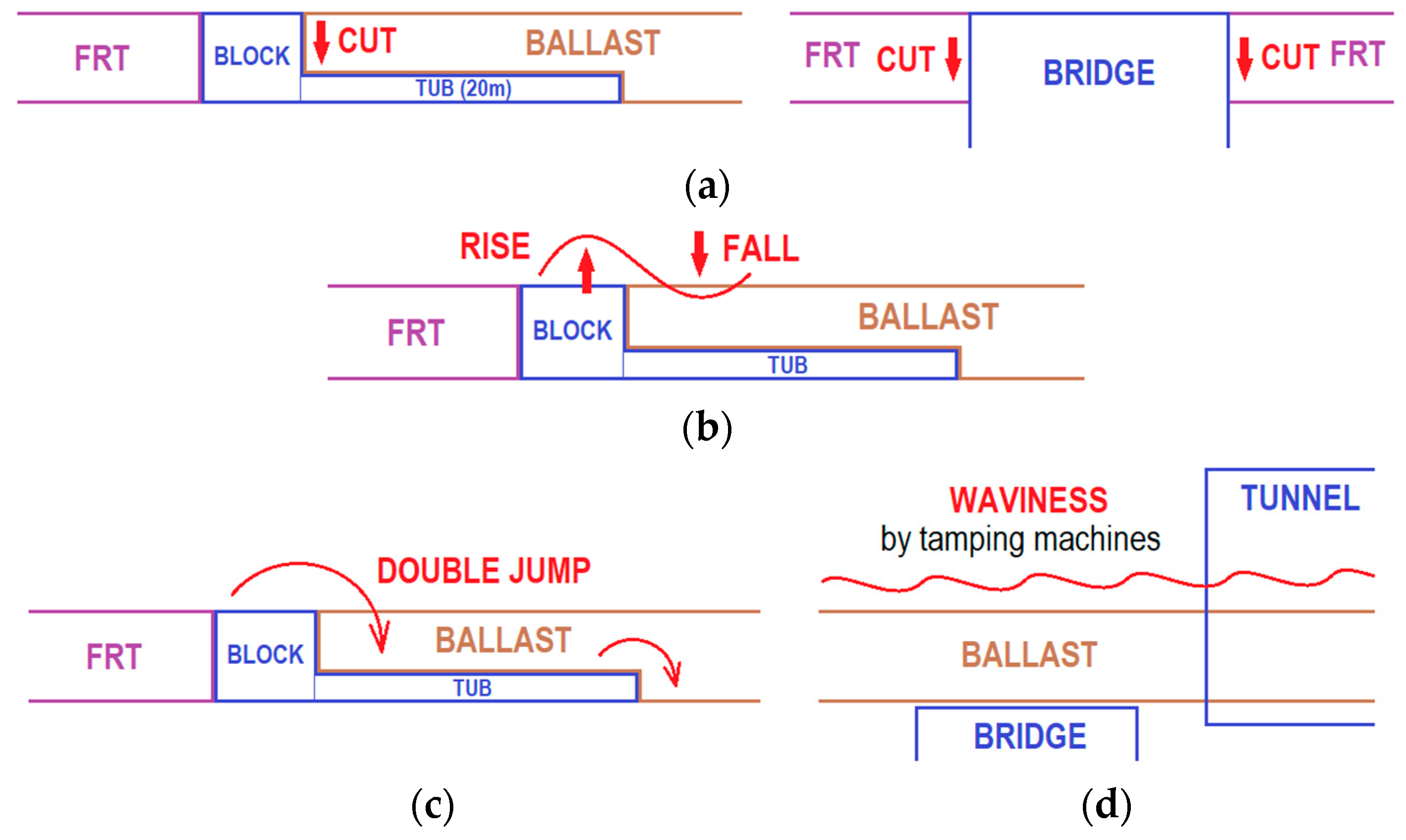

The lower parts of all figures with LHD curves present the composition of the structural parts of a particular transition zone (e.g. bridge, tunnel, portal, ballast, FRT, FRT-block, tub, etc.).

The height deformation of rail R in

Figure 1b is more significant than rail L in

Figure 1a because it is the outermost rail R on the slope of this embankment. Although the gravel bed decreases to a minimal extent due to running away into the hill, the track meets the criteria for operation. Measuring sensors S1 to S4 are also located under this rail R, which caused small height shifts in these places. After the next tamping of the track with tamping machines, the heights will be levelled like the L rail in

Figure 1a.

These resulting deflections of the LHD height geometry of the R/L rails are evident in details of this bridge object in

Figure 2. We note that the height waves at the LHD in the continuous track bed are not as significant as at the ends of the fixed carriageway. This is because a layer of the track ballast dampens the sudden transition change in the railway substructure to the bridge object. As a rule, the track bed is tamped with tamping machines to the required prescribed geometric position and heights of the track (in contrast to a fixed railway track).

Regular tamping works with automatic tamping machines (to the prescribed, designed position and heights) do not allow monitoring the time course of the LHD deflection with the KRAB trolley and similar devices. Evaluations can only be done at intervals between two tampings of the track bed, as tamping returns the heights to the same prescribed height position.

This is confirmed by measurements on the fixed railway track near the tunnels and the classic ballasted track (next chapter). A railway line with a classic construction is generally tamped to the projected height (or optimised, prescribed) regularly according to the criteria for evaluating the operational condition in STN 736360-2 [

16] for track monitoring, unlike FRT, where tamping works are not possible. These are operational deviations for the AL level – monitoring limit, IL – intervention or repair limit, and the IAL limit deviation – the limit of immediate intervention in the track.

It is assumed that shocks and shock waves at construction objects under the track bed in the railway substructure. The track will more easily guide the vehicle over these objects in places of stiffness change. This applies if the track is correctly and qualitatively built without subsequent deformations. The FRT demonstrates long-term stability; only when the FRT is affected by a change in the stiffness of the lower track structure does it adjust in height - it deforms.

The following results of experimental measurements when changing a track with FRT to a track with a track bed point to problems when changing the stiffness of the railway track. In these places, one structure is interrupted, and there are significant shocks from the wheels of train sets, for example, in

Figure 3,

Figure 4,

Figure 5 and

Figure 6.

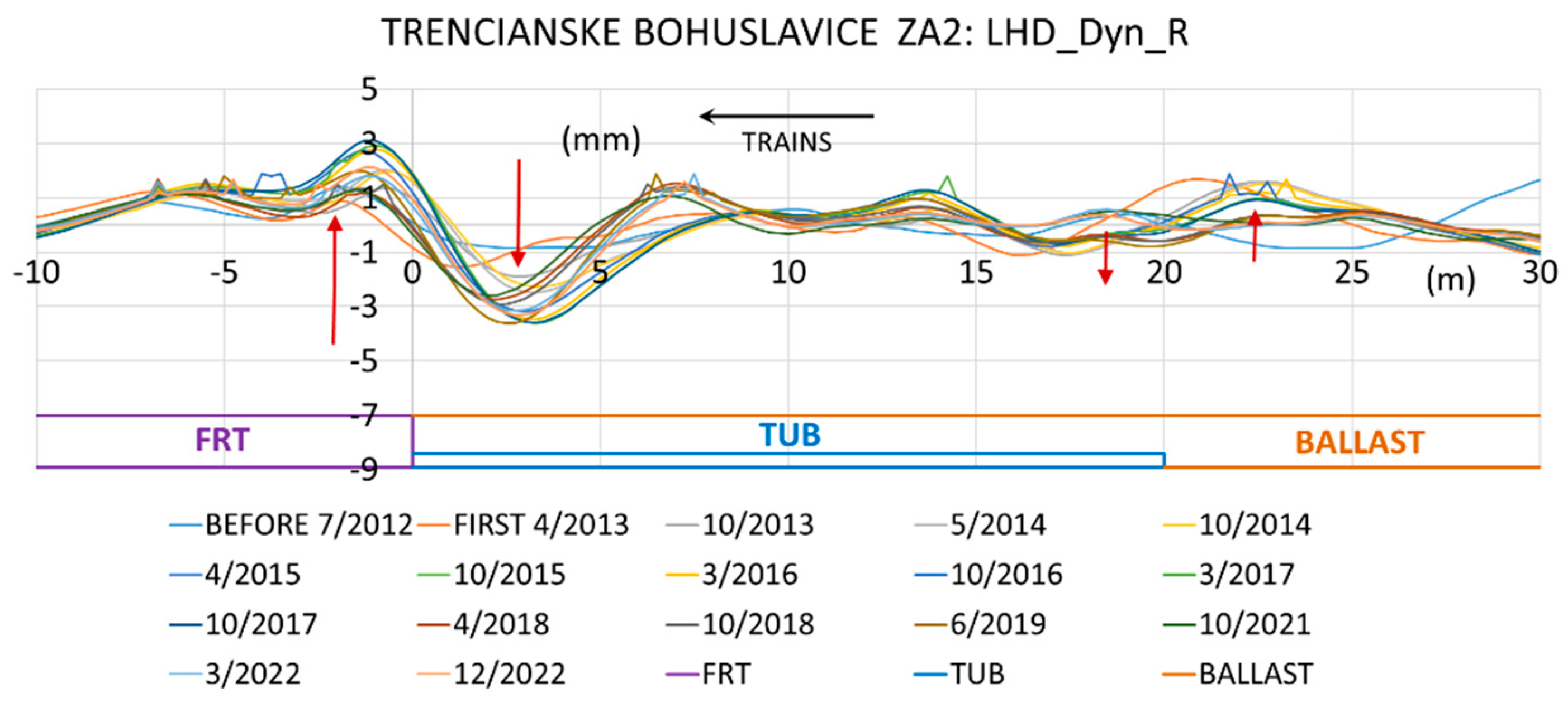

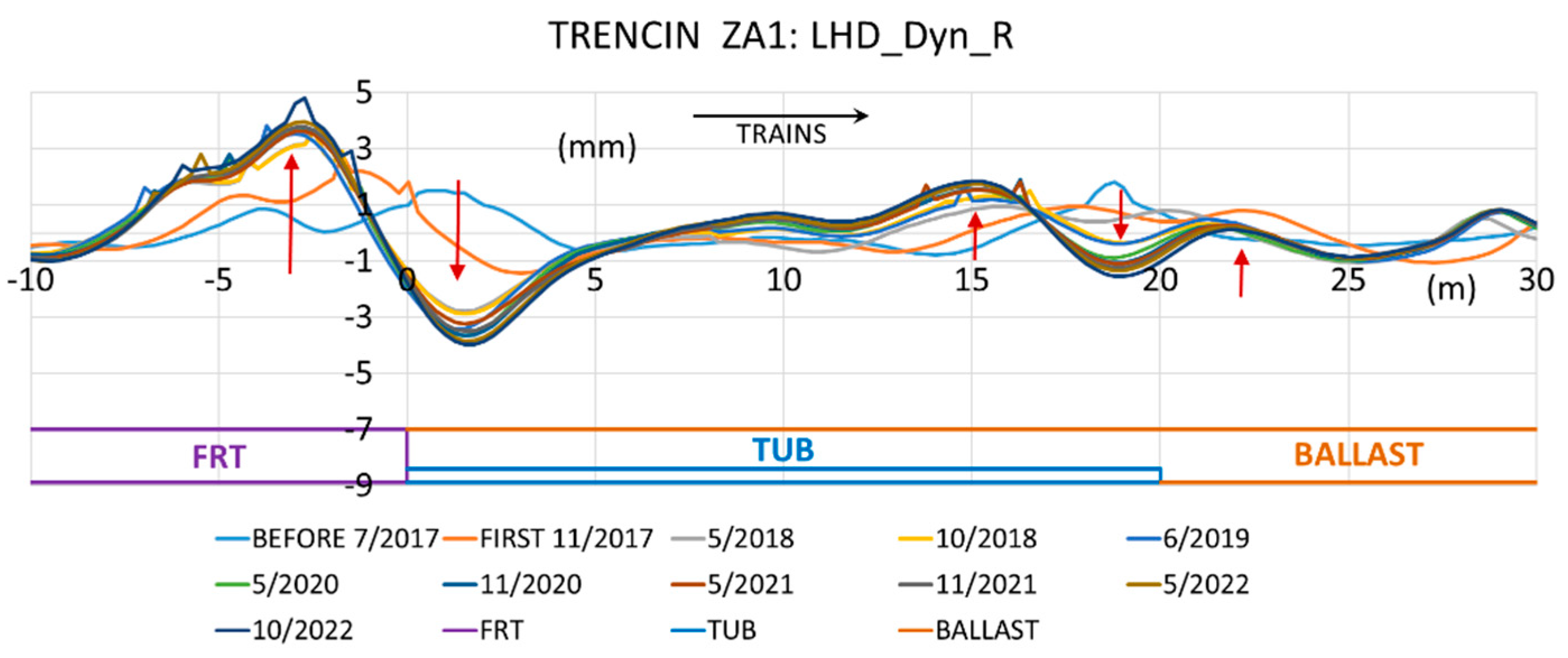

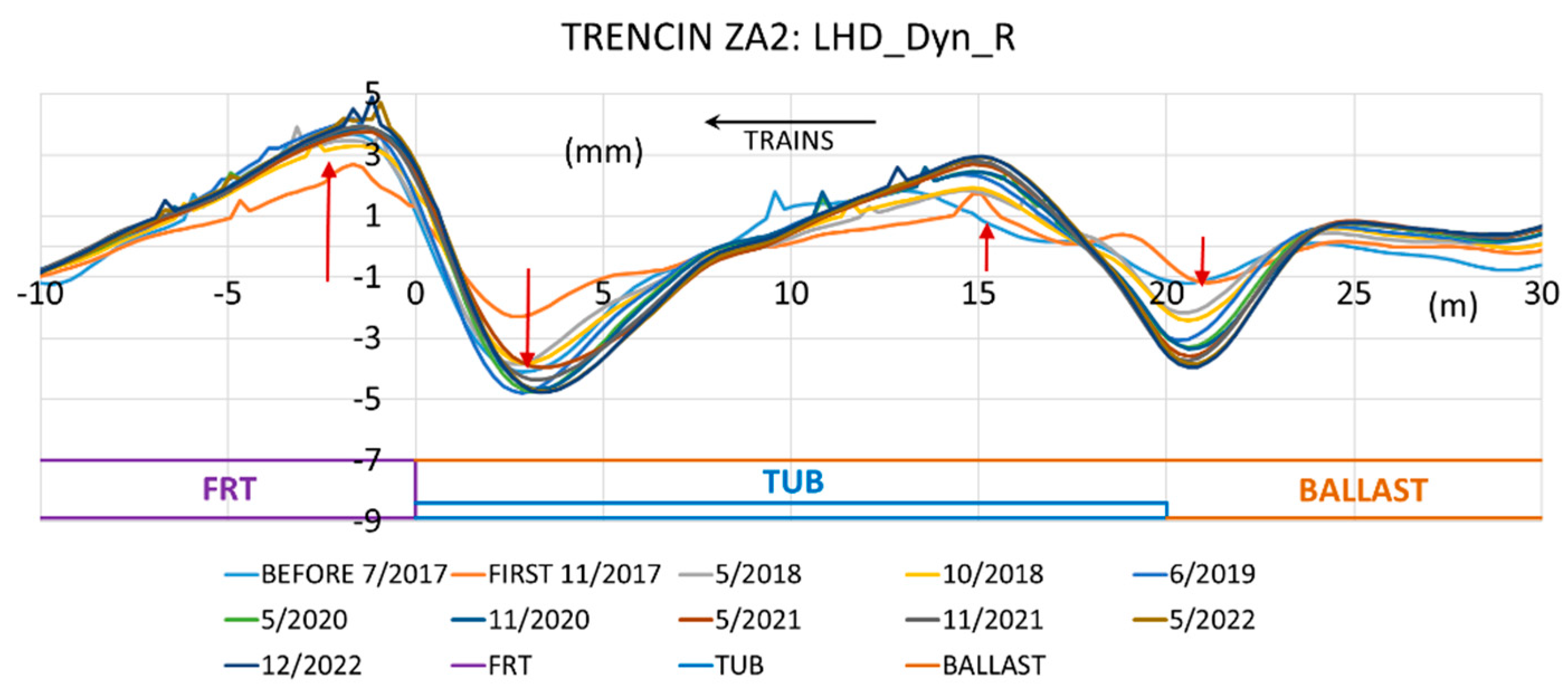

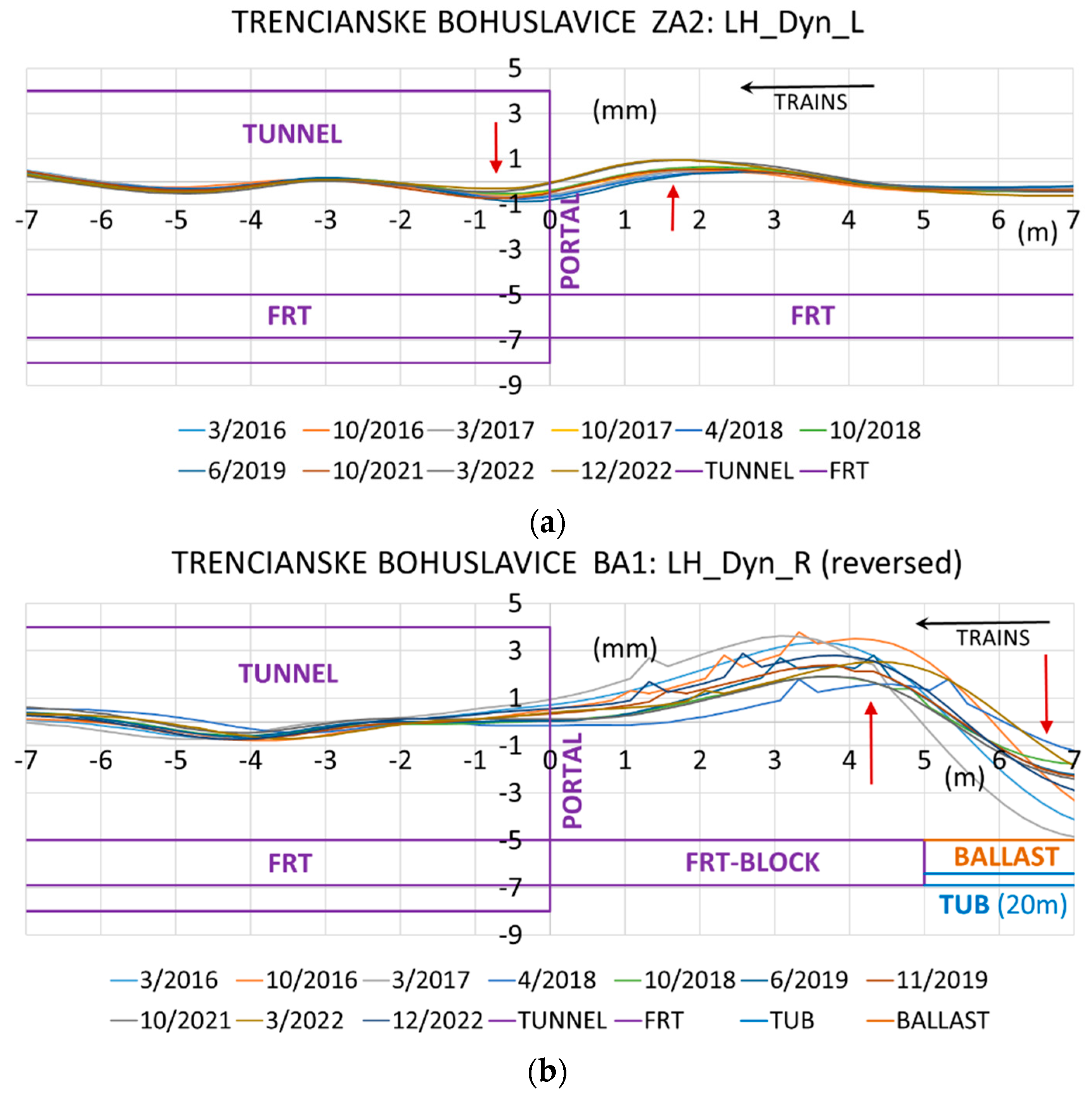

To comparison, measurements are presented from the monitoring of a direct transition (at the point of change in track stiffness) from a fixed railway track to a track with a railway bed, for example, sections near the Turecky Vrch tunnel near the city of Trencianske Bohuslavice according to

Figure 3 or near the bridge in the town of Trencin in

Figure 6. Reinforced concrete tubs for the track bed are designed here as transition zones. The zero point "0" represents this transition ("jump") where structural layers and objects are deformed, and the resulting values are R/L rail geometry position LHD deflections.

Based on the results of long-term experimental measurements, we can conclude that the transition zone with its beginnings and ends of the fixed railway track (the ends of the FRT), where there is a transition from a reinforced concrete slab to the track bed, or the end of a bridge structure without a track bed, causes more significant problems on the railway line. In contrast to the FRT, in the transition zone from the gravel track bed, for example, at a bridge object located at the railway bottom of the track, here, the track can be tamped regularly with automatic machine tampers (provided that the structural layers of the railway's lower substructure under the transition zone can affect their deformations, i.e., the TZ).

During this transition at the end of the FRT structure, a "vertical cut" occurs in the longitudinal profile of the track, causing a significant change in its stiffness. This start or end of FRT at zero point "0" approximately above 1 m in the track bed is tamped poorly. Also, for this reason, "jumps" (deformation waves) arise, created by the forces of the wheels of train sets at these points.

The research shows that the most significant height wave of the change in the geometry of the R/L rails occurs at the transition point, and in the case of the constructed reinforced concrete tub, also at its end (schemes – lower parts of figures), but approx. with half the value of the height/depth of the wave ("double jump" height curve, in this case, the length of the tub is 20 m). When the trains travel in the opposite direction, the material at this point is pushed under the fixed track or the transitional reinforced concrete tub, or the structural layers of materials under the concrete objects or the reinforced concrete tub of the transition zone are deformed.

These longitudinal height deformations (LHD) of the R/L rails are significant (higher values) mainly because they are places on the railway track where there is a transition between the reinforced concrete slab (FRT) and the railway ballast. For this reason, research is being carried out on these sections with a change in the stiffness of the railway track. In addition, according to

Figure 3, we assume changes in the heights of the underlying layers, as it is a high railway embankment of 6 to 8 m, and the said section has problems during the entire period of operation of the railway line. According to this figure, we can also state that the first stage measurements before and after the track is put into operation are curves that indicate that at the point "0", where the end of the reinforced concrete block FRT (its fall and subsequent extrusion of the material).

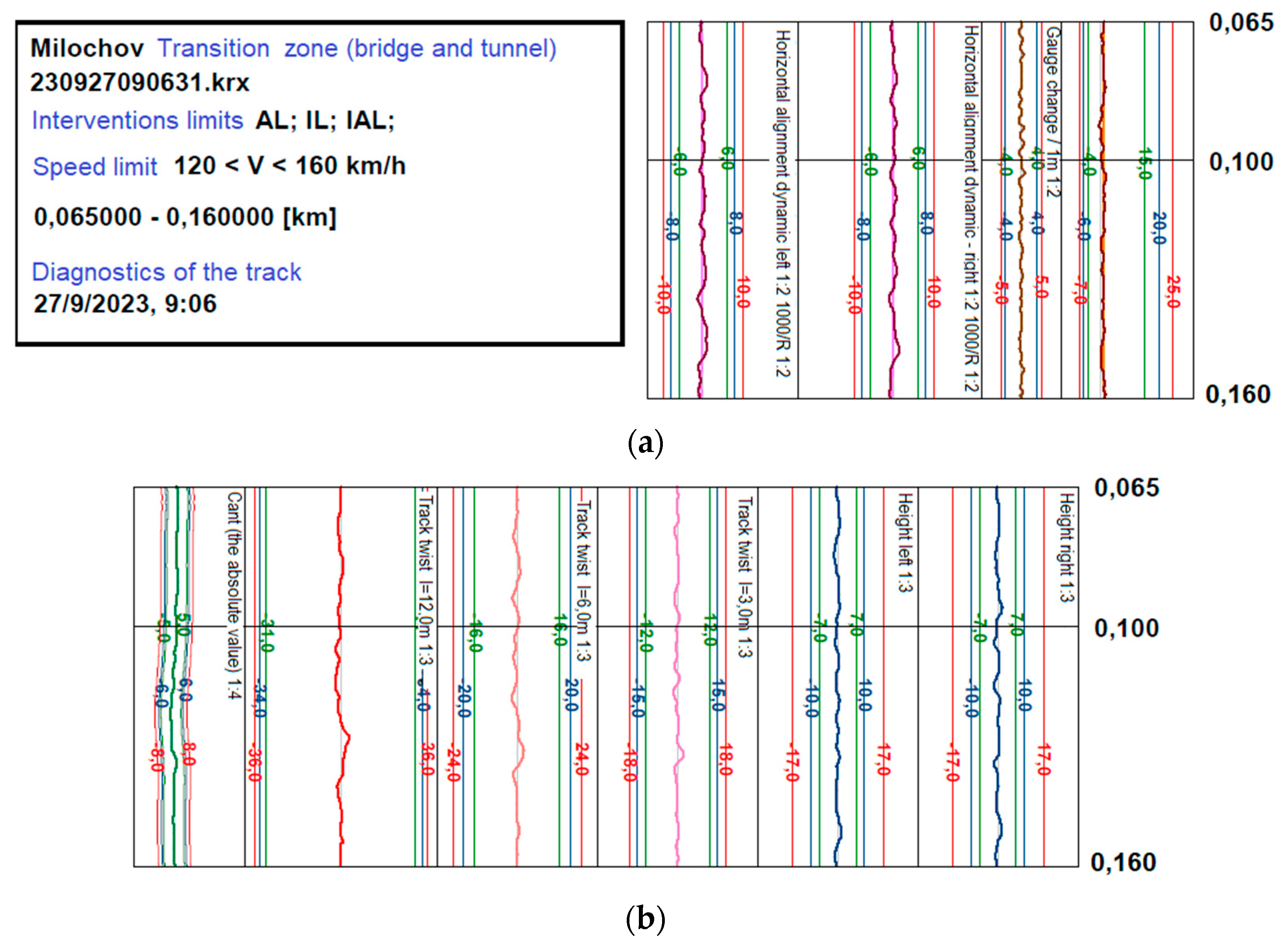

Even if these height waves of the geometric position of the R/L rails (LHD) are detected, solved and analysed, the track in the given section meets the criteria of operational deviations. As an illustration, the resulting graphs from measurements by the continuous KRAB trolley with all its parameters are shown in

Figure 7. The primary task of the research is to reduce the effects of shocks from the wheels of train sets, vibrations, deformations, etc., on objects of track construction, including stress and wear of structural parts of train sets, and increase the comfort of driving on the track (people, goods). If these deformations are not considered, the geometric position and heights may collapse at the point of change in track stiffness.

These limit values are differentiated by colour for the specific level of intervention in the track: AL level – monitoring limit (green), IL – intervention or repair limit (blue), and the IAL limit deviation – the limit of immediate intervention in the track (red). The limits are set according to the importance of the track, for example, the European railway corridor with a track speed of 160 km/h.

3.2. Tunnel Portals

Other track stiffness changes, such as tunnel portals, behave similarly to the vertical deformation deflections of the track geometry.

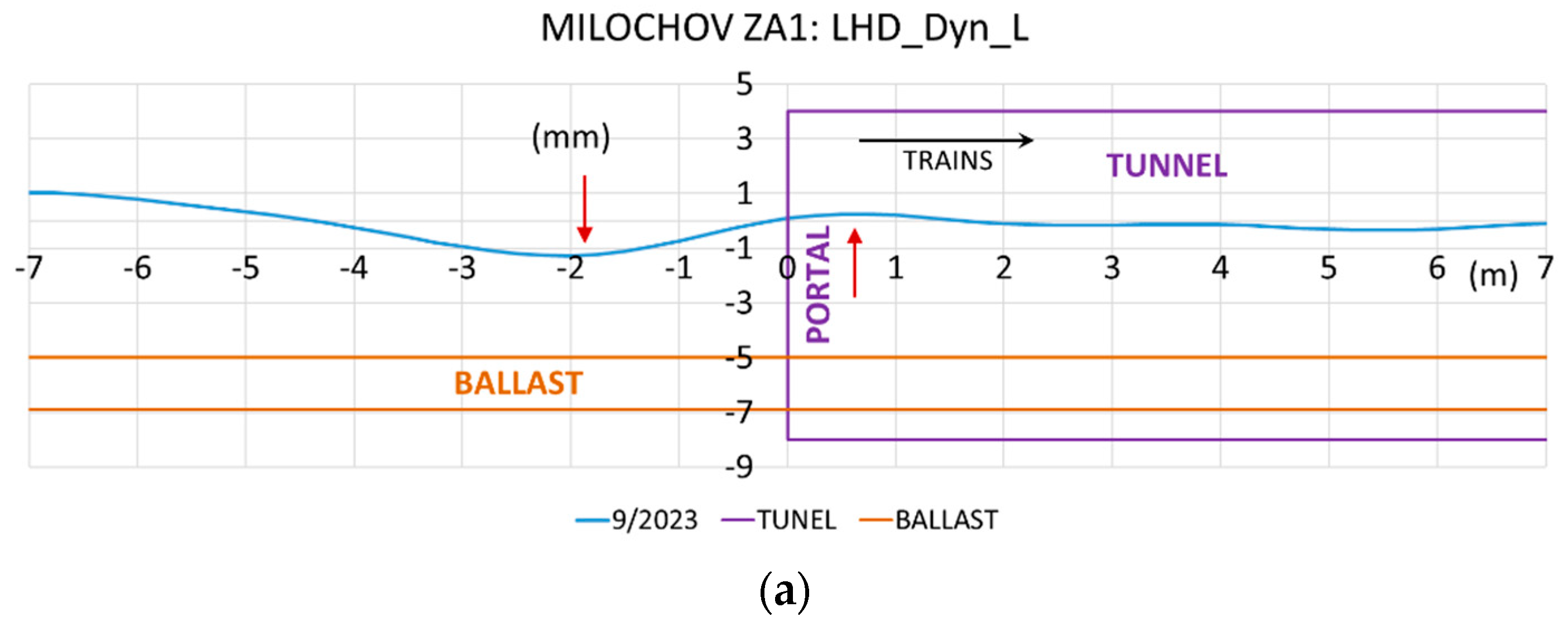

Data are monitored in the measured research section of the transition zone near the portal of the Milochov tunnel, according to

Figure 8, where there are height changes on the R/L rails. Since it is a classic construction of a railway line with a track bed, the section is tamped with automatic tamping machines to the prescribed geometric position and height of the track according to the AL, IL, IAL criteria according to the standard STN 736360-2 [

16].

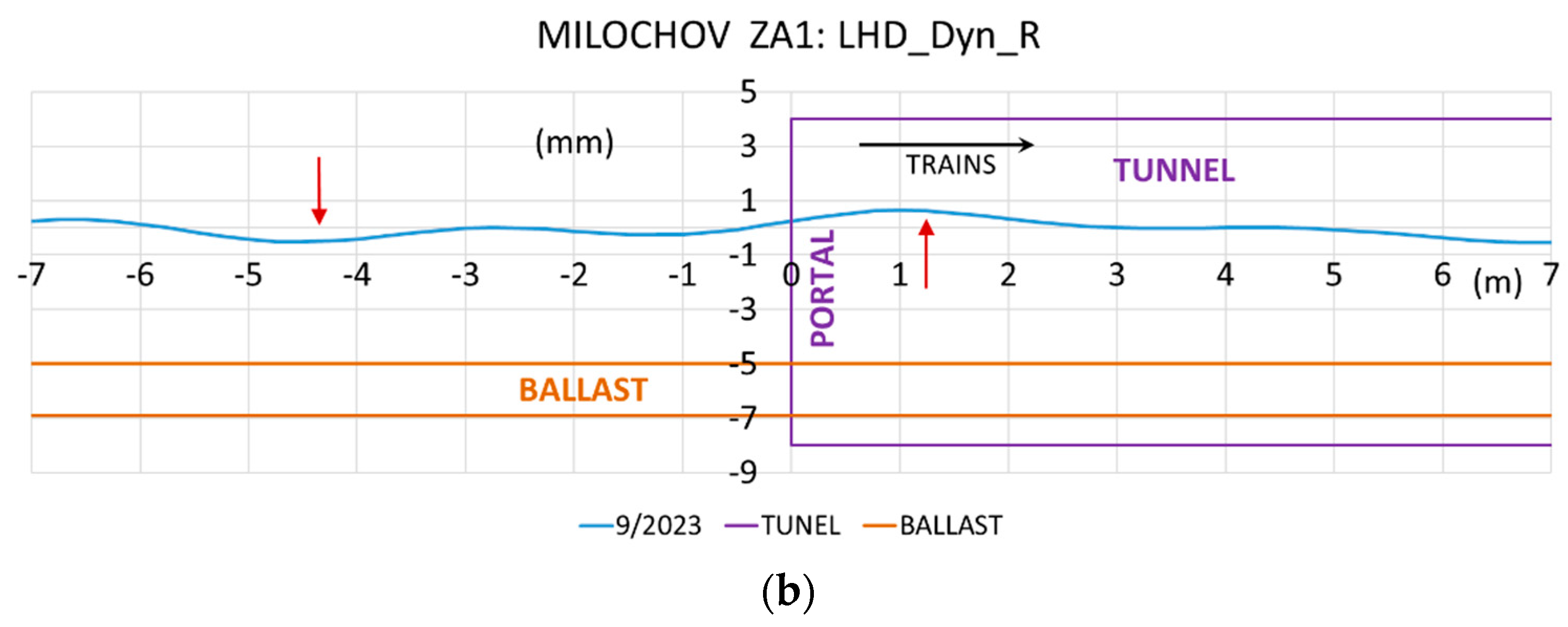

In the case of tunnels with FRT, the research monitoring registered the height changes of the wave of the geometrical position of the track (tunnel portals), where it is proven that there is a pushing of the material into the part of the track with its softer stiffness of the track with the subsequent pushing out of the material of the structural layers at zero point "0" of change. There is also an uplift of the track geometry at the beginning of the reinforced concrete track,

Figure 9b (

Figure 9a is OK).

The positive deformation arises because it is a place with a sudden change in the stiffness of the railway track. In this case, in

Figure 9b, the train pushes a pressure wave that hits the reinforced concrete slab. In front of the tunnel, there is still a terminal block of the fixed railway line FRT-BLOCK with a length of 5.08 m, on which there is still an FRT; therefore, the change in stiffness is shifted up to this point, where the TUB-BALLAST track bed begins.

Figure 9a is just a continuous FRT track. Since it is a long-term effect of pressure wave forces on the object, there are elevations of these ends of the FRT track, which is proven by all the figures in the paper.

The driving of various vehicles during tunnel maintenance, which enters the tunnel from the road network in this location, or the loading of parts and machines at the tunnel portals can contribute to the deformations to a certain extent. Alternatively, there can be a double transition zone, i.e., the end of the fixed carriageway and the associated tunnel portal (2 transition zones in a row in

Figure 9b).

Experimental measurements were carried out using different structural combinations of the railway tracks at the tunnel portals. The results with a continuous track bed were first presented in the paper, but the results are more interesting regarding the results for the railway track formed by the FRT-reinforced concrete track or slabs. In the case of continuous FRT construction at the portal site, it is influenced by this tunnel portal (its massive construction), for example, by the FRT track in front of the portal, or vice versa by the fall or lift of the portal. For a long time, research was mainly carried out for portals with a sudden structural change in the stiffness of the carriageway, where the FRT ends (designed only in the tunnel tube). In these cases, the proposed reinforced concrete tub for the track bed is before the tunnel portal. These transition zones have a proposed reinforced concrete block glued to the foundations of the portal, and here, a "cut" occurs between these objects; for example, they are presented in research publications [

11,

12] and [

14].