1. Introduction

Self-compacting concrete (SCC) represents a significant advancement in concrete technology, offering enhanced strength and performance characteristics that are particularly advantageous for Department of Public Works and Highways (DPWH) projects. This study explores the application of SCC within DPW projects from a value engineering perspective, focusing on the methodologies and benefits associated with optimizing the strength and performance of SCC.

The strength and performance of SCC are key considerations in its application within DPWH projects. SCC is designed to flow and consolidate under its own weight, without the need for mechanical vibration, thereby ensuring complete filling of complex forms and reinforcing elements [

1]. To enhance its strength, SCC formulations typically involve a meticulous blend of fine powders, superplasticizers, and viscosity-modifying agents to achieve optimal flowability, while maintaining mechanical properties such as compressive strength, durability, and resistance to segregation [

2].

In addition to conventional concrete constituents, the inclusion of supplementary cementitious materials (SCMs) like fly ash or silica fume can further enhance the strength and durability of SCC [

3]. The careful selection and proportioning of these materials are critical to achieving desired performance criteria, such as high early strength development and reduced permeability.

The unique flow characteristics of SCC are attributed to its rheological properties, influenced by the use of high-range water-reducing admixtures (HRWR) and viscosity-modifying agents (VMA). These admixtures impart a high degree of workability, enabling SCC to flow effortlessly around congested reinforcement and into intricate formwork without segregation. The stability of SCC during placement and its ability to maintain homogeneity over time are key factors in optimizing its performance [

4].

The integration of SCC in DPWH projects presents several practical advantages. Firstly, SCC facilitates rapid and efficient construction, reducing labor requirements and construction time due to its self-leveling and self-compacting properties [

6]. This is particularly beneficial in projects involving complex geometries or congested reinforcement, where traditional concrete placement methods are challenging [

8].

The use of SCC can enhance construction quality and durability, minimizing the risk of defects such as honeycombing and voids [

5]. The improved durability and reduced maintenance needs of SCC contribute to the longevity and sustainability of DPWH infrastructure, aligning with the overarching goals of public infrastructure development.

The utilization of SCC in DPW projects exemplifies a value engineering approach, combining enhanced material performance with efficient construction practices to deliver durable and resilient infrastructure. This study aims to explore the specific methodologies and benefits associated with optimizing SCC for integration within the realm of Department of Public Works and Highways projects.

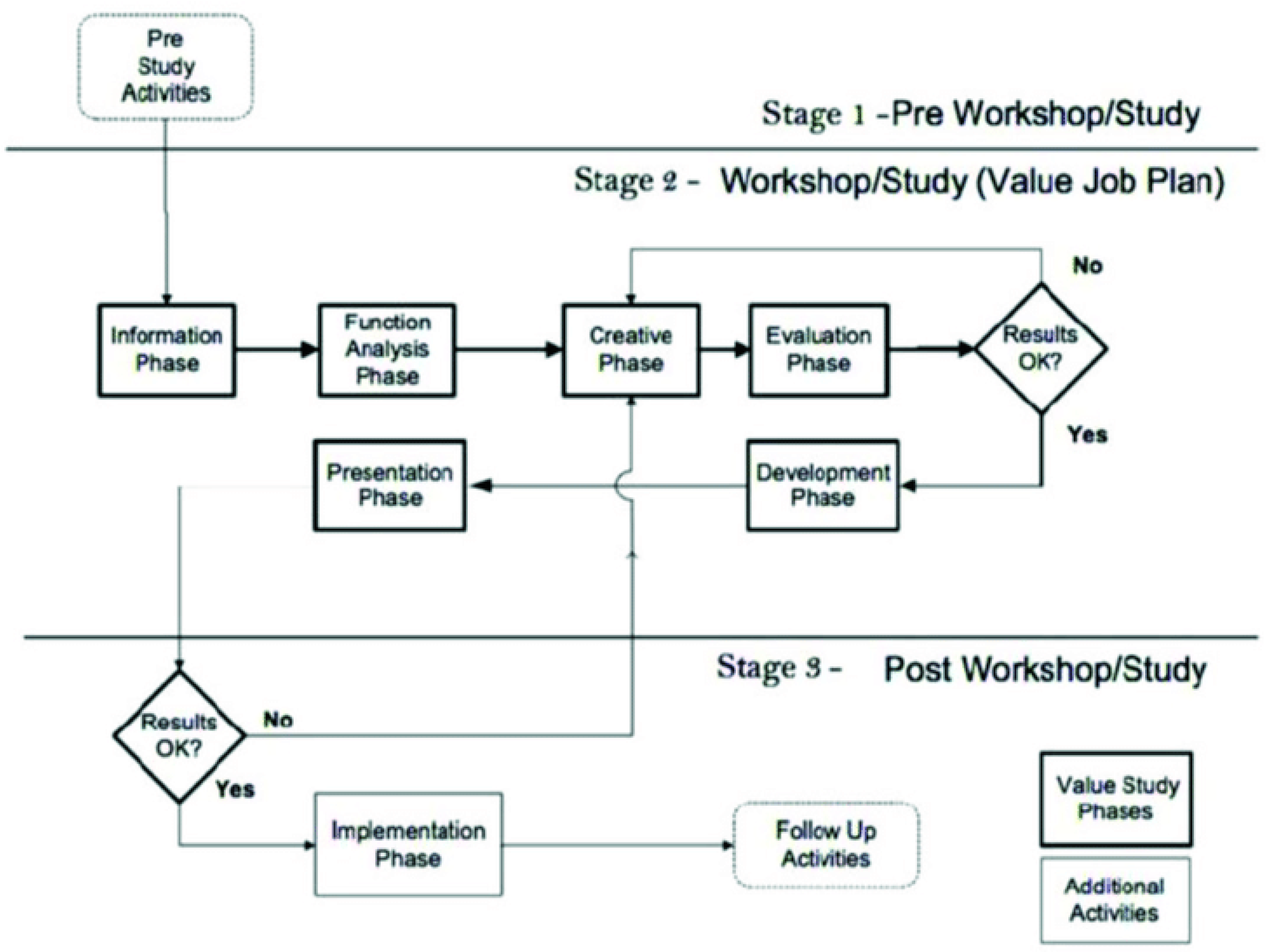

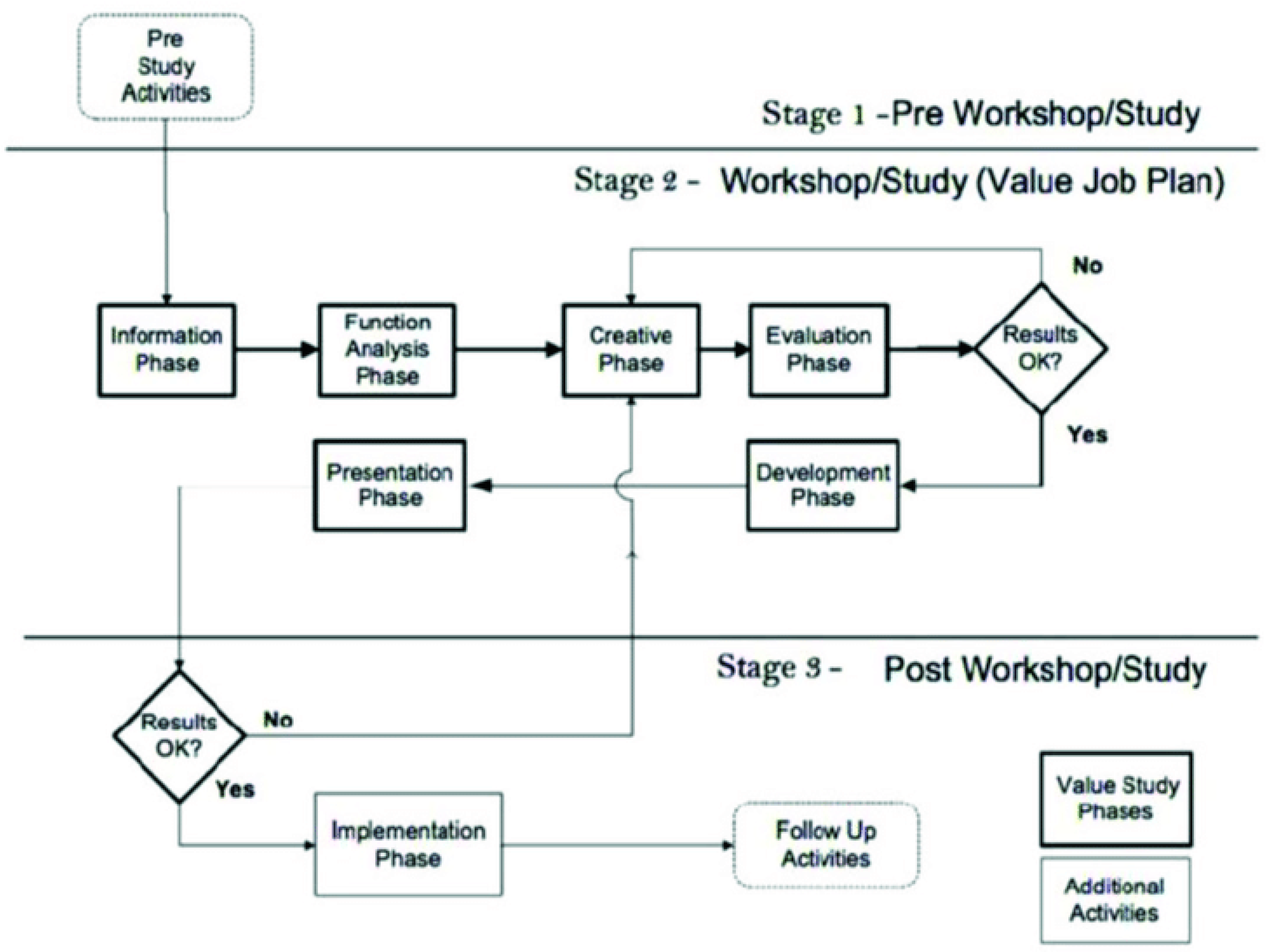

2. Review Methodology

The review methodology employed in this study is designed to comprehensively explore strategies and methodologies for enhancing the strength and performance of self-compacting concrete (SCC) within the context of Department of Public Works and Highways (DPWH) projects. Initially, a systematic literature review was conducted to gather a broad range of research articles, technical papers, and industry reports related to SCC technology and its application in public infrastructure [

10]. This review encompassed databases such as Scopus, Engineering Village, and Google Scholar, utilizing keywords like "self-compacting concrete," "strength enhancement," "performance optimization," and "public works projects” [

7]. The aim was to identify fundamental concepts, methodologies, and case studies regarding the use of SCC in DPWH projects.

Through the literature review, critical parameters influencing SCC's strength and performance in DPW projects were pinpointed. These parameters include mix design considerations such as cementitious materials and admixtures, construction techniques like formwork design and casting methods, and quality control measures such as testing protocols and acceptance criteria [

12]. Following this, an analysis of best practices in SCC formulation, design, and implementation was conducted based on the identified parameters [

14]. This analysis involved reviewing case studies and project reports illustrating successful applications of SCC in DPWH projects, showcasing strategies employed to optimize strength, durability, and workability while addressing project-specific constraints.

Moreover, the study integrated a value engineering framework to evaluate the practical values associated with SCC utilization in DPWH projects. This involved assessing cost-effectiveness, constructability, and long-term performance benefits of SCC versus conventional concrete solutions. Value engineering principles were utilized to optimize SCC formulations and construction methods to meet project-specific requirements while maximizing benefits [

13]. Expert interviews and consultations with professionals in civil engineering, materials science, and construction management were also conducted to gain practical insights into challenges, opportunities, and emerging trends in SCC technology for DPWH applications.

Ultimately, the findings from the literature review, analysis of best practices, and value engineering assessment were synthesized to develop a holistic understanding of methodologies and benefits for enhancing SCC within DPWH projects. This synthesis forms the foundation for the recommendations and conclusions presented in the study, aiming to contribute to the advancement and application of SCC technology in the realm of Department of Public Works and Highways.

3. Strength and Performance of SCC Concrete

One key aspect of SCC's strength enhancement lies in its carefully engineered mix design. SCC typically incorporates a higher content of fine powders such as cement, fly ash, and silica fume, which contribute to denser concrete microstructure and improved packing of particles [

13]. This finer particle size distribution enhances the interfacial transition zone between cement paste and aggregates, leading to increased compressive strength and reduced permeability [

11].

In addition to the use of supplementary cementitious materials (SCMs), SCC often utilizes high-range water-reducing admixtures (HRWR) to achieve the desired flowability without compromising strength [

12]. The optimized combination of materials and admixtures allows for higher cementitious content while maintaining workability, resulting in SCC with superior mechanical properties and durability.

SCC's performance characteristics are primarily defined by its ability to flow and consolidate under its own weight, filling intricate formwork and congested reinforcement without the need for mechanical vibration. This self-leveling behavior ensures uniform distribution of concrete and minimizes the risk of voids or honeycombing, which are common issues in conventional concrete construction [

14].

The rheological properties of SCC, controlled by viscosity-modifying agents (VMAs), enable stable and consistent flow during placement. This stability enhances the homogeneity of concrete throughout the structure, promoting uniform strength development and reducing the potential for segregation or bleeding [

16].

The strength and performance attributes of SCC have significant implications for DPWH projects. In infrastructure applications such as bridge construction, SCC's ability to flow and fill complex formwork reduces labor requirements and construction time. This efficiency not only enhances productivity but also minimizes the risk of construction defects, ensuring the structural integrity and durability of public works infrastructure [

15].

Furthermore, the enhanced durability of SCC contributes to the longevity of DPWH projects, reducing the need for maintenance and repair over the structure's lifespan. The reduced permeability of SCC also enhances resistance to environmental factors such as freeze-thaw cycles and chemical attack, making it suitable for various DPWH applications where durability is paramount [

20].

The strength and performance characteristics of SCC offer significant advantages for DPWH projects, including improved compressive strength, enhanced durability, and efficient construction practices. By leveraging the unique properties of SCC, public works agencies can optimize infrastructure performance while minimizing life cycle costs, ultimately enhancing the sustainability and resilience of civil infrastructure.

4. SCC Formulation, Design, and Casting Methods

The formulation of SCC involves a precise balance of materials and admixtures to achieve the desired flowability, workability, and strength. Key components include cementitious materials (Portland cement, fly ash, silica fume), aggregates (fine and coarse), water, high-range water-reducing admixtures (HRWR), and viscosity-modifying agents (VMAs) [

20]. The selection and proportioning of these materials are critical to controlling SCC's rheological properties, ensuring optimal flow and stability during placement.

SCC formulations are tailored based on project requirements, considering factors such as ambient temperature, desired strength, and exposure conditions. The incorporation of supplementary cementitious materials (SCMs) enhances strength and durability, while HRWRs reduce water content and improve flowability without compromising concrete strength [

17].

SCC design considerations encompass various aspects, including mix proportions, aggregate grading, and admixture dosage. Mix proportions are optimized to achieve the desired balance between flowability and mechanical properties [

18]. Fine aggregate content is adjusted to optimize packing density and reduce bleeding, while coarse aggregate sizes are selected based on formwork constraints and structural requirements [

19].

Admixture dosage is carefully controlled to achieve the desired workability and viscosity characteristics. HRWRs are added to reduce water content and improve flowability, while VMAs enhance cohesion and prevent segregation [

21]. The design process involves laboratory testing and trial mixes to validate performance criteria and ensure compatibility with construction methods.

SCC casting methods are tailored to capitalize on its self-leveling and self-compacting properties. Unlike conventional concrete, which requires vibration to eliminate air voids and ensure consolidation, SCC flows effortlessly into intricate formwork and around congested reinforcement without segregation [

23]. This eliminates the need for manual compaction and reduces labor-intensive tasks during construction.

Casting techniques such as pump placement and gravity flow are commonly used for SCC applications. Pump placement enables rapid and efficient concrete placement, particularly in vertical or overhead applications, while gravity flow is suitable for horizontal elements such as slabs and beams [

22]. Formwork design is optimized to accommodate SCC's flow characteristics, minimizing obstructions and ensuring uniform concrete distribution.

In DPWH projects, SCC casting methods offer advantages in terms of construction efficiency, quality control, and structural performance. By leveraging SCC's unique properties, public works agencies can streamline construction processes, reduce labor costs, and enhance the durability and longevity of civil infrastructure. The adoption of advanced SCC formulation and casting methods represents a paradigm shift in concrete technology, offering sustainable solutions for modern infrastructure challenges.

5. Strategies to Optimize Strength, Durability, and Workability

The strategies to optimize the strength, durability, and workability of self-compacting concrete (SCC) is fundamental to achieving successful integration within Department of Public Works and Highways (DPWH) projects. The following strategies are commonly employed to enhance the overall performance of SCC:

Material Selection: Utilizing high-quality cementitious materials such as Portland cement, fly ash, and silica fume can enhance the compressive strength of SCC. The judicious use of supplementary cementitious materials (SCMs) contributes to improved microstructure and long-term strength development [

25].

Admixture Utilization: Incorporating high-range water-reducing admixtures (HRWRs) helps reduce water content while maintaining workability, resulting in higher strength due to reduced water-cement ratio [

24]. Additionally, superplasticizers can enhance the dispersion of cement particles, further improving strength characteristics.

Proper Mix Design: Balancing the proportions of cement, aggregates, and admixtures through rigorous mix design trials ensures optimal packing density and cementitious paste distribution, leading to increased compressive and flexural strength [

27].

Enhancing Durability:

Incorporation of SCMs: Adding fly ash, silica fume, or slag as partial replacements for Portland cement can improve the durability of SCC by reducing permeability, enhancing sulfate resistance, and mitigating alkali-silica reaction (ASR) potential [

26].

Controlled Permeability Formwork (CPF): Utilizing CPF technology during casting can reduce the ingress of water and aggressive chemicals, thereby enhancing the durability and minimizing the risk of corrosion in reinforced concrete structures [

29].

Optimized Curing Regime: Implementing appropriate curing methods such as moist curing or curing compound application ensures adequate hydration and promotes the development of durable concrete [

28].

Improving Workability:

Fine-Tuning Mix Proportions: Adjusting the particle size distribution of aggregates and optimizing the paste volume-to-total volume ratio enhances SCC's flowability and filling ability, facilitating ease of placement without segregation [

30].

Viscosity-Modifying Agents (VMAs): Incorporating VMAs helps control the rheology of SCC, improving cohesion and reducing bleeding and segregation [

31]. This ensures stable flow behavior during placement and allows for effective filling of complex formwork configurations.

Temperature Control: Managing concrete temperature during mixing, transportation, and placement is critical for maintaining workability and avoiding rapid slump loss, particularly in hot weather conditions [

32].

Implementing these strategies requires a holistic approach that considers material properties, mix design optimization, construction practices, and quality control measures. By integrating these strategies, DPW projects can benefit from SCC's enhanced strength, durability, and workability, ultimately leading to the construction of resilient and sustainable infrastructure. Ongoing research and development in SCC technology continue to refine these strategies, offering innovative solutions to address evolving challenges in civil engineering and construction [

35].

6. Practical Values of SCC Utilization

The practical values associated with the utilization of self-compacting concrete (SCC) in Department of Public Works (DPW) projects are multifaceted, encompassing efficiency, quality, sustainability, and long-term cost savings. The following points elaborate on the practical values of SCC integration within DPWH infrastructure:

SCC offers significant advantages in terms of construction efficiency and productivity. Its self-leveling and self-compacting properties eliminate the need for mechanical vibration during placement, reducing labor requirements and construction time [

37]. This efficiency is particularly beneficial in projects involving complex geometries, congested reinforcement, or inaccessible areas where traditional concrete placement methods are challenging. SCC facilitates faster and more efficient construction processes, enabling accelerated project schedules and timely project delivery.

The use of SCC promotes superior quality control and consistency in concrete placement. The self-leveling nature of SCC ensures uniform distribution and compaction without voids or honeycombing, minimizing the risk of construction defects [

38]. This results in enhanced structural integrity, durability, and aesthetic appeal of DPW infrastructure [

33]. Moreover, SCC's ability to flow effortlessly around reinforcement and into intricate formwork supports accurate and precise concrete placement, contributing to overall construction quality.

SCC formulations can be optimized to enhance durability and long-term performance. By incorporating supplementary cementitious materials (SCMs) and controlling the water-cement ratio, SCC exhibits reduced permeability and improved resistance to chemical attack, freeze-thaw cycles, and environmental degradation [

31]. The enhanced durability of SCC translates to extended service life and reduced maintenance requirements for DPWH projects, resulting in cost savings over the structure's lifespan.

The use of SCC aligns with sustainable construction practices and environmental stewardship. SCC formulations often incorporate industrial by-products such as fly ash and slag, reducing reliance on virgin materials and mitigating carbon emissions associated with cement production [

39]. The efficient use of resources, coupled with reduced construction waste and lower energy consumption during placement, contributes to the overall sustainability of DPWH projects. Furthermore, SCC's enhanced durability and longevity reduce the environmental impact of infrastructure maintenance and repair activities.

Despite potential initial cost considerations, SCC offers long-term cost savings through improved construction efficiency, reduced labor requirements, and minimized maintenance expenses. The upfront investment in SCC technology is justified by its tangible benefits in terms of project timelines, construction quality, and operational longevity [

40]. The life cycle cost analysis of SCC demonstrates its economic viability and positive return on investment for DPWH projects.

The practical values of SCC utilization in Department of Public Works and Highways projects extend beyond technical performance to encompass construction efficiency, quality assurance, sustainability, and economic viability [

31]. By leveraging the unique properties of SCC, public works agencies can optimize project outcomes, enhance infrastructure resilience, and contribute to the advancement of sustainable and resilient civil engineering practices.

7. Gaps and Challenges

The identification of gaps and challenges in the utilization of self-compacting concrete (SCC) within Department of Public Works and Highways (DPWH) projects is essential for understanding current limitations and opportunities for improvement. This section addresses key gaps and challenges associated with SCC integration in DPWH infrastructure:

1. Performance Verification and Standardization: One of the primary challenges is the need for standardized performance verification protocols specific to SCC in DPWH applications. Existing standards often focus on conventional concrete, which may not fully capture the unique properties and behavior of SCC [

33]. There is a lack of comprehensive guidelines and acceptance criteria tailored to SCC's flowability, stability, and long-term durability within DPWH projects. Establishing standardized testing methods and performance specifications for SCC can enhance confidence in its application and facilitate broader adoption.

2. Mix Design Optimization for Specific Applications: While SCC offers versatility in construction, optimizing mix designs for specific DPW applications remains a challenge. Different infrastructure projects (e.g., bridges, tunnels, culverts) require tailored SCC formulations to meet performance requirements under varying environmental conditions and structural demands [

35]. Achieving optimal balance between workability, strength, and durability parameters requires ongoing research and development to refine mix design methodologies and address project-specific challenges.

3. Construction Practices and Quality Control: Effective implementation of SCC poses challenges in terms of construction practices and quality control. Proper training and education of construction personnel are essential to ensure correct handling, placement, and finishing of SCC [

32]. Maintaining consistent concrete quality throughout the construction process, including transportation, pumping, and casting, requires advanced monitoring and quality assurance protocols. The complexity of SCC's rheological behavior necessitates specialized construction techniques and equipment, which may not be readily available or familiar to DPWH contractors.

4. Cost Considerations and Economic Viability: While SCC offers long-term benefits, initial cost considerations and economic viability can be perceived as barriers to adoption in DPWH projects. The upfront investment in specialized materials, admixtures, and equipment for SCC may exceed traditional concrete costs [

39]. Demonstrating the life cycle cost savings and economic benefits of SCC, including reduced labor, maintenance, and lifecycle expenses, is critical to justify its implementation and garner stakeholder support within DPWH agencies.

5. Sustainability and Environmental Impact: Although SCC incorporates supplementary cementitious materials (SCMs) and reduces construction waste, challenges remain in quantifying its overall sustainability and environmental impact. Balancing environmental benefits with SCC's performance requirements and project constraints requires comprehensive life cycle assessments and eco-efficiency analyses [

40]. Addressing sustainability concerns through optimized material selection, energy-efficient production methods, and reduced carbon footprint is imperative for advancing SCC's role in sustainable DPWH infrastructure.

Addressing the gaps and challenges associated with SCC integration in Department of Public Works and Highways projects requires collaborative efforts among researchers, engineers, contractors, and policymakers. Overcoming these challenges through innovation, standardization, and knowledge sharing will accelerate the adoption of SCC as a transformative technology for resilient and sustainable civil infrastructure development.

8. Conclusions

The study on enhancing the strength and performance of self-compacting concrete (SCC) for integration in Department of Public Works and Highways (DPWH) projects has provided valuable insights into the benefits, challenges, and opportunities associated with SCC technology. The following conclusions summarize the key findings and implications of this research:

SCC offers substantial advantages for DPW projects, including improved construction efficiency, enhanced quality control, and superior durability. Its self-leveling and self-compacting properties streamline construction processes, reduce labor requirements, and minimize the risk of construction defects, contributing to the overall quality and longevity of DPWH infrastructure.

Various strategies, such as optimizing mix designs, incorporating supplementary cementitious materials (SCMs), and utilizing advanced admixtures, are effective in enhancing SCC's strength, durability, and workability. The study emphasizes the importance of tailored mix designs and construction practices to achieve optimal performance in diverse DPWH applications.

Despite the benefits, challenges associated with SCC integration in DPWH projects include performance verification, standardized testing protocols, and cost considerations. Addressing gaps in mix design optimization, construction practices, and quality control is essential to overcoming barriers and promoting broader adoption of SCC within DPWH infrastructure.

The study underscores the significance of sustainability and economic viability in SCC utilization. Demonstrating the life cycle cost savings, environmental benefits, and long-term performance advantages of SCC is crucial for gaining stakeholder acceptance and support within DPW agencies.

Future research should focus on developing standardized guidelines, performance specifications, and acceptance criteria specific to SCC in DPWH projects. Collaboration among researchers, engineers, contractors, and policymakers is essential to advancing SCC technology and addressing evolving challenges in civil infrastructure development.

The integration of SCC within Department of Public Works and Highways projects represents a transformative approach to construction practices, offering sustainable, efficient, and resilient solutions for modern infrastructure challenges. By leveraging innovative strategies and overcoming existing barriers, SCC has the potential to enhance the quality, durability, and sustainability of DPWH infrastructure, paving the way for future advancements in civil engineering and construction.

Author Contributions

Conceptualization, review methodology, validation, writing, preparation, review and editing, and finalization.

Funding

No funding has been allocated to this study from public or private entities.

Data Availability Statement

Data sharing is not applicable in this article.

Acknowledgements

The author fully acknowledges and thanks the references contributors for their support and guidance in the conduct of this study.

Conflicts of Interest

The author declares no conflict of interest.

References

- Al-Kheetan, M. J., Rahman, M. M., Balakrishna, M. N., & Chamberlain, D. A. (2019). Performance enhancement of self-compacting concrete in saline environment by hydrophobic surface protection. Canadian Journal of Civil Engineering, 46(8), 677-686. [CrossRef]

- Amalia, G., & Riyadi, M. (2020). Performance of self compacting concrete (SCC) with precious slag ball as fine aggregate substitute. Proceedings of the 9th Annual Southeast Asian International Seminar. [CrossRef]

- Anusha, G. (2024). Review of: "Shear performance of polypropylene fiber reinforced high-strength self-compacting concrete beams". [CrossRef]

- Arivalagan, S. (2021). Flexural behaviour of hybrid fibre (steel fiber and silica fume) reinforced self-compacting composite concrete members. World Journal of Engineering, 11(4), 323-330. [CrossRef]

- Arunchaitanya, S., & Arunakanthi, E. (2021). Effect of electrically precipitated fly Ash(EPFA) on fresh and hardened properties of high strength self- Compacting concrete. [CrossRef]

- Ashish, D. K., & Verma, S. K. (2021). Robustness of self-compacting concrete containing waste foundry sand and metakaolin: A sustainable approach. Journal of Hazardous Materials, 401, 123329. [CrossRef]

- Ashish, D. K., Verma, S. K., Ju, M., & Sharma, H. (2023). High volume waste foundry sand self-compacting concrete – Transitioning industrial symbiosis. Process Safety and Environmental Protection, 173, 666-692. [CrossRef]

- Aslani, F., Hamidi, F., & Ma, Q. (2019). Fire performance of heavyweight self-compacting concrete and heavyweight high strength concrete. Materials, 12(5), 822. [CrossRef]

- Aslani, F., Hamidi, F., Valizadeh, A., & Dang, A. T. (2020). High-performance fibre-reinforced heavyweight self-compacting concrete: Analysis of fresh and mechanical properties. Construction and Building Materials, 232, 117230. [CrossRef]

- Barley, G. F. (2023). Erratum: An experimental study on strength and durability properties of self-compacting and self-curing concrete using light weight aggregates. Matéria (Rio de Janeiro), 28(4). [CrossRef]

- Dey, S., Kumar, V. V., & Phani Manoj, A. V. (2022). An experimental study on strength and durability characteristics of self-curing self-compacting concrete. Structural Concrete, 23(5), 3169-3198. [CrossRef]

- Harrows, G. A. (2019). Self-compacting concrete with partial replacement of sand by waste foundry sand. International Journal of Advance Engineering and Research Development, 4(09). [CrossRef]

- Hassan, A. (2019). Assessment of elevated temperature effects on self-compacting and high-strength concrete beams in comparison with normal concrete beams. International Journal of GEOMATE, 17(64). [CrossRef]

- Jha, S. (2023). Study on the flexural strength of glass fiber reinforced M20 grade self-compacting bacterial concrete. CARDIOMETRY, (25), 1771-1778. [CrossRef]

- Jiang, Z. (2022). Self-compacting concrete with manufactured sand. Green High-Performance Concrete with Manufactured Sand, 305-349. [CrossRef]

- Kadhar, S. A., Gopal, E., & Sivakumar, V. (2023). An experimental study on strength and durability properties of self-compacting and self-curing concrete using light weight aggregates. Matéria (Rio de Janeiro), 28(3). [CrossRef]

- Kadhar, S. A., Gopal, E., Sivakumar, V., & Anbarasu, N. A. (2024). Optimizing flow, strength, and durability in high-strength self-compacting and self-curing concrete utilizing lightweight aggregates. Matéria (Rio de Janeiro), 29(1). [CrossRef]

- Kanagaraj, B., Anand, N., Jerry, R., Raj, S., & Lubloy, E. (2023). Axial compressive behaviour and physical characteristics of high strength self-compacting geopolymer concrete (Hsgc) columns exposed to elevated temperature. [CrossRef]

- Kaushik, S., & Jain, S. (2021). Exploring the chemical and structural performance of self-compacting lightweight concrete incorporating perlite. European Chemical Bulletin. [CrossRef]

- Kumar, K. R., Shyamala, G., & Adesina, A. (2021). Structural performance of corroded reinforced concrete beams made with fiber-reinforced self-compacting concrete. Structures, 32, 1145-1155. [CrossRef]

- Kumar, S., & Rai, B. (2022). Synergetic effect of fly ash and silica fume on the performance of high volume fly ash self-compacting concrete. Journal of Structural Integrity and Maintenance, 7(1), 61-74. [CrossRef]

- Lalitha Surya Tejaswini, G., & Venkateswara Rao, A. (2020). A detailed report on various behavioral aspects of self-compacting concrete. Materials Today: Proceedings, 33, 839-844. [CrossRef]

- Mallek, J., Daoud, A., Omikrine-Metalssi, O., & Loulizi, A. (2021). Performance of self-compacting rubberized concrete against carbonation and chloride penetration. Structural Concrete, 22(5), 2720-2735. [CrossRef]

- Martins, M., Silva, L., Kuffner, B., Barros, R., & Melo, M. (2022). Behavior of high strength self-compacting concrete with marble/granite processing waste and waste foundry exhaust sand, subjected to chemical attacks. Construction and Building Materials, 323, 126492. [CrossRef]

- Meko, B., Ighalo, J. O., & Ofuyatan, O. M. (2021). Enhancement of self-compactability of fresh self-compacting concrete: A review. Cleaner Materials, 1, 100019. [CrossRef]

- Moravvej, M., & Rashidi, M. (2020). Structural performance of self-compacting concrete. Self-Compacting Concrete: Materials, Properties and Applications, 371-387. [CrossRef]

- Muhammad, A., & Thienel, K. (2023). Properties of self-compacting concrete produced with optimized volume of calcined clay and rice husk ash—Emphasis on rheology, time dependent workability and durability. [CrossRef]

- Muthusamy Kavitha, S., Venkatesan, G., Avudaiappan, S., & Saavedra Flores, E. (2020). Mechanical and flexural performance of self compacting concrete with natural fiber. Revista de la construcción, 19(2), 370-380. [CrossRef]

- Nili, M., Sasanipour, H., & Aslani, F. (2019). The effect of fine and coarse recycled aggregates on fresh and mechanical properties of self-compacting concrete. Materials, 12(7), 1120. [CrossRef]

- Parashar, A., Aggarwal, P., Saini, B., Aggarwal, Y., & Bishnoi, S. (2020). Study on performance enhancement of self-compacting concrete incorporating waste foundry sand. Construction and Building Materials, 251, 118875. [CrossRef]

- Rajah Surya, T., Prakash, M., Satyanarayanan, K., Keneth Celestine, A., & Parthasarathi, N. (2021). Compressive strength of self compacting concrete under elevated temperature. Materials Today: Proceedings, 40, S83-S87. [CrossRef]

- Rana, R. A. (2023). A review: Mechanical properties of self-compacting concrete (SCC) and influential factors. [CrossRef]

- Saba, A. M., Khan, A. H., Akhtar, M. N., Khan, N. A., Rahimian Koloor, S. S., Petrů, M., & Radwan, N. (2021). Strength and flexural behavior of steel fiber and silica fume incorporated self-compacting concrete. Journal of Materials Research and Technology, 12, 1380-1390. [CrossRef]

- Saloma, S. (2022). Influence of hooked-end steel fibers on flexural behavior of steel fiber reinforced self-compacting concrete (Sfrscc). International Journal of GEOMATE, 23(95). [CrossRef]

- Sandhu, R. K., & Siddique, R. (2019). Strength properties and microstructural analysis of self-compacting concrete incorporating waste foundry sand. Construction and Building Materials, 225, 371-383. [CrossRef]

- Sandhu, R. K., & Siddique, R. (2021). Durability performance of self-compacting concrete made with waste foundry sand. Structural Concrete, 23(2), 722-738. [CrossRef]

- Sivanandam, G., & Venkataraman, S. (2023). Mechanical and durability properties of CCD-optimised fibre-reinforced self-compacting concrete. Processes, 11(2), 455. [CrossRef]

- Ting, T., Rahman, M., & Lau, H. (2019). Compressive strength of OPS based self-compacting concrete incorporated with fly ash under elevated temperature. IOP Conference Series: Materials Science and Engineering, 495, 012086. [CrossRef]

- Vinajan, K. A., & Natarajan, K. G. (2022). Gravimetric weight loss of steel in self-compacting concrete blended with wood ash and silica fume. [CrossRef]

- Zuhair, M., & Deshmukh, S. K. (2021). Effect of different fibers on compressive strength of self-compacting concrete at elevated temperature. IOP Conference Series: Materials Science and Engineering, 410, 012007. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).