Submitted:

25 July 2024

Posted:

29 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

- (1)

- Steel fibers can significantly enhance the mechanical properties and durability of fly ash concrete structures, however, their contribution in terms of toughness is low. In case of large deformation of concrete or severe impacts, steel fibers are unable to absorb enough energy to resist the occurrence of fracture situations. Tiberti et al. [1] investigated the use of steel fiber concrete as a partial wire mesh lining to determine the feasibility of using steel fiber concrete lining to reinforce the critical connection zone between the tunnel’s up arch and the steps. Kaufmann W et al. [2] found that steel fibers incorporated in concrete are very beneficial for shear transfer across cracks, which balances the compressive stresses on the crack faces and greatly enhances the aggregate’s interlocking effect. Tests by Kooiman et al. [3] showed that steel fiber concrete has a high tensile stress resistance and can effectively reduce ductile damage and mitigate cracking when properly incorporated into concrete. Wu et al. [4] analyzed the effect of different types and dosages of steel fibers on the performance of concrete and finally found that the increase in the volume of fibers can improve the compressive and flexural strength and reduce the shrinkage properties of ultra-high-performance concrete. However, the concrete properties were limited by the toughness of the fibers when the steel fiber dosage exceeded 2%. Buratti et al. [5] found that steel fibers can optimally reduce the thickness of tunnel lining and the bridging effect of the fibers can significantly reduce the crack width of the tunnel lining. Zhang et al. [6] prepared two sets of high-flow steel-fiber concretes (HF-SFRC) doped with silica fume or fly ash and tested them. The synergistic effect between fly ash or silica fume, steel fibers, and cement in the mixtures enhanced the flowability and improved the mechanical properties of HF-SFRC. Wu et al. [7] investigated the effect of the type and dosage of steel fibers on the abrasion resistance of fibrous concrete. The results showed that the short straight and medium hooked-end fibers had a better distribution of space and bridging effect, and had a better resistance to debris flow abrasion. Liu.[8] studied the bending angle of the end hook type steel fiber end hook, and found that the compressive strength, tensile strength, bending strength, and elastic modulus of SFRC were affected by the aspect ratio, content, and end hook bending angle of steel fiber. Nehdi et al. [9] conducted a preliminary study on ultra-high-performance steel fiber concrete tunnel lining pipe sheets with different steel fiber lengths and admixtures. It was found that the short fibers are more capable of improving the strain-hardening phase of the lining concrete and are fully capable of replacing the steel reinforcement in corrosive environments. Chiaia et al. [10] investigated the application of steel fibers in cast-in-place steel fiber concrete tunnel lining in both normal service conditions and extreme conditions provided the corresponding structural advantages, and the fibers were able to reduce the crack width. Shao G.d. [11] took samples from the inner and outer surfaces of a tunnel lining, respectively, and studied the anti-chlorine ion penetration performance. The results showed that the chloride ion diffusion coefficient of steel fiber concrete was reduced by 34% to 41% compared with that of ordinary concrete, and the steel fibers could effectively prevent the diffusion of chloride ions in the concrete, and it was better to be located in the inner side of the tunnel. Zhang et al. [12] found that steel fibers significantly improved the durability of concrete, and the chloride diffusion coefficient (CDC) of nano-concrete was reduced by 17.1% when the SF admixture was 1.5%. You [13] et al. added synthetic steel fibers into concrete and finally concluded that coarse synthetic steel fibers improved the densification of the concrete structures, and inhibited the entry of sulfate ions into the interior of the concrete. Thus, the degradation of concrete by sulfate was reduced. By studying the load-bearing characteristics of plain concrete, reinforced concrete, and steel fiber concrete lining, it was found that steel fibers can improve the load-bearing capacity of the lining structure, but the number of cracks in steel fiber concrete lining is more and the development path is more tortuous [14]. Liu et al.[15] found that after adding steel fibers to the concrete, the mechanical properties of the concrete and the ability of territorial rupture have been improved, but the working capacity has a certain magnitude of Cui et al.[16] investigated the damage mechanism of fiber concrete lining in tunnel applications and carried out flexural simulation tests and found that the flexural effect of mixed fiber concrete lining was better than that of steel fiber concrete lining. Therefore, the addition of plant fibers with superior toughness based on single-mixed steel fibers can substantially enhance the flexural and tensile properties of concrete.

- (2)

- The introduction of coconut fibers significantly improves the toughness of fly ash concrete and enhances the ductile performance of the structure during flexural action, in addition, the corrosion resistance of coconut fibers makes it excellent in resisting harsh environmental factors such as chloride attack and sulfate corrosion, which makes it an ideal choice of construction material for coastal and other environmental conditions. Chain-arranged cellulose molecules form the basis of coconut fibers and largely determine the tensile properties of plant fibers [17]. Ali et al. [18] discussed the suitability of coconut fiber-reinforced concrete in various projects and concluded that coconut fibers can have an improvement in tensile strength, flexural strength, and fracture toughness of concrete. Hwang et al. [19] found that the addition of coconut fibers to concrete has a positive effect on the initial crack deflection, toughness index, plastic cracking and impact resistance of the composites can be positively affected. Reis [20] conducted a three-point bending test to investigate the flexural strength, and fracture toughness of epoxy polymer concrete reinforced with coconut, bagasse, and banana fibers. It was found that coconut fiber reinforced polymer concrete had the highest fracture toughness and coconut fiber increased the flexural strength of concrete by 25%. Wu Hui [21] et al. added coconut fiber (CF) to magnesium phosphate cement and tested its compressive properties, the results showed that when the CF dosage was higher than 1%, the brittleness of magnesium phosphate cement was significantly reduced, and the specimen damage morphology was changed from brittleness to a certain degree of ductility when the CF dosage was 2%. Ahmad et al. [22] investigated the effect of coconut fibers with different lengths and volumetric additions on the properties of high-performance concrete and found that the best overall performance was obtained with a coconut fiber length of 50 mm and volume addition of 1.5%. While enhancing the toughness of concrete matrix, coconut fibers are also beneficial in terms of concrete durability. Ramli et al. [23] investigated the strength and durability of coconut fiber concrete in aggressive environments such as seawater and air exposure for different times. The durability tests such as depth of carbonation, intrinsic permeability, and chloride ion penetration tests, and the microstructure were investigated using a scanning electron microscope and X-ray diffractometer and it was found that due to the incorporation of coconut fibers, the durability properties such as chloride ion permeability were improved in addition to the improvement in compression and flexural properties. B. Ali et al. [24] summarized the literature on coconut fiber as a reinforcing material for concrete and found that although coconut fiber improves the toughness of concrete, its improvement in compressive strength and modulus of elasticity of concrete is limited.

- (3)

- Due to the coastal area tunnels were not only subjected to environmental loads and other external forces, and suffered many chloride salts, sulfates and other aggressive ions corrosion, resulting in cracks spalling and other phenomena. Steel fibers have good compressive properties, coconut fibers have high toughness and corrosion resistance, the complementary role of the two fibers is very suitable for the coastal area tunnel lining environment. In this study, the NEL chloride diffusion coefficient test as well as the sulfate corrosion test were carried out based on testing the working and mechanical properties of concrete. In addition, in-depth structural analyses of the reinforcement mechanism of fibers in fly ash concrete were carried out in this study, aiming to reveal the interaction between the fibers and the concrete matrix and its effect on the macroscopic properties of the material.

2. Materials and Methods

2.1. Test Preparation

2.1.1. Raw Materials

2.1.2. Mixing Ratio

2.1.3. Preparation of Specimens

2.2. Test Methods

2.2.1. Compression Test, Splitting Tensile Test and Flexural Test

- 4)

- The principle of compressive strength test is as follows:

- 5)

- The principle of splitting tensile strength test is as follows:

- 6)

- The principle of flexural strength test is as follows:

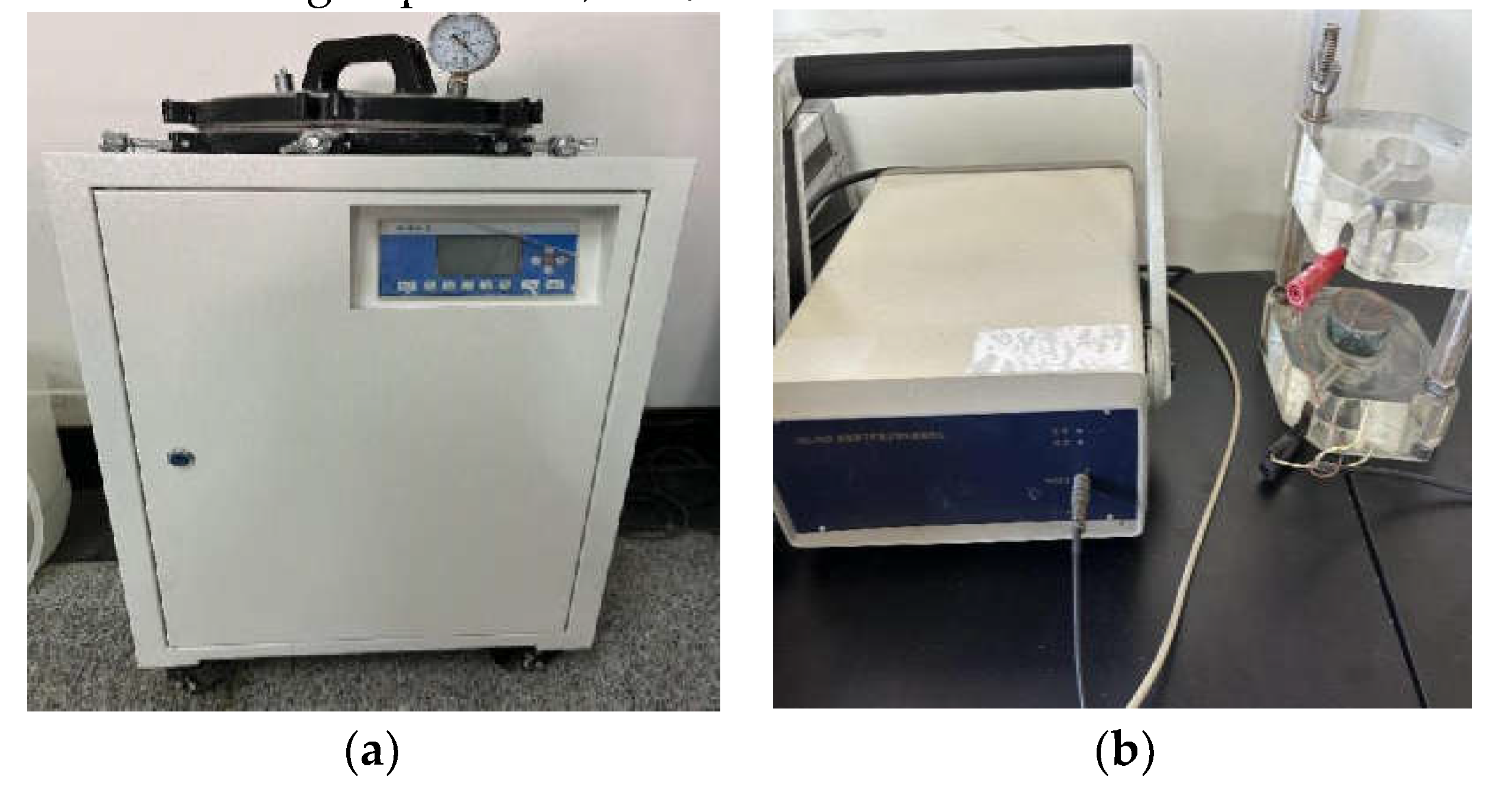

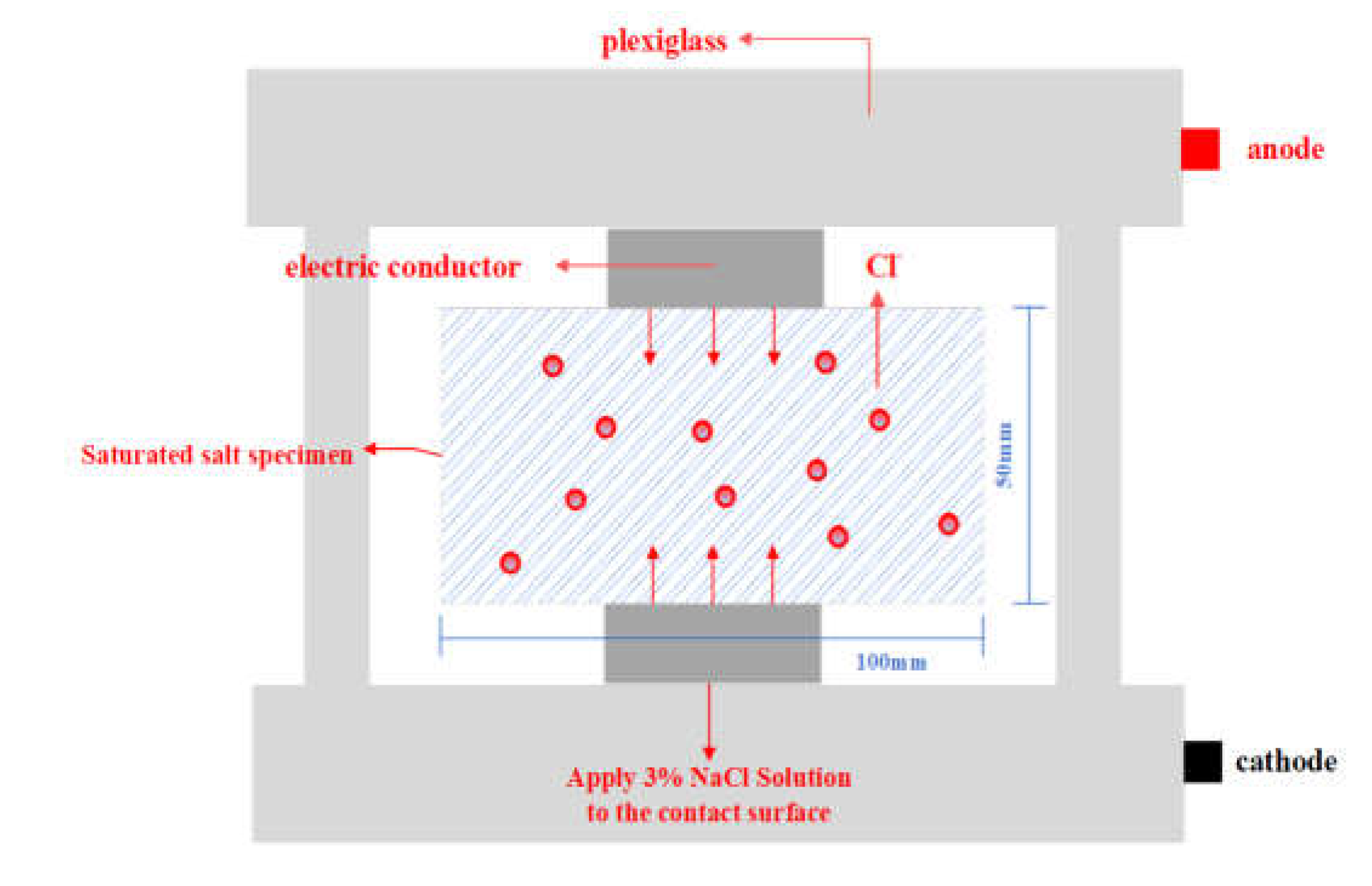

2.2.2. NEL Chloride Diffusion Coefficient Test

2.2.3. Sulfate Corrosion Resistance Test

3. Analysis and Discussion of Results

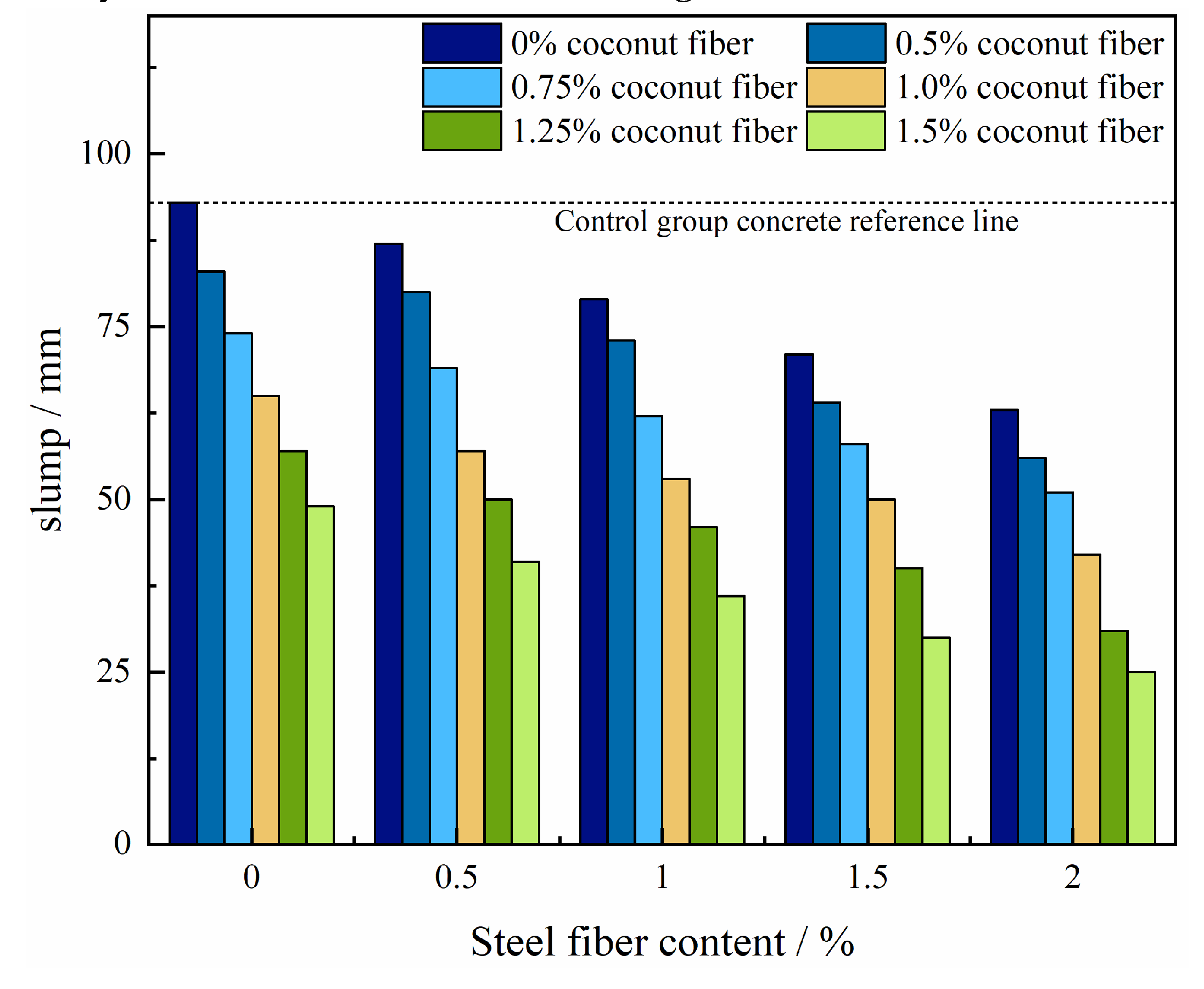

3.1. Slump Value

3.2. Mechanical Properties of Concrete

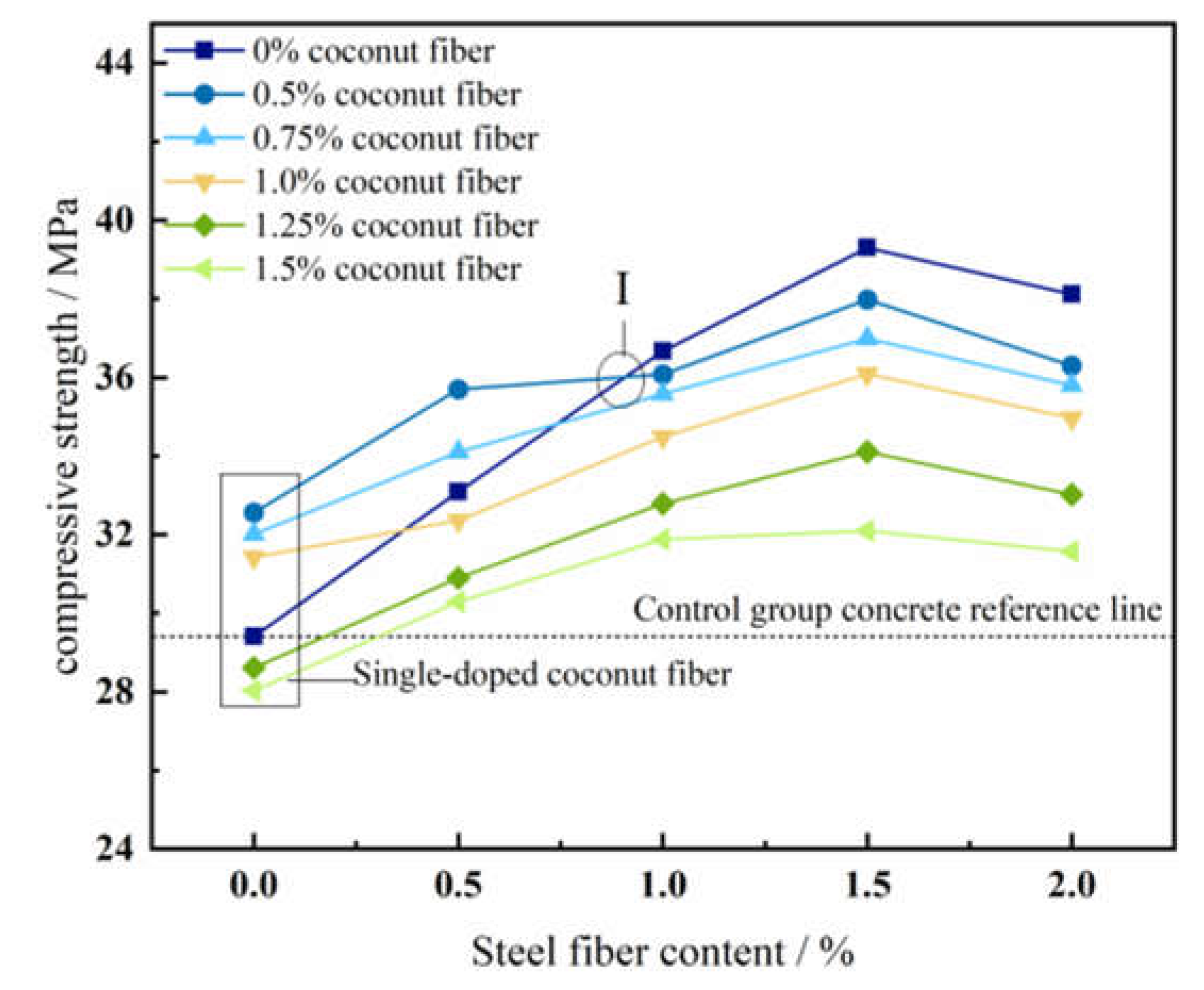

3.2.1. Compressive Strength

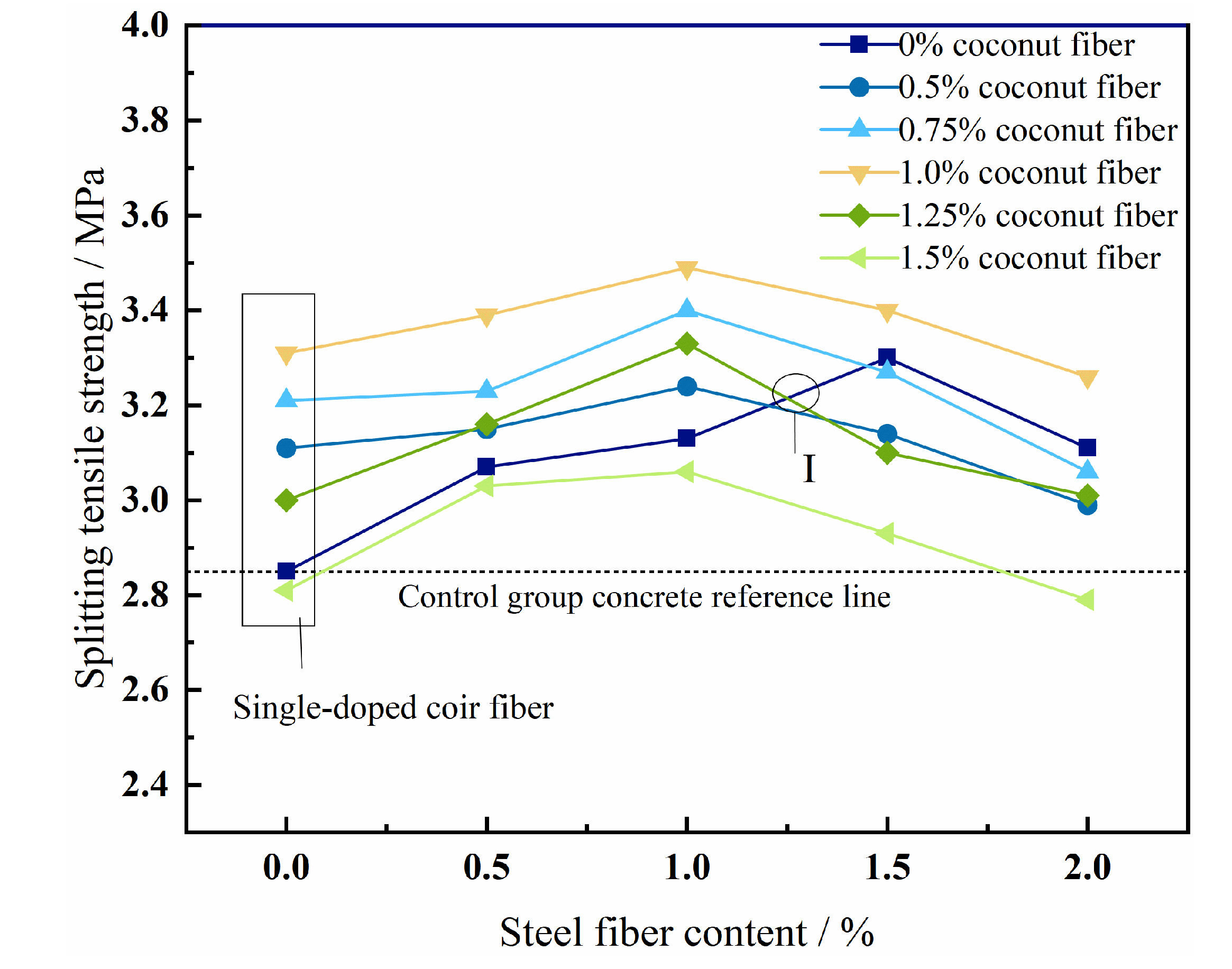

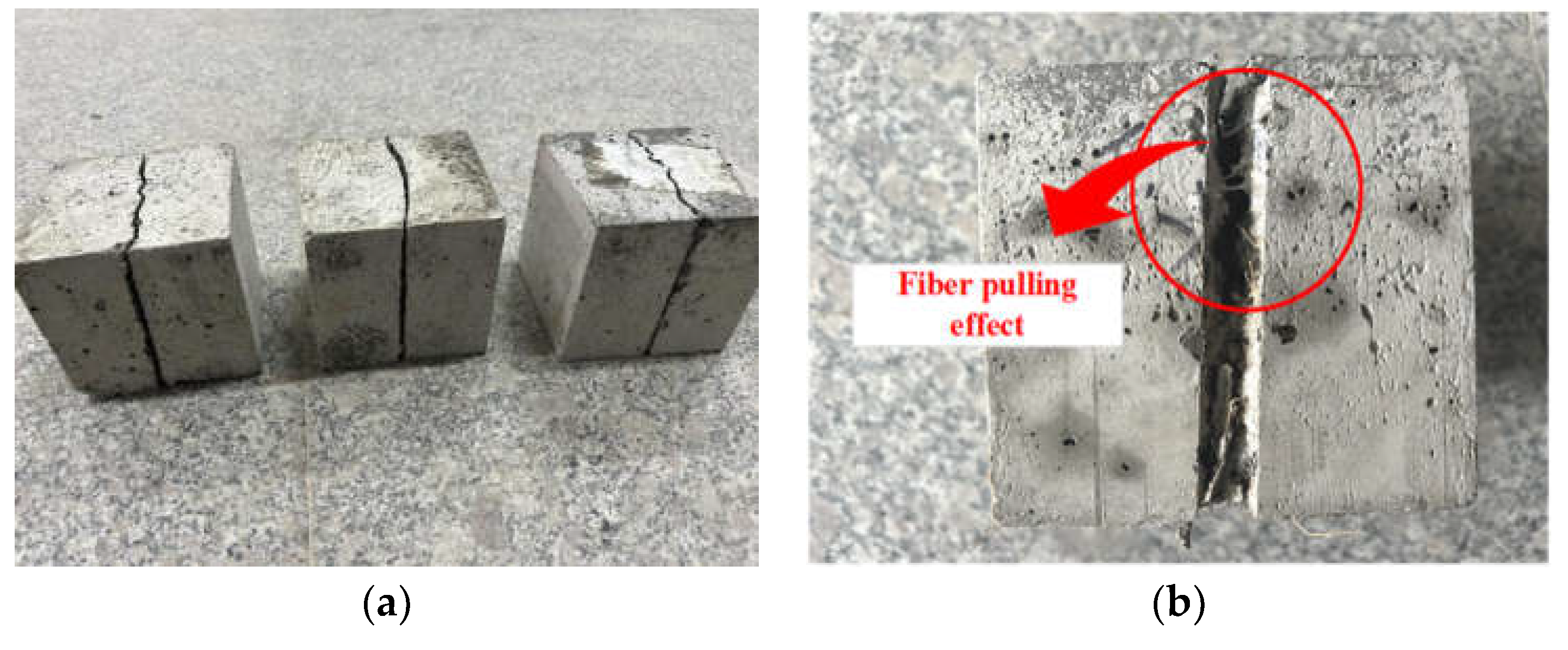

3.2.2. Splitting Tensile Strength

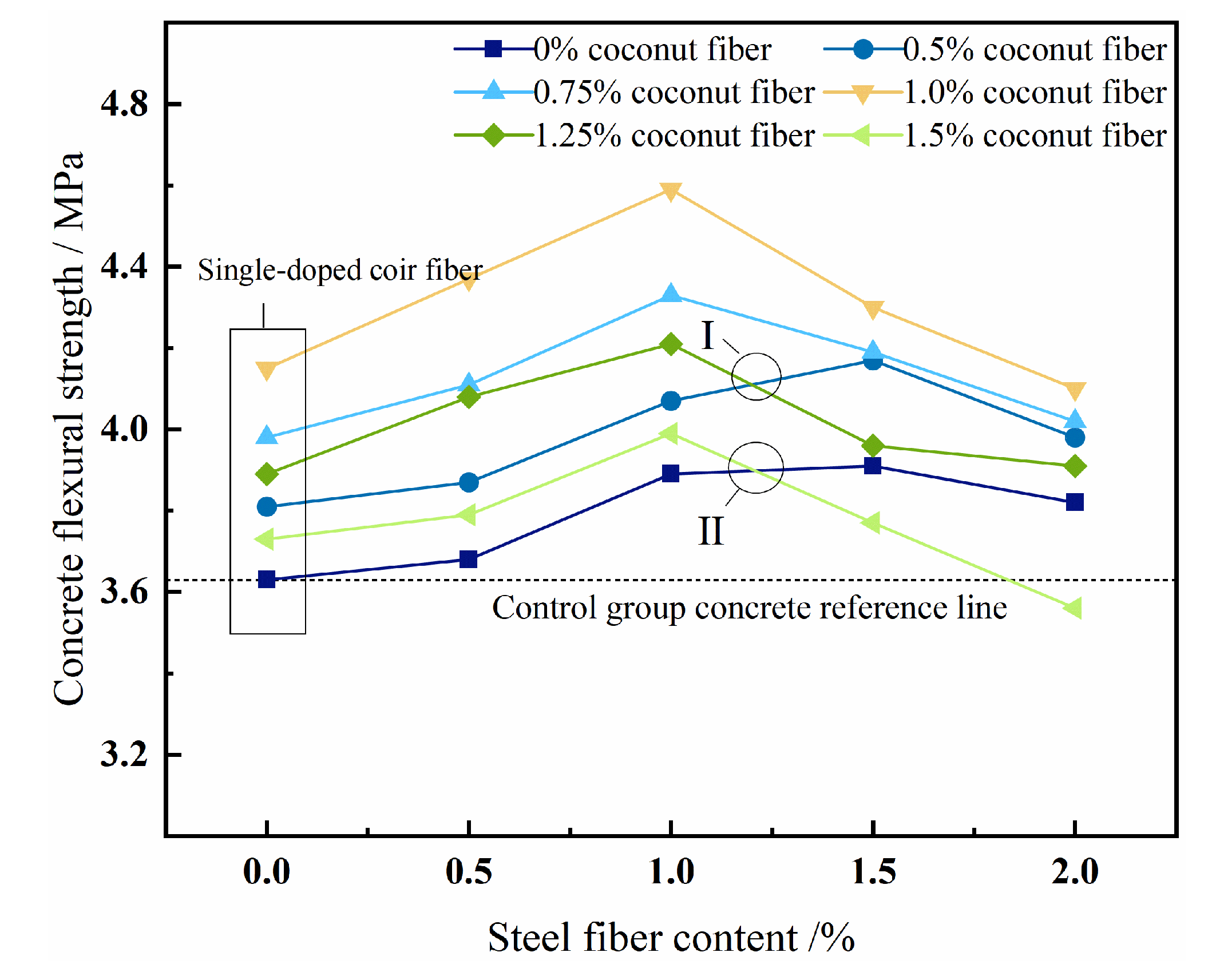

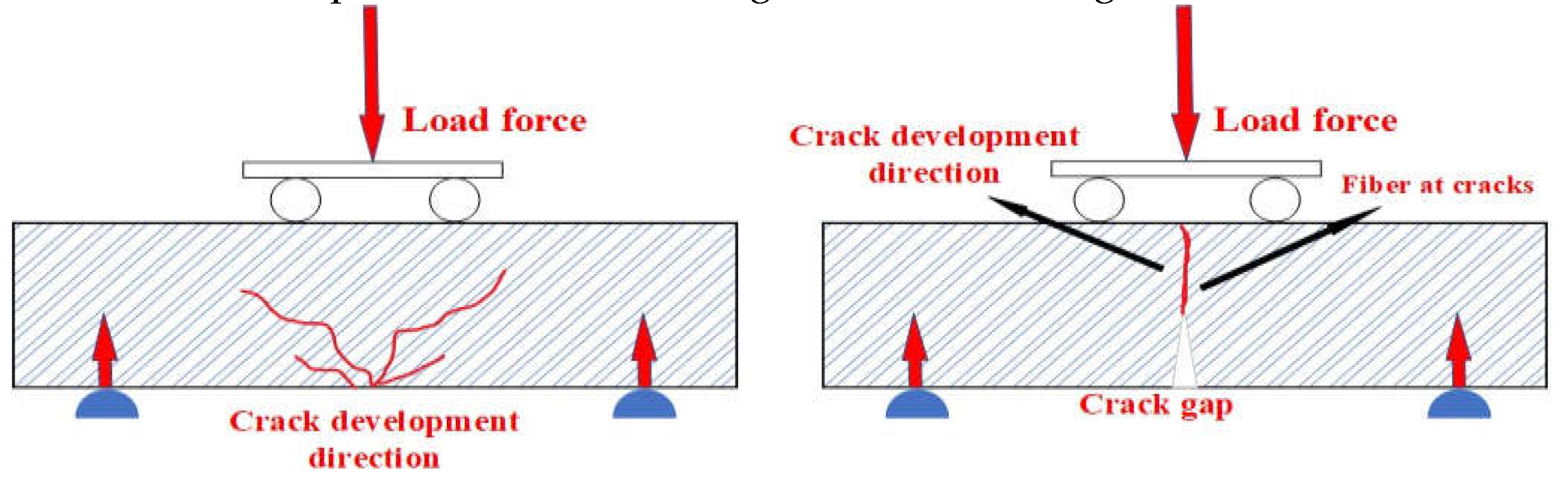

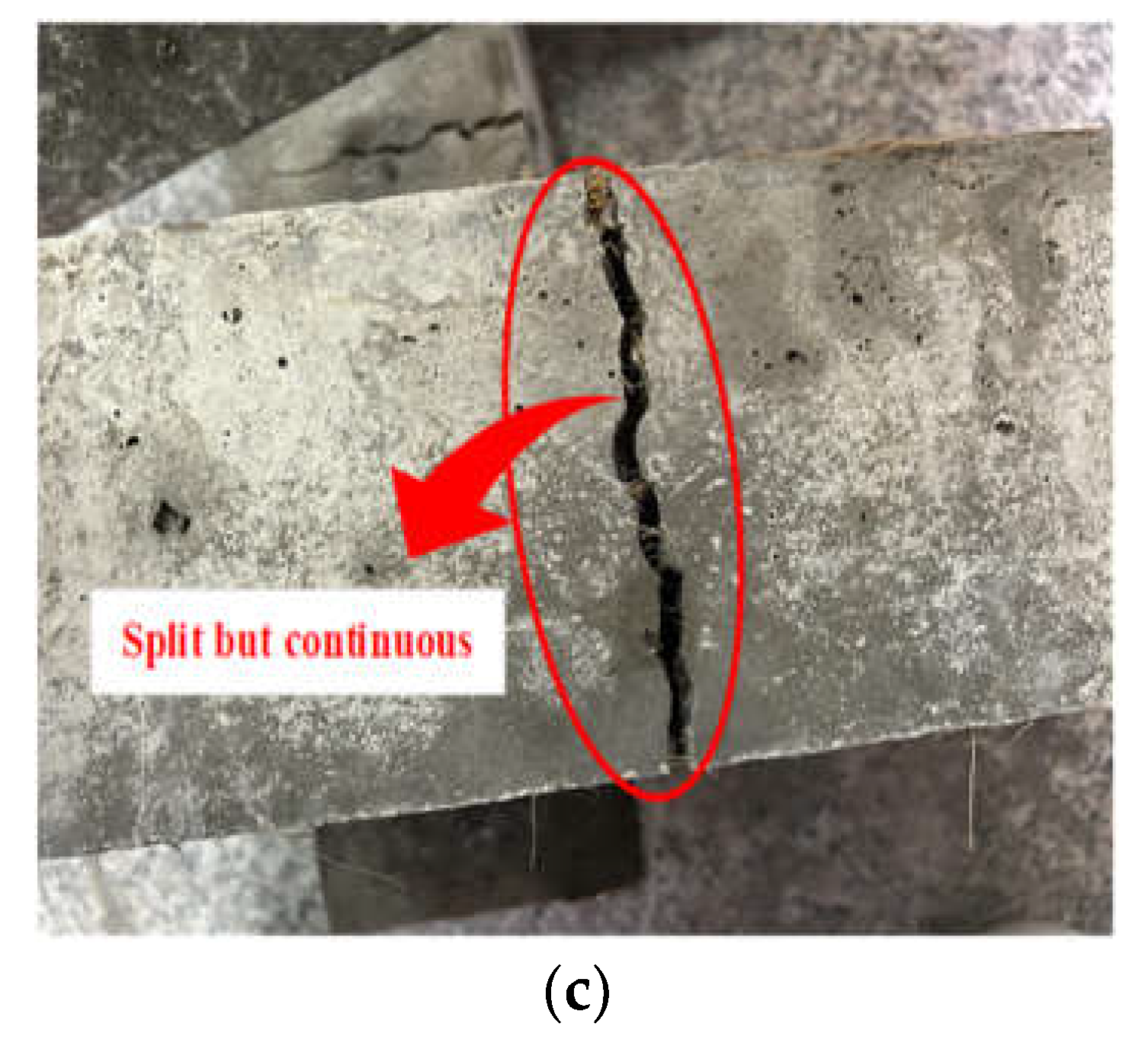

3.2.3. Flexural Strength

3.3. Concrete Durability Properties

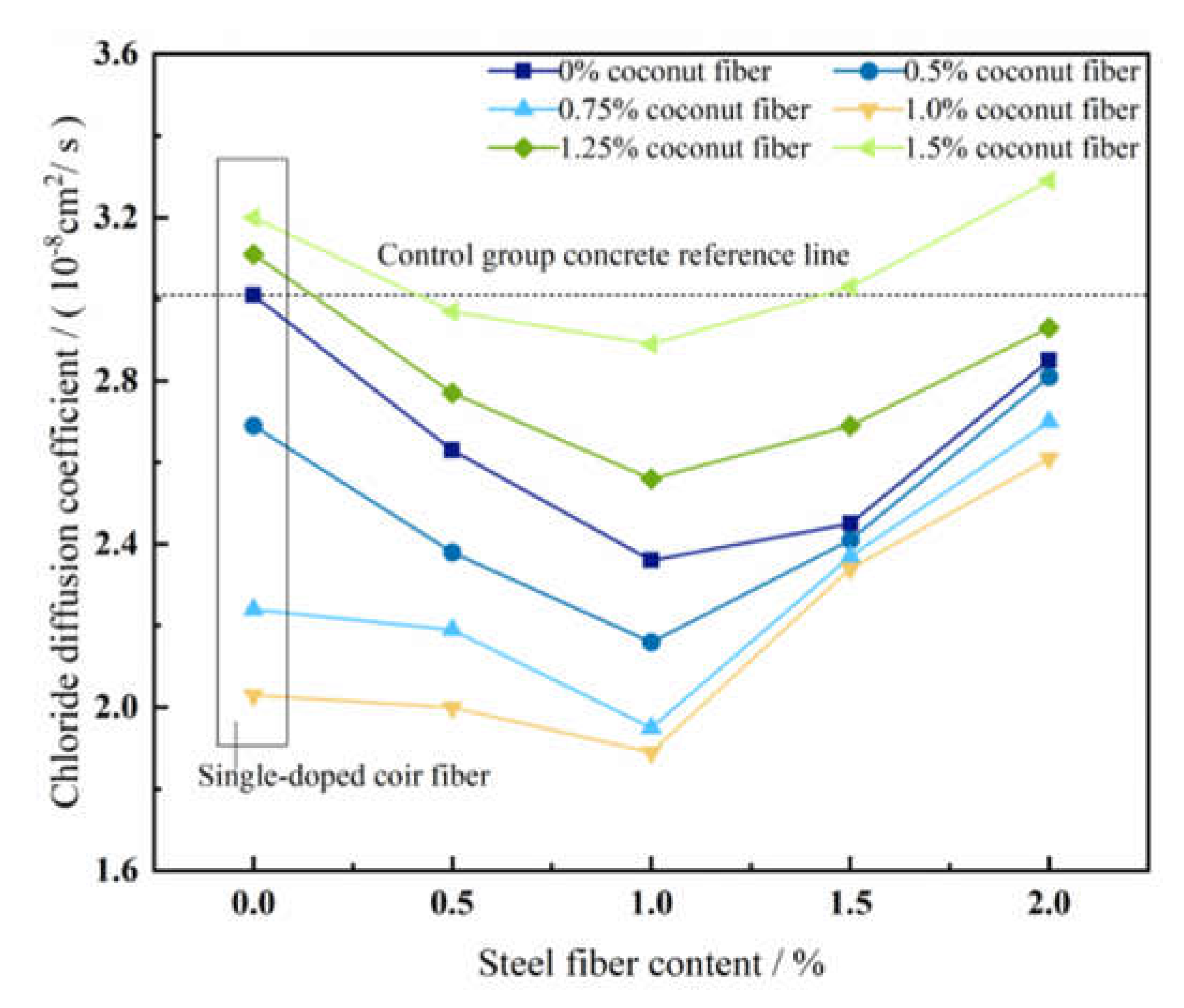

3.3.1. NEL Chloride Diffusion Coefficient

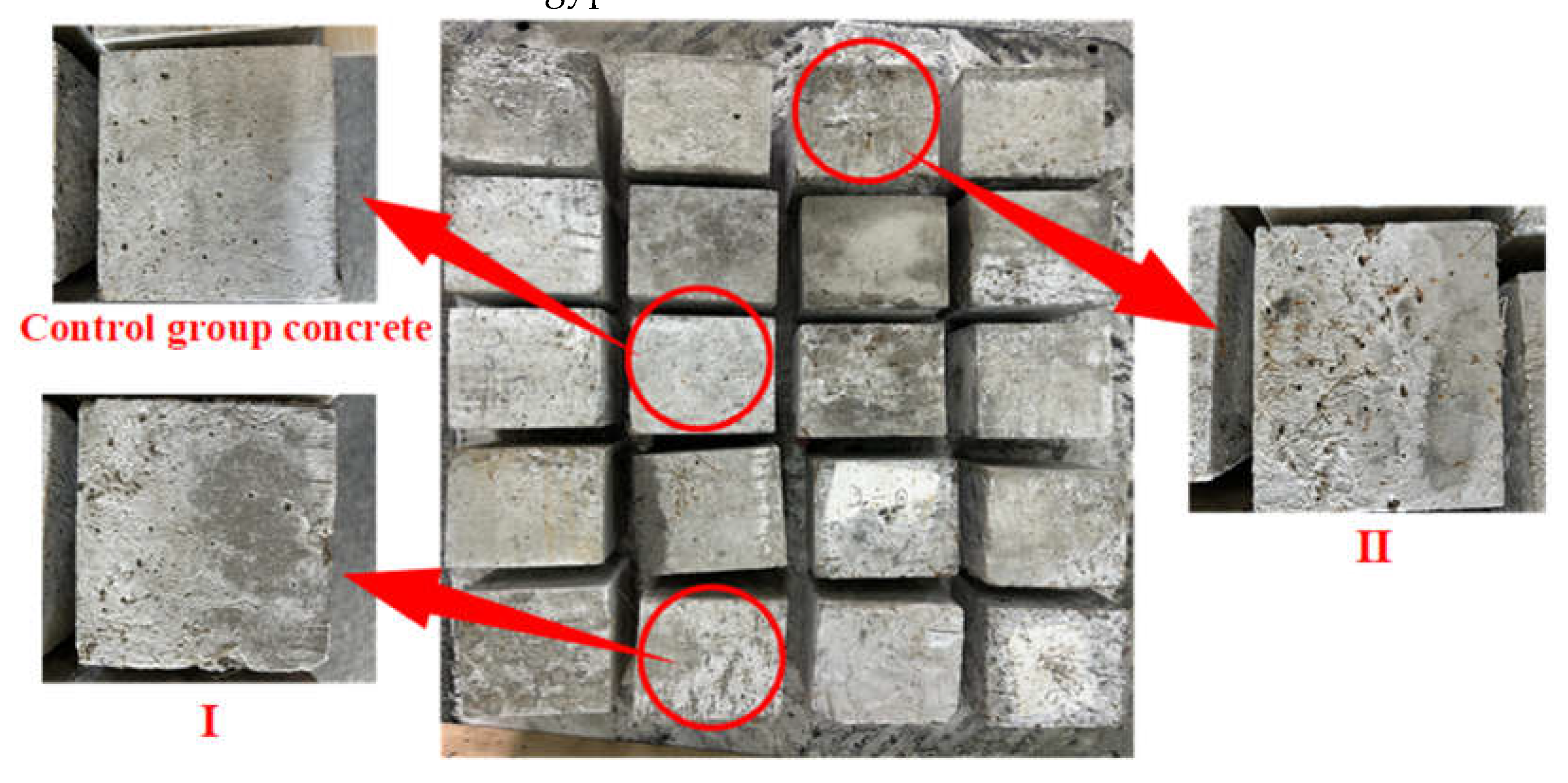

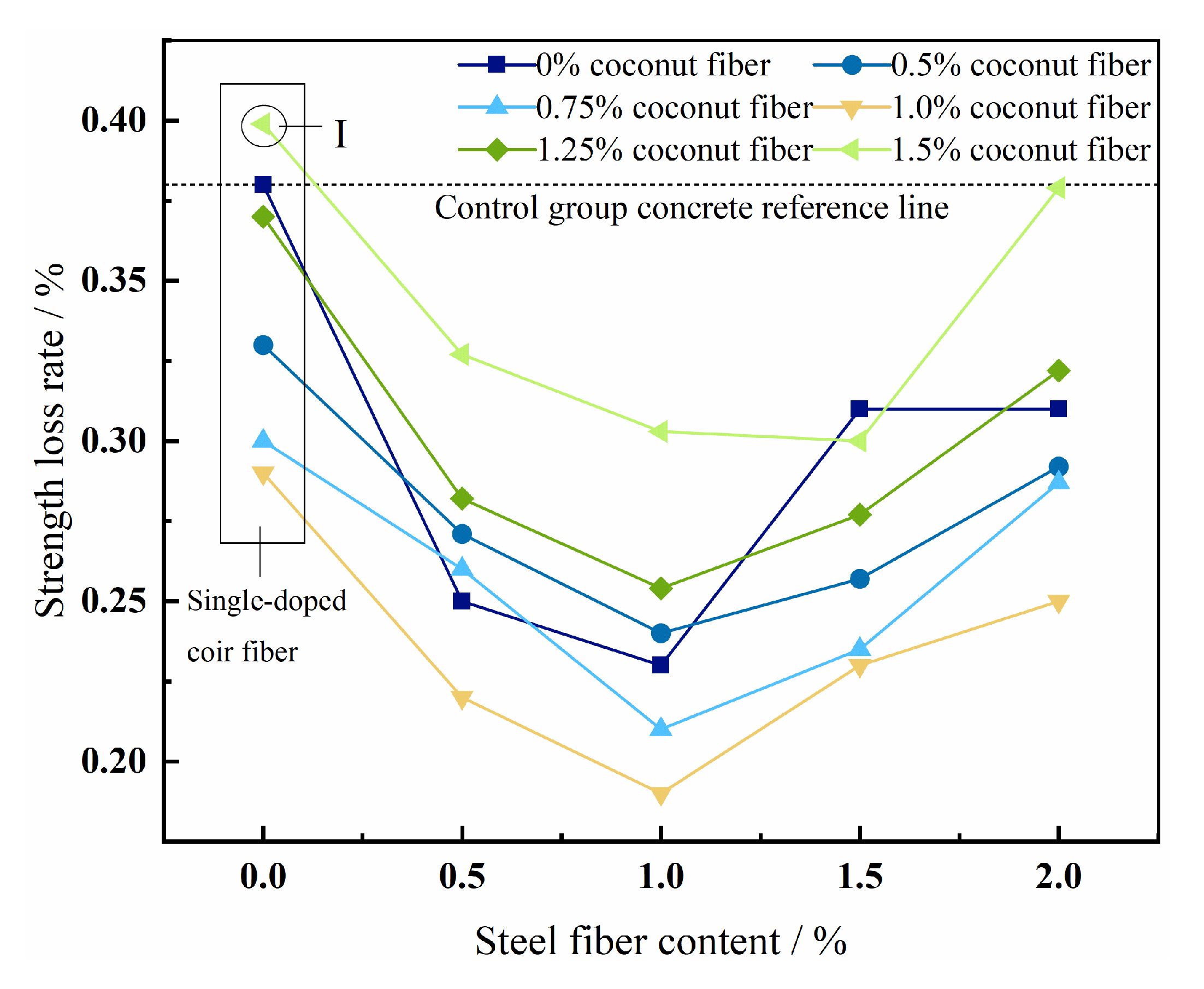

3.3.2. Resistance to Sulphate Corrosion

4. Conclusions

- With the admixture of fibers, the mechanical properties of fly ash concrete all showed a trend of first increase and then decrease. The compressive strength of concrete suffered adverse effects when coconut fibers were added alone more than 1.0 %. The overall properties of concrete were all impaired to different degrees when steel fibers alone were added at a dosage of more than 1.5 %.

- The results of mechanical properties tests showed that the inclusion of appropriate amount of fibers can induce the fly ash concrete to change the brittle damage of the matrix into ductile damage at the time of destruction. When the volume admixture of both steel fibers and coconut fibers were 1.0%. The bridging effect of fibers significantly enhanced the flexural strength of fly ash concrete. The strength was enhanced by 26.58% as compared to the control group.

- The results of the durability tests showed that when steel fibers were mixed with coconut fibers at an equal volume ratio of 1.0 %, they not only effectively reduced the diffusion of chloride ions, but also resisted the erosive effect of sulfates to the maximum extent. The appropriate amount of fibers can effectively inhibit the extension of concrete cracks, thus preventing the penetration and diffusion of aggressive substances.

- In this study, the key indexes of compressive strength, flexural strength, and Resistance to sulphate corrosion of the mix were considered for the tunnel lining environment in coastal areas. The optimal ratio of hybrid fiber fly ash concrete to enhance the comprehensive performance was found through tests. The durability of the matrix was significantly enhanced while improving the toughness and crack resistance of the concrete. The composite application of steel fibers and coconut fibers can effectively extend the service life of the tunnel lining structure and improve its sustainable utilization.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tiberti, G.; Minelli, F.; Plizzari, G. Reinforcement optimization of fiber reinforced concrete linings for conventional tunnels. Composites Part B: Engineering. 2014, 58, 199–207. [Google Scholar] [CrossRef]

- Kaufmann, W.; Amin, A.; Beck, A.; Lee, M. Shear transfer across cracks in steel fibre reinforced concrete. Engineering Structures. 2019, 186, 508–524. [Google Scholar] [CrossRef]

- Kooiman, A.G. Modelling steel fibre reinforced concrete for structural design. 2000. http://resolver.tudelft.nl/uuid:e7a12191-4484-4fc3-b4c5-e8c0d51271a0.

- Wu, Z.; Shi, C.; Khayat, K.H. Investigation of mechanical properties and shrinkage of ultra-high performance concrete: Influence of steel fiber content and shape. Composites Part B: Engineering, 2019; 174. [Google Scholar] [CrossRef]

- Buratti, N.; Ferracuti, B.; Savoia, M. Concrete crack reduction in tunnel linings by steel fibre-reinforced concretes. Construction and Building Materials. 2013, 44, 249–259. [Google Scholar] [CrossRef]

- Zhang, H.; Cao, L.; Duan, Y.; Tang, Z.; Hu, F.; Chen, Z. High-flowable and high-performance steel fiber reinforced concrete adapted by fly ash and silica fume. Case Studies in Construction Materials. 2024, 20, e02796. [Google Scholar] [CrossRef]

- Wu, F.; Yu, Q.; Chen, X. Effects of steel fibre type and dosage on abrasion resistance of concrete against debris flow. Cement and Concrete Composites. 2022, 134, 104776. [Google Scholar] [CrossRef]

- Haoyun Liu; Sihao Qiao; Shaoqi Wu; Feiyang Zhao; Lin Liao. Study on the in fluence of parameters of single hooked-end steel fiber on the flexural properties of concrete. Concrete. 2023,10,25-31. [CrossRef]

- Nehdi, M.L.; Abbas, S.; Soliman, A.M. Exploratory study of ultra-high performance fiber reinforced concrete tunnel lining segments with varying steel fiber lengths and dosages. Engineering Structures. 2015, 101, 733–742. [Google Scholar] [CrossRef]

- Chiaia, B.; Fantilli, A.P.; Vallini, P. Combining fiber-reinforced concrete with traditional reinforcement in tunnel linings. Engineering Structures. 2009, 31, 1600–1606. [Google Scholar] [CrossRef]

- Shao G.D. Research on Mechanical Properties and Durability of Tunnel Prefabricated Lining Blocks. Modern urban rail transportation. 2017, 71-74. (In Chinese).

- Zhang, P.; Zhang, H.; Cui, G.; Yue, X.; Guo, J.; Hui, D. Effect of steel fiber on impact resistance and durability of concrete containing nano-SiO2. Nanotechnology Reviews. 2021, 10, 504–517. [Google Scholar] [CrossRef]

- You, S.; Ji, H.; Liu, J.; Song, C.; Tang, W. Fracture performance of macro synthetic steel fiber concrete exposed to a sulfate environment. Anti-Corrosion Methods and Materials. 2016, 63, 236–244. [Google Scholar] [CrossRef]

- Cui, G.-Y.; Qi, J.-S.; Wang, D.-Y. Experimental study on load bearing characteristics of steel fiber reinforced concrete lining in the soft surrounding rock tunnel. Advances in Civil Engineering. 2020, 2020, 4976238. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, C.; Zhang, Z.; Li, N.; Shi, D. Mechanical and fracture properties of ultra-high performance geopolymer concrete: Effects of steel fiber and silica fume. Cement and Concrete Composites. 2020, 112, 103665. [Google Scholar] [CrossRef]

- Cui, G.-Y.; Wang, X.-L.; Wang, D.-Y. Study on the model test of the antibreaking effect of fiber reinforced concrete lining in tunnel. Shock and Vibration 2020. 2020, 5419650. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Mechanical properties of alkali treated plant fibres and their potential as reinforcement materials II. Sisal fibres. Journal of materials science. 2006, 41, 2497–2508. [Google Scholar] [CrossRef]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and dynamic properties of coconut fibre reinforced concrete. Construction and Building Materials. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- Hwang, C.-L.; Tran, V.-A.; Hong, J.-W.; Hsieh, Y.-C. Effects of short coconut fiber on the mechanical properties, plastic cracking behavior, and impact resistance of cementitious composites. Construction and Building Materials. 2016, 127, 984–992. [Google Scholar] [CrossRef]

- Reis, J. Fracture and flexural characterization of natural fiber-reinforced polymer concrete. Construction and building materials. 2006, 20, 673–678. [Google Scholar] [CrossRef]

- Hui Wu; Min Huang; Liwen Zhang; Zhujian Xie; Junping Zhang. Experimental study on compressive performance of coconut fiber MPC compositen cement-based materials. J. Xi’an Univ. of Arch. &Tech. (Natural Science Edition). 2022,54,257-266. [CrossRef]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, A.; Aslam, F.; Yousef, R.A.; Abduljabbar, H.A.; Sufian, M. Effect of coconut fiber length and content on properties of high strength concrete. Materials. 2020, 13, 1075. [Google Scholar] [CrossRef] [PubMed]

- Ramli, M.; Kwan, W.H.; Abas, N.F. Strength and durability of coconut-fiber-reinforced concrete in aggressive environments. Construction and Building Materials. 2013, 38, 554–566. [Google Scholar] [CrossRef]

- Ali, B.; Hawreen, A.; Kahla, N.B.; Amir, M.T.; Azab, M.; Raza, A. A critical review on the utilization of coconut (coconut fiber) in cementitious materials. Construction and Building Materials. 2022, 351. [Google Scholar] [CrossRef]

- GB/T 39698-2020; Confirmation Methods for Delivering Common Portland Cement. State Market Regulatory Administration: Beijing, China, 2020.

- JGJ 52-2006; Standard for Technical Requirements and Test Method of Sand and Crushed Stone for Ordinary Concrete. China Academy of Building Research: Beijing, China, 2006.

- GB/T 50081-2019; Standard for Test Method of Mechanical and Physical Performance Concrete. China Architecture and Building Press: Beijing, China, 2019.

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2009.

- Lu, X. Application of the Nernst-Einstein equation to concrete. Cement and concrete research. 1997, 27, 293–302. [Google Scholar] [CrossRef]

- Rudraswamy, M.; Patagundi, B.; Prakash, K. The Workability Studies of Hybrid Fiber Reinforced Concrete Formed by Using Fibs of Different Aspect Ratio. International Journal of Civil Engineering and Technology, 9(7), 2018, pp. 1293 1301. http://iaeme.com/Home/issue/IJCIET?Volume=9&Issue=7.

- Song, P.; Hwang, S. Mechanical properties of high-strength steel fiber-reinforced concrete. Construction and Building Materials. 2004, 18, 669–673. [Google Scholar] [CrossRef]

- Folino, P.; Lima, C.; Martinelli, E.; Pepe, M.; Caggiano. On the mechanical response of hybrid fiber reinforced concrete with recycled and industrial steel fibers. Construction and Building Materials. 2017, 147, 286–295. [Google Scholar] [CrossRef]

- Sathyan, D.; Madhavan, M.K.; Raj, A.; Raj. Mechanical and durability properties of hybrid fiber reinforced foam concrete. Construction and Building Materials. 2020, 245, 118373. [Google Scholar] [CrossRef]

- Yufei Xie; Meng Sheng; Yifan Lv. Experimental Study on Mechanical Properties of Steel Fiber Concrete. Sichuan Cement, 2020, 14-15. (In Chinese).

- Santhanam, M.; Sivakumar. Mechanical properties of high strength concrete reinforced with metallic and non-metallic fibres. Cement and Concrete Composites. 2007, 29, 603–608. [Google Scholar] [CrossRef]

- Das, S.; Sobuz, M.H.R.; Tam, V.W.; Akid, A.S.M.; Sutan, N.M.; Rahman, F.M. Effects of incorporating hybrid fibres on rheological and mechanical properties of fibre reinforced concrete. Construction and Building Materials. 2020, 262, 120561. [Google Scholar] [CrossRef]

- Min Bai; Ditao Niu; Guixiu Jiang; Xiong Wu. Study on the influence of steel fiber content on chloride ion permeability of concrete. CHINA CONCRETE AND CEMENT PRODUCTS. 2015,49-52. https://link.oversea.cnki.net/doi/10.19761/j.1000-4637.2015.11.012.

- Paul, S.C.; van Zijl, G.P.; Šavija, B. Effect of fibers on durability of concrete: A practical review. Materials. 2020, 13, 4562. [Google Scholar] [CrossRef] [PubMed]

| Fiber class | Length (mm) | Width (mm) | Density(g/cm-3) |

|---|---|---|---|

| Steel fiber | 40 | 4 | 7.90 |

| Coconut fiber | 40~50 | 0.4 | 1.12 |

| water cement ratio |

Water | binding material | Fine aggregate |

Coarse aggregate |

Admixture |

|---|---|---|---|---|---|

| Kg·m3 | |||||

| 0.5 | 195 | 390 | 672.2 | 1142.8 | 1.95 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).