1. Introduction

The rapid globalisation and urbanisation in the latter part of the 20th century has made it more difficult to optimize management of urban spaces and resources. Consequently, urban development has resulted in numerous environmental issues at local, regional, and global levels [

1]. Therefore, it is critically important to manage both new and old infrastructure from an economic and environmental standpoint. Governments globally have acknowledged the inefficiencies in city and building management and have either suggested or mandated the adoption of new and advanced solutions to reverse the declining trend [

2].

Most of the building’s expenses during the lifecycle are incurred during the operation phase. It is estimated that these costs can range from five to seven times greater than the initial investment and three times higher than construction costs [

2]. Traditional paradigms and approaches often prevail, impeding the potential improvements that could arise from adopting digital tools and methods. There is still limited progress in digitalisation, particularly during the asset’s operational phase [

3].

Greater importance is being given to the evolving demands of the building occupants these days. By 2025, millennials, who are known for their adeptness with technology, are projected to make up 75% of the workforce in office spaces, with a similar tendency anticipated across various other building categories such as hospitals, airports, and hotels. This new generation of customers’ demands a heightened level of building functionality, adaptability, and versatility in both the design and utilization aimed to improve user productivity [

4].

In the past few decades, the advent of the latest generation of information technologies [

5] such as the Internet of Things (IoT), artificial intelligence (AI), cloud computing and big data analytics, has accelerated the digitalisation of different systems and processes across various sectors including architecture, engineering and construction [

1].

Through digital transformation and integrated adoption of technologies, the entities and their conditions, behaviours, and interactions in the physical world are comprehensively digitized thus Digitalisation is emerging as one of the primary forces behind innovation across AEC industries [

5]. Such technologies lead to many IT-focused solutions, such as smart asset management, which is a promising approach that enhances performance and leads to greater economic profitability [

3].

DT, as a tool for smart asset management, offers the opportunity to integrate physical objects with their virtual counterparts throughout their life cycle to replicate their real-world behaviours [

1]. A technology trend report identified DT as one of the top four emerging technologies among a selection of fifteen [

6]. It is a revolutionary and innovative technology that enables a quicker and more efficient management, monitoring, and prediction of assets [

7]. DT is drawing interest from both the academic and the industrial sectors [

5] and has recently gained popularity in the AEC. It is increasingly becoming an essential tool for smart management and monitoring in the AEC sector [

7] and is identified among the top 10 technological trends holding strategic significance for three years, spanning from 2017 to 2019 [

5].

This paper is organized as follows; The article firstly studies the various definitions of the DT concept and briefly review its applications across different industries. Then it examines DT from similar digital modelling techniques to provide a clear and precise understanding of what DT represents in the industry. Next the article analyses the digitalisation sophistication spectrum and categorize the levels of DT maturity, and then explores the capabilities of DT to determine ways it can transform traditional methods. Next, the challenges and obstacles to the full deployment of DT are discussed. Lastly, the research gaps and future possibilities for the application of DT in the AEC industries are explored.

2. Understanding Digital Twin Technology: Concepts, Applications, and Evolution

2.1. The Terminology and Core Concepts of Digital Twin

In recent years, there has been a significant increase in the number of publications focusing on DT research. The growing popularity of DTs reflects the inevitable trend that the virtual and physical worlds are becoming more interconnected and integrated as a whole [

5]. Despite the lack of clear and formal definition of what DT really is or what it will evolve into in the future [

6], it is essential to establish a comprehensive and unified definition of DT to mitigate the confusion and unrealistic expectation associated with this technology [

8].

DT is founded on some current technologies, including but not limited to 3D modelling, system simulation, and functional and behavioural prototyping [

5]. It has been used in aerospace and astronautics for implementation of as-builts and next generation aircrafts for years [

9]. Since 1970, NASA and air force research laboratory have been developing replicated systems to monitor inaccessible physical spaces (e.g., spacecrafts on mission) and, in turn, identify solutions to challenges [

10]. While the concept of DT has remained stable over the years [

9], its application has been expanded beyond its initial utilization of military and aerospace domain into the civilian sectors, and DT encounters increasing number of services from various industries, users, and businesses [

5].

In product lifecycle management, the concept of DT was initially defined in 2002 by Michael Grieves as “a virtual, digital counterpart to a physical product” [

9]. Later in 2014, Grieves defined the three primary components of a basic DT model in a whitepaper: (a) physical products in Real Space, (b) virtual products in Virtual Space, and (c) the data and information connections that bind the virtual and real products together [

5]. A more thorough and widely accepted definition of a “Digital Twin” in research is offered by Glaessgen and Stargel, as “an integrated multi-physics, multi-scale, probabilistic simulation of a complex product and uses the best available physical models, sensor updates, etc., to mirror the life of its corresponding twin” [

11].

A DT can be the digital representation of a real-world entity, a concept, or a notion. Real-world entities are identified as having physical form, such as an aircraft engine, a bicycle, or a human heart. However, an entity represented by a DT can also be something abstract that is without traditional physical form. Such as a business or a manufacturing process [

6].

2.2. Transformative Applications of Digital Twin Technology Across Various Industries

DT technology has emerged as a transformative force across diverse industries, offering unparalleled opportunities for innovation and efficiency. From aerospace to healthcare, transportation to construction, DT applications are revolutionizing operations by enabling real-time insights, predictive maintenance, and enhanced decision-making. This section explores the industries that lead the adoption of DTand studies its transformative influence on their processes, productivity, and prospects.

From an aerospace perspective, DT can be described as an integrating tool for a highly realistic simulation setup. It incorporates historical data including maintenance and fleet information in an onboard health platform [

12], for diagnostics purposes, [

10] to locate and forecast the extent of damage in the aircraft [

13]. The primary application of DT in aerospace industry is predictive maintenance. It is applied for producing an accurate fatigue life estimate, running what-if analysis scenarios [

11], identifying critical and harmful structural changes and subsequently activating self-healing mechanisms [

10]. In aerospace and defense organisations, DT can be implemented for decision support, assets ground support [

13] and life support [

12].

Management in the energy industry is currently prioritizing digitalization of the sector [

14]. DT technology is gaining attention across the energy industry [

15] and is increasingly influencing various sectors [

16], contributing to security, efficiency, and durability of energy systems [

14]. However, in the wind energy sector, it holds significant potential [

15]. Developing a DT for a wind turbine can significantly improve its Operation and Maintenance. It can monitor, analyse, and predict the turbine’s performance, allowing for early identification of potential issues and facilitating preventative maintenance [

17].

DTs have found extensive application in the manufacturing sector [

18], facilitating programming and control program creation [

19]. They can replicate the entire lifecycle of a product and predict machine performance; therefore, they play a leading role in the production phase, from the design stage, production planning and control, to the finished product [

13,

20,

21]. DT technology reduces the production of unwanted items, contributing to sustainable and smart manufacturing practices [

13,

18]. Moreover, different sectors within the industry employ DT methodology for maintenance purposes in manufacturing operations, particularly in areas where maintenance costs exceed the average [

1].

DT technology enables the dynamic monitoring of the life cycle of road infrastructure through the utilization of sensors and network communication technologies. DT also enhances asset management processes leading to cost savings and emissions reduction across all road networks [

22]. In vehicle design phase, DT can analyse vehicle behaviour, determine its performance, and predict anomalies prior to manufacturing. Additionally, it enables automated control systems such as lane monitoring, hands-free driving, and proximity sensors [

13]. The integration of these efforts allows information exchange between vehicles and road infrastructure, leading to reduction of traffic congestion, improvement in road network efficiency, preventing accidents, conserving energy, and reducing pollution levels [

21,

22].

DT has been applied to healthcare initially for the purpose of predictive maintenance of medical devices and optimizing their performance. Hospital lifecycle optimization is one of DT technology’s other applications [

10]. By combining IoT and BIM, facility managers can better understand user behaviour which leads to more effective space allocation for patients, medical staff, and rational distribution of resources [

23]. In medical and clinical domains, Interest in DT technology frequently stems from the objective of constructing a human DT. By analysing the personal history of the real twin and the current situation, including location, time, and activity, a human DT could predict the onset of a disease by showing what is happening inside the linked physical twin’s body [

10].

2.3. Distinguishing Digital Twin Technology from Related Concepts

As a part of various digitalisation initiatives, DT’s utilization in literature often resembles conventional digital modelling techniques [

8], sharing similarities that could lead to confusion due to their interconnected nature [

1]. However, the scope of DT extends beyond these traditional methods of digital modelling techniques [

7]. Often, the source of confusion arises because the concept is among the components of a DT [

24]. In the construction context, DT represents a strategy that utilizes various technological tools to drive improvement, including BIM [

25], Computer Aided Design (CAD) [

24], and simulation [

8]. Although, there is no agreement regarding distinctions or similarities between these ideas, the evolution of DT is impacted by these technologies [

18]. Additionally, identifying key components of the concept can aid in clearly categorizing what qualifies as a DT, setting it apart from other analogous digital technologies [

8].

The key and most fundamental distinction between DT and traditional digital models lie in the dynamic nature of DT. This characteristic is reflected in the real-time updates of the DT, which are linked to changes in the represented physical object, enabling the DT to evolve and age alongside it. This attribute is known as the real-time self-evolution of DT [

16]. All CAD systems create files primarily consisting of vectors, associated line types, and layer identifications. As these systems were further developed, additional information was incorporated into the components. Subsequently, the aim shifted from drawings and 3D models to the data itself [

26], resulting in Building Information Modelling.

Currently, BIM is the most widely used digital modelling technology in the construction sector [

25] and although it is commonly perceived as intelligent 3D and 4D modelling techniques for construction, its primary focus is on fostering collaboration and eliminating data among various construction stakeholders [

3]. Compared to BIM, DTs offer greater complexity and integration possibilities as they aim to establish a user-centric, functional platform. DT is primarily concerned with representing how individuals interact with the asset, whereas BIM focuses mostly on the asset [

25]. Furthermore, the primary application of BIM is during the design and construction phases, whereas DT can monitor physical assets under construction or constructed and evaluate the performance of installed equipment in real-time, aiming to enhance operational efficiency by the enabling predictive maintenance structures [

18].

Simulation on the other hand, involves utilizing a digital prototype of a physical system. It is often used during the design process to determine how the system of interest would function under presumed conditions, such as operation, loads and degradation mechanisms. Since simulation models mimic physical system behaviour they can occasionally be confused with DTs. The primary distinction between a simulation model and a DT is that a simulation model forecasts the future states of a physical system by relying on basic assumptions, whereas DT monitors the actual experience of a physical system, as well as the past and current states of a specific instance of the system [

8].

Another aspect to highlight is that by enabling the implementation of what-if scenarios, DT enables more data-driven decision-making compared to other asset management methods [

27]. Moreover, BIMs have limited self-learning capabilities and are unable to function autonomously or analyse data from external sources [

18], unlike the self-evolving nature of DTs. DTs are in constant interaction with the physical assets, continuously enhancing and evolving by receiving, analysing, and applying the data obtained from the physical space [

1].

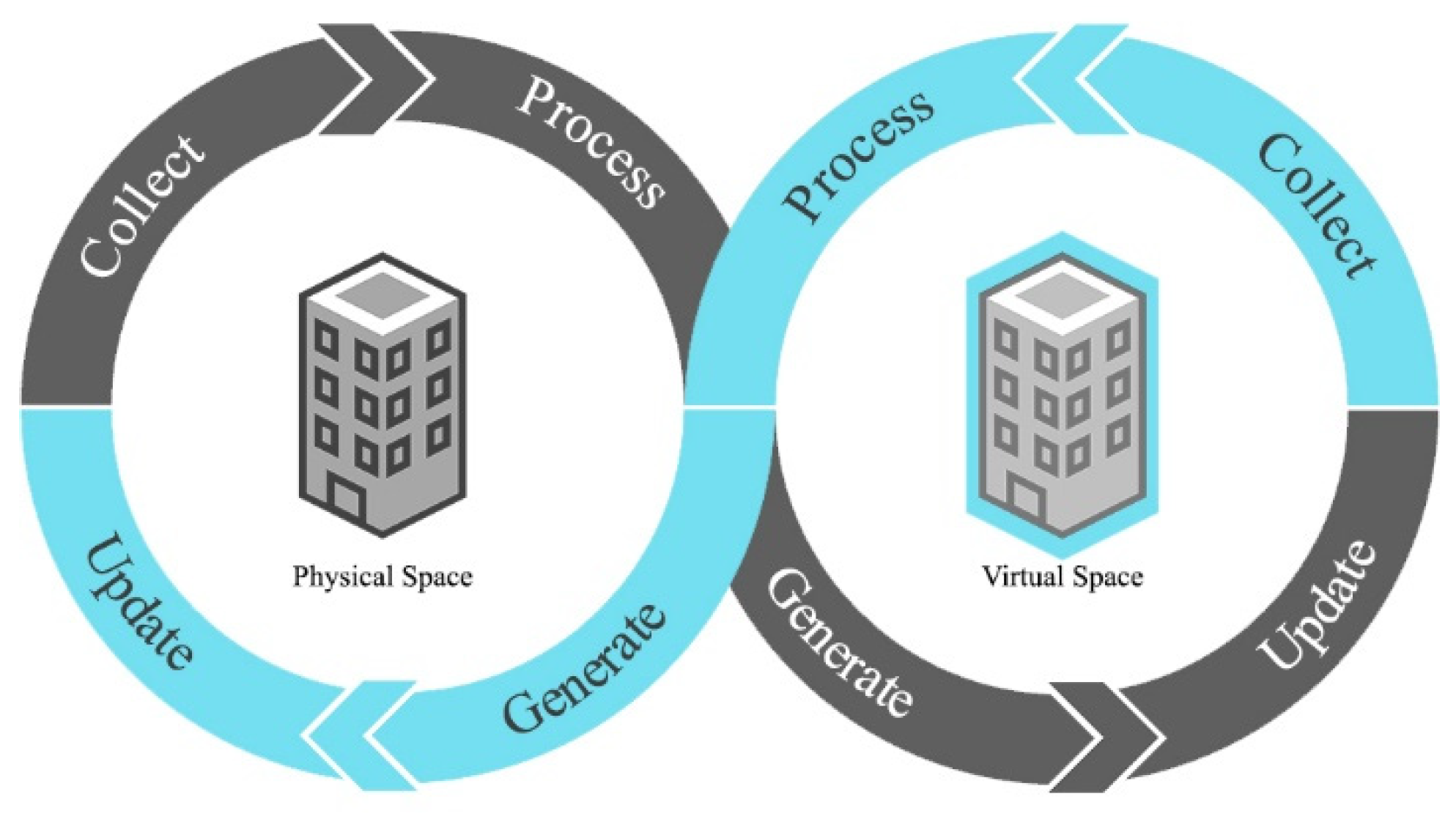

In summary, as shown in

Figure 1, DT’s characteristics can be outlined as follows:

Real-time reflection: In DTs, the physical and virtual space can maintain a high fidelity and synchronized connection.

Interaction and convergence: DTs are uniformed simulation of historical data and real-time data, where the physical and virtual worlds interact through an automatic bidirectional data flow.

Self-evolution: DTs are capable of real-time data updates, allowing for continuous enhancement of virtual models [

11].

2.4. The Different Levels of Digital Twin Maturity

DT maturity is determined by how a developed DT is compared to its full potential. The DT maturity model systematically outlines the conceptual scope, capability requirements, developmental process, and stage objectives, allowing for an effective assessment of its current development level and capabilities, as well as an understanding of the adoption and implementation of new technologies and approaches. There have been multiple efforts to define and develop a DT maturity model; however, a unified and thorough explanation of DT maturity is still lacking [

7,

16].

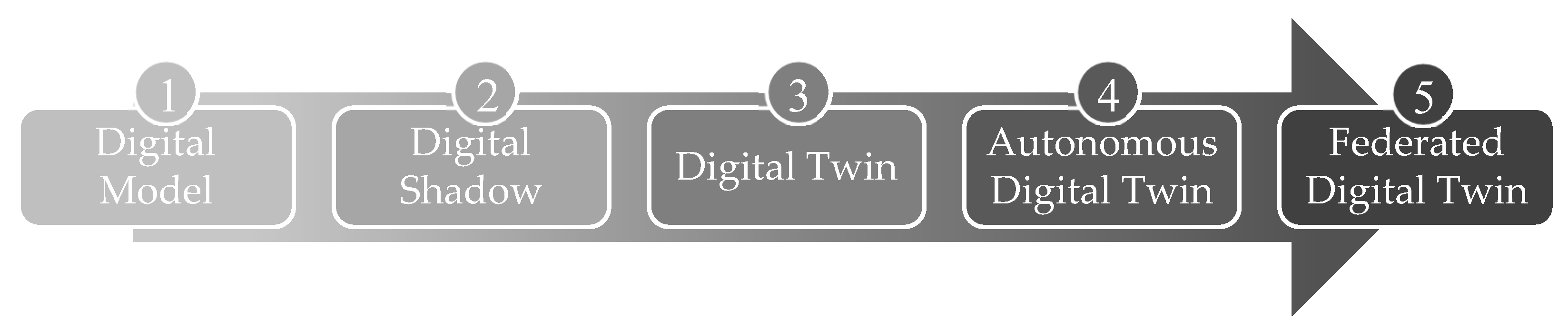

There are prior advancements in DT maturity, based on its capabilities, enabling technologies, direction of data flow, levels of autonomy and intelligence and cross-system integrations [

16]. Combining these efforts with the key factors outlined in this paper, we propose five stages of DT maturity levels along its evolutionary spectrum, as depicted in

Figure 2.

Digital Model is the primary concept where automatic information flow is not present and the interaction between the physical object and the digital model are conducted through manual modification [

28]. Working as an offline system, Digital Model captures the physical and geometric properties and characteristic data of physical objects [

16], while aiding in decision-making during the early stages of design such as concept design. This system is usually developed prior to the construction of the physical prototypes [

29].

Regarding Digital Shadow, data transfers automatically from the physical object to the digital counterpart, but not the other way around. This creates a one-way data flow, allowing virtual models to mirror the operating process, condition and behaviour of the physical objects simultaneously and accurately [

16]. This is best represented by a system in which sensors collect data from the physical model and send signals to the virtual model. Regardless of how the information is transferred, if the process is automatic, the integration level can be classified as a digital shadow [

28].

In contrast, in the case of a DT, the interaction between the two objects, is both automatic and bidirectional. The two-way communication forms a complete data loop. The virtual model receives historical and real-time data from the physical object, and subsequently provide simulation results back to the physical object, influencing its behaviour [

30], and facilitating real-time planning and decision-making in operations, maintenance, and support [

29].

Autonomous DT as a self-governance system with comprehensive oversight and transparency [

28], employs various unsupervised machine learning capability and AI algorithms to remain synchronized with the physical objects and identify objects and patterns in the environment [

16,

29]. At this level, the system exhibits a high degree of autonomy and can analyse detailed performance [

29]. It can perform automatic prediction and operation under various unknown situations to ensure the safety of the physical entity [

31]. This twin can autonomously develop decision suggestions to correct issues, provide feedback or act on behalf of users [

32].

On a larger scale, Autonomous DTs of different domains can be integrated to develop a Federated DT that empowers coordination, improves interoperability and secure communications, and enables seamless asset management [

16,

33]. For instance, Federated DTs can be used in developing smart cities, allowing for DT-enabled city management and contributing to the city’s sustainability [

34].

In the literature, most DT concepts are at the primary maturity levels of digital model and digital shadow, with few integrating real-time data streams to achieve DT. This is mainly due to the challenges of collecting, filtering, and processing data in real-time, as well as the possibility of device malfunction and poor calibration which leads to anomalies or missing data [

28]. It is important to remember that a higher level of maturity leads to greater technical complexity and increased functional requirements [

16].

3. Digital Twin Applications and Impacts in AEC Industries

In the AEC sector, digitalisation has been slow compared to other sectors despite the significant potential they hold for various stakeholders [

3]. In the construction sector, digital innovations stand out as one of the most promising avenues for growth, with the potential to enhance global construction productivity by as much as 14% to 15% [

3]. However, between the years of 2005 to 2014, digitalisation adoption in the construction industry has a rate of 1.4%, notably lower than the Information and Communications Technology industry [

13]. The digitalisation of the construction industry and the implementation of smart technologies offer the potential to bring a building to life as well as allowing users to engage with it in more productive and efficient ways [

4,

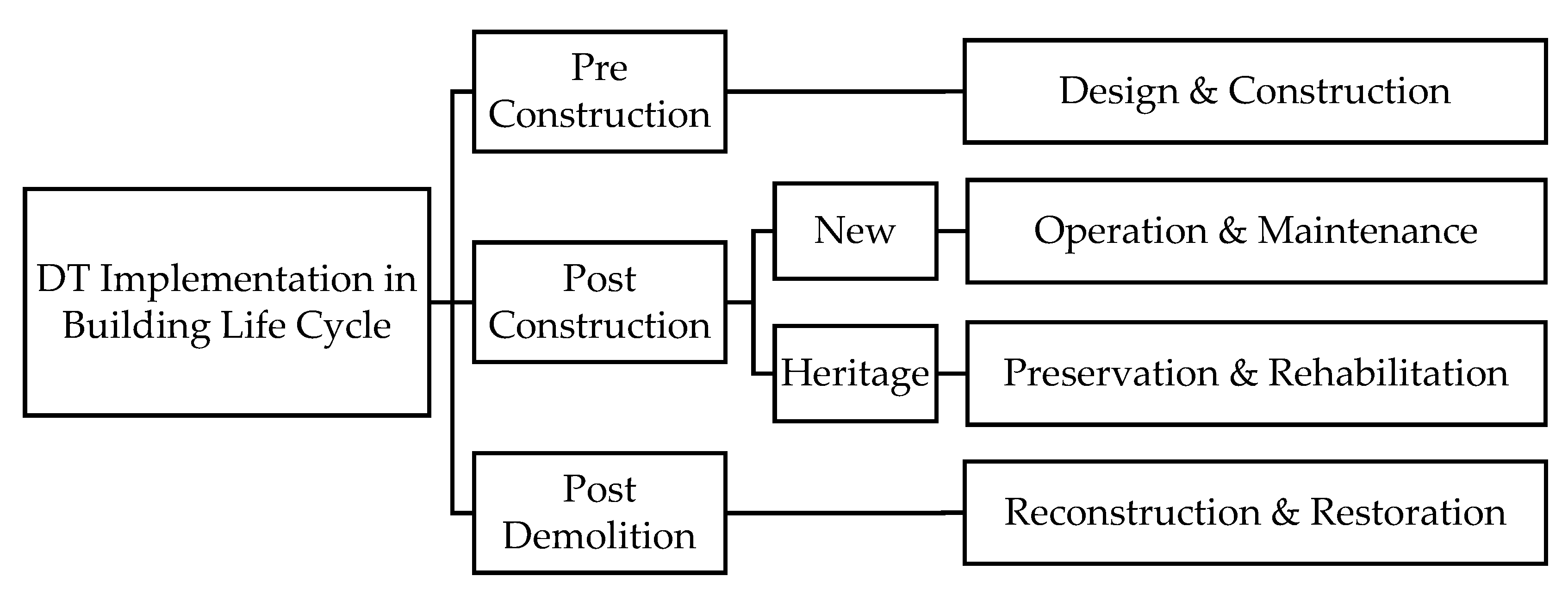

13]. As

Figure 3 shows, DT implementation has numerous applications across a building’s life cycle [

35], and depending on the demand it can be utilized for design, construction, operation, maintenance and etc. [

35].

In the planning and design phase, various disciplines and consultants traditionally separately conduct the process. This lack of coordination might lead to significant issues during the construction stage. Using a DT for planning across several disciplines enables the development of a coordinated multidisciplinary solution, which can help bridge the gap between people and urban design processes. DT can also assist stakeholders in analysing the feasibility of designs [

4], selecting the best design for the project [

20], and explore different scenarios through simulation to conduct what-if analysis [

13].

Despite its widespread application in design and construction, DT’s potential within the Facility Management (FM) domain has received less attention [

36]. This is noteworthy considering Operation and Maintenance (O&M) account for more than 80% of the project’s overall cost [

37], and represent the longest phase of a building’s life cycle—approximately 15 to 25 times longer than design and construction [

38]. FM requires timely preventive maintenance and identify any equipment malfunctions to maintain the facility’s optimal state [

39]. The traditional method of FM, which relies on manual labour, may encounter numerous shortcomings [

38], such as low data quality, prolonged notification times and delays in O&M activities [

39]. These challenges present significant obstacles for facility managers in their efforts to maintain satisfactory building performance for both owners and occupants [

38].

DT is increasingly being investigated as a means of decision-making support during the building maintenance phase [

37]. DT models prove valuable for forecasting or back-casting, allowing the determination of an asset’s future state and contrast it against a planned, desirable state [

20]. In contrast to the conventional facility management approach [

38], DTs can be employed to analyse the building’s dynamic response to changes, tackle operational challenges, suggest the necessity for building maintenance or upgrades [

4], and reduce the time and cost associated with updating FM system databases [

38].

Studies have also investigated the evolving applications of DT in historic buildings. The potential of digital technologies has been applied in the field of cultural heritage and archaeology [

40], in various areas such as health monitoring [

41], disaster simulation [

42], digital preservation, restoration, conservation management, and 3D visualisation for research, education, and engagement. In recent years, DT applications in the heritage sector have primarily centred around digital documentation of assets, driven by advancements in 3D data capture technologies such as photogrammetry and laser scanning [

43]. As shown in

Table 1. digital technologies have been used in a post-disaster context in the reconstruction process of Notre-Dame Cathedral in Paris, and in the archaeology sector for semantic simulation of the ruins of the convent of the Paolotti in Italy [

40].

Additionally, it is common to develop visually interactive platforms for management and virtual tours of historic buildings using 3D models and augmented reality. These approaches effectively explore the extensive application of digital methods in heritage conservation [

42]. In a post-disaster context, such as the case of Notre-Dame Cathedral, the use of DT technology provides a framework to assess the value and resilience of heritage assets from their construction through to their destruction and subsequent restoration. It also helps ensure the authenticity and monitoring of archaeological remains for their future reuse during reconstruction [

44].

Lastly, the adaptive nature of DT enables flexible application across diverse sectors [

13], enhancing functionality and providing dynamic and real-time information for control and planning processes [

20]. Certain types of projects can significantly benefit from the utilization of digital models:

Large-scale projects such as buildings, bridges, and other complex structures that are subject to stringent engineering regulations.

Projects with complex mechanical components like jet turbines, automobiles, and aircraft. DTs can be used to enhance the efficiency of massive engines and complex machinery.

Power-related equipment, including both the systems for power generation and transmission [

45].

4. Case Studies of Digital Twin Development

Multiple efforts have been made in developing DT platforms for AEC projects, varying in scale, goals, target audience, utilized technologies etc. Case studies of DT development illustrate how this innovative technology is being applied, providing a comprehensive understanding of the practical challenges, and showcasing their potential and successes associated with the integration of DT in AEC projects. In the subsequent section, ten projects are discussed regarding their objectives, approaches, and maturity levels, as indicated in

Table 1.

The Sydney Opera House is one of the most well-documented examples of successful BIM implementation in FM. The Opera House is a complex and large building with a highly irregular configuration, making it a challenging case [

46]. Since BIM was not derived from the design and construction process due to the building’s age, it was specifically modelled for FM purposes [

47]. The restoration team of the Sydney Opera House created a unified central data repository [

48] as well as an accurate, reliable, and relevant integrated building model to support O&M, modifications and additions to building and service systems, and asset management. This was accomplished by the progressive incremental development of a model using master models and sub-models, while complying to operational, logistical, and financial constraints. The master model for the Sydney Opera House is divided into various logical discipline-specific sub-models. Its aim is to incorporate data, such as Cadastre, Land Use, Terrain, Utilities and Asset Register [

46].

The pilot evaluation study of the proposed building DT was carried out at the Institute for Manufacturing building at the University of Cambridge’s West Cambridge campus. Based on the designed architecture, the developed DT features five layers, integrates multiple data sources, enables effective information search and decision-making, supports anomaly detection of building assets, and is essential for daily operations, maintenance, and management. To analyse and show the effectiveness of the proposed framework, a case study involving the pumps in the HVAC system was conducted. The results demonstrated that system provided continuous condition monitoring of building assets (e.g., pumps) and enhanced efficient and automated asset monitoring in daily activities [

48].

Since 2014, Ryerson University has been developing a BIM for facility management to create a virtual campus model, beginning with the Kerr Hall building. This project focuses on the automation processes for data preparation and transfer, while concurrently discussing the FM information requirements used to develop and utilize the results of these investigations. The objectives of this project are:

To develop a virtual campus model consisting of BIM-FM models for all campus buildings integrated within a larger site model.

To interface the individual BIM models with FM data, providing a single source of operations information for all campus buildings.

To explore potential BIM applications within the FM context and assess their benefits in real operational situations.

To develop improved methodologies for FM-BIM data transfer, addressing known barriers to BIM adoption in FM [

49].

This research conducted a long-term case study analysis of the University of British Columbia, a large owner-operator organisation containing 225 main University-owned buildings. The project is focused on the Building Operations Department, which oversees the O&M of UBS’s educational buildings. The research particularly concentrates on asset management, maintenance management, records management, and facility information management. The study aimed to explore the alignment of FM practices across organisational and project contexts, and to examine current organisational practices to better understand the benefits and challenges of transitioning from a paper-based to a model-based approach in handover and operations. The study presents current handover, information management and facility management methods, as well as a framework for assessing the alignment of organisational structures, available technology, project artifacts and owner requirements [

50].

The opportunity to apply the GeoBIM approach (integration of GIS and BIM) to asset management at the Leonardo Campus of the Politecnico di Milano, Italy, led to a case study to evaluate the effectiveness of this approach. The building, with a gross internal area of approximately 3,700 sqm, consists of one underground floor and three above-ground floors, and is surrounded by a private open space to the north and west, and public open spaces to the east and south. Preserving the functionality and overall quality of this urban environment involves not only maintaining the building and their equipment, but also by considering the surrounding infrastructure and services. This necessitates an operations, maintenance and repair service at the built environment level that can address various management scales in an integrated manner. The BIM model of the existing building was developed with a low level of geometrical detail, aiming to support streamlined space assessment. Mechanical, electrical, and plumbing systems were modelled only when they were visible and accessible for visual inspection. This approach reduces the time required for BIM modelling [

3].

The study was conducted within the context of the UK Government’s BIM effort. Gaining a deeper understanding of the key challenges involved in transitioning from traditional FM to BIM-FM is essential for development of guidelines. A case study was undertaken to explore the use of BIM-FM in the Manchester City Council Town Hall Complex project in Manchester, UK. This study builds on a previous investigation conducted during the same project’s design and construction phase in 2011, Based on the collected information, the research team created two process maps, an as-is map without BIM, which represents the current state of the reactive maintenance system and a to-be map depicting the future state with BIM integrated into the routine process. Finally, a comparative analysis of these two scenarios was conducted. The research had four objectives:

Mapping hard (building systems and fabric) and soft (catering, cleaning, health & safety) services to gain a better understanding of FM operations and organisation.

Investigating the benefits and drawbacks of using information models in FM, with an emphasis on reactive maintenance services.

Assessing BIM-FM maturity levels to better understand and develop an application of the BIM maturity model for FM purposes.

Identifying enablers and barriers to BIM-based FM [

47].

To enhance maintenance strategies for building facilities, a data-driven predictive maintenance planning framework for FM was developed, integrating BIM and IoT technologies. This framework consists of two layers: information and application. To test the proposed data-driven predictive maintenance planning system, three academic buildings on the Hong Kong University of Science and Technology campus were investigated and used as an example. Four chillers serve three campus buildings. To monitor the chillers, three types of sensors were installed: temperature sensors, pressure sensors, and flow rate sensors. The signals from these sensors were collected and transmitted through a sensor network to the BIM models [

51].

The case study was conducted on Northumbria University’s city campus, located in Newcastle, UK, consisting of 32 non-residential buildings. The University engaged five developers to create building information models aimed at enhancing space management performance. The developers utilized existing floor plans from the Estates Department in DWG format, along with scans of original elevations and sections in JPEG format, as well as space information in Excel databases and the models were completed within five weeks. Since the case study involved an existing asset, significant challenges had to be considered when applying BIM for FM purposes. These challenges pertain to the strategic considerations and the business case for transitioning from the traditional FM processes to BIM-based FM processes. The case study included individuals from the University’s estates department, who participated in thorough discussions to evaluate the value and challenges of BIM for managing the spaces within the existing university campus [

2].

In the aftermath of the Notre-Dame Cathedral fire, ensuring the authenticity and monitoring of archaeological remains is essential for their possible reuse in reconstruction. Since the start of the scientific efforts on Notre-Dame, the digital data working group has been developing an innovative digital ecosystem. This system integrates data the cathedral’s current and past states. By utilizing a DT framework, this paper examines the collapsed transverse arch from the nave of Notre-Dame as a reconstruction case study. A new type of DT was developed for the post-disaster reconstruction of heritage buildings, focusing on the collapsed transverse arch of Notre-Dame de Paris Cathedral. The findings show that the proposed modeling method aids in formalizing and validating the reconstruction issue, thereby enhancing the effectiveness of the solutions [

44].

This research explores an architectural survey conducted using digital photogrammetry and terrestrial laser scanning. It discusses the process of generating and manipulating information and outlines the steps necessary to create a 3D model using BIM software for integration into an HBIM (Heritage BIM) workflow methodology. The Engine House of the Instituto Superior de Agronomia in Lisbon was used as a case study to illustrate the process. The aim of this project was to facilitate the building’s rehabilitation. Although the initial requirements were traditional plans, sections, and elevations, the team opted for a scan-to-BIM approach due to its superior results [

52].

Table 1.

Summary of Selected DT Case Studies.

Table 1.

Summary of Selected DT Case Studies.

| Selected Cases |

Case Objectives |

Developed Approaches |

Application |

Maturity Level |

Ref. |

| Sydney Opera House |

To show benefits of digitising documentation

and using standardised BIM to support FM |

A BIM-based digital platform |

Operation &

Maintenance |

2 |

[46] |

Institute for Manufacturing building, University of

Cambridge |

To develop a DT-enabled anomaly

detection system for asset monitoring

in daily O&M management |

A DT prototype based on Autodesk

Forge and AI techniques |

Operation &

Maintenance |

3 |

[48] |

| The Kerr Hall East Building, Ryerson University |

To automate information transfer

between BIM models and FM systems |

A DT prototype based

on Dynamo BIM |

Operation &

Maintenance |

3 |

[49] |

University of British

Columbia Campus |

To transition from a paper-

based approach to a BIM-based

facility management practice |

A framework to characterize alignment between

organizational constructs, available technology,

project artifacts and owner requirements |

Operation &

Maintenance |

1 |

[50] |

Leonardo Campus,

Politecnico di Milano |

To support decision making on

the operations, maintenance, and

repair of digital built environment |

A GeoBIM approach to

improve digital AM |

Operation &

Maintenance |

2 |

[3] |

Manchester Town Hall

Complex |

To document issues in the adoption of

BIM in FM and identify the enablers &

barriers to BIM implementation in FM |

A BIM-supported map for

reactive maintenance process |

Operation &

Maintenance |

2 |

[47] |

| Hong Kong University of Science and Technology campus |

To predict maintenance of MEP

components of buildings |

A data-driven predictive maintenance

framework of MEP components |

Operation &

Maintenance |

2 |

[51] |

| Northumbria University City Campus |

To investigate the value and challenges of

BIM in FM for new and existing assets with

a focus on improving space management |

A BIM-based platform for FM processes |

Operation &

Maintenance |

1 |

[2] |

| Notre-Dame de Paris |

To monitor & analyze collapsed arches

of the Cathedral and propose a

hybrid reconstruction hypothesis |

A DT for post-disaster heritage building

used for data acquisition and processing to

develop a hybrid reconstruction hypothesis |

Reconstruction & Restoration |

1 |

[44] |

| The Engine House Paços Reais |

To produce the documentation

for heritage assets rehabilitation |

An HBIM using scan-to-BIM approach,

3D laser scanning and photogrammetry |

Preservation &

Rehabilitation |

1 |

[52] |

5. The Versatile Capabilities of Digital Twins

Digital technologies provide new ways of generating and securing value across the lifecycle of an asset, enabling widespread transformations in methodology. The advantages of employing technology such as enhancing efficiency and performance of assets can be attained through enabling and then maintaining the change [

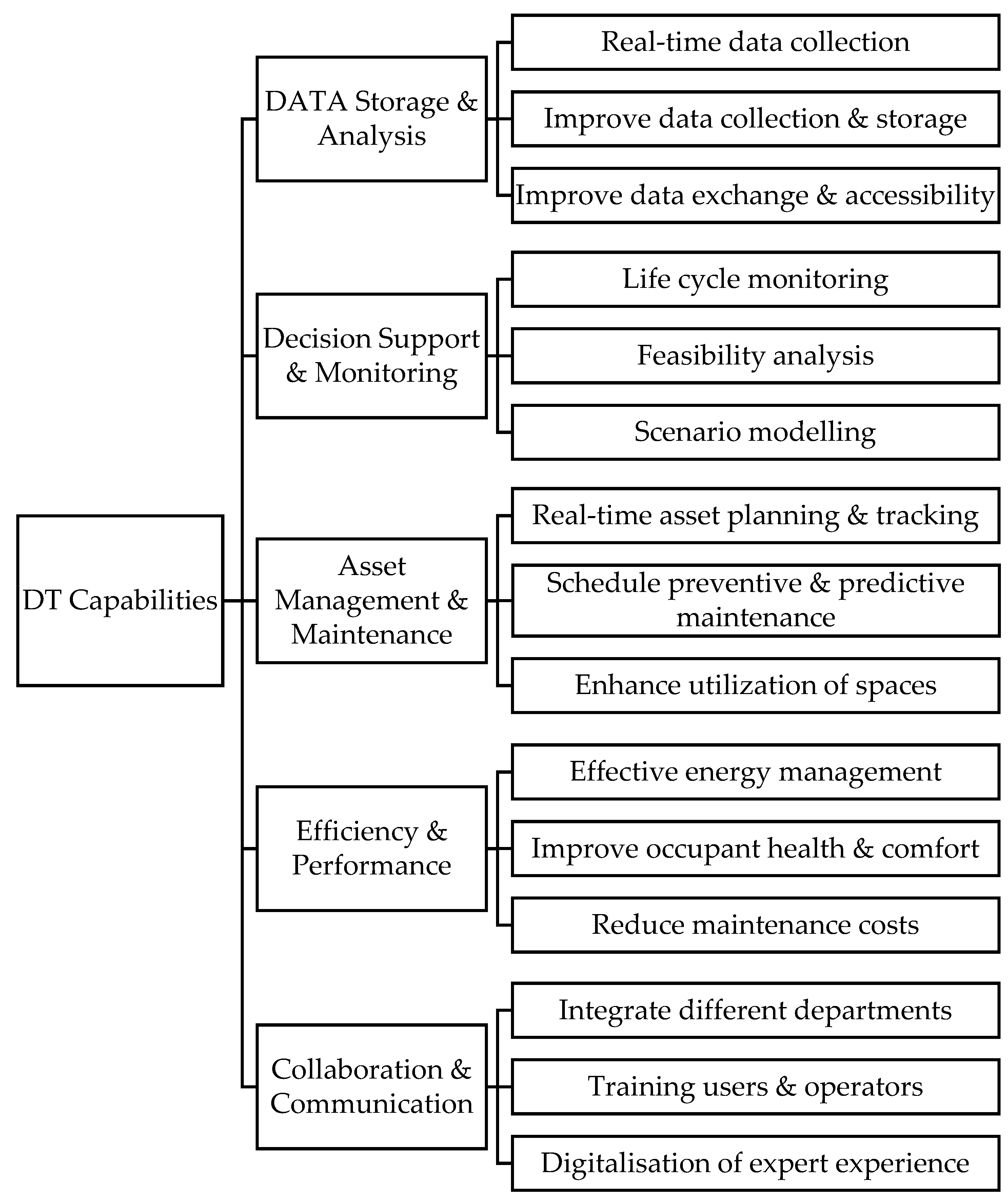

35]. As shown in

Figure 4, DTs transform and enhance current methods in five categories:

5.1. Data Storage and Analysis

Traditionally Facility Management data transfer relies on paper records and Excel sheets, a method still widely used today [

51]. However, during this approach information may occasionally become lost or inaccessible [

53], leading to delays in addressing service requests and a decrease in operational and maintenance efficiency [

51]. To overcome these obstacles a DT can be utilized. DT technology can collect and manage data in real time [

38], providing a shared repository for all project-related data, past and present. This results in updated as-built models, minimizes redundant data collection and re-entry, and improves information exchange and accessibility throughout the organisation’s operational activities [

50,

53].

5.2. Decision Support and Monitoring

One advantage of implementing DT in the AEC industries is the ability to visualize the operations of physical assets in a virtual model [

13]. By gathering both present and past data over time [

29] and analysing current conditions and previous issues [

5], DT can be employed for automated progress monitoring [

13], diagnostics, prognostics, and optimization [

5]. This results in statistically based decision making and enhancing the management the system [

54]. Another potential advantage of DT is design feasibility analysis before construction. It serves as a crucial tool in the planning and coordinating multi-disciplinary solutions, allowing for early verification and validation of design choices [

4].

5.3. Asset Management and Maintenance

The application of DT in asset management offers several benefits, such as resource planning, logistics optimization, and efficient equipment usage [

13]. DT serves as a central information repository and keeping track of equipment locations and conditions [

55]. It also manages repair part inventories [

13] and provides information about the required parts at the appropriate time and location, minimizing inventory during facility construction or operation [

13], and enabling efficient utilization and planning of resources [

39].

Furthermore, in traditional asset inspections or maintenance, a technician examines the equipment, investigates the causes, make numerous notes, and offer specific solutions. This may result in errors or imprecise results [

55]. By utilizing smart sensors [

38] DT can schedule preventive and predictive maintenance tasks [

13] by assessing the current state of assets, analysing their behaviour, and predicting the degradation of components [

1], leading to more accurate work, better results, and reduced downtime [

55]. On top of that, DT assists in tracking real-time locations of people and utilization of spaces across the facility [

4], as well as planning orders, activities, schedules, and labour [

56].

5.4. Efficiency and Performance

One major challenge that organizations face during digitalisation is effectively demonstrating the benefits and value of investing in developing digital technologies. With decreasing storage and computation costs, the number of use cases and possibilities for enabling a DT has increased dramatically [

4]. Based on a cost-benefit analysis, despite requiring a substantial initial investment, DT provides significant returns in the long run [

29].

Building energy efficiency stands out as one of the foremost research areas, given that buildings contribute to 40% of the global energy consumption [

39]. DT can assist in illustrating the problems and limitations to stakeholders, such as estimating energy consumptions [

20]. Furthermore, by integrating operational data with advanced control strategies, the energy management process can be enhanced through offering insights into operational status of buildings and optimization of equipment operation via user behaviour analysis, indoor environment condition monitoring, and building performance analysis [

23].

A key factor contributing to the business value of a DT is its scalability. The data generated by the DT can be used to develop new applications with minimal effort and cost. For example, real-time data from the HVAC sensors can also be used to determine room occupancy, enhancing energy efficiency by automatically turning off the HVAC or switching to economy mode when the room is unoccupied [

4].

Another benefit of Efficient FM is the ability to improve occupant health and comfort. Given that people spend around 80% of their lives in buildings, maintaining a healthy and comfortable indoor environment is crucial for their well-being and productivity. Implementing a real-time interior condition monitoring system can improve the overall quality of facility services, reduce repair costs and building energy use [

39].

5.5. Collaboration and Communication

One of the primary goals of establishing an asset management system is to integrate various disparate systems, such as backend business [

13], to eliminate the traditional organisational silo effect and improve collaboration between different departments [

56]. DT can also be utilized for training of users, operators, maintainers, and service providers. Additionally, DT enables the digitalisation of expert experience, which can then be documented, transferred, and modified across an organisation to minimize the knowledge gap [

5].

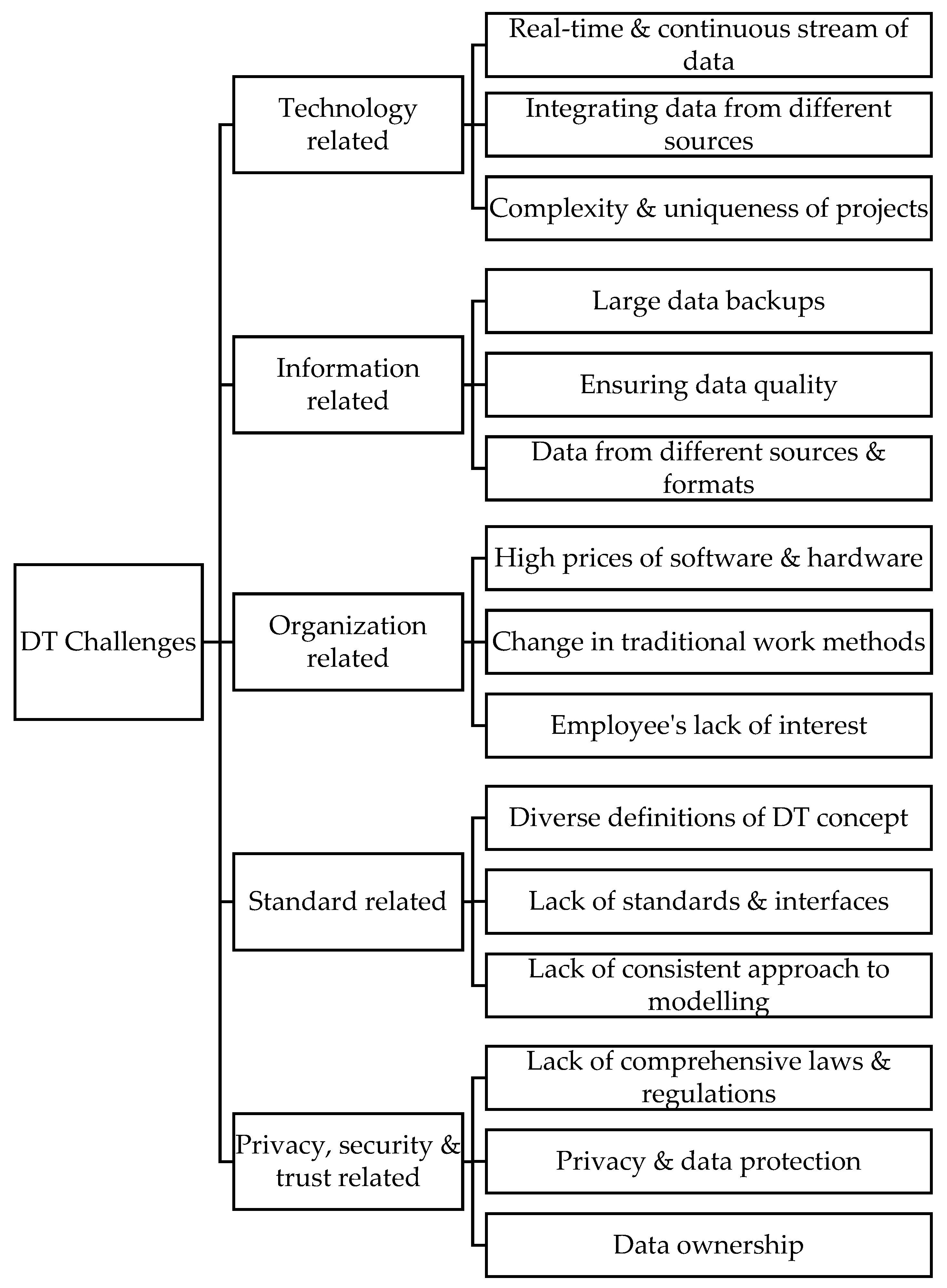

6. Challenges in Implementing Digital Twins for AEC Projects

Although IoT has brought benefits and advancements to the building industry, there are still challenges and issues in various domains that need to be addressed [

39]. Significant efforts have been made by numerous organisations and researchers to accelerate the advancement of DT applications [

56]. The obstacles that create setbacks in DT adoption in the AEC industries are classified in five groups as shown in

Figure 5.

6.1. Technology Related Issues

The primary challenge lies in the overall IT infrastructure. To execute the algorithms, the latest technologies with high-performance infrastructure are required and the infrastructure needs regular updates in both software and hardware to support the successful operation of such systems [

34]. To develop a DT environment, it is also necessary to re-evaluate and alter the foundational software platform, along with the hardware of production machines and their cloud/physical interface [

4], which may potentially limit the widespread adoption of DT technologies [

10].

For the DT to function effectively, data must be transmitted from the physical asset to the digital model in real-time. Ensuring the system has a continuous feedback loop without any interruptions is essential [

20]. Above that, the data required for DT models is stored in separate systems, making it challenging to ensure data consistency across the system. Therefore, the major challenge in the construction sector remains the integration of data from various stakeholders and multiple technology sources in different formats. Standardizing and developing the formats of BIMs and the semantic web data of IoT devices are necessary to facilitate seamless data integration [

20].

The complexities of the construction sector and the dynamic and unstable nature of the industry, contribute to the delayed adoption of digitalisation in this field [

13]. Implementing DT within a large owner organisation, which encompasses numerous departments, processes, cultures, networks of systems and databases, and individuals from diverse backgrounds [

50] poses a highly complex task that might take a considerable amount of time [

20]. Furthermore, every project in the construction industry is unique. In contrast to construction, in manufacturing and other industries, DT implementation requires straightforward replications for all manufactured products. However, the construction industry requires different DT demands for various construction projects [

13].

6.2. Information Related Issues

Given that IoT systems gather massive amounts of data [

39], a large number of hardware devices is required for the data backup, posing financial risks, particularly in large-scale buildings [

38]. Hence, it is crucial to optimize the design of the storage architecture to ensure that data is consistently accessible for retrieval and can be easily recovered from backup [

39].

The utilized sensors and other devices generate large amounts of data of various types, This information also varies among different types of buildings [

39]. The collected data must meet the quality standards for its intended use, but this quality can degrade during extraction from the source or during transformation [

20]. To ensure that meaningful data is collected thus guaranteeing the best quality of data input into the AI algorithms [

34], the system must be able to perform the following steps:

data transition, which enables robust data transfer from raw sensors to repository.

data cleaning, which involves removing corrupted and null data.

data consistency checking, which ensures that the data is neither duplicated nor contradictory [

39].

Data formatting is a challenge after the data collection step since data from various sources sometimes exists in different formats. Asset, operational, historical maintenance activity, and historical asset evolution data are some examples of these data sources. For instance, data from humans may be in the form of voice recordings and images, while data from appliances consists of textual content. Reformatting this data in a consistent and timely manner, while integrating it from multiple sources [

1], to ensure that the output of the formatted data is ready to be utilized by potential solutions, is a complex task [

39].

6.3. Organisation Related Issues

The comparatively high prices of purchasing appropriate software tools [

4], along with the increased costs of technology initiation due to the complexity of technologies and the demanding fidelity, accuracy, and computational requirements, pose significant obstacles to adopting smart FM [

23]. Furthermore, the exclusion of “digital” planning and simulation from budget considerations and project fee structures creates a barrier to DT adoption in the construction industry [

4].

Transitioning from traditional facilities management practices to BIM-based practices necessitates changes in work methods [

50]. Since computerisation technology is advancing rapidly, training personnel to stay updated on the latest knowledge and developments can be challenging for industries [

57]. Additionally, another potential is employees’ and workers’ lack of interest due to fear of losing their jobs [

13]. Therefore, to prevent redundancy of tacit knowledge within the workforce and embrace the concept of lifelong higher education institutes must collaborate more closely with practitioners [

57].

6.4. Standard Related Issues

The diverse definitions of DT concept [

34] some created by researchers, some by industry and some by standards committees result in an absence of any agreed-upon definition [

6]. This broad scope extends to managing information throughout the entire lifespan of an asset and involves multiple stakeholders in the process [

56], contributes to the setback in DT adoption [

13].

Another barrier to the development of DT technology is the lack of standards and interfaces [

4]. The AEC sector demands tailored DT standards for each unique project, which can results in inconsistencies among DT projects [

34]. In contrast, the manufacturing industry requires a uniform standard across all products, For instance, in the case of implementing DT technology in the design and production of a particular model of a vehicle [

13].

In the existing standards, there is a fundamental absence of a framework to facilitate the development of DT within Operations and Maintenance and asset management (AM) contexts and support the alignment of technical standards and specifications [

56]. Furthermore, a small number of manufacturers in the construction sector have been able to supply BIM-compatible data for their components [

4], and the existing standards are developed for individual lifecycles and disciplines [

56].

Another contributing factor is that there is no standardised approach to modelling. From the initial design phase to the simulation of DT there is a need for a standard method and a consistent approach that ensures domain and user comprehension while facilitating information flow across each stage of development [

34].

6.5. Privacy, Security and Trust Related Issues

Cybersecurity poses a significant concern in the adoption of DTs particularly in web-based environments [

18]. Addressing cybersecurity and building trust should be prioritized early on for any new digital technology. Since the field of DT technology is still in its infancy [

6], comprehensive laws and regulations have yet to be fully established [

34]. The vulnerabilities and security risks inherent in IoT systems span various components, including web interfaces, network services, software [

39], exposing DTs to cyber threats [

34], potentially jeopardizing the physical entities being twinned [

10].

From users’ perspective [

39], privacy and data protection are key priorities [

20]. Since many applications include [

39] users’ private, confidential, or valuable data [

10], an insecure system not only raises concerns about unauthorized access to individuals’ confidential information [

18] but also diminishes their willingness to adopt the technology. For instance, the utilization of cameras in office buildings for safety monitoring and GPS for localization purposes, can lead to discomfort among individuals [

39].

Data ownership, involving the establishment of access levels and permissions, is another critical and unresolved issue for DTs. Regulation, privacy policies, legal constraints [

10] and data accessibility limitations are necessary for involved stakeholders [

18] to safeguard personal data [

34]. This is particularly crucial for government-owned assets or DTs at the city level [

18].

7. Future Potentials and Research Gaps

Implementing DT is a complex and lengthy process that involves integration and collaboration of multiple technologies developed by different companies [

5]. In many current research and industry applications, a lack of collaboration has prevented the full utilization of IoT in the building industry. Therefore, there is a need to increase collaboration between technical teams with civil engineering and building technology researchers to further advance IoT’s application in building industry. Effective collaboration allows IoT developers to revise and optimize the system [

39]. Another beneficial approach can be a comparative analysis of DT applications in the AEC sector with those in more technologically advanced industries such as aerospace and automotive. Such analyses could facilitate the transfer existing solutions to AEC industries. The challenges require innovative solutions to transform industry practices, which can be enhanced by stronger interdisciplinary research and collaborations [

57].

As it was previously discussed, in the construction industry, no two projects are the same; they consist of wide ranges of activities with social, economic, and environmental dimensions [

58], and maturity level of a DT platform largely depends on the asset to which it is applied [

25]. Therefore, there are notable differences in model size, operational rules, data management, etc. For instance, city DTs and shop-floor DTs are entirely distinct projects [

5]. Hence, a potential research area can be to develop DT platforms of diverse real-world projects through scientific testing and validation [

25,

57]. Additionally, most DT development studies have typically been conducted in lab environments, depending on controlled variables and simulated data and overlooking numerous practical issues that could arise in practical settings. To date, only a few studies have tested their platform on in-use buildings. Therefore, multi-disciplinary teams should focus on the full integration of complex and dynamic environments. The potential benefits of DTs can be substantiated by employing real world case-studies [

39,

57,

59].

DT goes beyond just a collection of new technologies; it also represents a new approach to conducting business activities and a different mindset. While different stakeholders may have varying expectations regarding the extent of connectivity and digitalisation they require [

25], the goal of DTs is to achieve the highest possible level of digital maturity. As no existing example of a DT has fully realized its capabilities, the concept of DT remains somewhat undefined, making it challenging to determine when a DT has reached its full potential [

60].

8. Conclusion

The transition from traditional asset management to DT technology in the AEC industries marks a significant leap in productivity and performance. This paper has provided an in-depth review of DT definitions, applications, capabilities, and challenges, emphasising the profound impact DTs can have in this field. Our comprehensive literature review and case studies illustrate the notable benefits of DTs in enhancing data storage, decision support, asset management, and collaboration.

DT technology offers numerous advantages, such as optimising lifecycle energy use, facilitating predictive maintenance, and improving user adaptability. By merging real-time data from IoT sensors with advanced analytics, DTs generate dynamic and actionable insights that enhance decision-making and resource management. These capabilities are crucial for building design, construction, and facility management, driving operational efficiency and sustainability.

However, several challenges hinder the widespread adoption of DT technology. Key obstacles include technological integration, data consistency, organisational adaptation, and cybersecurity concerns. Overcoming these challenges necessitates interdisciplinary collaboration, standardization of data formats, and the creation of universal DT design and development platforms. Additionally, the high initial costs and the need for specialised skills to manage and operate DT systems present further barriers.

Future research should priorities real-world case studies to validate the practical applications and benefits of DT technology in the AEC sector. Encouraging interdisciplinary collaboration among researchers, industry practitioners, and policymakers is essential to develop holistic solutions that address the diverse challenges of DT adoption. Standardising DT platforms will aid in the integration and scalability of DT applications across various projects and sectors.

Furthermore, comparing DT applications in the AEC industries with those in more technologically advanced industries, such as aerospace and automotive, can provide valuable insights for adapting existing solutions to the construction sector. Exploring DT technology’s potential in areas such as smart cities and heritage building preservation can also pave the way for new research and application opportunities.

In conclusion, DT technology is set to revolutionize the AEC industries by enabling autonomous, data-driven decision-making and optimizing building operations for enhanced productivity and performance. As the industry progresses, embracing DT technology will be vital for achieving sustainable and efficient building management practices, fostering innovation, and maintaining a competitive edge. By addressing the current challenges and utilizing the full potential of DTs, the AEC industries can look forward to a future characterised by smarter, more resilient, and more efficient built environments.

Author Contributions

Conceptualization, Yalda Mousavi, Zahra Gharineiat; methodology, Yalda Mousavi, Zahra Gharineiat; investigation, Yalda Mousavi; writing—original draft preparation, Yalda Mousavi; writing—review and editing, Zahra Gharineiat, Armin Agha Karimi, Kevin McDougall; supervision, Zahra Gharineiat, Armin Agha Karimi, Kevin McDougall. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Errandonea, I.; Beltrán, S.; Arrizabalaga, S. Digital Twin for maintenance: A literature review. Computers in Industry 2020, 123. [Google Scholar] [CrossRef]

- Kassem, M.; et al. BIM in facilities management applications: a case study of a large university complex. Built Environment Project and Asset Management 2015, 5, 261–277. [Google Scholar] [CrossRef]

- Moretti, N.; et al. GeoBIM for built environment condition assessment supporting asset management decision making. Automation in Construction 2021, 130, 103859. [Google Scholar] [CrossRef]

- Siemens, Digital twin – Driving business value throughout the building life cycle. 2018.

- Qi, Q.; et al. Enabling technologies and tools for digital twin. Journal of Manufacturing Systems 2021, 58, 3–21. [Google Scholar] [CrossRef]

- Harper, K.E.; Malakuti, S.; Ganz, C. Digital twin architecture and standards. 2019. [Google Scholar]

- Chen, L.; et al. Gemini principles-based digital twin maturity model for asset management. Sustainability 2021, 13, 8224. [Google Scholar] [CrossRef]

- VanDerHorn, E.; Mahadevan, S. Digital Twin: Generalization, characterization and implementation. Decision support systems 2021, 145, 113524. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. Transdisciplinary perspectives on complex systems: New findings and approaches 2017, 85–113. [Google Scholar]

- Barricelli, B.R.; Casiraghi, E.; Fogli, D. A survey on digital twin: Definitions, characteristics, applications, and design implications. IEEE access 2019, 7, 167653–167671. [Google Scholar] [CrossRef]

- Tao, F.; et al. Digital twin-driven product design, manufacturing and service with big data. The International Journal of Advanced Manufacturing Technology 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Phanden, R.K.; Sharma, P.; Dubey, A. A review on simulation in digital twin for aerospace, manufacturing and robotics. Materials today: proceedings 2021, 38, 174–178. [Google Scholar] [CrossRef]

- Madubuike, O.C.; Anumba, C.J.; Khallaf, R. A review of digital twin applications in construction. Journal of Information Technology in Construction 2022, 27. [Google Scholar] [CrossRef]

- Ghenai, C.; et al. Recent trends of digital twin technologies in the energy sector: A comprehensive review. Sustainable Energy Technologies and Assessments 2022, 54, 102837. [Google Scholar] [CrossRef]

- Olatunji, O.O.; et al. Overview of digital twin technology in wind turbine fault diagnosis and condition monitoring. in 2021 IEEE 12th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT). 2021, IEEE. [Google Scholar]

- Liu, Y.; et al. A review of digital twin capabilities, technologies, and applications based on the maturity model. Advanced Engineering Informatics 2024, 62, 102592. [Google Scholar] [CrossRef]

- Mahmoud, M.; et al. Designing and prototyping the architecture of a digital twin for wind turbine. International Journal of Thermofluids 2024, 22, 100622. [Google Scholar] [CrossRef]

- Shahzad, M.; et al. Digital twins in built environments: an investigation of the characteristics, applications, and challenges. Buildings 2022, 12, 120. [Google Scholar] [CrossRef]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of digital twin applications in manufacturing. Computers in industry 2019, 113, 103130. [Google Scholar] [CrossRef]

- Feng, H.; Chen, Q.; de Soto, B.G. Application of digital twin technologies in construction: an overview of opportunities and challenges. in ISARC. Proceedings of the International Symposium on Automation and Robotics in Construction. 2021, IAARC Publications.

- Karaarslan, E.; et al. Digital Twin Driven Intelligent Systems and Emerging Metaverse. 2023: Springer Nature.

- Wu, J.; et al. Digital twins and artificial intelligence in transportation infrastructure: Classification, application, and future research directions. Computers and Electrical Engineering 2022, 101, 107983. [Google Scholar] [CrossRef]

- Zhan, H.; et al. Towards a sustainable built environment industry in Singapore: Drivers, barriers, and strategies in the adoption of smart facilities management. Journal of Cleaner Production 2023, 425, 138726. [Google Scholar] [CrossRef]

- Boje, C.; et al. Towards a semantic Construction Digital Twin: Directions for future research. Automation in construction 2020, 114, 103179. [Google Scholar] [CrossRef]

- Moshood, T.D.; et al. Infrastructure digital twin technology: A new paradigm for future construction industry. Technology in Society 2024, 77, 102519. [Google Scholar] [CrossRef]

- Sacks, R. BIM handbook : a guide to building information modeling for owners, managers, designers, engineers and contractors. Third edition. ed. 2018, Hoboken, New Jersey: Wiley.

- Khajavi, S.H.; et al. Digital twin: vision, benefits, boundaries, and creation for buildings. IEEE access 2019, 7, 147406–147419. [Google Scholar] [CrossRef]

- Botín-Sanabria, D.M.; et al. Digital twin technology challenges and applications: A comprehensive review. Remote Sensing 2022, 14, 1335. [Google Scholar] [CrossRef]

- Madni, A.; Madni, C.; Lucero, S. Leveraging digital twin technology in model-based systems engineering. Systems 2019, 7, 7. [Google Scholar] [CrossRef]

- Kritzinger, W.; et al. Digital Twin in manufacturing: A categorical literature review and classification. Ifac-PapersOnline 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Hu, W.; et al. A new quantitative digital twin maturity model for high-end equipment. Journal of Manufacturing Systems 2023, 66, 248–259. [Google Scholar] [CrossRef]

- Ramu, S.P.; et al. Federated learning enabled digital twins for smart cities: Concepts, recent advances, and future directions. Sustainable Cities and Society 2022, 79, 103663. [Google Scholar] [CrossRef]

- Moretti, N.; et al. Federated data modeling for built environment digital twins. Journal of Computing in Civil Engineering 2023, 37, 04023013. [Google Scholar] [CrossRef]

- Fuller, A.; et al. Digital twin: Enabling technologies, challenges and open research. IEEE access 2020, 8, 108952–108971. [Google Scholar] [CrossRef]

- Love, P.E.; Matthews, J. The ‘how’of benefits management for digital technology: From engineering to asset management. Automation in Construction 2019, 107, 102930. [Google Scholar] [CrossRef]

- Qiuchen Lu, V.; et al. Developing a dynamic digital twin at a building level: Using Cambridge campus as case study. in International Conference on Smart Infrastructure and Construction 2019 (ICSIC) Driving data-informed decision-making. 2019, ICE Publishing.

- Wang, T.; et al. Digital twin-enabled built environment sensing and monitoring through semantic enrichment of BIM with SensorML. Automation in Construction 2022, 144, 104625. [Google Scholar] [CrossRef]

- Zhao, J.; et al. Developing a conceptual framework for the application of digital twin technologies to revamp building operation and maintenance processes. Journal of Building Engineering 2022, 49, 104028. [Google Scholar] [CrossRef]

- Jia, M.; et al. Adopting Internet of Things for the development of smart buildings: A review of enabling technologies and applications. Automation in Construction 2019, 101, 111–126. [Google Scholar] [CrossRef]

- Gonizzi Barsanti, S.; Giner, S.L.; Rossi, A. Digital data and semantic simulation—The survey of the ruins of the convent of the Paolotti (12th Century AD). Remote Sensing 2022, 14, 5152. [Google Scholar] [CrossRef]

- Kong, X.; Hucks, R.G. Preserving our heritage: A photogrammetry-based digital twin framework for monitoring deteriorations of historic structures. Automation in Construction 2023, 152, 104928. [Google Scholar] [CrossRef]

- Tan, J.; et al. Digital twin for Xiegong’s architectural archaeological research: A case study of Xuanluo Hall, Sichuan, China. Buildings 2022, 12, 1053. [Google Scholar] [CrossRef]

- Hull, J.; Ewart, I.J. Conservation data parameters for BIM-enabled heritage asset management. Automation in Construction 2020, 119, 103333. [Google Scholar] [CrossRef]

- Gros, A.; et al. Faceting the post-disaster built heritage reconstruction process within the digital twin framework for Notre-Dame de Paris. Scientific Reports 2023, 13, 5981. [Google Scholar] [CrossRef]

- What is a digital twin? Available online: https://www.ibm.com/topics/what-is-a-digital-twin (accessed on 14 May 2024).

- Innovation, C.R.C.f.C.; Adopting BIM for facilities management - Solutions for managing the Sydney Opera House. 2007.

- Kiviniemi, A.; Codinhoto, R. Challenges in the Implementation of BIM for FM— Case Manchester Town Hall Complex, in Computing in Civil and Building Engineering (2014). 2014, p. 665-672.

- Lu, Q.; et al. Digital twin-enabled anomaly detection for built asset monitoring in operation and maintenance. Automation in Construction 2020, 118, 103277. [Google Scholar]

- Khaja, M.; Seo, J.; McArthur, J. Optimizing BIM metadata manipulation using parametric tools. Procedia Engineering 2016, 145, 259–266. [Google Scholar]

- Cavka, H.B.; Staub-French, S.; Pottinger, R. Evaluating the alignment of organizational and project contexts for BIM adoption: a case study of a large owner organization. Buildings 2015, 5, 1265–1300. [Google Scholar] [CrossRef]

- Cheng, J.C.; et al. Data-driven predictive maintenance planning framework for MEP components based on BIM and IoT using machine learning algorithms. Automation in Construction 2020, 112, 103087. [Google Scholar] [CrossRef]

- Rocha, G.; et al. A scan-to-BIM methodology applied to heritage buildings. Heritage 2020, 3, 47–67. [Google Scholar] [CrossRef]

- Wijeratne, P.U.; et al. BIM enabler for facilities management: A review of 33 cases. International Journal of Construction Management 2024, 24, 251–260. [Google Scholar] [CrossRef]

- Macchi, M.; et al. Exploring the role of digital twin for asset lifecycle management. IFAC-PapersOnLine 2018, 51, 790–795. [Google Scholar] [CrossRef]

- Re Cecconi, F.; Maltese, S.; Dejaco, M.C. Leveraging BIM for digital built environment asset management. Innovative Infrastructure Solutions 2017, 2, 1–16. [Google Scholar] [CrossRef]

- Lu, Q.; et al. From BIM towards digital twin: strategy and future development for smart asset management. Service Oriented, Holonic and Multi-agent Manufacturing Systems for Industry of the Future: Proceedings of SOHOMA 2019 9, 2020, 392-404.

- Pärn, E.A.; Edwards, D.J.; Sing, M.C. The building information modelling trajectory in facilities management: A review. Automation in construction 2017, 75, 45–55. [Google Scholar] [CrossRef]

- Lei, B.; et al. Challenges of urban digital twins: A systematic review and a Delphi expert survey. Automation in Construction 2023, 147, 104716. [Google Scholar] [CrossRef]

- Ozturk, G.B. Digital twin research in the AECO-FM industry. Journal of Building Engineering 2021, 40, 102730. [Google Scholar] [CrossRef]

- Camposano, J.C.; Smolander, K.; Ruippo, T. Seven metaphors to understand digital twins of built assets. IEEE Access 2021, 9, 27167–27181. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).