Submitted:

18 July 2024

Posted:

19 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experimental Methodology

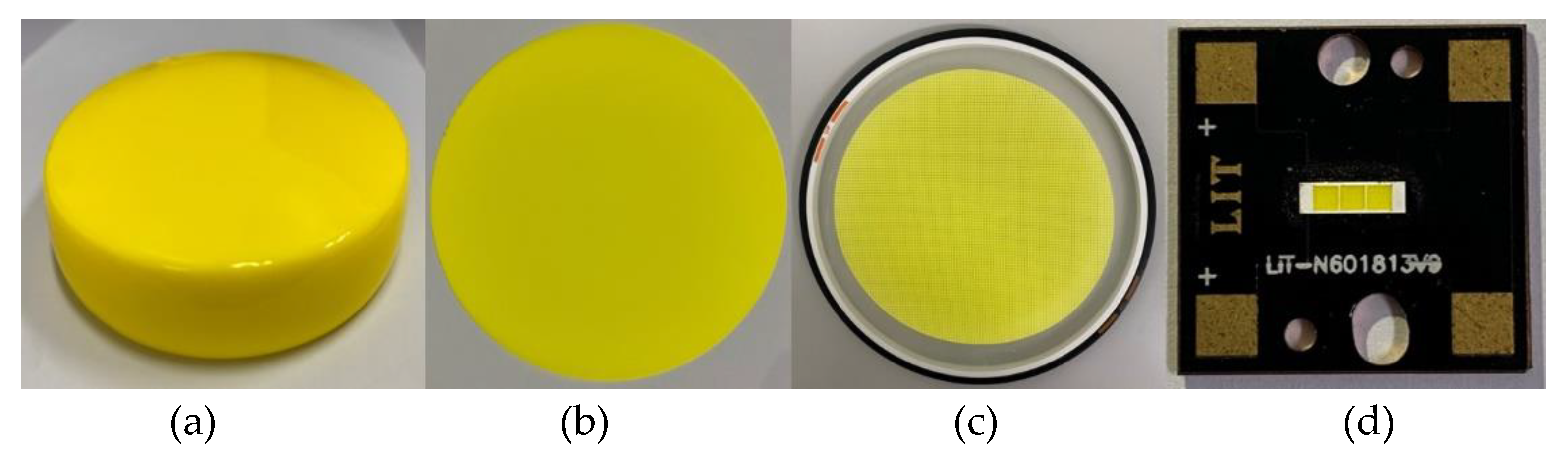

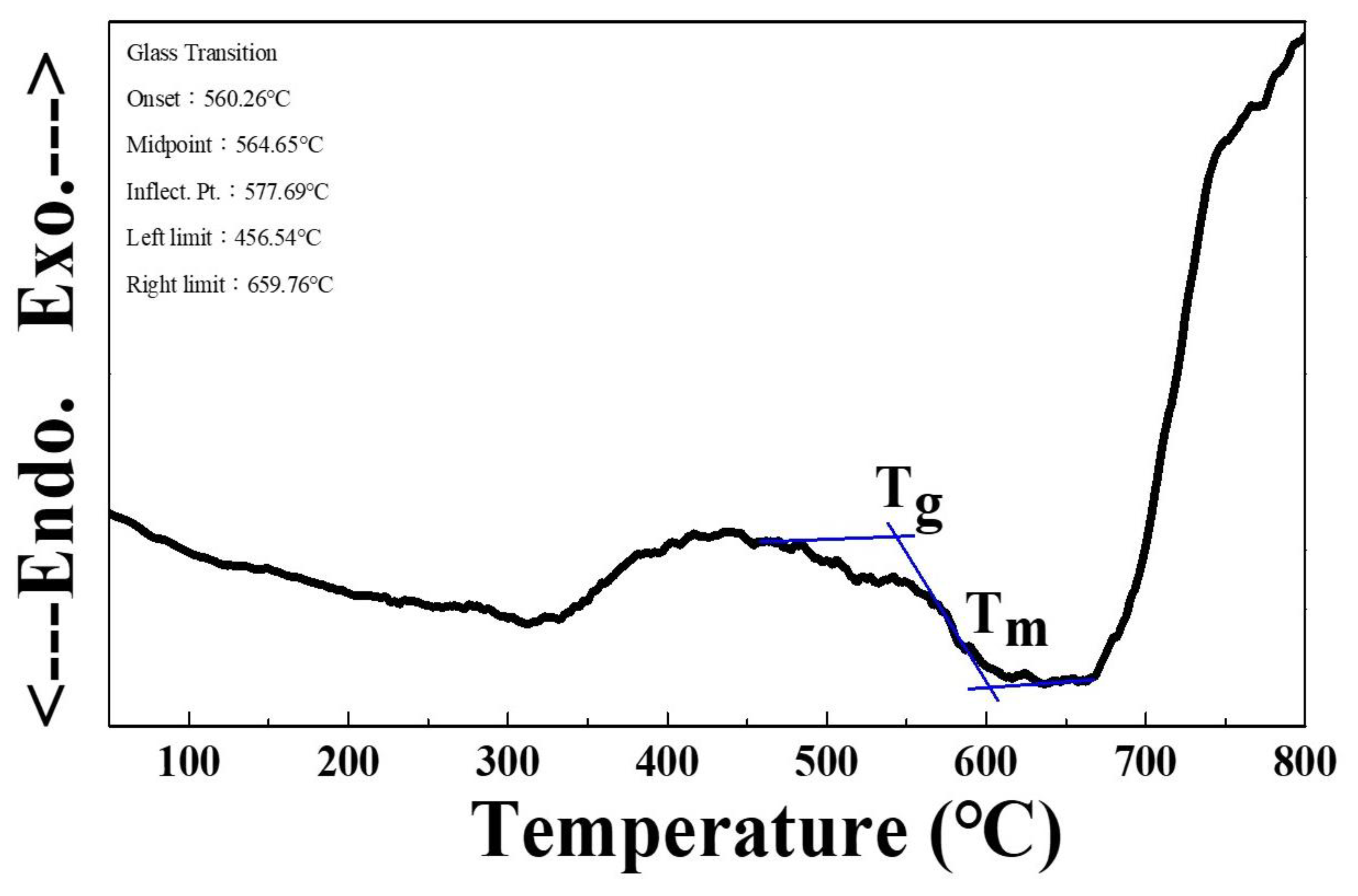

2.1. Manufacturing the Phosphor-in-Glass

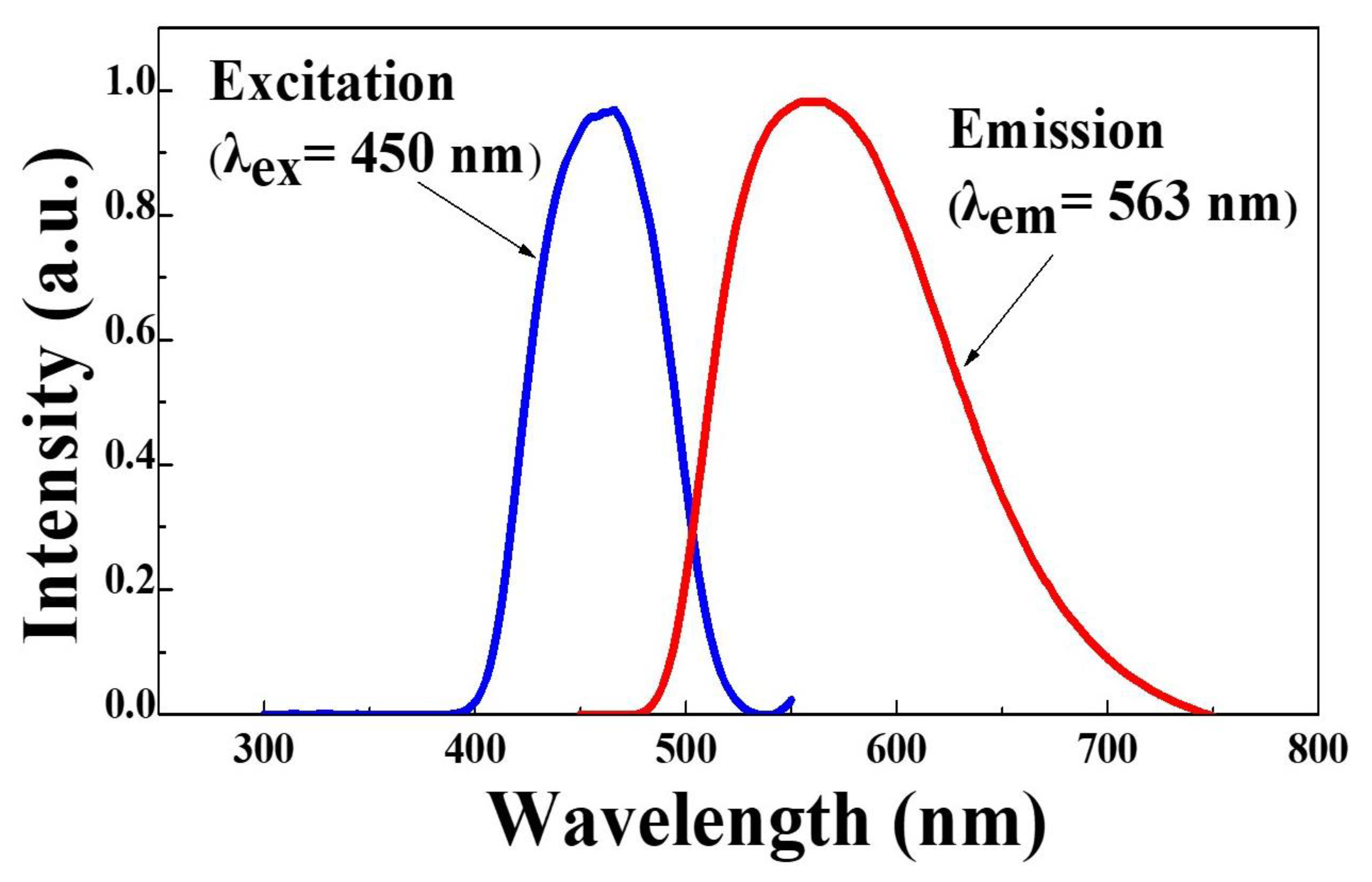

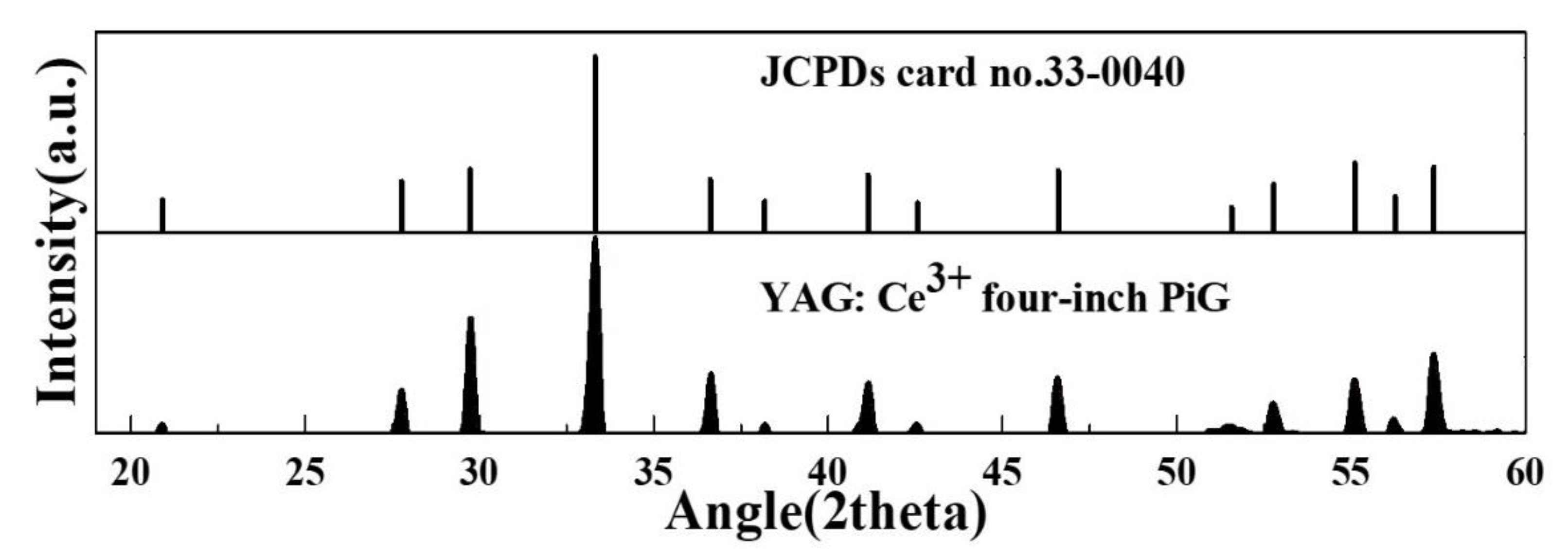

2.2. Measurements of Phosphor-in-Glass

2.3. Thermal Stress Aging Tests

3. Results and Discussion

4. Discussion and Conclusion

Funding

Disclosures

References

- Shih, H. K.; Liu, C. N.; Cheng, W. C.; Cheng, W. H. High color rendering index of 94 in white LEDs employing novel CaAlSiN3: Eu2+ and Lu3Al5O12: Ce3+ co-doped phosphor-in-glass. Opt. Express 2020, 28, 28218–28225. [Google Scholar] [CrossRef] [PubMed]

- Singh, P.; Tan, C. M. Degradation physics of high-power LEDs in outdoor environment and the role of phosphor in the degradation process. Sci. Rep. 2016, 6, 24052. [Google Scholar] [CrossRef] [PubMed]

- Sun, C. C.; Wu, C. S.; Lin, Y. S.; Lin, Y. J.; Hsieh, C. Y.; Lin, S. K.; Yang, T. H.; Yu, Y. W. Review of optical design for vehicle forward lighting based on white LEDs. Opt. Eng. 2021, 60, 091501. [Google Scholar] [CrossRef]

- Toney, G.; Bhargava, C. Adaptive Headlamps in Automobile: A Review on the Models, Detection Techniques, and Mathematical Models. IEEE Access. 2021, 9, 87462–87474. [Google Scholar] [CrossRef]

- Jiao, J.; Wang, B. Etendue Concerns for Automotive Headlamps Using White LEDs, Proc. SPIE 2004, 5187, 234–242. [Google Scholar]

- Xu, Y.; Long, J.; Zhang, R.; Du, Y.; Guan, S.; Wang, Y.; Huang, L.; Wei, H.; Liu, L.; Huang, Y. Greatly improving thermal stability of silicone resins by modification with POSS. Polym. Degrad. Stabil. 2020, 174, 109082. [Google Scholar] [CrossRef]

- Liu, C. N.; Shih, H. K.; Chen, Y. C.; Chen, Y. H.; Cheng, W. C.; Cheng, W. H. High reliability and luminance of the color wheel by phosphor-in-inorganic silicone. Opt. Mater. Express 2023, 13, 1092–1100. [Google Scholar] [CrossRef]

- Chen, D.; Chen, Y. Transparent Ce3+: Y3Al5O12 glass ceramic for organic-resin-free white-light-emitting diodes. Ceram Int. 2014, 40, 15325–15329. [Google Scholar] [CrossRef]

- Shih, H. K.; Chang, Y. P.; Liu, C. N.; Li, K.; Cheng, W. H. Laser-excited single crystal phosphor in white LED for wide field of view and high enhanced central brightness for vehicle headlights. AIP Advances 2022, 12, 015018. [Google Scholar] [CrossRef]

- Yoon, C. B.; Kim, S.; Choi, S. W.; Yoon, C.; Ahn, S. H.; Chung, W. J. Highly improved reliability of amber light emitting diode with Ca –α–SiAlON phosphor in glass formed by gas pressure sintering for automotive applications. Opt. Lett. 2016, 41, 1590–1593. [Google Scholar] [CrossRef] [PubMed]

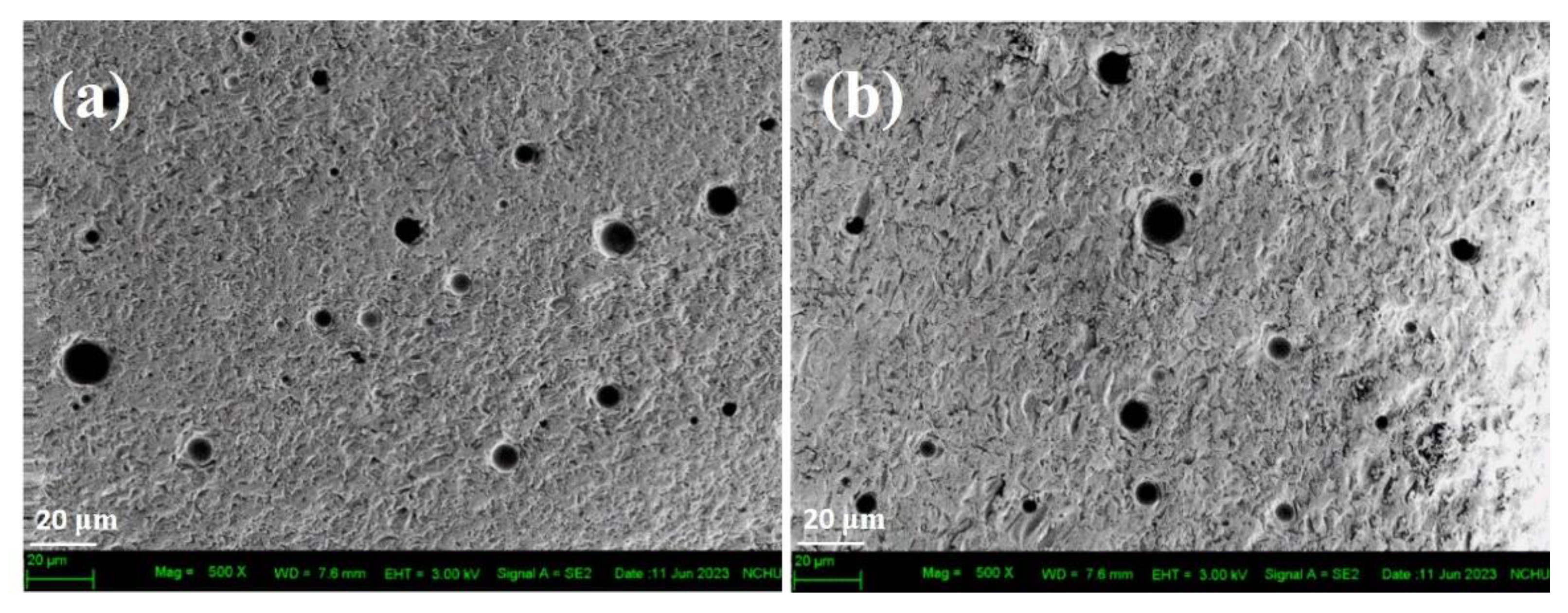

- Kim, S.; Yie, H.; Choi, S.; Sung, A.; Kim, H. Pore characteristics for improving luminous efficacy of phosphor-in-glass. Opt. Express 2015, 23, A1499–A1511. [Google Scholar] [CrossRef] [PubMed]

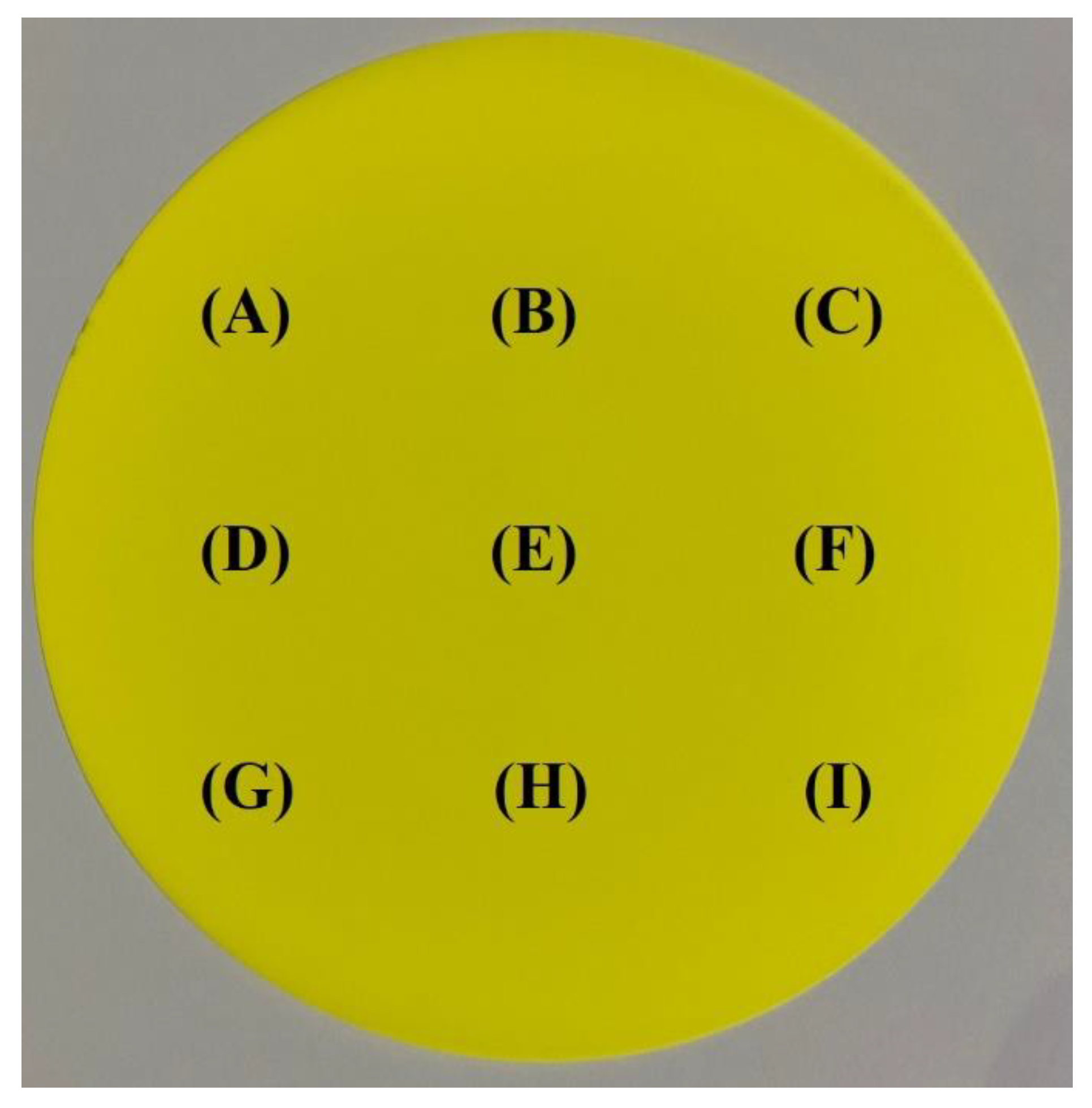

- Shih, H. K.; Liu, C. N.; Cheng W., C.; Cheng, W. H. High Performance and Reliability of Two-Inch Phosphor-in-Glass for White Light-Emitting Diodes Employing Novel Wet-Type Cold Isostatic Pressing. IEEE Photonics J. 2021, 13, 1–10. [Google Scholar] [CrossRef]

- Chen, L. Y.; Cheng, W. C.; Tsai, C. C.; Chang, J. K.; Huang, Y. C.; Huang, J. C.; Cheng, W. H. Novel broadband glass phosphors for high CRI WLEDs. Opt. Express 2014, 22, A671–A678. [Google Scholar] [CrossRef] [PubMed]

- Chen, L. Y.; Chang, J. K.; Cheng, W. C.; Huang, J. C.; Huang, Y. C.; Cheng, W. H. Chromaticity tailorable glass-based phosphor-converted white light-emitting diodes with high color rendering index. Opt. Express 2015, 23, A1024–A1029. [Google Scholar] [CrossRef] [PubMed]

| Formula | PiG-0.08 mm | PiG-0.10 mm | PiG-0.12 mm | PiG-0.15 mm |

|---|---|---|---|---|

| Amount of mixture (g) | 500 | 500 | 500 | 500 |

| Amount of glass matrix (g) | 350 | 380 | 400 | 420 |

| Amount of YAG: Ce3+ (g) | 150 | 120 | 100 | 80 |

| Sintering temperature (°C) | 700 | 700 | 700 | 700 |

| Diameter (inch) | 4 | 4 | 4 | 4 |

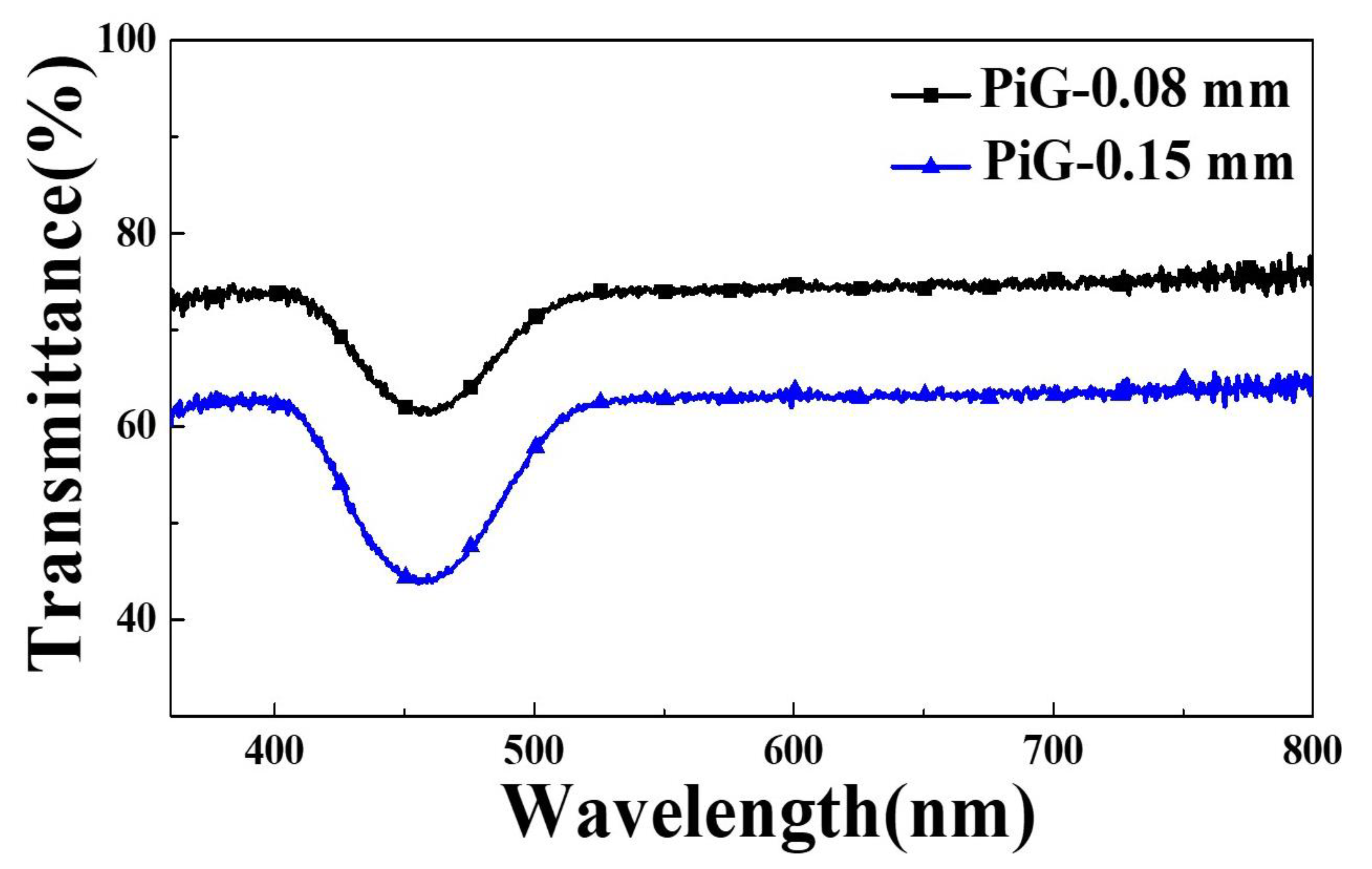

| Thickness of PiG bulk/plate (mm) | 25/0.08 | 25/0.10 | 25/0.12 | 25/0.15 |

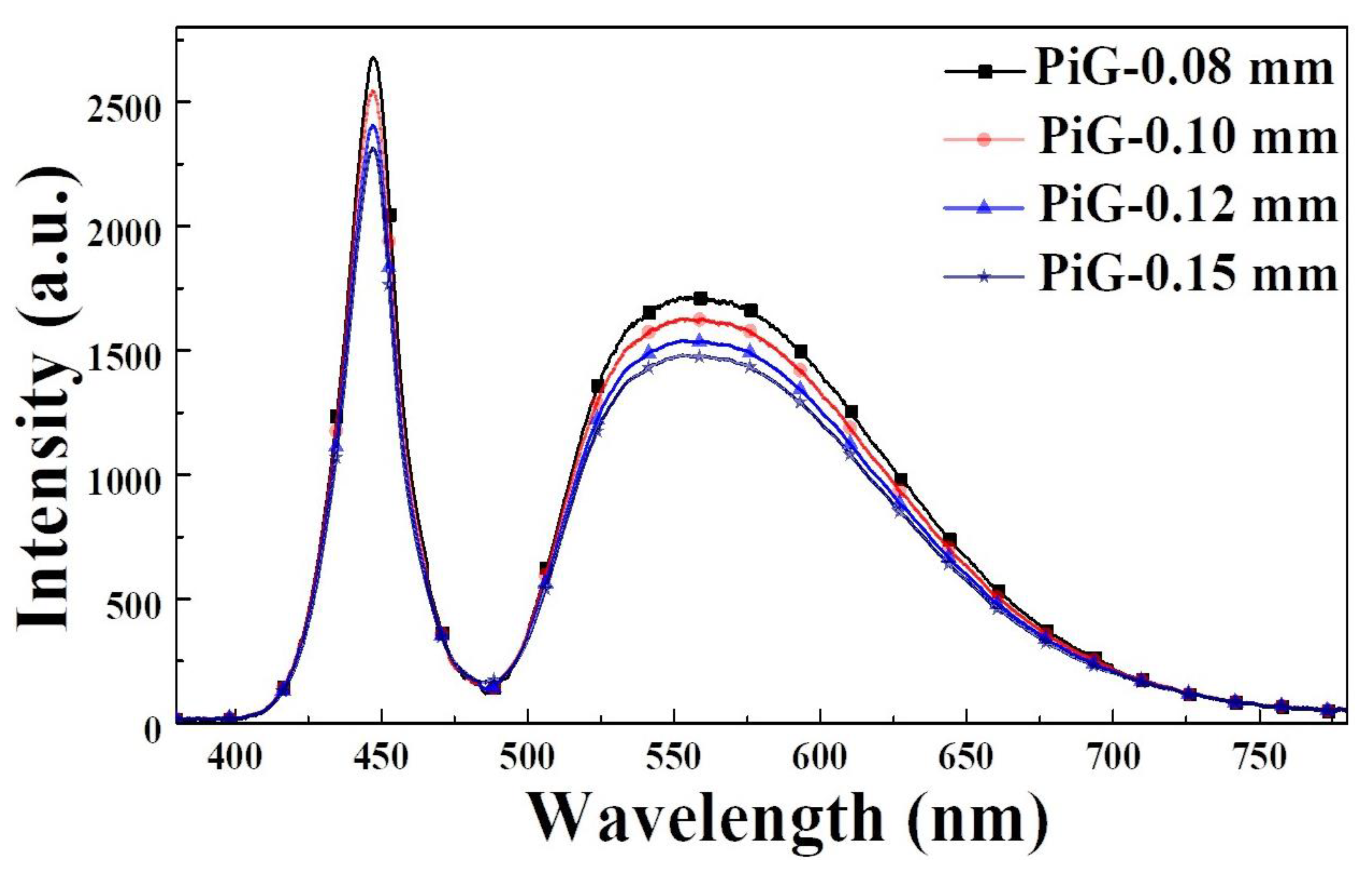

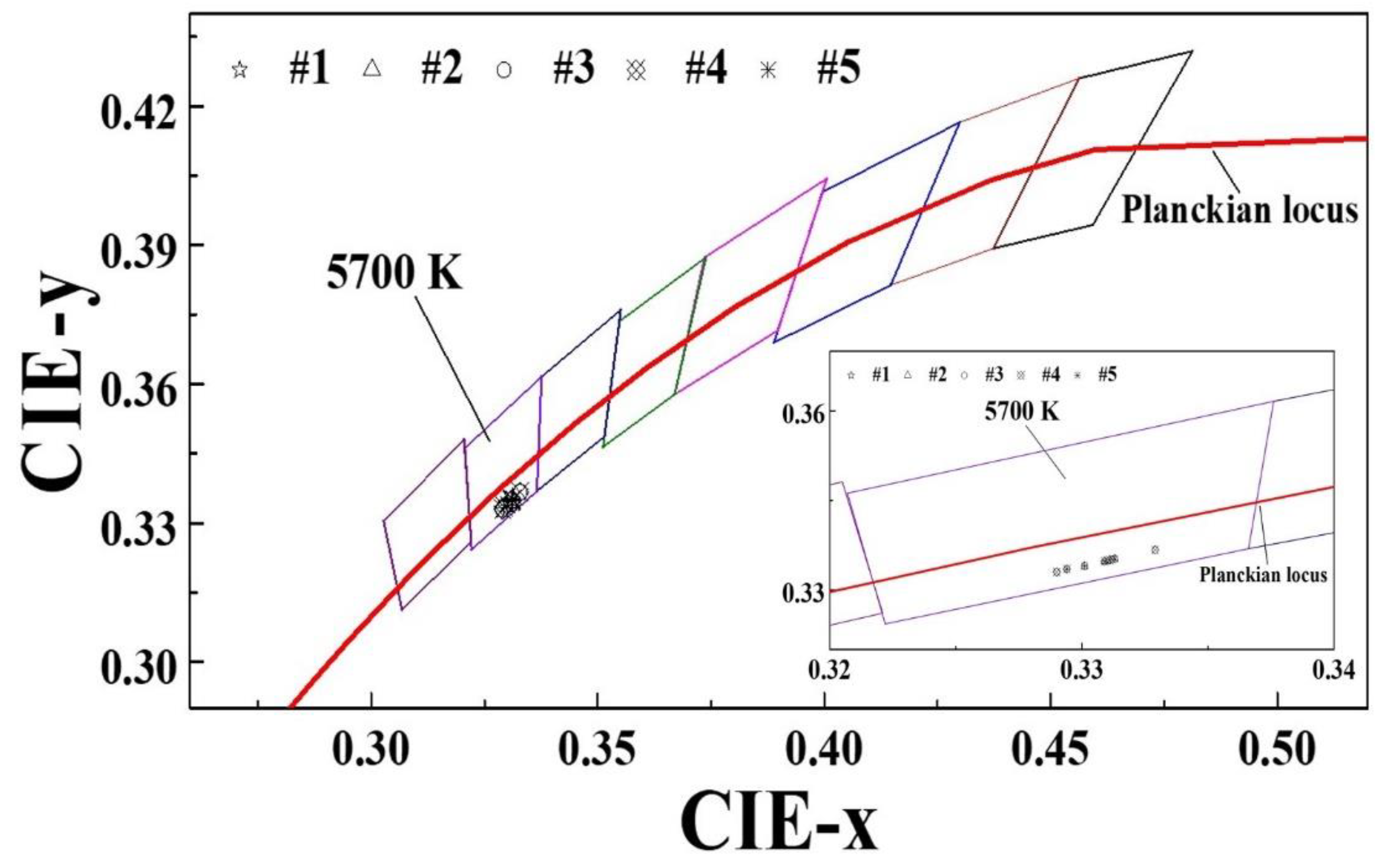

| Formula | Thickness (mm) | Light up | CIE (x, y) | CCT (K) | Luminous efficacy (lm/W) |

| PiG-0.15 mm | 0.15 |  |

(0.326, 0.335) | 5,700K ± 300 | 101 |

| PiG-0.12 mm | 0.12 |  |

(0.328, 0.337) | 5,700K ± 300 | 105 |

| PiG-0.10 mm | 0.10 |  |

(0.329, 0.338) | 5,700K ± 300 | 111 |

| PiG-0.08 mm | 0.08 |  |

(0.327, 0.336) | 5,700K ± 300 | 118 |

| Formula | PiG-0.08 mm | PiG-0.10 mm | PiG-0.12 mm | PiG-0.15 mm |

|---|---|---|---|---|

| Porosity of four-inch PiG (%) | 1.34 | 1.37 | 1.38 | 1.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).