Submitted:

25 April 2024

Posted:

28 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

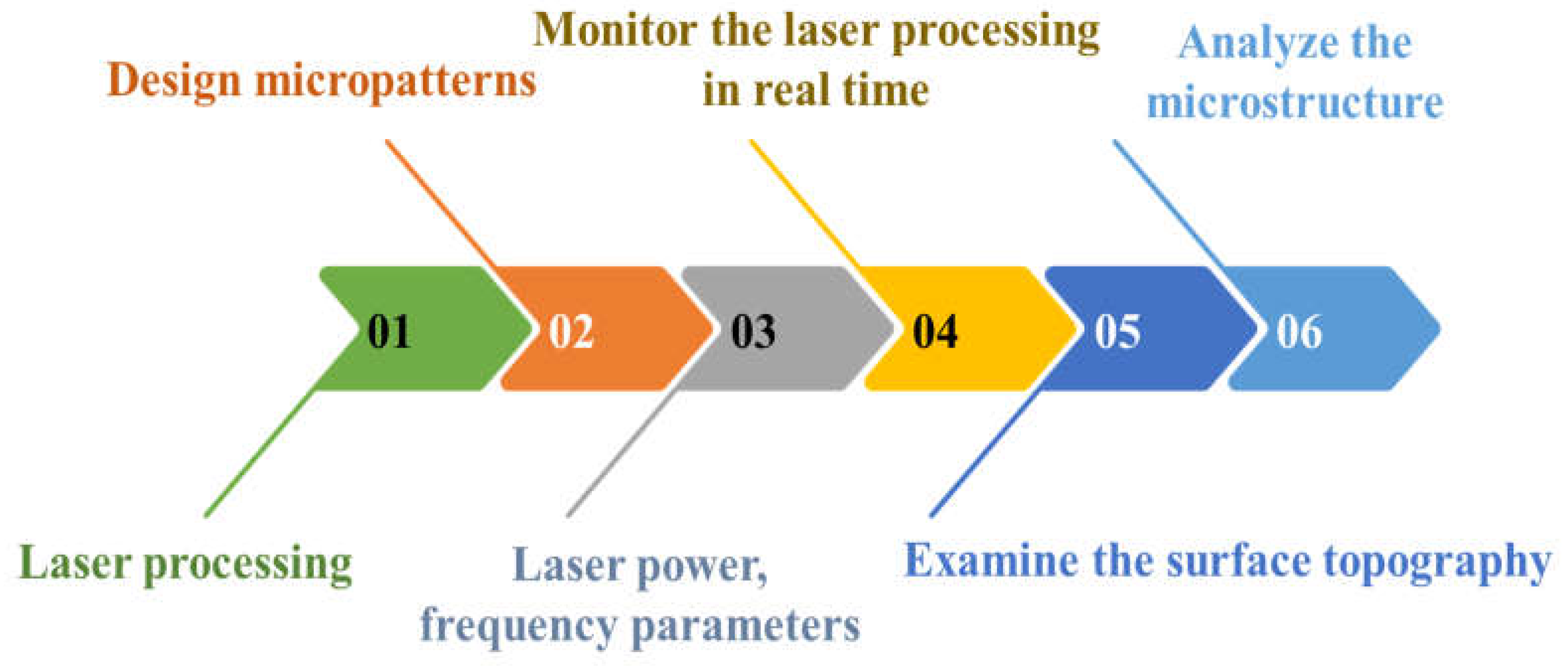

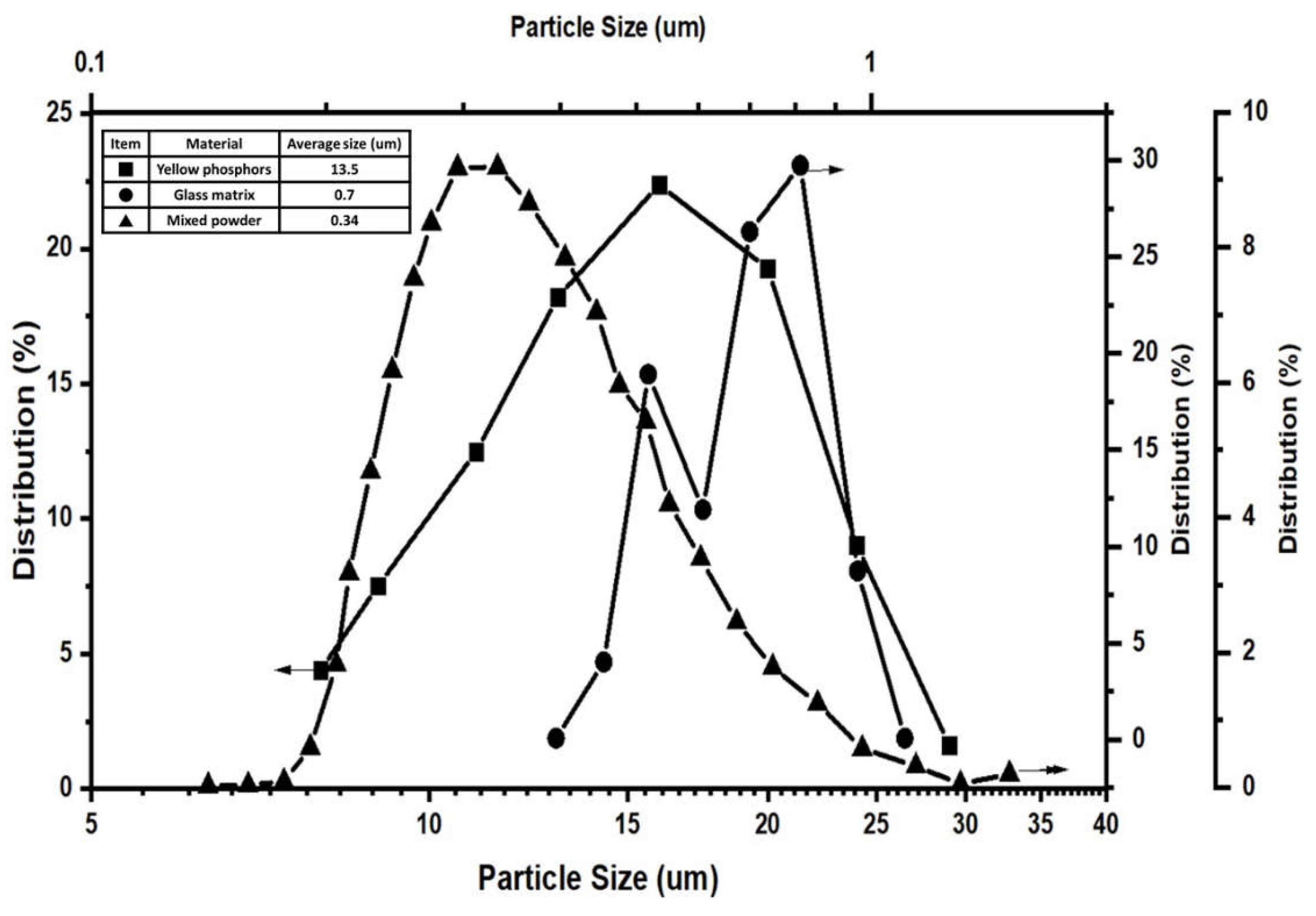

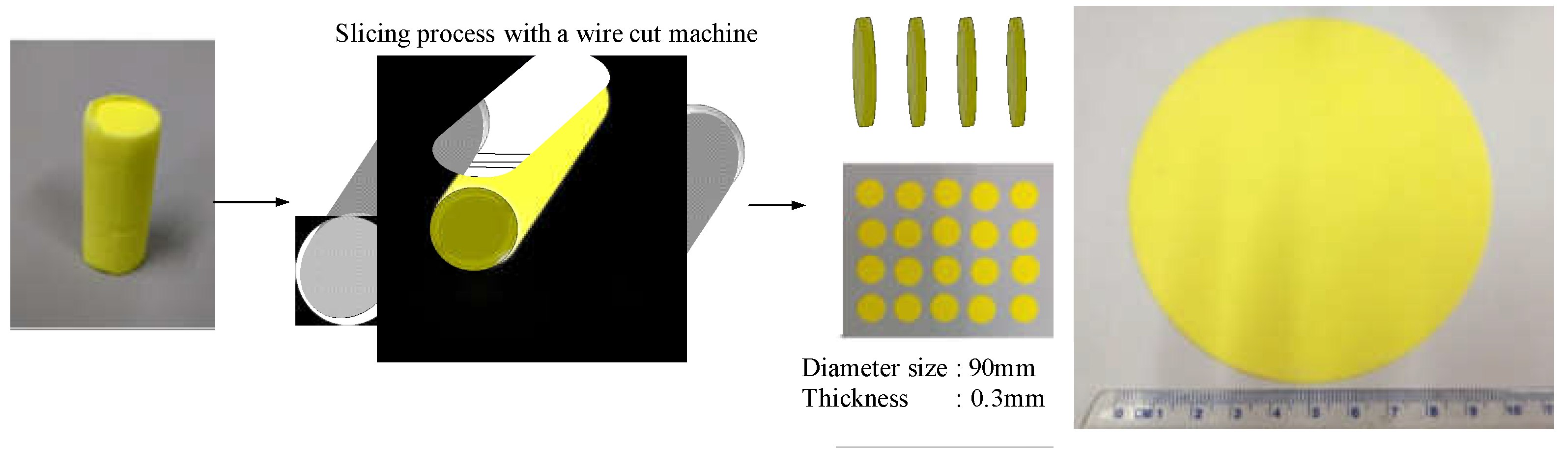

2. Fabrication

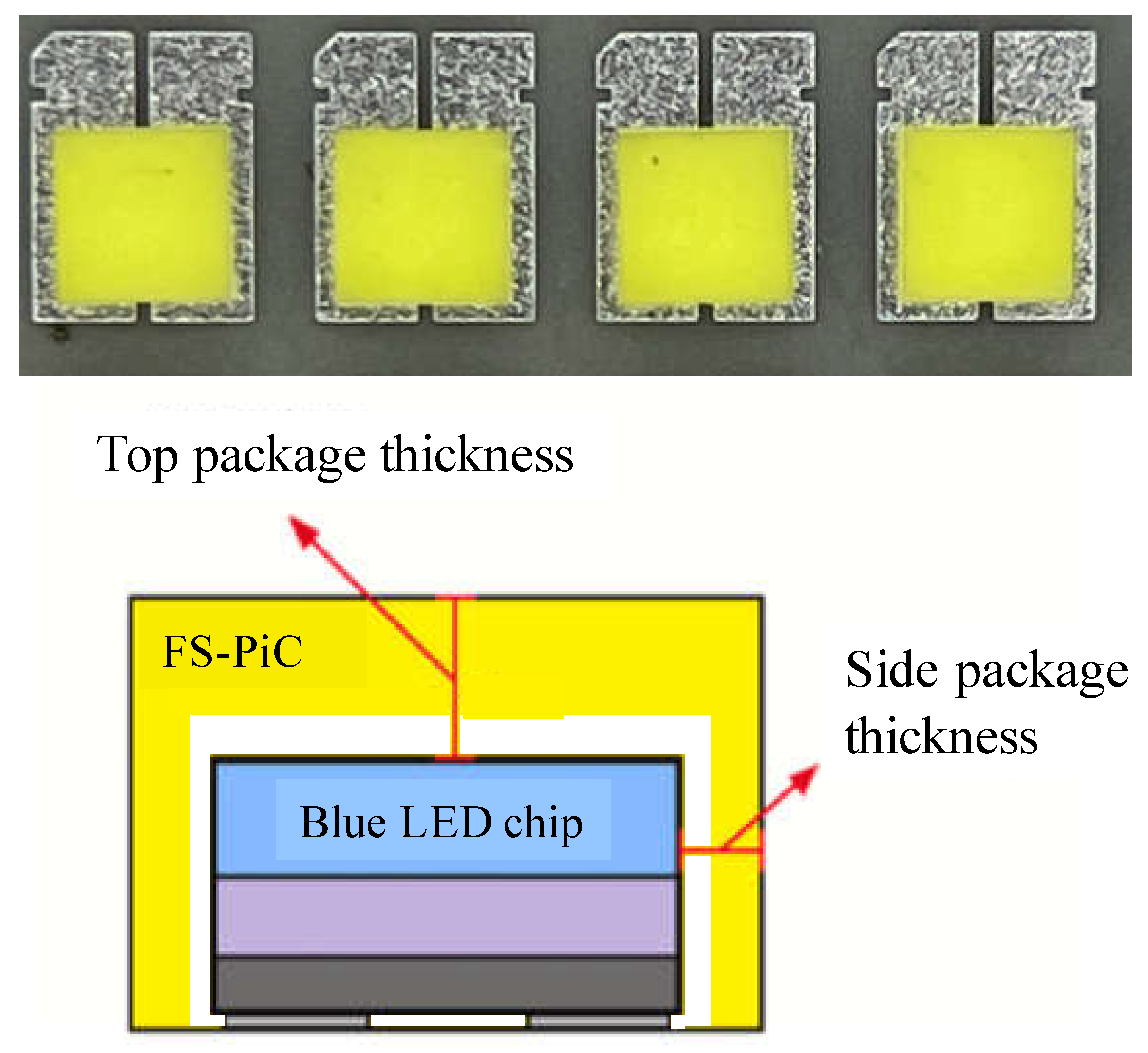

- Step 1:

- Positioning each FS-PiC structure and the blue LED array with the substrate ensures the surface is clean and dust-free to prepare the CSP.

- Step 2:

- Utilize a dispenser to apply translucent epoxy glue on each blue LED to ensure precise control of the glue's amount and placement.

- Step 3:

- The FS-PiC structure can be picked up using the vacuum nozzle and then transferred to the appropriate position before being placed onto the blue LED. Then, the pressing machine forms a sealed cavity between itself and the platform of the operating table, and it pumps the cavity into a vacuum, with a vacuum degree ranging from -95 to 100 kPa.

- Step 4:

- We controlled a fixed pressure of 20-30 kgf/cm2 and pressed for 5-10 mins with the pressing platform.

- Step 5:

- We put the blue LED-covered FS-PiC chip into the oven for sintering and curing to enable the adhesive to solidify. We maintain the sintering temperature at 150°C, usually taking about 2 hours. To achieve complete curing of the epoxy resin, we control the curing temperature at 120°C for 4 hours, as shown in Fugure 5.

3. Results and Discussion

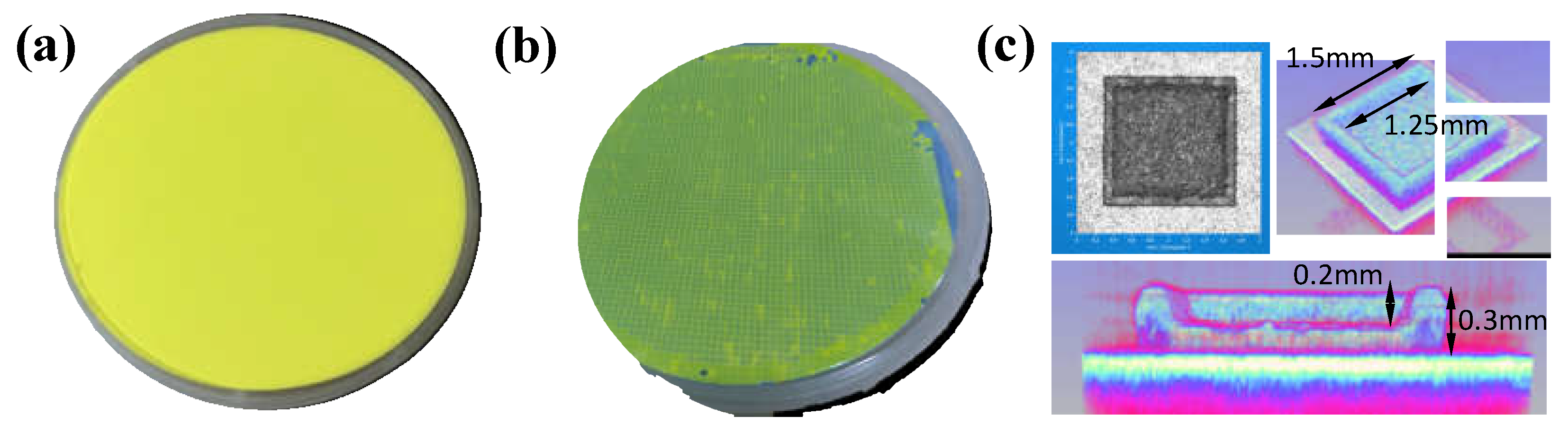

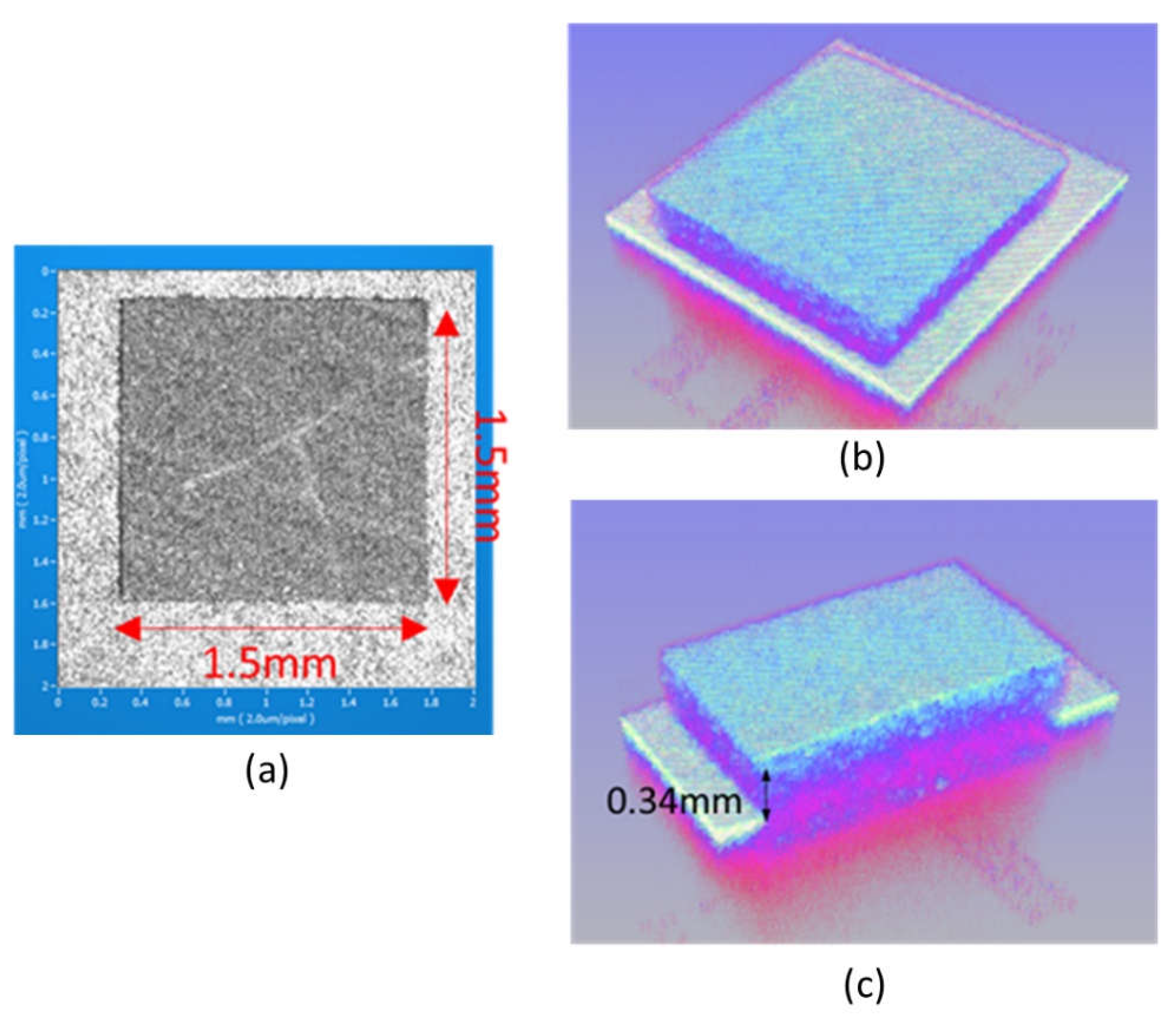

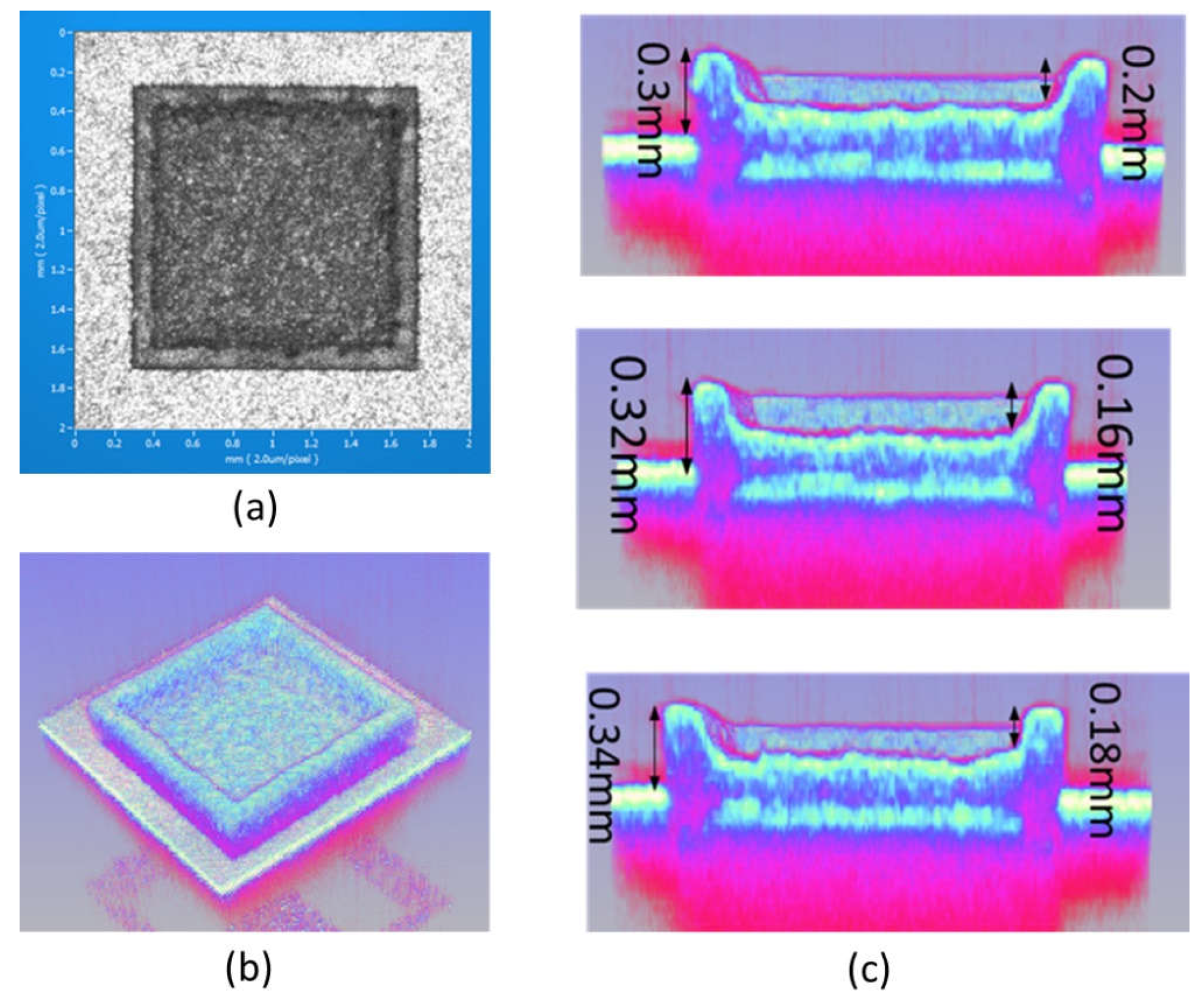

3.1. Analysis of the Laser Processing

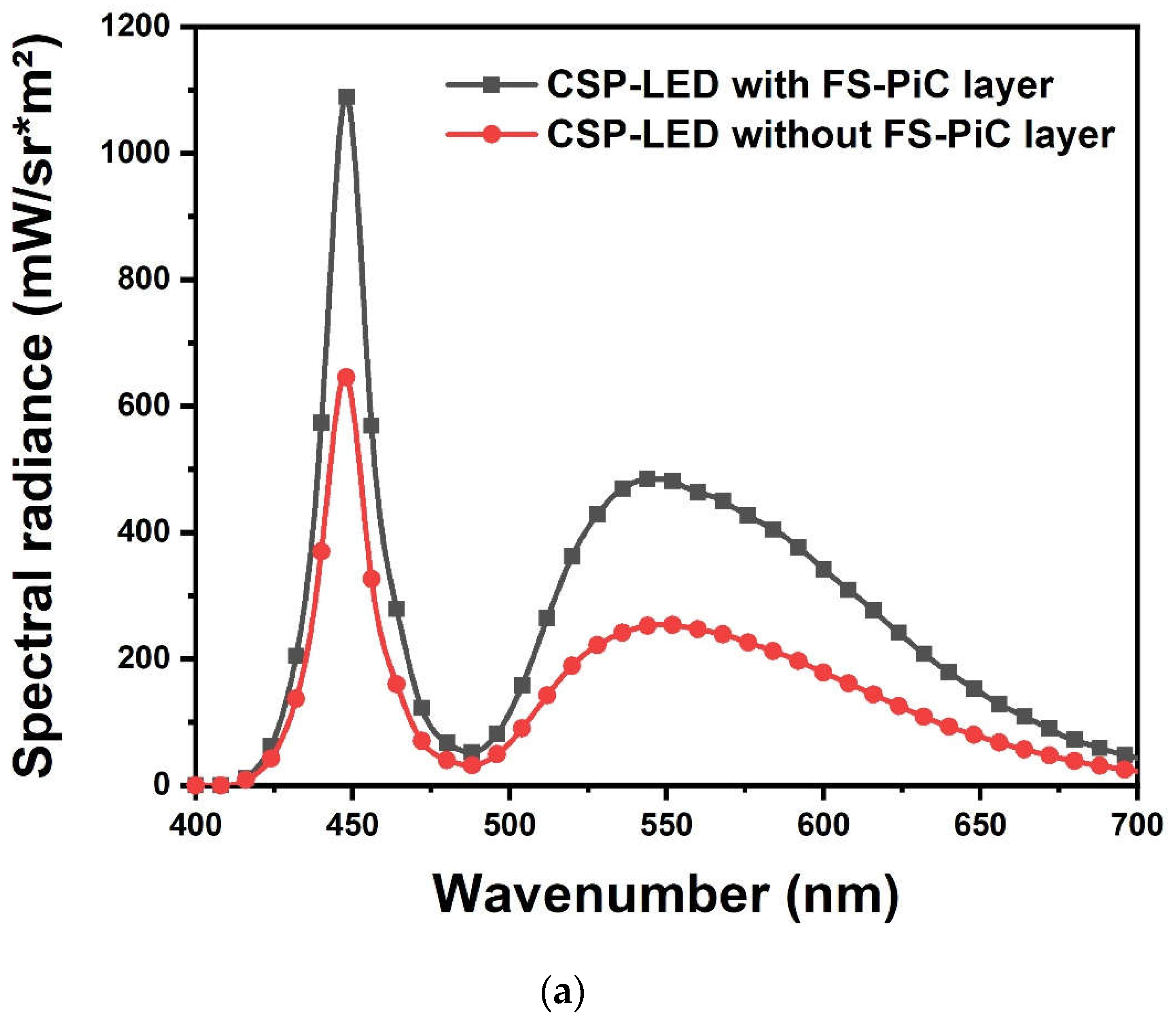

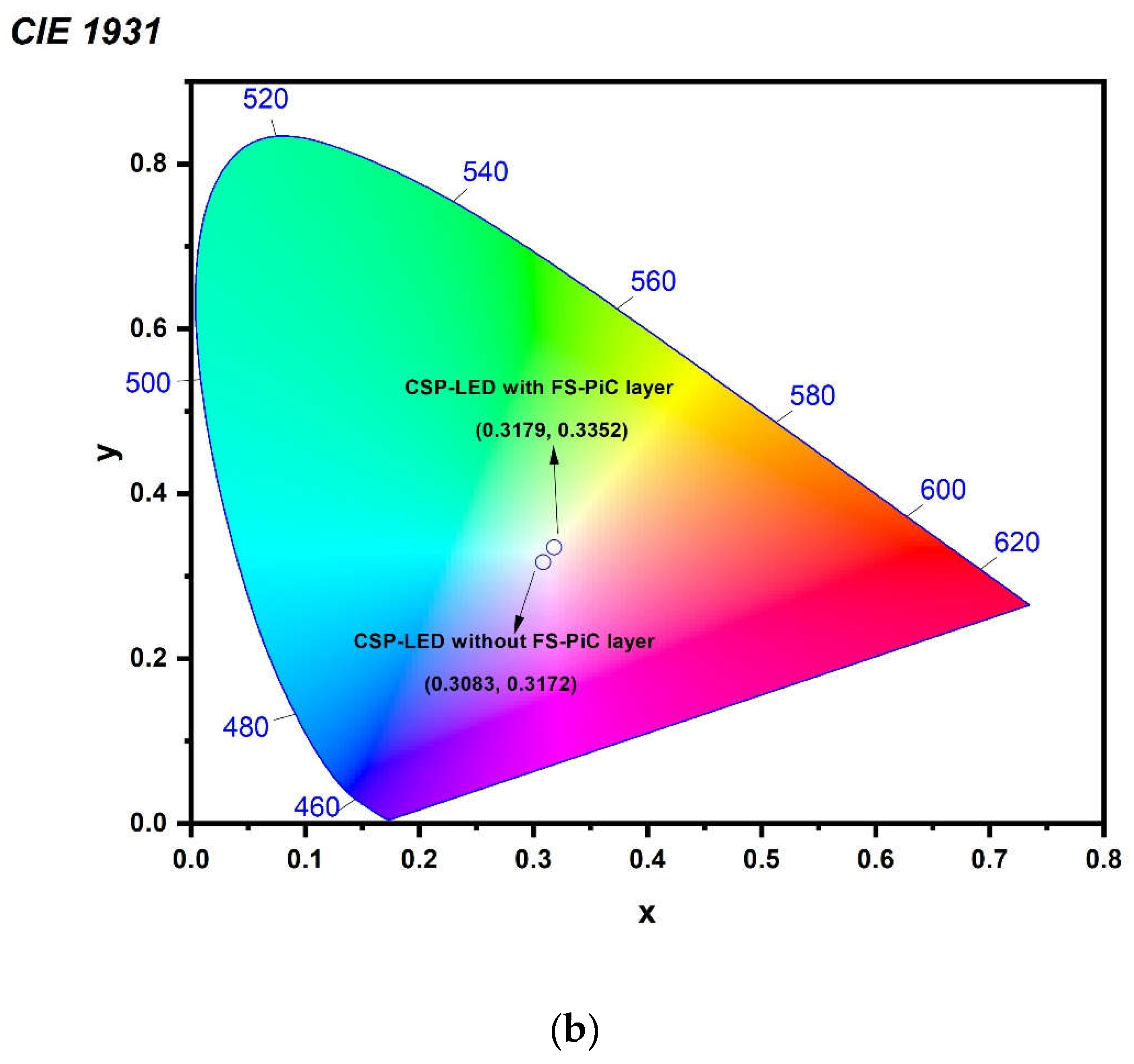

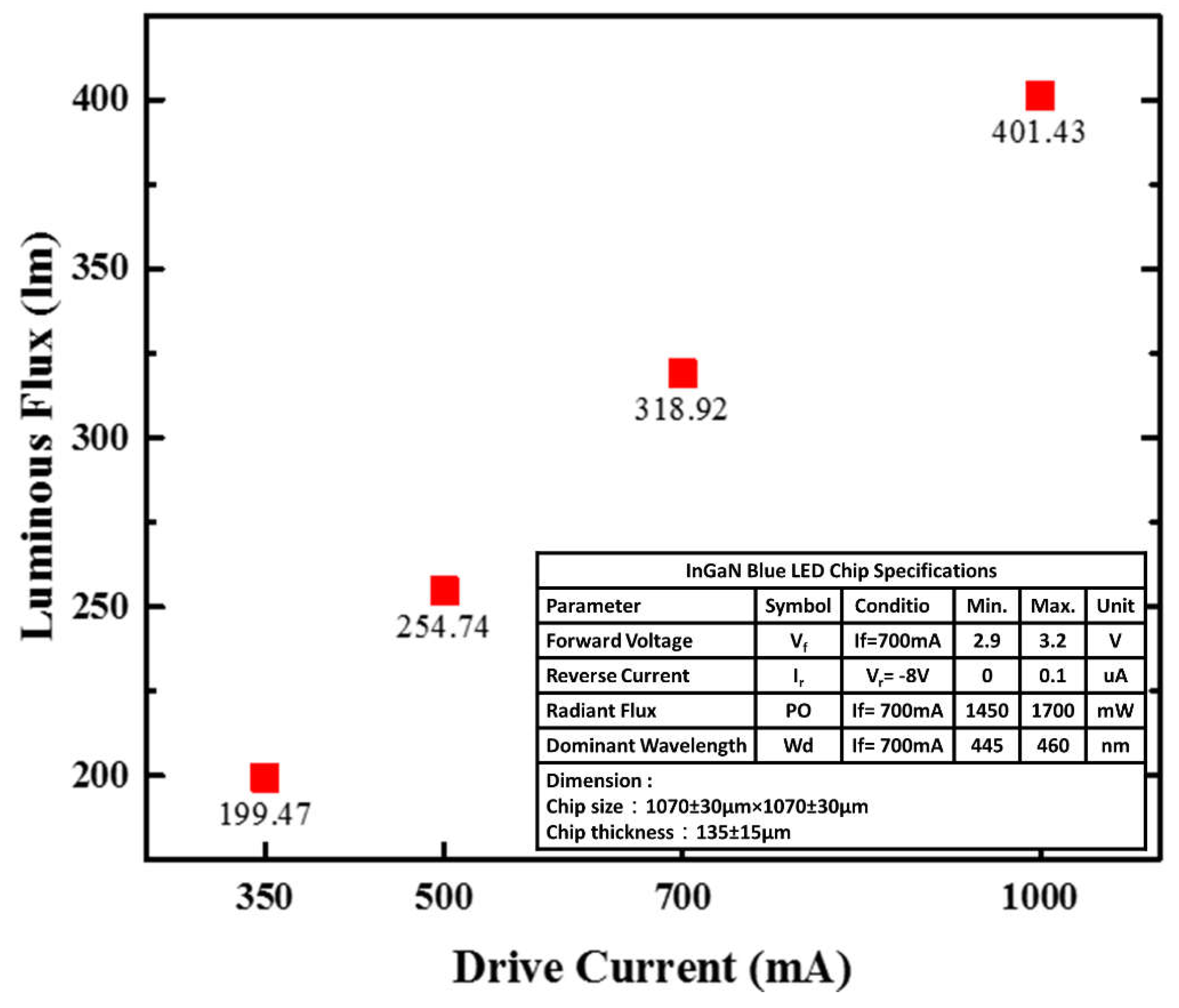

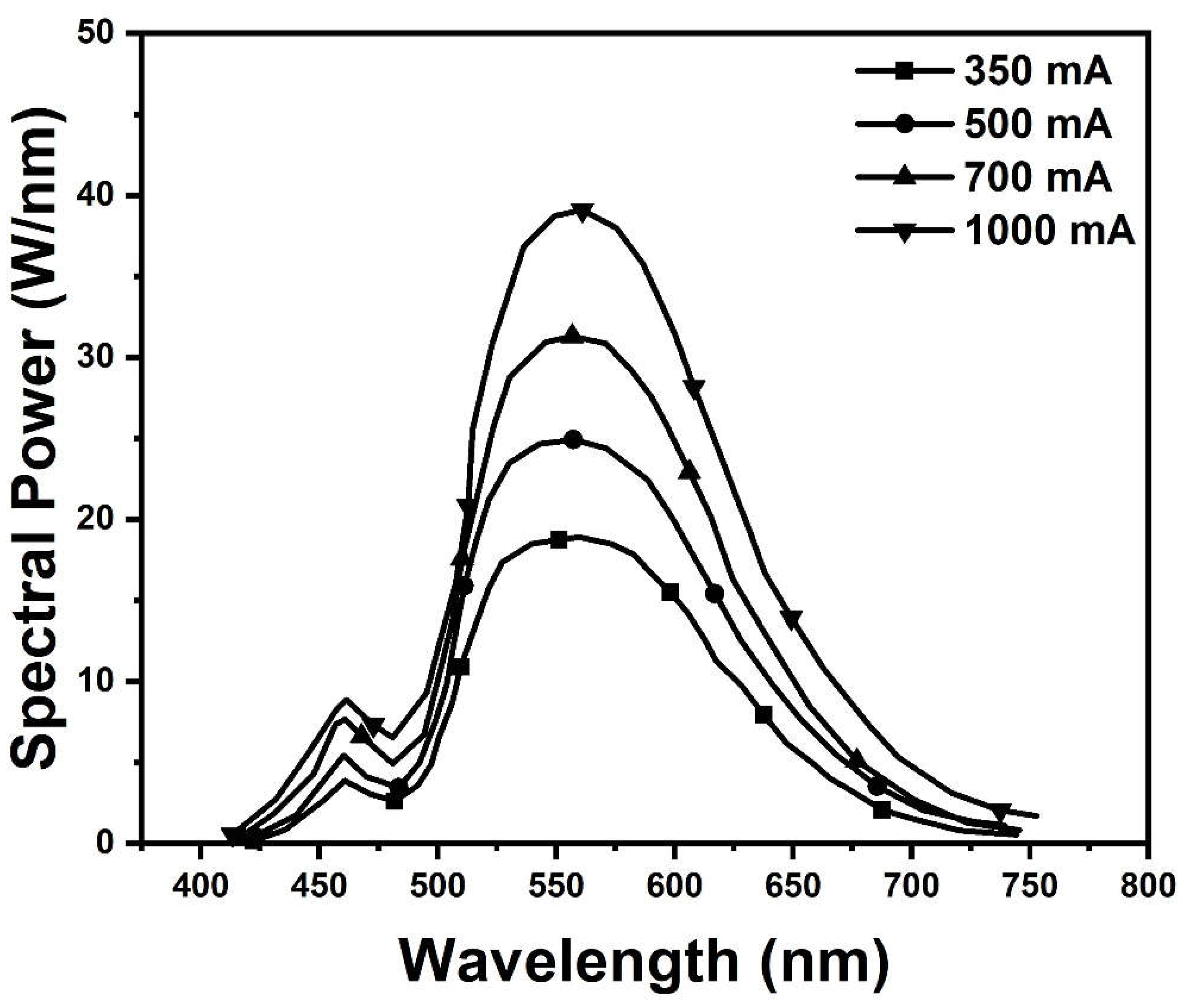

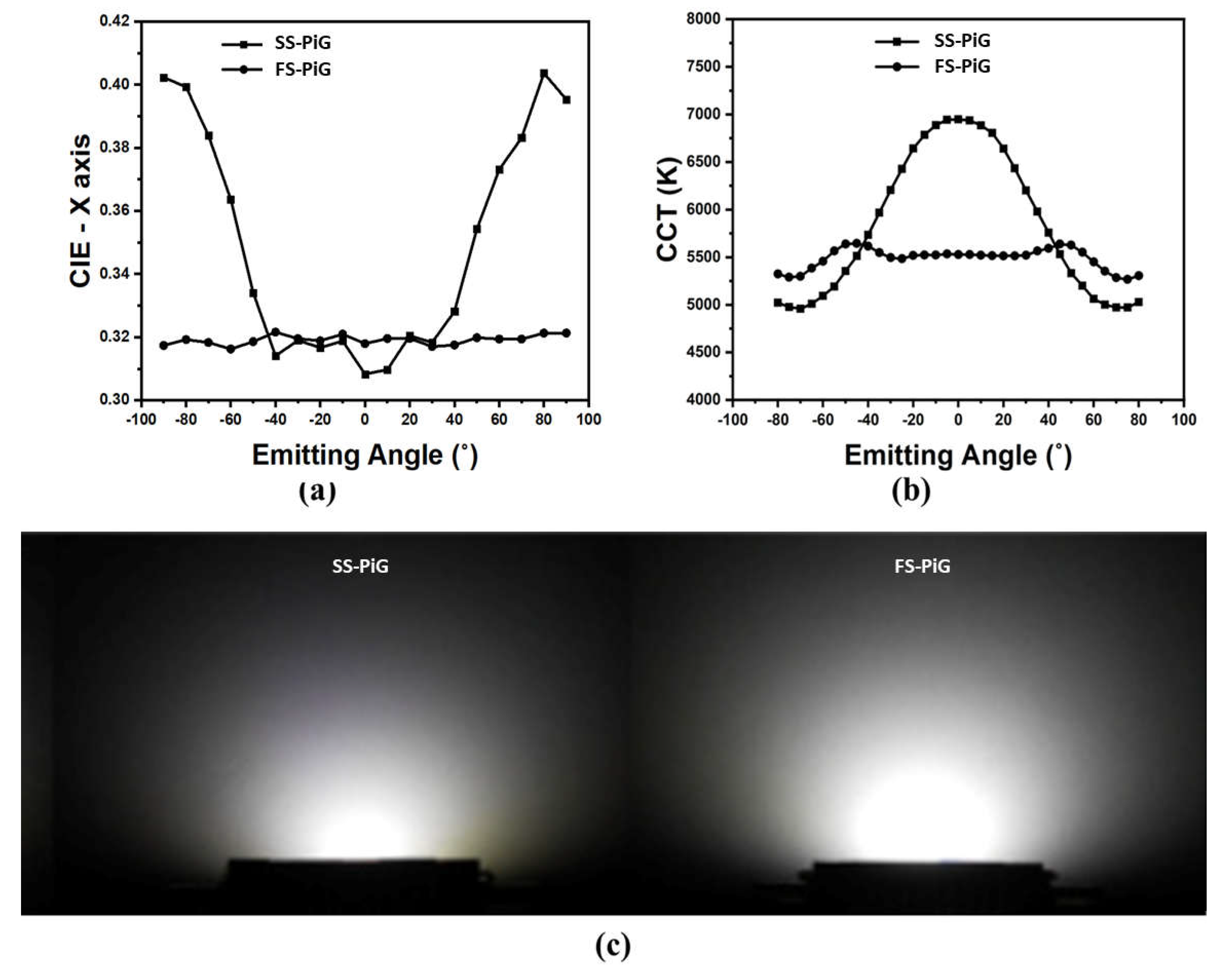

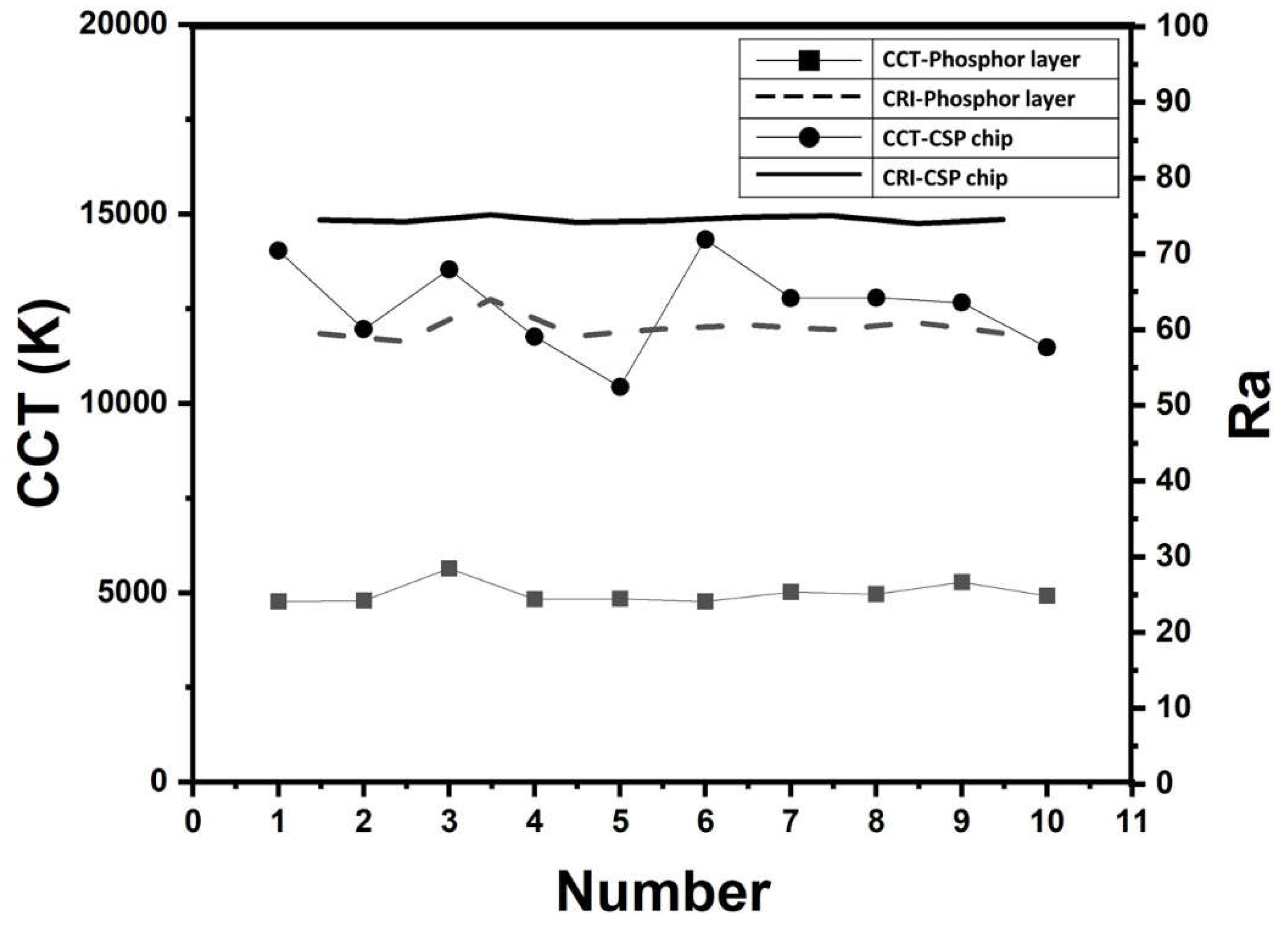

3.2. Optical Characterization

- Improved precision: Uniform light distribution can enhance measurement accuracy in optical measurements. The uniform light generated by FS-PiG LEDs helps reduce measurement deviations caused by uneven light spots or shadows.

- Reduction of deviations: Softer light can reduce light reflection and refraction, thereby minimizing optical deviations that may occur in sensors, enhancing measurement accuracy and reliability.

- Increased coverage: Due to the broader illumination range, FS-PiG LEDs can cover larger sensing areas, expanding the application range of sensors to accommodate a wider variety of objects of different sizes and shapes.

- Reduced calibration requirements: Uniform and soft lighting helps reduce the calibration needs of sensors. Sensor calibration becomes more accessible and accurate with a more stable and consistent light environment for measurements.

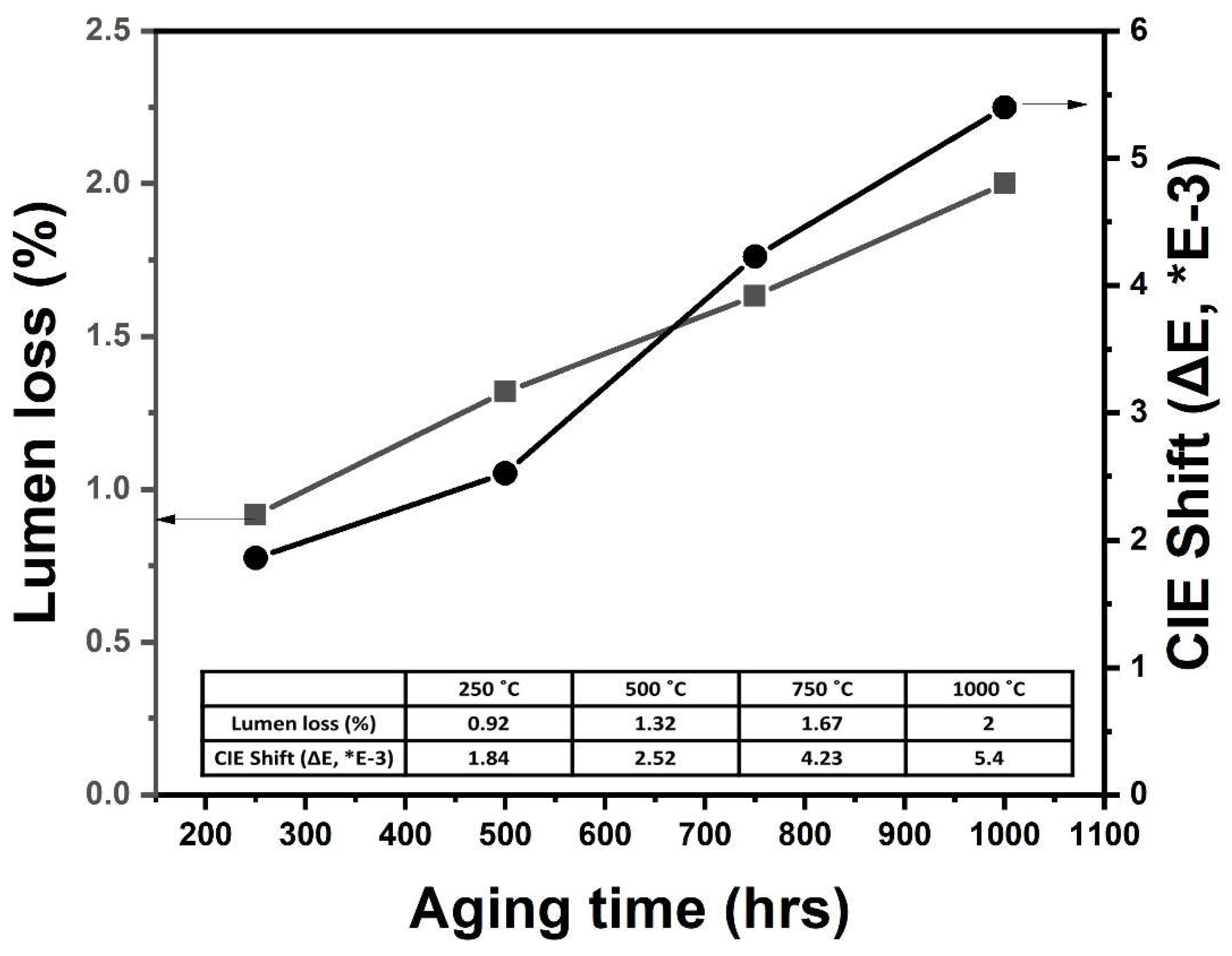

3.3. Thermal Stability

4. Discussion and Conclusions

5. Funding and Disclosures

5.1. Funding

5.2. Disclosures

References

- Pust, P.; Schmidt, P. J. and Schnick, W. A revolution in lighting. Nat. Mater. 2015, 14, 454–458. [Google Scholar] [PubMed]

- McKittrick, J.; Shea-Rohwer, L. E. Review: Down conversion materials for solid-state lighting. J. Amer. Ceram. Soc. 2014, 97, 1327–1352. [Google Scholar] [CrossRef]

- Chen, K. J.; Han, H. V.; Chen, H. C.; Lin, C. C.; Chien, S. H.; Huang, C. C.; Chen, T. M.; Shih, M. H.; Kuo, H. C. White light-emitting diodes with enhanced CCT uniformity and luminous flux using ZrO2 nanoparticles. Nanoscale 2014, 6, 5378–5383. [Google Scholar] [CrossRef] [PubMed]

- Ding, X.; Li, J.; Chen, Q.; Tang, Y.; Li, Z.; Yu, B. Improving LED CCT uniformity using micropatterned films optimized by combining ray tracing and FDTD methods. Opt. Exp. 2015, 23, A180–A191. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z. Y.; Li, C.; Yu, B. H.; Wang, Y. H.; Niu, H. B. Effects of YAG: Ce phosphor particle size on luminous flux and angular color uniformity of phosphor-converted white LEDs. J. Display Technol. 2012, 8, 329–335. [Google Scholar] [CrossRef]

- Sommer, C.; Krenn, J. R.; Hartmann, P.; Pachler, P.; Schweighart, M.; Tasch, S.; Wenzl, F. P. The effect of the phosphor particle sizes on the angular homogeneity of phosphor-converted high-power white LED light sources,” IEEE J. Sel. Top. Quant. 2009, 15, 1181–1188. [Google Scholar] [CrossRef]

- Li, J. S.; Chen, Y. H.; Li, Z. T.; Yu, S. D.; Tang, Y.; Ding, X. R.; Yuan, W. ACU optimization of pcLEDs by combining the pulsed spray and feedback method. J. Display Technol. 2016, 12, 1229–1234. [Google Scholar] [CrossRef]

- Li, J.; Li, Z.; Liang, G.; Yu, S.; Tang, Y.; Ding, X. Color uniformity enhancement for COBWLEDs using a remote phosphor film with two freeform surfaces. Opt. Exp. 2016, 24, 23685–23696. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Liu, S.; Wang, K.; Luo, X. Optical analysis of color distribution in white LEDs with various packaging methods. IEEE Photon. Technol. Lett. 2008, 20, 2027–2029. [Google Scholar]

- Kuo, H. C.; Hung, C. W.; Chen, H. C.; Chen, K. j.; Wang, C. H.; Sher, C. W.; Yeh, C. C.; Lin, C. C.; Cheng, Y. J. Patterned structure of remote phosphor for phosphor- converted white LEDs. Opt. Exp. 2011, 19, A930–A936. [Google Scholar] [CrossRef] [PubMed]

- Zheng, H.; Zhao, Z.; Wang, Y.; Li, L.; Liu, S. Effect of patterned substrate on light extraction efficiency of chip-on-board packaging LEDs, in IEEE 64th Electron. Compon. Technol. Conf. (ECTC) 2014, 1876–1879. [Google Scholar]

- Mao, P.; Mahapatra, A. K.; Chen, J.; Chen, M.; Wanf, G.; Han, M. Fabrication of Polystyrene/ZnO Micronano Hierarchical Structure Applied for Light Extraction of Light-Emitting Devices. ACS Appl. Mater. Interfaces 2015, 7, 19179–19188. [Google Scholar] [CrossRef] [PubMed]

- Sun, B.; Zhao, L.; Wei, T.; Yi, X.; Liu, Z.; Wang, G.; Li, J.; Yi, F. Light extraction enhancement of bulk GaN light-emitting diode with hemisphere-cones-hybrid surface. J. Display Technol. 2013, 9, 317–323. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Tang, Y.; Li, J.; Wu, C.; Ding, X.; Yu, B. High Color Uniformity of White Light-Emitting Diodes Using Chip-Scaled Package. IEEE Photonic. Tech. L. 2018, 30, 989–992. [Google Scholar] [CrossRef]

- Li, Z. T.; Tang, Y.; Liu, Z. Y.; Tan, Y. E.; Zhu, B. M. Detailed study on pulse-sprayed conformal phosphor configurations for LEDs. J. Display Technol. 2013, 9, 433–440. [Google Scholar] [CrossRef]

- Zheng, H.; Ma, J.; Luo, X. Conformal phosphor distribution for white lighting emitting diode packaging by conventional dispensing coating method with structure control. IEEE Trans. Compon. Packag. Manuf. Technol. 2013, 3, 417–421. [Google Scholar] [CrossRef]

- Kwon, S. B.; Yoo, J. H.; Choi, S. H.; Na, M.; Kim, B. Y.; Lee, S. Y.; Jeong, H. J.; Kim, W. H.; Park, S. H.; Yoon, H. S.; Kang, B. K.; Song, Y. H.; Yoon, D. H. Preparation of high-quality YAG:Ce3+ ceramic phosphor by high-frequency induction heated press sintering methods. Sci. Rep. 2022, 12, 20477. [Google Scholar] [CrossRef]

- Pulli, T.; Dönsberg, T.; Poikonen, T.; Manoocheri, F.; Kärhä, P.; Ikonen, E. Advantages of white LED lamps and new detector technology in photometry. Light Sci. Appl. 2015, 4, e332. [Google Scholar] [CrossRef]

| Glass matrix (wt%) | YAG: Ce3+ (wt%) | Sintering temperature (˚C) | Diameter (in) | |

|---|---|---|---|---|

| PiC | 84 | 16 | 700 | 4 |

| Parameter | |

|---|---|

| Wavelength | 1064 nm |

| Laser power | 44 W |

| Pulse repetition rate | 350 kHz |

| Focal spot diameter | 13μm to 15 μm |

| Pulse width | 15 ps |

| Cutting speed | 1300 mm/s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).