Submitted:

03 July 2024

Posted:

04 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

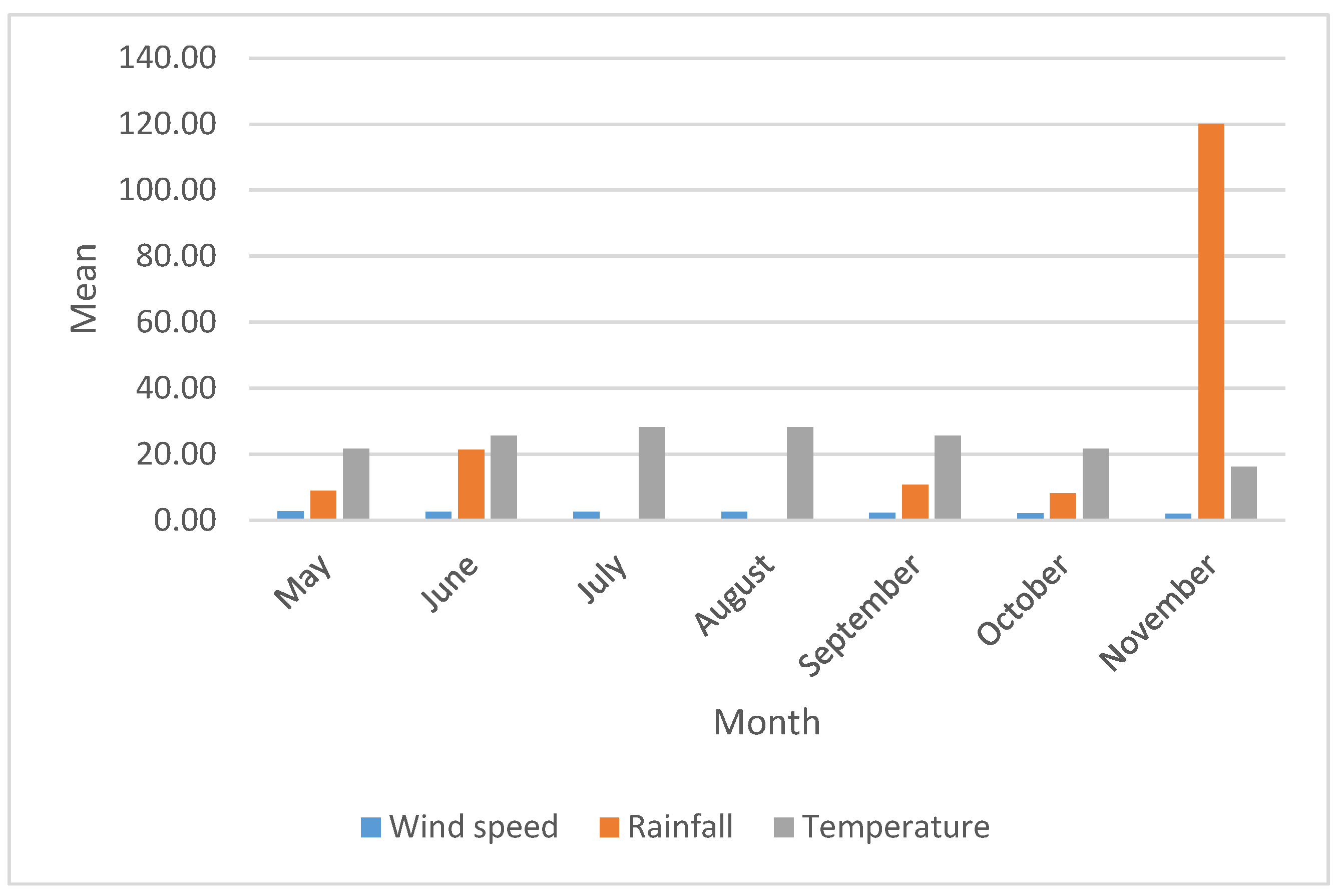

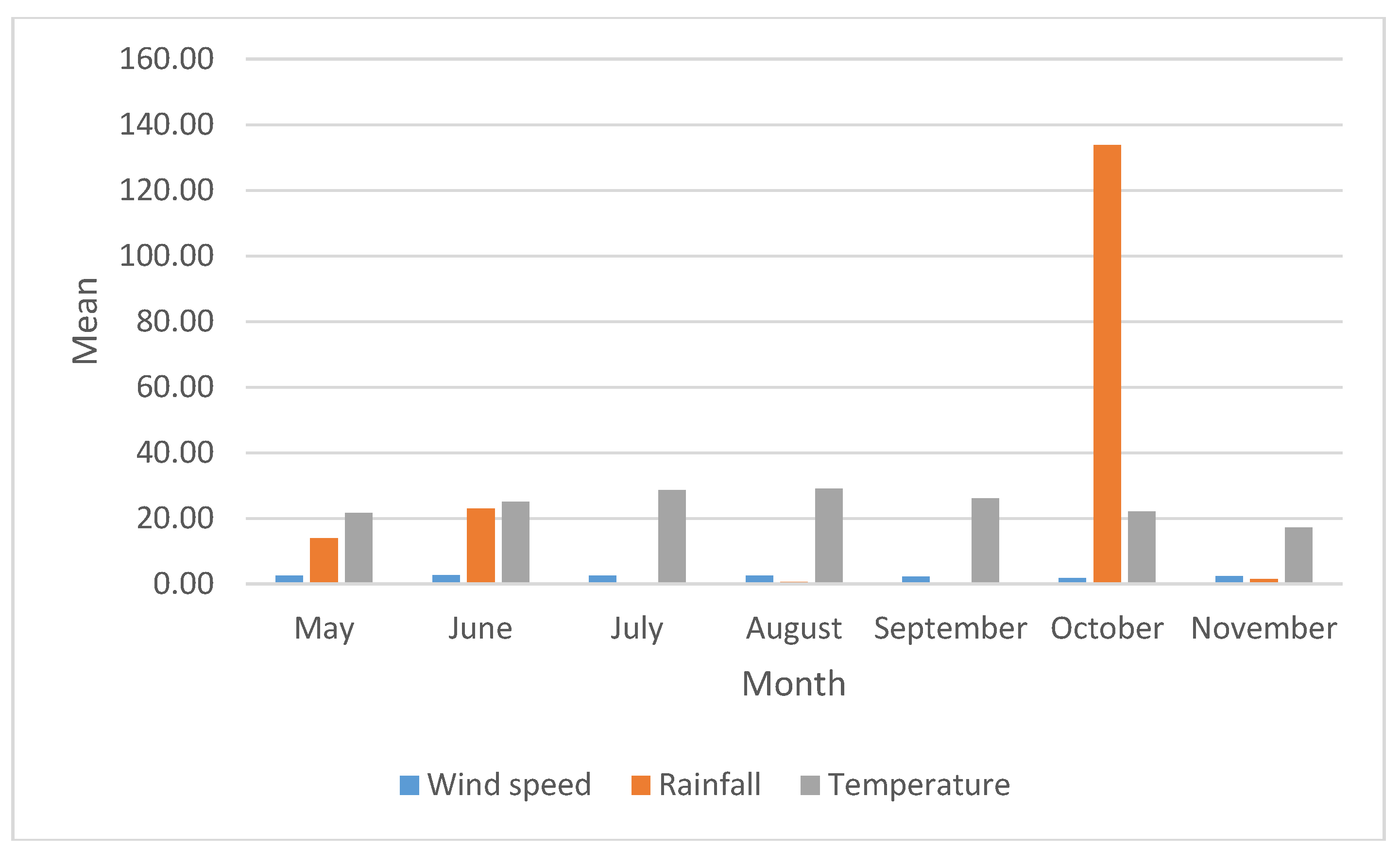

2.1. Description of the Study Site

2.2. Experimental Design, Treatments and Field Management

2.3. Data Collection

- i.

- Canopy architecture

- ii.

- Fiber percent

- iii.

- Fiber quality

2.4. Statistical Analysis

3. Results

3.1. Analysis of Variance (ANOVA)

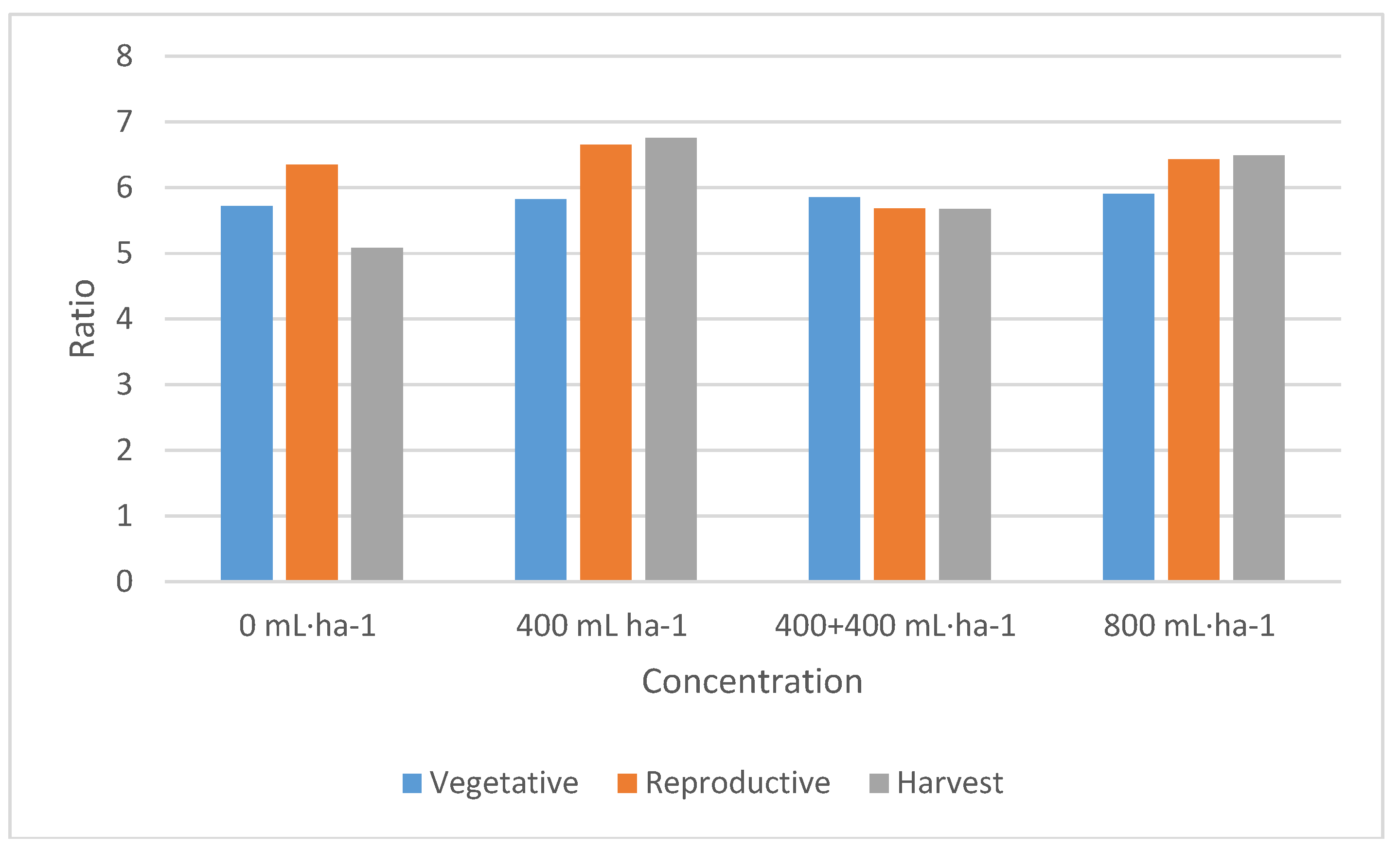

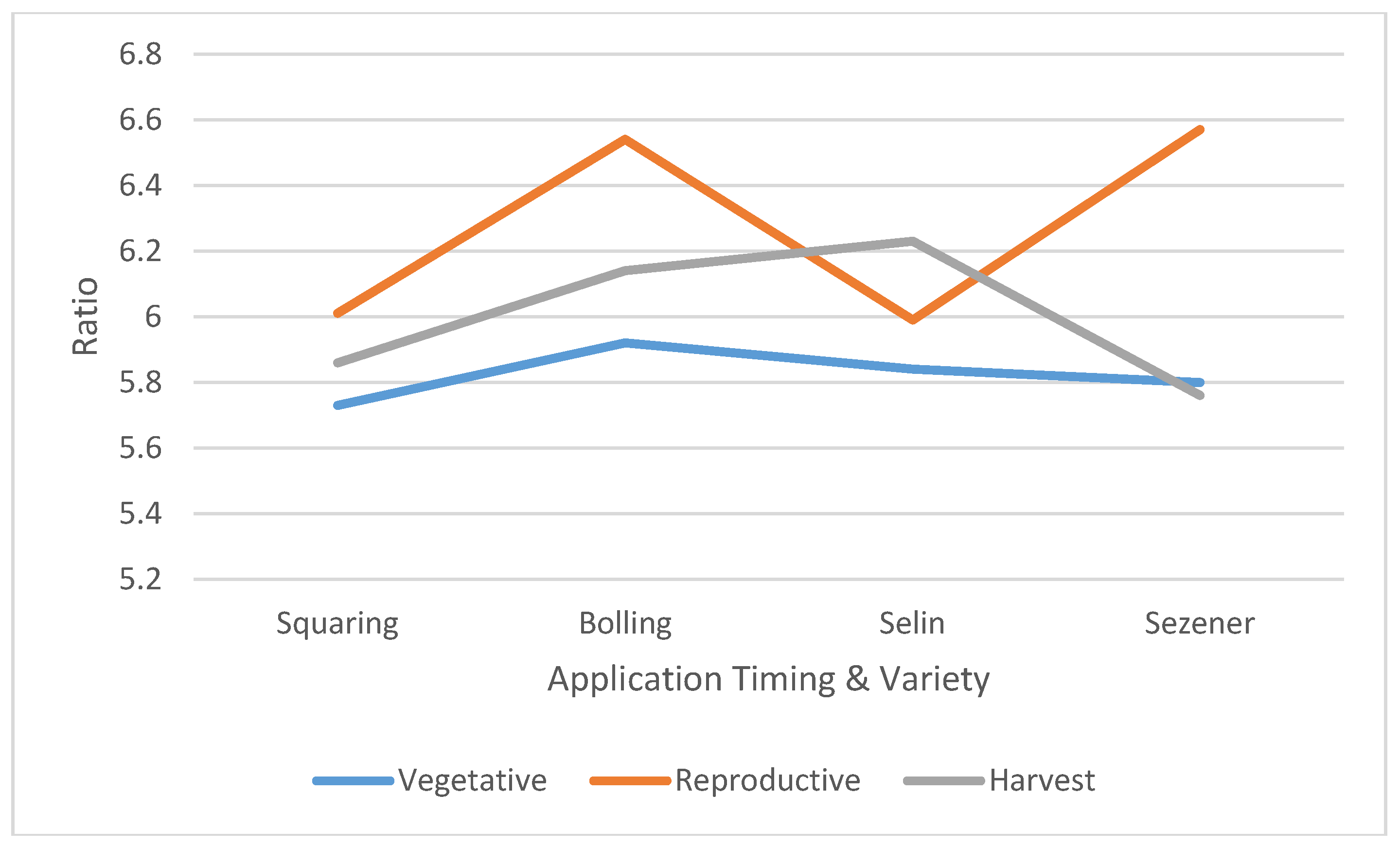

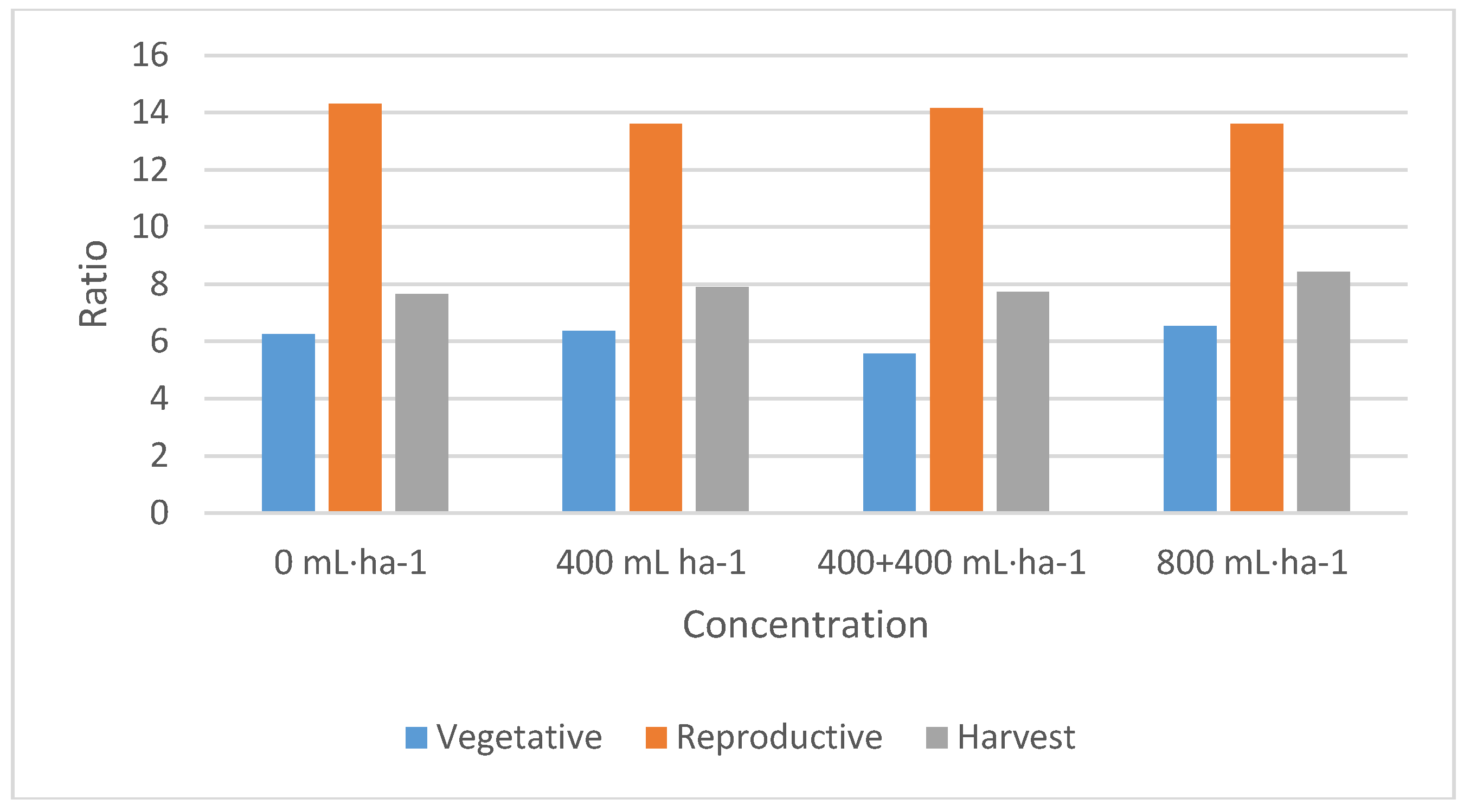

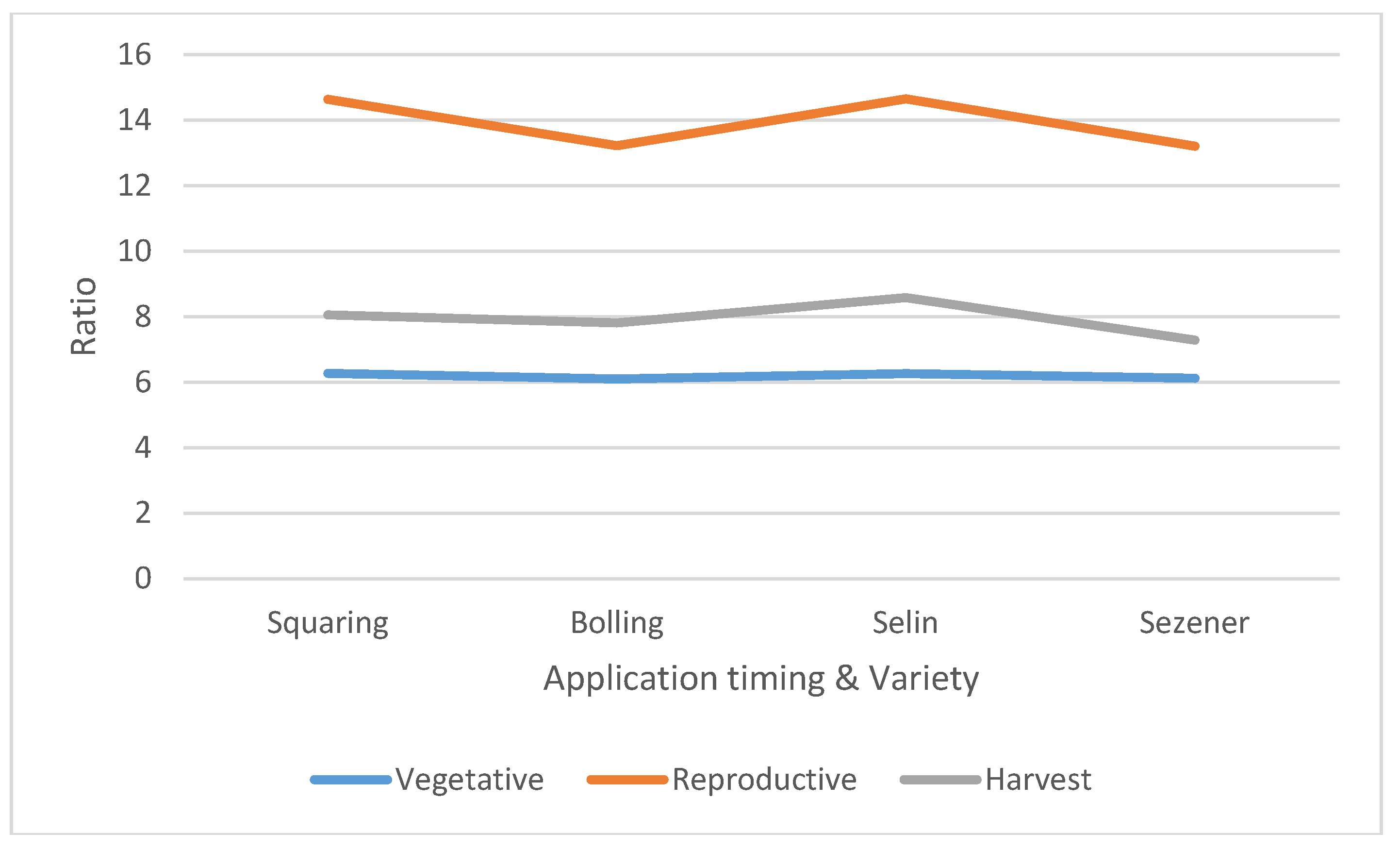

3.2. Outcome of Mepiquat Chloride on Shoot-Root Ratio at Different Growth Stages

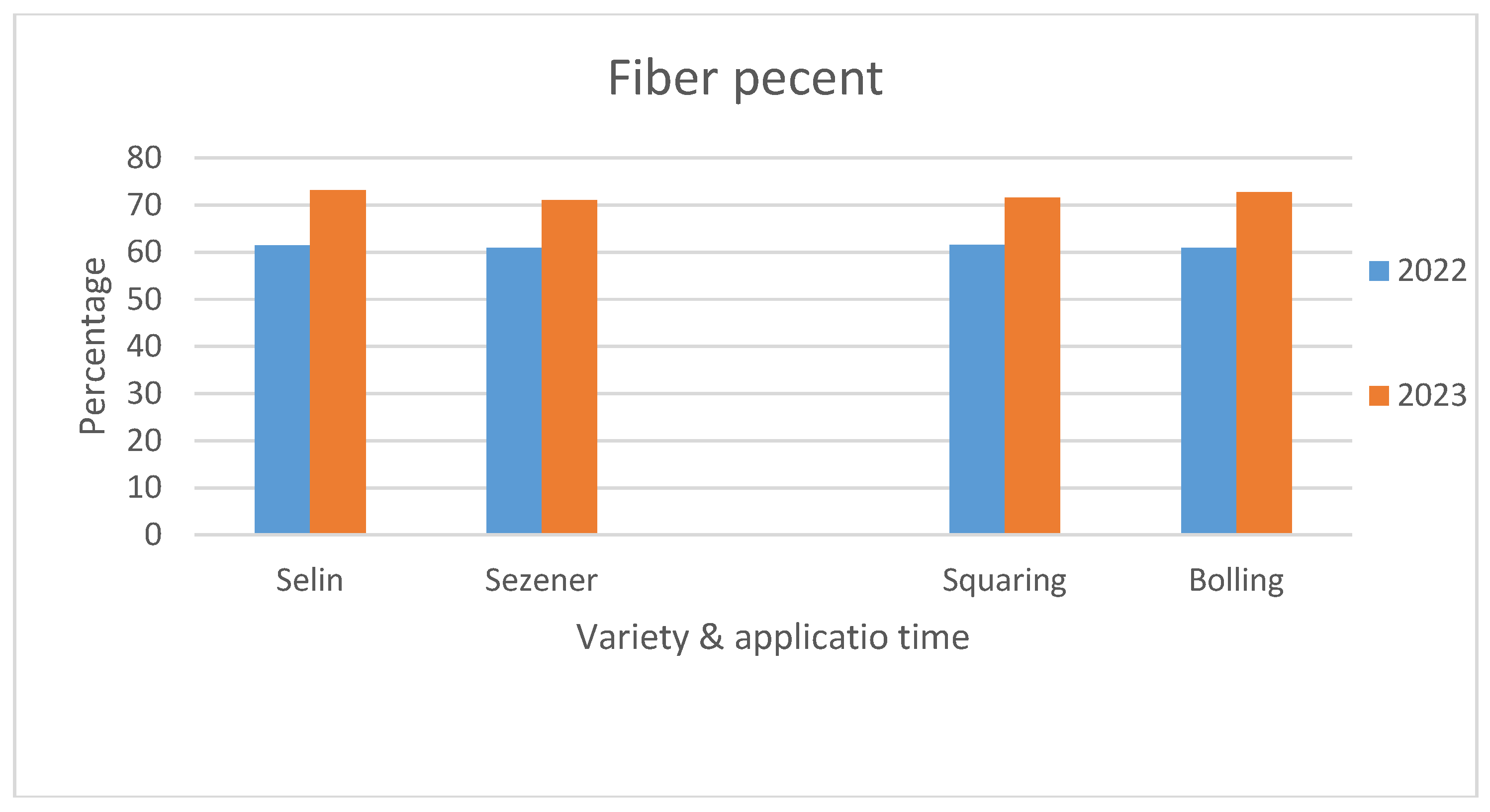

3.3. Outcome of Mepiquat Chloride on fiber percent

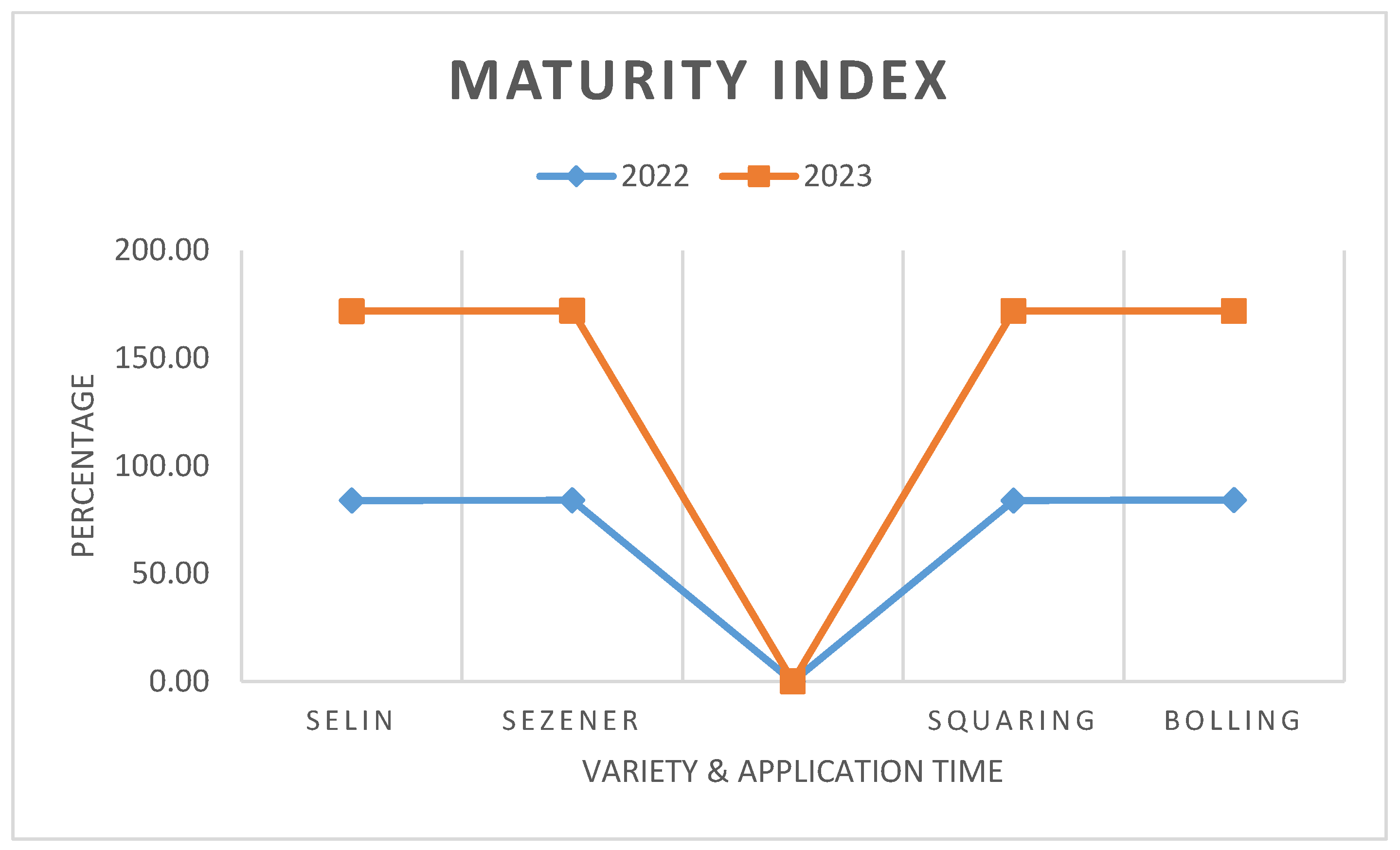

3.4. Outcome of Mepiquat Chloride on maturity index

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- K. Priyanka, M. S. Rekha, K. Lakshman, and C. S. Rao, “Effect of plant growth regulators on growth and yield of HDPS cotton,” Journal of Cotton Research and Development, vol. 36, no. 1, pp. 65–70, 2022.

- Huckell, L.W. Plant Remains from the PinaleñO Cotton Cache, Arizona. KIVA 1993, 59, 147–203. [Google Scholar] [CrossRef]

- Fatima, S.; Aslam, R.; Shahzadi, K.; Awan, H.; Nadeem, M.; Shabir, M.; Shafiq, Y.; Hamid, M. Effect of Drought Stress at Growth and Development of Pea (Pisum sativum L.). Asian J. Res. Crop. Sci. 2024, 9, 76–80. [Google Scholar] [CrossRef]

- S. Çelik, “Assessing Drought Tolerance in a Large Number of Upland Cotton Plants (Gossypium hirsutum L.) under Different Irrigation Regimes at the Seedling Stage,” Life, vol. 13, no. 10, p. 2067, Oct. 2023. [CrossRef]

- M. Kossivi Soviadan, E. Mitowanou Koffi-Tessio, A. Anibueze Enete, N. Jackson Nweze, and M. K. Soviadan, “Impact of Climate Change on Cotton Production: Case of Savannah Region, Northern Togo,” Agricultural Sciences, Scientific research, vol. 10, no. 07, pp. 927–947, 1974. [CrossRef]

- Farooq, A., Shakeel, S. Ahmad, T. M. Khan, and I. Afzal, “Evaluation of breeding potential of cotton germplasm of Pakistan origin for fiber quality traits under heat stress,” Int J Agric Biol, vol. 23, no. 2, 2020. [CrossRef]

- R. Ekinci, S. Basbağ, E. Karademir, and Ç. Karademir, “THE EFFECTS OF HIGH TEMPERATURE STRESS ON SOME AGRONOMIC CHARACTERS IN COTTON,” Pak. J. Bot, vol. 49, no. 2, pp. 503–508, 2017.

- Mertoğlu, K.; Evrenosoğlu, Y.; Polat, M. Combined effects of ethephon and mepiquat chloride on late blooming, fruit set, and phytochemical characteristics of Black Diamond plum. Turk. J. Agric. For. 2019, 43, 544–553. [Google Scholar] [CrossRef]

- Jans, Y.; von Bloh, W.; Schaphoff, S.; Müller, C. Global cotton production under climate change – Implications for yield and water consumption. Hydrol. Earth Syst. Sci. 2021, 25, 2027–2044. [Google Scholar] [CrossRef]

- Wu, F.; Yang, B.; Guo, S.; Huang, W.; Lei, Y.; Xiong, S.; Han, Y.; Wang, Z.; Feng, L.; Li, X.; et al. Adopting different cotton cropping systems may regulate the spatiotemporal variation in soil moisture and affect the growth, WUE and yield of cotton. Ind. Crop. Prod. 2022, 186. [Google Scholar] [CrossRef]

- Effects of Drought Stress on Crop Production and Productivity. Int. J. Res. Stud. Agric. Sci. 2020, 6. [CrossRef]

- Çinar, V.M.; ÜNAY, A. Pamuğun (Gossypium hirsutum l. ) Erken Uygulanan Chlormequat Chloride’e Tepkisi. 2021, 18, 127–131. [Google Scholar] [CrossRef]

- Jia, Y.; Yang, B.; Han, Y.; Wang, G.; Su, T.; Li, X.; Lei, Y.; Zhi, X.; Xiong, S.; Xin, M.; et al. Enhanced Cotton Yield and Fiber Quality by Optimizing Irrigation Amount and Frequency in Arid Areas of Northwest China. Agronomy 2024, 14, 266. [Google Scholar] [CrossRef]

- Murtza, K.; Ishfaq, M.; Akbar, N.; Hussain, S.; Anjum, S.A.; Bukhari, N.A.; AlGarawi, A.M.; Hatamleh, A.A. Effect of Mepiquat Chloride on Phenology, Yield and Quality of Cotton as a Function of Application Time Using Different Sowing Techniques. Agronomy 2022, 12, 1200. [Google Scholar] [CrossRef]

- Priyadrashini, M.; Santoshkumar, G.; Nagabushanam, U.; Reddy, K.P.C. Growth and Yield Attributes of Bt Cotton (Gossypium hirusutum L.) Attributed to Plant Growth Regulators and Defoliants under High Density Planting System. Int. J. Environ. Clim. Chang. 2023, 13, 2252–2260. [Google Scholar] [CrossRef]

- Cao, Z.; Wang, X.; Gao, Y. Effect of Plant Growth Regulators on Cotton Seedling Root Growth Parameters and Enzyme Activity. Plants 2022, 11, 2964. [Google Scholar] [CrossRef] [PubMed]

- T. V Reddy, B. R. Patel, P. Chaudhary, and M. Chaudhary, “Effect of mepiquat chloride on yield attributes, yield and economics of Bt cotton under high density planting system,” The Pharma Innovation Journal, vol. 10, no. 12, pp. 1503–1507, 2021, [Online]. Available: http://www.thepharmajournal.com.

- Arekhi, E.; Bezdi, K.G.; Norozei, H.A.; Faghani, E. The Effect of Growth Regulators on Biochemical Properties, Yield, and Fiber Quality of Different Cultivars of cotton (Gossypium Hirsutum) Under Different Irrigation Intervals. J. Plant Growth Regul. 2023, 42, 5574–5586. [Google Scholar] [CrossRef]

- Hu, T.; Liu, Z.; Jin, D.; Chen, Y.; Zhang, X.; Chen, D. Effects of Growth Regulator and Planting Density on Cotton Yield and N, P, and K Accumulation in Direct-Seeded Cotton. Agronomy 2023, 13, 501. [Google Scholar] [CrossRef]

- Gomez Arturo, A. and Gomez Kwanchai A., Statistical Procedures for Agricultural Research, 2nd ed. New York: John Wiley and Sons Co, 1984.

- Hessini, K.; Martínez, J.P.; Gandour, M.; Albouchi, A.; Soltani, A.; Abdelly, C. Effect of water stress on growth, osmotic adjustment, cell wall elasticity and water-use efficiency in Spartina alterniflora. Environ. Exp. Bot. 2009, 67, 312–319. [Google Scholar] [CrossRef]

- P. Bernier, M. Lamhamedi, and D. G. Simpson, “Shoot:root ratio is of limited use in evaluating the quality of container conifer stock,” Tree Planters’ Notes, vol. 46, no. 3, pp. 102–106, Jan. 1995.

- K. Singh, P. Rathore, K. Singh, and S. Mishra, “Manipulations of source sink relationships through mepiquat chloride for enhancing cotton productivity and monetary returns in north western India,” Indian Journal of Cotton Research and Development, vol. 31, no. 1, pp. 62–68, Feb. 2017.

- Kenanoğlu, B.B.; Mertoğlu, K.; Durul, M.S.; Korkmaz, N.; Çolak, A.M. Maternal Environment and Priming Agents Effect Germination and Seedling Quality in Pitaya under Salt Stress. Horticulturae 2023, 9, 1170. [Google Scholar] [CrossRef]

- Collins, G.D.; Edmisten, K.L.; Wells, R.; Whitaker, J.R. The Effects of Mepiquat Chloride Applied to Cotton at Early Bloom and Physiological Cutout. J. Cotton Sci. 2017, 21, 183–189. [Google Scholar] [CrossRef]

- Sawan, Z.M. "Plant Density; Plant Growth Retardants: Its Direct and Residual Effects On Cotton Yield and Fiber Properties". Int. J. Environ. Sci. Nat. Resour. 2017, 5. [Google Scholar] [CrossRef]

- Kaul, A.; Deol, J.S.; Brar, A.S. Response of different Bt cotton (Gossypium hirsutum L.) hybrids to canopy modification practices. J. Appl. Nat. Sci. 2016, 8, 1188–1197. [Google Scholar] [CrossRef]

- Zhang, Q.-C.; Deng, X.-X.; Wang, J.-G. The effects of mepiquat chloride (DPC) on the soluble protein content and the activities of protective enzymes in cotton in response to aphid feeding and on the activities of detoxifying enzymes in aphids. BMC Plant Biol. 2022, 22, 1–15. [Google Scholar] [CrossRef]

- Samples, C.; Dodds, D.; Catchot, A.; Golden, B.; Gore, J.; Varco, J. Determining Optimum Plant Growth Regulator Application Rates in Response to Fruiting Structure and Flower Bud Removal. J. Cotton Sci. 2015, 19, 359–367. [Google Scholar] [CrossRef]

- F. Killi, L. Efe, and S. Mustafayev, “Genetic and Environmental Variability in Yield, Yield Components and Lint Quality Traits of Cotton,” Int J Agric Biol, vol. 7, pp. 1007–1010, Jun. 2005.

- D. M. Oosterhuis, K. Kosmidou, and J. T. Cothren, “Managing Cotton Growth and Development with Plant Growth Regulators,” in Proceedings of the World Cotton Research Conference -2, Athens - Greece, Sep. 1998, pp. 46–68.

- O. S. Khetre, V. Shinde, B. Asewar, and M. Iab, “Response of growth and yield of Bt cotton to planting densities as influenced by growth regulators,” International Journal of Chemical Studies, vol. 6, no. 4, pp. 485–488, Jun. 2018.

- Mondino, M.H.; A Peterlin, O.; Garay, F. RESPONSE OF LATE-PLANTED COTTON TO THE APPLICATION OF A GROWTH REGULATOR (Chlorocholine chloride, CYCOCEL 75). Exp. Agric. 2004, 40, 381–387. [Google Scholar] [CrossRef]

- C. York, “Cotton Cultivar Response to Mepiquat Chloride,” Agron J, vol. 75, no. 4, pp. 663–667, Jul. 1983.

- Kaur, S.; Singh, K.; Deol, J.S.; Malik, S.; Kaur, N. Effect of plant growth regulators and defoliants on growth and productivity of american cotton (Gossypium hirsutum L.). Agric. Res. J. 2021, 58, 650–656. [Google Scholar] [CrossRef]

- K. Priyanka, M. S. Rekha, K. Lakshman, and R. CH. Sujani, “Influence of plant growth regulators in cotton under HDPS.,” The Pharma Innovation International Journal, vol. 10, no. 7, pp. 329–357, 2021.

- R. Gobi, V. Vaiyapuri, Vinoth Kumar SR, and Murugan G, “Effects of Nutrients and Plant Growth Regulators on Yield and Quality Characters of Cotton,” J Pharmacogn Phytochem, vol. 8, no. 2, pp. 391–393, 2019.

- Stuart, B.L.; Isbell, V.R.; Wendt, C.W.; Abernathy, J.R. Modification of Cotton Water Relations and Growth with Mepiquat Chloride1. Agron. J. 1984, 76, 651–655. [Google Scholar] [CrossRef]

- Abbas, H.; Wahid, M.A.; Sattar, A.; Tung, S.A.; Saleem, M.F.; Irshad, S.; Alkahtani, J.; Elshikh, M.S.; Cheema, M.; Li, Y. Foliar application of mepiquat chloride and nitrogen improves yield and fiber quality traits of cotton (Gossypium hirsutum L.). PLOS ONE 2022, 17, e0268907. [Google Scholar] [CrossRef] [PubMed]

- Zhao, W.; Yan, Q.; Yang, H.; Yang, X.; Wang, L.; Chen, B.; Meng, Y.; Zhou, Z. Effects of mepiquat chloride on yield and main properties of cottonseed under different plant densities. J. Cotton Res. 2019, 2, 1–10. [Google Scholar] [CrossRef]

- O. Çopur, U. Demirel, and M. Karakuş, “Effects of Several Plant Growth Regulators on the Yield and Fiber Quality of Cotton (Gossypium hirsutum L.),” Not Bot Horti Agrobot Cluj Napoca, vol. 38, no. 3, pp. 104–110, 2010. [CrossRef]

- S. Sravanthi, M. S. Rekha, B. Venkateswarlu, Rao Ch. Sujani, and K. Jayalalitha, “Effect of Defoliants on Percent Defoliation and Yield of American Cotton (Gossypium Hirsutum),” Research on Crops, vol. 23, no. 2, pp. 458–465, 2022.

- S. Khamdullaev, S. Nabiev, A. Azimov, J. Shavkiev, and U. Yuldashov, “Combining Ability of Yield and Yield Components in Upland Cotton (G. hirsutum L.) Genotypes Under Normal and Water-Deficit Conditions,” Plant Cell Biotechnol Mol Biol, vol. 22, no. 35 & 36, pp. 176–186, May 2021.

- R. Vistro et al., “Effect of KCl Priming on Wheat Seed Germination and Early Seedling Growth,” International Journal of Agricultural Technology, vol. 13, no. 3, pp. 353–362, 2017.

- L. M. Verhalen, B. E. Greenhagen, and R. W. Thacker, “Lint Yield, Lint Percentage, and Fiber Quality Response in Bollgard, Roundup Ready, and Bollgard/Roundup Ready Cotton,” J Cotton Sci, vol. 7, no. 2, pp. 23–38, 2003, [Online]. Available: http://journal.cotton.

- Yasar, S.; Karademir, E. DETERMINATION OF THE FACTORS LIMITING COTTON FIBER QUALITY IN TURKEY. Spring 2021, 185, 85–99. [Google Scholar] [CrossRef]

- S. Shahat, H. Arafa, and M. Sief, “Comparative Study on Egyptian cotton Fiber Maturity Measurements Using Direct and Indirect Methods,” IOSR Journal of Polymer and Textile Engineering, vol. 9, no. 3, pp. 1–9, Aug. 2022. [CrossRef]

- Watts, D.B.; Runion, G.B.; Nannenga, K.W.S.; Torbert, H.A. Enhanced-Efficiency Fertilizer Effects on Cotton Yield and Quality in the Coastal Plains. Agron. J. 2014, 106, 745–752. [Google Scholar] [CrossRef]

- S. Shahat, H. Arafa, and M. Sief, “Impact of fiber maturity levels on fineness, maturity, strength and elongation measurements in Egyptian cotton,” IOSR Journal of Polymer and Textile Engineering, vol. 9, no. 4, pp. 13–23, Aug. 2022. [CrossRef]

- Qi, H.-K.; DU, M.-W.; Meng, L.; Xie, L.-W.; Eneji, A.E.; Xu, D.-Y.; Tian, X.-L.; Li, Z.-H. Cotton maturity and responses to harvest aids following chemical topping with mepiquat chloride during bloom period. J. Integr. Agric. 2022, 21, 2577–2587. [Google Scholar] [CrossRef]

- K. Singh, P. Rathore, and K. Singh, “Dose and Time Dependent Efficacy Alteration of Different Defoliants on Seed Cotton Yield,” J Environ Biol, vol. 36, no. 4, pp. 891–895, Sep. 2015.

- Echer, F.R.; Rosolem, C.A. Plant growth regulator losses in cotton as affected by adjuvants and rain. Cienc. Rural. 2012, 42, 2138–2144. [Google Scholar] [CrossRef]

- D. M. Oosterhuis, J. T. Cothren, J. A. Landivar, J. A. Hickey, and A. Steger, “Late-Season Applications of PGR-LV to Remediate Fruit Shed and Enhance Maturity and Yield,” in Beltwide Cotton Production Conference, C. P. Dugger and A. D. Richter, Eds., New Orleans, LA, Jan. 1997, p. 1399.

- J. T. Cothren, J. A. Landivar, and D. M. Oosterhui, “Mid-Flowering Application of PGR-IV to Enhance Cotton Maturity and Yield,” in Beltwide Cotton Production Conference, C. P. Dugger and D. A. Richter, Eds., Nashville, TN, Jan. 1996, p. 1149.

| Shoot-to-root ratio | Fiber Percent (%) | Maturity Index (%) | |||||||||

| Source of Variation | df | 2022 | 2023 | 2022 | 2023 | 2022 | 2023 | ||||

| Vegetative | Reproductive | Harvest | Vegetative | Reproductive | Harvest | ||||||

| Conc | 3 | ns | ns | * | ns | ns | ns | ns | ns | ns | ns |

| App. T | 1 | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns |

| Var | 1 | ns | * | ns | ns | ns | ns | ns | ns | ns | ns |

| App. T X Conc | 3 | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns |

| Var X Conc | 3 | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns |

| App. T X Var | 1 | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns |

| Conc X App. T X Var | 3 | ns | ns | ns | ns | ns | ns | ns | ns | ns | ns |

| Sources of variations | Fiber percent (%) | ||||

| Variety | Application Time | T0 | T1 | T2 | T3 |

| Selin | Squaring | 64.60 ± 1.11 | 61.73 ± 2.06 | 60.31 ± 1.21 | 58.29 ± 3.00 |

| Bolling | 60.77 ± 2.64 | 66.29 ± 4.16 | 55.66 ± 3.12 | 64.30 ± 4.22 | |

| Sezener | Squaring | 62.76 ± 4.10 | 60.39 ± 3.06 | 59.61 ± 4.19 | 64.52 ± 2.62 |

| Bolling | 62.05 ± 4.34 | 55.06 ± 1.19 | 60.65 ± 2.56 | 62.11 ± 1.97 | |

| Grand Mean | 61.194 | ||||

| SE | 5.311 | ||||

| CV (%) | 8.678 | ||||

| Sources of variations | Fiber percent (%) | ||||

| Variety | Application Time | T0 | T1 | T2 | T3 |

| Selin | Squaring | 71.65 ± 3.16 | 70.54 ± 0.92 | 72.26 ± 0.77 | 72.86 ± 2.13 |

| Bolling | 76.36 ± 0.78 | 74.74 ± 2.66 | 74.57 ± 1.36 | 72.48 ± 2.28 | |

| Sezener | Squaring | 71.62 ± 3.66 | 70.19 ± 2.59 | 73.87 ± 1.76 | 69.34 ± 1.87 |

| Bolling | 72.49 ± 1.06 | 72.67 ± 4.03 | 68.42 ± 1.26 | 69.88 ± 1.05 | |

| Grand Mean | 72.122 | ||||

| SE | 3.774 | ||||

| CV (%) | 5.233 | ||||

| Sources of variations | Maturity Index (%) | ||||

| Variety | Application Time | T0 | T1 | T2 | T3 |

| Selin | Squaring | 83.33 ± 0.33 | 83.67 ± 0.33 | 84.00 ± 0.58 | 84.33 ± 0.33 |

| Bolling | 83.67 ± 0.21 | 84.33 ± 0.33 | 84.33 ± 0.33 | 84.00 ± 0.58 | |

| Sezener | Squaring | 84.00 ± 0.58 | 84.33 ± 0.33 | 83.67 ± 0.33 | 84.33 ± 0.33 |

| Bolling | 84.33 ± 0.67 | 84.17 ± 0.17 | 84.00 ± 0.58 | 84.33 ± 0.33 | |

| Grand Mean | 84.063 | ||||

| SE | 0.665 | ||||

| CV (%) | 0.792 | ||||

| Sources of variations | Maturity Index (%) | ||||

| Variety | Application Time | T0 | T1 | T2 | T3 |

| Selin | Squaring | 87.88 ± 0.17 | 87.50 ± 0.51 | 88.02 ± 0.24 | 87.95 ± 0.10 |

| Bolling | 87.96 ± 0.28 | 88.00 ± 0.21 | 87.32 ± 0.36 | 88.06 ± 0.04 | |

| Sezener | Squaring | 87.37 ± 0.66 | 88.25 ± 0.59 | 88.65 ± 0.42 | 87.79 ± 0.37 |

| Bolling | 86.89 ± 0.68 | 87.94 ± 0.35 | 87.79 ± 0.41 | 88.07 ± 0.62 | |

| Grand Mean | 87.840 | ||||

| SE | 0.725 | ||||

| CV (%) | 0.825 | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).