Submitted:

30 June 2024

Posted:

02 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1 Material and Characterization Equipment

2.2 Experimental Processing

3. Results and discussion

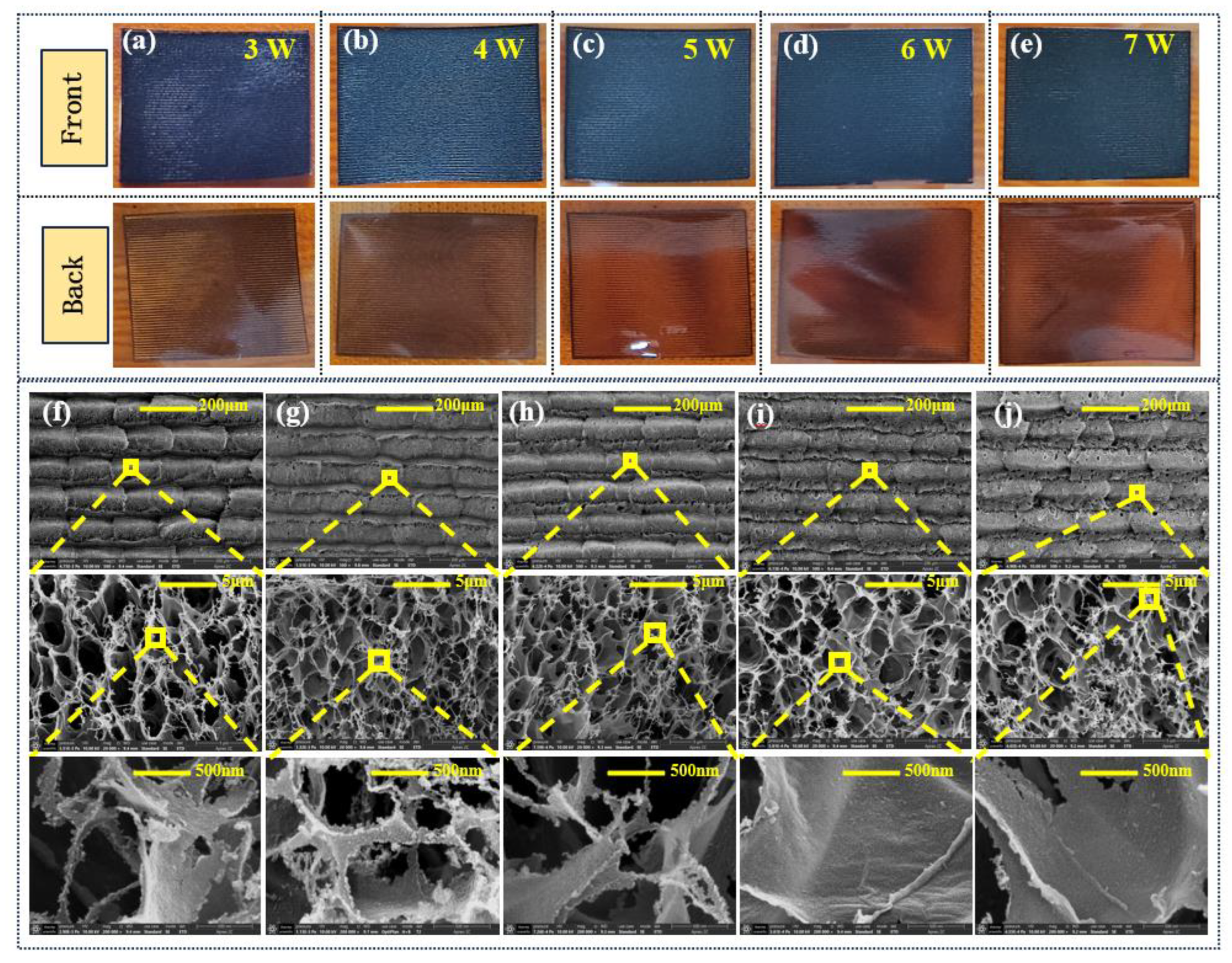

3.1. Surface Morphology of LIG

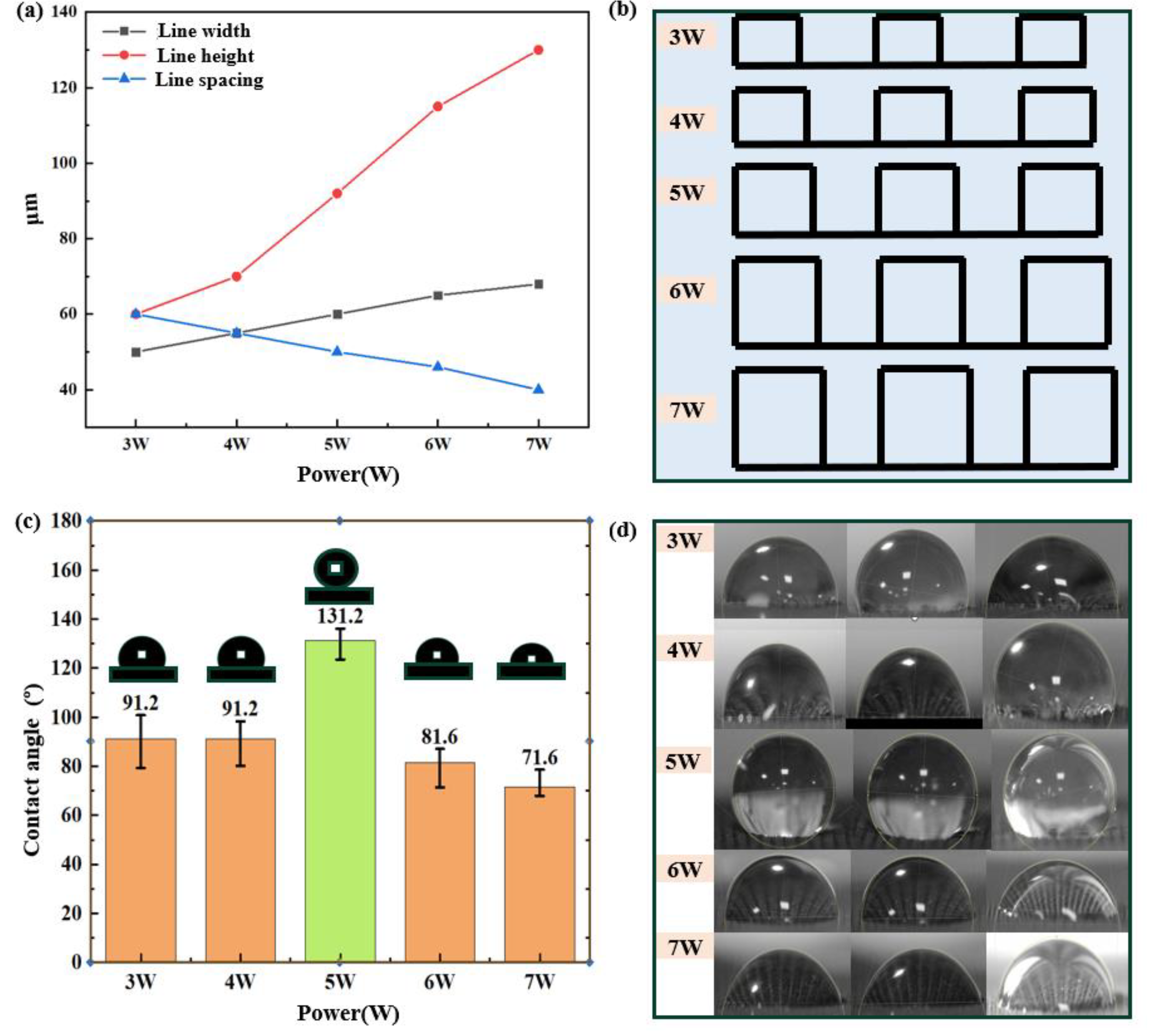

3.2. Composition Analysis of the LIG

3.3. Hydrophobicity of the LIG

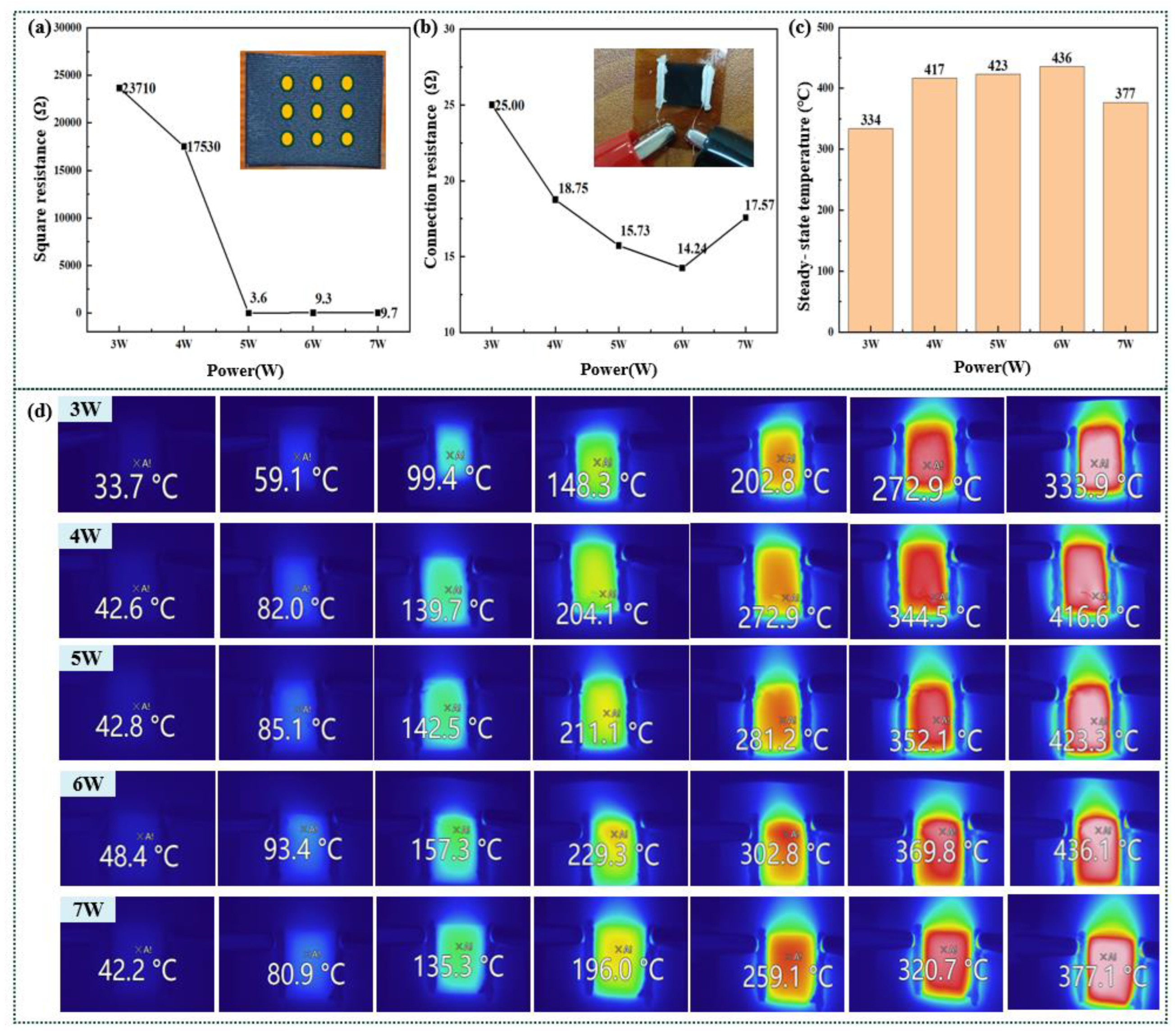

3.4. Electrical Conductivity of the LIG

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- He Q, Li K, Xu Z, et al. Research progress on construction strategy and technical evaluation of aircraft icing accretion protection system. Chinese J Aeronaut, 2023, 36, 1–23. [Google Scholar] [CrossRef]

- Zhu C, Zhu C. Aircraft icing and its protection. Beijing: Science Press, 2016.

- Liu Y, Wu Y, Ma Y, et al. Reversible thermochromic and heat storage coating for adaptive de/anti-icing and thermal regulation[J]. Chem Eng J, 2024, 482, 148837. [Google Scholar] [CrossRef]

- Zhang S, Gao F, Jiang Z, et al. Bioinspired durable interpenetrating network anti-icing coatings enabled by binders and hydrophobic-ion specific synergies. Chem Eng J, 2024, 479, 147836. [Google Scholar] [CrossRef]

- Xue Y, Wang Y, Wang Y, et al. A superhydrophobic Fe3O4/PEI nanocomposite film with active activation function for anti-icing/deicing applications. Mater Today Sustain, 2023, 24, 100588. [Google Scholar] [CrossRef]

- Chen L, Xu J, Luo X, et al. Micro/nano manufacturing aircraft surface with anti-icing and deicing performances: An overview. Nanotechnol Rev, 2023, 12, 20230105. [Google Scholar] [CrossRef]

- Wu H, Shi F, Zhang Z, et al. Effect of carbon fiber bundles spacing on composites and their electro-thermal and anti/deicing properties. Mat Sci Eng B-ADV, 2024, 299, 117021. [Google Scholar] [CrossRef]

- Zhang W, Wang D, Sun Z, et al. Robust super hydrophobicity: mechanisms and strategies. Chem Soc Rev, 2021, 50, 4031–4061. [Google Scholar] [CrossRef]

- Liu S, Wang Y, Tang X, et al. Fabrication of polydimethylsiloxane superhydrophobic coatings with self-healing properties using the template method. J Mater Eng Perform, 2024, 33, 1349–1357. [Google Scholar] [CrossRef]

- Pan R, Zhong M L. Fabrication of superwetting surfaces by ultrafast lasers and mechanical durability of superhydrophobic surfaces. Chin Sci Bull, 2019, 64, 1268–1289. [Google Scholar] [CrossRef]

- Li Z, Zhen Z, Chai M, et al. Transparent electrothermal film defoggers and antiicing coatings based on wrinkled graphene. Small, 2020, 16, 1905945. [Google Scholar] [CrossRef]

- Xiao Z, Chen C, Liu S, et al. Endowing durable icephobicity by combination of a rough powder coating and a superamphiphobic coating. Chem Eng J, 2024, 482, 149001. [Google Scholar] [CrossRef]

- Zhang R, Ding Z, Wang K, et al. Enhanced anti/de-icing performance on rough surfaces based on the synergistic effect of fluorinated resin and embedded graphene. Small Methods, 2024, 1, 2301262. [Google Scholar]

- Zhang B, Yang G, Xu W, et al. Hybrid superamphiphobic anti-corrosion coating with integrated functionalities of liquid repellency, self-cleaning, and anti-icing. J Mater Sci Technol, 2024, 184, 256–268. [Google Scholar] [CrossRef]

- Chen Q, Shen X, Zhang Z, et al. Robust superhydrophobic SiO2/GPE/MWCNTs durable composite coating with photothermal and electrothermal effect for passive anti-icing/active de-icing. Prog Org Coat, 2024, 191, 108438. [Google Scholar] [CrossRef]

- Zhao Z, Chen H, Zhu Y, et al. A robust superhydrophobic anti-icing/de-icing composite coating with electrothermal and auxiliary photothermal performances. Comp Sci Technol, 2022, 227, 109578. [Google Scholar] [CrossRef]

- Hou Y, Wang M, Choy K L. Scalable high-efficiency multilayered anti-icing/de-icing coating: Superhydrophobic upper layer boosts the performance of the electrothermal system. Prog Org Coat, 2022, 168, 106866. [Google Scholar] [CrossRef]

- Fan J, Long Z, Wu J, et al. Electrothermal superhydrophobic epoxy nanocomposite coating for anti-icing/deicing. J Coat Technol Res, 2023, 20, 1557–1568. [Google Scholar] [CrossRef]

- Duy L X, Peng Z, Li Y, et al. Laser-induced graphene fibers[J]. Carbon, 2018, 126, 472–479. [Google Scholar] [CrossRef]

- Ye R, James D K, Tour J M. Laser-induced graphene. Accounts Chem Res, 2018, 51, 1609–1620. [Google Scholar] [CrossRef] [PubMed]

- Kim K Y, Choi H, Van Tran C, et al. Simultaneous densification and nitrogen doping of laser-induced graphene by duplicated pyrolysis for supercapacitor applications. J Power Sources, 2019, 441, 227199. [Google Scholar] [CrossRef]

- Li Y L, Luong D X, Zhang J B, et al. Laser-induced graphene in controlled atmospheres: from superhydrophilic to superhydrophobic surfaces. Adv Mater, 2017, 29, 1700496. [Google Scholar] [CrossRef] [PubMed]

- Tittle C M, Yilman D, Pope M A, et al. Robust superhydrophobic laser-induced graphene for desalination applications. Adv Mater Technol, 2018, 3, 1700207. [Google Scholar] [CrossRef]

- Nasser J, Lin J, Zhang L, et al. Laser induced graphene printing of spatially controlled super-hydrophobic/hydrophilic surfaces. Carbon, 2020, 162, 570–578. [Google Scholar] [CrossRef]

- Lee J U, Lee C W, Cho S C, et al. Laser-induced graphene heater pad for de-icing. Nanomaterials, 2021, 11, 3093. [Google Scholar] [CrossRef] [PubMed]

- Deshmukh S, Banerjee D, Quintero J S M, et al. Polarity dependent electrowetting for directional transport of water through patterned superhydrophobic laser induced graphene fibers. Carbon, 2021, 182, 605–614. [Google Scholar] [CrossRef]

- Han Y, Han Y, Sun J, et al. Controllable nanoparticle aggregation through a superhydrophobic laser-induced graphene dynamic system for surface-enhanced Raman scattering detection. ACS Appl Mater Interfaces, 2022, 14, 3504–3514. [Google Scholar] [CrossRef] [PubMed]

- Wu W, Liang R, Lu L, et al. Preparation of superhydrophobic laser-induced graphene using taro leaf structure as templates. Surf Coat Tech, 2020, 393, 125744. [Google Scholar] [CrossRef]

- Wang W, Lu L, Lu X, et al. Laser-induced jigsaw-like graphene structure inspired by Oxalis corniculata Linn. leaf. Bio-Des Manuf, 2022, 5, 700–713. [Google Scholar] [CrossRef]

- He Q, Ma Y, Wang X, et al. Superhydrophobic flexible silicone rubber with stable performance, anti-icing, and multilevel rough structure. ACS Appl Poly Mater, 2023, 5, 4729–4737. [Google Scholar] [CrossRef]

- Li A, Wei Z, Zhang F, et al. A high reliability super hydrophobic silicone rubber. Colloid Surface A, 2023, 671, 131639. [Google Scholar] [CrossRef]

- Li S, Zhong M, Zou Y, et al. Fabrication of micron-structured heatable graphene hydrophobic surfaces for deicing and anti-icing by laser direct writing[J]. Coatings, 2023, 13, 1559. [Google Scholar] [CrossRef]

- Zhong M, Li S C, Zou Y, et al. Hydrophobic surface array structure based on laser-induced graphene for deicing and anti-icing application. Micromachines, 2024, 15, 285. [Google Scholar] [CrossRef]

- He Q, Xu Y, Zhang F; et al. He Q, Xu Y, Zhang F, et al. Preparation methods and research progress of super-hydrophobic anti-icing surface[J]. Adv Colloid Interface Sci 2023, 103069. [Google Scholar]

- Han Y, Han Y, Huang Y, et al. Laser-induced graphene superhydrophobic surface transition from pinning to rolling for multiple applications. Small Methods, 2022, 6, 2200096. [Google Scholar] [CrossRef] [PubMed]

- Wang Y, Wang Y, Zhang P, et al. Laser-induced freestanding graphene papers: A new route of scalable fabrication with tunable morphologies and properties for multifunctional devices and structures. Small, 2018, 14, 1802350. [Google Scholar] [CrossRef]

- Jia Y, He Q, Liu Y, et al. Anti-icing system based on multi-level micro-nano and electric heating dual structure[J]. Colloid Surface A, 2024, 683, 133105. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).