Submitted:

03 June 2024

Posted:

04 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

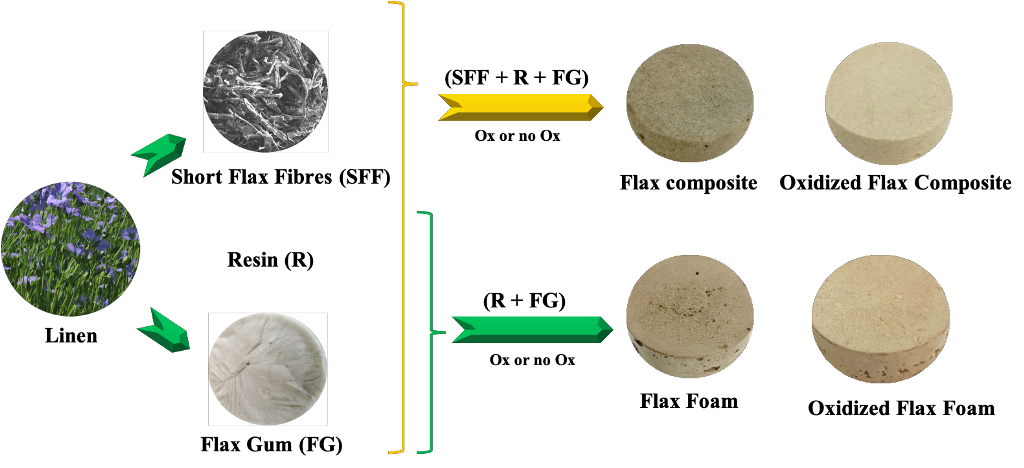

2. Materials and Methods

2.1. Oxidation of Flax Gum and Flax Fibers

2.2. Preparation of Flax Foams

2.3. Characterization

3. Results

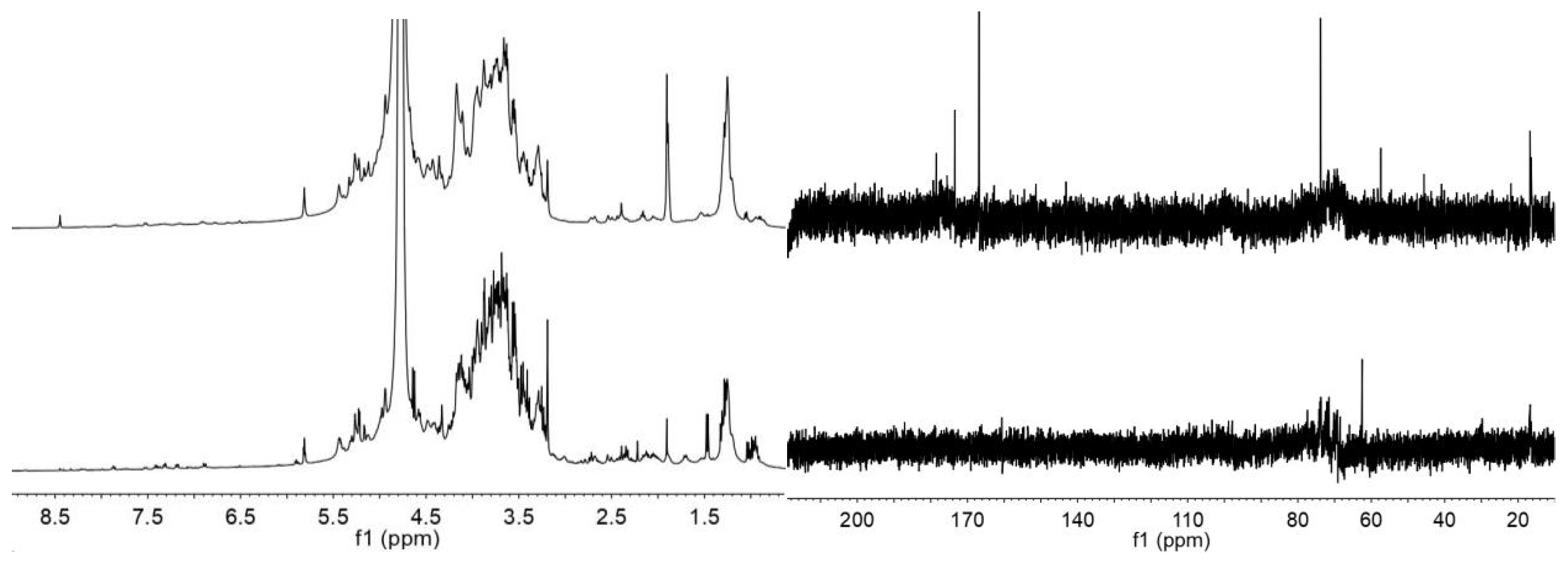

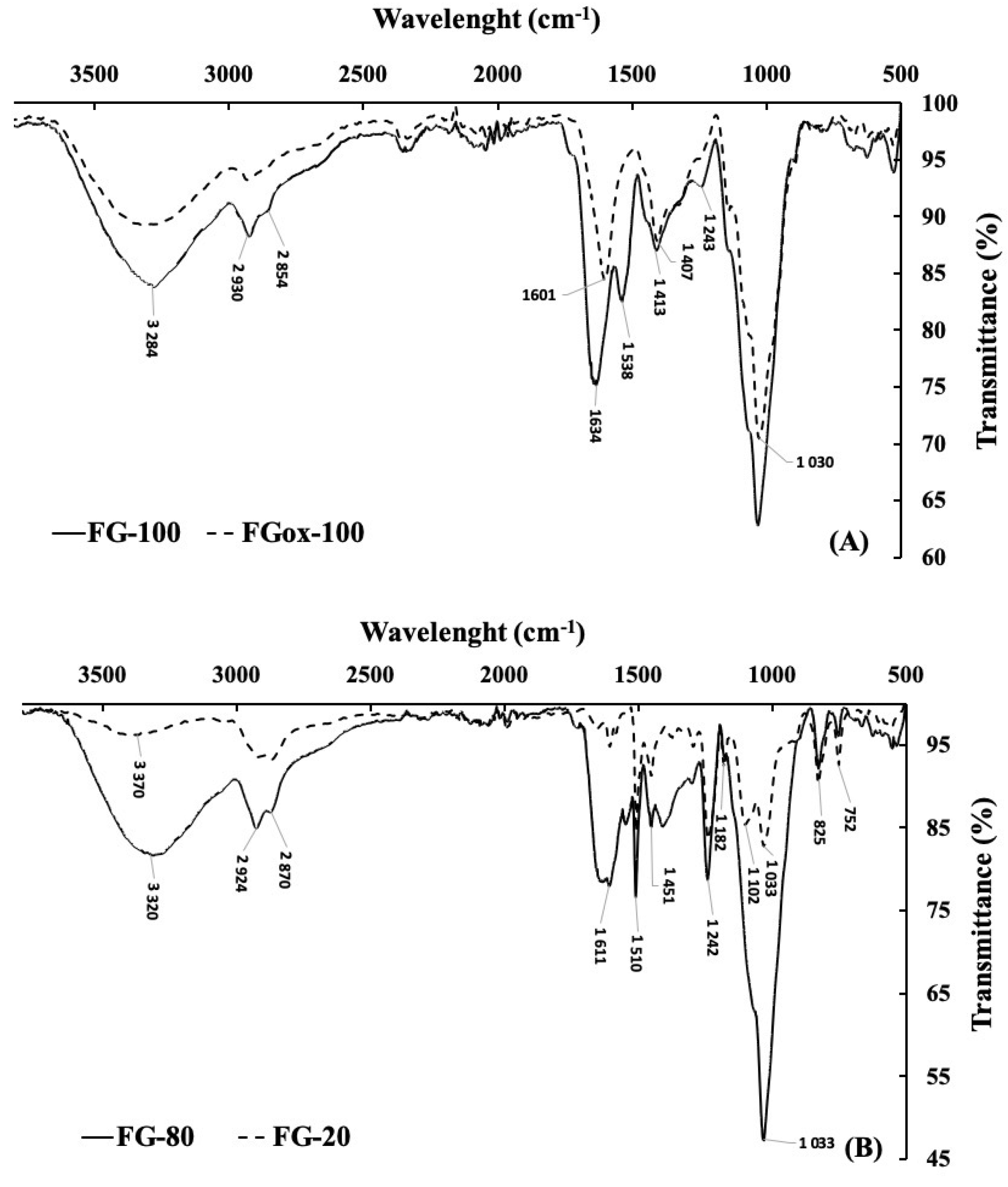

3.1. Characterization of Flax Products Following TEMPO Oxidation

| Carboxylate(mmol/g) | Aldehyde (mmol/g) | Carboxylate(mmol/g) | Aldehyde (mmol/g) | ||

| FG | 0.59 ± 0.01 | 1.64 ± 0.45 | Fiber | 1.25 ± 0.15 | 3.41 ± 0.03 |

| FGox | 1.13 ± 0.32 | 2.56 ± 0.55 | Ox. Fiber | 2.46 ± 0.08 | 4.60 ± 0.04 |

| R ox | 1.90 | 1.56 | 1.97 | 1.35 |

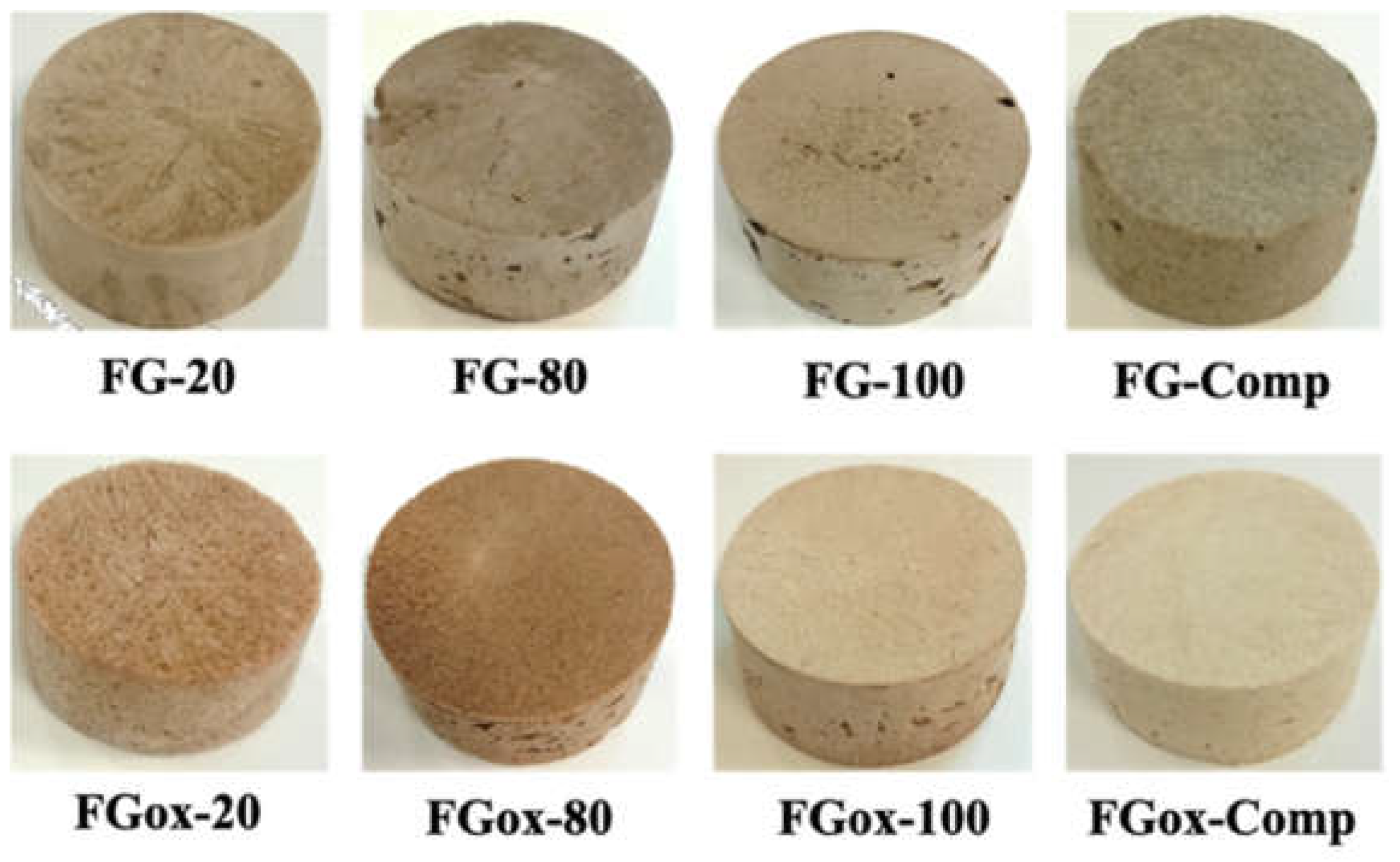

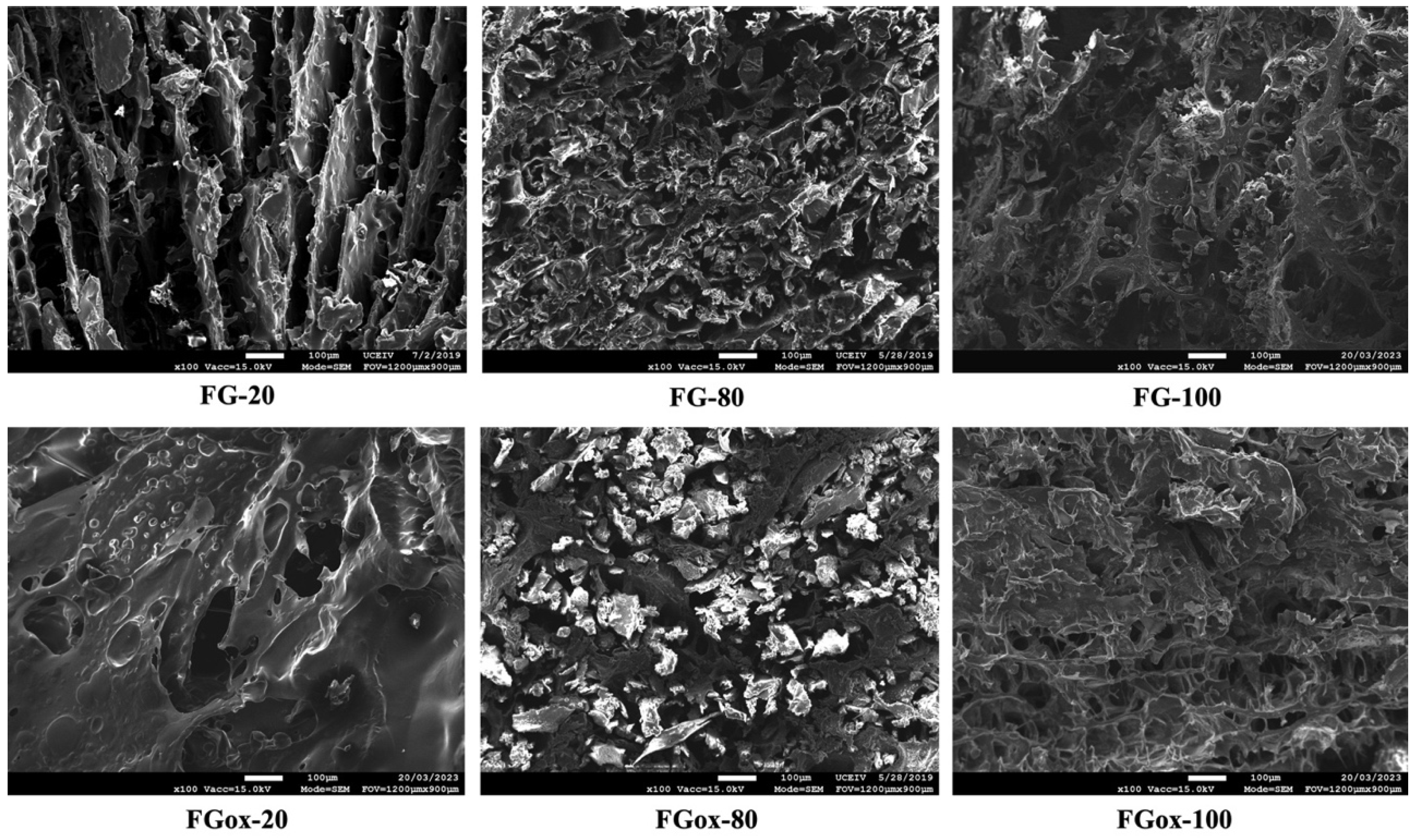

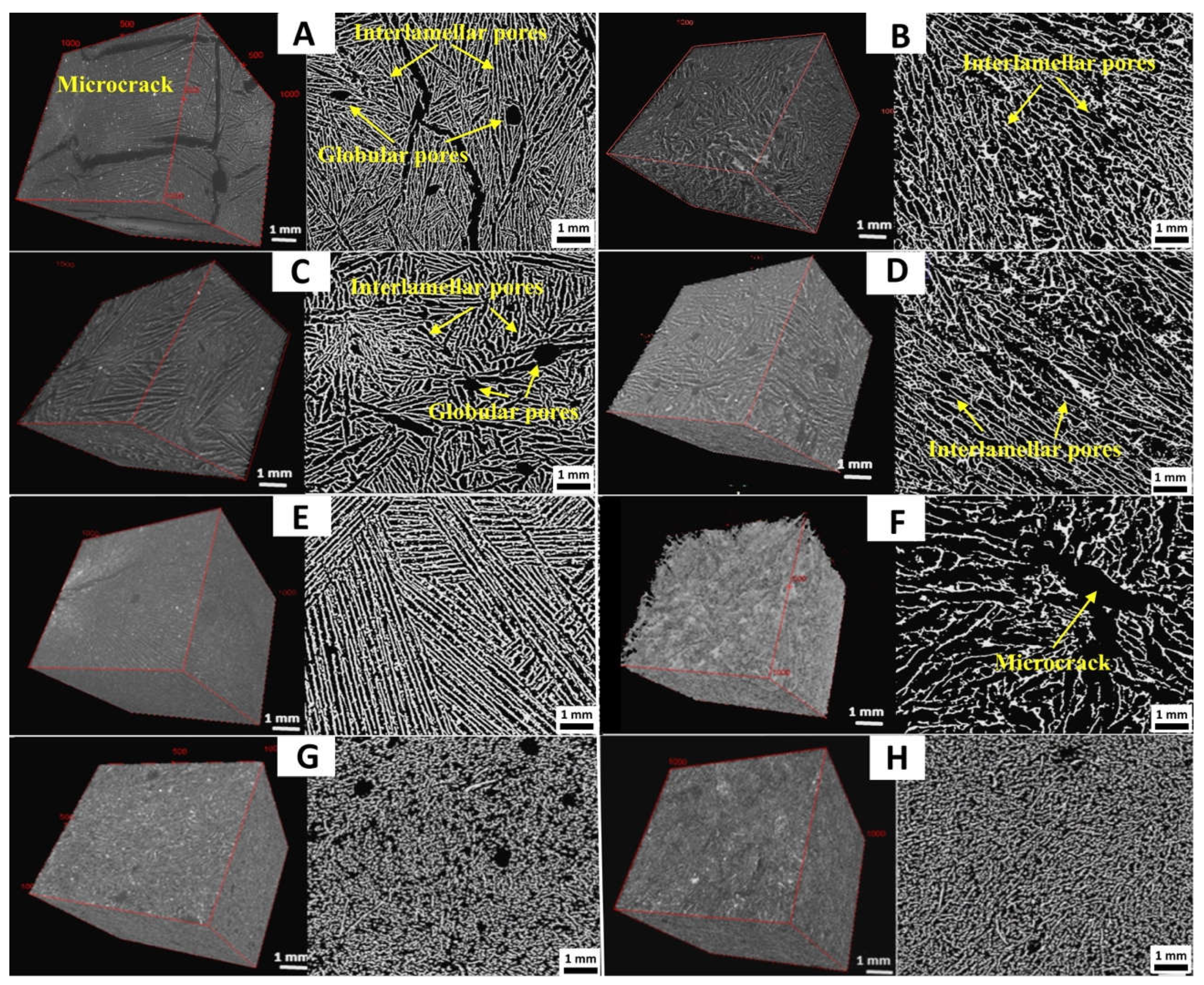

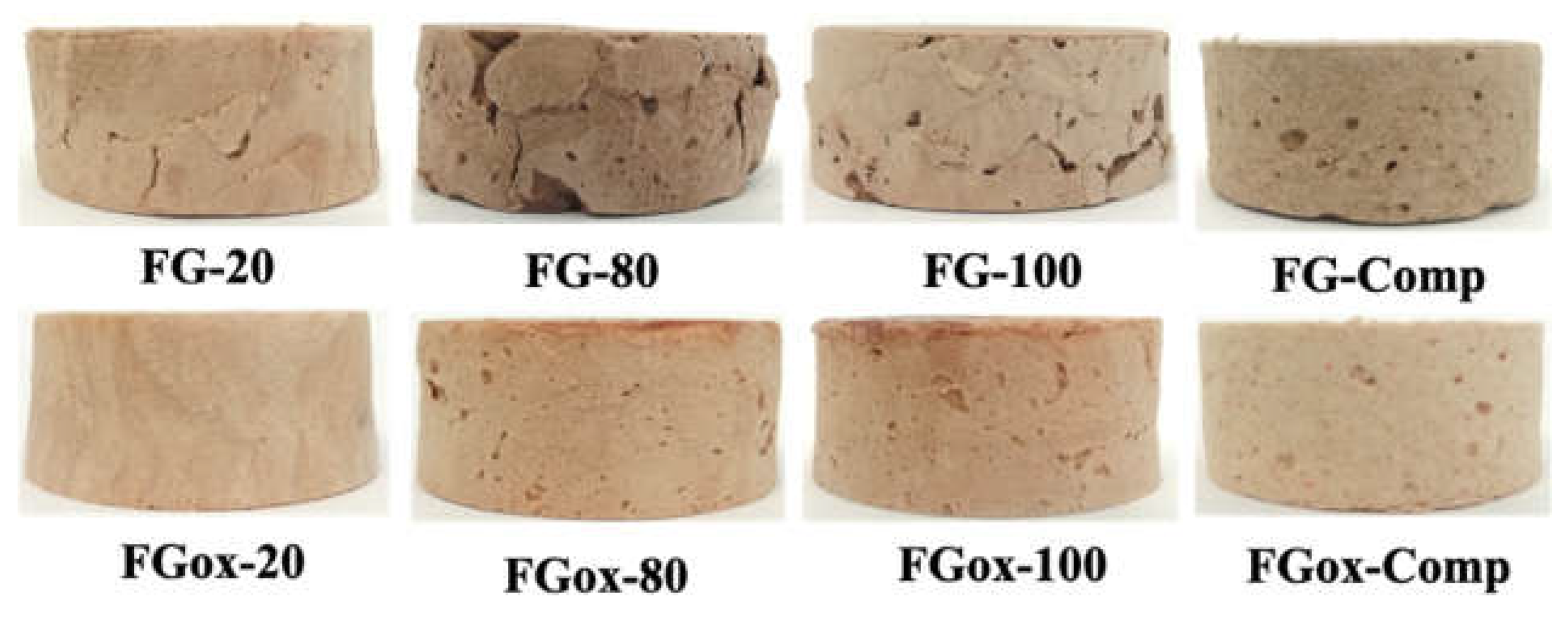

3.2. Characterization of Flax Gum Foams and Composites

| Sample | Density(kg. m-3) | Section Indent (%) | Porosity* (%) | Sample | Density(kg. m-3) | Section Indent (%) | Porosity*(%) |

| FG-100 | 228.9 ± 9.3 | 9.8 | 68 ± 2.4 | FGox-100 | 311.4 ± 3.4 | 13.0 | 69 ± 1.1 |

| FG-80 | 231.7 ± 8.2 | 7.9 | 68 ± 2.5 | FGox-80 | 286.0 ± 5.6 | 11.9 | 73 ± 1.1 |

| FG-20 | 219.5 ± 3.0 | 5.6 | 61 ± 3.0 | FGox-20 | 236.7 ± 4.7 | 7.6 | 79 ± 1.1 |

| FG-Comp | 194.4 ± 5.3 | 0.1 | 65 ± 1.1 | FGox-Comp | 209.4 ± 2.5 | 0.6 | 67 ± 1.1 |

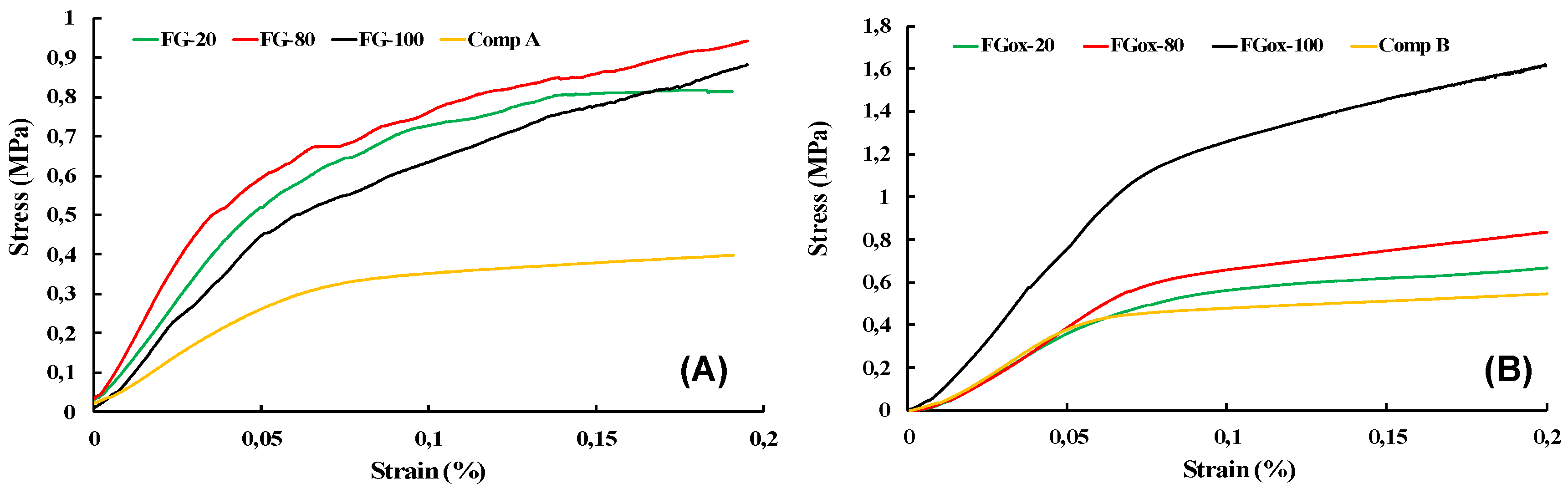

3.3. Mechanical Analysis of Flax-Gum Foams and Composites

3.4. Thermal Properties of Flax-Gum Foams and Composites

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ngo, T.D. Natural Fibers for Sustainable Bio-Composites. Natural and Artificial Fiber-Reinforced Composites as Renewable Sources (Chapter 7) 2018, 107–126. [Google Scholar]

- Rouilly, A.; Vaca-Garcia, C. Bio-based Materials. Introduction to Chemicals from Biomass; Second Edition; 2015; Edited by James Clark and Fabien Deswarte. Published by John Wiley & Sons, Ltd. [Google Scholar]

- Shah, D.U. Developing plant fiber composites for structural applications by optimizing composite parameters: a critical review. J. Mater. Sci. 2013, 48, 6083–6107. [Google Scholar] [CrossRef]

- Chen, J.; Nichols, B.; Norris, A.; Frazier, C.E.; Edgar, K.J. All-polysaccharide, self-healing injectable hydrogels based on chitosan and oxidized hydroxypropyl polysaccharides. Biomacromol. 2020, 4261–4272. [Google Scholar] [CrossRef] [PubMed]

- Azeredo, H.M.C.; Waldron, K.W. Crosslinking in polysaccharide and protein films and coatings for food contact—A review. Trends Food. Sci. & Technol. 2016, 52, 109–122. [Google Scholar] [CrossRef]

- Varma, A.J.; Jamdade, Y.K. On the Dual Role of Starch, Cellulose and their Dialdehydes as Fillers and Accelerators in the Tertiary Amine Catalysed Curing of Epoxy Resin. Carbohydr. Polym. 1985, 5, 309–316. [Google Scholar] [CrossRef]

- Hassan, N.A.A.; Ahmad, S.; Chen, R.S.; Natarajan, V.D. Synergistically enhanced mechanical, combustion and acoustic properties of biopolymer composite foams reinforcement by kenaf fiber. Comp. Part A 2022, 202155, 106826. [Google Scholar] [CrossRef]

- Yang, K.; Zhang, Z.; Liu, Y.; Li, S.; Chen, D.; Li, Z. Biomass-based porous composites with heat transfer characteristics: preparation, performance and evaluation—A review. J. Por. Mat. 2002, 29, 1667–1687. [Google Scholar] [CrossRef]

- Wei, X.; Ding, S.; Liu, S.; Yang, K.; Cai, J.; Li, F.; Wang, C.; Lin, S.; Tian, F. Polysaccharides-modified chitosan as improved and rapid hemostasis foam sponges. Carbohydr. Polym. 2021, 264, 118028. [Google Scholar] [CrossRef] [PubMed]

- Mello, L.R.P.F.; Mali, S. Use of malt bagasse to produce biodegradable baked foams made from cassava starch. Ind. Crops Prod. 2014, 55, 187–193. [Google Scholar] [CrossRef]

- González-García, S.; Hospido, A.; Feijoo, G.; Moreira, M.T. Life cycle assessment of raw materials for non-wood pulp mills: Hemp and flax. Res. Conserv. Recycl. 2010, 4, 923–930. [Google Scholar] [CrossRef]

- Soykeabkaew, N.; Supaphol, P.; Rujiravanit, R. Preparation and characterization of jute- and flax-reinforced starch-based composite foams. Carbohydr. Polym. 2004, 58, 53–63. [Google Scholar] [CrossRef]

- Ramesh, M. Flax (Linum usitatissimum L.) fibre reinforced polymer composite materials: A review on preparation, properties and prospects. Prog. Mat. Sci. 2019, 102, 109–166. [Google Scholar] [CrossRef]

- Musa, C.; Kervoëlen, A.; Danjou, P.-E.; Bourmaud, A.; Delattre, F. Bio-based unidirectional composite made of flax fibre and isosorbide-based epoxy resin. Mat. Lett. 2020, 258. [Google Scholar] [CrossRef]

- Alix, S.; Marais, S.; Morvan, C.; Lebrun, L. Biocomposite materials from flax plants: Preparation and properties. Comp. Part A 2008, 39, 1793–1801. [Google Scholar] [CrossRef]

- Paynel, F.; Pavlov, A.; Colasse, L.; Rihouey, C.; Follain, N.; Duriatti, D.; Bizet, L.; Allan, I.; Lebrun, L.; Marais, S.; Morvan, C. Preparation and characterization of flax biocomposites made of seed mucilage reinforced by fibers. Comp. Part A 2015, 69, 299–305. [Google Scholar] [CrossRef]

- Cui, W.; Mazza, G.; Biliaderi, C.G. Chemical structure, molecular size distribution and rheological properties of flaxseed gum. J. Agric. Food. Chem. 1994, 199442, 1891–1895. [Google Scholar] [CrossRef]

- Olsson, E.; Menzel, C.; Johansson, C.; Andersson, R.; Koch, K.; Järnström, L. The effect of pH on hydrolysis, cross-linking and barrier properties of starch barriers containing citric acid. Carbohydr. Polym. 2013, 98, 1505–1513. [Google Scholar] [CrossRef]

- Kato, Y.; Matsuo, R.; Isogai, A. Oxidation process of water-soluble starch in TEMPO-mediated system. Carbohydr. Polym. 2003, 51, 69–75. [Google Scholar] [CrossRef]

- Sbiai, A.; Maazouz, A.; Fleury, E.; Sautereau, H.; Kaddami, H. TEMPO-Mediated Oxidation of Lignocellulosic Fibers from Date Palm Leaves. Carbohydr. Polym. 2012, 86, 149–186. [Google Scholar] [CrossRef]

- Da Silva Perez, D.; Montanari, S.; Vignon, M.R. TEMPO-mediated oxidation of cellulose III. Biomacromol. 2003, 4, 1417–1425. [Google Scholar] [CrossRef]

- Xie, M.; Jia, M.; Zhao, H.; Zhang, L. Visual Determination of Oxidation of Edible Oil by a Nanofiber Mat Prepared from Polyvinyl Alcohol and Schiff’s Reagent. Microchim. Acta 2020, 187, 597. [Google Scholar] [CrossRef] [PubMed]

- Feldkamp, L.A.; Davis, L.C.; Kress, J.W. Practical cone-beam algorithm. J. Opt. Soc. Am. 1984, 612–619. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Arzt, M.; Deschamps, J.; Schmied, C.; Pietzsch, T.; Schmidt, D.; Tomancak, P.; Haase, R.; Jug, F. LABKIT: Labeling and Segmentation Toolkit for Big Image Data. Front. Comput. Sci. 2022, 4. [Google Scholar] [CrossRef]

- Zaidi, M.; Baillis, D.; Naouar, N.; Depriester, M.; Delattre, F. Thermal Conductivity and Microstructure of Novel Flaxseed-Gum-Filled Epoxy Resin Biocomposite: Analytical Models and X-ray Computed Tomography. Materials 2023, 16, 6318. [Google Scholar] [CrossRef]

- ASTM standard D1621. Standard Test Method for Compressive Properties Of Rigid Cellular Plastics. ASTM International. 2004, 5–8.

- ASTM standard D7984-21. Standard Test Method for Measurement of Thermal Effusivity of Fabrics Using a Modified Transient Plane Source (MTPS) Instrument. ASTM International. 2021, 5.

- Wojtasik, W.; Kulma, A.; Kostyn, K.; Szopa, J. The changes in pectin metabolism in flax infected with Fusarium. Plant. Phys. Biochem. 2011, 49, 862–872. [Google Scholar] [CrossRef]

- Dubois, F.; Musa, C.; Duponchel, B.; Tifahy, L.; Sécordel, X.; Mallard, I.; Delattre, F. Nuclear magnetic resonance and calorimetric investigations of extraction mode on flaxseed gum composition. Polym. 2020, 12, 2654. [Google Scholar] [CrossRef]

- Petera, B.; Delattre, C.; Pierre, G.; Wadouachi, A.; Elboutachfaiti, R.; Engel, E.; Poughon, L.; Michaud, P.; Fenoradosoa, T.A. Characterization of arabinogalactan-rich mucilage from Cereus triangularis cladodes. Carbohydr. Polym. 2015, 127, 372–380. [Google Scholar] [CrossRef]

- Liu, X.; Renard, C.M.G.C.; Bureau, S.; Le Bourvellec, C. Revisiting the contribution of ATR-FTIR spectroscopy to characterize plant cell wall polysaccharides. Carbohydr. Polym. 2021, 262, 117935. [Google Scholar] [CrossRef] [PubMed]

- Borkotoky, S.S.; Ghosh, T.; Bhagabati, P.; Katiyar, V. Poly(lactic acid)/modified gum arabic (MG) based microcellular composite foam: Effect of MG on foam properties, thermal and crystallization behavior. Int. J. Biol. Macromol. 2019, 125, 159–170. [Google Scholar] [CrossRef] [PubMed]

- Paladini, G.; Venuti, V.; Crupi, V.; Majolino, D.; Fiorati, A.; Punta, C. FTIR-ATR analysis of the H-bond network of water in branched polyethyleneimine/TEMPO-oxidized cellulose nano-fiber xerogels. Cellulose 2020, 27, 8605–8618. [Google Scholar] [CrossRef]

- Nie, J.; Mou, W.; Ding, J.; Chen, Y. Bio-based epoxidized natural rubber/chitin nanocrystals composites Self-healing and enhanced mechanical properties. Comp. Part B 2019, 172, 152–160. [Google Scholar] [CrossRef]

- Ferreira, E.S.; Rezende, C.A.; Cranston, E.D. Fundamentals of cellulose lightweight materials: bio-based assemblies with tailored properties. Green. Chem. 2021, 23, 3542–3568. [Google Scholar] [CrossRef]

- Liu, P.; Li, X.; Min, P.; Chang, X.; Shu, C.; Ding, Y.; Yu, Z.Z. 3D lamellar-structured graphene aerogels for thermal interface composites with high through-plane thermal conductivity and fracture toughness. Nano-Micro Lett. 2021, 13, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Chen, H.; Yang, S.; Guo, Y.; Li, N.; Zhou, H.; Cao, Y. Frozen slurry-based laminated object manufacturing to fabricate porous ceramic with oriented lamellar structure. J. Euro. Ceram. Soc. 2018, 38, 4014–4019. [Google Scholar] [CrossRef]

- Prado, N.S.; Silva, I.S.V.D.; Silva, T.A.L.; Oliveira, W.J.D.; Motta, L.A.D.C.; Pasquini, D.; Otaguro, H. Nanocomposite films based on flaxseed gum and cellulose nanocrystals. Mat. Res. 2018, 21. [Google Scholar] [CrossRef]

- Valette, V.; Kébir, N.; Tiavarison, F.B.; Burel, F.; Lecamp, L. Preparation of flexible biobased non-isocyanate polyurethane (NIPU) foams using the transurethanization approach. React. Func. Polym. 2022, 181, 105416. [Google Scholar] [CrossRef]

- Peyrton, J.; Avérous, L. Structure-properties relationships of cellular materials from biobased polyurethane foams. Mater. Sci. Eng. Reports 2021, 145, 100608. [Google Scholar] [CrossRef]

- Ambli, K.G.; Dodamani, B.M.; Jagadeesh, A.; Vanarotti, M.B. Heterogeneous composites for low and medium temperature thermal insulation: A review. Energ. Build. 2019, 199, 455–460. [Google Scholar] [CrossRef]

- Kymäläinen, H.R.; Sjöberg, A.M. Flax and hemp fibres as raw materials for thermal insulations. Build. Env. 2008, 43, 1261–1269. [Google Scholar] [CrossRef]

| Sample | Eca (Mpa) | σ10b (kPa) | Sample | Ec* (Mpa) | σ10b (kPa) |

| FG-100 | 10.6 ± 1.2 | 742 ± 100 | FGox-100 | 19.2 ± 0.4 | 1275 ± 28 |

| FG-80 | 14.9 ± 2.3 | 784 ± 110 | FGox-80 | 11.9 ± 2.0 | 722 ± 52 |

| FG-20 | 11.8 ± 0.5 | 721 ± 9 | FGox-20 | 10.3 ± 1.5 | 654 ± 39 |

| FG-Comp | 5.6 ± 0.1 | 352 ± 1 | FGox-Comp | 10.1 ± 0.6 | 454 ± 28 |

| Sample |

Conductivity W.m-1.K-1 |

Diffusivity m²/s |

| FG-100 | 0.054 ± 0.001 | (1.53 ± 0.07).10-7 |

| FG-80 | 0.065 ± 0.001 | (1.40 ± 0.09).10-7 |

| FG-20 | 0.057 ± 0.001 | (1.45 ± 0.06).10-7 |

| FG-Comp | 0.064 ± 0.001 | (1.40 ± 0.05).10-7 |

| FGox-100 | 0.082 ± 0.001 | (1.42 ± 0.07).10-7 |

| FGox-80 | 0.095 ± 0.002 | (1.53 ± 0.06).10-7 |

| FGox-20 | 0.041 ± 0.001 | (2.55 ± 0.17).10-7 |

| FGox-Comp | 0.078 ± 0.001 | (1.40 ± 0.07).10-7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).