Submitted:

22 May 2024

Posted:

23 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

3. Results and Discussion

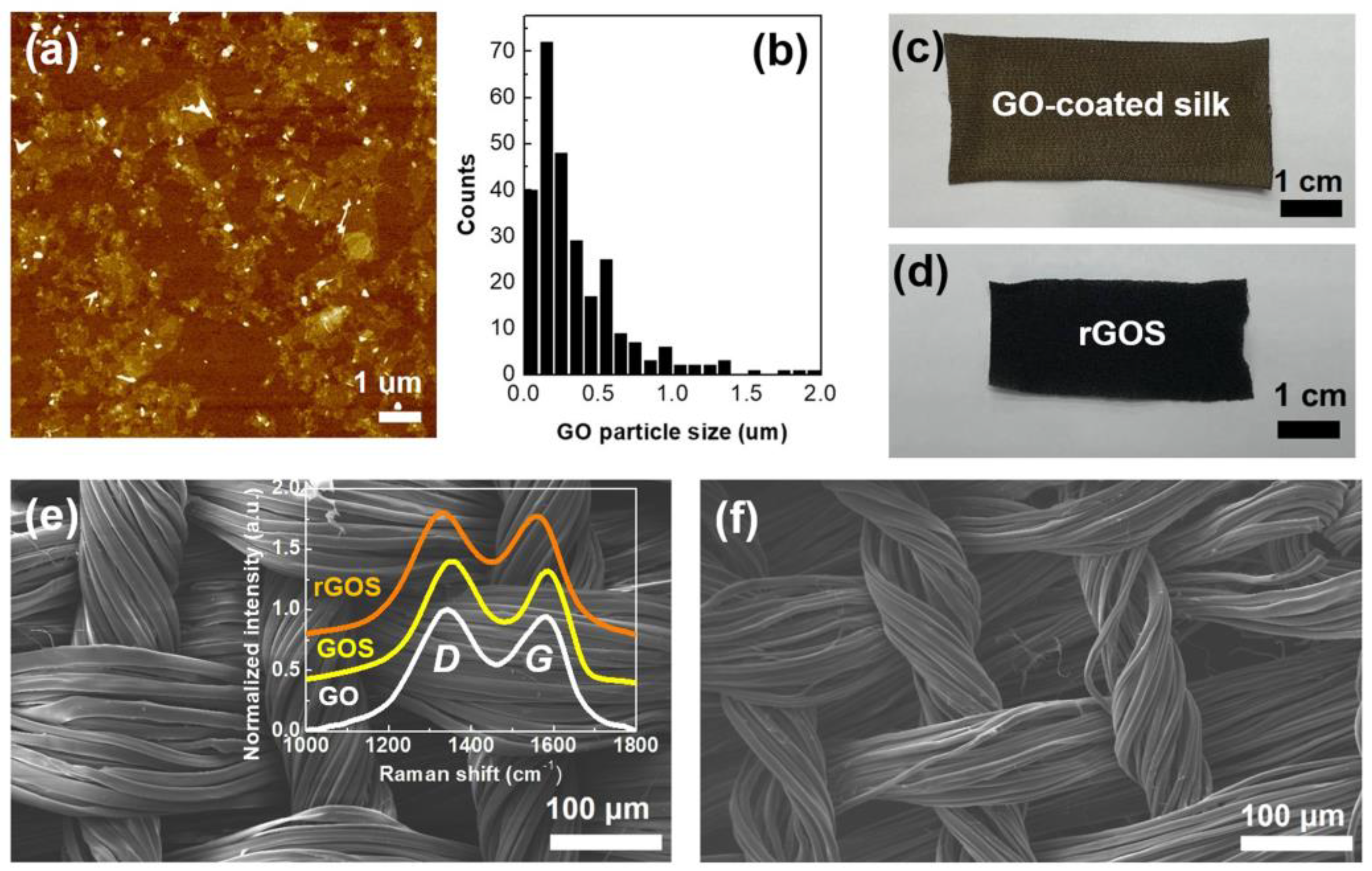

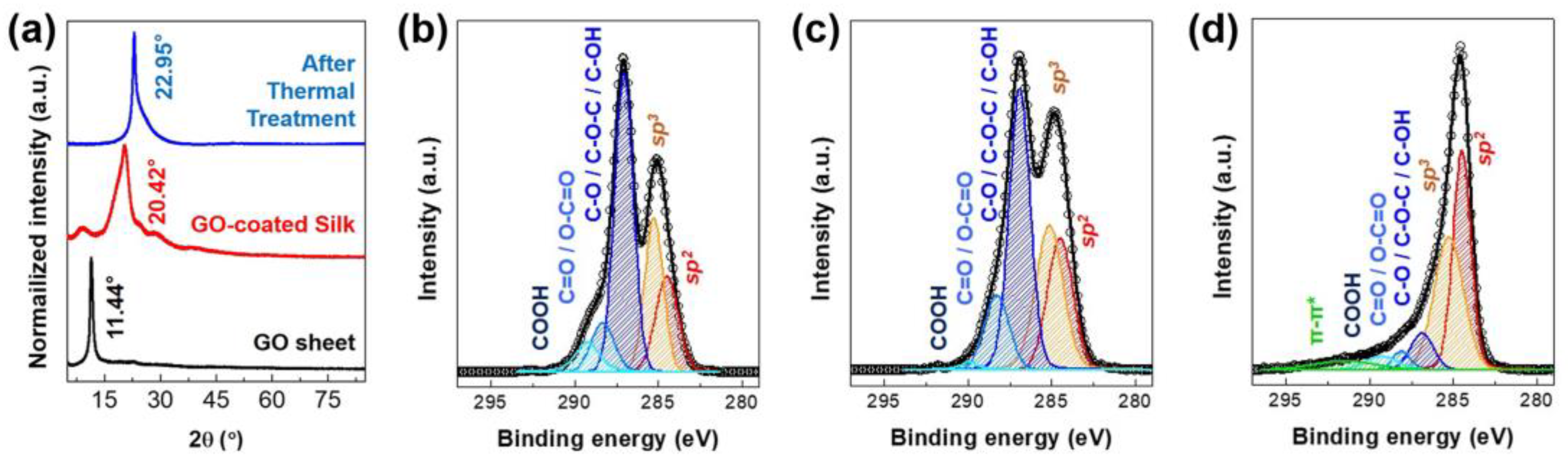

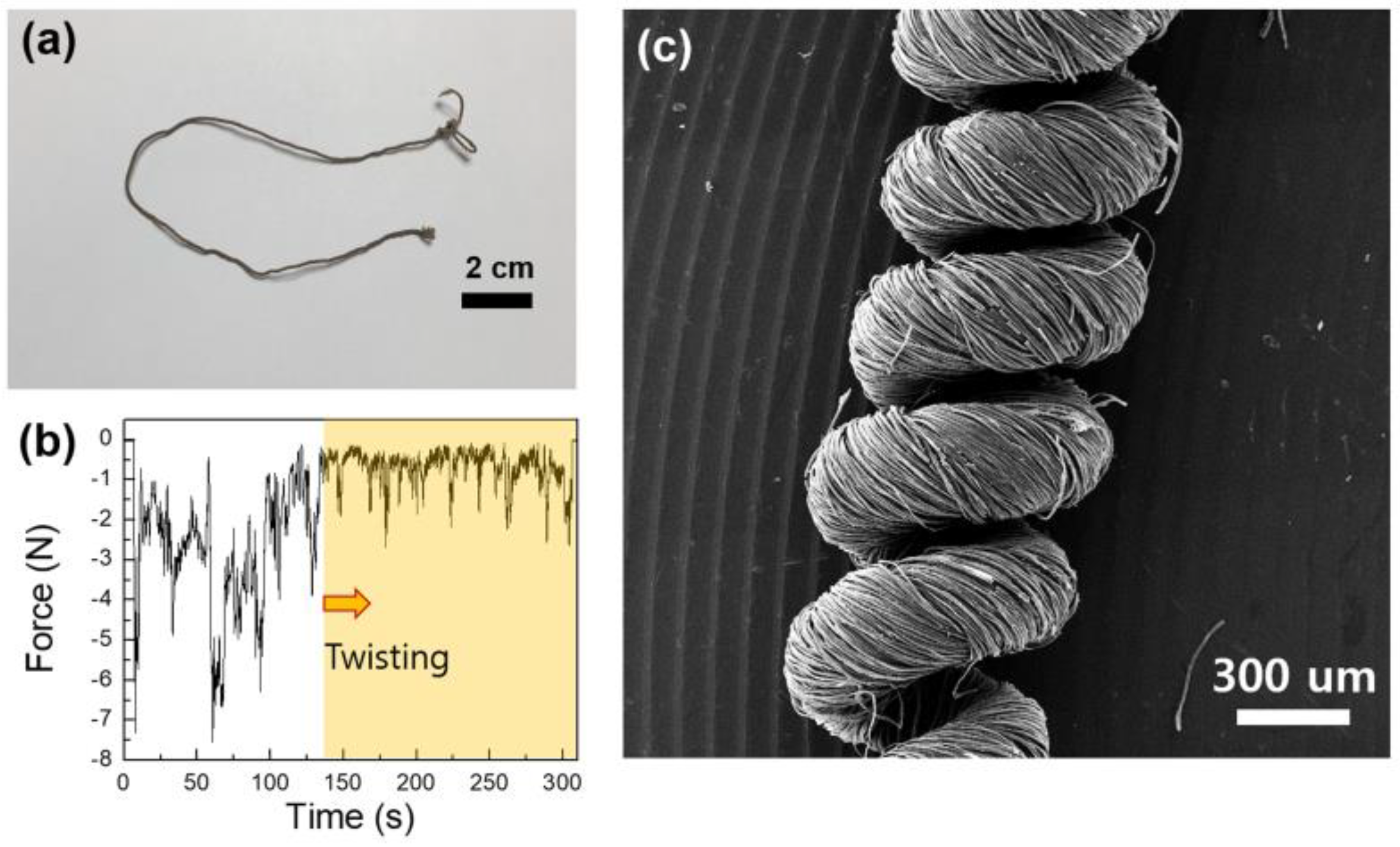

3.1. Structural Investigation

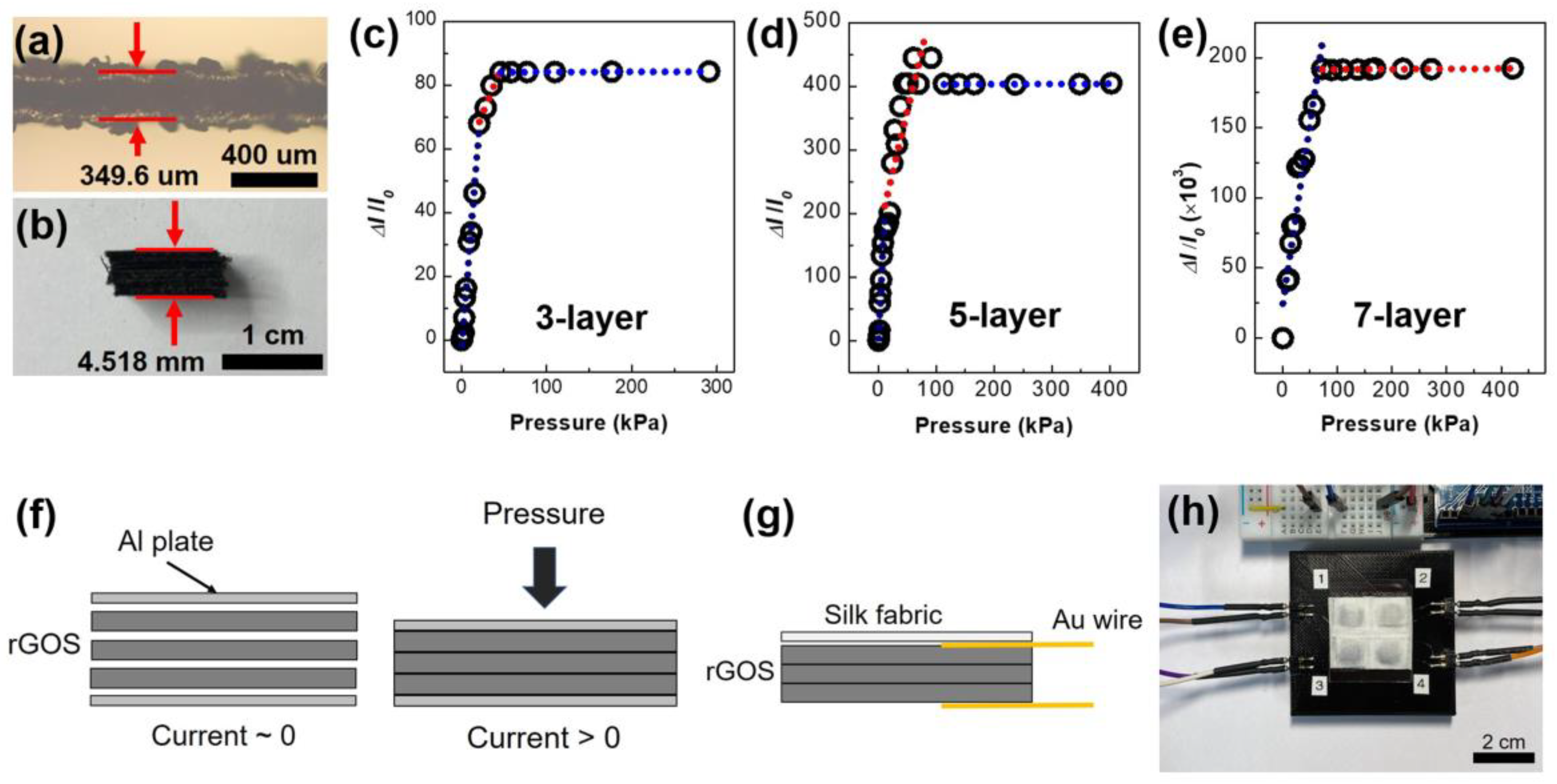

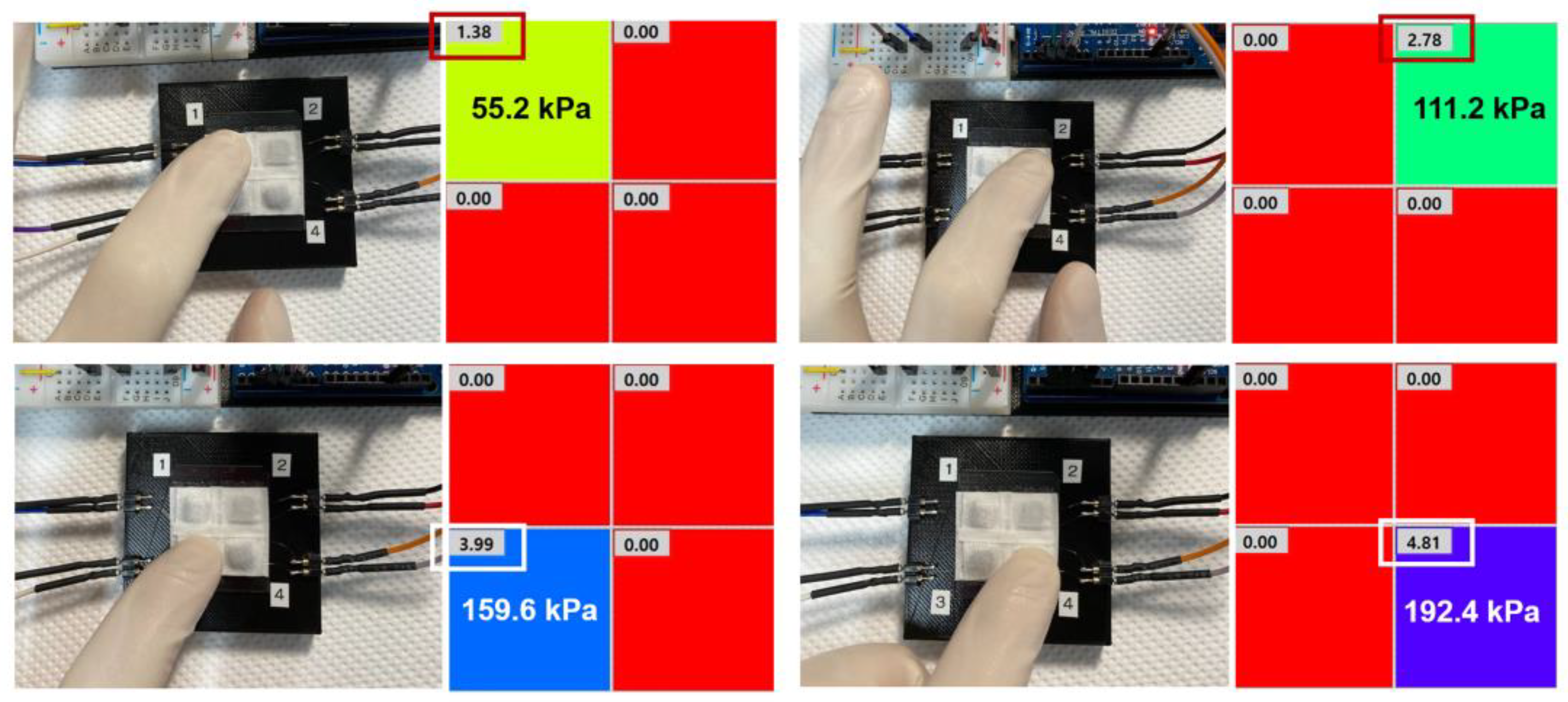

3.2. Pressure Sensors

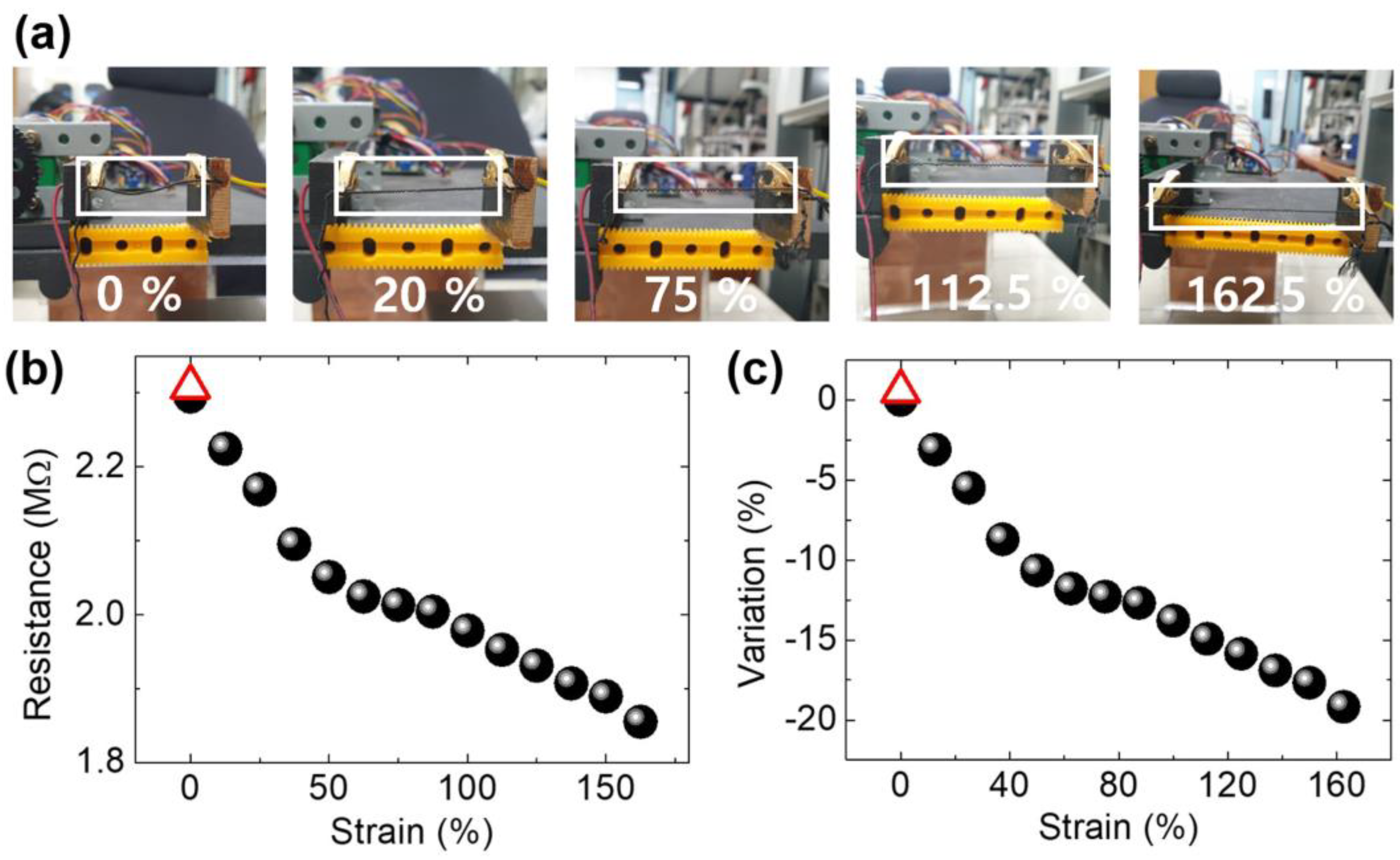

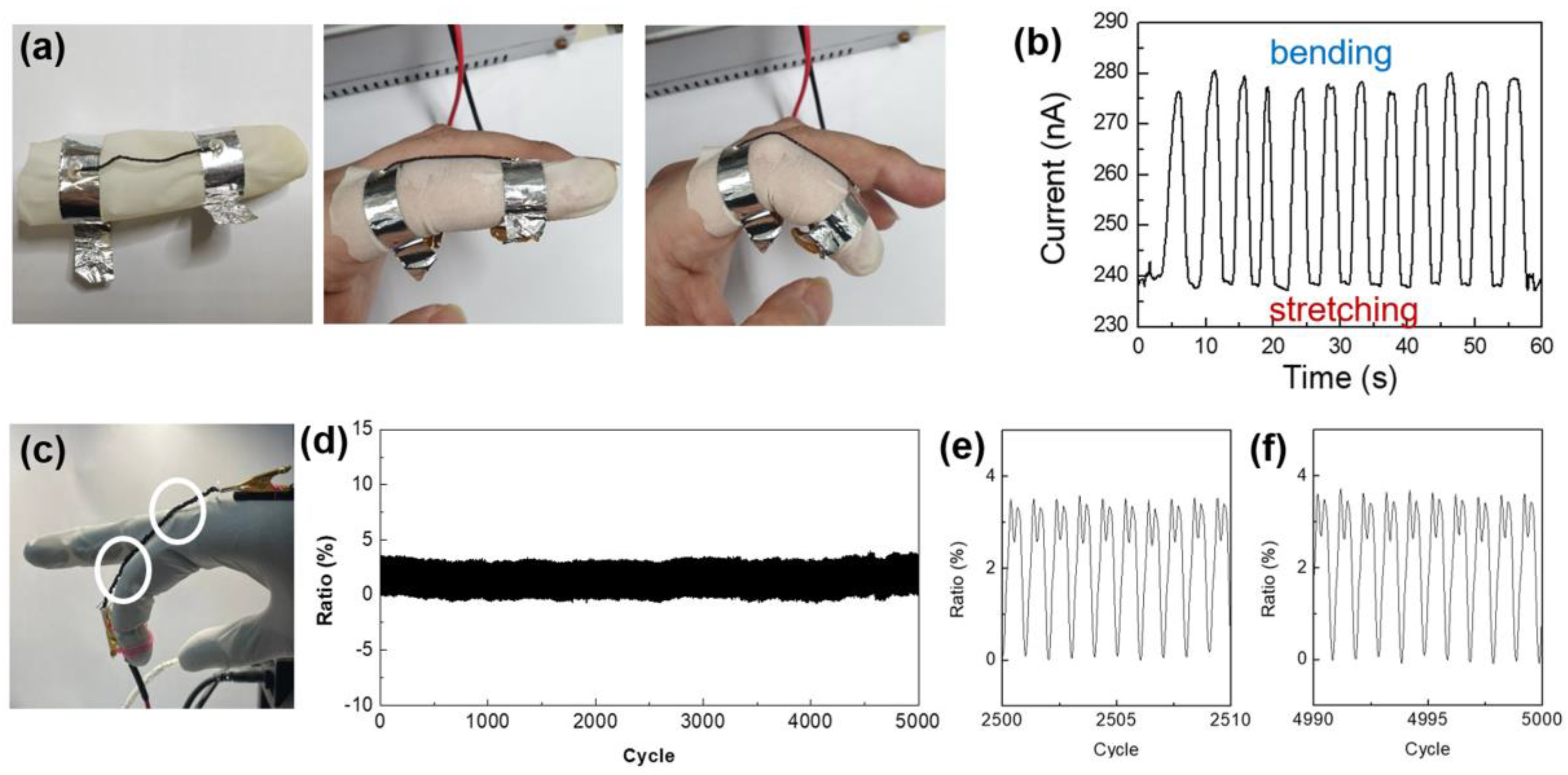

3.3. Motion Sensors

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yun, Y.J.; Hong, W.G.; Kim, W.; Jun, Y.; Kim, B.H. A Novel Method for Applying Reduced Graphene Oxide Directly to Electronic Textiles from Yarns to Fabrics. Adv. Mater. 2013, 25, 5701–5705. [Google Scholar] [CrossRef]

- Jeon, J.W.; Cho, S.Y.; Jeong, Y.J.; Shin, D.S.; Kim, N.R.; Yun, Y.S.; Kim, H.-T.; Choi, S.B.; Hong, W.G.; Kim, H.J.; et al. Pyroprotein-Based Electronic Textiles with High Stability. Adv. Mater. 2017, 29, 1605479. [Google Scholar] [CrossRef] [PubMed]

- Jeon, J.W.; Oh, J.Y.; Cho, S.Y.; Lee, S.; Jang, H.-S.; Jung, W.T.; Kim, J.-G.; Kim, H.; Kim, H.J.; Kim, S.; et al. Pyroprotein-based electronic textiles with high thermal durability. Mater. Today 2018, 21, 944–950. [Google Scholar] [CrossRef]

- Jang, H.-S.; Kim, S.; Park, I.; Jung, W.T.; Seo, J.H.; Kwon, J.-H.; Hong, W.G.; Mrówczyński, R.; Lee, H.; Choi, S.B.; et al. Long-range ordered graphitic structure in silk fibers delaminated using dopamine and thermal treatment for super-flexible electronic textiles: Possible applications for magnetic and thermoelectric textiles. Adv. Compos. Hybrid Mater. 2024, 7, 37. [Google Scholar] [CrossRef]

- Zhang, L.; Shi, X.-L.; Yang, Y.-L.; Chen, Z.-G. Flexible thermoelectric materials and devices: From materials to applications. Mater. Today 2021, 46, 62–108. [Google Scholar] [CrossRef]

- Li, X.; Cai, K.; Gao, M.; Du, Y.; Shen, S. Recent advances in flexible thermoelectric films and devices. Nano Energy 2021, 89, 106309. [Google Scholar] [CrossRef]

- Cao, T.; Shi, X.-L.; Chen, Z.-G. Advances in the design and assembly of flexible thermoelectric device. Prog. Mater. Sci. 2023, 131, 101003. [Google Scholar] [CrossRef]

- Liu, W.; Liu, Y.; Yang, Z.; Xu, C.; Li, X.; Huang, S.; Shi, J.; Du, J.; Han, A.; Yang, Y.; et al. Flexible solar cells based on foldable silicon wafers with blunted edges. Nature 2023, 617, 717–723. [Google Scholar] [CrossRef] [PubMed]

- Yeon, J. S.; Park, S. K.; Kim, S.; Jang, G.; Bae, J.; Jang, H.-S.; Kim, B. H.; Kim, Y.; Park, H. S. Self-supported VO2 on polydopamine-derived pyroprotein-based fibers for ultrastable and flexible aqueous zinc-ion batteries. Carbon Energy 2024, e469. [Google Scholar] [CrossRef]

- Ou, L.-X.; Liu, M.-Y.; Zhu, L.-Y.; Zhang, D.W.; Lu, H.-L. Recent Progress on Flexible Room-Temperature Gas Sensors Based on Metal Oxide Semiconductor. Nano-Micro Lett. 2022, 14, 206. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-H.; Mirzaei, A.; Kim, H.W.; Kim, S.S. Flexible and low power CO gas sensor with Au-functionalized 2D WS2 nanoflakes. Sensors Actuators B: Chem. 2020, 313, 128040. [Google Scholar] [CrossRef]

- Jung, W. T.; Jeon, J. W.; Jang, H.-S.; Kim, D. Y.; Lee, H.-K.; Kim, B. H. ; Commercial silk-based electronic textiles for NO2 gas sensing. Sens. Actuators B: Chem. 2020, 307, 127596. [Google Scholar] [CrossRef]

- Chen, G.; Xiao, X.; Zhao, X.; Tat, T.; Bick, M.; Chen, J. Electronic Textiles for Wearable Point-of-Care Systems. Chem. Rev. 2021, 122, 3259–3291. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Miao, J.; Fan, Q.; Zhang, W.; Zuo, X.; Tian, M.; Zhu, S.; Zhang, X.; Qu, L. Recent Progress on Smart Fiber and Textile Based Wearable Strain Sensors: Materials, Fabrications and Applications. Adv. Fiber Mater. 2022, 4, 361–389. [Google Scholar] [CrossRef]

- Zhang, J.-W.; Zhang, Y.; Li, Y.-Y.; Wang, P. Textile-Based Flexible Pressure Sensors: A Review. Polym. Rev. 2021, 62, 65–94. [Google Scholar] [CrossRef]

- Chen, J.; He, T.; Du, Z.; Lee, C. Review of textile-based wearable electronics: From the structure of the multi-level hierarchy textiles. Nano Energy 2023, 117, 108898. [Google Scholar] [CrossRef]

- Lian, Y.; Yu, H.; Wang, M.; Yang, X.; Li, Z.; Yang, F.; Wang, Y.; Tai, H.; Liao, Y.; Wu, J.; et al. A multifunctional wearable E-textile via integrated nanowire-coated fabrics. J. Mater. Chem. C 2020, 8, 8399–8409. [Google Scholar] [CrossRef]

- Lai, C.; Wu, X.; Huang, C.; Yuan, X.; Liang, H.; Wang, S.; Lin, K.; Wang, Y. Fabrication and performance of full textile-based flexible piezoresistive pressure sensor. J. Mater. Sci. Mater. Electron. 2022, 33, 4755–4763. [Google Scholar] [CrossRef]

- Lv, J.; Liu, Z.; Zhang, L.; Li, K.; Zhang, S.; Xu, H.; Mao, Z.; Zhang, H.; Chen, J.; Pan, G. Multifunctional polypyrrole and rose-like silver flower-decorated E-textile with outstanding pressure/strain sensing and energy storage performance. Chem. Eng. J. 2022, 427, 130823. [Google Scholar] [CrossRef]

- Honda, S.; Zhu, Q.; Satoh, S.; Arie, T.; Akita, S.; Takei, K. Textile-Based Flexible Tactile Force Sensor Sheet. Adv. Funct. Mater. 2019, 29, 1807957. [Google Scholar] [CrossRef]

- Kim, Y.; Bin Park, J.; Kwon, Y.J.; Hong, J.-Y.; Jeon, Y.-P.; Lee, J.U. Fabrication of highly conductive graphene/textile hybrid electrodes via hot pressing and their application as piezoresistive pressure sensors. J. Mater. Chem. C 2022, 10, 9364–9376. [Google Scholar] [CrossRef]

- Li, X.; Li, X.; Wang, M.; Zheng, R.; Jin, Y.; Gu, Z. Flexible and strain conductive cotton yarn enabled by low-temperature sintering of silver paste with multifunctional sensing capability in human motion detection and wearable applications. Chem. Eng. J. 2023, 471, 144843. [Google Scholar] [CrossRef]

- Lim, S.J.; Bae, J.H.; Jang, S.J.; Lim, J.Y.; Ko, J.H. Development of Textile-based Pressure Sensor and Its Application. Fibers Polym. 2018, 19, 2622–2630. [Google Scholar] [CrossRef]

- Lan, L.; Zhao, F.; Yao, Y.; Ping, J.; Ying, Y. One-Step and Spontaneous in Situ Growth of Popcorn-like Nanostructures on Stretchable Double-Twisted Fiber for Ultrasensitive Textile Pressure Sensor. ACS Appl. Mater. Interfaces 2020, 12, 10689–10696. [Google Scholar] [CrossRef] [PubMed]

- Alam, T.; Saidane, F.; al Faisal, A.; Khan, A.; Hossain, G. Smart- textile strain sensor for human joint monitoring. Sensors Actuators A: Phys. 2022, 341, 113587. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, Y.; Sun, X.; Liang, C.; Han, Y.; Wu, X.; Wang, Z. All textile-based robust pressure sensors for smart garments. Chem. Eng. J. 2023, 454, 140302. [Google Scholar] [CrossRef]

- Zhong, W.; Ming, X.; Jiang, H.; Ke, Y.; Ding, X.; Li, M.; Jia, K.; Wang, D. Full-Textile Human Motion Detection Systems Integrated by Facile Weaving with Hierarchical Core–Shell Piezoresistive Yarns. ACS Appl. Mater. Interfaces 2021, 13, 52901–52911. [Google Scholar] [CrossRef]

- Zhu, H.; Dai, S.; Cao, J.; Bai, H.; Zhong, Y.; Zhang, Z.; Cheng, G.; Yuan, N.; Ding, J. A high-performance textile pressure sensor based on carbon black/carbon nanotube-polyurethane coated fabrics with porous structure for monitoring human motion. Mater. Today Commun. 2022, 33, 104541. [Google Scholar] [CrossRef]

- Ma, J.; Qing, Y.; Song, H.; Yao, Y.; Xu, X.; Long, C.; Liu, N.; Li, H.; Liu, C. Micro-/nanofiber-coupled superhydrophobic and conductive textile for underwater wearable strain sensors with full-scale human motion detection ability. J. Mater. Chem. C 2023, 11, 9539–9551. [Google Scholar] [CrossRef]

- He, W.; Sohn, M.; Ma, R.; Kang, D.J. Flexible single-electrode triboelectric nanogenerators with MXene/PDMS composite film for biomechanical motion sensors. Nano Energy 2020, 78, 105383. [Google Scholar] [CrossRef]

- Zheng, X.; Wang, P.; Zhang, X.; Hu, Q.; Wang, Z.; Nie, W.; Zou, L.; Li, C.; Han, X. Breathable, durable and bark-shaped MXene/textiles for high-performance wearable pressure sensors, EMI shielding and heat physiotherapy. Compos. Part A: Appl. Sci. Manuf. 2022, 152, 106700. [Google Scholar] [CrossRef]

- Meena, J.S.; Bin Choi, S.; Khanh, T.D.; Shin, H.S.; Choi, J.S.; Joo, J.; Kim, J.-W. Highly stretchable and robust textile-based capacitive mechanical sensor for human motion detection. Appl. Surf. Sci. 2023, 613, 155961. [Google Scholar] [CrossRef]

- Ma, J.; Qing, Y.; Song, H.; Cheng, X.; Li, Z.; Long, C.; Liu, C. Synergistically coupled double conductive coating-based electronic textiles with superhydrophobic and high-performance strain sensing properties for underwater human motion sensing applications. Chem. Eng. J. 2023, 471, 144284. [Google Scholar] [CrossRef]

- Yao, D.; Tang, Z.; Liang, Z.; Zhang, L.; Sun, Q.-J.; Fan, J.; Zhong, G.; Liu, Q.-X.; Jiang, Y.-P.; Tang, X.-G.; et al. Adhesive, multifunctional, and wearable electronics based on MXene-coated textile for personal heating systems, electromagnetic interference shielding, and pressure sensing. J. Colloid Interface Sci. 2023, 630, 23–33. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Li, X.; Gao, E.; Jian, M.; Xia, K.; Wang, Q.; Xu, Z.; Ren, T.; Zhang, Y. Carbonized Silk Fabric for Ultrastretchable, Highly Sensitive, and Wearable Strain Sensors. Adv. Mater. 2016, 28, 6640–6648. [Google Scholar] [CrossRef] [PubMed]

- Wu, R.; Ma, L.; Hou, C.; Meng, Z.; Guo, W.; Yu, W.; Yu, R.; Hu, F.; Liu, X.Y. Silk Composite Electronic Textile Sensor for High Space Precision 2D Combo Temperature–Pressure Sensing. Small 2019, 15, e1901558. [Google Scholar] [CrossRef]

- Ma, X.; Kong, Z.; Gao, Y.; Bai, Y.; Wang, W.; Tan, H.; Cai, X.; Cai, J. Anisotropic Free-Standing Aerogels Based on Graphene/Silk for Pressure Sensing and Efficient Adsorption. ACS Appl. Mater. Interfaces 2023, 15, 30630–30642. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Yao, B.; Li, C.; Shi, G. An improved Hummers method for eco-friendly synthesis of graphene oxide. Carbon 2013, 64, 225–229. [Google Scholar] [CrossRef]

- Perumbilavil, S.; Sankar, P.; Rose, T.P.; Philip, R. White light Z-scan measurements of ultrafast optical nonlinearity in reduced graphene oxide nanosheets in the 400–700 nm region. Appl. Phys. Lett. 2015, 107, 4928124. [Google Scholar] [CrossRef]

- Jang, H.-S.; Jung, W.T.; Chung, C.; Kim, M.; So, Y.; Song, S.; Kim, B.H. Charge Transport at the Interface between Graphene Oxide and Silk in Highly Flexible Commercial Silk-Based e-Textile Treated at High Temperatures. ACS Appl. Electron. Mater. 2022, 4, 3543–3548. [Google Scholar] [CrossRef]

- Jung, W.T.; Jang, H.-S.; Jeon, J.W.; Kim, B.H. Effect of Oxygen Functional Groups in Reduced Graphene Oxide-Coated Silk Electronic Textiles for Enhancement of NO2 Gas-Sensing Performance. ACS Omega 2021, 6, 27080–27088. [Google Scholar] [CrossRef] [PubMed]

- Si, S.; Sun, C.; Qiu, J.; Liu, J.; Yang, J. Knitting integral conformal all-textile strain sensor with commercial apparel characteristics for smart textiles. Appl. Mater. Today 2022, 27, 101508. [Google Scholar] [CrossRef]

- Liu, M.; Pu, X.; Jiang, C.; Liu, T.; Huang, X.; Chen, L.; Du, C.; Sun, J.; Hu, W.; Wang, Z.L. Large-Area All-Textile Pressure Sensors for Monitoring Human Motion and Physiological Signals. Adv. Mater. 2017, 29, 1703700. [Google Scholar] [CrossRef] [PubMed]

| Textile | Materials/methods | Sensitivity (kPa-1) | Ref. |

|---|---|---|---|

| Silk | Silkworm cocoon, GO, C6H12O6, NaOH/hydrothermal and freeze-drying | 0.54 ~ 0.21 | 37 |

| Silk | Silkworm fiber, AgNW, PU, CNT/Coiling AgNW onto silk fiber-wrapped PU yarn | 0.136 | 36 |

| Cotton | Cotton fabric, polyester, Kapton tape, sodium dodecylbenzene sulfonate, VHB film, CNT, Ni/CNT-coating on cotton fabric by dipping, patterning using CO2 laser scribing, Ni-coating with the aid of the mask via electroless plating, | 14.4 | 43 |

| Cotton | Cotton fabric, AgNW, FeCl3, ethylene glycol, poly(vinylpyrrolidone), Ag paste/Synthesis of AgNW using a hydrothermal method, Fabrication of Ag paste on the cotton fabric by screen printing process, AgNW coating on a cotton by soaking process | 4.42 ×103, (Comparable to the results in this study) |

18 |

| Cotton | Cotton fabric, AgNW, isopropyl alcohol, polyvinyl pyrrolidone, ethylene glycol, AgNO3, NaCl/Synthesis of AgNW using hydrothermal method, AgNW coating on a cotton by dipping | 2.16 ×104 | 17 |

| Cotton | Knitted cotton/spandex fabric (KSCF), pyrrole, ferric chloride hexahydrate, sodium 5-sulfosalicylate, cyclohexane, AgNO3, sodium citrate, KNO3, Na2SO4/Synthesis of PPy@KSCF using in situ polymerization method, preparation of PPy@KSCF with Ag flower using an electrodeposition process | 17.41 | 19 |

| Cotton | Cotton, graphite, stainless steel, PDMS, (NH4)2SO4, NMP, NaOH/ Electrochemically exfoliation of graphene (EEG), Coating of EEG films on cotton using a hot press |

0.16 | 21 |

| Nylon, cotton, silk | Nylon, cotton, silk, PU filament/Ag coating on nylon yarn by ion plating method, wrapping of cotton yarn around PU filament and silk around Ag-coated nylon yarn using covering machine | 0.01884 | 42 |

| Polyester | Polyester, MoS2, HAuCl4, ethanol/Treatment of the fiber with air plasma, MoS2 coating by dropping, immersing of the fiber in an aqueous HAuCl4 to grow Au nanostructure | 0.19 | 24 |

| Polyester | Polyester fabric, carbon ink, waterborne PU (WPU), CNT, Venetian fabric, CNT paste/Coating of carbon ink on polyester by screen-printing and curing at 100 °C, mixture of cationic WPU and anionic WPU with CNT suspension, Electrostatic deposition of WPU/CNT by dipping of Venetian fabric into WPU/CNT suspensions | 3.42 | 26 |

| Silk | GO, commercial silk/GO coating on silk by dipping method, thermal treatment at 400 °C to reduce GO | 2.58 ×103 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).