Submitted:

20 May 2024

Posted:

20 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. PHA Composites

3. Polymer Composites with Natural Waste Fillers

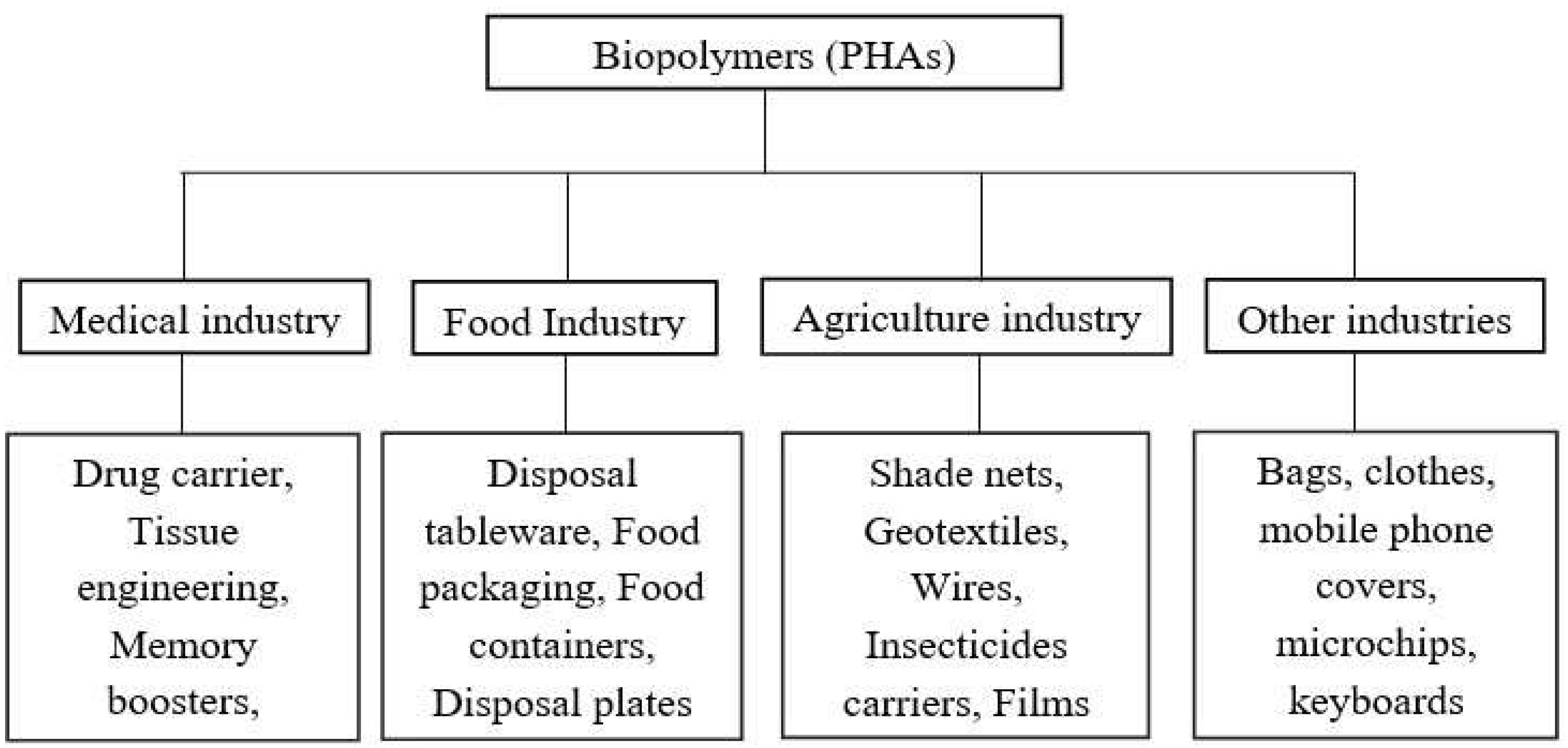

4. Applications and Properties

- Active and intelligent food packaging;

- Bio-packaging;

- Biomedical applications;

- Wound healing;

- Bio-based composites as fertilizer delivery and their applications as agricultural inputs;

- Applications for Wood-PHA Composites (Rigid tableware, Disposable tableware);

- Other innovative bio-based composites applications

5. Current Developments

6. Challenges and Future Aspects

7. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- European Union. https://environment.ec.europa.eu/news/eu-calls-global-ban-some-plastic-products-fight-pollution-2024-04-19_en.

- Andrady, A.L. Assessment of Environmental Biodegradation of Synthetic Polymers. Journal of Macromolecular Science, Part C: Polymer Reviews 1994, 34, 25–76. [CrossRef]

- Zaaba, N.F.; Ismail, H. Thermoplastic/Natural Filler Composites: A Short Review. Journal of Physical Science 2019, 30. [CrossRef]

- Philip, S.; Keshavarz, T.; Roy, I. Polyhydroxyalkanoates: Biodegradable Polymers with a Range of Applications. Journal of chemical technology & biotechnology: International research in process, Environmental & clean technology 2007, 82, 233–247.

- Mukherjee, A.; Koller, M. Microbial polyHydroxyAlkanoate (PHA) Biopolymers—Intrinsically Natural. Bioengineering 2023, 10, 855. [CrossRef]

- Cinelli, P.; Mallegni, N.; Gigante, V.; Montanari, A.; Seggiani, M.; Coltelli, M.B.; Bronco, S.; Lazzeri, A. Biocomposites Based on Polyhydroxyalkanoates and Natural Fibres from Renewable Byproducts. Applied Food Biotechnology 2019, 6, 35–43.

- Mohit, H.; Mavinkere Rangappa, S.; Siengchin, S.; Gorbatyuk, S.; Manimaran, P.; Alka Kumari, C.; Khan, A.; Doddamani, M. A Comprehensive Review on Performance and Machinability of Plant Fiber Polymer Composites. Polymer Composites 2022, 43, 608–623. [CrossRef]

- Dacko, P.; Kowalczuk, M.; Janeczek, H.; Sobota, M. Physical Properties of the Biodegradable Polymer Compositions Containing Natural Polyesters and Their Synthetic Analogues. In Proceedings of the Macromolecular symposia; Wiley Online Library, 2006; Vol. 239, pp. 209–216. [CrossRef]

- Das, P.P.; Chaudhary, V. Moving towards the Era of Bio Fibre Based Polymer Composites. Cleaner engineering and technology 2021, 4, 100182. [CrossRef]

- Tumu, K.; Vorst, K.; Curtzwiler, G. Global Plastic Waste Recycling and Extended Producer Responsibility Laws. Journal of Environmental Management 2023, 348, 119242. [CrossRef]

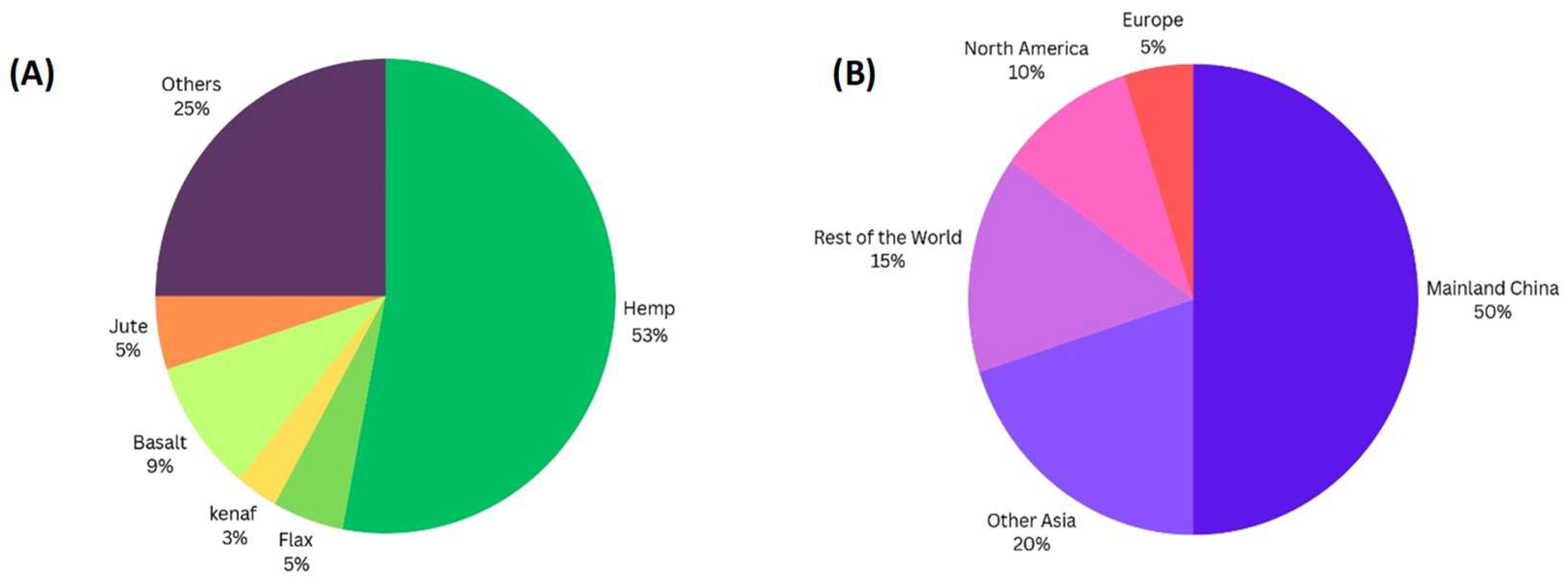

- Thapliyal, D.; Verma, S.; Sen, P.; Kumar, R.; Thakur, A.; Tiwari, A.K.; Singh, D.; Verros, G.D.; Arya, R.K. Natural Fibers Composites: Origin, Importance, Consumption Pattern, and Challenges. Journal of Composites Science 2023, 7, 506.

- Ramu, S.; Senthilkumar, N. Approaches of Material Selection, Alignment and Methods of Fabrication for Natural Fiber Polymer Composites: A Review. Journal of Applied and Natural Science 2022, 14, 490–499. [CrossRef]

- Townsend, T. 1B - World Natural Fibre Production and Employment. In Handbook of Natural Fibres (Second Edition); Kozłowski, R.M., Mackiewicz-Talarczyk, M., Eds.; Woodhead Publishing Series in Textiles; Woodhead Publishing, 2020; pp. 15–36 ISBN 978-0-12-818398-4.

- Akinmulewo, A.B.; Nwinyi, O.C. Polyhydroxyalkanoate: A Biodegradable Polymer (a Mini Review). In Proceedings of the Journal of physics: Conference series; IOP Publishing, 2019; Vol. 1378, p. 042007.

- Vannini, M.; Marchese, P.; Sisti, L.; Saccani, A.; Mu, T.; Sun, H.; Celli, A. Integrated Efforts for the Valorization of Sweet Potato By-Products within a Circular Economy Concept: Biocomposites for Packaging Applications Close the Loop. Polymers 2021, 13, 1048. [CrossRef]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Frontiers in Materials 2019, 6, 226. [CrossRef]

- Raj, H.; Tripathi, S.; Bauri, S.; Choudhary, A.; Mandal, S.; Maiti, P. Green Composites Using Naturally Occurring Fibers: A Comprehensive Review. Sustainable Polymer & Energy 2023, 1, 10010. [CrossRef]

- Dobrogojski, J.; Spychalski, M.; Luciński, R.; Borek, S. Transgenic Plants as a Source of Polyhydroxyalkanoates. Acta Physiologiae Plantarum 2018, 40, 1–17. [CrossRef]

- Sun, J.; Shen, J.; Chen, S.; Cooper, M.A.; Fu, H.; Wu, D.; Yang, Z. Nanofiller Reinforced Biodegradable PLA/PHA Composites: Current Status and Future Trends. Polymers 2018, 10, 505. [CrossRef]

- Chodak, I. Polyhydroxyalkanoates: Origin, Properties and Applications. In Monomers, polymers and composites from renewable resources; Elsevier, 2008; pp. 451–477.

- Maiti, S.; Islam, M.R.; Uddin, M.A.; Afroj, S.; Eichhorn, S.J.; Karim, N. Sustainable Fiber-reinforced Composites: A Review. Advanced Sustainable Systems 2022, 6, 2200258. [CrossRef]

- Abd El-malek, F.; Khairy, H.; Farag, A.; Omar, S. The Sustainability of Microbial Bioplastics, Production and Applications. International journal of biological macromolecules 2020, 157, 319–328.

- Aeschelmann, F.; Carus, M. Bio-Based Building Blocks and Polymers in the World. Capacities, production and applications: Status quo and trends towards 2020 2015.

- Vandi, L.-J.; Chan, C.M.; Werker, A.; Richardson, D.; Laycock, B.; Pratt, S. Wood-PHA Composites: Mapping Opportunities. Polymers 2018, 10, 751. [CrossRef]

- Huang, J.S.; Liew, J.X.; Ademiloye, A.S.; Liew, K.M. Artificial Intelligence in Materials Modeling and Design. Archives of Computational Methods in Engineering 2021, 28, 3399–3413. [CrossRef]

- Kalak, T. Potential Use of Industrial Biomass Waste as a Sustainable Energy Source in the Future. Energies 2023, 16, 1783. [CrossRef]

- Jaffur, N.; Kumar, G.; Jeetah, P.; Ramakrishna, S.; Bhatia, S.K. Current Advances and Emerging Trends in Sustainable Polyhydroxyalkanoate Modification from Organic Waste Streams for Material Applications. International Journal of Biological Macromolecules 2023, 126781. [CrossRef]

- Acharjee, S.A.; Bharali, P.; Gogoi, B.; Sorhie, V.; Walling, B.; Alemtoshi PHA-Based Bioplastic: A Potential Alternative to Address Microplastic Pollution. Water, Air, & Soil Pollution 2023, 234, 21.

- Musioł, M.; Rydz, J.; Janeczek, H.; Kordyka, A.; Andrzejewski, J.; Sterzyński, T.; Jurczyk, S.; Cristea, M.; Musioł, K.; Kampik, M. (Bio) Degradable Biochar Composites–Studies on Degradation and Electrostatic Properties. Materials Science and Engineering: B 2022, 275, 115515. [CrossRef]

- Battista, F.; Frison, N.; Pavan, P.; Cavinato, C.; Gottardo, M.; Fatone, F.; Eusebi, A.L.; Majone, M.; Zeppilli, M.; Valentino, F. Food Wastes and Sewage Sludge as Feedstock for an Urban Biorefinery Producing Biofuels and Added-value Bioproducts. Journal of Chemical Technology & Biotechnology 2020, 95, 328–338. [CrossRef]

- Khan, A.; Saxena, K.K. A Review on Enhancement of Mechanical Properties of Fiber Reinforcement Polymer Composite under Different Loading Rates. Materials Today: Proceedings 2022, 56, 2316–2322. [CrossRef]

- Kordi, M.; Farrokhi, N.; Pech-Canul, M.I.; Ahmadikhah, A. Rice Husk at a Glance: From Agro-Industrial to Modern Applications. Rice Science 2023. [CrossRef]

- Jabu, M.A.; Alugongo, A.A.; Nkomo, N.Z. Application of Natural Fibre Composites in Interior Panels in the Automotive Industry: A Review. [CrossRef]

- Mohammed, L.; Ansari, M.N.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. International journal of polymer science 2015, 2015. [CrossRef]

- Nikodinovic-Runic, J.; Guzik, M.; Kenny, S.T.; Babu, R.; Werker, A.; Connor, K.E. Carbon-Rich Wastes as Feedstocks for Biodegradable Polymer (Polyhydroxyalkanoate) Production Using Bacteria. Advances in applied microbiology 2013, 84, 139–200.

- Coats, E.R.; Loge, F.J.; Wolcott, M.P.; Englund, K.; McDonald, A.G. Synthesis of Polyhydroxyalkanoates in Municipal Wastewater Treatment. Water Environment Research 2007, 79, 2396–2403. [CrossRef]

- Jiang, G.; Hill, D.J.; Kowalczuk, M.; Johnston, B.; Adamus, G.; Irorere, V.; Radecka, I. Carbon Sources for Polyhydroxyalkanoates and an Integrated Biorefinery. International Journal of Molecular Sciences 2016, 17, 1157. [CrossRef]

- Chirdon, W.M. Utilization of Biorefinery Waste Proteins as Feed, Glues, Composites, and Other Co-Products. Algal Biorefineries: Volume 2: Products and Refinery Design 2015, 367–392.

- Brebu, M. Environmental Degradation of Plastic Composites with Natural Fillers—a Review. Polymers 2020, 12, 166. [CrossRef]

- La Mantia, F.P.; Morreale, M. Green Composites: A Brief Review. Composites Part A: Applied Science and Manufacturing 2011, 42, 579–588.

- Dina, I.A.; Gimba, C.E.; Hamza, A.; Ekwumemgbo, P. THE STUDY OF USING NATURAL FILLERS ON THE BIODEGRADATION PROPERTIES OF VIRGIN/WASTE LOW DENSITY POLYETHYLENE AND VIRGIN/WASTE HIGH DENSITY POLYETHYLENE COMPOSITES. Journal of Chemical Society of Nigeria 2023, 48. [CrossRef]

- Kaniuk, Ł.; Stachewicz, U. Development and Advantages of Biodegradable PHA Polymers Based on Electrospun PHBV Fibers for Tissue Engineering and Other Biomedical Applications. ACS biomaterials science & engineering 2021, 7, 5339–5362. [CrossRef]

- Saber, D.; Abdelnaby, A.H. Recent Developments in Natural Fiber as Reinforcement in Polymeric Composites: A Review. Recent Developments in Natural Fiber as Reinforcement in Polymeric Composites: A Review (October 19, 2022). D. Saber & AH Abdelnaby" Recent Developments in Natural Fiber as Reinforcement in Polymeric Composites: A Review" Asian Journal of Applied Science and Technology (AJAST) Volume 2022, 6, 56–75.

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedri, M.; Nasri, M.; Garnier, C. A Comprehensive Review of Natural Fibers and Their Composites: An Eco-Friendly Alternative to Conventional Materials. Results in Engineering 2023, 101271. [CrossRef]

- Andrew, J.J.; Dhakal, H.N. Sustainable Biobased Composites for Advanced Applications: Recent Trends and Future Opportunities–A Critical Review. Composites Part C: Open Access 2022, 7, 100220. [CrossRef]

- Koohestani, B.; Darban, A.K.; Mokhtari, P.; Yilmaz, E.; Darezereshki, E. Comparison of Different Natural Fiber Treatments: A Literature Review. International Journal of Environmental Science and Technology 2019, 16, 629–642. [CrossRef]

- Ortega, F.; Versino, F.; López, O.V.; García, M.A. Biobased Composites from Agro-Industrial Wastes and by-Products. Emergent Materials 2022, 5, 873–921. [CrossRef]

- Sikorska, W.; Dacko, P.; Sobota, M.; Rydz, J.; Musioł, M.; Kowalczuk, M. Degradation Study of Polymers from Renewable Resources and Their Compositions in Industrial Composting Pile. In Proceedings of the Macromolecular symposia; Wiley Online Library, 2008; Vol. 272, pp. 132–135. [CrossRef]

- Musioł, M.; Janeczek, H.; Jurczyk, S.; Kwiecień, I.; Sobota, M.; Marcinkowski, A.; Rydz, J. (Bio) Degradation Studies of Degradable Polymer Composites with Jute in Different Environments. Fibers and Polymers 2015, 16, 1362–1369. [CrossRef]

- Anwajler, B.; Zdybel, E.; Tomaszewska-Ciosk, E. Innovative Polymer Composites with Natural Fillers Produced by Additive Manufacturing (3D Printing)—A Literature Review. Polymers 2023, 15, 3534. [CrossRef]

- Jurczyk, S.; Musioł, M.; Sobota, M.; Klim, M.; Hercog, A.; Kurcok, P.; Janeczek, H.; Rydz, J. (Bio) Degradable Polymeric Materials for Sustainable Future—Part 2: Degradation Studies of P (3HB-Co-4HB)/Cork Composites in Different Environments. Polymers 2019, 11, 547.

- Musioł, M.; Jurczyk, S.; Sobota, M.; Klim, M.; Sikorska, W.; Zięba, M.; Janeczek, H.; Rydz, J.; Kurcok, P.; Johnston, B. (Bio) Degradable Polymeric Materials for Sustainable Future—Part 3: Degradation Studies of the PHA/Wood Flour-Based Composites and Preliminary Tests of Antimicrobial Activity. Materials 2020, 13, 2200. [CrossRef]

- Kamarudin, S.H.; Mohd Basri, M.S.; Rayung, M.; Abu, F.; Ahmad, S.; Norizan, M.N.; Osman, S.; Sarifuddin, N.; Desa, M.S.Z.M.; Abdullah, U.H. A Review on Natural Fiber Reinforced Polymer Composites (NFRPC) for Sustainable Industrial Applications. Polymers 2022, 14, 3698. [CrossRef]

- Markevičiūtė, Z.; Varžinskas, V. Smart Material Choice: The Importance of Circular Design Strategy Applications for Bio-Based Food Packaging Preproduction and End-of-Life Life Cycle Stages. Sustainability 2022, 14, 6366. [CrossRef]

- Jan-Georg, R.; Langer, R.; Giovanni, T. Bioplastics for a Circular Economy. Nature Reviews. Materials 2022, 7, 117–137.

- Naser, A.Z.; Deiab, I.; Darras, B.M. Poly (Lactic Acid)(PLA) and Polyhydroxyalkanoates (PHAs), Green Alternatives to Petroleum-Based Plastics: A Review. RSC advances 2021, 11, 17151–17196.

- Melendez-Rodriguez, B.; Torres-Giner, S.; Aldureid, A.; Cabedo, L.; Lagaron, J.M. Reactive Melt Mixing of Poly (3-Hydroxybutyrate)/Rice Husk Flour Composites with Purified Biosustainably Produced Poly (3-Hydroxybutyrate-Co-3-Hydroxyvalerate). Materials 2019, 12, 2152.

- Jaffur, N.; Kumar, G.; Jeetah, P.; Ramakrishna, S.; Bhatia, S.K. Current Advances and Emerging Trends in Sustainable Polyhydroxyalkanoate Modification from Organic Waste Streams for Material Applications. International Journal of Biological Macromolecules 2023, 126781. [CrossRef]

- Zhang, K.; Misra, M.; Mohanty, A.K. Toughened Sustainable Green Composites from Poly (3-Hydroxybutyrate-Co-3-Hydroxyvalerate) Based Ternary Blends and Miscanthus Biofiber. ACS Sustainable Chemistry & Engineering 2014, 2, 2345–2354. [CrossRef]

- Oliver-Ortega, H.; Julian, F.; Espinach, F.X.; Tarrés, Q.; Ardanuy, M.; Mutjé, P. Research on the Use of Lignocellulosic Fibers Reinforced Bio-Polyamide 11 with Composites for Automotive Parts: Car Door Handle Case Study. Journal of cleaner production 2019, 226, 64–73. [CrossRef]

- Berzin, F.; Vergnes, B. Thermoplastic Natural Fiber Based Composites. In Fiber Reinforced Composites; Elsevier, 2021; pp. 113–139.

- Halley, P.J.; Dorgan, J.R. Next-Generation Biopolymers: Advanced Functionality and Improved Sustainability. MRS bulletin 2011, 36, 687–691. [CrossRef]

- Khamkong, T.; Penkhrue, W.; Lumyong, S. Optimization of Production of Polyhydroxyalkanoates (PHAs) from Newly Isolated Ensifer Sp. Strain HD34 by Response Surface Methodology. Processes 2022, 10, 1632.

- Suhaily, S.S.; Khalil, H.A.; Nadirah, W.W.; Jawaid, M. Bamboo Based Biocomposites Material, Design and Applications. In Materials science-advanced topics; IntechOpen, 2013 ISBN 953-51-1140-X.

- Lange, J.-P. Managing Plastic Waste─ Sorting, Recycling, Disposal, and Product Redesign. ACS Sustainable Chemistry & Engineering 2021, 9, 15722–15738.

- Mishra, T.; Mandal, P.; Rout, A.K.; Sahoo, D. A State-of-the-Art Review on Potential Applications of Natural Fiber-Reinforced Polymer Composite Filled with Inorganic Nanoparticle. Composites Part C: Open Access 2022, 9, 100298. [CrossRef]

- Marciniak, P.; Możejko-Ciesielska, J. What Is New in the Field of Industrial Wastes Conversion into Polyhydroxyalkanoates by Bacteria? Polymers 2021, 13, 1731.

- Mohanty, A.K.; Misra, M. and; Hinrichsen, G.I. Biofibres, Biodegradable Polymers and Biocomposites: An Overview. Macromolecular materials and Engineering 2000, 276, 1–24.

- Boey, J.Y.; Mohamad, L.; Khok, Y.S.; Tay, G.S.; Baidurah, S. A Review of the Applications and Biodegradation of Polyhydroxyalkanoates and Poly (Lactic Acid) and Its Composites. Polymers 2021, 13, 1544. [CrossRef]

- Islam, M.Z.; Sarker, M.E.; Rahman, M.M.; Islam, M.R.; Ahmed, A.F.; Mahmud, M.S.; Syduzzaman, M. Green Composites from Natural Fibers and Biopolymers: A Review on Processing, Properties, and Applications. Journal of Reinforced Plastics and Composites 2022, 41, 526–557.

- Dubey, S.C.; Mishra, V.; Sharma, A. A Review on Polymer Composite with Waste Material as Reinforcement. Materials Today: Proceedings 2021, 47, 2846–2851. [CrossRef]

- Rydz, J.; Duale, K.; Sikorska, W.; Musioł, M.; Janeczek, H.; Marcinkowski, A.; Siwy, M.; Adamus, G.; Mielczarek, P.; Silberring, J. Oligopeptide-Based Molecular Labelling of (Bio) Degradable Polyester Biomaterials. International Journal of Biological Macromolecules 2024, 131561. [CrossRef]

- Rydz, J.; Musioł, M.; Zawidlak-Węgrzyńska, B.; Sikorska, W. Present and Future of Biodegradable Polymers for Food Packaging Applications. Biopolymers for food design 2018, 431–467.

| Waste substrate | Commercial Volume (million Tonnes/year) |

Applications |

|---|---|---|

| Food waste Animal waste Agriculture waste Municipal waste Industrial waste Sewage waste Forest residue Paper waste Waste water Lignocellulosic waste |

931 1400 2500 2010 3400 10.4 4600 67.4 0.6-13.5 1300 |

Bio-gas Fertilizers, Bio-energy Recycling Materials Energy resource Coal Combustion products Fertilizer, Soil improver Bio-fuel production Newspapers, Paper towels Treated waste water Animal feed |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).