Submitted:

16 May 2024

Posted:

16 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

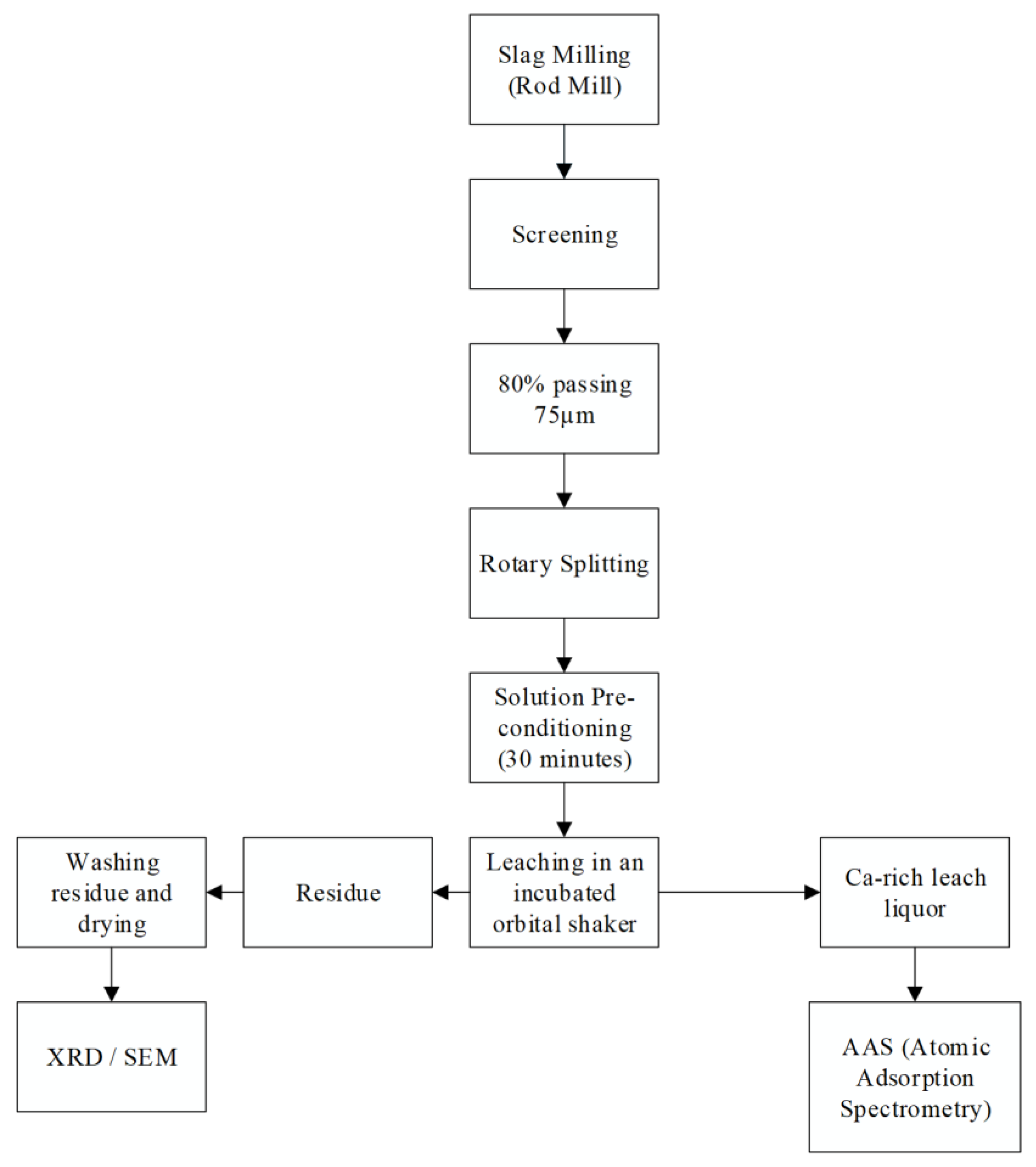

2.2. Calcium Mineral Extraction Stage

2.3. Chemical Analysis and Material Characterization

3. Results

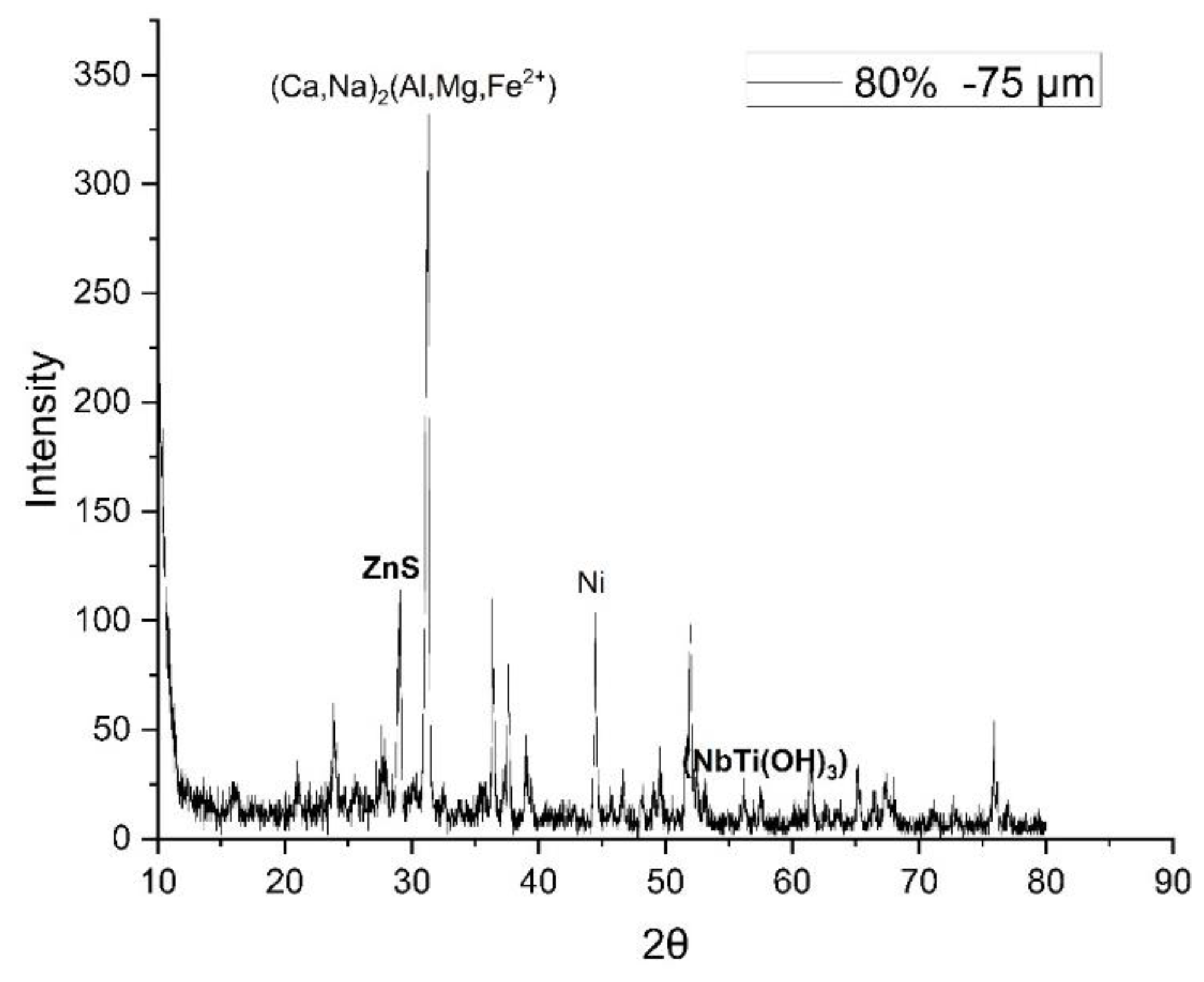

3.1. Characterisation of the Ironmaking Blast Furnace Slag Sample

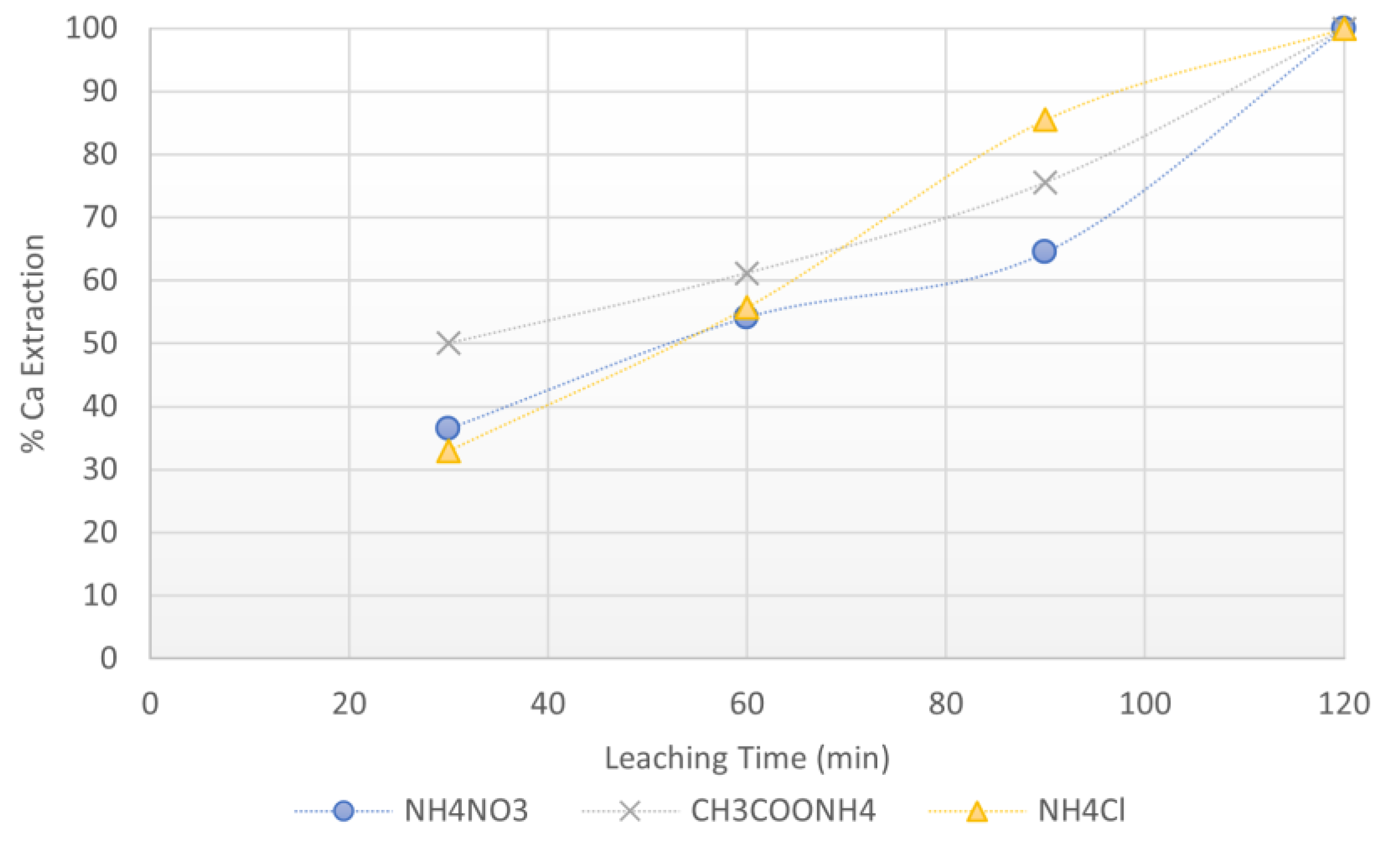

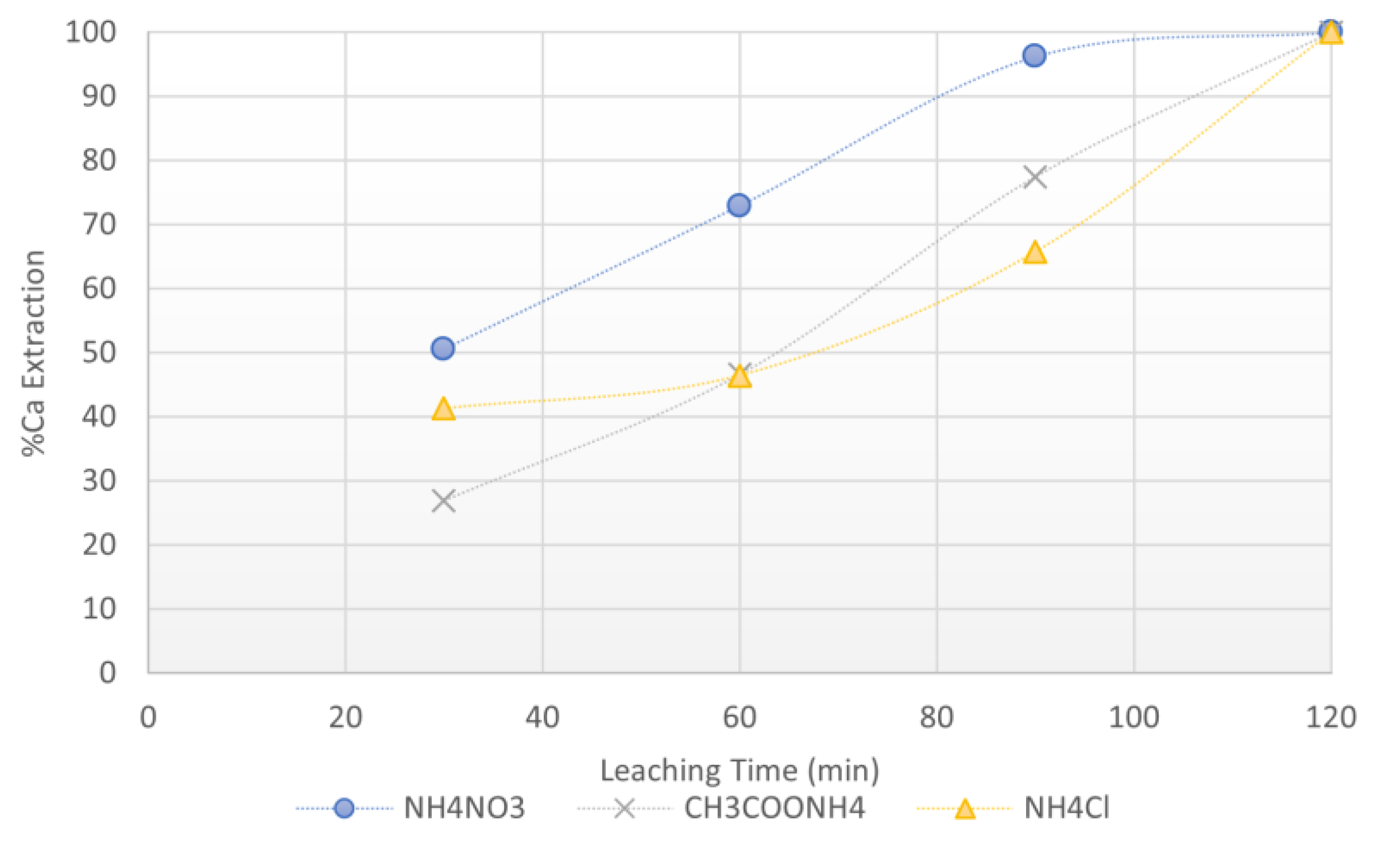

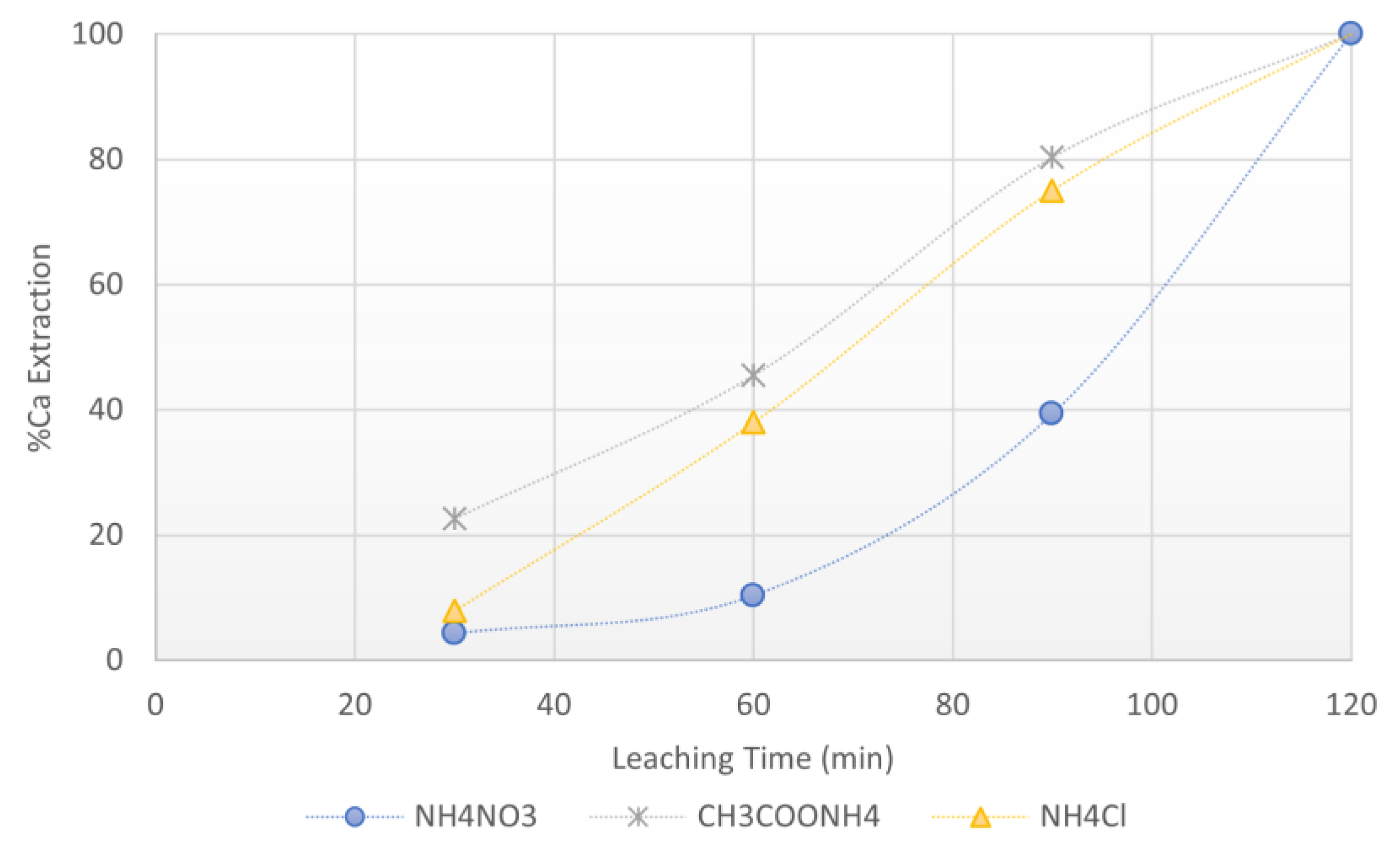

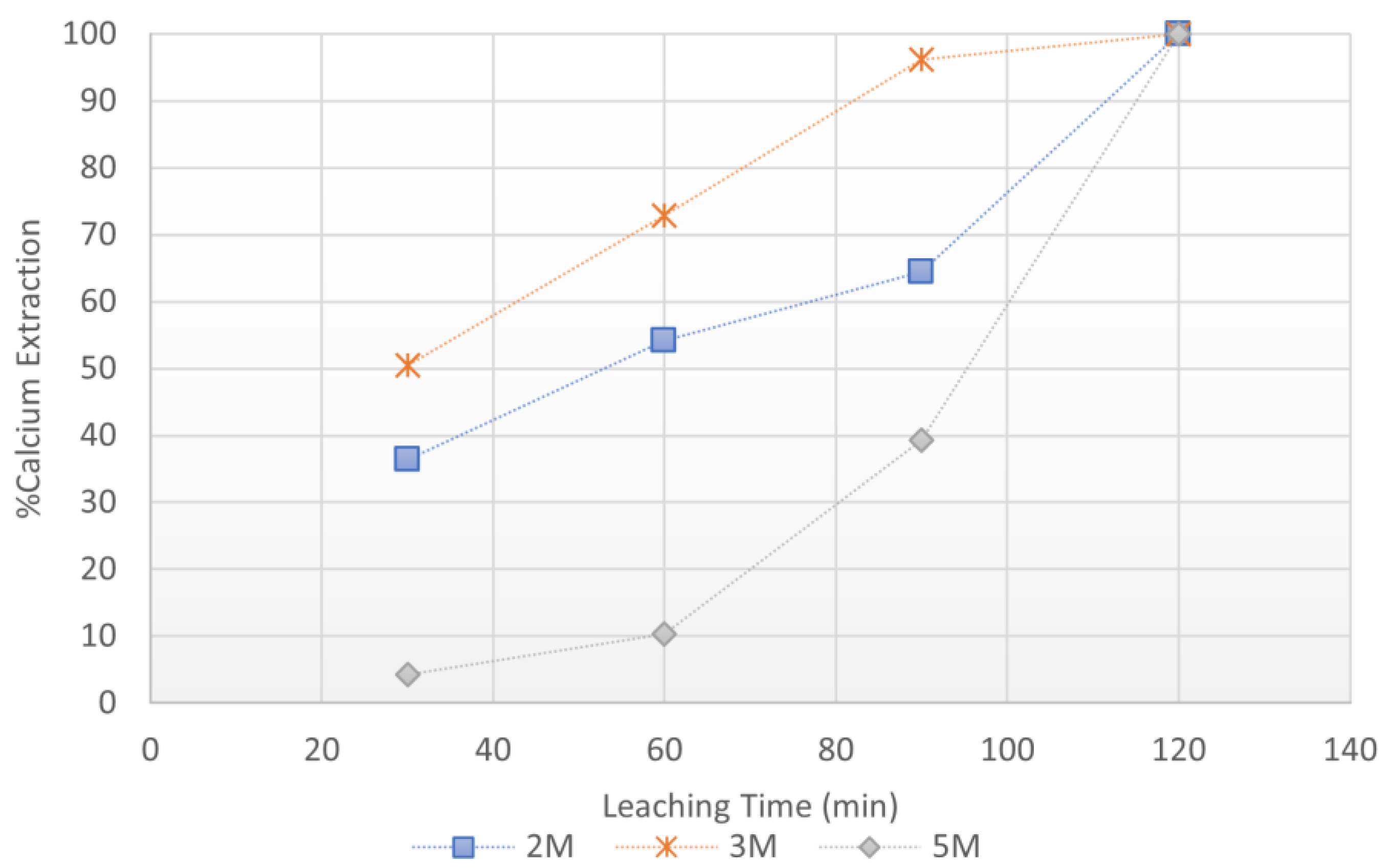

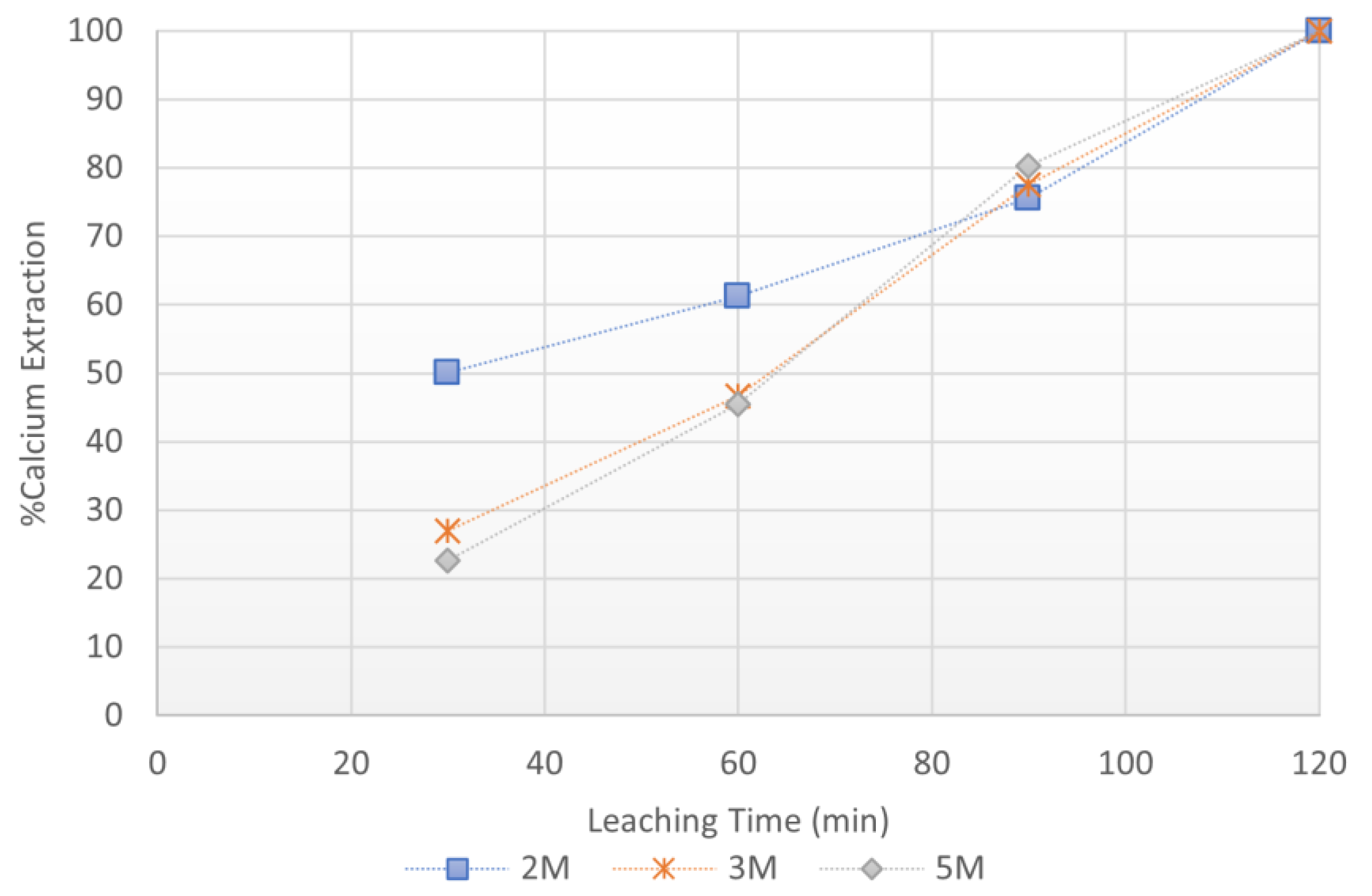

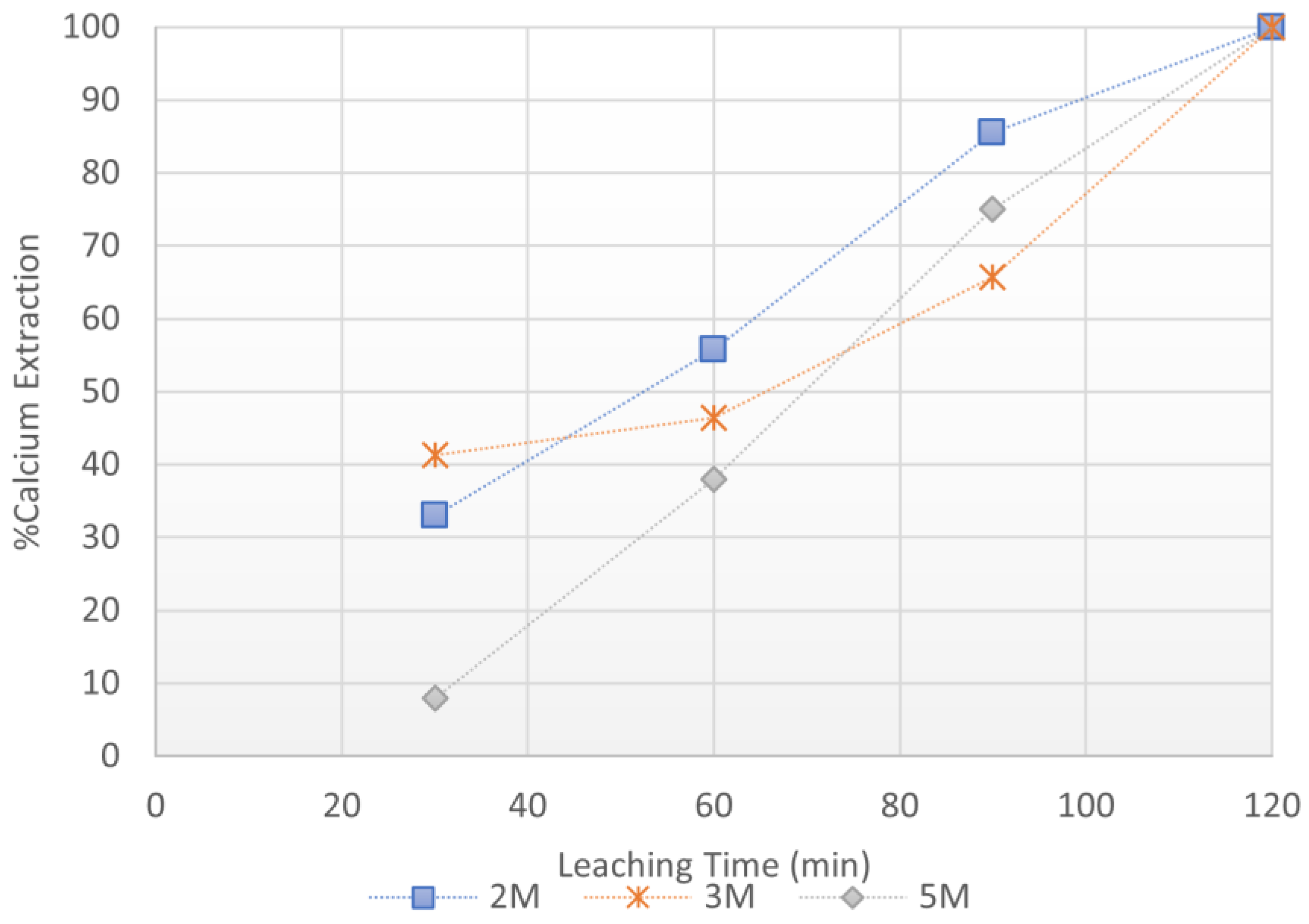

3.2. Effect of Ammonium Lixiviants, Concentration and Dissolution Time

3.3. Overall Summary of Results

4. Discussion

4.1. The Effect of Lixiviant Molar Concentration

4.2. The Effect of Anion Type of Ammonium Salts on the Percentage Calcium Extraction

5. Conclusions

Acknowledgments

References

- Clift:, R. Climate Change and Energy Policy: The Importance of Sustainability Arguments. Energy 2007, 32, 262–268. [Google Scholar] [CrossRef]

- Kabir, M.; Habiba, U.E.; Khan, W.; Shah, A.; Rahim, S.; Rios-Escalante, P.R.D. los; Farooqi, Z.U.R.; Ali, L. Climate Change Due to Increasing Concentration of Carbon Dioxide and Its Impacts on Environment in 21st Century; a Mini Review. J King Saud Univ Sci 2023, 35, 102693. [Google Scholar] [CrossRef]

- Nunes, L.J.R. The Rising Threat of Atmospheric CO2: A Review on the Causes, Impacts, and Mitigation Strategies. Environments 2023, 10, 66. [Google Scholar] [CrossRef]

- Osman, K.; Coquelet, C.; Ramjugernath, D. Review of Carbon Dioxide Capture and Storage with Relevance to the South African Power Sector. S Afr J Sci 2014, 110, 12. [Google Scholar] [CrossRef]

- Sanna, A.; Uibu, M.; Caramanna, G.; Kuusik, R.; Maroto-Valer, M.M. A Review of Mineral Carbonation Technologies to Sequester CO2. Chem Soc Rev 2014, 43, 8049–8080. [Google Scholar] [CrossRef]

- Surridge, A.D.; Cloete, M. Carbon Capture and Storage in South Africa. Energy Procedia 2009, 1, 2741–2744. [Google Scholar] [CrossRef]

- DME Digest of South African Energy Statistics : 2009.; Dept of Energy, 2010; ISBN 9781920448257.

- Griscom, B.W.; Adams, J.; Ellis, P.W.; Houghton, R.A.; Lomax, G.; Miteva, D.A.; Schlesinger, W.H.; Shoch, D.; Siikamäki, J. V.; Smith, P.; et al. Natural Climate Solutions. Proc Natl Acad Sci U S A 2017, 114, 11645–11650. [Google Scholar] [CrossRef] [PubMed]

- Teir, S.; Eloneva, S.; Fogelholm, C.J.; Zevenhoven, R. Dissolution of Steelmaking Slags in Acetic Acid for Precipitated Calcium Carbonate Production. Energy 2007, 32, 528–539. [Google Scholar] [CrossRef]

- Kotoane, A.M. DEVELOPMENT AND OPTIMIZATION OF SELECTIVE LEACHING PROCESSES FOR THE EXTRACTION OF CALCIUM FROM STEEL SLAG IN VIEW OF SEQUESTERING CARBON DIOXIDE; 2013.

- Naidoo, Y. A Study into the Viability of Mineral Carbonation as a Means of CO 2 Sequestration in South Africa. 2013. [Google Scholar]

- Yogo, K.; Teng, Y.; Yashima, T.; Yamada, K. Development of a New CO2 Fixation/Utilization Process (1): Recovery of Calcium Form Steelmaking Slag and Chemical Fixation of Carbon Dioxide by Carbonation Reaction. Greenhouse Gas Control Technologies 2005, 2427–2430. [Google Scholar] [CrossRef]

- Kodama, S.; Nishimoto, T.; Yamamoto, N.; Yogo, K.; Yamada, K. Development of a New PH-Swing CO2 Mineralization Process with a Recyclable Reaction Solution. Energy 2008, 33, 776–784. [Google Scholar] [CrossRef]

- Yi, H.; Xu, G.; Cheng, H.; Wang, J.; Wan, Y.; Chen, H. An Overview of Utilization of Steel Slag. Procedia Environ Sci 2012, 16, 791–801. [Google Scholar] [CrossRef]

- Doucet, F.J. Effective CO2-Specific Sequestration Capacity of Steel Slags and Variability in Their Leaching Behaviour in View of Industrial Mineral Carbonation. Miner Eng 2010, 23, 262–269. [Google Scholar] [CrossRef]

- Miranda-Pizarro, J.; Perejón, A.; Valverde, J.M.; Sánchez-Jiménez, P.E.; Pérez-Maqueda, L.A. Use of Steel Slag for CO2 Capture under Realistic Calcium-Looping Conditions. RSC Adv 2016, 6, 37656–37663. [Google Scholar] [CrossRef]

- He, D.; Yang, L.; Luo, Y.; Liu, G.; Wu, Z. Synergistic Calcium Leaching and Iron Enrichment by Indirect Carbonation of Thermally Modified Steel Slag. Constr Build Mater 2024, 411. [Google Scholar] [CrossRef]

- Moon, S.; Kim, E.; Noh, S.; Triwigati, P.T.; Choi, S.; Park, Y. Carbon Mineralization of Steel and Iron-Making Slag: Paving the Way for a Sustainable and Carbon-Neutral Future. J Environ Chem Eng 2024, 112448. [Google Scholar] [CrossRef]

- FRUEHAN, R.J. UNIQUE FUNCTIONS OF SLAGS IN STEELMAKING 263. 2004. [Google Scholar]

- Teir, S.; Eloneva, S.; Zevenhoven, R. Production of Precipitated Calcium Carbonate from Calcium Silicates and Carbon Dioxide. Energy Convers Manag 2005, 46, 2954–2979. [Google Scholar] [CrossRef]

- Teir, S.; Eloneva, S.; Fogelholm, C.J.; Zevenhoven, R. Dissolution of Steelmaking Slags in Acetic Acid for Precipitated Calcium Carbonate Production. Energy 2007, 32, 528–539. [Google Scholar] [CrossRef]

- Eloneva, S.; Teir, S.; Salminen, J.; Fogelholm, C.J.; Zevenhoven, R. Steel Converter Slag as a Raw Material for Precipitation of Pure Calcium Carbonate. Ind Eng Chem Res 2008, 47, 7104–7111. [Google Scholar] [CrossRef]

- Teir, Sebastian.; Picaset) Fixation of Carbon Dioxide by Producing Carbonates from Minerals and Steelmaking Slags; Helsinki University of Technology, 2008; ISBN 9789512293520.

- Eloneva, S.; Mannisto, P.; Said, A.; Fogelholm, C.J.; Zevenhoven, R. Ammonium Salt-Based Steelmaking Slag Carbonation: Precipitation of CaCO3 and Ammonia Losses Assessment. Greenhouse Gases: Science and Technology 2011, 1, 305–311. [Google Scholar] [CrossRef]

- Jo, H.; Park, S.H.; Jang, Y.N.; Chae, S.C.; Lee, P.K.; Jo, H.Y. Metal Extraction and Indirect Mineral Carbonation of Waste Cement Material Using Ammonium Salt Solutions. Chemical Engineering Journal 2014, 254, 313–323. [Google Scholar] [CrossRef]

- Blamey, J.; Yao, J.G.; Arai, Y.; Fennell, P. Enhancement of Natural Limestone Sorbents for Calcium Looping Processes. In Calcium and Chemical Looping Technology for Power Generation and Carbon Dioxide (CO2) Capture; Elsevier, 2015; pp. 73–105.

- Tamilselvi Dananjayan, R.R.; Kandasamy, P.; Andimuthu, R. Direct Mineral Carbonation of Coal Fly Ash for CO2 Sequestration. J Clean Prod 2016, 112, 4173–4182. [Google Scholar] [CrossRef]

- Coppola, A.; Scala, F.; Azadi, M. Direct Dry Carbonation of Mining and Industrial Wastes in a Fluidized Bed for Offsetting Carbon Emissions. Processes 2022, 10, 582. [Google Scholar] [CrossRef]

- Olajire, A.A. A Review of Mineral Carbonation Technology in Sequestration of CO2. J Pet Sci Eng 2013, 109, 364–392. [Google Scholar] [CrossRef]

- Yanagisawa, Y. A New CO2 Disposal Process via Artificial Weathering of Calcium Silicate Accelerated by Acetic Acid. Energy 2001, 26, 341–354. [Google Scholar] [CrossRef]

- Eloneva, S.; Said, A.; Fogelholm, C.J.; Zevenhoven, R. Preliminary Assessment of a Method Utilizing Carbon Dioxide and Steelmaking Slags to Produce Precipitated Calcium Carbonate. Appl Energy 2012, 90, 329–334. [Google Scholar] [CrossRef]

- Liu, Y.M.; Cui, X.; Hao, C.M.; Tao, F.R.; Li, J.Y. Modified Gelatin with Quaternary Ammonium Salts Containing Epoxide Groups. Chinese Chemical Letters 2014, 25, 1193–1197. [Google Scholar] [CrossRef]

- Hosseini, T.; Haque, N.; Selomulya, C.; Zhang, L. Mineral Carbonation of Victorian Brown Coal Fly Ash Using Regenerative Ammonium Chloride - Process Simulation and Techno-Economic Analysis. Appl Energy 2016, 175, 54–68. [Google Scholar] [CrossRef]

- Bao, W.; Li, H.; Yi, Z. Selective Leaching of Steelmaking Slag for Indirect CO2 Mineral Sequestration. Ind Eng Chem Res 2010, 49, 2055–2063. [Google Scholar] [CrossRef]

- Sun, Y.; Yao, M.S.; Zhang, J.P.; Yang, G. Indirect CO2 Mineral Sequestration by Steelmaking Slag with NH4Cl as Leaching Solution. Chemical Engineering Journal 2011, 173, 437–445. [Google Scholar] [CrossRef]

- Lee, H.; Kim, T.W.; Kim, S.H.; Lin, Y.-W.; Li, C.-T.; Choi, Y.; Choi, C. Carbon Dioxide Capture and Product Characteristics Using Steel Slag in a Mineral Carbonation Plant. Processes 2023, 11, 1676. [Google Scholar] [CrossRef]

- Wei, C.; Dong, J.; Hu, Z.; Zhang, H.; Wang, X.; Tong, Z.; Liao, C. CO2 Sequestration Exploration Utilizing Converter Slag and Cold-Rolling Waste Water: The Effect of Carbonation Parameters. Process Safety and Environmental Protection 2021, 148, 1233–1242. [Google Scholar] [CrossRef]

- Eloneva, S.; Teir, S.; Revitzer, H.; Salminen, J.; Said, A.; Fogelholm, C.-J.; Zevenhoven, R. Process Metallurgy Reduction of CO2 Emissions from Steel Plants by Using Steelmaking Slags for Production of Marketable Calcium Carbonate. 2010. [CrossRef]

- Lin, Y.; Yan, B.; Mitas, B.; Li, C.; Fabritius, T.; Shu, Q. Calcium Carbonate Synthesis from Kambara Reactor Desulphurization Slag via Indirect Carbonation for CO2 Capture and Utilization. J Environ Manage 2024, 351. [Google Scholar] [CrossRef] [PubMed]

- Kang, J.; Yu, Z.; Zhang, Y.; Xu, T.; Guo, L.; Hao, S. Optimization of CO2 Sequestration in Alkaline Industrial Residues: The Enhancement Mechanism of Saline Soil. Chemical Engineering Journal 2024, 486. [Google Scholar] [CrossRef]

- Wang, S.; Kim, J.; Qin, T. Mineral Carbonation of Iron and Steel By-Products: State-of-the-Art Techniques and Economic, Environmental, and Health Implications. Journal of CO2 Utilization 2024, 81. [Google Scholar] [CrossRef]

- Lin, X.; Zhang, Y.; Liu, H.; Boczkaj, G.; Cao, Y.; Wang, C. Carbon Dioxide Sequestration by Industrial Wastes through Mineral Carbonation: Current Status and Perspectives. J Clean Prod 2024, 434. [Google Scholar] [CrossRef]

- Liu, L.; Gan, M.; Fan, X.; Gao, Z.; Sun, Z.; Ji, Z.; Wei, J.; Ma, S. Mechanism of Ultrasonic Enhanced Acetic Acid Efficiently Leaching of Steel Slag and Synthesis of Calcium Carbonate Whiskers. Sep Purif Technol 2024, 339. [Google Scholar] [CrossRef]

- Liu, L.; Fan, X.; Gan, M.; Wei, J.; Gao, Z.; Sun, Z.; Ji, Z.; Wu, Y.; Li, J. Microwave-Enhanced Selective Leaching Calcium from Steelmaking Slag to Fix CO2 and Produce High Value-Added CaCO3. Sep Purif Technol 2024, 330. [Google Scholar] [CrossRef]

- Mattila, H.P.; Grigaliu-naite, I.; Zevenhoven, R. Chemical Kinetics Modeling and Process Parameter Sensitivity for Precipitated Calcium Carbonate Production from Steelmaking Slags. Chemical Engineering Journal 2012, 192, 77–89. [Google Scholar] [CrossRef]

- Said, A.; Mattila, O.; Eloneva, S.; Järvinen, M. Enhancement of Calcium Dissolution from Steel Slag by Ultrasound. Chemical Engineering and Processing: Process Intensification 2015, 89, 1–8. [Google Scholar] [CrossRef]

- Lee, S.; Kim, J.W.; Chae, S.; Bang, J.H.; Lee, S.W. CO2 Sequestration Technology through Mineral Carbonation: An Extraction and Carbonation of Blast Slag. Journal of CO2 Utilization 2016, 16, 336–345. [Google Scholar] [CrossRef]

- Eloneva, S.; Said, A.; Fogelholm, C.J.; Zevenhoven, R. Preliminary Assessment of a Method Utilizing Carbon Dioxide and Steelmaking Slags to Produce Precipitated Calcium Carbonate. Appl Energy 2012, 90, 329–334. [Google Scholar] [CrossRef]

- Stange, W. The Process Design of Gold Leaching and Carbon-in-Pulp Circuits Figure 2-The Carbon-In-Pulp (CIP) Process.

- Wills, B.A.; Napier-Munn, T. Mineral Processing Technology. An Introduction to the Practical Aspect of Ore Treatment and Mineral Recovery; Elsevier Science & Technology Books, 2006; Vol. 7th.

- Monshi, A.; Foroughi, M.R.; Monshi, M.R. Modified Scherrer Equation to Estimate More Accurately Nano-Crystallite Size Using XRD. World Journal of Nano Science and Engineering 2012, 02, 154–160. [Google Scholar] [CrossRef]

- Jiang, Y.; Ling, T.C.; Shi, C.; Pan, S.Y. Characteristics of Steel Slags and Their Use in Cement and Concrete—A Review. Resour Conserv Recycl 2018, 136, 187–197. [Google Scholar] [CrossRef]

- Shen, H.; Forssberg, E. An Overview of Recovery of Metals from Slags. Waste Management 2003, 23, 933–949. [Google Scholar] [CrossRef] [PubMed]

- Yi, H.; Xu, G.; Cheng, H.; Wang, J.; Wan, Y.; Chen, H. An Overview of Utilization of Steel Slag. Procedia Environ Sci 2012, 16, 791–801. [Google Scholar] [CrossRef]

- Baciocchi, R.; Costa, G.; Polettini, A.; Pomi, R. Influence of Particle Size on the Carbonation of Stainless Steel Slag for CO2 Storage. Energy Procedia 2009, 1, 4859–4866. [Google Scholar] [CrossRef]

- Chiang, Y.W.; Santos, R.M.; Elsen, J.; Meesschaert, B.; Martens, J.A.; Van Gerven, T. Towards Zero-Waste Mineral Carbon Sequestration via Two-Way Valorization of Ironmaking Slag. Chemical Engineering Journal 2014, 249, 260–269. [Google Scholar] [CrossRef]

- Engström, F. Mineralogical Influence on Leaching Behaviour of Steelmaking Slags : A Laboratory Investigation. A doctoral thesis. Luleå University of Technology Department of Chemical Engineering and Geoscience Division of Minerals and Metallurgical Engineering SE-97187 Luleå Sweden 2010.

- Polettini, A.; Pomi, R.; Stramazzo, A. Carbon Sequestration through Accelerated Carbonation of BOF Slag: Influence of Particle Size Characteristics. Chemical Engineering Journal 2016, 298, 26–35. [Google Scholar] [CrossRef]

| Oxides | Compositions (wt.%) |

|---|---|

|

Na2O MgO Al2O3 SiO2 P2O5 K2O CaO TiO2 MnO Fe2O3 |

0.10 1.08 5.57 24 0.90 1.27 57.40 1.70 3.93 4.10 |

| Elements | Compositions (wt.%) |

|---|---|

|

Mg Al Si P S Cl K Ca Mn Fe Sr |

0.80 3.67 13.90 0.55 1.28 0.22 1.51 66.50 5.39 5.60 0.63 |

| % Calcium Extraction | Solution pH | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Time (min) | 30 | 60 | 90 | 120 | 0 | 30 | 60 | 90 | 120 |

| Lixiviant | 2 M Solutions | 2 M Solutions | |||||||

| NH4NO3 | 36.41 | 54.14 | 64.46 | 100 | 6.34 | 6.94 | 6.46 | 6.58 | 6.86 |

| CH3COONH4 | 50.01 | 61.17 | 75.60 | 99.99 | 8.03 | 8.25 | 8.33 | 8.26 | 8.22 |

| NH4Cl | 32.94 | 55.74 | 85.50 | 99.99 | 7.66 | 7.75 | 7.74 | 7.8 | 7.83 |

| 3 M Solutions | 3 M Solutions | ||||||||

| NH4NO3 | 50.49 | 72.92 | 96.21 | 100 | 5.2 | 5.75 | 5.73 | 5.77 | 5.8 |

| CH3COONH4 | 26.96 | 46.61 | 77.45 | 100 | 7.93 | 7.97 | 8.05 | 7.91 | 7.95 |

| NH4Cl | 41.27 | 46.43 | 65.74 | 99.99 | 7.57 | 7.63 | 7.72 | 7.8 | 7.71 |

| 5 M Solutions | 5 M Solutions | ||||||||

| NH4NO3 | 4.24 | 10.32 | 39.33 | 100 | 5.68 | 5.8 | 5.86 | 5.84 | 5.86 |

| CH3COONH4 | 22.64 | 45.49 | 80.33 | 100 | 7.67 | 7.71 | 7.82 | 7.91 | 7.7 |

| NH4Cl | 7.92 | 37.97 | 75.02 | 100 | 7.26 | 7.33 | 7.38 | 7.38 | 7.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).