Submitted:

11 May 2024

Posted:

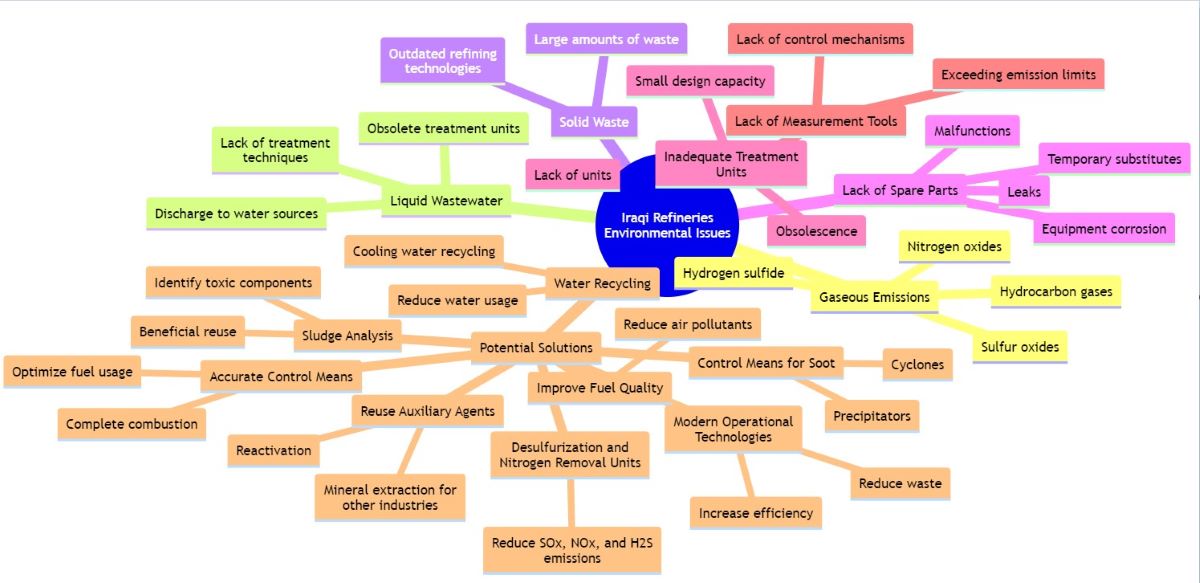

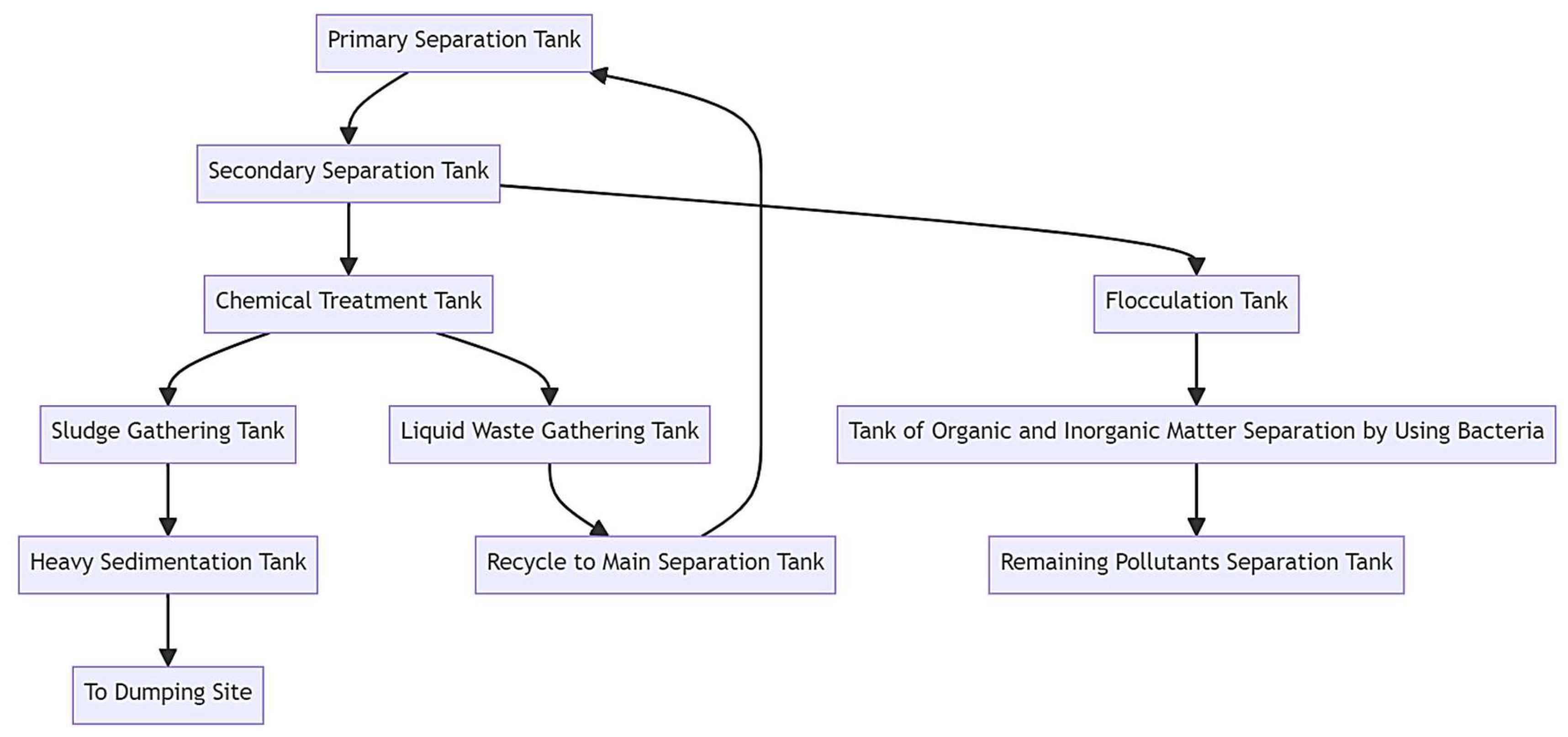

14 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

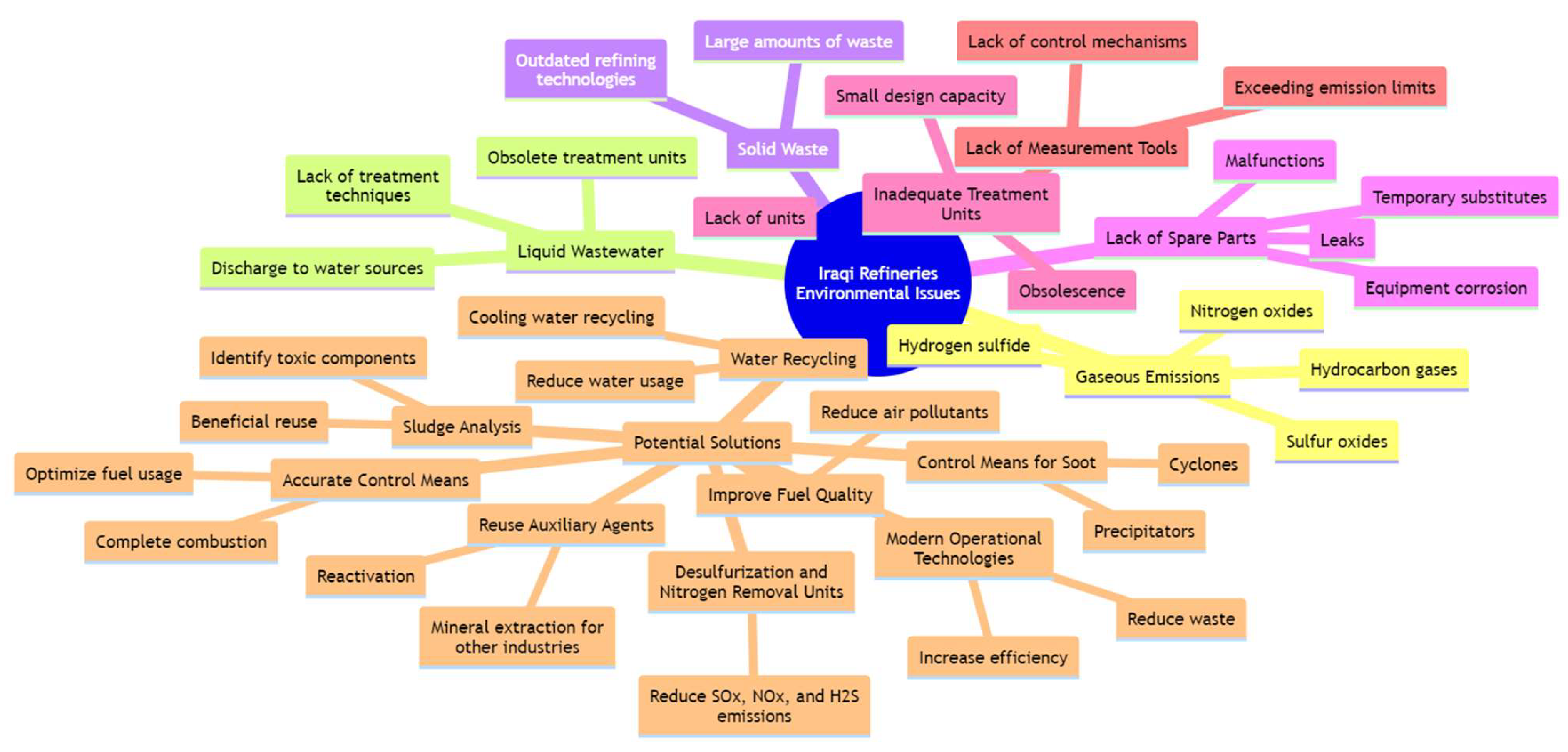

2. Refining Processes in Iraqi Refineries

3. Environmental Impact of Iraqi Oil Refineries

3.1. Gaseous and Particulate Emissions

3.2. Liquid Wastes

3.3. Solid Wastes

4. Means Employed for Waste Management and Treatment in Iraqi Refineries

4.1. Gaseous Wastes Controlling

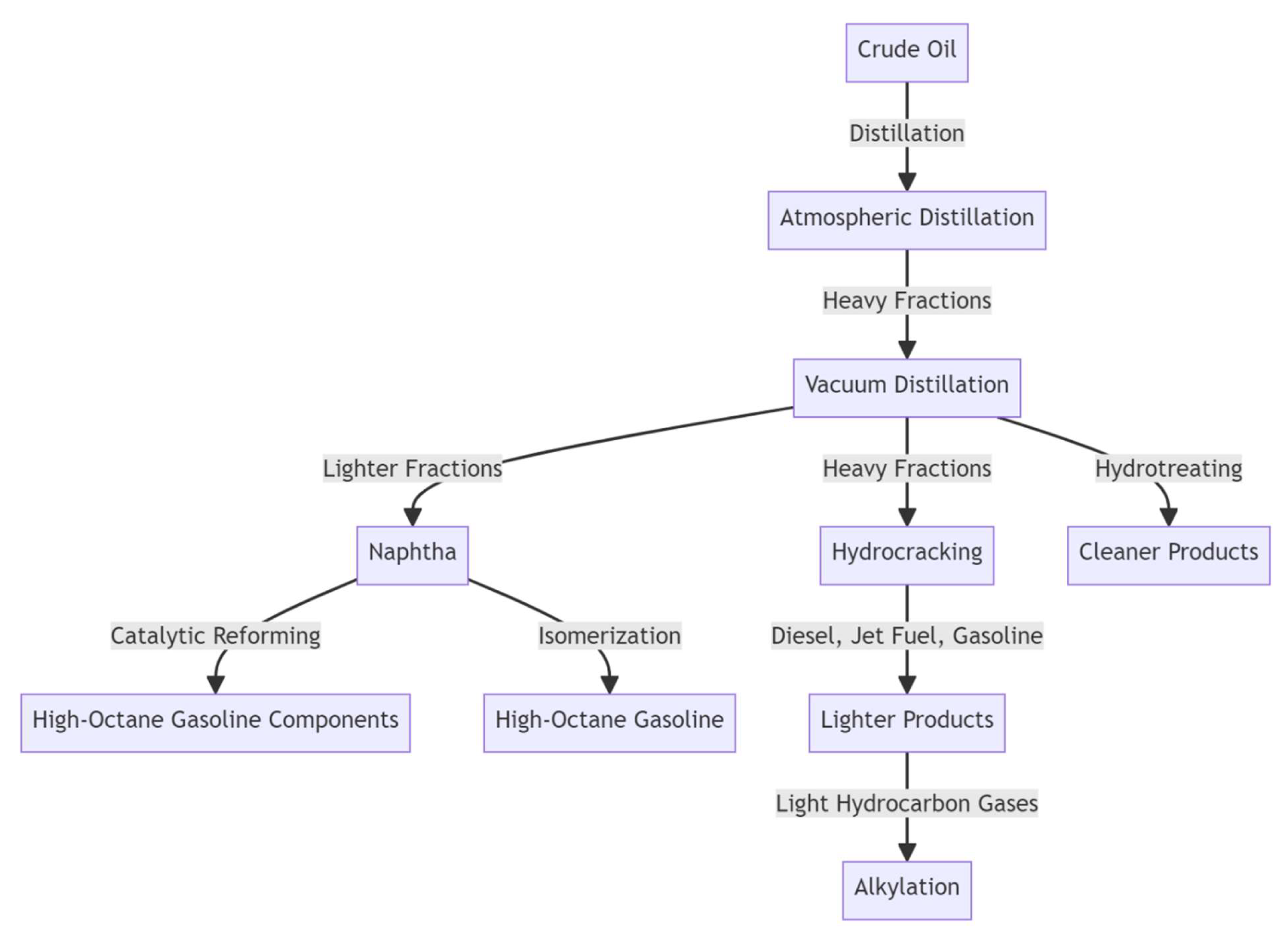

4.2. Liquid Effluents Treatment

4.3. Solid Wastes

5. Environmental Impact Assessment of Iraqi Refineries

Conclusions

References

- Issa, H.M. Streamlining aromatic content detection in automotive gasoline for environmental protection: Utilizing a rapid and simplified prediction model based on some physical characteristics and regression analysis. Results Eng. 2024, 21. [Google Scholar] [CrossRef]

- Semenova, T.; Al-Dirawi, A. Economic Development of the Iraqi Gas Sector in Conjunction with the Oil Industry. Energies 2022, 15, 2306. [Google Scholar] [CrossRef]

- Soltanieh, M.; Zohrabian, A.; Gholipour, M.J.; Kalnay, E. A review of global gas flaring and venting and impact on the environment: Case study of Iran. Int. J. Greenh. Gas Control. 2016, 49, 488–509. [Google Scholar] [CrossRef]

- Issa, H.M. Prediction of octane numbers for commercial gasoline using distillation curves: a comparative regression analysis between principal component and partial least squares methods. Pet. Sci. Technol. 2024, 42, 1233–1249. [Google Scholar] [CrossRef]

- Mokif, L.A.; Jasim, H.K.; Abdulhusain, N.A. Petroleum and oily wastewater treatment methods: A mini review. Mater. Today: Proc. 2022, 49, 2671–2674. [Google Scholar] [CrossRef]

- Essa, H.M. Removal of Corrosion Product from Inside Heat Exchanger Tubes Used in Topping Unit in Azzawia Refinery/Libya by Chemical Methods. J. Corros. Sci. Eng. 2006, 10, 1–10. [Google Scholar]

- Fahad, A.Y.; Shaalan, H.Y. Investment Trends in the Iraqi Oil Sector (Upstream–Oil Refining–Gas Treatment-Transportation-Distribution)(2003–2020). J. Pet. Res. Stud. 2022, 12, 123–147. [Google Scholar]

- Abdullah, I.S. Foreign Direct Investment and its Impact on the Oil Sector in Iraq. Al-Anbar University Journal of Economic & Administration Sciences 2020. 12(31).

- Aljamali, N.M.; Salih, N.S. Review on chemical separation of crude oil and analysis of its components. J. Pet. Eng. Technol. 2021, 11, 35–49p. [Google Scholar]

- Ekaab, N.S.; Hamza, N.H.; Chaichan, M.T. Performance and emitted pollutants assessment of diesel engine fuelled with biokerosene. Case Stud. Therm. Eng. 2019, 13, 100381. [Google Scholar] [CrossRef]

- Issa, H.M.; Salih, R.H.H. Efficient and Simplified Modeling for Kerosene Processing Quality Detection Using Partial Least Squares-Discriminant Analysis Regression. ARO-THE Sci. J. KOYA Univ. 2024, 12, 135–142. [Google Scholar] [CrossRef]

- Adebiyi, F.M. Air quality and management in petroleum refining industry: A review. Environ. Chem. Ecotoxicol. 2022, 4, 89–96. [Google Scholar] [CrossRef]

- Issa, H.M. An initial environmental assessment for the potential risk of the developing industry impact on the surface water resources in the Kurdistan Region-Iraq. J. Garmian Univ. 2014, 1, 35–48. [Google Scholar]

- Abdulhussein, Z.A.; Al-Sharify, Z.T.; Alzuraiji, M. Flow of crude oil in pipes and its environmental impact. A review. PROCEEDINGS OF THE TIM20-21 PHYSICS CONFERENCE. LOCATION OF CONFERENCE, RomaniaDATE OF CONFERENCE;

- Glushkov, D.O.; Paushkina, K.K.; Shabardin, D.P. Co-combustion of coal processing waste, oil refining waste and municipal solid waste: Mechanism, characteristics, emissions. Chemosphere 2019, 240, 124892. [Google Scholar] [CrossRef] [PubMed]

- Elmobarak, W.F.; Hameed, B.H.; Almomani, F.; Abdullah, A.Z. A Review on the Treatment of Petroleum Refinery Wastewater Using Advanced Oxidation Processes. Catalysts 2021, 11, 782. [Google Scholar] [CrossRef]

- Haruna, A.; Tanimu, G.; Ibrahim, I.; Garba, Z.N.; Yahaya, S.M.; Musa, S.G.; Merican, Z.M.A. Mitigating oil and gas pollutants for a sustainable environment – Critical review and prospects. J. Clean. Prod. 2023, 416. [Google Scholar] [CrossRef]

- Radelyuk, I.; Tussupova, K.; Klemeš, J.J.; Persson, K.M. Oil refinery and water pollution in the context of sustainable development: Developing and developed countries. J. Clean. Prod. 2021, 302, 126987. [Google Scholar] [CrossRef]

- Shahbaz, M.; Rashid, N.; Saleem, J.; Mackey, H.; McKay, G.; Al-Ansari, T. A review of waste management approaches to maximise sustainable value of waste from the oil and gas industry and potential for the State of Qatar. Fuel 2023, 332. [Google Scholar] [CrossRef]

- Issa, H.M.; Albarzanji, A.A. Quantitative prediction of Reid vapor pressure for a light crude oil using a simplified and proper correlation. Pet. Sci. Technol. 2020, 38, 745–753. [Google Scholar] [CrossRef]

- Ramesh, M.; Deepa, C.; Kumar, L.R.; Sanjay, M.R.; Siengchin, S. Life-cycle and environmental impact assessments on processing of plant fibres and its bio-composites: A critical review. J. Ind. Text. 2022, 51, 5518S–5542S. [Google Scholar] [CrossRef]

- Jabbar, K.J.; Zein, S.H.; Hasan, A.H.; Ahmed, U.; Jalil, A.A. Process design Optimisation, heat integration, and techno-economic analysis of oil refinery: A case study. Energy Sources, Part A: Recover. Util. Environ. Eff. 2023, 45, 4931–4947. [Google Scholar] [CrossRef]

- Semenov, A.; Podkamennyi, Y.; Bebikhov, Y.; Yakushev, I. Saving the environment by automation of crude oil distillation in a rectification column. E3S Web Conf. 2023, 371, 01093. [Google Scholar] [CrossRef]

- Al-Nidawi, M.R.; Ahmed, D.J.; Chali, M.; Bahjat, A. Purification of Used Lubricating Oils Using Vacuum Distillation. J. Pet. Res. Stud. 2024, 14, 111–130. [Google Scholar] [CrossRef]

- Zhao, Z.; Qin, W.; Long, J.; Lei, J.; Xu, W.; Wang, Z. The removal of organic impurities from industrial waste salt by pyrolysis. Environ. Sci. Pollut. Res. 2022, 30, 21671–21682. [Google Scholar] [CrossRef] [PubMed]

- Almaliky, M. and J. Alkazrajy, Oxidative Techniques for Naphtha Desulfurization: Review for Materials and Challenges in Refineries. 2023.

- Bekheet, H.N.; Al-Sudany, N.K.; Najm, S.S. Iraqi Economy and Renewable Energy Projects Between Economic Necessity and Investment Challenges. Int. J. Prof. Bus. Rev. 2023, 8, e03435–e03435. [Google Scholar] [CrossRef]

- Ismayyir, D.K.; Dawood, L.M. Analytical Study of Affecting Gasoline Quality Properties on Environment and Its Conformity with Specifications. Eng. Technol. J. 2021, 39, 306–315. [Google Scholar] [CrossRef]

- A Naji, F.; Ateeq, A.A.; Al-Mayyah, M.A. Optimization of blending operation for the Iraqi oils. J. Physics: Conf. Ser. 2021, 1773, 012037. [Google Scholar] [CrossRef]

- Jawad, E.H. Statistical Methods for Controlling the Quality of Crude Oil Products in Iraq. J. Econ. Adm. Sci. 2023, 29, 101–120. [Google Scholar] [CrossRef]

- Ahmad, W.; Muhammad, T.; Ahmad, I.; Khan, M.; Nazneen, S. Adsorption of hydrocarbon pollutants from wastewater using Cu- and Zn-loaded activated carbon derived from waste tires. Environ. Prog. Sustain. Energy 2024. [Google Scholar] [CrossRef]

- Nematollahi, M.J.; Mehr, M.R.; Shakeri, A.; Amjadian, K.; Ebrahimi, P.; Pirouei, M. Polycyclic aromatic hydrocarbons (PAHs) in soils around oil refineries; Case study: Erbil and Kirkuk refineries, Iraq- A modelling approach. J. Environ. Heal. Sci. Eng. 2022, 20, 699–716. [Google Scholar] [CrossRef]

- Al-Rubaye, A.H.; Jasim, D.J.; Jassam, S.A.; Jasim, H.M.; Ameen, H.F.M.; Al-Robai, H.A. The Side Effect of Oil Refineries on Environment: As a mini Review. IOP Conf. Series: Earth Environ. Sci. 2023, 1262. [Google Scholar] [CrossRef]

- Issa, H.M. A new correlation for vapor pressure prediction of natural gas mixture. Pet. Sci. Technol. 2016, 34, 1913–1919. [Google Scholar] [CrossRef]

- Issa, H.M. An Investigation of the Comparative Performance of Diverse Vapor Pressure Prediction Techniques of Sour Natural Gas. Pet. Sci. Technol. 2015, 33, 1443–1448. [Google Scholar] [CrossRef]

- Rahi, M.N.; Jaeel, A.J.; Abbas, A.J. Treatment of petroleum refinery effluents and wastewater in Iraq: A mini review. IOP Conf. Series: Mater. Sci. Eng. 2021, 1058, 012072. [Google Scholar] [CrossRef]

- Murtadah, I.; Al-Sharify, Z.T.; Hasan, M.B. Atmospheric Concentration Saturated and Aromatic Hydrocarbons Around Dura Refinery. IOP Conf. Series: Mater. Sci. Eng. 2020, 870. [Google Scholar] [CrossRef]

- Al-Abadi, N.J.A. The role of the oil industry in environmental pollution-effects and suggested solutions. British Journal of Global Ecology and Sustainable Development 2023, 12, 67–87. [Google Scholar]

- Salman, N.A. , et al., Air Pollution in the Southern Part of Iraq and Its Health Risks, in Aerosol Optical Depth and Precipitation: Measuring Particle Concentration, Health Risks and Environmental Impacts, S. Gautam, R.P. Kumar, and C. Samuel, Editors. 2024, Springer Nature Switzerland: Cham. p. 107-122.

- Al-Dabbas, M., L. Ali, and A. Afaj, The effect of Kirkuk oil refinery on air pollution of Kirkuk city-Iraq. Iraqi Journal of Science, 2012. 53(Remote Sensing-Conf): p. 8-18.

- Samanta, M. and D. Mitra, Treatment of Petroleum Hydrocarbon Pollutants in Water, in Water Pollution and Remediation: Organic Pollutants, Inamuddin, M.I. Ahamed, and E. Lichtfouse, Editors. 2021, Springer International Publishing: Cham. p. 229-275.

- Sultan, M.A.; Sultan, H.H. Biological Reduction of Chemical Oxygen Demand (COD) & Biological Oxygen Demand (BOD) of AL-Najaf Oil Refinery Wastewater Using Locally Bacterial Isolates of Pseumonasaeruginosa, Alcaligenesfaecalis. Annals of the Romanian Society for Cell Biology 2021, 25, 6021–6030. [Google Scholar]

- Mohammed, W.J.; Salih, M.I. Studying the Physical and Chemical Properties of the Industrial Wastewater of the North Refineries Company-Beiji. J. Res. Appl. Sci. Biotechnol. 2023, 2, 274–283. [Google Scholar] [CrossRef]

- Abbas, A.R.; Junh, Q.H. Environmental problems arising from the Dora industrial refinery complex site. lark 2020, 13, 937–912. [Google Scholar]

- Obiad, A.J.; A Al-Sultan, A. CWWQI on the Evaluation of Effluent Wastewater from Al-Dora Refinery WWTP. IOP Conf. Series: Mater. Sci. Eng. 2020, 737. [Google Scholar] [CrossRef]

- Mahmood, M.S. Impact of Iraqi Refinery Operations in the Surrounding Environment of Air Quality, Water Sources and Soil. Journal of Education College 2016, 8, 1–15. [Google Scholar]

- Issa, H.M.; Alshatteri, A.H. Impacts of wastewater discharge from Kalar city on Diyala-Sirwan river water quality, Iraq: pollution evaluation, health risks of heavy metals contamination. Appl. Water Sci. 2021, 11, 1–13. [Google Scholar] [CrossRef]

- Abdulqader, M.A.; Syed-Hassan, S.S.A.; Jawad, A.H.; Habeeb, O.A. Characterization Study of Oily Sludge Produced from North Refineries Company Baiji to Determine the Suitability for Conversion into Solid Fuel. Egypt. J. Chem. 2021, 64, 2775–2781. [Google Scholar] [CrossRef]

- Hashim, B.M.; Sultan, M.A.; Al Maliki, A.; Al-Ansari, N. Estimation of Greenhouse Gases Emitted from Energy Industry (Oil Refining and Electricity Generation) in Iraq Using IPCC Methodology. Atmosphere 2020, 11, 662. [Google Scholar] [CrossRef]

- Saleh, S.H.; Hassoon, A.F. Atmospheric stability classes and its effect on co concentration emission around Kirkuk refinery. J. Physics: Conf. Ser. 2021, 1963. [Google Scholar] [CrossRef]

- Watkins, S. , Gas Flaring Deals Could Solve One Of Iraq’s Biggest Problems, in OILPRICE. 2021: UK.

- Issa, H. Evaluation of Water Quality and Performance for a Water Treatment Plant: Khanaqin City as a Case Study. J. Garmian Univ. 2017, 3, 802–821. [Google Scholar] [CrossRef]

- Jabbar, H.A.; Alatabe, M.J. COAGULATION/FLOCCULATION PROCESS FOR OILY WASTEWATER TREATMENT. J. Eng. Sustain. Dev. 2021, 25, 3–68. [Google Scholar] [CrossRef]

- Azeez, R.A.; Al-Zuhairi, F.K. Bio-Treatment Technologies of Produced Water: A Review. Eng. Technol. J. 2022, 40, 1–15. [Google Scholar] [CrossRef]

- Shuokr, Q.A.; Sazan, M.A. Characteristics, treatment techniques, and operational limitations for refinery wastewater: Review. Reciklaza i odrzivi Razvoj 2021, 14, 19–30. [Google Scholar] [CrossRef]

- Waheeb, O.M., M. M. Salman, and R.Q. Kadhim, Study of Change Surface Aerator to Submerged Nonporous Aerator in Biological Pond in an Industrial Wastewater Treatment in Daura Refinery. 2022.

- Grmasha, R.A.; Stenger-Kovács, C.; Bedewy, B.A.H.; Al-Sareji, O.J.; Al-Juboori, R.A.; Meiczinger, M.; Hashim, K.S. Ecological and human health risk assessment of polycyclic aromatic hydrocarbons (PAH) in Tigris river near the oil refineries in Iraq. Environ. Res. 2023, 227, 115791. [Google Scholar] [CrossRef]

- Kareem, K.K.H.; Abdulla, S.S. DETERMINATION OF HEAVY METALS AND TOTAL PETROLEUM HYDROCARBONS IN SOIL SAMPLES AND PLANT LEAVES AROUND OIL REFINERIES LOCATED ON ERBIL-GWER ROAD. Sci. J. Univ. Zakho 2023, 11, 492–498. [Google Scholar] [CrossRef]

- Zaki, H.F.; et al. A case study of industrial wastewater treatment for the petrochemical industry with a full recycling system/iraq: A review article. Academia Repository 2023, 4, 24–35. [Google Scholar]

- Syed Hassan, S.S.; Jawad, A.H.; Habeeb, O.A. Characterization Study of Petroleum Oily Sludge Produced from North Refineries Company Baiji to Determine the Suitability for Conversion into Solid Fuel. Egyptian Journal of Chemistry 2021, 64, 2775–2781. [Google Scholar]

- Almukhtar, R.; Hammoodi, S.I.; Omar, R. Comparison study between pyrolysis products of oil refinery sludge and sludge from municipal wastewater treatment plants. THIRD VIRTUAL INTERNATIONAL CONFERENCE ON MATERIALS, MANUFACTURING AND NANOTECHNOLOGY. LOCATION OF CONFERENCE, IndiaDATE OF CONFERENCE; p. 030022.

- Al-Bari, E.S.A. Reality of the environmental of oil refineries Al Doura refinery as a case study. in AIP Conference Proceedings. 2023. AIP Publishing.

- Issa, H.M. Optimization of Wastewater Treatment Plant Design using Process Dynamic Simulation: A Case Study from Kurdistan, Iraq. ARO-THE Sci. J. KOYA Univ. 2019, 7, 59–66. [Google Scholar] [CrossRef]

- Al-Doury, M.M.I. Upgrading of crude oil desalting unit of Baiji oil refinery. Petroleum Science and Technology 2024, 2024. 42, 689–705. [Google Scholar] [CrossRef]

- Issa, H. , A Perception Analysis of Environmental Sustainability Processes in Industry: A Prospective Eco-Innovation Strategy Implementation in An Electrical Motor Manufacturing Plant, in ChemRxiv. 2024, ChemRxiv.

- ALMokhef, A.; et al. The importance of lean management principles for maintenance in iraqi refineries. Journal of Engineering Science and Technology 2023, 18, 3029–3046. [Google Scholar]

- Ajeel, M.A.; Ajeel, A.A.; Nejres, A.M.; Salih, R.A. Assessment of Heavy Metals and Related Impacts on Antioxidants and Physiological Parameters in Oil Refinery Workers in Iraq. J. Heal. Pollut. 2021, 11. [Google Scholar] [CrossRef] [PubMed]

- Issa, H.M. Long-term Evaluation of Temporal Variation in Groundwater Physicochemical Quality: A Case Study of Erbil City. Eurasian Journal of Science & Engineering 2018, 4, 32–48. [Google Scholar]

- Issa, H.M. Parametric and Nonparametric Approaches of Reid Vapor Pressure Prediction for Gasoline Containing Oxygenates: A Comparative Analysis Using Partial Least Squares, Nonlinear, and LOWESS Regression Modelling Strategies with Physical Properties. Model. Simul. Eng. 2024, 2024, 1–15. [Google Scholar] [CrossRef]

- Hassoon, A.F.; Fattah, A.H.; Shubbar, R.M. Evaluate Air Pollution Dispersion in Al-Daura Refinery After Used Desulfurization Techniques. Iraqi Geol. J. 2021, 54, 43–56. [Google Scholar] [CrossRef]

- Issa, H.M. Energy-water nexus in East Iraq: capacity potential analysis and spatial assessment for an integrated CSP solar power & RO brackish water desalination plant in Khanaqin area. Water Pr. Technol. 2021, 16, 904–923. [Google Scholar] [CrossRef]

- Alanood, A.A. , et al., Remove Liquid Radioactive Wastes Utilizing Nanofiltration, Ultrafiltration, and Microfiltration Membranes. Engineering and Technology Journal 2022, 2022. 40, 1231–1259. [Google Scholar]

- Kulkarni, S.J. , Petroleum and Refining Sector: Towards Cost Effective and Sustainable Practices. 2019: Literatureslight Publishing.

- Alzahawy, A. and H. Issa, Intelligent Petroleum Processing: A Short Review on Applying AI/ML to Petroleum Products Optimization, in Preprints. 2024, Preprints.

| Refinery | SOx | NOx | CO2 |

| Midland Refineries Company, Al-Dura | 4862.6 | 641.6 | 204948.13 |

| Southern Refineries Company | 3545 | 4041 | 13593713 |

| Refinery | Discharge/ rate | BOD | pH | Oil and grease | NO3 | SO3 | Cl- | TDS | PO3 |

| Midland Refineries Company, Al-Dura | Tigris, 600 m3/h |

9.82 | 7.7 | 2.36 | 2.1 | 350 | 129 | 1954 | 0.38 |

| Northern Refineries Company, Baiji | Tigris, 50 m3/h |

9.35 | 7.6 | 7.59 | - | - | 602.14 | 391.29 | 0.93 |

| Southern Refineries Company, Basra | Shat Alarab, 450 m3/h |

10.8 | 7.2 | 8.4 | 7.2 | 420 | 688.2 | 1622 | 0.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).