Submitted:

11 May 2024

Posted:

13 May 2024

You are already at the latest version

Abstract

Keywords:

Introduction

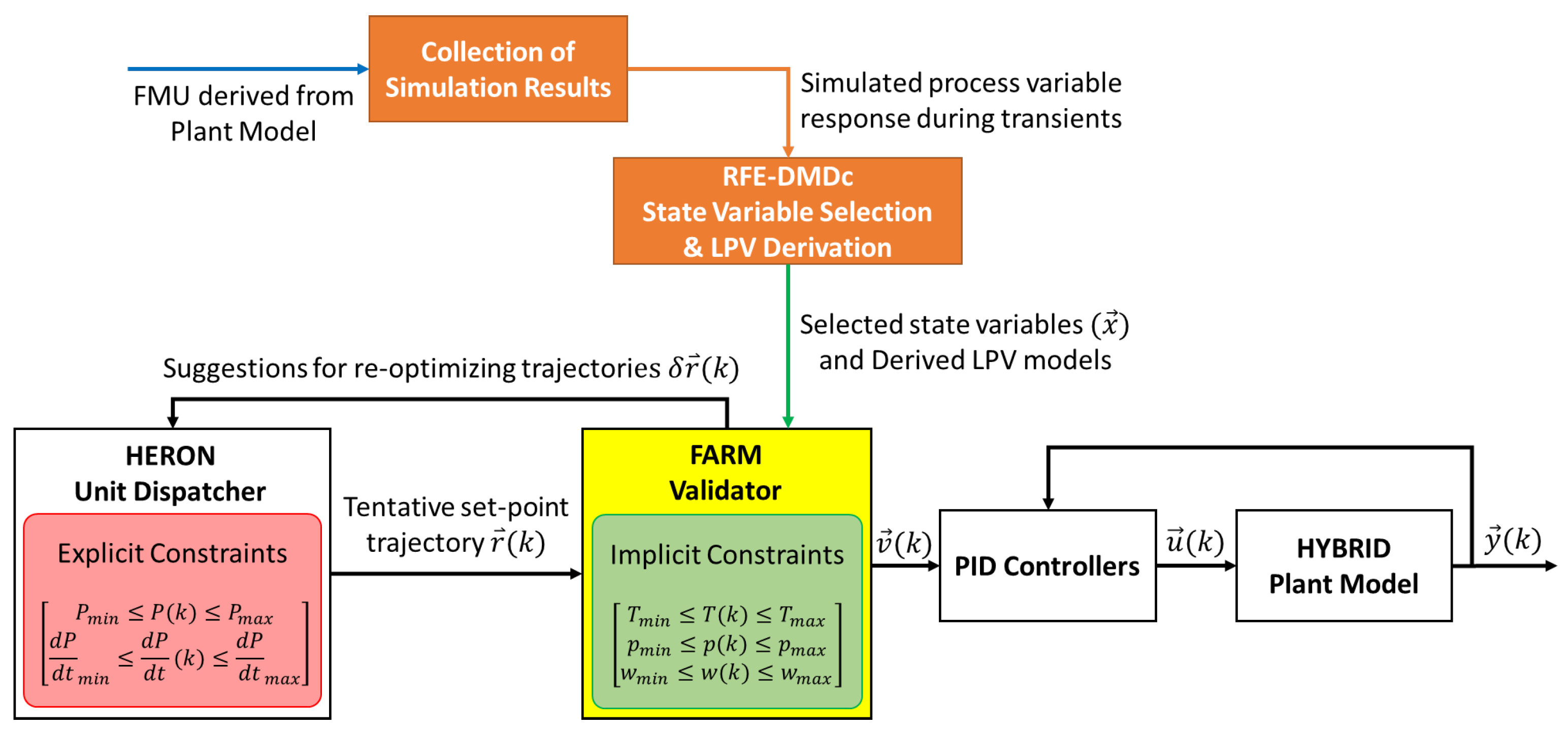

1. Description of a New Approach to the Solution of Unit Dispatch Problems

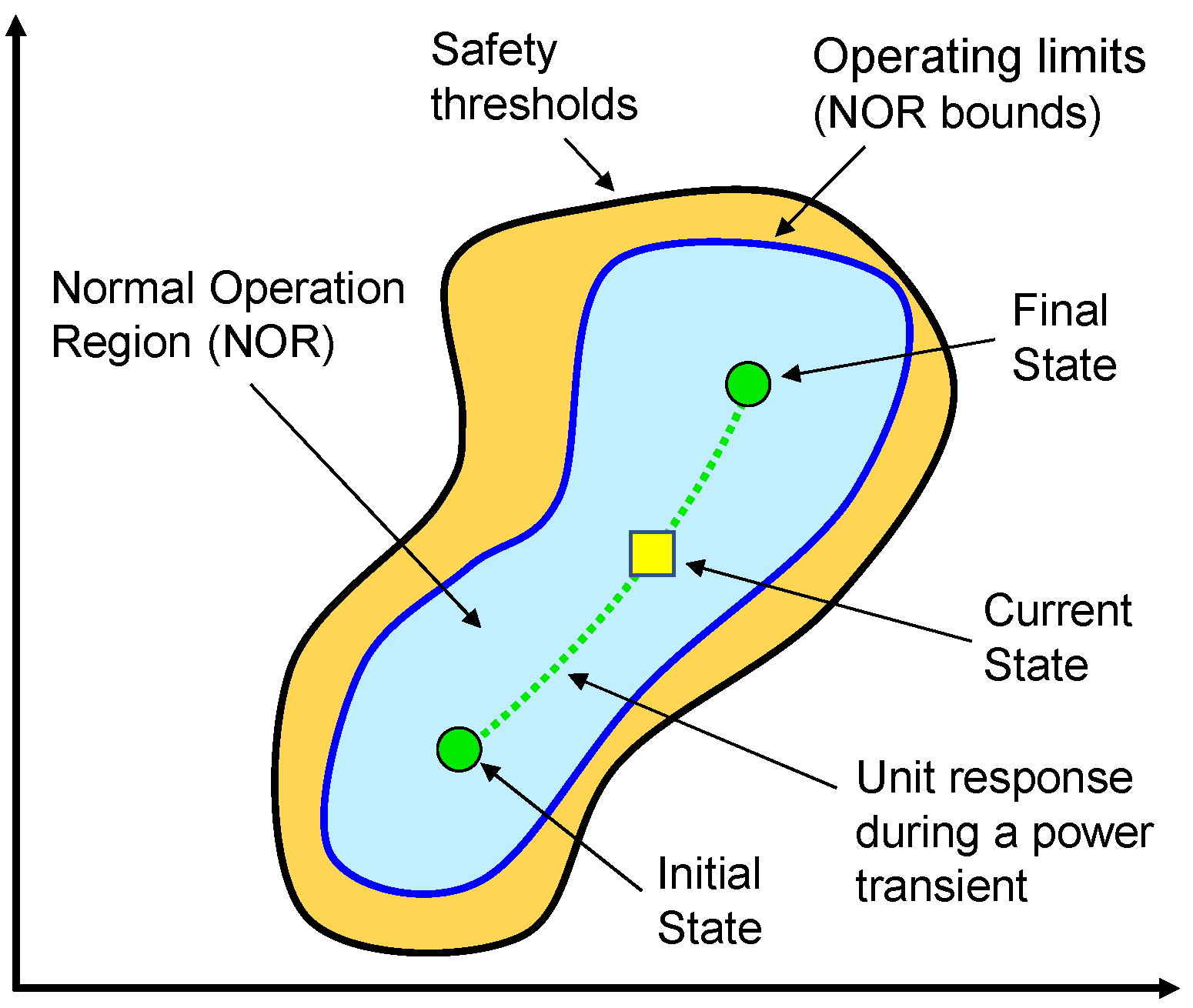

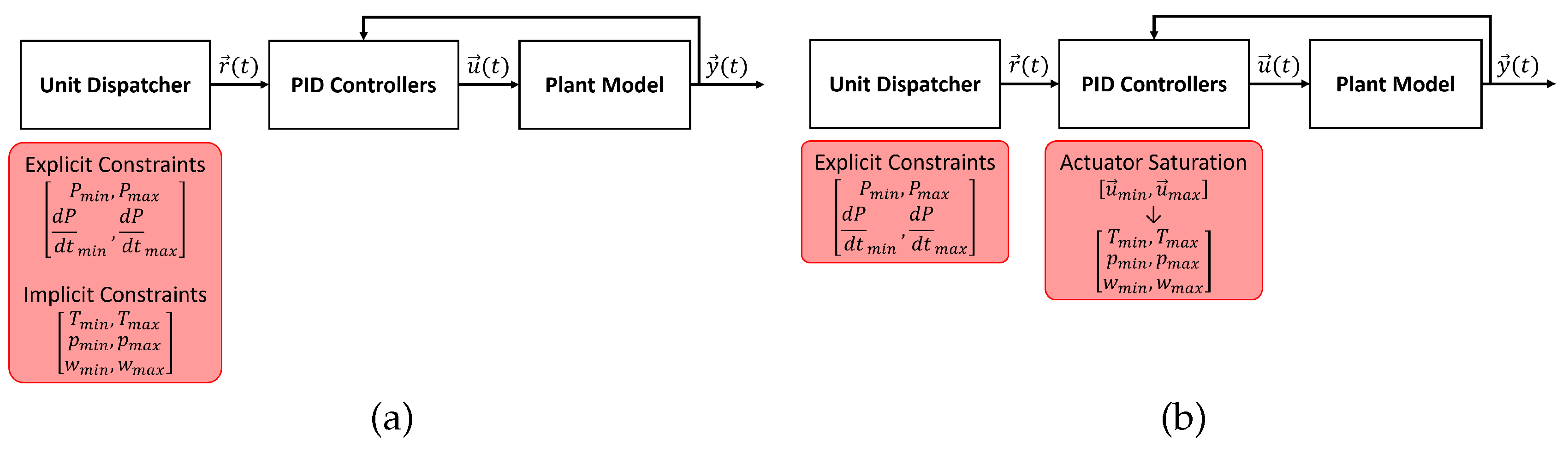

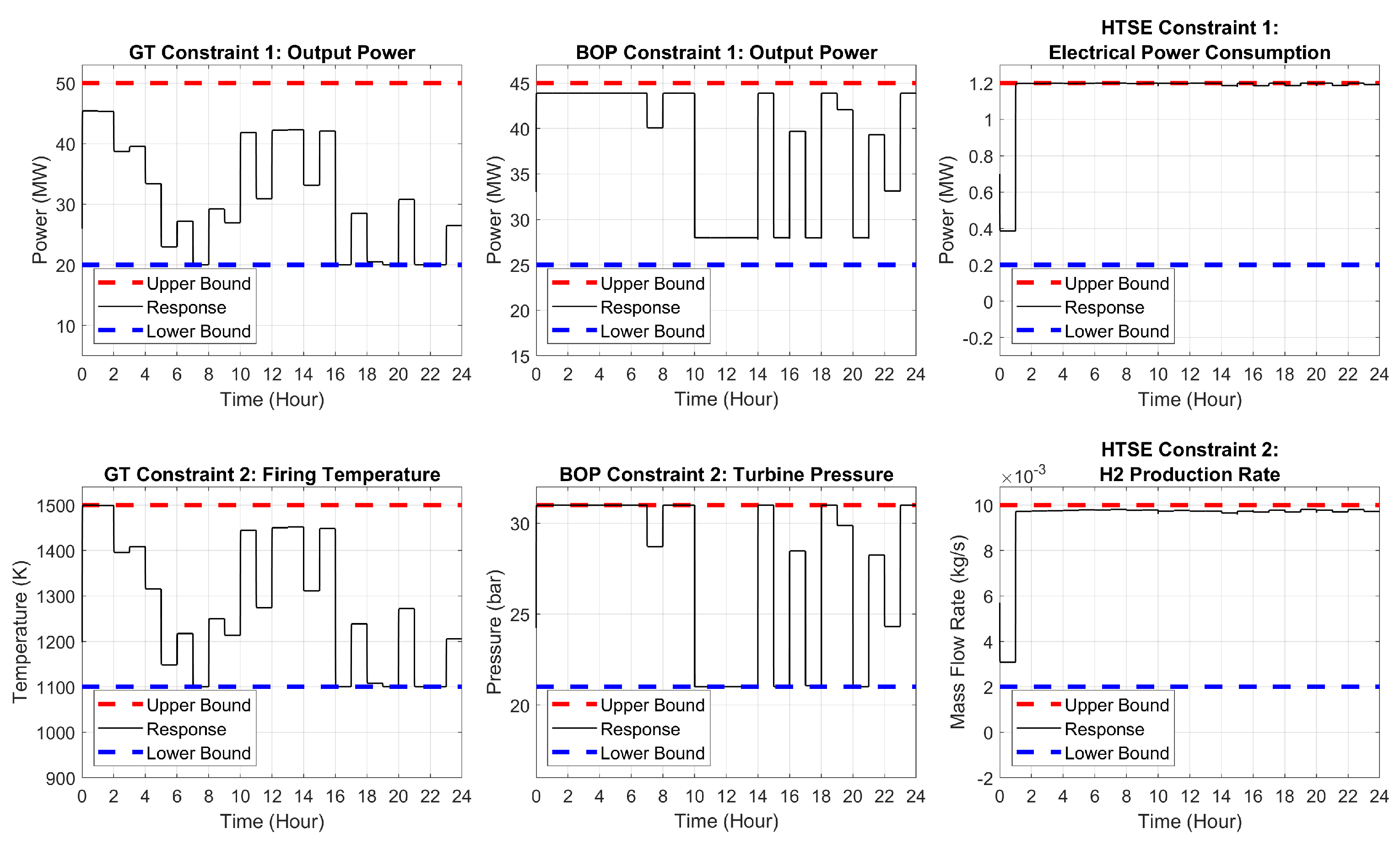

- Explicit constraints: the electrical power output can assume any value within a characteristic window, i.e., (power output limits). Electrical power variations cannot be too steep either, i.e., (power ramp-rate limits). Explicit constraints are also defined as low-resolution physics constraints because they represent fewer physics details.

- Implicit constraints: to prevent thermomechanical loads from surpassing the design limits, constraints on temperature, pressure, and flow rate must be taken into account, i.e., , , and . Implicit constraints are also defined as high-resolution physics constraints since they account for a large number of aspects that govern the processes.

- The capacities of the IES unit subsystems (i.e., maximum power output/consumption) are defined by the user;

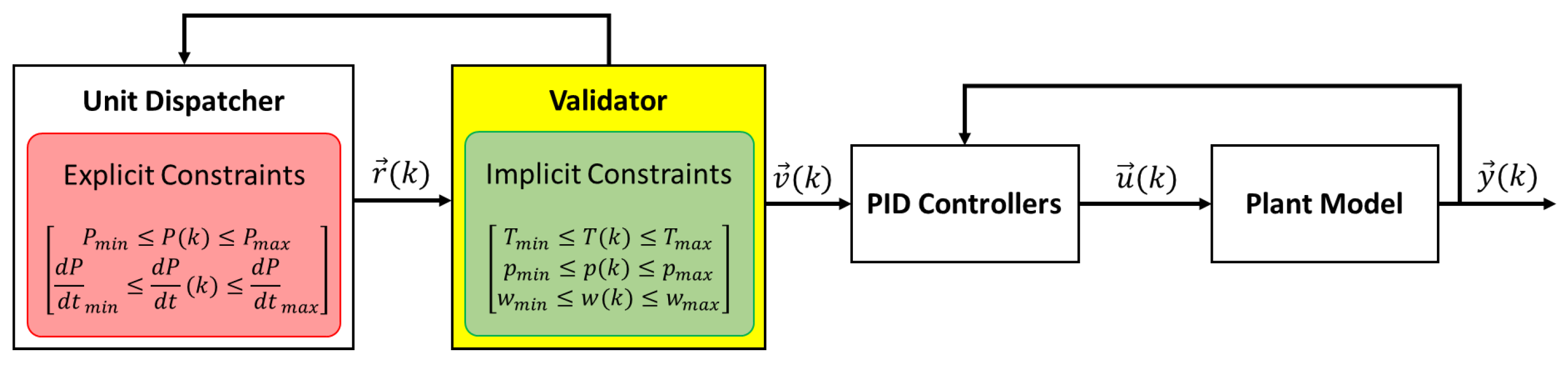

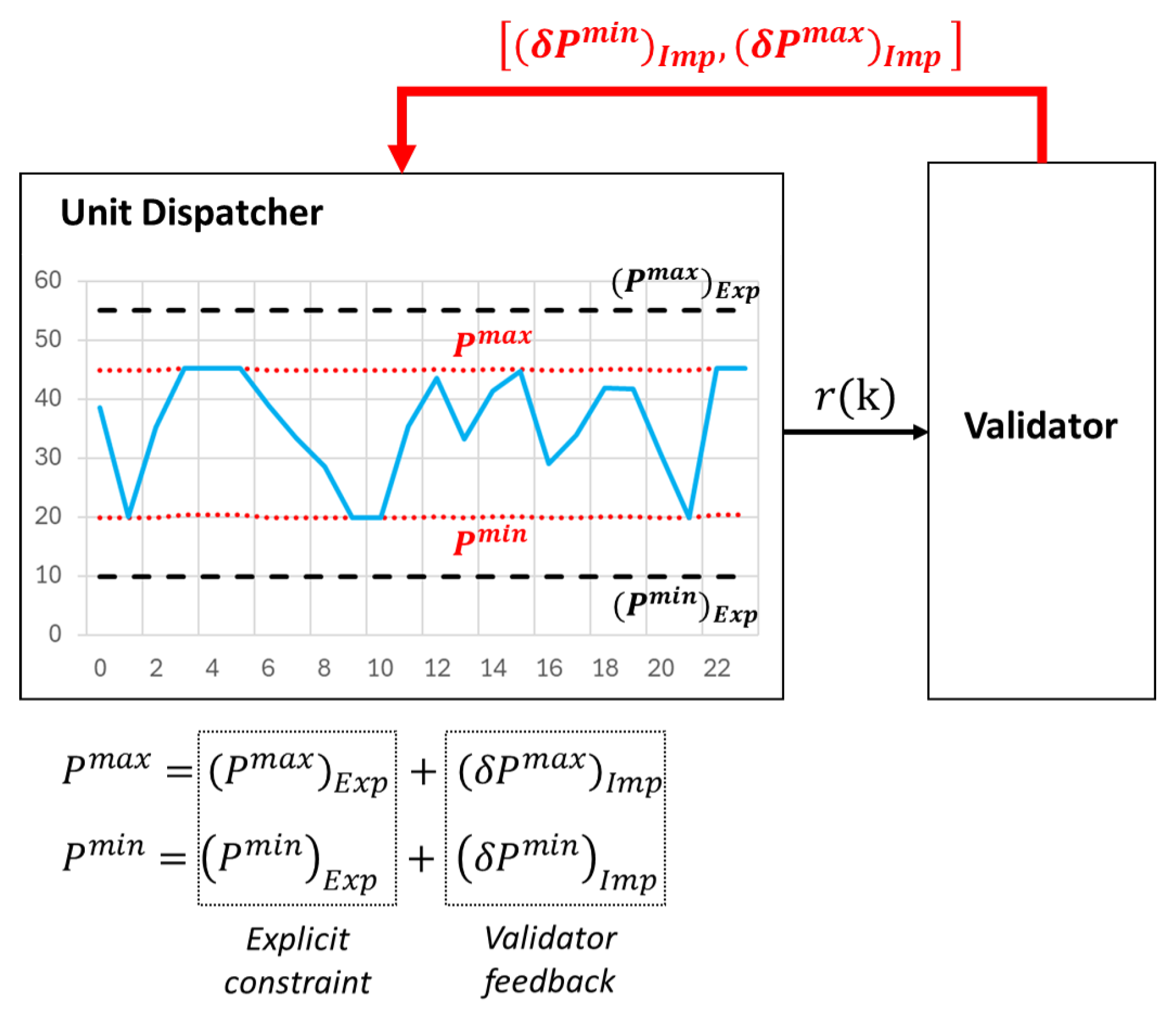

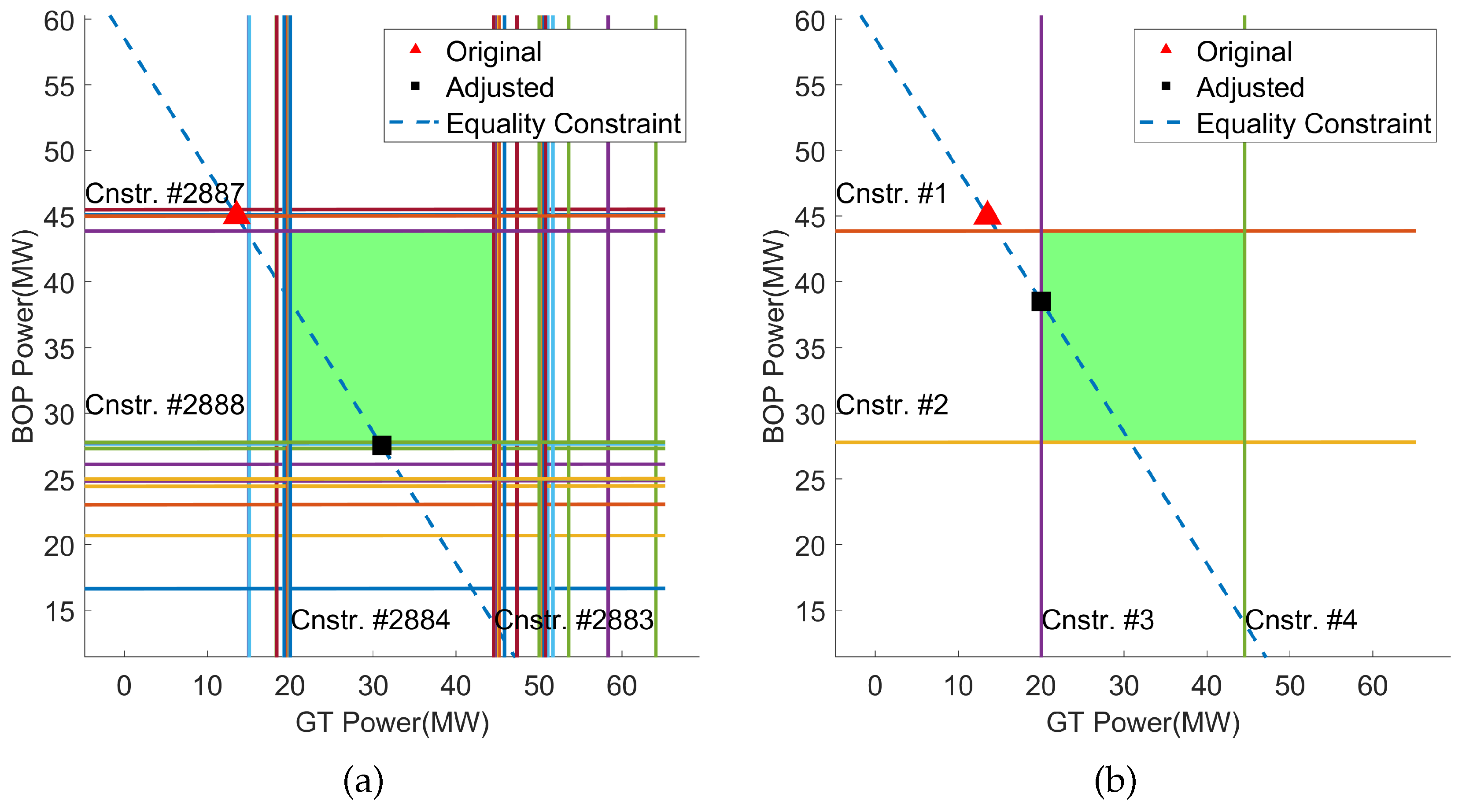

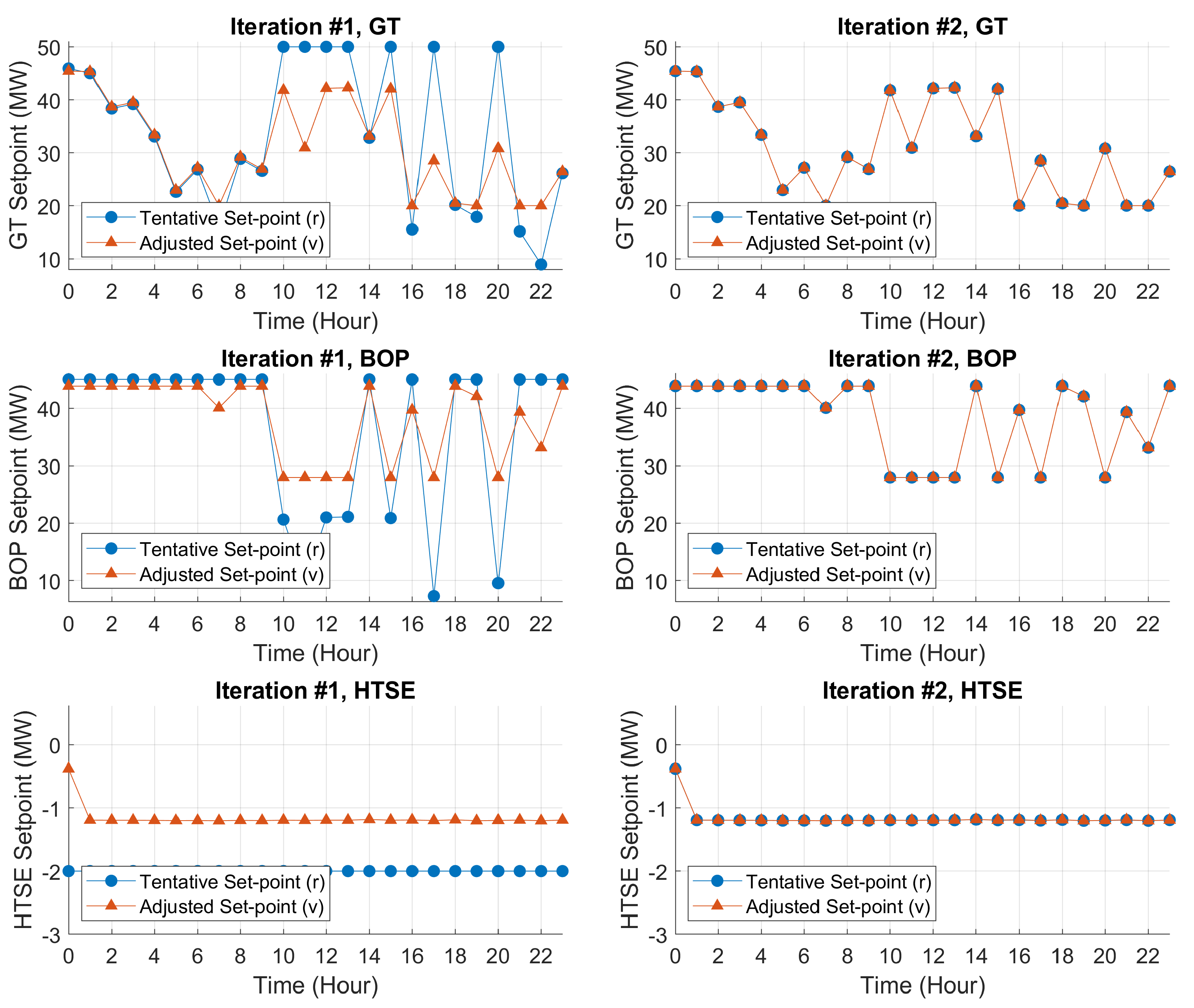

- Given the subsystem capacities, the HERON dispatcher solves the constrained optimization problem by approximating the optimal power output/consumption for each subsystem. These trajectories () satisfy the explicit constraints (Figure 3);

- The CG determines if the trajectories calculated by the HERON unit dispatcher satisfy the implicit constraints as well. If not, the CG will provide trajectories complying with both explicit and implicit constraints (), and return them to the unit dispatcher for re-optimization;

- From trajectories, the HERON dispatcher derives a feedback to adjust the values of the explicit constraints. The outputs of the single subsystem are modified accordingly;

- Steps (2) through (4) are repeated until and are identical, i.e., the optimal trajectories satisfying heat and electrical power demands are also compliant with both explicit and implicit constraints. The “approved” set-points are then issued to the PID controllers that calculate the control actions () to simulate the prescribed power transients.

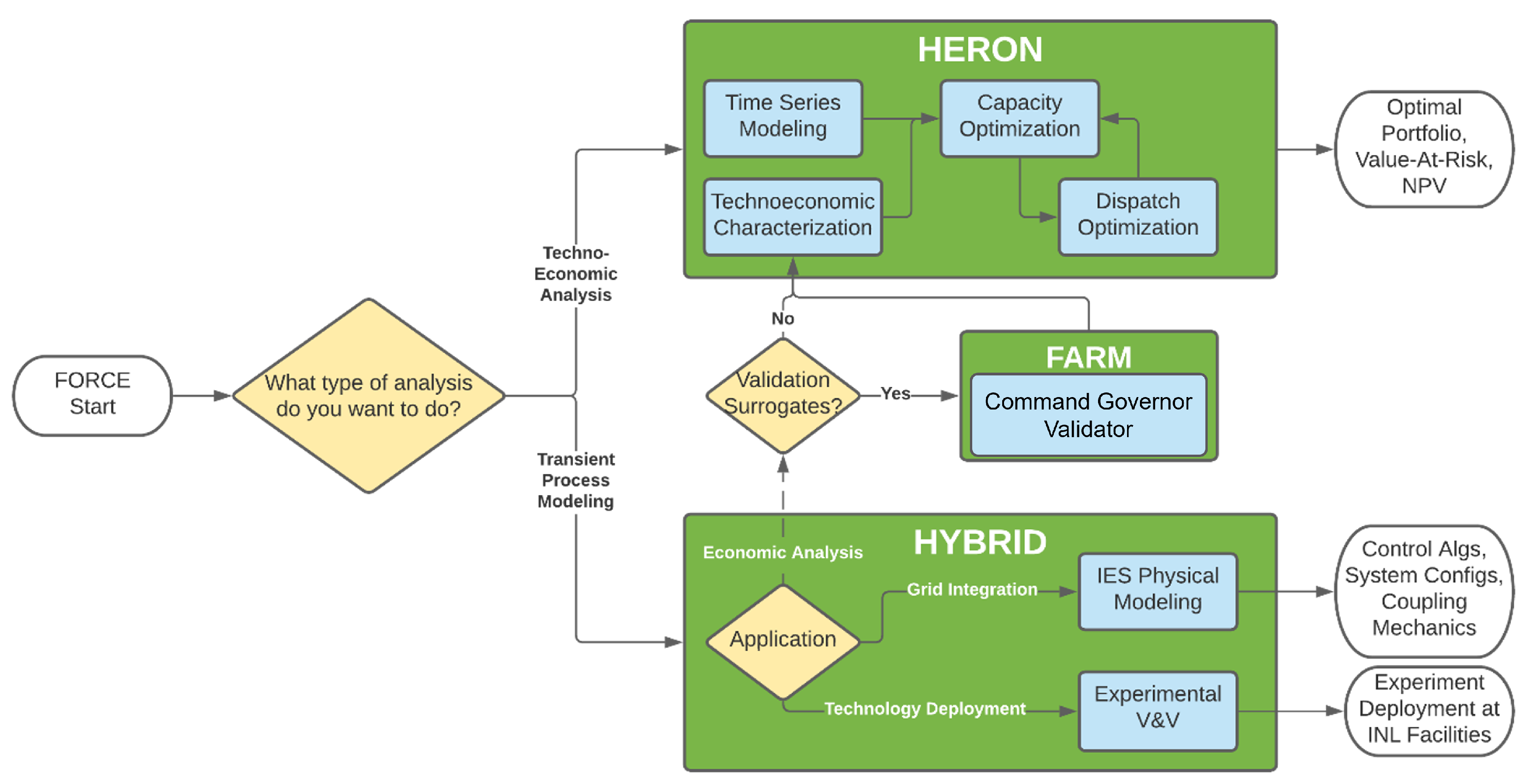

2. Description of the Modeling Framework for Solving the Unit Dispatch Problem for IES Units

- RAVEN (Risk Analysis Virtual Environment) is a multipurpose uncertainty quantification (UQ), regression analysis, data analysis and optimization framework [20]. RAVEN is the central engine for the deployment of all the analysis needs, providing the tools for the construction of the analysis workflows. RAVEN is charged with deploying the optimization methodology and algorithms that are used for the capacity optimization. In addition, the framework delivers the techniques for the generation of synthetic scenarios via its time series generators [21]. The capability of generating synthetic scenarios based on existing grids, starting from available datasets, is crucial. In this way, hypothetical scenarios characterized by larger penetration of renewable energy sources or higher level of variability in the demand profile can be investigated.

- HYBRID software is a collection of component models developed primarily using the Modelica language and deployed using the Dymola software suite [22]. An IES unit is constituted by traditional power plants whose dynamics are characterized by very different time constants, i.e., along with a nuclear power plant, there are gas turbines that can be started up from cold shutdown conditions in 20 minutes. To obtain a realistic description of the system performance, the capability of accurately simulating the dynamic response of the IES components over different time scales is crucial. HYBRID contains low-fidelity and high-fidelity models for all the energy systems and components that have been selected as part of the IES framework.

- HERON (Holistic Energy Resource Optimization Network) is a plug-in that allows performing stochastic full-system techno-economic analysis of grid energy-resource systems with economic drivers [23]. The development targets analysis of electricity and secondary product generation and consumption in regional balancing areas, including flexibility to include arbitrary resources as well as arbitrary resource consumers and producers. HERON is the tool for the construction of the overall IES/FORCE workflow, providing tools for deploying systems’ dispatching strategies and capacity optimization.

- TEAL (Tool for Economic AnaLysis) is a discounted cash flow analysis plug-in that allows for a generic definition of cash flows, with drivers provided by RAVEN. It includes flexible options to deal with taxes, inflation, discounting and offers capabilities to compute a combined cash flow for components with different component lives [24]. TEAL is tasked with deployment of the economic analysis within the IES methodological framework.

3. Description of the Algorithms Embedded in FARM

- Command Governor: it performs a multi-dimensional optimization of set-point trajectories fed by the unit dispatcher (Section 3.1).

- Convex Hull: it removes the redundant constraints (Section 3.2)

- Dynamic Mode Decomposition with Control: it derives the matrices that constitute the state-space model (Section 3.3).

- Recursive Feature Elimination with DMDc: it provides the list of state variables of the derive state-space model (Section 3.4).

3.1. Command Governor (CG) for Enforcing Implicit Constraints

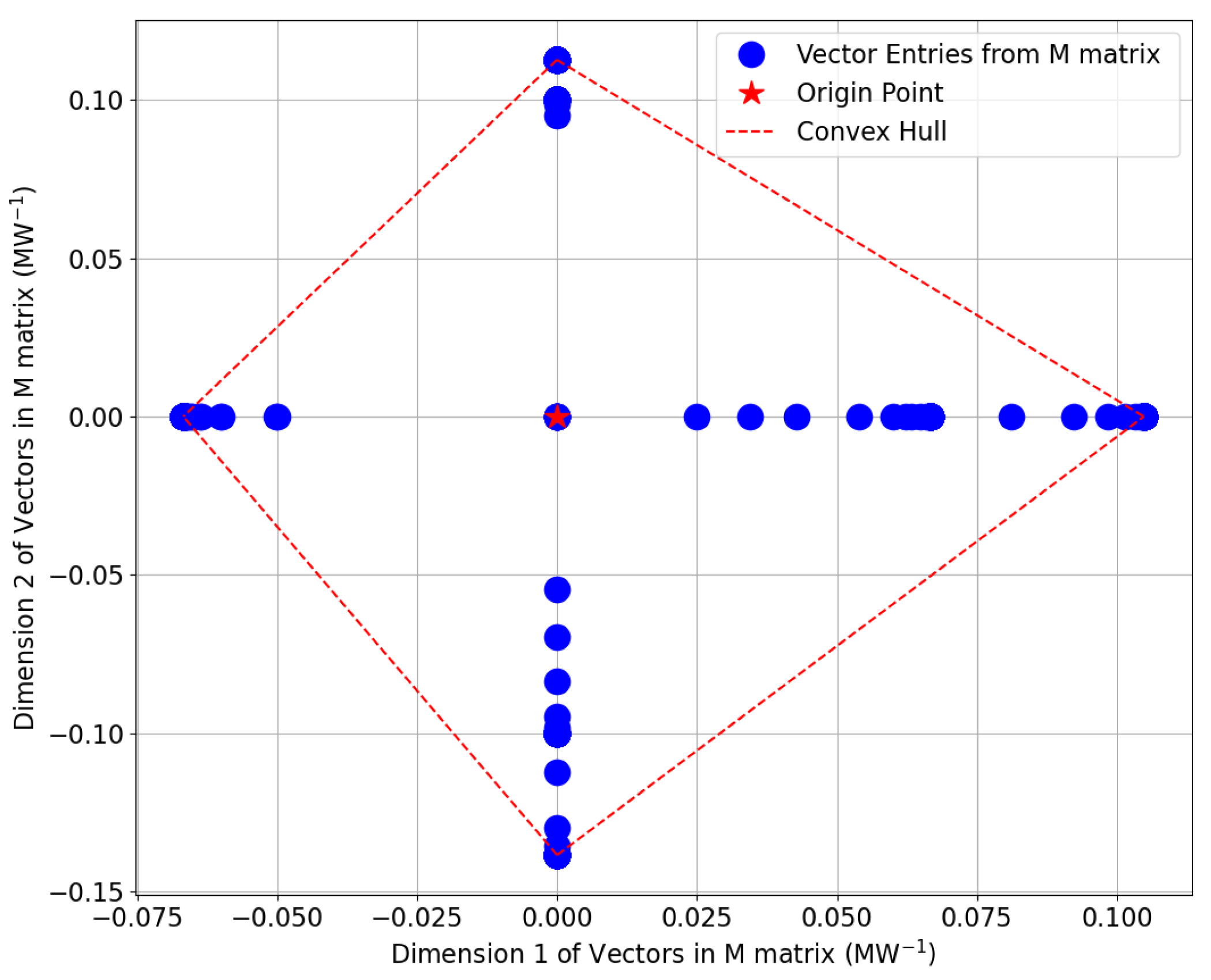

3.2. Convex Hull Method for Removing Redundant Constraints

3.3. Dynamic Mode Decomposition with Control for Deriving the State-Space Matrices

3.4. Recursive Feature Elimination for Selecting the State Variables

- Construct an evaluation model, trained on a complete feature space data-set.

-

Rank the features by using one of the following method:

- (a)

- Sensitivity ranking method (ranking of the features based on their sensitivity coefficients);

- (b)

- Correlation ranking approach (ranking of the features based on their correlation coefficients);

- (c)

- A model-based importance ranking method exploiting the mathematical formulation of the evaluation model (e.g., linear model coefficients, etc.).

- Remove the features with the lowest scores calculated by the selected ranking criterion.

- Repeat the process until the user-defined number of variables are selected.

- is the original value of the element in the row and column of ;

- is the row of ;

- and are the minimum and maximum values in the row of , respectively.

-

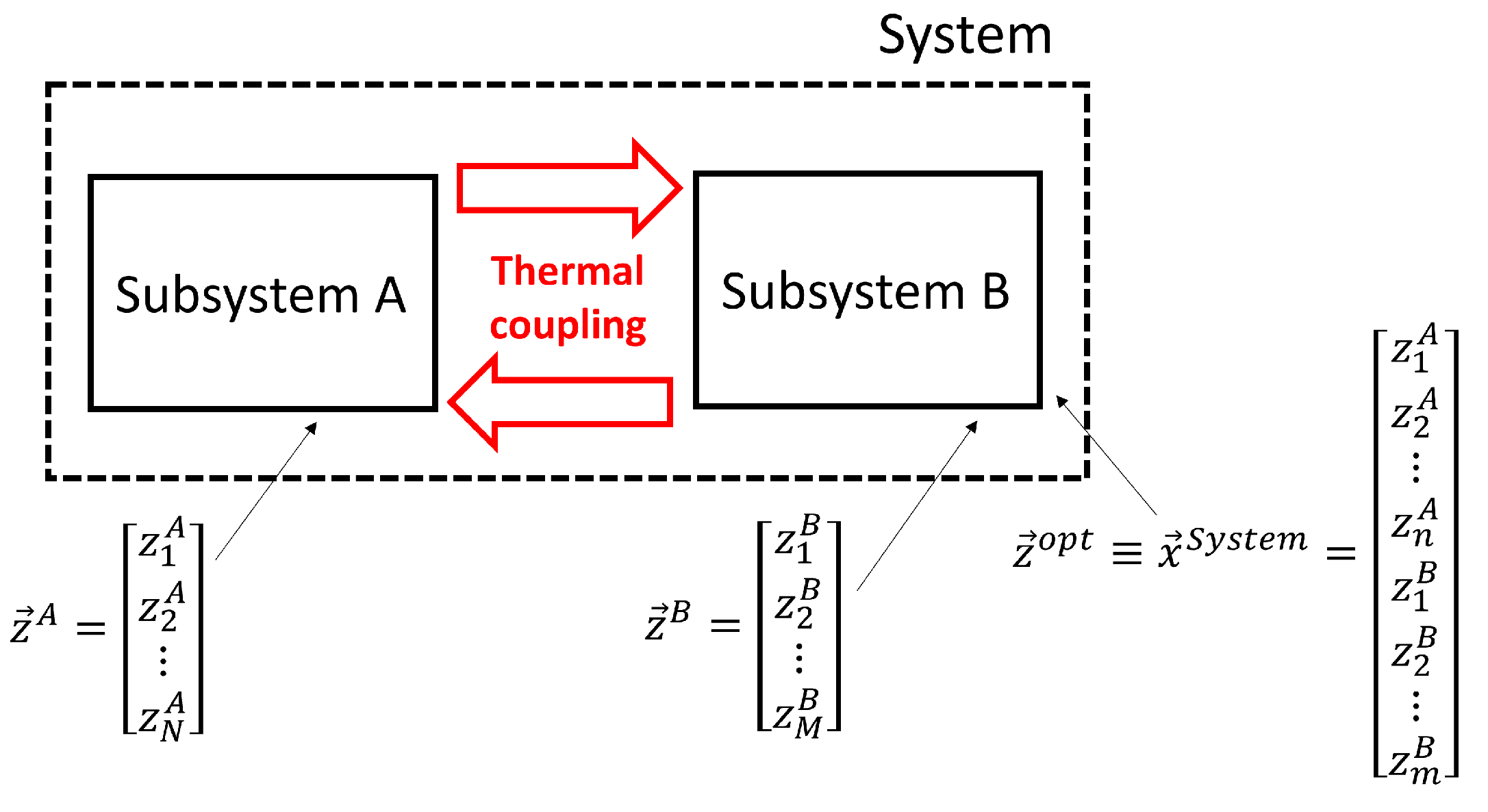

Step IThe RFE selection is performed on each subsystem, i.e., A and B are independently studied. At the end of this stage, the two sets of candidate state variables for subsystems A and B are selected ( and ).

-

Step IIThe two sets of recorded process variables are analyzed with a cross-correlation technique. This step is crucial even when the subsystems are not interacting since the process variables of a subsystem can be "privileged", being characterized by a higher scores through the importance metrics (Eq.(33)). The influence that variables perform on the candidate state variables () and the output variables () of B is evaluated and vice versa. It is worth stressing that the impact on both the candidate state variables and the output variables needs to be accounted for (Eqs.(34)(35)). As a result, two new sets of candidate state variables are obtained ( and ).

-

Step IIIA cross-system set of candidate state variables is generated (). The optimal set () is evaluated by maximizing the accuracy of the model in reconstructing the state variable and the output variables spaces. A parallel searching is then performed over all the combinations of the cross-system set of candidate state variables by minimizing the cost function (Eq.(31)).

4. Description of the Test-Case System and Operational Constraints

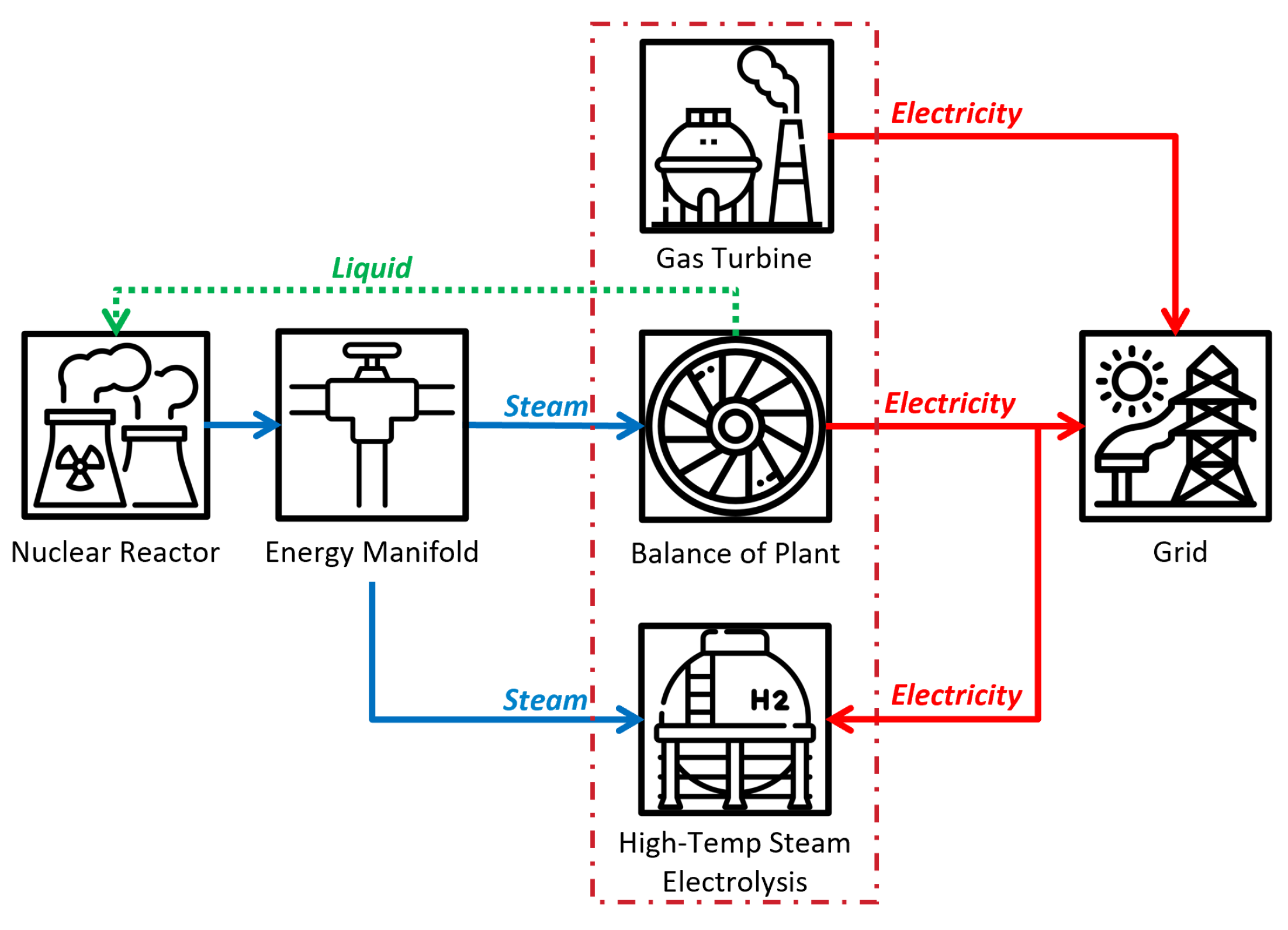

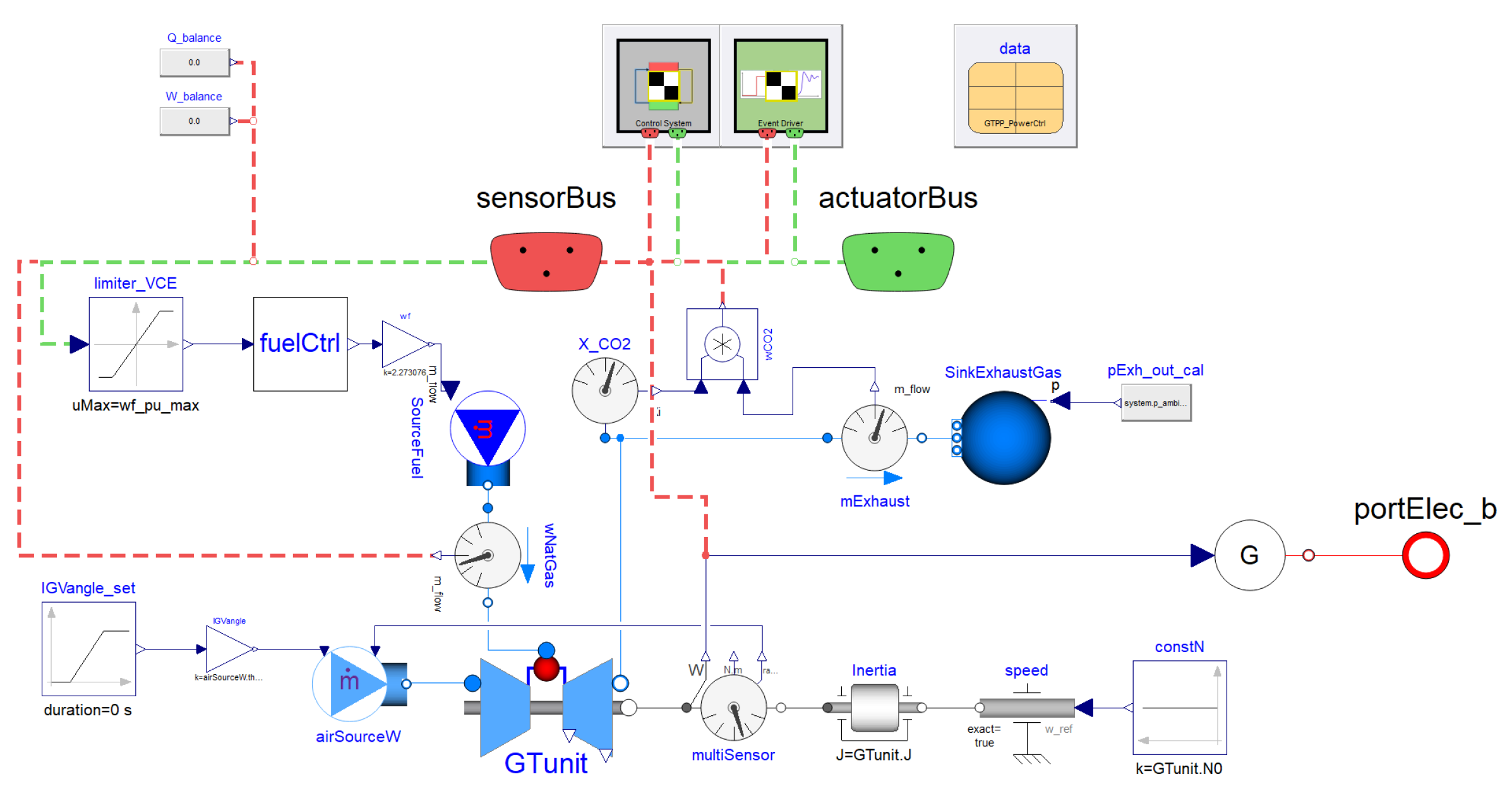

4.1. Gas Turbine (GT)

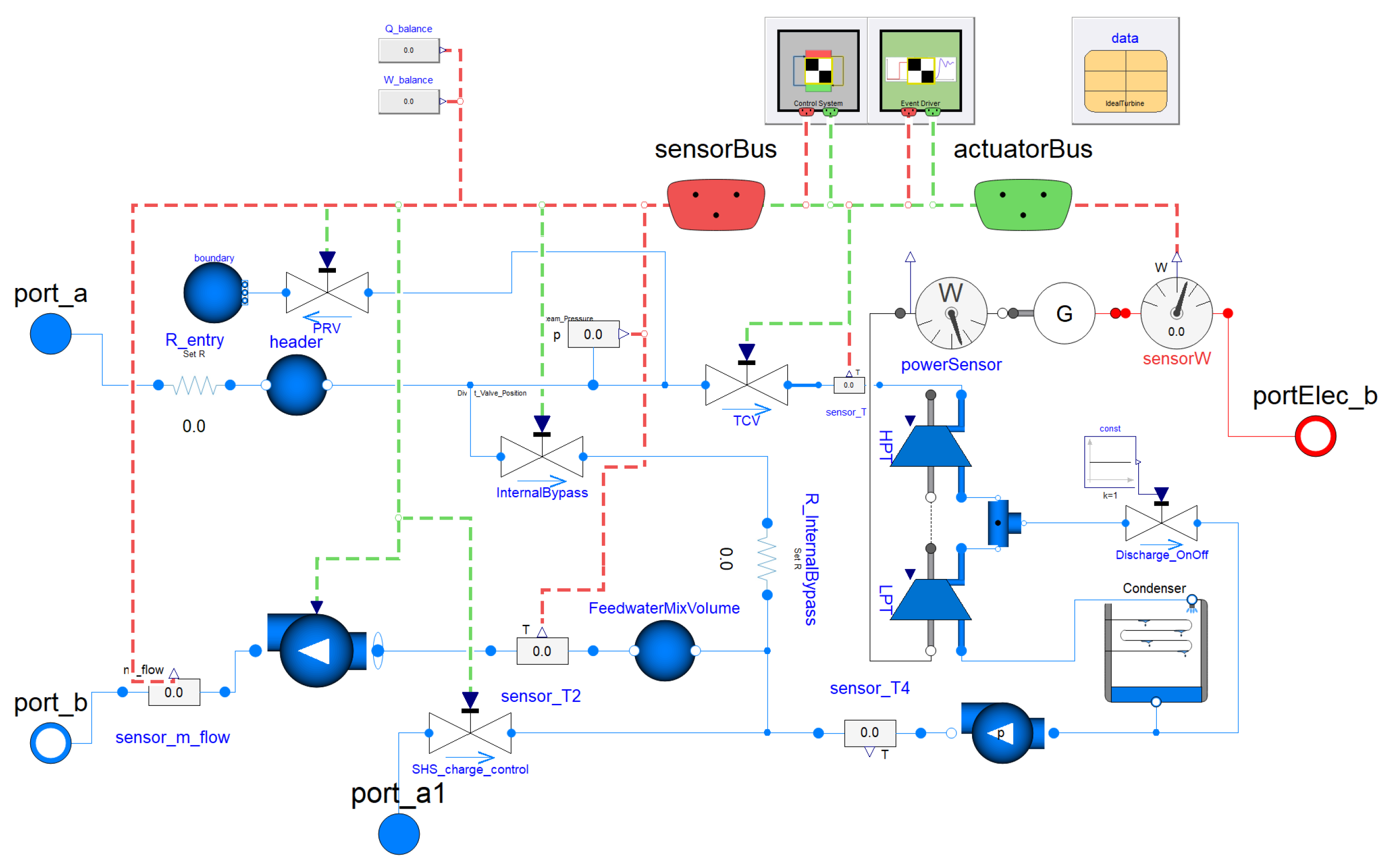

4.2. Balance of Plant (BOP)

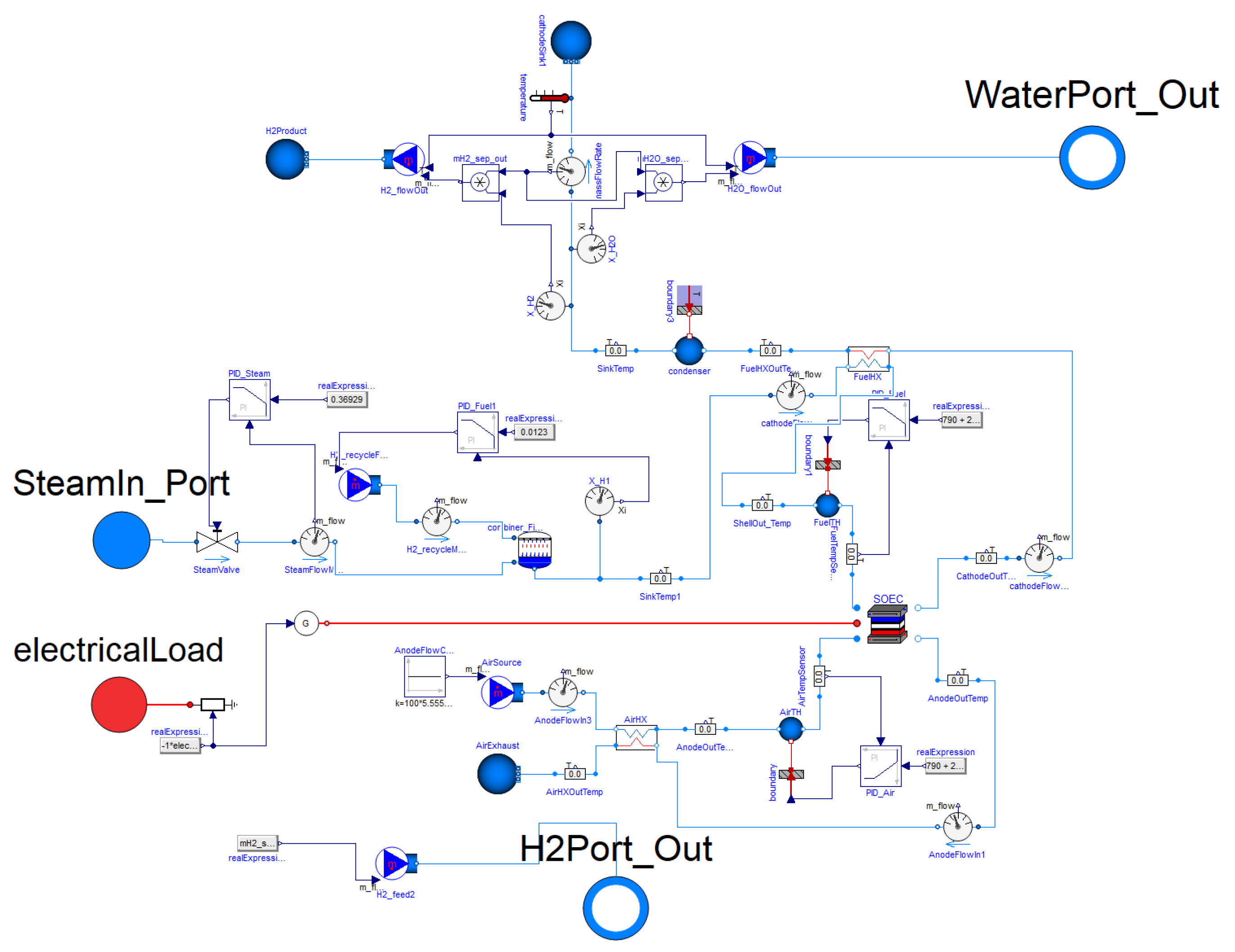

4.3. High-Temperature Steam Electrolysis (HTSE)

5. Solution of the Unit Dispatch Problem for the Studied IES Unit

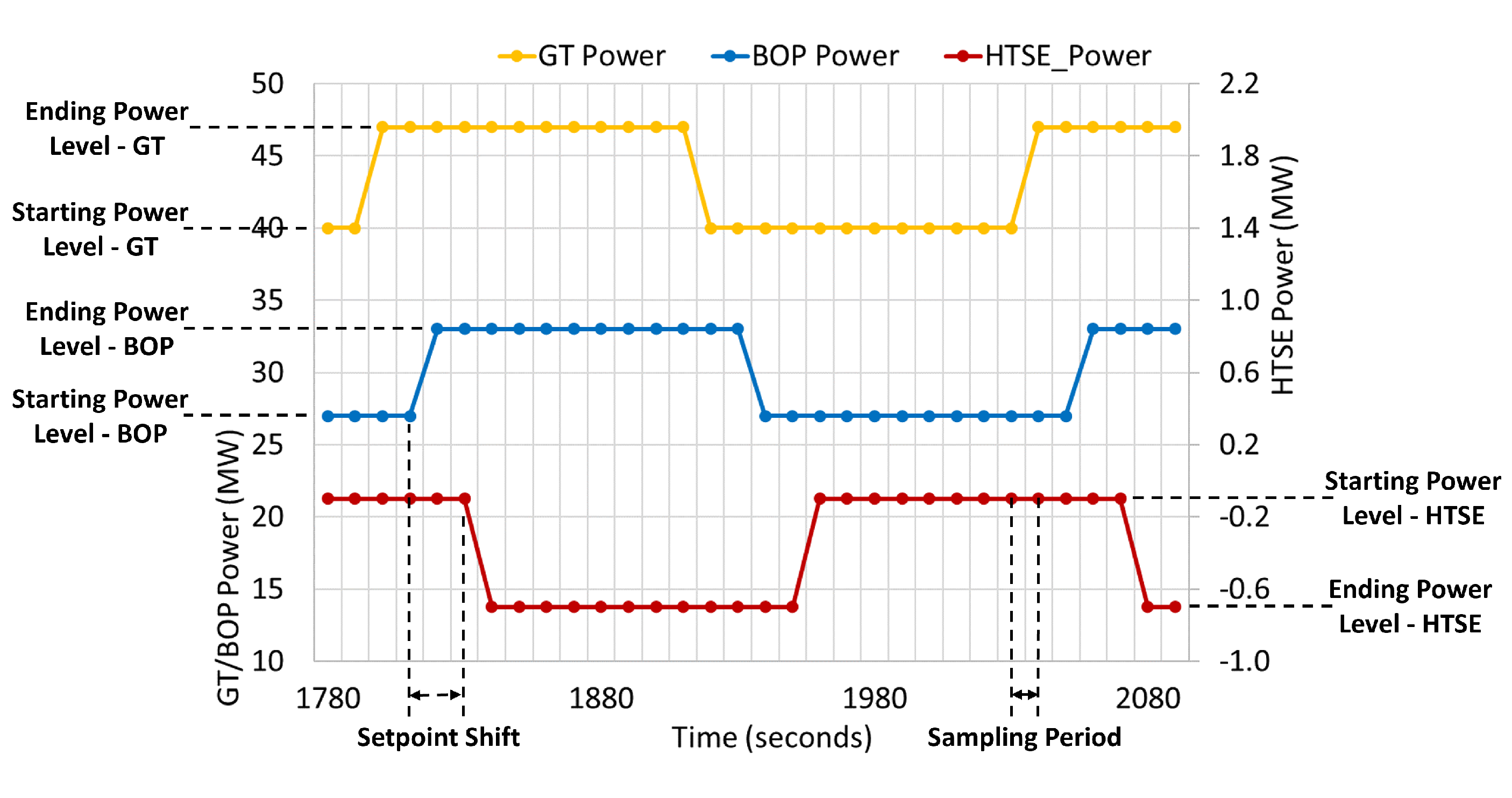

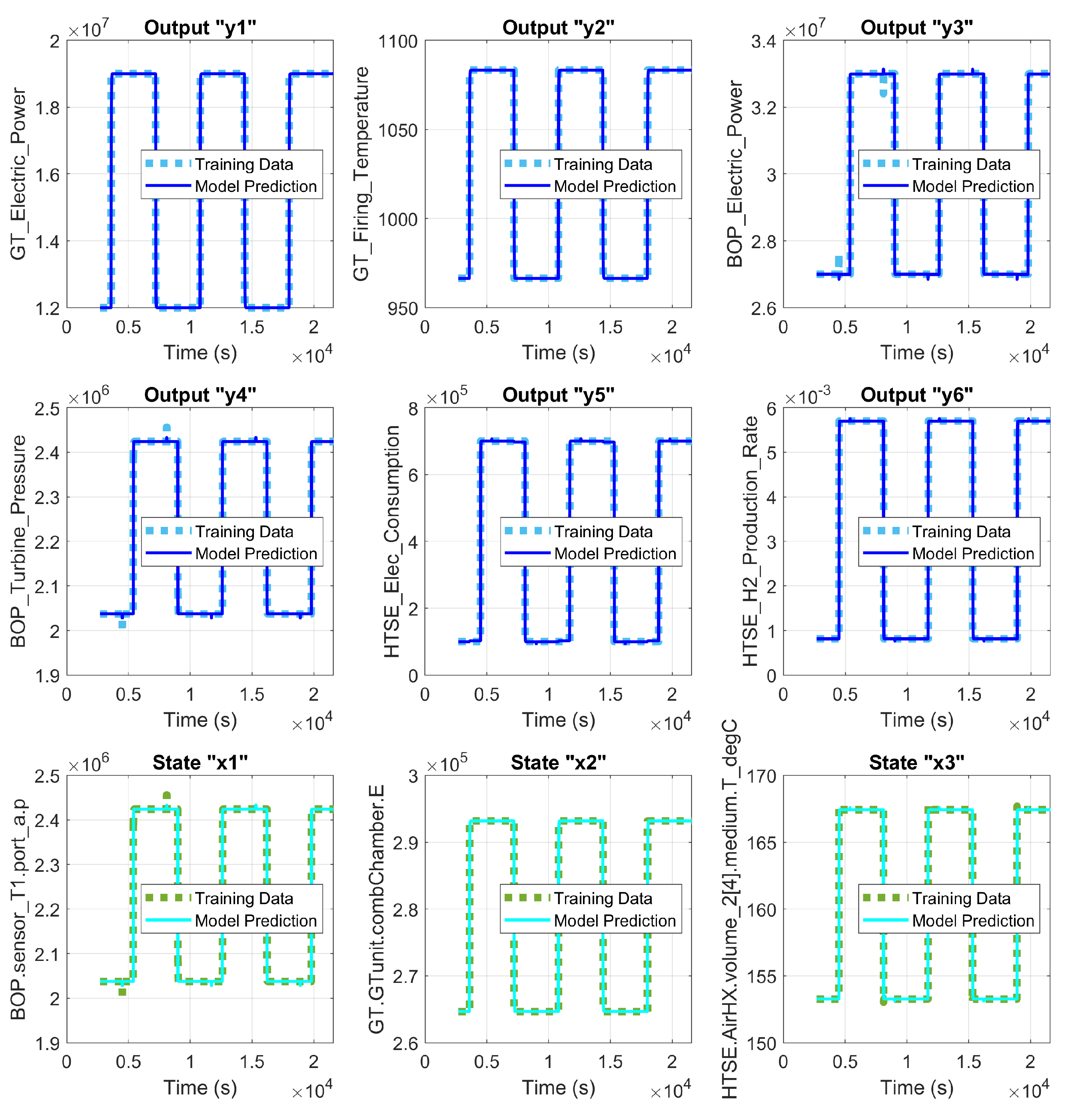

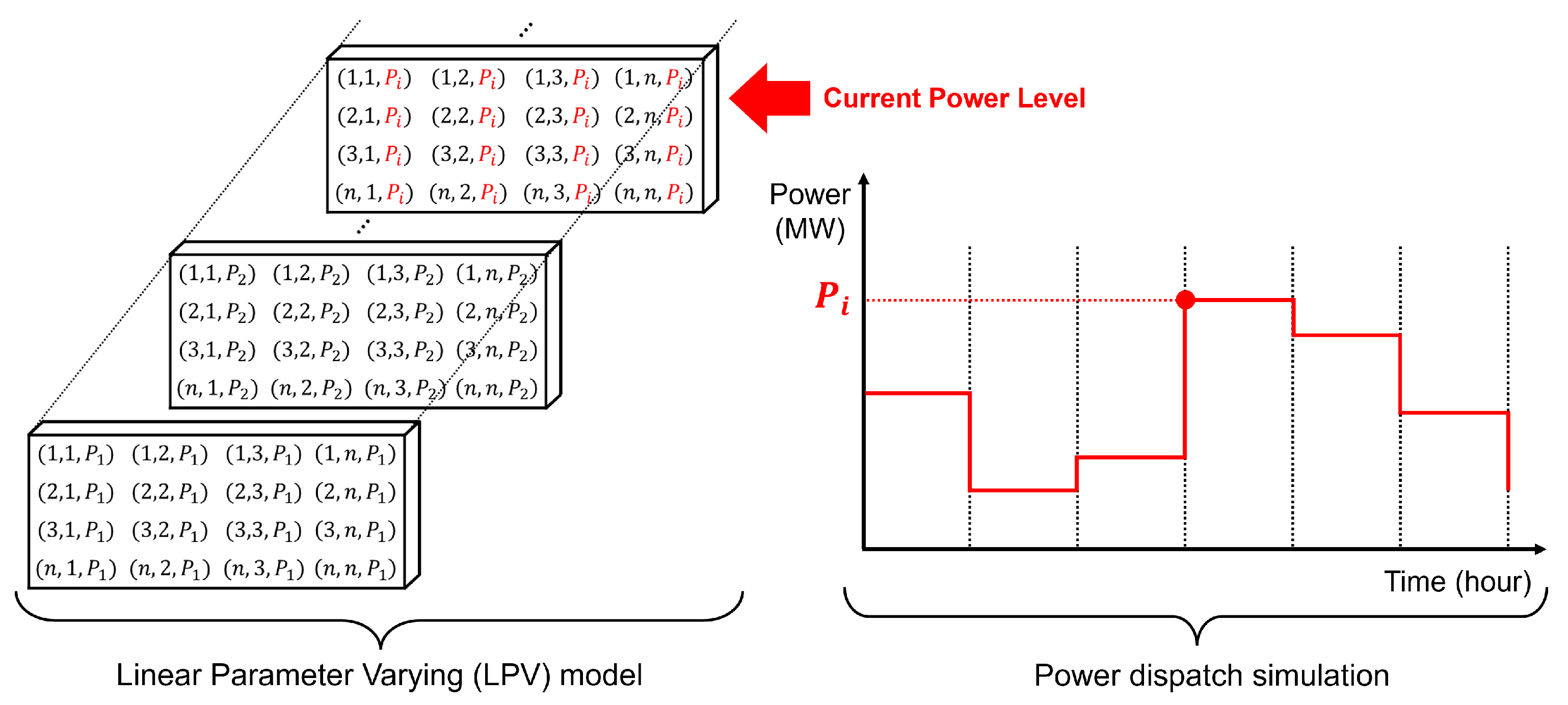

5.1. Derivation of the LPV State-Space Model

5.2. Unit Dispatch Problem 1: Time-Varying Power Generation Cost for GT

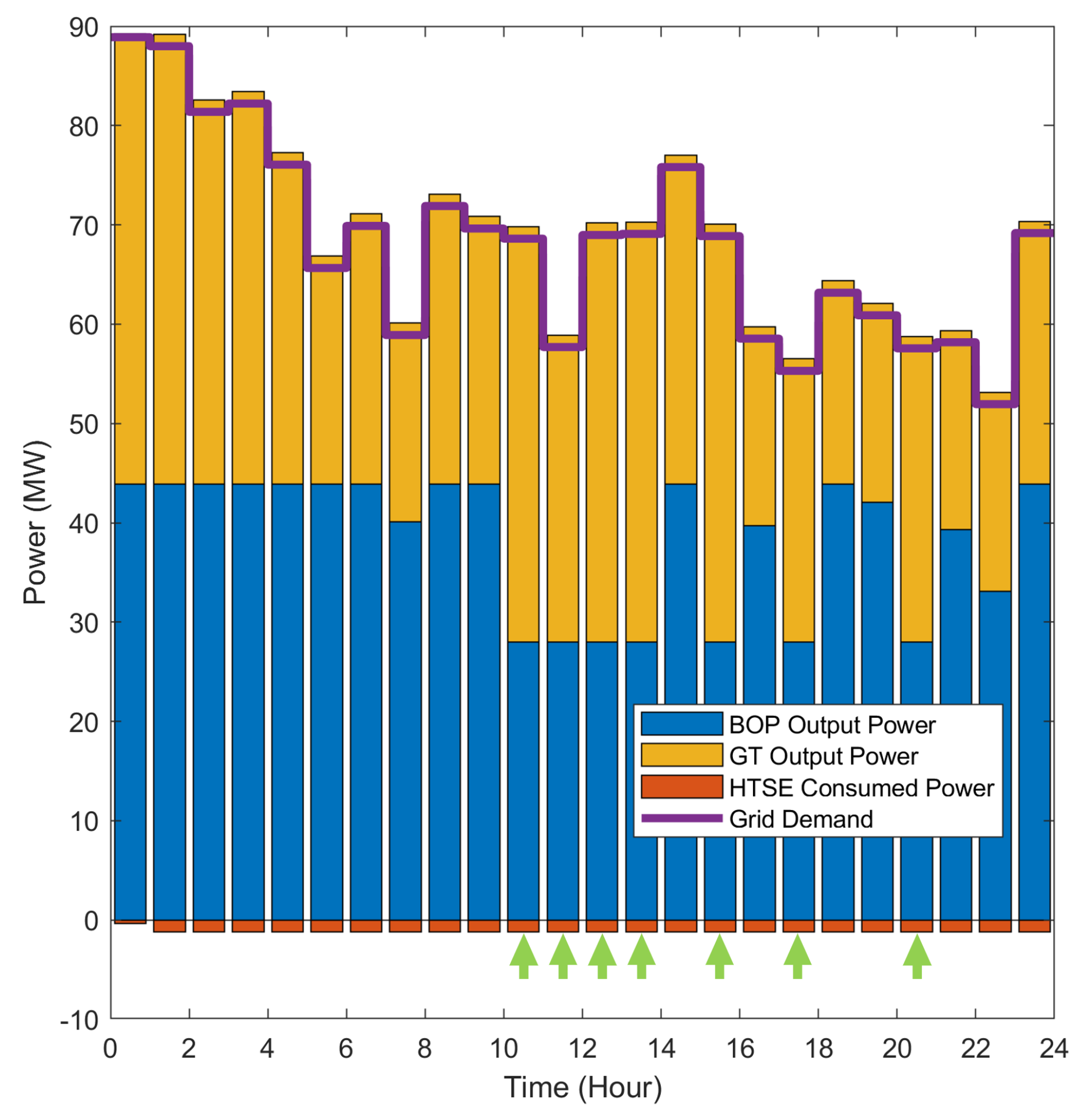

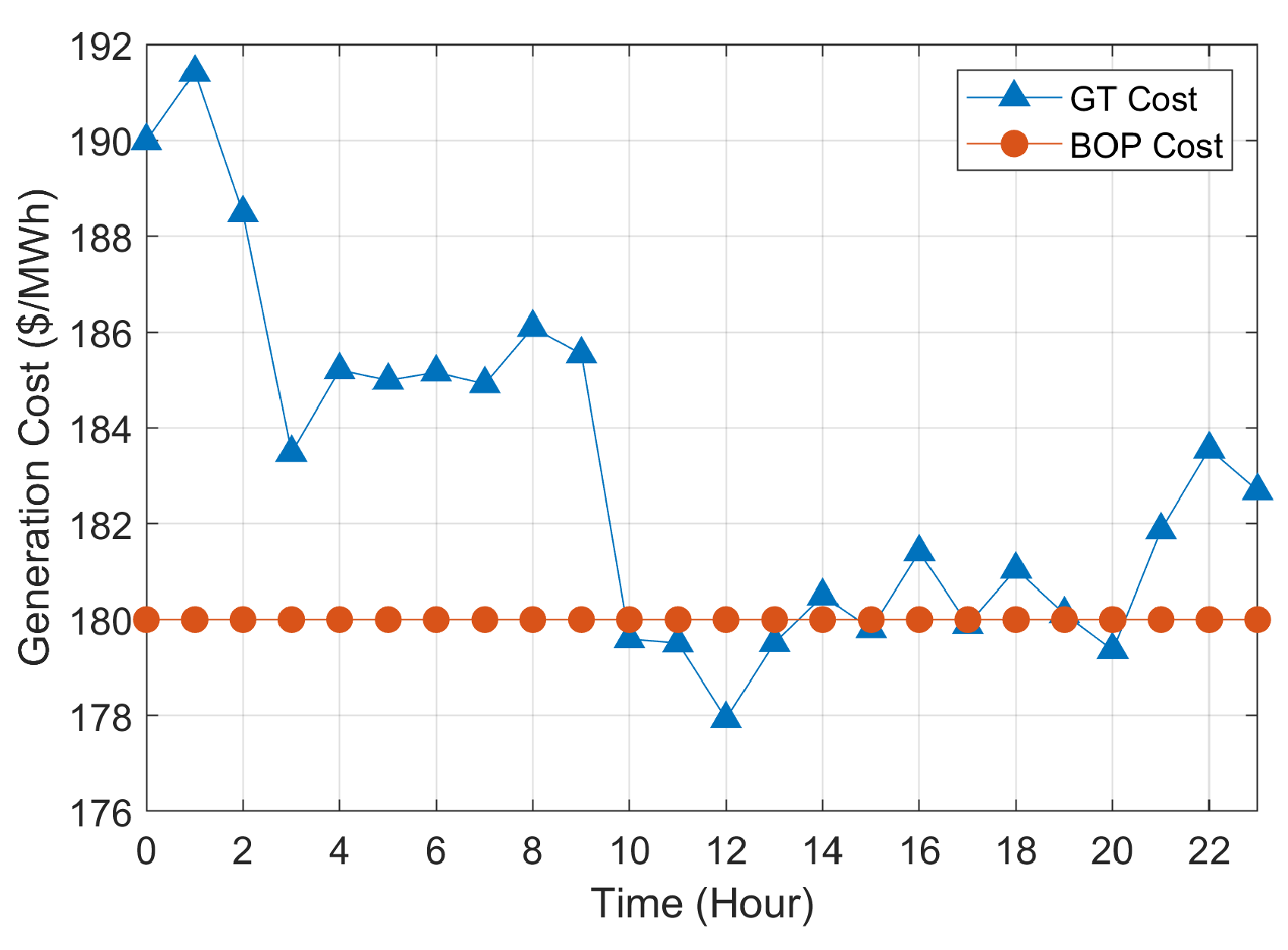

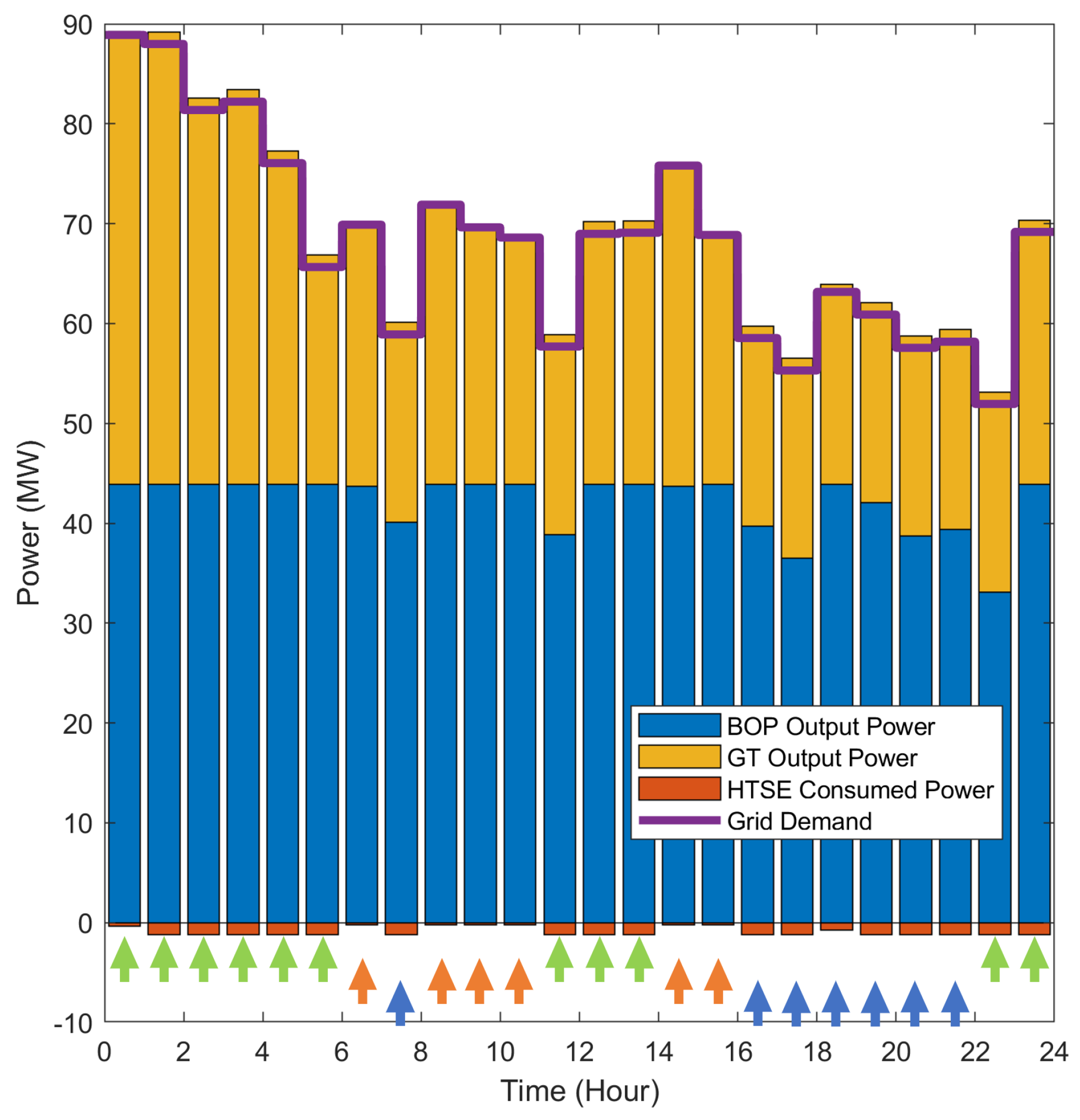

- Due to higher sales price, selling electricity is more profitable than selling hydrogen. Thus, the primary focus is the electrical power generation. Because of the insufficient electricity supply, the hydrogen production is interrupted at .

- Since the sales price of hydrogen could cover the generation cost of the consumed electricity, HTSE tends to generate hydrogen at maximum rate given the steam and electrical power surplus.

- During the hours when GT power generation costs are lower than those of BOP (, and , as marked by the green arrows), it is more profitable to generate electricity using GT, which results in the BOP producing at its minimum rate.

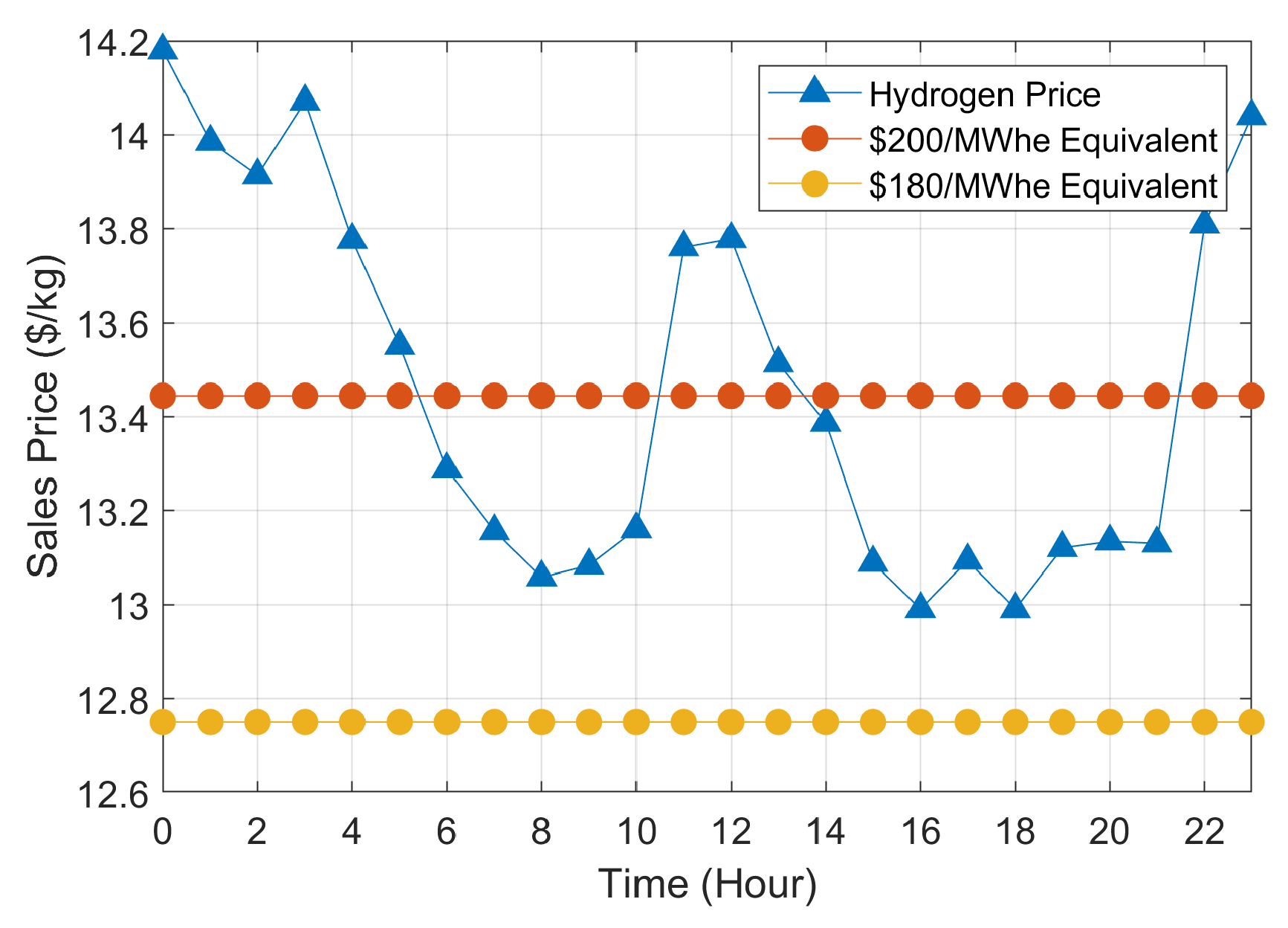

5.3. Unit Dispatch Problem 2: Time-Varying Hydrogen Sales Price

- When the revenue from hydrogen sales surpasses the expenses incurred in electrical power production by the GT and BOP (, , and , as marked by the green arrows), it is preferable to produce as much hydrogen as possible using the excess steam and electricity once grid demand has been met. As stressed in Section 5.2, generating electricity has higher priority due to the higher sales price, which suppressed the hydrogen production at . BOP tends to generate at its maximum rate due to its lower generation cost than GT.

-

When the income from hydrogen sales does not exceed the costs associated with GT power generation:

- (a)

- During high demand periods (, , and , as marked by the orange arrows), the BOP output is maximized to supply to the grid, GT addresses the demand fluctuations, and HTSE operates at minimum rate to avoid further loss.

- (b)

- During low demand periods (, and , as marked by the blue arrows), the GT output is minimized, the BOP addresses demand fluctuations, and the HTSE operates at maximum rate to maximize the profit.

5.4. Computational Efficiency of the Proposed Scheme for Solving the Unit Dispatch Problem

- Data-driven procedure for deriving the LPV model from simulation data during Self-learning phase ("LPV Derivation" task) The computational time associated with this task is affected by the complexity of the FMU or other high-fidelity model of the studied system used to generate the training data, i.e., the time for running simulations and collecting data may significantly differ. In this analysis, the computational time to complete this task was measured from loading the simulation data from hard drive to generating the database of state-space representation matrices.

- Solution to the unit dispatch problem by HERON, addressing only the explicit constraints during Dispatch phase ("HERON Dispatcher" task) The evaluation of the computational time to perform the tasks during the Dispatch phase is more complicated. Since the HERON dispatcher and the FARM validator two processes are in a feedback loop (Figure 6), it is challenging to distinguish the individual computational time from the overall time of the Dispatch phase. To this end, the computational time for the HERON dispatcher was estimated by solving the unit dispatch problem without using the FARM validator. The measured value serves as a baseline.

- Validation of the HERON-provided solution by the FARM validator during the Dispatch phase ("FARM Validator" task) The computational time for the FARM validator was calculated by subtracting the HERON dispatcher contribution from the overall computational time for the Dispatch phase. The values reported below include the set-point validation using the FARM Validator and the prediction of the system response using the LPV model. The computational time may significantly increase if the capability to update the LPV model via FMU simulation is utilized during the Dispatch phase (Section 2).

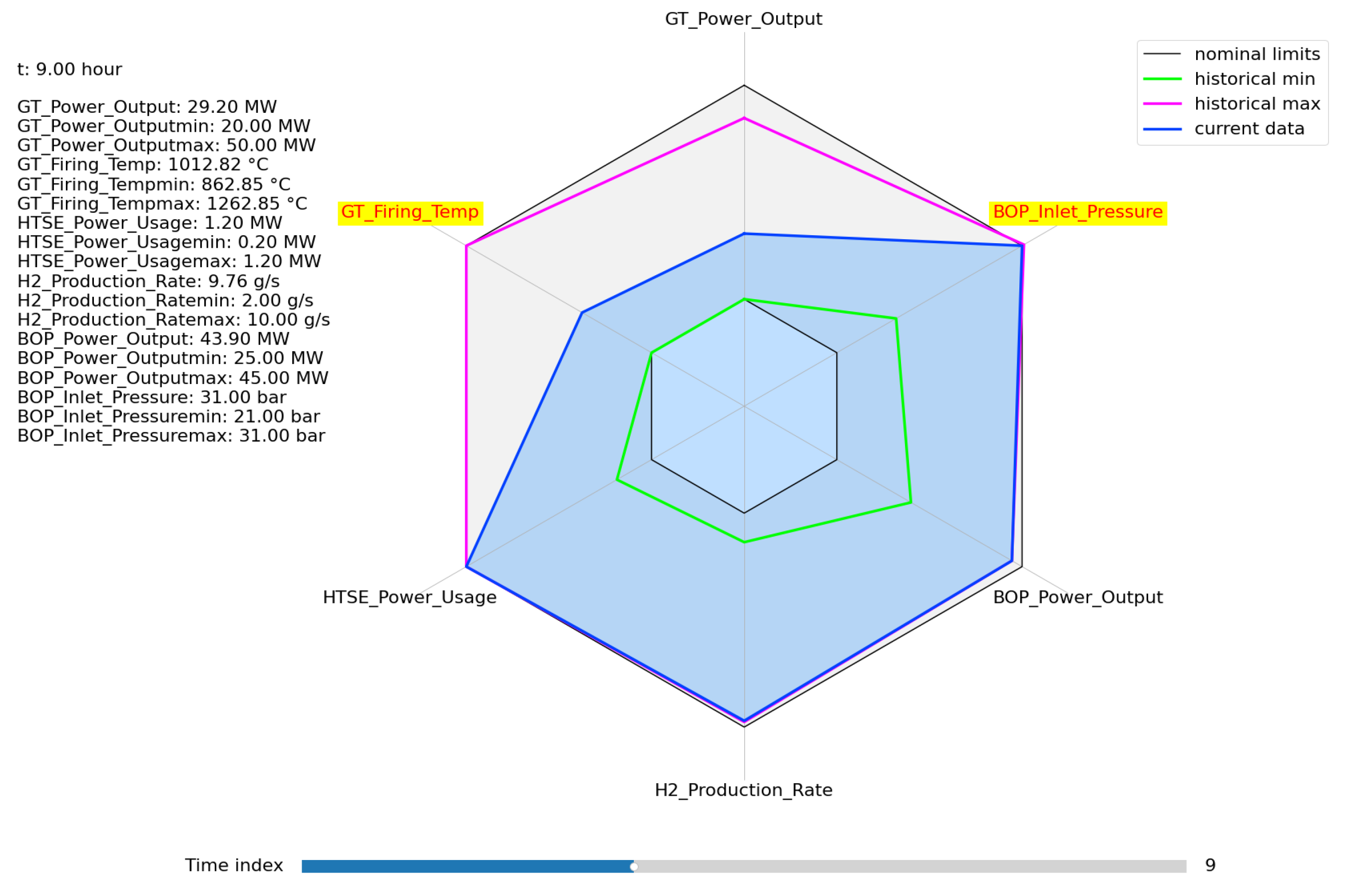

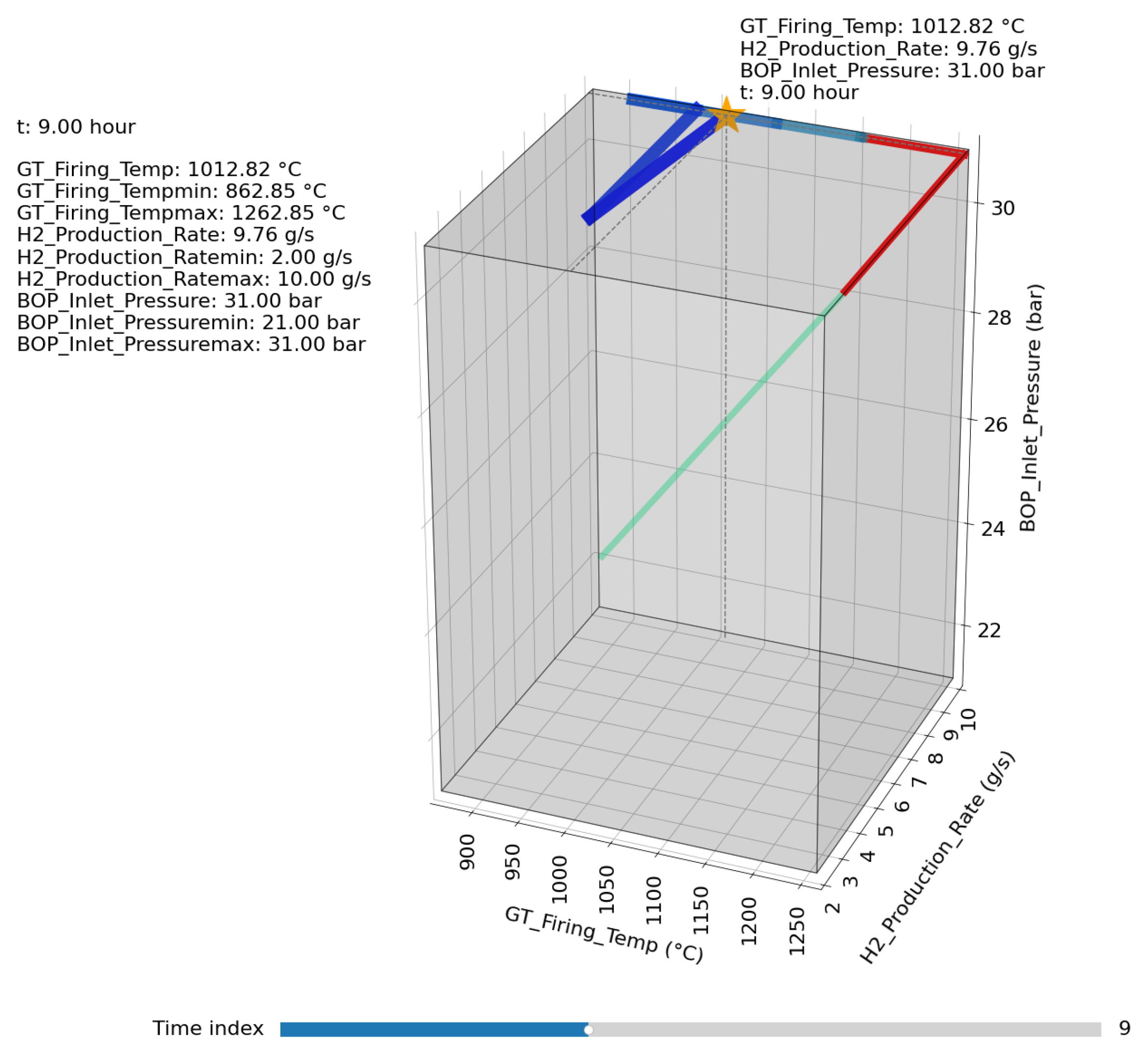

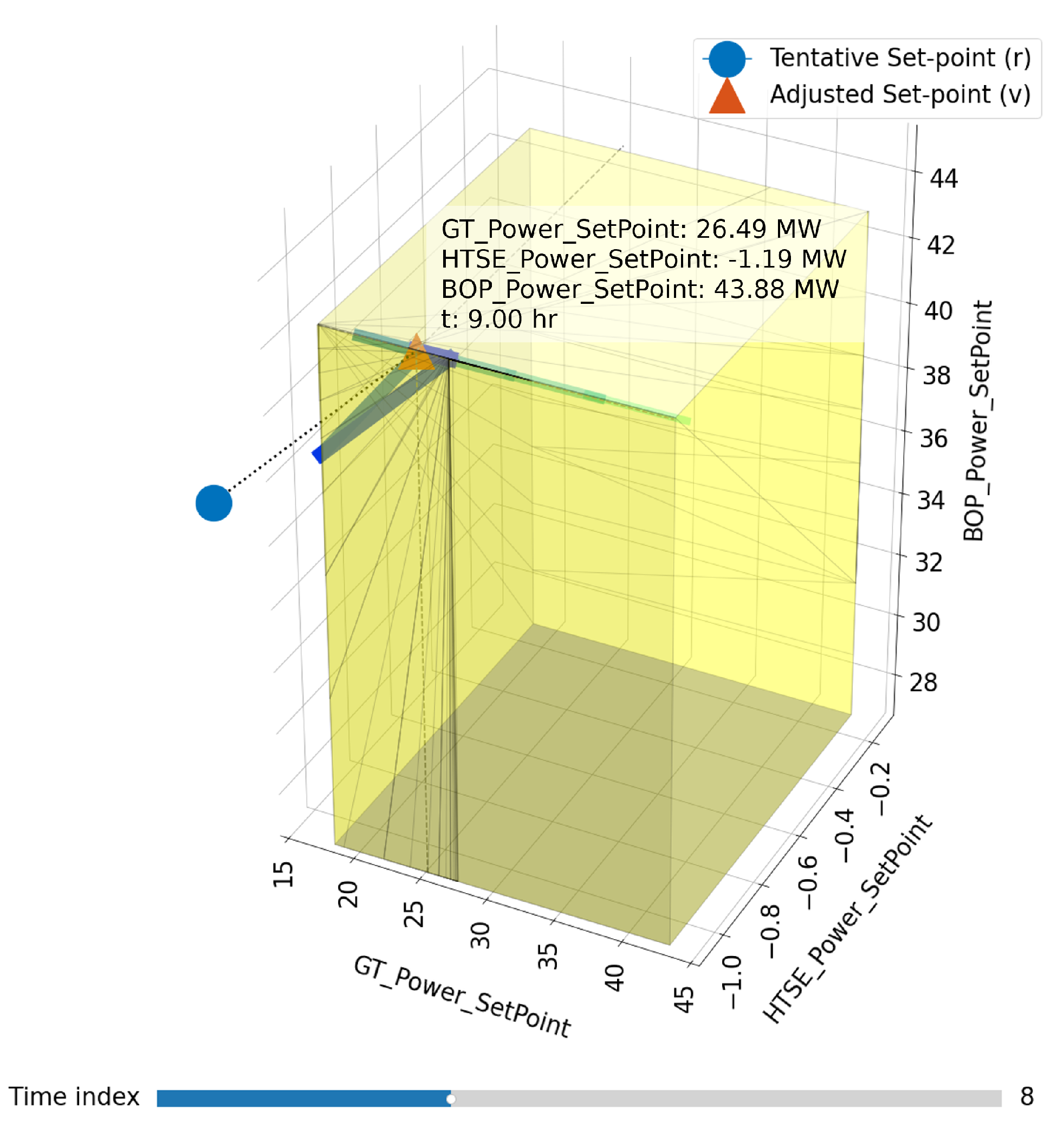

6. Visualization Techniques for Displaying the Solution of the Unit Dispatch Problem

6.1. Graphical Representation of the Normal Operation Region for Process Variables

6.2. Graphical Representation of the Admissible Region for the Power Set-Point Trajectories

7. Conclusions

- Design of a dedicated tool for solving the Unit Dispatch problem for Advanced Energy Systems When solving the unit dispatch problem for an Advanced Energy System as an IES unit, it is necessary to consider the operational limits on the power outputs and the main process variables for all the subsystems that constitute the multi-asset system. The iterative dispatcher-validator scheme presented in this work permits addressing all the imposed constraints without excessively increasing the computational costs. The scheme was tested on IES unit constituted by a BOP, a GT and a HTSE that produce both electrical power and hydrogen. One of the key reasons for the inherent efficiency of this scheme is that the validator intervention is not always required. Often, meeting the limits on power outputs and the corresponding rates of variation is sufficient to get a feasible solution, eliminating the need for any adjustments to the tentative set-point trajectories. In these cases, there are no iterations, and the validator simply approves the trajectories estimated by the dispatcher.

- Computationally-efficient enforcement of constraints on Process Variables The central premise of the developed scheme is that attempting to solve the optimization problem by simultaneously addressing both explicit and implicit constraints would result in prohibitively high computational costs. A more efficient approach consists of tackling the problem as a two-phase process. Traditionally used as a control algorithm, the CG was proposed as a tool to favor the convergence to the feasible solution maximizing the cost function. Nonetheless, when too many redundant constraints are provided, the QP solver is challenged, and a sub-optimal solution is occasionally returned. To address this issue, the CG algorithm was modified by adding the Convex Hull method that permits dropping redundant constraints.

- Development of a DT of the studied system When solving the unit dispatch problem, a DT that mimics the behavior of the studied system is necessary to avoid power transients that could compromise the integrity of the components. In this work, a dedicated procedure for building a DT was embedded into FARM module. It is constituted by an algorithm for selecting the state variables, an algorithm for deriving the state-space matrices from tracked variables, and the protocol for updating the model. The tool is quite versatile and can also be used to other real-time applications. The adopted data-driven approach relies on sampled data to derive the state-space model of the system. In this work, data provided by a simulator were utilized, but sensor readings from an actual system could also be used. This capability is crucial to account for the evolution of physical parameters during operation that might get the model outdated over time. In this way, latest, most accurate description of the system dynamics is always available.

- Enhanced Monitoring capabilities through innovative Visualization Techniques To ensure the demanded operational performance of a complex multi-asset system as an IES unit without damaging system components, an efficient real-time monitoring tool for assessing component conditions is necessary. Currently available techniques need to be improved to handle the mass of real-time data from the plant and from the power grid and determine a solution minimizing the power generation costs and respecting all the limits on materials and components. In this work, two tools for displaying the response of the process variables of interest during system operation and another tool aiding the operator at making decisions were developed and tested.

Author Contributions

Acknowledgments

Conflicts of Interest

Abbreviations

| BOP | Balance of Plant |

| CG | Command Governor |

| DAE | Differential-Algebraic Equations |

| DP | Dynamic Programming |

| DT | Digital Twin |

| DMDc | Dynamic Mode Decomposition with Control |

| EID | Ecological Interface Design |

| FARM | Feasible Actuator Range Modifier |

| FMI | Functional Mock-up Interface |

| FMU | Functional Mock-up Unit |

| FORCE | Framework for Optimization of ResourCes and Economics |

| GT | Gas Turbine |

| GUI | Graphical User Interface |

| HERON | Holistic Energy Resource Optimization Network |

| HPT | High Pressure Turbine |

| HTSE | High-Temperature Steam Electrolysis |

| IES | Integrated Energy System |

| IRR | Internal Rate of Return |

| LCOE | Levelized Cost of Electricity |

| LPT | Low Pressure Turbine |

| LPV | Linear Parameter-Varying |

| LTI | Linear Time-Invariant |

| MSE | Mean Square Error |

| MILP | Mixed-Integer Linear Programming |

| MIMO | Multiple Input Multiple Output |

| MOAS | Maximal Output Admissible Set |

| NOR | Normal Operation Region |

| NPV | Net Present Value |

| NRC | Nuclear Regulatory Commission |

| PI | Profitability Index |

| PID | Proportional Integral Derivative |

| PWR | Pressurized Water Reactor |

| QP | Quadratic Programming |

| RES | Renewable Energy Sources |

| RFE | Recursive Feature Elimination |

| SVD | Singular Value Decomposition |

| TEAL | Tool for Economic AnaLysis |

| UQ | Uncertainty Quantification |

References

- Javanshir, N.; Syri, S. Techno-Economic Analysis of a Highly Renewable and Electrified District Heating Network Operating in the Balancing Markets. Energies 2023, 16(24), 8117.

- Nikolewski, R. How hard is it to develop California’s electric grid of the future? Like repairing a car while driving. Los Angeles Times January 29, 2024.

- Mulder, S.; Klein, S. Techno-Economic Comparison of Electricity Storage Options in a Fully Renewable Energy System. Energies 2024, 17(5), 1084.

- Ponciroli, R.; Wang, Y.; Zhou, Z.; Botterud, A.; Jenkins, J.; Vilim, R.B.; Ganda, F. Profitability Evaluation of Load-Following Nuclear Units with Physics-Induced Operational Constraints. Nucl. Technol. 2017, 200(3), 189–207.

- Vaglio-Gaudard, C. et al.. The TANDEM Euratom project: Context, objectives and workplan. Nucl. Eng. Technol. 2024, 56(3), 993–1001.

- Bragg-Sitton, S.M.; Rabiti, C.; Boardman, O’Brien, J.; Morton, T.J.; Yoon, S.J.; Yoo, J.S.; Frick, K.; Sabharwall, P.; Harrison, T.J.; Greenwood, M.S.; R.B. Vilim. Integrated Energy Systems: 2020 Roadmap, INL/EXT-20-57708 Rev 1.; Idaho National Laboratory: Idaho Falls, ID, 2020.

- Wu, X.; Dai, H.; Zhang, N.; Kong, W. Development Outlook of Integrated Energy System in China. In Proceedings of the 6th International Conference on Power and Renewable Energy (ICPRE), Shanghai, China, September 17-20, 2021.

- Bragg-Sitton, S.M.; Boardman, R.D.; Rabiti, C.; Kim, J.; McKellar, M.; Sabharwall, P.; Chen, J.; Cetiner, S.; Harrison, T.J.; Qualls, A.L. Nuclear-Renewable Hybrid Energy Systems: 2016 Technology Development Program Plan, INL/EXT-16-38165 Rev 1.; Idaho National Laboratory: Idaho Falls, ID, 2016.

- Xu, Y., Zhang, W. and Liu, W., . Distributed dynamic programming-based approach for economic dispatch in smart grids. IEEE Transactions on Industrial Informatics 2014, 11(1), 166-175.

- Feng, Z.K., Niu, W.J., Wang, W.C., Zhou, J.Z., and Cheng, C.T. A mixed integer linear programming model for unit commitment of thermal plants with peak shaving operation aspect in regional power grid lack of flexible hydropower energy. Energy, 2019, 175, 618-629.

- Ganda, F.; Kim, T.K.; Taiwo, T.A.; Hansen, J.; Wigeland, R. Economic Evaluation of Promising Options, FCRD-FCO-2015-000013; Argonne National Laboratory: Lemont, IL, 2015.

- Kalman, R.E. A New Approach to Linear Filtering and Prediction Problems. Transactions of the ASME - Journal of Basic Engineering 1960, 82, 35–45.

- Garone, E.; Di Cairano, S.; Kolmanovsky, I. Reference and command governors for systems with constraints: A survey on theory and applications. Automatica 2017, 75, 306–-328.

- Bemporad, A.; Mosca, E. Constraint fulfilment in control systems via predictive reference management. In Proceedings of 1994 33rd IEEE Conference on Decision and Control, Lake Buena Vista, FL, December 14-16, 1994.

- Passerini, S.; Ponciroli, R.; Vilim, R.B. Impact of Active Control on Passive Safety Response Characteristics of Sodium-Cooled Fast Reactors: I — Theoretical Background. Nuclear Technology 2017, 199(1), 1–-15.

- Wang, H.; Ponciroli, R.; Elmer, T.; Ley, H.; Dave, A.J.; Vilim, R.B. Quantitative Estimation and Visualization of the Normal Operation Region for Power Transient Planning. In Proceedings of 13th Nuclear Plant Instrumentation, Control & Human-Machine Interface Technologies, Knoxville, TN, July 15-20, 2023.

- Wang, H.; Ponciroli, R.; Vilim, R.B.; Alfonsi, A. Validation and Demonstration of Control System Functional Capabilities within the IES Plug-and-Play Simulation Environment, ANL/NSE-21/5; Argonne National Laboratory: Lemont, IL, 2021.

- Bemporad, A. Reference Governor for Constrained Nonlinear Systems. IEEE Trans. Automat. Contr. 1998, 43(3), 415–-419.

- Force of Integrated Energy Systems. Available online: https://ies.inl.gov/SitePages/FORCE.aspx (accessed on July 28, 2022).

- Rabiti, C.; Alfonsi, A.; Mandelli, D.; Cogliati, J.J.; Wang, C.; Talbot, P.W.; Maljovec, D.P.; Kinoshita, R.A.; Abdo, M.G.; Sen, S.; Chen, J. RAVEN user manual, INL/EXT-15-34123-Rev.07; Idaho National Laboratory: Idaho Falls, ID, 2021.

- Chen, J.; Rabiti, C. Synthetic wind speed scenarios generation for probabilistic analysis of hybrid energy systems. Energy 2017, 120, 507–517.

- Alfonsi, A.; Frick, K.; Rabiti, C.; Bragg-Sitton, S.M. Status Report on the INL IES Plug-and-Play Framework, INL/EXT-21-63204-Rev.0; Idaho National Laboratory: Idaho Falls, ID, 2021.

- Talbot, P.W.; Gairola, A.; Prateek, P.; Alfonsi, A.; Rabiti, C.; Boardman, R.D. HERON as a Tool for LWR Market Interaction in a Deregulated Market, INL/EXT-19-56933; Idaho National Laboratory: Idaho Falls, ID, 2020.

- Epiney, A.; Rabiti, C.; Talbot, P.W.; Alfonsi, A. Economic analysis of a nuclear hybrid energy system in a stochastic environment including wind turbines in an electricity grid. Appl. Energy 2020, 260(15).

- Wang, H.; Ponciroli, R.; Vilim, R.B.; Alfonsi, A. Development of Control System Functional Capabilities within the IES Plug-and-Play Simulation Environment, ANL/NSE-20/35; Argonne National Laboratory: Lemont, IL, 2020.

- Bachnas, A.A.; Tóth, R.; Ludlage, J.H.A..; Mesbah, A. A review on data-driven linear parameter-varying modeling approaches: A high-purity distillation column case study. J. Process Control 2014, 24, 272–285.

- Kunkel, P.; Mehrmann, V. Differential-algebraic equations: analysis and numerical solution. European Mathematical Society 2006, 2.

- Lawrence Berkeley National Laboratory, FMU Export of a Python-driven Simulation Program, Release 1.0.0rc15, Lawrence Berkeley National Laboratory, Berkeley, CA, 2018.

- Fiorina, C.; Habtemariam, N.; Lorenzi, S.; Scolaro, A.; Guilbaud, T.; Alfonsi, A. The Functional Mock-Up Interface as a Unified Framework to Enable Multi-Scale, Multi-Fidelity and Control-Oriented Simulations of Nuclear Reactors. In Proceedings of The International Conference on Mathematics and Computational Methods Applied to Nuclear Science and Engineering, Niagara Falls (Canada), August 13–17, 2023.

- Casavola, A.; Garone, E.; Tedesco, F. Distributed reference management strategies for a networked water distribution system. In Proceedings of 18th IFAC World Congress, Milan, Italy, August 28 - September 2, 2011.

- Tedesco, F.; Casavola, A.; Garone, E. A distributed parallel command governor strategy for the coordination of multi-agent networked systems. In Proceedings of 4th IFAC Nonlinear Model Predictive Control conference, Noordwijkerhout, Netherlands, August 23-27, 2012.

- Garcia, C.; Prett, D.; Morari, M. Model predictive control: Theory and practice—A survey. Automatica 1989, 25(3), 335-348.

- Glicksman, A.M. An introduction to linear programming and the theory of games. Courier Corporation 2001.

- cvxpy: A Python-embedded modeling language for convex optimization problems. Available online: https://www.cvxpy.org/ (accessed on July 25, 2022).

- Wang, H.; Ponciroli, R.; Vilim, R.B.. Integrate FARM with PID controllers, ANL/NSE-23/32; Argonne National Laboratory: Lemont, IL, 2023.

- Rockafellar, R.T. Convex analysis. Princeton mathematical series 1970, 28.

- Wang, H.; Ponciroli, R.; Vilim, R.B. Control system for multi-system coordination via a single reference governor, ANL/NSE-22/26; Argonne National Laboratory: Lemont, IL, 2022.

- scipy/scipy: SciPy 1.9. 0. Available online: https://doi.org/10.5281/zenodo.6940349 (accessed on 20 September 2023).

- Proctor, J.L.; Brunton, S.L.; Kutz, J.N. Dynamic Mode Decomposition with Control. SIAM J. Appl. Dyn. Syst. 2016, 15(1), 142–161.

- Moore, E.H. On the Reciprocal of the General Algebraic Matrix. Bull. Am. Math. Soc. 1920, 26, 394–395.

- Van Overschee, P.; De Moor, B. Subspace identification for linear systems: Theory—Implementation—Applications, 1st ed.; Publisher: Springer Science & Business Media, United States, 2012.

- Wang, H.; Alfonsi, A.; Ponciroli, R.; Vilim, R.B. A Data-driven approach for selecting the State Variables of a Dynamic System. SIAM Journal on Applied Dynamical Systems 2024, Submitted, xx–xx.

- Guyon, I.; Weston, J.; Barnhill, S.; Vapnik, V. Gene selection for cancer classification using support vector machines. Mach. Learn. 2002, 46, 389–422.

- Mullner, D. Modern hierarchical, agglomerative clustering algorithms. arXiv:1109.2378v 2011.

- Flaticon.com: Vector Icons and Stickers. Available online: https://www.flaticon.com/ (accessed on February 19, 2024).

- Ho, A.; Shigrekar, A.; Mikkelson, D.; Greenwood, S.; Frick, K.L.; Epiney, A. HYBRID Modeling of the DETAIL Experimental Facility, INL/EXT-22-02188 ; Idaho National Laboratory: Idaho Falls, ID, 2022.

- New York Independent System Operator: Energy Market & Operational Data - Load Data. Available online: https:// www.nyiso.com/load-data (accessed on December 7, 2023).

- Business Insider: Natural Gas Price Today. Available oline: https://markets.businessinsider.com/commodities/natural-gas-price (accessed on January 2, 2024).

- Lazard Ltd., Lazard’s Levelized Cost of Energy Analysis—Version 16.0, https://www.lazard.com/, (accessed on January 4, 2024).

- New York Independent System Operator: Energy Market & Operational Data - Pricing Data. Available online: https:// www.nyiso.com/energy-market-operational-data (accessed on December 7, 2023).

- U.S. Department of Energy: Hydrogen Fuel Cell Vehicles. Available online: https://www.energy.gov/energysaver/hydrogen-fuel-cell-vehicles (accessed on January 10, 2024).

- Vicente, K.J.; Rasmussen, J. Ecological Interface Design: Theoretical Foundations. IEEE Transactions on Systems, Man, and Cybernetics: Systems 1992, 22(4), 589–606.

- Anokhin, A.; Ivkin, A.; Dorokhovich, S. Application of ecological interface design in nuclear power plant (NPP) operator support system. Nuclear Engineering and Technology 2018, 50, 619–626.

- Carrasco, C.; Jamieson, G.A.; St-Cyr, O. Revisiting three ecological interface design experiments to investigate performance and control stability effects under normal conditions. In IEEE International Conference on Systems, Man and Cybernetics (SMC), San Diego, CA, October 5-8, 2014.

- Kim, S.K.; Suh, S.M.; Jang, G.S.; Hong, S.K.; Park, J.C. Empirical research on an ecological interface design for improving situation awareness of operators in an advanced control room. Nuclear Engineering and Design 2012, 253, 226–237.

- Porter, M.M.; Niksiar, P. Multidimensional mechanics: Performance mapping of natural biological systems using permutated radar charts. PLoS ONE 2018, 13(9).

- Rejas, L.; Parrado, I.; Fernandez, S.; Ortega, F. Operating displays e new concept: high performance displays. In Proceedings of 10th Nuclear Plant Instrumentation, Control & Human-Machine Interface Technologies, San Francisco, CA, June 11-15 2017.

| Subsystem | Input (v) | Outputs () | Lower | Upper |

|---|---|---|---|---|

| Bounds | Bounds | |||

| GT | Power set- | Electrical power output () | 20.0 MW | 50.0 MW |

| point () | Firing temperature () | 1100 K | 1500 K | |

| BOP | Power set- | Electrical power output () | 25.0 MW | 45.0 MW |

| point () | Turbine inlet pressure () | 21.0 bar | 31.0 bar | |

| HTSE | Power set- | Electrical power consumption () | 0.2 MW | 1.2 MW |

| point () | Hydrogen production rate () | 2.0 g/s | 10.0 g/s |

| Subsystem | Starting Power Level (MWe) | Ending Power Level (MWe) |

|---|---|---|

| GT | 19.0 | 26.0 |

| 26.0 | 33.0 | |

| 33.0 | 40.0 | |

| 40.0 | 47.0 | |

| 47.0 | 19.0 | |

| BOP | 27.0 | 33.0 |

| 33.0 | 39.0 | |

| 39.0 | 45.0 | |

| 45.0 | 27.0 | |

| HTSE | -0.11 | -0.71 |

| -0.71 | -1.31 | |

| -1.31 | -0.11 |

| State Variable | Name and Physical Meaning |

|---|---|

| BOP.sensor_T1.port_a.p | |

| (Steam pressure at High Pressure Turbine inlet (Pa)) | |

| GT.GTunit.combChamber.E | |

| (Total gas energy within the Combustion chamber (J)) | |

| HTSE.AirHX.volume_2[4].medium.T_degC | |

| (Air temperature at node 4 of Air Heater exchanger hot side volume (°C)) |

| Parameter | Dispatch Problem 1 | Dispatch Problem 2 |

|---|---|---|

| BOP Generation Cost | $180.0/MWh | $180.0/MWh |

| GT Generation Cost | Time-varying | Constant |

| $177.9 - $191.4/MWh | $200.0/MWh | |

| Hydrogen Sales Price | Constant | Time-varying |

| $14.0/kg | $13.0 - $14.2/kg | |

| ($216.0/MWh of | ($186.9 - $221.2/MWh of | |

| consumed electricity) | consumed electricity) | |

| Electricity Sales Price | $400.0/MWh | $400.0/MWh |

| Sample Time | LPV Derivation | HERON Dispatcher | FARM Validator |

|---|---|---|---|

| 30.0 | |||

| 60.0 | |||

| 100.0 | |||

| 150.0 | |||

| 225.0 | |||

| 300.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).