Submitted:

07 May 2024

Posted:

07 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Literature Review

2.1. Heat Generation

2.2. Cooling for a Static BESS in VPPS

2.2. Classifications and Characteristics of TMS

2.2. TMS Metrics and Their Assessment

2.2. Case Studies and Practical Applications

- i

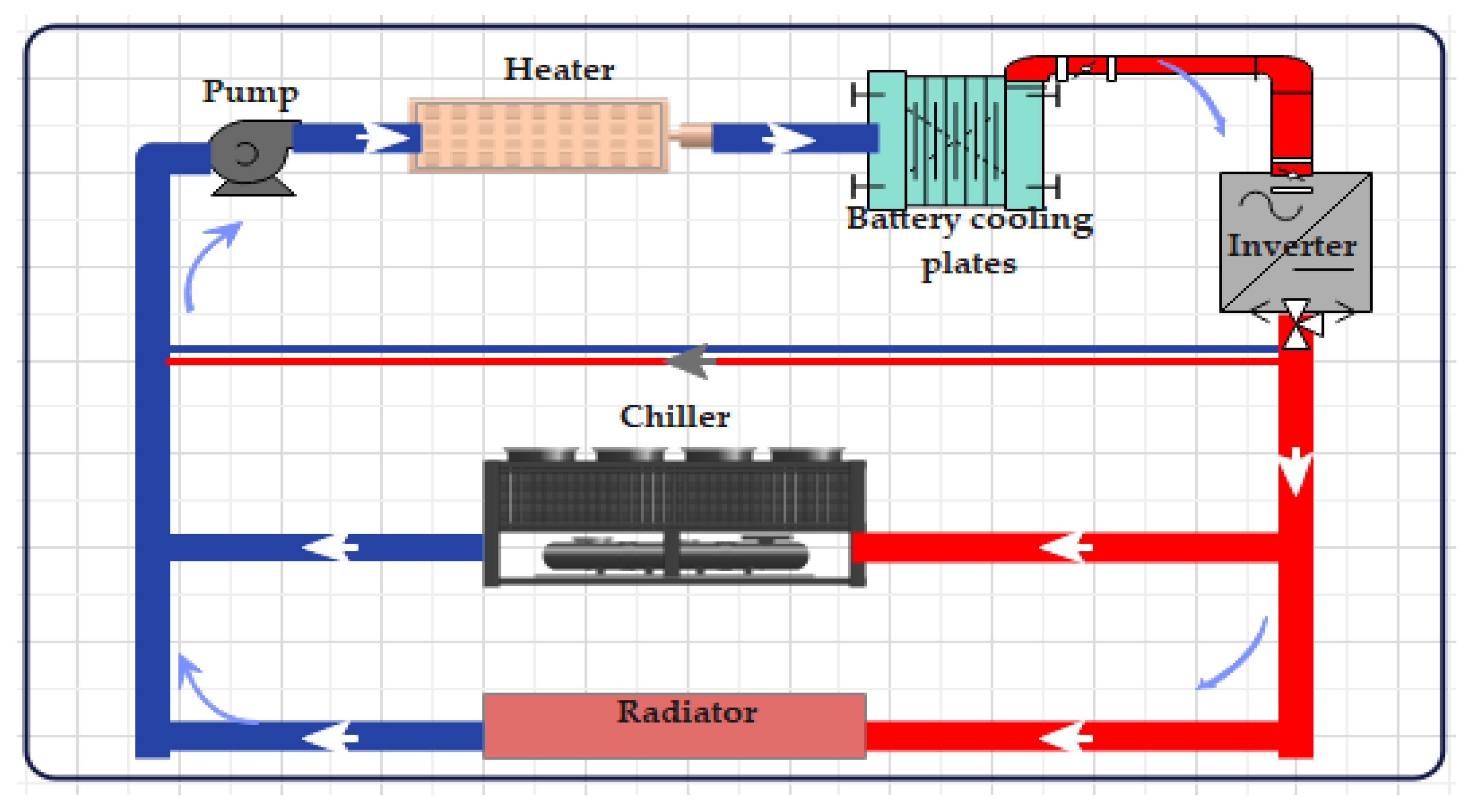

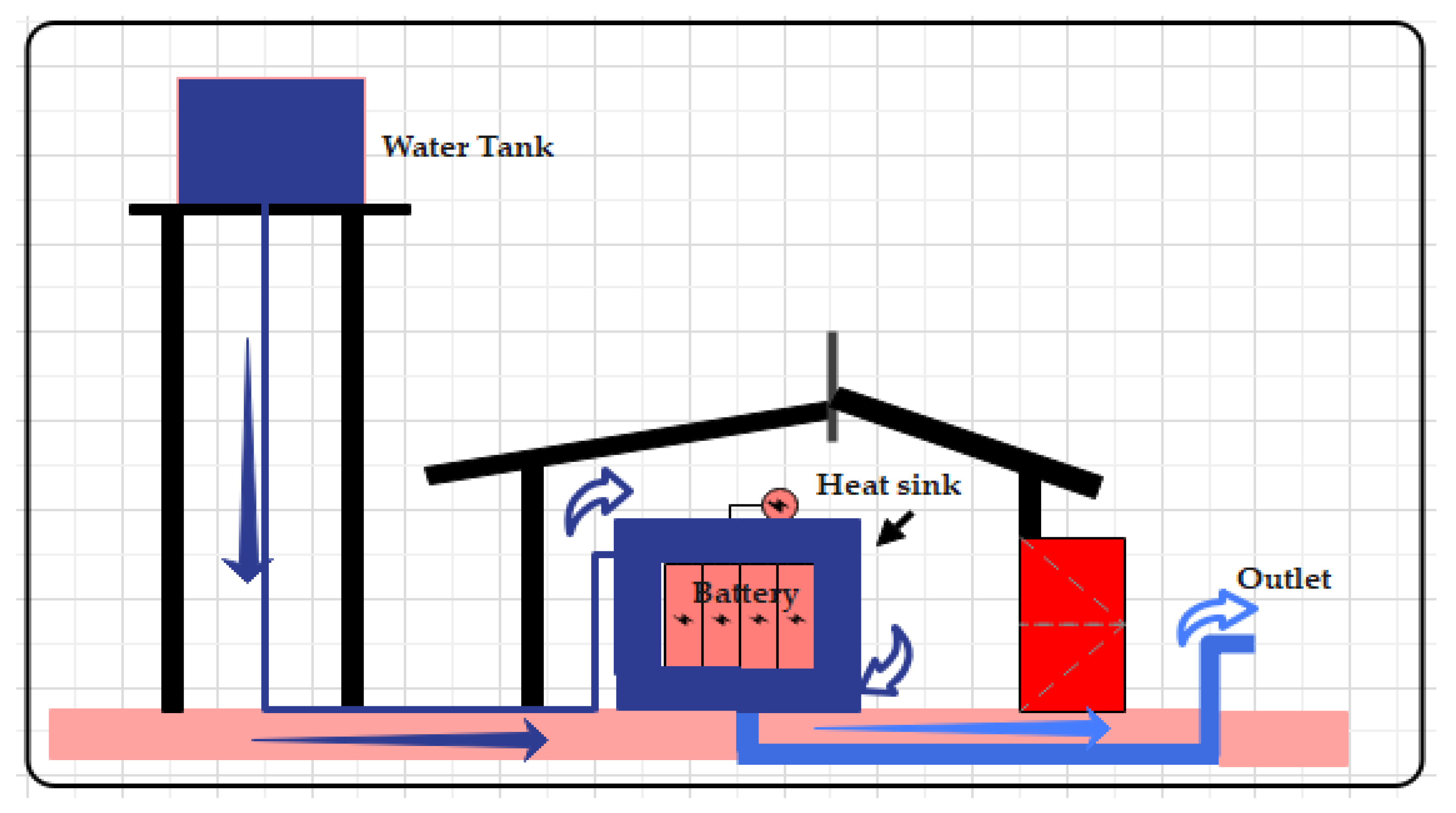

- Liquid active cooling

- ii

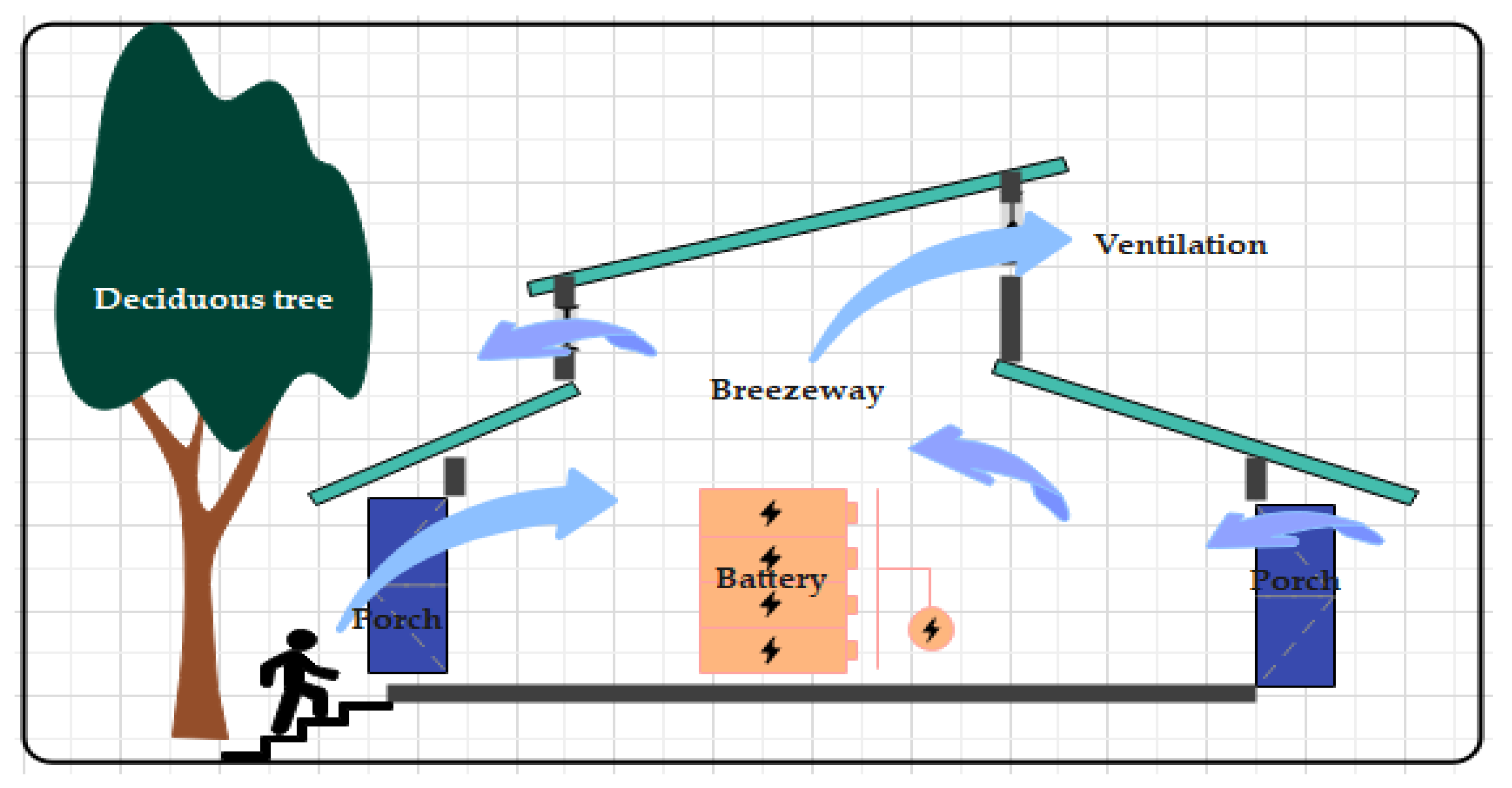

- Natural convection

- iii

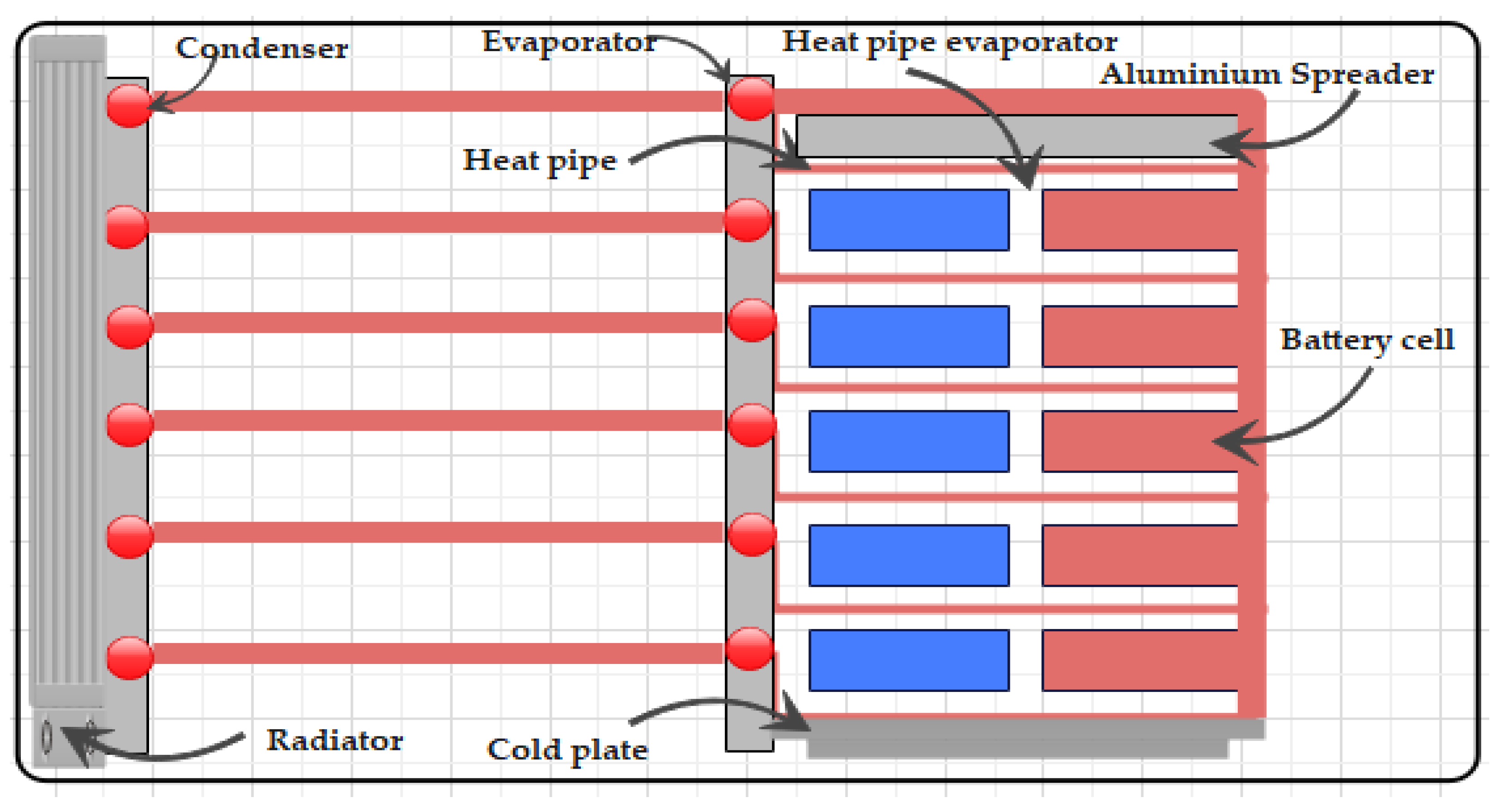

- Heat pipes

- iv

- Liquid and air as cooling media in hybrid cooling

- v

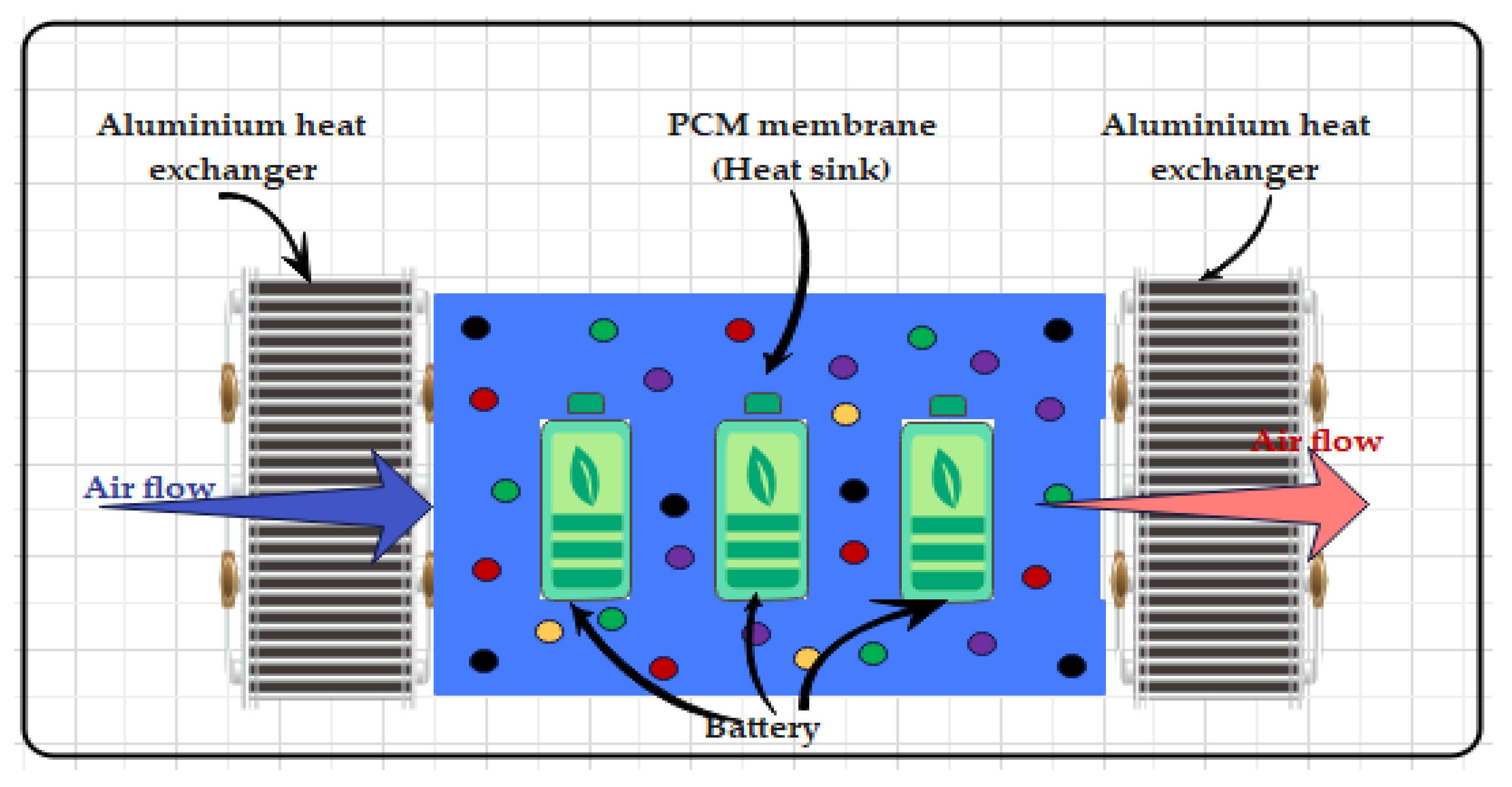

- PCM based cooling

- vi

- Liquid passive cooling

- vii

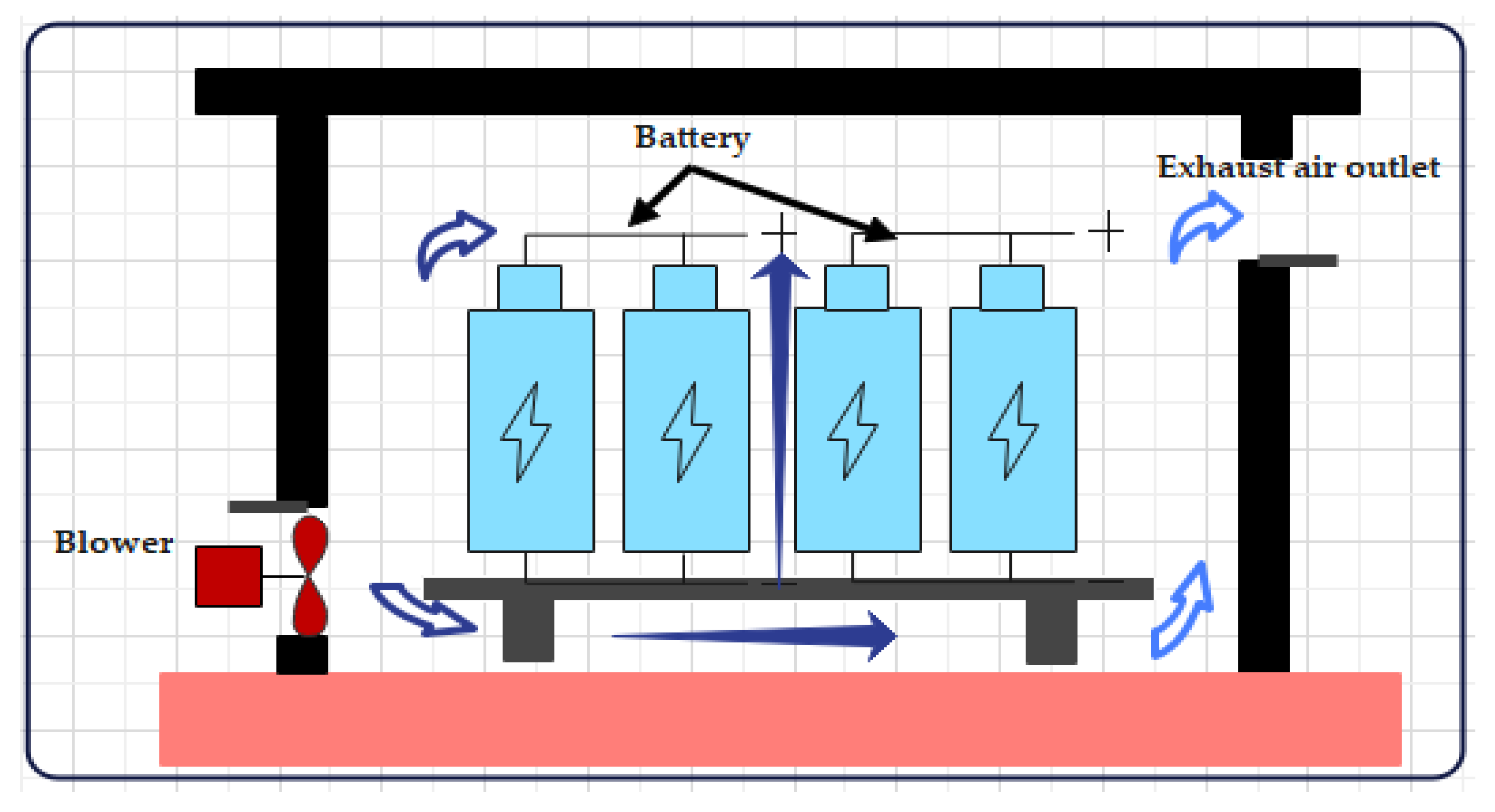

- Air-forced convection

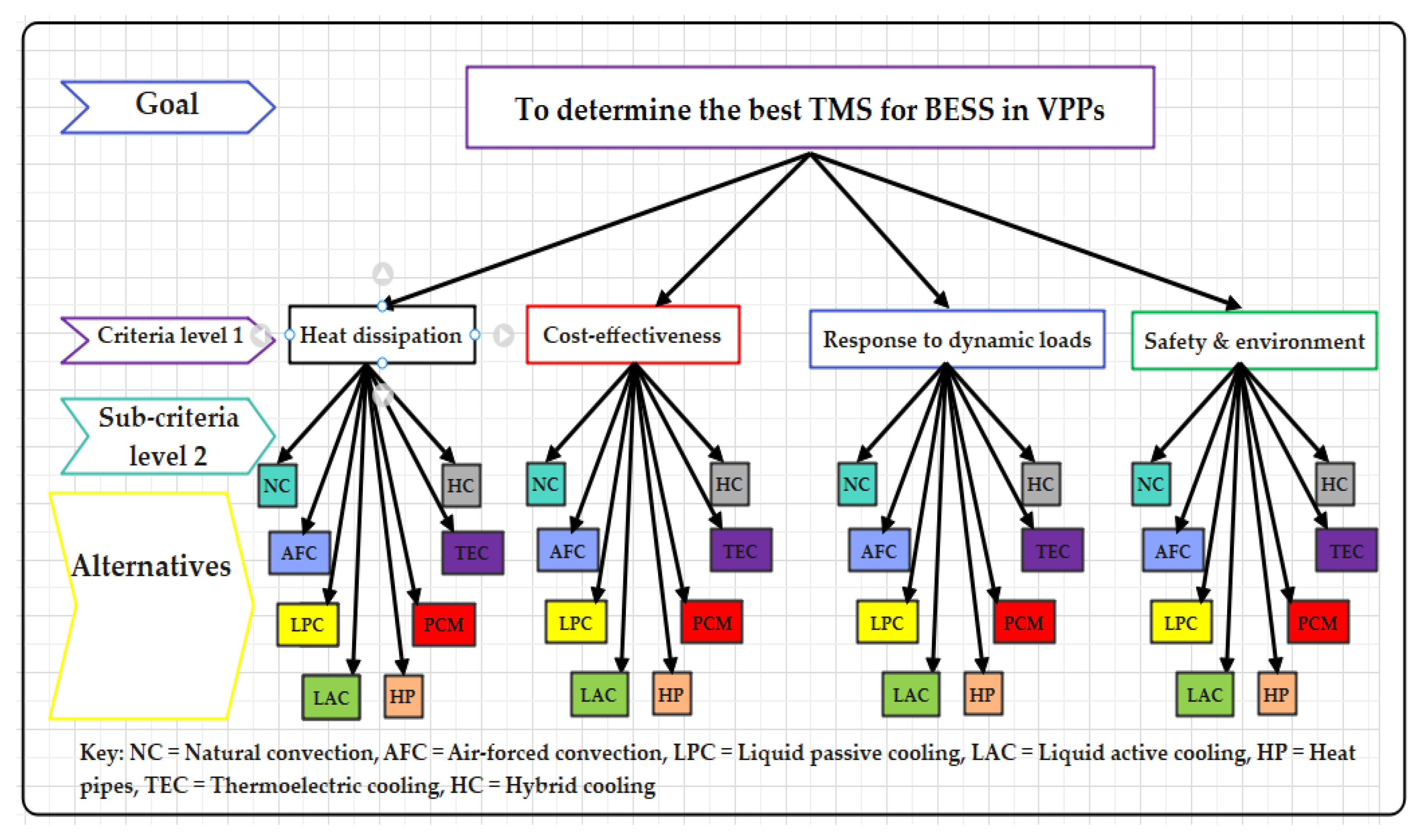

3. Methodology

3.1. TMS Metrics Comparison

3.1. Comparison Data Concerning TMS Metrics

- i

- Heat dissipation

- ii

- Cost-effectiveness

- iii

- Response to dynamic loads

- iv

- Safety and environment

4. Results and Discussion

- i.

- Heat pipes + PCM: This combination yields an average effectiveness score of 14.60%. Heat pipes are renowned for their ability to conduct heat efficiently away from heat sources with minimal temperature differences, making them excellent for rapid heat transfer. When combined with PCM, which absorbs and releases thermal energy during phase changes, this hybrid system can offer continuous thermal regulation. This is especially advantageous during peak load conditions where the BESS experiences significant thermal stress. The PCM component provides a buffer that absorbs excess heat, thereby preventing overheating and enhancing the system's response to thermal fluctuations.

- ii.

- Heat pipes + liquid passive cooling: With an average effectiveness score of 14.55%, this combination capitalizes on the efficient heat transfer capabilities of heat pipes and the consistent cooling offered by liquid passive systems. Liquid passive cooling utilizes a coolant to transfer heat away from the battery cells, operating on the principle of natural convection without the need for mechanical pumps. This method is inherently reliable and requires minimal maintenance. Coupled with heat pipes, it ensures that heat is not only quickly removed from hot spots but also evenly dissipated across the BESS, maintaining an optimal operational temperature range.

5. Conclusions

Funding

Conflicts of Interest

Appendix

References

- Dehghani-Sanij, A.R.; Tharumalingam, E.; Dusseault, M.B.; Fraser, R. Study of energy storage systems and environmental challenges of batteries. Renew. Sustain. Energy Rev. 2019, 104, 192–208. [Google Scholar] [CrossRef]

- Zichen, W.; Changqing, D. A comprehensive review on thermal management systems for power lithium-ion batteries. Renew. Sustain. Energy Rev. 2021, 139, 110685. [Google Scholar] [CrossRef]

- Shahjalal, M.; Shams, T.; Islam, E.; Alam, W.; Modak, M.; Bin Hossain, S.; Ramadesigan, V.; Ahmed, R.; Ahmed, H.; Iqbal, A. A review of thermal management for Li-ion batteries: Prospects, challenges, and issues. J. Energy Storage 2021, 39, 102518. [Google Scholar] [CrossRef]

- Hannan, M.A.; Al-Shetwi, A.Q.; Begum, R.A.; Young, S.E.; Hoque, M.M.; Ker, P.; Mansur, M.; Alzaareer, K. The value of thermal management control strategies for battery energy storage in grid decarbonization: Issues and recommendations. J. Clean. Prod. 2020, 276, 124223. [Google Scholar] [CrossRef]

- Boulaire, F.; Love, J.; Mackinnon, I. An adaptive renewable energy plant (AREP)-To power local premises and vehicles with 100% renewables. Energy Strat. Rev. 2021, 38, 100703. [Google Scholar] [CrossRef]

- Sakr, W.S.; El-Sehiemy, R.A.; Azmy, A.M.; El-Ghany, H.A.A. Identifying optimal border of virtual power plants considering uncertainties and demand response. Alex. Eng. J. 2022, 61, 9673–9713. [Google Scholar] [CrossRef]

- Sharaf, M.; Yousef, M.S.; Huzayyin, A.S. Review of cooling techniques used to enhance the efficiency of photovoltaic power systems. Environ. Sci. Pollut. Res. 2022, 29, 26131–26159. [Google Scholar] [CrossRef]

- Ye, X.; Zhao, Y.; Quan, Z. Experimental study on heat dissipation for lithium-ion battery based on micro heat pipe array (MHPA). Appl. Therm. Eng. 2018, 130, 74–82. [Google Scholar] [CrossRef]

- Liu, H.; Wei, Z.; He, W.; Zhao, J. Thermal issues about Li-ion batteries and recent progress in battery thermal management systems: A review. Energy Convers. Manag. 2017, 150, 304–330. [Google Scholar] [CrossRef]

- Hamed, M.M.; El-Tayeb, A.; Moukhtar, I.; El Dein, A.; Abdelhameed, E.H. A review on recent key technologies of lithium-ion battery thermal management: External cooling systems. Results Eng. 2022, 16, 100703. [Google Scholar] [CrossRef]

- Fathoni, A.M.; Putra, N.; Mahlia, T.I. A systematic review of battery thermal management systems based on heat pipes. J. Energy Storage 2023, 73, 109081. [Google Scholar] [CrossRef]

- Liu, X.; Yao, L.-C.; Su, C.-Q.; Xiong, X.; Wang, Y.-P. A hybrid battery thermal management system coupling with PCM and optimized thermoelectric cooling for high-rate discharge condition. Case Stud. Therm. Eng. 2023, 49, 103269. [Google Scholar] [CrossRef]

- Hu, S.; Wang, S.; Ma, C.; Li, S.; Liu, X.; Zhang, Y. A hybrid cooling method with low energy consumption for lithium-ion battery under extreme conditions. Energy Convers. Manag. 2022, 266, 115831. [Google Scholar] [CrossRef]

- Martín-Martín, L.; Gastelurrutia, J.; Nieto, N.; Ramos, J.C.; Rivas, A.; Gil, I. Modeling based on design of thermal management systems for vertical elevation applications powered by lithium-ion batteries. Appl. Therm. Eng. 2016, 102, 1081–1094. [Google Scholar] [CrossRef]

- Odukomaiya, A.; Woods, J.; James, N.; Kaur, S.; Gluesenkamp, K.R.; Kumar, N.; Mumme, S.; Jackson, R.; Prasher, R. Addressing energy storage needs at lower cost via on-site thermal energy storage in buildings. Energy Environ. Sci. 2021, 14, 5315–5329. [Google Scholar] [CrossRef]

- Rao, Z.; Lyu, P.; Du, P.; He, D.; Huo, Y.; Liu, C. Thermal safety and thermal management of batteries. Batter. Energy 2022, 1, 1–19. [Google Scholar] [CrossRef]

- Haiyang Liu, “Contribution of Battery Energy Storage System (BESS) to Power Systems Resilience,” 2022.

- Diaz, L.B.; He, X.; Hu, Z.; Restuccia, F.; Marinescu, M.; Barreras, J.V.; Patel, Y.; Offer, G.; Rein, G. Meta-Review of Fire Safety of Lithium-Ion Batteries: Industry Challenges and Research Contributions. J. Electrochem. Soc. 2020, 167, 090559. [Google Scholar] [CrossRef]

- Jeevarajan, J.A.; Joshi, T.; Parhizi, M.; Rauhala, T.; Juarez-Robles, D. Battery Hazards for Large Energy Storage Systems. ACS Energy Lett. 2022, 7, 2725–2733. [Google Scholar] [CrossRef]

- Rangarajan, A.; Foley, S.; Trück, S. Assessing the impact of battery storage on Australian electricity markets. Energy Econ. 2023, 120, 106601. [Google Scholar] [CrossRef]

- D. R. Borneo, “Grid Energy Storage? Overview and Trends.,” 2019, [Online]. Available: https://www.osti.gov/servlets/purl/1678820.

- Laaroussi, A.; Laaroussi, O.; Bouayad, A. Environmental impact study of the NOOR 1 solar project on the Southern Region of Morocco. Renew. Energy Environ. Sustain. 2023, 8, 9. [Google Scholar] [CrossRef]

- Fraser, T.; Chapman, A.J. Social equity impacts in Japan's mega-solar siting process. Energy Sustain. Dev. 2018, 42, 136–151. [Google Scholar] [CrossRef]

- Marema, B. Tlokolo, and A. Pandarum, “Socio-economic benefits of renewable and storage technologies in South Africa 2,” pp. 1–11, 2022, [Online]. Available: https://www.ameu.co.za/Socio-economic benefits of renewable energy technologies - Abram Marema.pdf.

- Pinel, P.; Cruickshank, C.A.; Beausoleil-Morrison, I.; Wills, A. A review of available methods for seasonal storage of solar thermal energy in residential applications. Renew. Sustain. Energy Rev. 2011, 15, 3341–3359. [Google Scholar] [CrossRef]

- Truong, C.N.; Naumann, M.; Karl, R.C.; Müller, M.; Jossen, A.; Hesse, H.C. Economics of Residential Photovoltaic Battery Systems in Germany: The Case of Tesla’s Powerwall. Batteries 2016, 2, 14. [Google Scholar] [CrossRef]

- Georgakarakos, M. Mayfield, A. H. Buckman, S. A. Jubb, and C. Wootton, “What are Smart Grid Optimised Buildings ?,” Living Sustain. An Environ. Crit. Des. Build. Pract. Local. Glob. London South Bank Univ. London, 08 – 09 Febr. 2017, no. November, pp. 21–36, 2018.

- Martin, S.; Mosier, N.; Nnorom, O.; Ou, Y.; Patel, L.; Triebe, O.; Cezar, G.; Levis, P.; Rajagopal, R. Software defined grid energy storage. BuildSys '22: The 9th ACM International Conference on Systems for Energy-Efficient Buildings, Cities, and Transportation. LOCATION OF CONFERENCE, United StatesDATE OF CONFERENCE;

- D. Peftitsis, “Systems : Practices, Difficulties and Prospects,” 2021.

- Lu, M.; Zhang, X.; Ji, J.; Xu, X.; Zhang, Y. Research progress on power battery cooling technology for electric vehicles. J. Energy Storage 2020, 27, 101155. [Google Scholar] [CrossRef]

- Walvekar, H.; Beltran, H.; Sripad, S.; Pecht, M. Implications of the Electric Vehicle Manufacturers’ Decision to Mass Adopt Lithium-Iron Phosphate Batteries. IEEE Access 2022, 10, 63834–63843. [Google Scholar] [CrossRef]

- Akbarzadeh, M.; Kalogiannis, T.; Jaguemont, J.; Jin, L.; Behi, H.; Karimi, D.; Beheshti, H.; Van Mierlo, J.; Berecibar, M. A comparative study between air cooling and liquid cooling thermal management systems for a high-energy lithium-ion battery module. Appl. Therm. Eng. 2021, 198, 117503. [Google Scholar] [CrossRef]

- S. Karlsson, “Life Cycle Assessment of Borehole Thermal Energy Storage,” no. 2019, 2022, [Online]. Available: http://urn.kb.se/resolve?urn=urn:nbn:se:kth:diva-310321. 2022.

- S. Colagrande and G. D’Ovidio, “Electric energy harvesting solutions review from roads pavements,” Transp. Means - Proc. Int. Conf., vol. 2018-Octob, no. Dc, pp. 5–10, 2018.

- Landini, S.; Leworthy, J.; O'Donovan, T.S. A Review of Phase Change Materials for the Thermal Management and Isothermalisation of Lithium-Ion Cells. J. Energy Storage 2019, 25, 100887. [Google Scholar] [CrossRef]

- Wang, H.; Soong, W.L.; Pourmousavi, S.A.; Zhang, X.; Ertugrul, N.; Xiong, B. Thermal dynamics assessment of vanadium redox flow batteries and thermal management by active temperature control. J. Power Sources 2023, 570, 233027. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Ji, Z.; Yang, Z.; Jiang, C.; Lin, H. Cooling the electrode tabs with air to manage the heat transferred through the collectors in traction battery. J. Energy Storage 2022, 48, 103982. [Google Scholar] [CrossRef]

- Goepel, K.D. Implementation of an Online Software Tool for the Analytic Hierarchy Process (AHP-OS). Int. J. Anal. Hierarchy Process 2018, 10, 469–487. [Google Scholar] [CrossRef]

- Das, D.; Sharma, R.K.; Saikia, P.; Rakshit, D. An integrated entropy-based multi-attribute decision-making model for phase change material selection and passive thermal management. Decis. Anal. J. 2021, 1, 100011. [Google Scholar] [CrossRef]

- Dwivedi, A.; Kumar, A.; Goel, V. A consolidated decision-making framework for nano-additives selection in battery thermal management applications. J. Energy Storage 2023, 59, 106565. [Google Scholar] [CrossRef]

- Bulut, M.; Özcan, E. A novel approach towards evaluation of joint technology performances of battery energy storage system in a fuzzy environment. J. Energy Storage 2021, 36, 102361. [Google Scholar] [CrossRef]

- Napa, N.; Agrawal, M.K.; Tamma, B. Design of novel thermal management system for Li-ion battery module using metal matrix based passive cooling method. J. Energy Storage 2023, 73, 109119. [Google Scholar] [CrossRef]

- Martín-Martín, L.; Gastelurrutia, J.; Larraona, G.S.; Antón, R.; del Portillo-Valdés, L.; Gil, I. Optimization of thermal management systems for vertical elevation applications powered by lithium-ion batteries. Appl. Therm. Eng. 2018, 147, 155–166. [Google Scholar] [CrossRef]

- Hassan, A.M.; Alwan, A.A.; Hamzah, H.K. Numerical Study of Fan Coil Heat Exchanger with Copper Foam. Int. J. Fluid Mach. Syst. 2023, 16, 73–88. [Google Scholar] [CrossRef]

- Can, A.; Selimefendigil, F.; Öztop, H.F. A review on soft computing and nanofluid applications for battery thermal management. J. Energy Storage 2022, 53, 105214. [Google Scholar] [CrossRef]

- Wüllner, J.; Reiners, N.; Millet, L.; Salibi, M.; Stortz, F.; Vetter, M. Review of Stationary Energy Storage Systems Applications, Their Placement, and Techno-Economic Potential. Curr. Sustain. Energy Rep. 2021, 8, 263–273. [Google Scholar] [CrossRef]

- Kaczorowska, D.; Rezmer, J.; Jasinski, M.; Sikorski, T.; Suresh, V.; Leonowicz, Z.; Kostyla, P.; Szymanda, J.; Janik, P. A Case Study on Battery Energy Storage System in a Virtual Power Plant: Defining Charging and Discharging Characteristics. Energies 2020, 13, 6670. [Google Scholar] [CrossRef]

- Hailu, G.; Henke, M.; Petersen, T. Stationary Battery Thermal Management: Analysis of Active Cooling Designs. Batteries 2022, 8, 23. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, W.; Guo, D.; Cao, W.; Sun, L.; Jiang, F. Thermofluidic modeling and temperature monitoring of Li-ion battery energy storage system. Appl. Therm. Eng. 2020, 181, 116026. [Google Scholar] [CrossRef]

- Qin, P.; Sun, J.; Yang, X.; Wang, Q. Battery thermal management system based on the forced-air convection: A review. eTransportation 2020, 7, 100097. [Google Scholar] [CrossRef]

- M. M. A. Elmaaref, A. A. M. M. A. Elmaaref, A. A. Askalany, M. Salem, and K. Harby, “Solar thermoelectric cooling technology,” Proc. 3rd Int. Conf. Energy Eng., no. December 2017, pp. 1–7, 2015.

- Peng, Z.; Li, Z.; Zeng, J.; Yu, J.; Lv, S. Thermo-economic analysis of absorption-compression hybrid cooling systems with parallel subcooling and recooling for small scale low-grade heat source and low temperature application. Int. J. Refrig. 2022, 138, 220–232. [Google Scholar] [CrossRef]

- Cai, S.; Li, Y. Incentive Policy for Battery Energy Storage Systems Based on Economic Evaluation Considering Flexibility and Reliability Benefits. Front. Energy Res. 2021, 9, 1–12. [Google Scholar] [CrossRef]

- Nižetić, S.; Papadopoulos, A.M.; Giama, E. Comprehensive analysis and general economic-environmental evaluation of cooling techniques for photovoltaic panels, Part I: Passive cooling techniques. Energy Convers. Manag. 2017, 149, 334–354. [Google Scholar] [CrossRef]

- Chen, Z.; Yu, Z.; Fu, J.; Yang, J. Analysis and design of air-heat pipe composite cooling of high power density motor. Appl. Therm. Eng. 2024, 236, 121495. [Google Scholar] [CrossRef]

- Nadjahi, C.; Louahlia, H.; Lemasson, S. A review of thermal management and innovative cooling strategies for data center. Sustain. Comput. Inform. Syst. 2018, 19, 14–28. [Google Scholar] [CrossRef]

- Behi, H.; Karimi, D.; Jaguemont, J.; Gandoman, F.H.; Kalogiannis, T.; Berecibar, M.; Van Mierlo, J. Novel thermal management methods to improve the performance of the Li-ion batteries in high discharge current applications. Energy 2021, 224, 120165. [Google Scholar] [CrossRef]

- Xin, Q.; Xiao, J.; Yang, T.; Zhang, H.; Long, X. Thermal management of lithium-ion batteries under high ambient temperature and rapid discharging using composite PCM and liquid cooling. Appl. Therm. Eng. 2022, 210, 118230. [Google Scholar] [CrossRef]

- Xu, K.; Zhang, H.; Zhu, J.; Qiu, G. Thermal Management for Battery Module with Liquid-Cooled Shell Structure under High Charge/Discharge Rates and Thermal Runaway Conditions. Batteries 2023, 9, 204. [Google Scholar] [CrossRef]

- Li, X.; Zhong, Z.; Luo, J.; Wang, Z.; Yuan, W.; Zhang, G.; Yang, C.; Yang, C. Experimental Investigation on a Thermoelectric Cooler for Thermal Management of a Lithium-Ion Battery Module. Int. J. Photoenergy 2019, 2019, 1–10. [Google Scholar] [CrossRef]

- Wazeer, A.; Das, A.; Abeykoon, C.; Sinha, A.; Karmakar, A. Phase change materials for battery thermal management of electric and hybrid vehicles: A review. Energy Nexus 2022, 7, 100131. [Google Scholar] [CrossRef]

- Hekmat, S.; Molaeimanesh, G. Hybrid thermal management of a Li-ion battery module with phase change material and cooling water pipes: An experimental investigation. Appl. Therm. Eng. 2019, 166, 114759. [Google Scholar] [CrossRef]

- Rahman, N.M.A.; Haw, L.C.; Kamaluddin, K.A.; Abdullah, M.S.I. Investigating photovoltaic module performance using aluminium heat sink and forced cold-air circulation method in tropical climate conditions. Energy Rep. 2023, 9, 2797–2809. [Google Scholar] [CrossRef]

- Youssef, R.; Hosen, S.; He, J.; Jaguemont, J.; De Sutter, L.; Van Mierlo, J.; Berecibar, M. Effect analysis on performance enhancement of a novel and environmental evaporative cooling system for lithium-ion battery applications. J. Energy Storage 2021, 37, 102475. [Google Scholar] [CrossRef]

- Chen, Y.; Kang, Y.; Zhao, Y.; Wang, L.; Liu, J.; Li, Y.; Liang, Z.; He, X.; Li, X.; Tavajohi, N.; et al. A review of lithium-ion battery safety concerns: The issues, strategies, and testing standards. J. Energy Chem. 2021, 59, 83–99. [Google Scholar] [CrossRef]

- Ning, Y.; Tao, R.; Luo, J.; Hu, Q. Application and Research Progress of Heat Pipe in Thermal Management of Lithium-Ion Battery. Trends Renew. Energy 2022, 8, 130–144. [Google Scholar] [CrossRef]

- Nishida, R.; Zhong, J.; Shinshi, T. Forced liquid cooling of piezoelectric stack actuator utilizing silicone oil. Precis. Eng. 2022, 75, 120–128. [Google Scholar] [CrossRef]

- R. M. Atta, “Thermoelectric cooling (Chpater 12),” pp. 247–267, 2018.

- Abdelkareem, M.A.; Maghrabie, H.M.; Abo-Khalil, A.G.; Adhari, O.H.K.; Sayed, E.T.; Radwan, A.; Elsaid, K.; Wilberforce, T.; Olabi, A. Battery thermal management systems based on nanofluids for electric vehicles. J. Energy Storage 2022, 50, 104385. [Google Scholar] [CrossRef]

- Dweiri, F.; Kumar, S.; Khan, S.A.; Jain, V. Designing an integrated AHP based decision support system for supplier selection in automotive industry. Expert Syst. Appl. 2016, 62, 273–283. [Google Scholar] [CrossRef]

| Scale | Numerical Rating | Reciprocal |

|---|---|---|

| Extremely preferred | 9 | 1/9 |

| Very strong to extremely | 8 | 1/8 |

| Very strongly preferred | 7 | 1/7 |

| Strongly to very strongly | 6 | 1/6 |

| Strongly preferred | 5 | 1/5 |

| Moderately to strongly | 4 | ¼ |

| Moderately preferred | 3 | 1/3 |

| Equally moderately | 2 | ½ |

| Equally preferred | 1 | 1 |

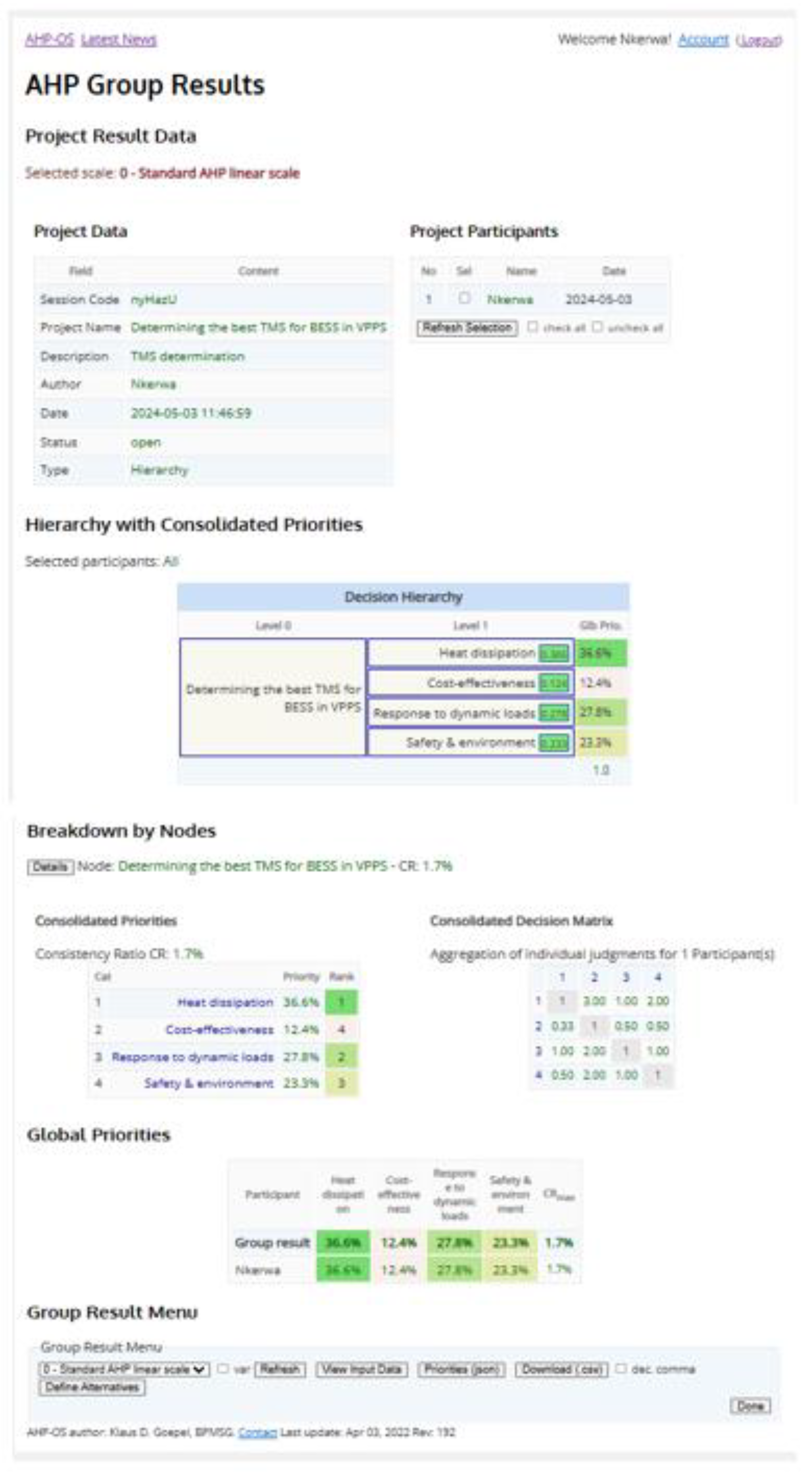

| TMS | Weight | AHPScale | References |

| Heat dissipation efficiency | Critical for maintaining battery efficiency and longevity by preventing overheating. Given the direct impact on performance and safety, it's highly important. | 9 | [14] |

| Cost-effectiveness | Important for the overall feasibility and economic viability of the BESS project. This includes both upfront and operational costs. | 3 | [15,16] |

| Response to dynamic loads | Paramount for systems that experience significant fluctuations in demand or operational conditions, impacting the ability to maintain optimal performance. | 7 | [17,15] |

| Safety & environment | Essential, considering the potential risks associated with battery operation and the increasing emphasis on sustainable energy solutions. | 5 | [18] |

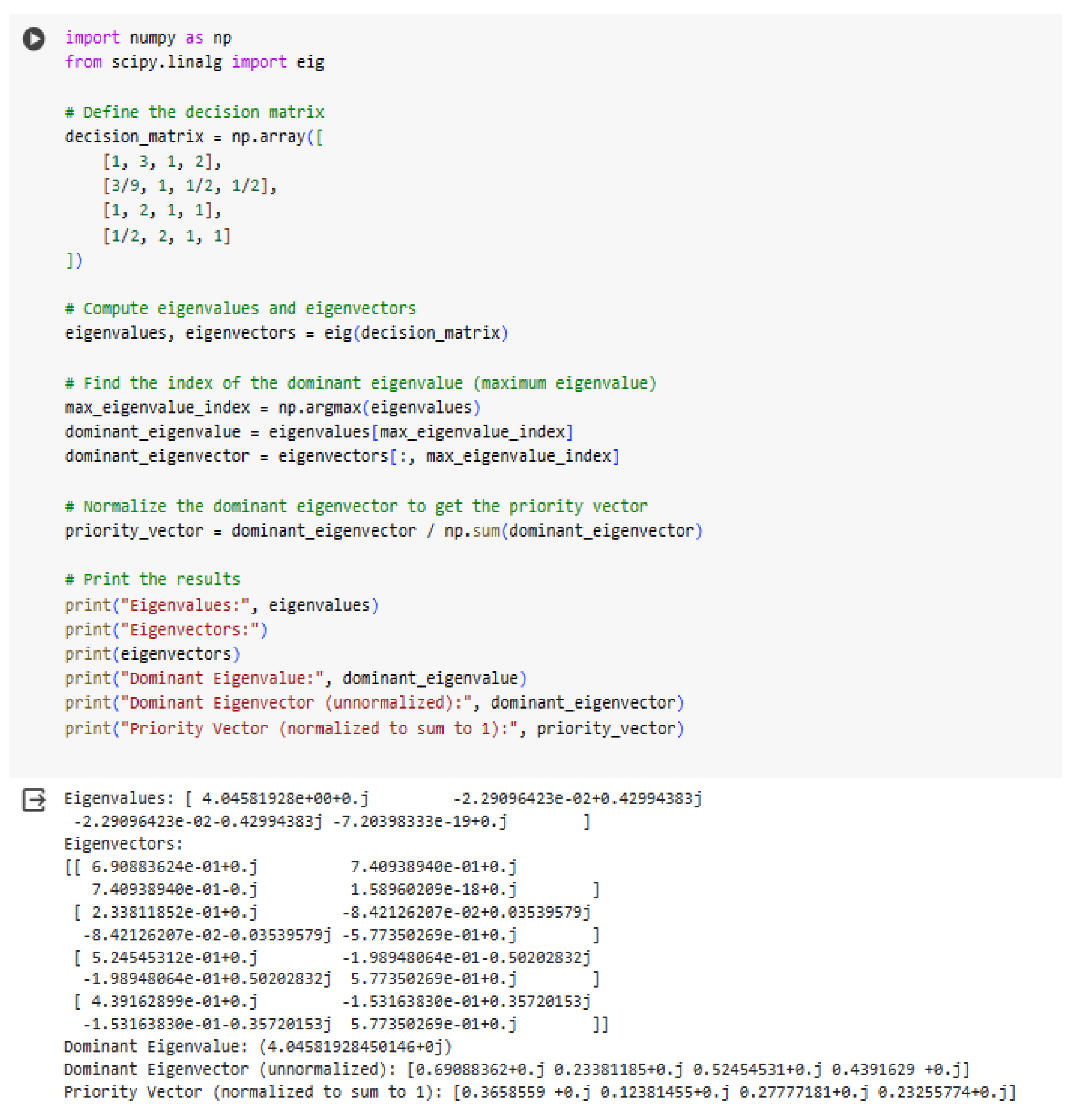

| HD | CE | RDL | SE | |

|---|---|---|---|---|

| HD | 1 | 3 | 1 | 2 |

| CE | 3/9 | 1 | 1/2 | 1/2 |

| RDL | 1 | 2 | 1 | 1 |

| SE | 1/2 | 2 | 1 | 1 |

| HD | CE | RDL | SE | |

|---|---|---|---|---|

| HD | 1/2.833 = 0.353 | 3/8 = 0.375 | 1/3.5 = 0.286 | 2/4.5 = 0.444 |

| CE | 0.333/2.833 = 0.118 | 1/8 = 0.125 | 0.5/3.5 = 0.143 | 0.5/4.5 = 0.111 |

| RDL | 1/2.833 = 0.353 | 2/8 = 0.250 | 1/3.5 = 0.286 | 1/4.5 = 0.222 |

| SE | 0.5/2.833 = 0.176 | 2/8 = 0.250 | 1/3.5 = 0.286 | 1/4.5 = 0.222 |

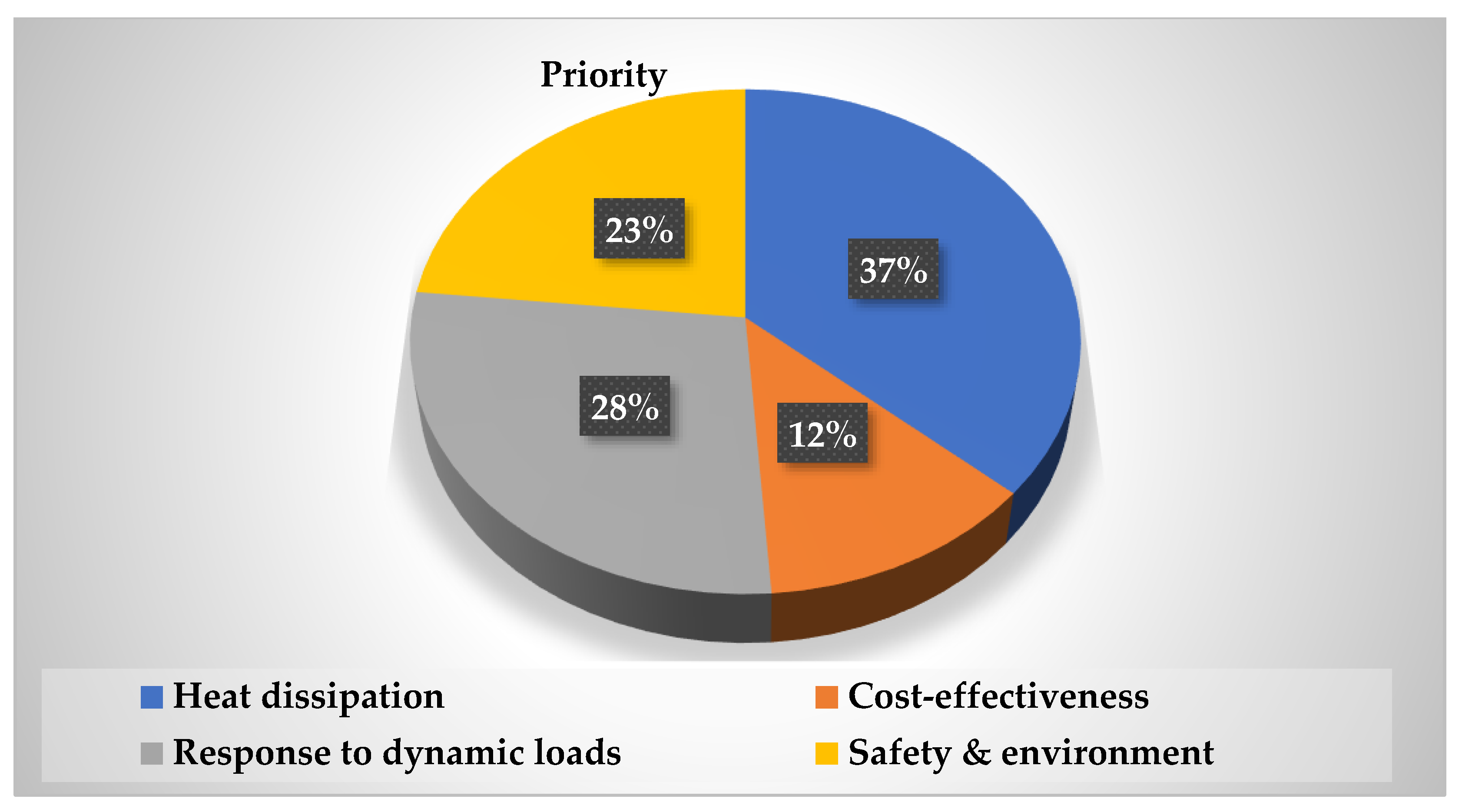

| Eigenvector (calculation) | Eigenvector | |

|---|---|---|

| HD | (0.353 + 0.375 + 0.286 + 0.444)/4 = 0.3645 | 36.45% |

| CE | (0.118 + 0.125 + 0.143 + 0.111)/4 = 0.1243 | 12.43% |

| RDL | (0.353 + 0.250 + 0.286 + 0.222)/4 = 0.2778 | 27.78% |

| SE | (0.176 + 0.250 + 0.286 + 0.222)/4 = 0.2335 | 23.35% |

| Approx. Eigenvector | Exact Eigenvector | Difference | |

|---|---|---|---|

| HD | 0.3645 | 0.3659 | 0.0014(0.383%) |

| CE | 0.1243 | 0.1238 | 0.0005(0.404%) |

| RDL | 0.2778 | 0.2778 | 0.0000(0.000%) |

| SE | 0.2335 | 0.2326 | 0.00387(0.387%) |

| Eigenvector | 0.3659 | 0.1238 | 0.2778 | 0.2326 |

| Total (Sum) | 2.833 | 8.000 | 3.500 | 4.500 |

| Max Eigenvalue (λmax) | (0.3659x2.833) + (0.1238x8.000) + (0.2778x3.500) + (0.2326x4.500) = 4.046 | |||

| N | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| RI | 0 | 0 | 0.58 | 0.9 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 |

| TMS | Weight | AHS Scale | References |

|---|---|---|---|

| Natural convection | Less effective in high-power applications due to its passive nature. | 2 | [46] |

| Air forced convection | More effective than natural convection due to the forced air movement but might still struggle with very high heat loads. | 4 | [46] |

| Liquid passive cooling | More effective than air cooling due to the higher heat transfer coefficients of liquids over air. | 6 | [46,47] |

| Liquid active cooling | By actively pumping coolant, this method can achieve even higher heat dissipation rates than passive systems. | 7 | [46,47,48] |

| Heat pipes | Effectively transfers heat away from the source with minimal temperature difference. | 7 | [46] |

| PCM | Absorb a large amount of heat with minimal temperature change. | 5 | [46] |

| Thermoelectric cooling | Generally not the most efficient for large-scale heat dissipation due to its power consumption. | 3 | [46] |

| Hybrid cooling | Can be designed to maximize heat dissipation effectiveness, adapting to various operational scenarios. | 8 | [46] |

| NC | AFC | LPC | LAC | HP | PCM | TEC | HC | |

|---|---|---|---|---|---|---|---|---|

| NC | 1.00 | 0.50 | 0.33 | 0.25 | 0.25 | 0.33 | 0.50 | 0.25 |

| AFC | 2.00 | 1.00 | 0.50 | 0.50 | 0.50 | 1.00 | 1.00 | 0.50 |

| LPC | 3.00 | 2.00 | 1.00 | 1.00 | 1.00 | 1.00 | 2.00 | 1.00 |

| LAC | 4.00 | 2.00 | 1.00 | 1.00 | 1.00 | 1.00 | 2.00 | 1.00 |

| HP | 4.00 | 2.00 | 1.00 | 1.00 | 1.00 | 1.00 | 2.00 | 1.00 |

| PCM | 3.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 2.00 | 1.00 |

| TEC | 2.00 | 1.00 | 0.50 | 0.50 | 0.50 | 0.50 | 1.00 | 0.33 |

| HC | 4.00 | 2.00 | 1.00 | 1.00 | 1.00 | 1.00 | 3.00 | 1.00 |

| TMS | Weight | AHS Scale | References |

|---|---|---|---|

| Natural convection | Highly cost-effective due to minimal components and maintenance needs. | 9 | [49] |

| Air forced convection | Moderate cost due to the need for fans/blowers and potential for higher operational energy costs. | 5 | [49] |

| Liquid passive cooling | High initial setup costs due to plumbing and coolant; but low operational costs. | 7 | [53] [54] |

| Liquid active cooling | High initial and operational costs due to the use of pumps and maintenance. | 3 | [48] |

| Heat pipes | Moderate to high cost-effectiveness. Initial costs can be offset by low maintenance and high efficiency. | 5 | [55] |

| PCM | High initial costs for PCM materials can be balanced by low operational costs, given their passive nature. | 7 | [56] |

| Thermoelectric cooling | It is the least cost-effective due to high energy consumption and the costs of thermoelectric materials. | 1 | [51] |

| Hybrid cooling | Depends on the specific combination of TMSs used. They are designed to optimize performance while being mindful of costs. | 7 | [52] |

| NC | AFC | LPC | LAC | HP | PCM | TEC | HC | |

| NC | 1.00 | 2.00 | 1.00 | 3.00 | 2.00 | 1.00 | 9.00 | 1.00 |

| AFC | 0.50 | 1.00 | 1.00 | 2.00 | 1.00 | 1.00 | 5.00 | 1.00 |

| LPC | 1.00 | 1.00 | 1.00 | 2.00 | 1.00 | 1.00 | 7.00 | 1.00 |

| LAC | 0.33 | 0.50 | 0.50 | 1.00 | 0.50 | 0.50 | 3.00 | 0.50 |

| HP | 0.50 | 1.00 | 1.00 | 2.00 | 1.00 | 1.00 | 5.00 | 1.00 |

| PCM | 1.00 | 1.00 | 1.00 | 2.00 | 1.00 | 1.00 | 7.00 | 1.00 |

| TEC | 0.11 | 0.20 | 0.14 | 0.33 | 0.20 | 0.14 | 1.00 | 0.14 |

| HC | 1.00 | 1.00 | 1.00 | 2.00 | 1.00 | 1.00 | 7.00 | 1.00 |

| TMS | Weight | AHS Scale | References |

|---|---|---|---|

| Natural convection | Slower to respond to sudden changes in thermal loads due to its passive nature. | 2 | [57,60] |

| Air forced convection | Better than natural convection due to forced air movement, but limited by air's thermal properties. | 4 | [57] |

| Liquid passive cooling | More responsive than air due to the higher thermal conductivity and heat capacity of liquids. | 5 | [59,58] |

| Liquid active cooling | Very responsive due to active circulation, allowing quick adjustment to changing thermal loads. | 7 | [58,59] |

| Heat pipes | Highly responsive due to their efficient heat transfer capabilities, quickly moving heat away from hot spots. | 7 | [57] |

| PCM | Can absorb a lot of heat quickly during phase change but might struggle once the material is fully melted or solidified. | 5 | [58] |

| Thermoelectric cooling | Can be very responsive as it allows for rapid adjustments in cooling power. Its effectiveness is dependent on the power supply and is energy-intensive. | 6 | [60] |

| Hybrid cooling | It can be highly effective if configured to leverage the strengths of each component system. | 8 | [62] |

| NC | AFC | LPC | LAC | HP | PCM | TEC | HC | |

|---|---|---|---|---|---|---|---|---|

| NC | 1.00 | 0.50 | 0.33 | 0.25 | 0.25 | 0.33 | 0.33 | 0.25 |

| AFC | 2.00 | 1.00 | 1.00 | 0.50 | 0.50 | 1.00 | 0.50 | 0.50 |

| LPC | 3.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| LAC | 4.00 | 2.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| HP | 4.00 | 2.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| PCM | 3.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| TEC | 3.00 | 2.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| HC | 4.00 | 2.00 | 1.00 | 1.00 | 1.00 | 2.00 | 1.00 | 1.00 |

| TMS | Weight | AHS Scale | References |

|---|---|---|---|

| Natural convection | High safety due to its simplicity and no moving parts; environmentally friendly due to passive operation. | 8 | [64] |

| Air forced convection | Safe, but fans and electrical components add complexity; energy use for fans impacts its environmental score. | 6 | [63] |

| Liquid passive cooling | Safe if leak-proof systems are used; coolant choice impacts environmental friendliness. | 5 | [65] |

| Liquid active cooling | Requires careful design to prevent leaks; the environmental impact depends on the coolant and energy use of pumps. | 4 | [67] |

| Heat pipes | Very safe due to sealed operation; environmentally friendly with correct material choice. | 7 | [66] |

| PCM | Safe and environmentally friendly due to passive operation; choice of PCM material determines environmental impact. | 7 | [61,54] |

| Thermoelectric cooling | Safety is generally high; however, the environmental impact of power consumption for cooling can be significant. | 4 | [68] |

| Hybrid cooling | Safety and environmental impact depends on the combination of systems used but designed for high safety and lower environmental impact. | 7 | [69] |

| NC | AFC | LPC | LAC | HP | PCM | TEC | HC | |

|---|---|---|---|---|---|---|---|---|

| NC | 1.00 | 1.00 | 1.00 | 2.00 | 1.00 | 1.00 | 2.00 | 1.00 |

| AFC | 1.00 | 1.00 | 1.00 | 2.00 | 1.00 | 1.00 | 2.00 | 1.00 |

| LPC | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 | 1.00 |

| LAC | 0.50 | 0.50 | 1.00 | 1.00 | 0.50 | 0.50 | 1.00 | 0.50 |

| HP | 1.00 | 1.00 | 1.00 | 2.00 | 1.00 | 1.00 | 2.00 | 1.00 |

| PCM | 1.00 | 1.00 | 1.00 | 2.00 | 1.00 | 1.00 | 2.00 | 1.00 |

| TEC | 0.50 | 0.50 | 1.00 | 1.00 | 0.50 | 0.50 | 1.00 | 0.50 |

| HC | 1.00 | 1.00 | 1.00 | 2.00 | 1.00 | 1.00 | 2.00 | 1.00 |

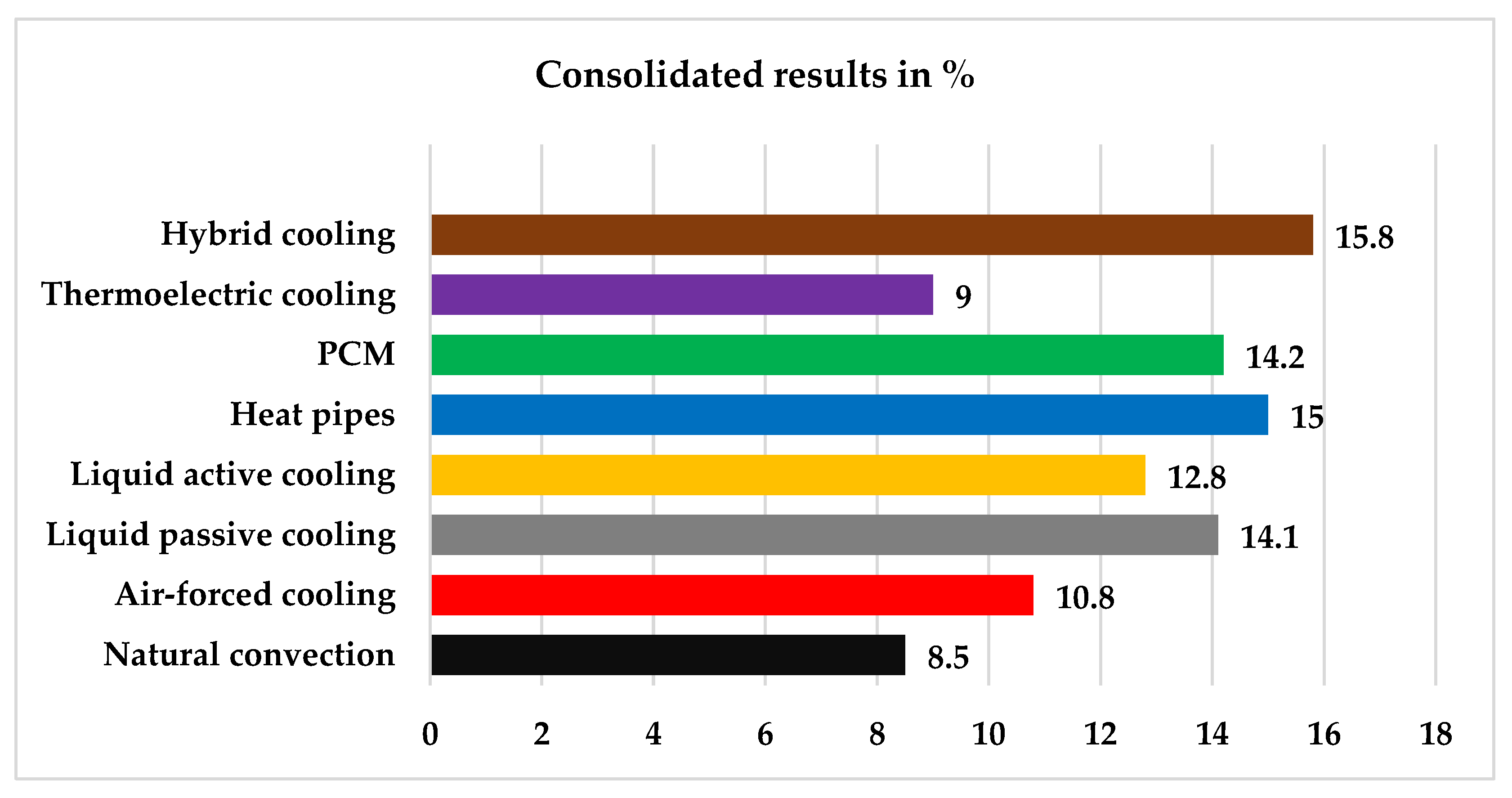

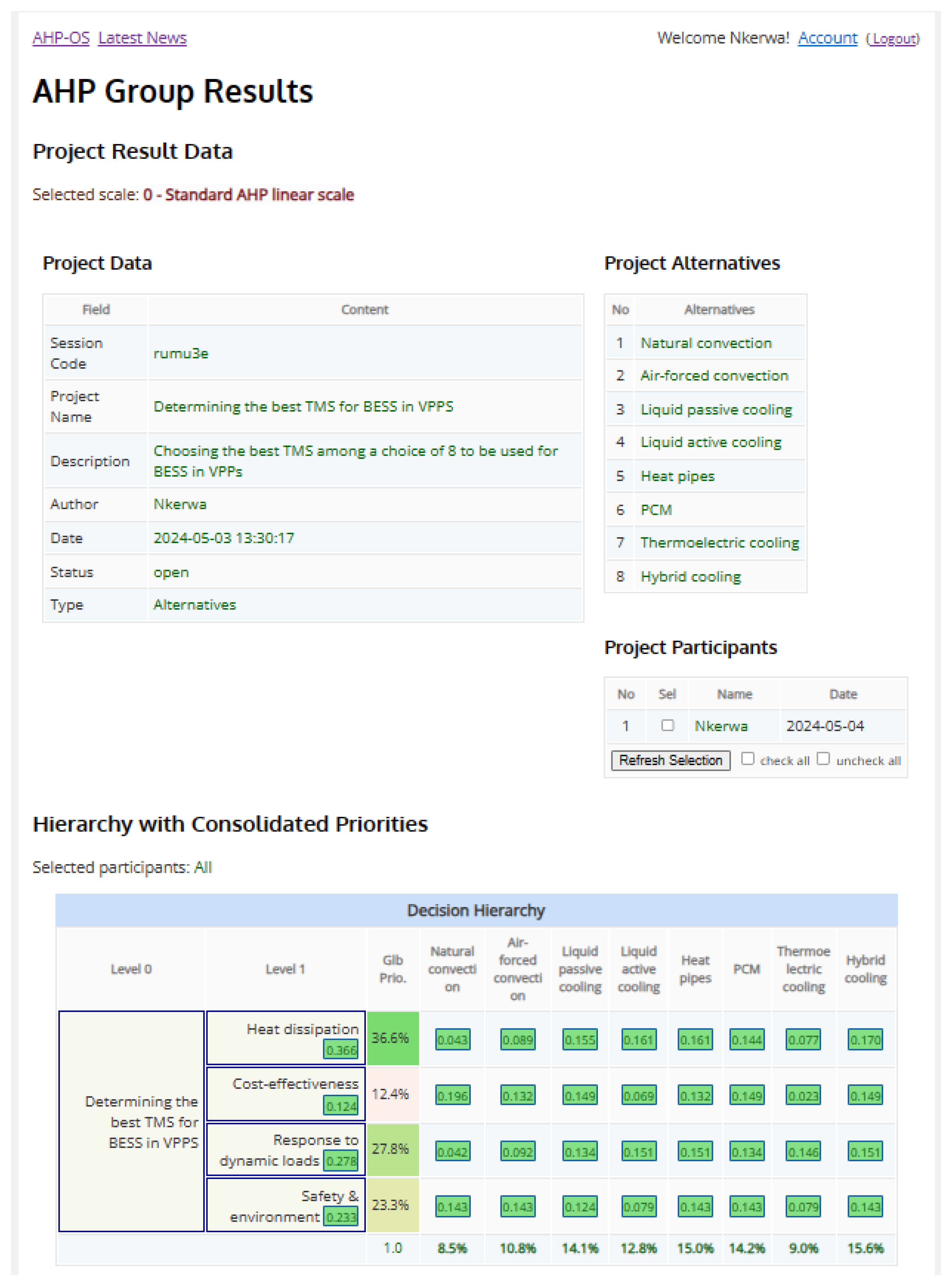

| Level 0 | Level 1 | Priority | NC | AFC | LPC | LAC | HP | PCM | TEC | HC |

|---|---|---|---|---|---|---|---|---|---|---|

| Determining the best TMS for BESS in VPPs | Heat dissipation | 0.366 | 0.043 | 0.089 | 0.155 | 0.161 | 0.161 | 0.144 | 0.077 | 0.170 |

| Cost-effectiveness | 0.124 | 0.132 | 0.149 | 0.069 | 0.132 | 0.149 | 0.023 | 0.049 | 0.149 | |

| Response to dynamic loads | 0.278 | 0.042 | 0.092 | 0.134 | 0.151 | 0.151 | 0.134 | 0.146 | 0.151 | |

| Safety & environment | 0.233 | 0.143 | 0.143 | 0.124 | 0.079 | 0.143 | 0.143 | 0.079 | 0.143 | |

| Consolidated weights of alternatives (%) | 8.5 | 10.8 | 14.1 | 12.8 | 15.0 | 14.2 | 9.0 | 15..6 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).