Submitted:

05 May 2024

Posted:

06 May 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Printing Samples

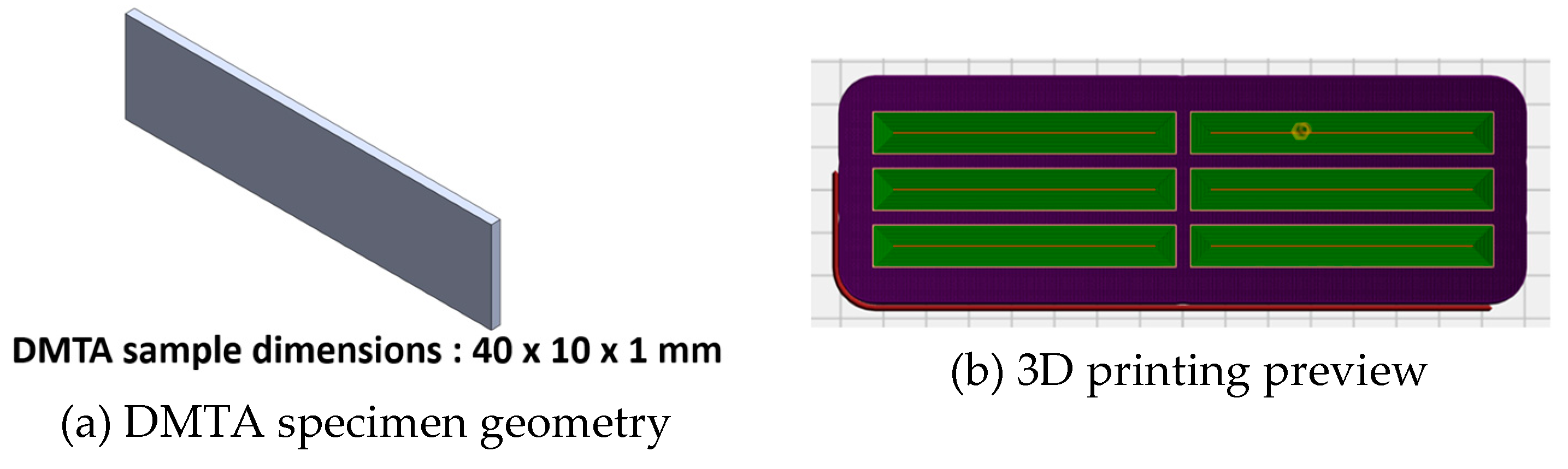

2.2. Dynamic Mechanical Thermal Analysis (DMTA) Measuring

2.3. Annealing Printed Specimen

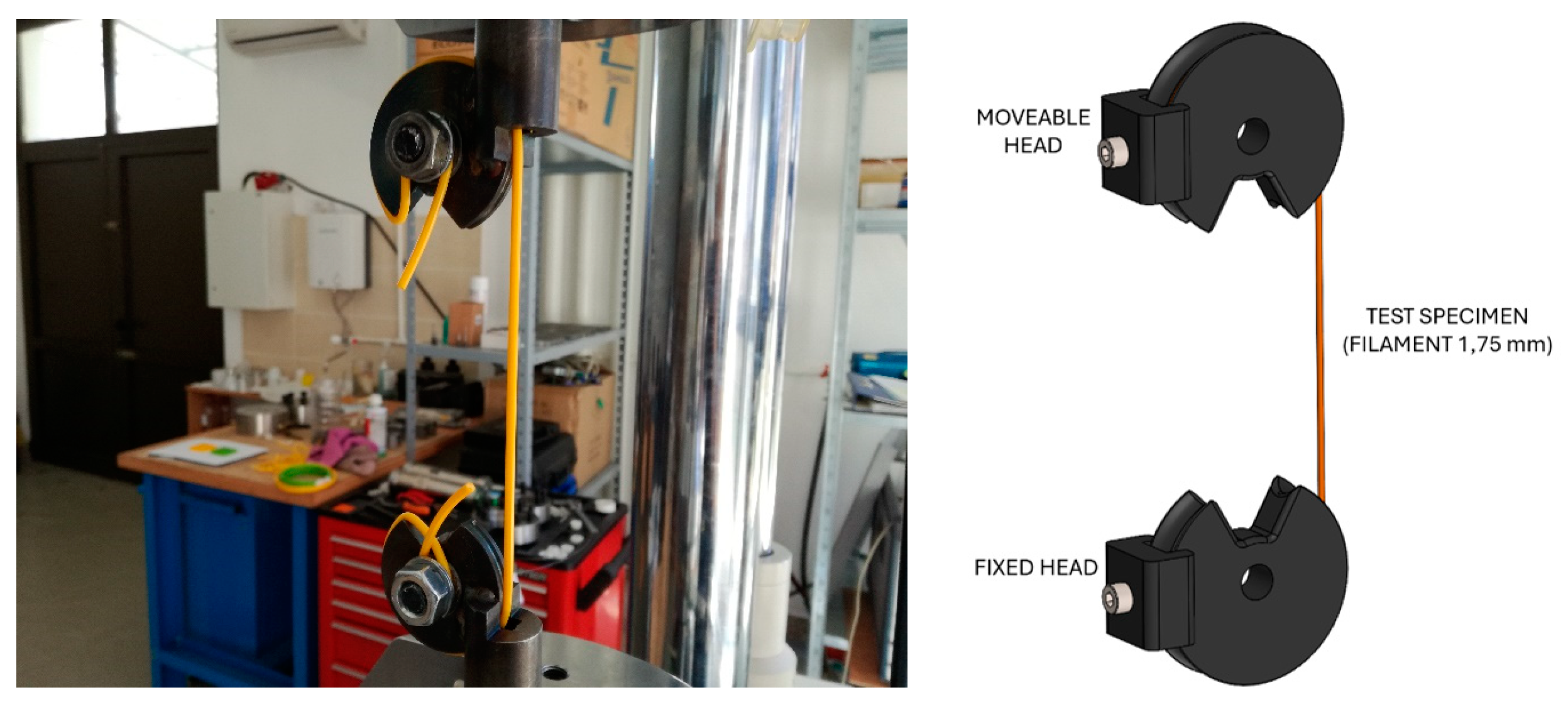

2.4. Uniaxial tests

2.5. Measurement of Temperature Change at High Strain Rates

3. Results and Discussion

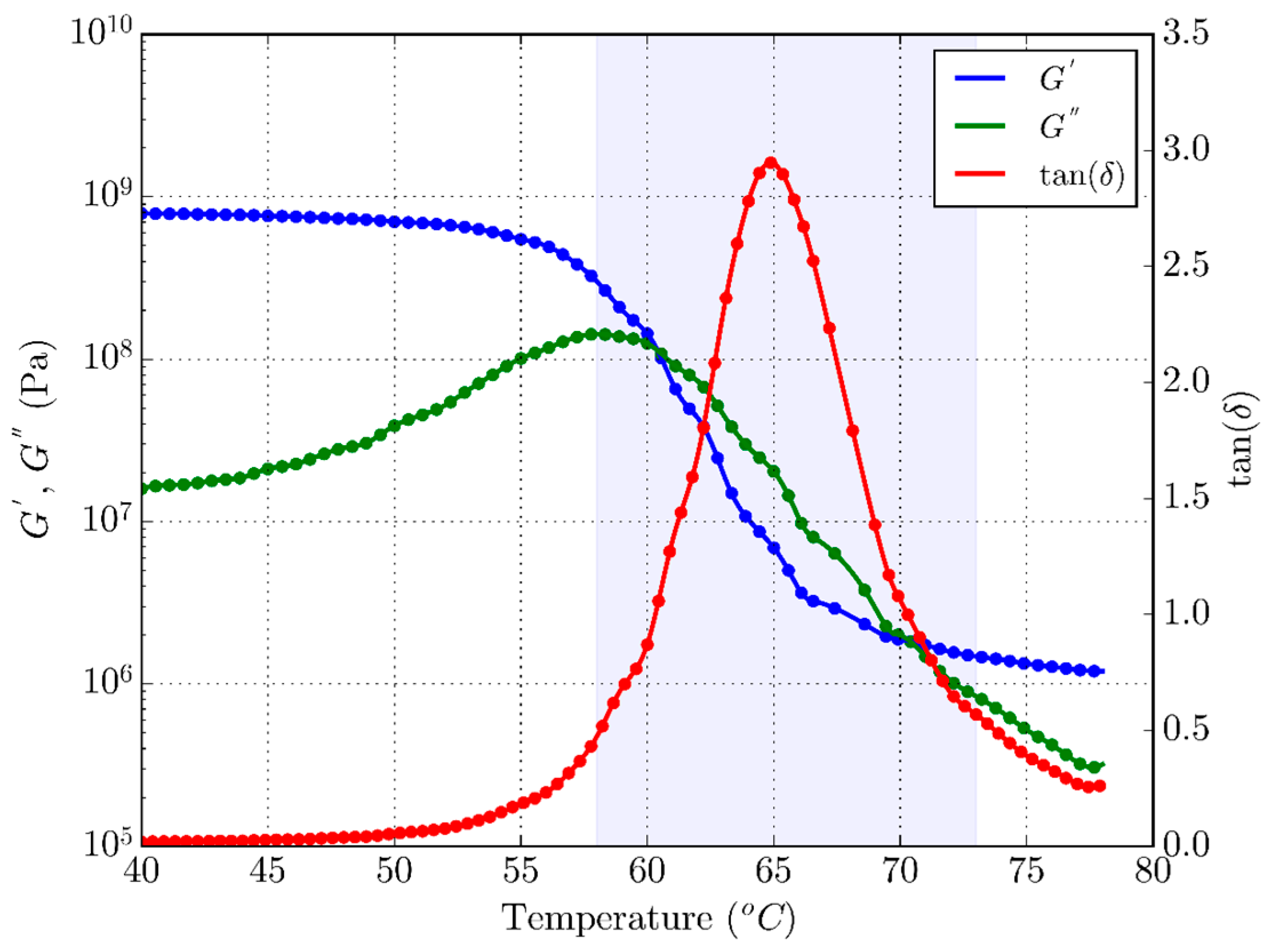

3.1. DMTA Results

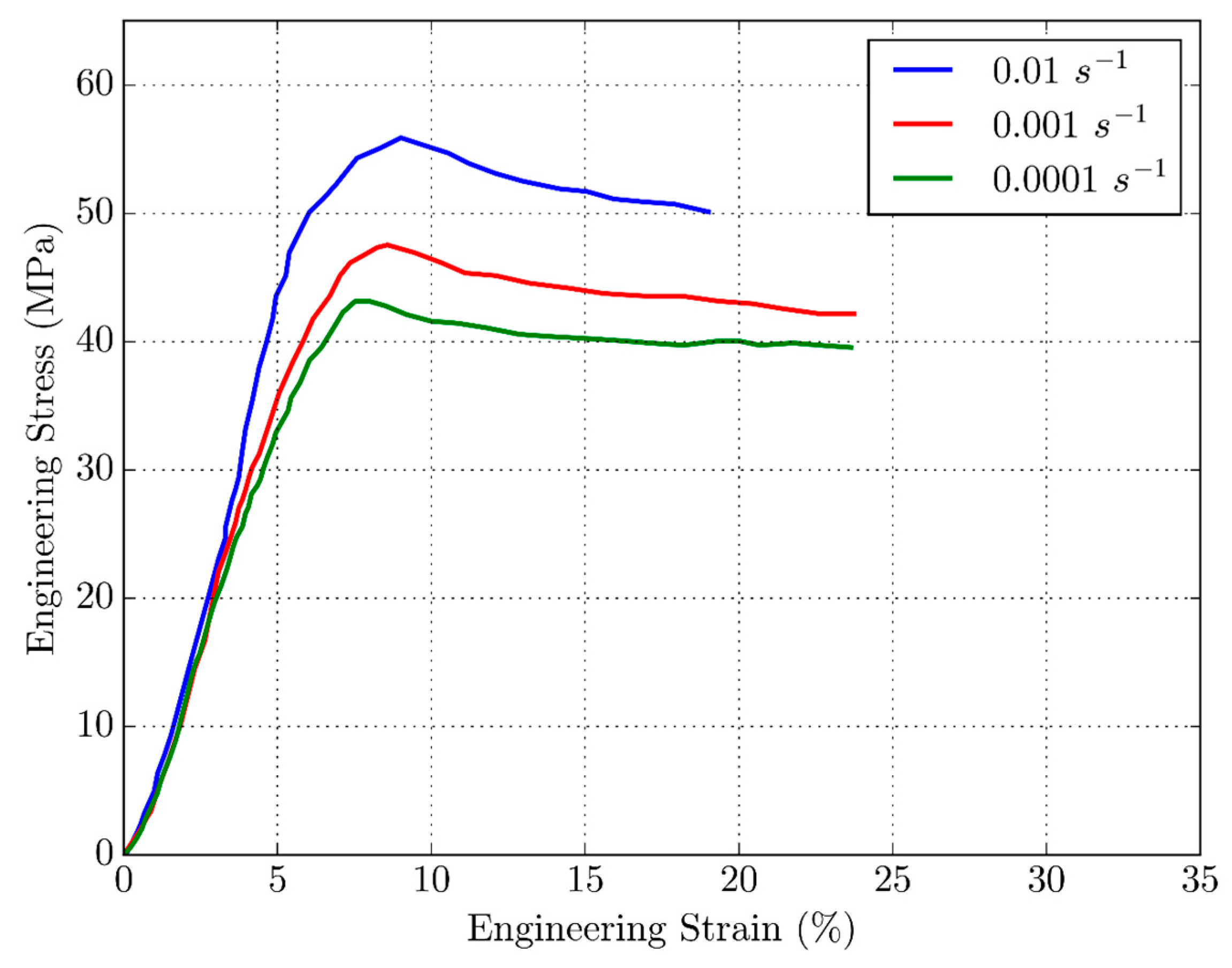

3.2. Uniaxial Tensile Tests of Filament

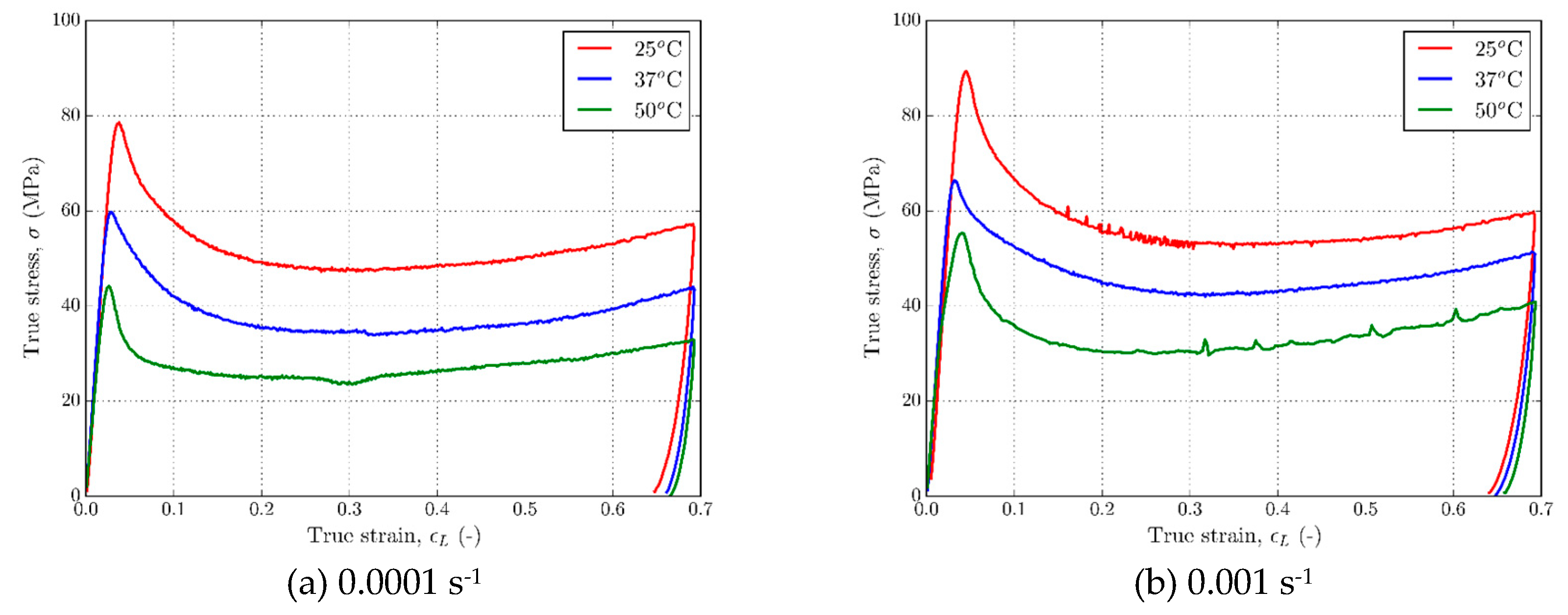

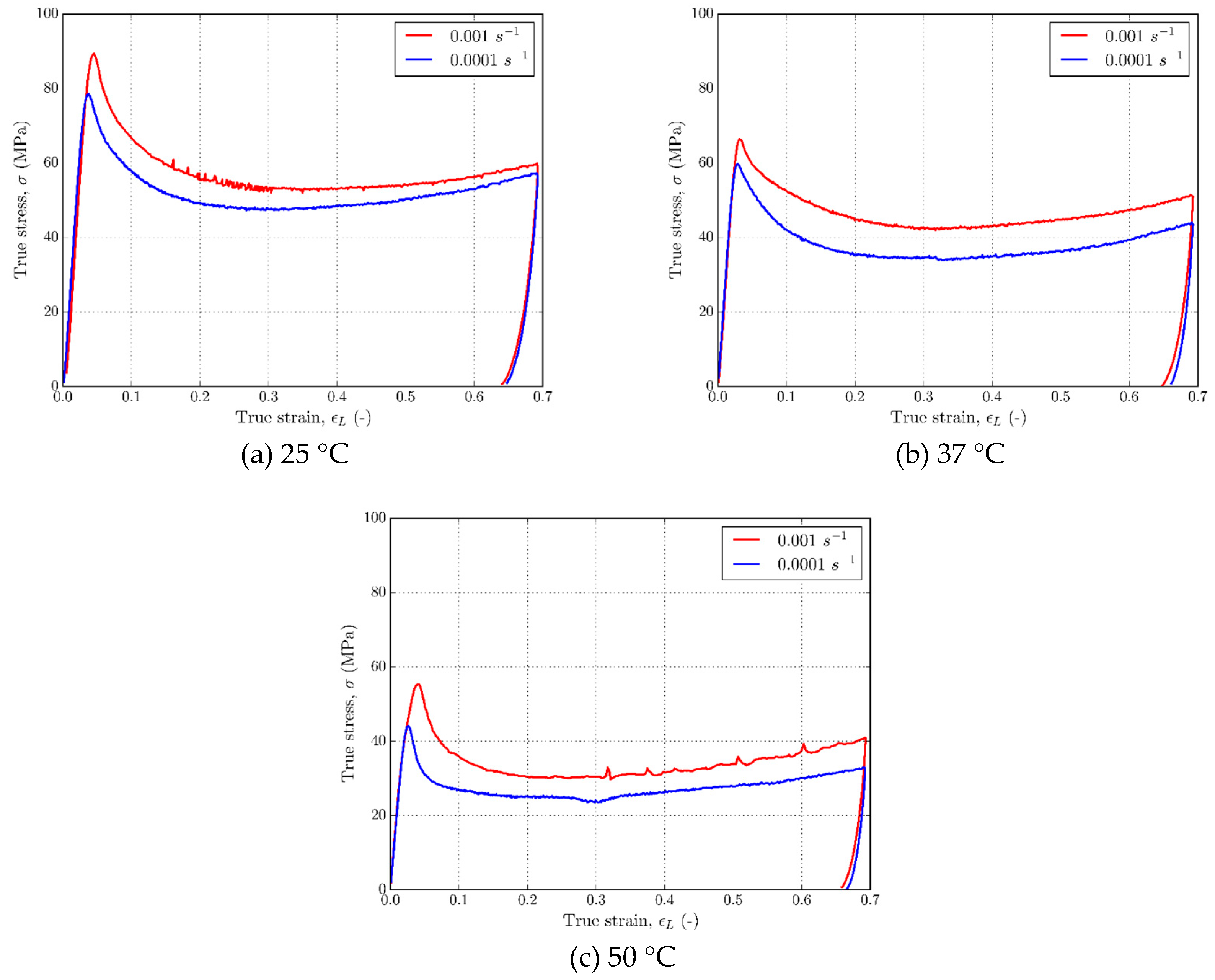

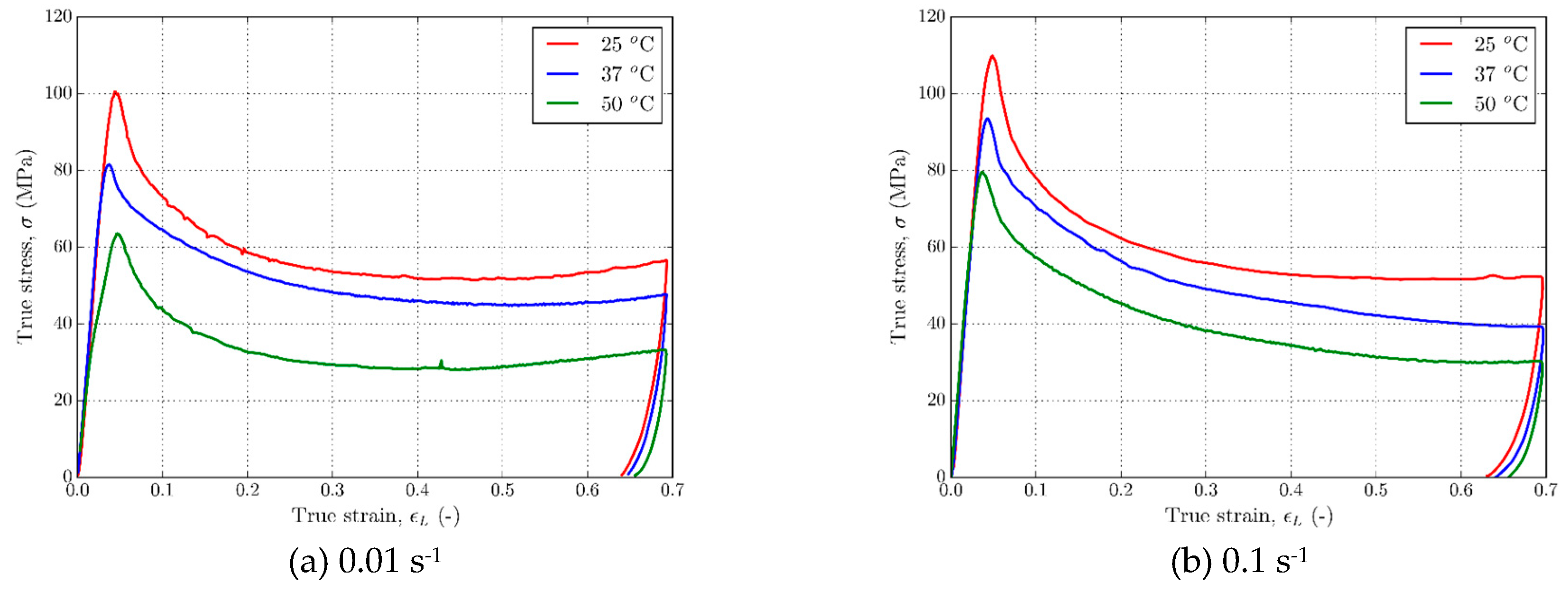

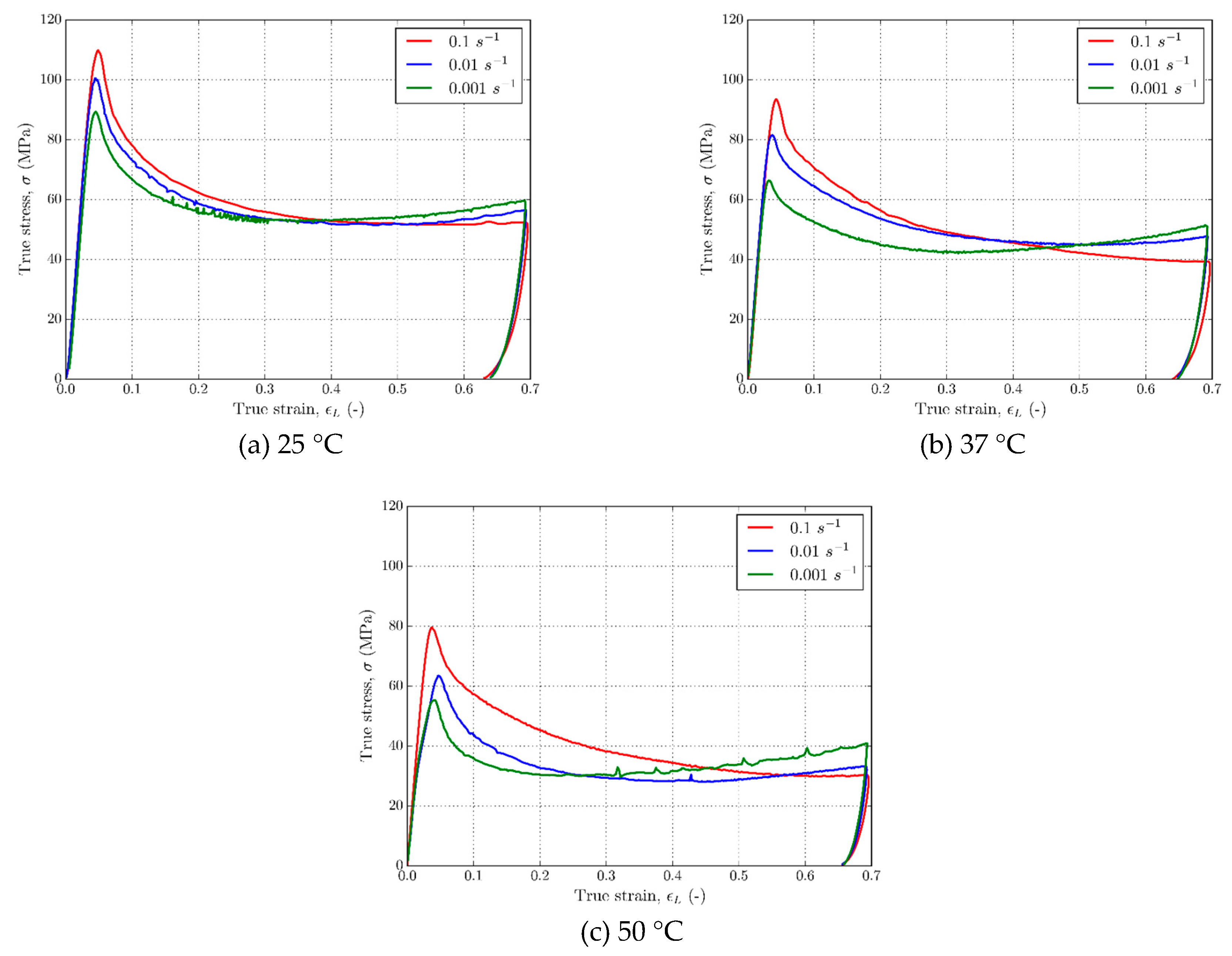

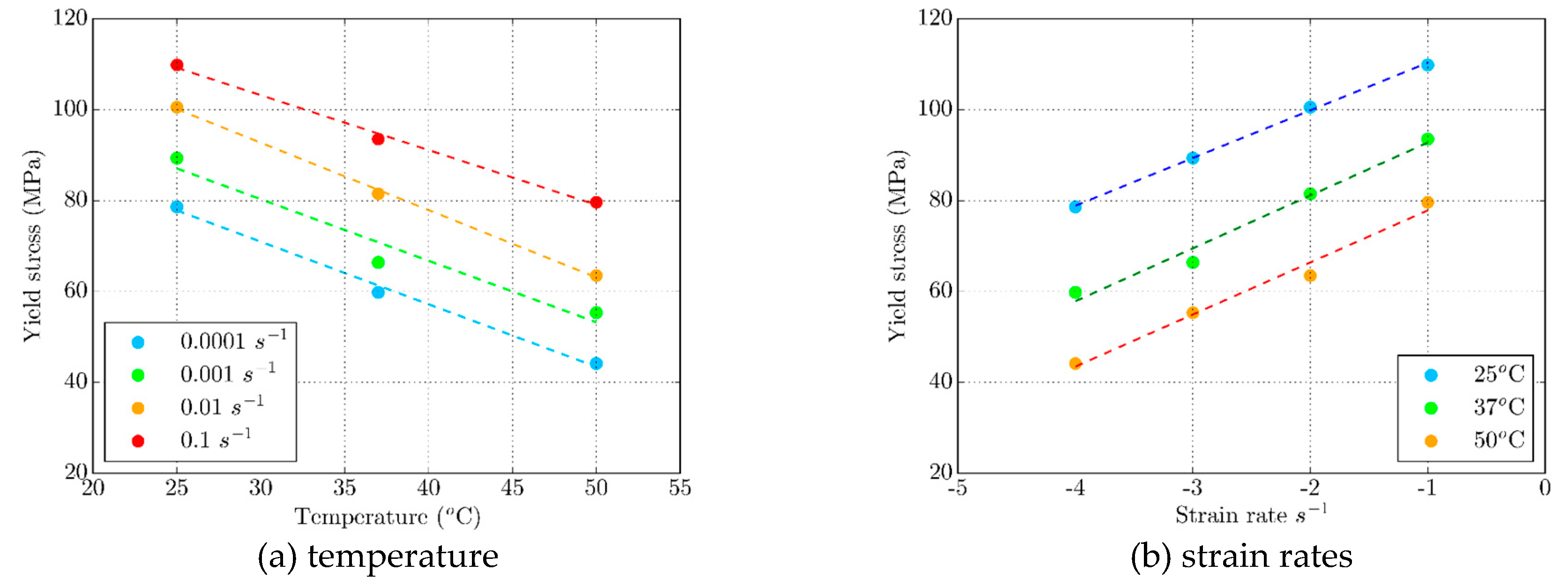

3.3. Uniaxial Compression Testing

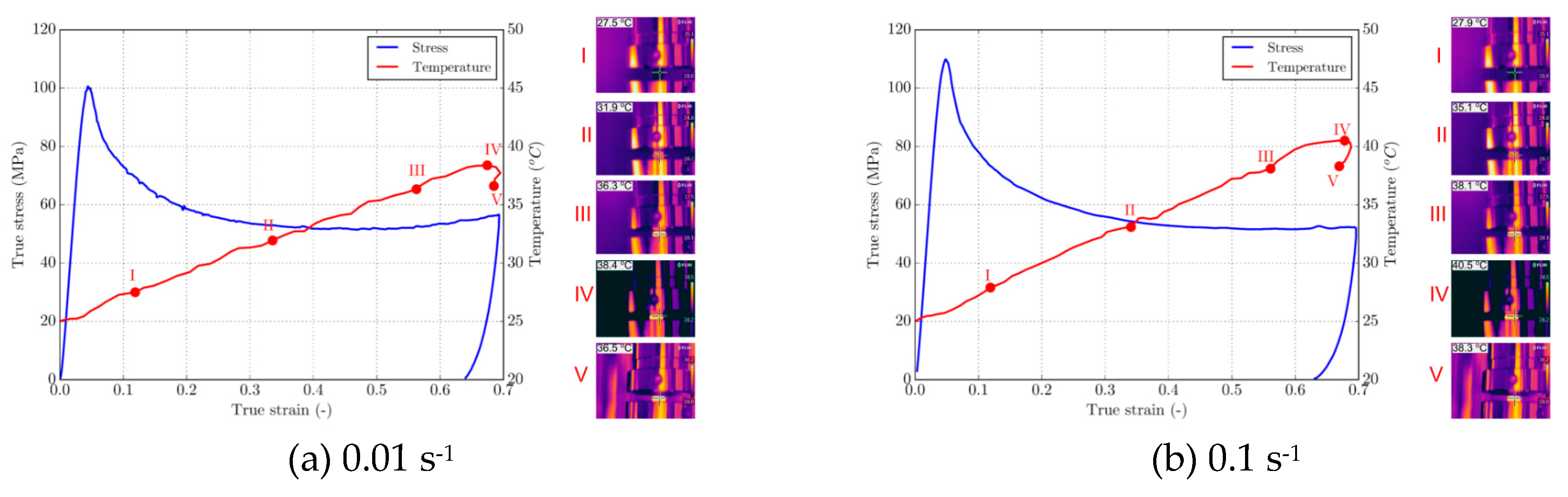

3.4. Adiabatic Tests with Self Heating and Strain Softening

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lendlein, A.; Jiang, H.; Jünger, O.; Langer, R. Light-Induced Shape-Memory Polymers. Nature 2005, 434, 879–882. [CrossRef]

- Lee, K.M.; Koerner, H.; Vaia, R.A.; Bunning, T.J.; White, T.J. Light-Activated Shape Memory of Glassy, Azobenzene Liquid Crystalline Polymer Networks. Soft Matter 2011, 7, 4318–4324. [CrossRef]

- Heuchel, M.; Sauter, T.; Kratz, K.; Lendlein, A. Thermally Induced Shape-Memory Effects in Polymers: Quantification and Related Modeling Approaches. Journal of Polymer Science Part B: Polymer Physics 2013, 51, 621–637. [CrossRef]

- Razzaq, M.Y.; Behl, M.; Nöchel, U.; Lendlein, A. Magnetically Controlled Shape-Memory Effects of Hybrid Nanocomposites from Oligo(Omega-Pentadecalactone) and Covalently Integrated Magnetite Nanoparticles. Polymer 2014, 55, 5953–5960. [CrossRef]

- Schmidt, A.M. Electromagnetic Activation of Shape Memory Polymer Networks Containing Magnetic Nanoparticles. Macromolecular Rapid Communications 2006, 27, 1168–1172. [CrossRef]

- Garces, I.T.; Aslanzadeh, S.; Boluk, Y.; Ayranci, C. Effect of Moisture on Shape Memory Polyurethane Polymers for Extrusion-Based Additive Manufacturing. Materials (Basel, Switzerland) 2019, 12, 244. [CrossRef]

- Liu, Y.; Li, Y.; Chen, H.; Yang, G.; Zheng, X.; Zhou, S. Water-Induced Shape-Memory Poly(D,L-Lactide)/Microcrystalline Cellulose Composites. Carbohydrate polymers 2014, 104, 101—108. [CrossRef]

- Bai, Y.; Chen, X. A Fast Water-Induced Shape Memory Polymer Based on Hydroxyethyl Cellulose/Graphene Oxide Composites. Composites Part A: Applied Science and Manufacturing 2017, 103, 9–16. [CrossRef]

- Petrini, L.; Migliavacca, F. Biomedical Applications of Shape Memory Alloys. Journal of Metallurgy 2011, 2011, 501483. [CrossRef]

- Hartl, D.J.; Lagoudas, D.C. Aerospace Applications of Shape Memory Alloys. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering 2007, 221, 535–552. [CrossRef]

- Kheirikhah, M.M.; Rabiee, S.; Edalat, M.E. A Review of Shape Memory Alloy Actuators in Robotics. In Proceedings of the RoboCup 2010: Robot Soccer World Cup XIV; Ruiz-del-Solar, J., Chown, E., Plöger, P.G., Eds.; Springer Berlin Heidelberg: Berlin, Heidelberg, 2011; pp. 206–217.

- Erkeçoğlu, S.; Sezer, A.D.; Bucak, S. Smart Delivery Systems with Shape Memory and Self-Folding Polymers. In Smart Drug Delivery System; Sezer, A.D., Ed.; IntechOpen: Rijeka, 2016.

- Korde, J.M.; Kandasubramanian, B. Naturally Biomimicked Smart Shape Memory Hydrogels for Biomedical Functions. Chemical Engineering Journal 2020, 379, 122430. [CrossRef]

- Huang, W.M.; Ding, Z.; Wang, C.C.; Wei, J.; Zhao, Y.; Purnawali, H. Shape Memory Materials. Materials Today 2010, 13, 54–61. [CrossRef]

- Liu, C.; Qin, H.; Mather, P.T. Review of Progress in Shape-Memory Polymers. J. Mater. Chem. 2007, 17, 1543–1558. [CrossRef]

- Hasan, M.R.; Davies, I.J.; Pramanik, A.; John, M.; Biswas, W.K. Potential of Recycled PLA in 3D Printing: A Review. Sustainable Manufacturing and Service Economics 2024, 3, 100020. [CrossRef]

- Mehrpouya, M.; Vahabi, H.; Janbaz, S.; Darafsheh, A.; Mazur, T.R.; Ramakrishna, S. 4D Printing of Shape Memory Polylactic Acid (PLA). Polymer 2021, 230, 124080. [CrossRef]

- Tibbits, S. The Emergence of “4D Printing.” TED Conference 2013.

- Liu, Y.; Zhang, W.; Zhang, F.; Lan, X.; Leng, J.; Liu, S.; Jia, X.; Cotton, C.; Sun, B.; Gu, B.; et al. Shape Memory Behavior and Recovery Force of 4D Printed Laminated Miura-Origami Structures Subjected to Compressive Loading. Composites Part B: Engineering 2018, 153, 233–242. [CrossRef]

- Dudek, P. FDM 3D Printing Technology in Manufacturing Composite Elements. Archives of Metallurgy and Materials 2013, Vol. 58, iss. 4, 1415–1418. [CrossRef]

- Jasveer, S.; Jian-bin, X. Comparison of Different Types of 3 D Printing Technologies.; 2018.

- Kuang, X.; Zhao, Z.; Chen, K.; Fang, D.; Kang, G.; Qi, H.J. High-Speed 3D Printing of High-Performance Thermosetting Polymers via Two-Stage Curing. Macromolecular Rapid Communications 2018, 39, 1700809. [CrossRef]

- Soleimani-Gorgani, A. 14 - Inkjet Printing. In Printing on Polymers; Izdebska, J., Thomas, S., Eds.; William Andrew Publishing, 2016; pp. 231–246 ISBN 978-0-323-37468-2.

- Riheen, M.A.; Saha, T.K.; Sekhar, P.K. Inkjet Printing on PET Substrate. Journal of The Electrochemical Society 2019, 166, B3036–B3039. [CrossRef]

- Aberoumand, M.; Soltanmohammadi, K.; Rahmatabadi, D.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. 4D Printing of Polyvinyl Chloride (PVC): A Detailed Analysis of Microstructure, Programming, and Shape Memory Performance. Macromolecular Materials and Engineering 2023, 308, 2200677. [CrossRef]

- Aberoumand, M.; Rahmatabadi, D.; Soltanmohammadi, K.; Soleyman, E.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; Baghani, M. Stress Recovery and Stress Relaxation Behaviors of PVC 4D Printed by FDM Technology for High-Performance Actuation Applications. Sensors and Actuators A: Physical 2023, 361, 114572. [CrossRef]

- Soleyman, E.; Rahmatabadi, D.; Soltanmohammadi, K.; Aberoumand, M.; Ghasemi, I.; Abrinia, K.; Baniassadi, M.; Wang, K.; Baghani, M. Shape Memory Performance of PETG 4D Printed Parts under Compression in Cold, Warm, and Hot Programming. Smart Materials and Structures 2022, 31, 085002. [CrossRef]

- Sælen, R.L.; Hopperstad, O.S.; Clausen, A.H. Mechanical Behaviour and Constitutive Modelling of an Additively Manufactured Stereolithography Polymer. Mechanics of Materials 2023, 185, 104777. [CrossRef]

- Mirasadi, K.; Rahmatabadi, D.; Ghasemi, I.; Khodaei, M.; Baniassadi, M.; Baghani, M. Investigating the Effect of ABS on the Mechanical Properties, Morphology, Printability, and 4D Printing of PETG-ABS Blends. Macromolecular Materials and Engineering n/a, 2400038. [CrossRef]

- Mehrpouya, M.; Ghalayaniesfahani, A.; Postmes, J.F.; Gibson, I. Tailoring Mechanical Properties in 3D Printed Multimaterial Architected Structures. Journal of the Mechanical Behavior of Biomedical Materials 2024, 152, 106431. [CrossRef]

- Hamad, K.; Kaseem, M.; Yang, H.W.; Deri, F.; Ko, Y.G. Properties and Medical Applications of Polylactic Acid: A Review. eXPRESS Polymer Letters 2015, 9, 435–455. [CrossRef]

- Soares, J.S.; Moore, J.E.; Rajagopal, K.R. Constitutive Framework for Biodegradable Polymers with Applications to Biodegradable Stents. ASAIO Journal 2008, 54, 295–301.

- Haers, P.E.; Suuronen, R.; Lindqvist, C.; Sailer, H. Biodegradable Polylactide Plates and Screws in Orthognathic Surgery: Technical Note. Journal of Cranio-Maxillo-Facial Surgery 2010, 26, 87–91. [CrossRef]

- Wiebe, J.; Nef, H.M.; Hamm, C.W. Current Status of Bioresorbable Scaffolds in the Treatment of Coronary Artery Disease. JOURNAL OF THE AMERICAN COLLEGE OF CARDIOLOGY 2014, 64, 415–424, doi:doi.org/10.1016/j.jacc.2014.09.041.

- Lasprilla, A.J.R.; Martinez, G.A.R.; Lunelli, B.H.; Jardini, A.L.; Filho, R.M. Poly Lactic Acid Synthesis for Application in Biomedical Devices — A Review. Biotechnology Advances 2012, 30, 321–328. [CrossRef]

- Gross, B.C.; Erkal, J.L.; Lockwood, S.Y.; Chen, C.; Spence, D.M. Evaluation of 3D Printing and Its Potential Impact on Biotechnology and the Chemical Sciences. Analytical Chemistry 2014, 86, 3240–3253. [CrossRef]

- Plesec, V.; Humar, J.; Dobnik-Dubrovski, P.; Harih, G. Numerical Analysis of a Transtibial Prosthesis Socket Using 3D-Printed Bio-Based PLA. Materials 2023, 16. [CrossRef]

- Milenkovic, S.; Slavkovic, V.; Fragassa, C.; Grujovic, N.; Palic, N.; Zivic, F. Effect of the Raster Orientation on Strength of the Continuous Fiber Reinforced PVDF/PLA Composites, Fabricated by Hand-Layup and Fused Deposition Modeling. Composite Structures 2021, 270, 114063. [CrossRef]

- Senatov, F.S.; Niaza, K.V.; Zadorozhnyy, M.Y.; Maksimkin, A.V.; Kaloshkin, S.D.; Estrin, Y.Z. Mechanical Properties and Shape Memory Effect of 3D-Printed PLA-Based Porous Scaffolds. Journal of the Mechanical Behavior of Biomedical Materials 2016, 57, 139–148. [CrossRef]

- Slavkovic, V.; Palic, N.; Milenkovic, S.; Zivic, F.; Grujovic, N. Thermo-Mechanical Characterization of 4D-Printed Biodegradable Shape-Memory Scaffolds Using Four-Axis 3D-Printing System. Materials 2023, 16. [CrossRef]

- Bodaghi, M.; Namvar, N.; Yousefi, A.; Teymouri, H.; Demoly, F.; Zolfagharian, A. Metamaterial Boat Fenders with Supreme Shape Recovery and Energy Absorption/Dissipation via FFF 4D Printing. Smart Materials and Structures 2023, 32, 095028. [CrossRef]

- Pham, D.B.; Huang, S.-C. A Novel Bio-Inspired Hierarchical Tetrachiral Structure That Enhances Energy Absorption Capacity. Journal of Mechanical Science and Technology 2023, 37, 3229–3237. [CrossRef]

- Choudhry, N.K.; Panda, B.; Dixit, U.S. Energy Absorption Characteristics of Fused Deposition Modeling 3D Printed Auxetic Re-Entrant Structures: A Review. Journal of Materials Engineering and Performance 2023, 32, 8981–8999. [CrossRef]

- Gisario, A.; Desole, M.P.; Mehrpouya, M.; Barletta, M. Energy Absorbing 4D Printed Meta-Sandwich Structures: Load Cycles and Shape Recovery. The International Journal of Advanced Manufacturing Technology 2023, 127, 1779–1795. [CrossRef]

- Novak, N.; Plesec, V.; Harih, G.; Cupar, A.; Kaljun, J.; Vesenjak, M. Development, Fabrication and Mechanical Characterisation of Auxetic Bicycle Handlebar Grip. Scientific Reports 2023, 13, 8158. [CrossRef]

- Zhao, W.; Yue, C.; Liu, L.; Leng, J.; Liu, Y. Mechanical Behavior Analyses of 4D Printed Metamaterials Structures with Excellent Energy Absorption Ability. Composite Structures 2023, 304, 116360. [CrossRef]

- Bodaghi, M.; Serjouei, A.; Zolfagharian, A.; Fotouhi, M.; Rahman, H.; Durand, D. Reversible Energy Absorbing Meta-Sandwiches by FDM 4D Printing. International Journal of Mechanical Sciences 2020, 173, 105451. [CrossRef]

- Rahmatabadi, D.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Baghani, M. 4D Printing of PLA-TPU Blends: Effect of PLA Concentration, Loading Mode, and Programming Temperature on the Shape Memory Effect. Journal of Materials Science 2023, 58, 7227–7243. [CrossRef]

- Morvayova, A.; Contuzzi, N.; Fabbiano, L.; Casalino, G. Multi-Attribute Decision Making: Parametric Optimization and Modeling of the FDM Manufacturing Process Using PLA/Wood Biocomposites. Materials 2024, 17. [CrossRef]

- Song, Y.; Li, Y.; Song, W.; Yee, K.; Lee, K.-Y.; Tagarielli, V.L. Measurements of the Mechanical Response of Unidirectional 3D-Printed PLA. Materials and Design 2017, 123, 154–164. [CrossRef]

- Luo, J.; Luo, Q.; Zhang, G.; Li, Q.; Sun, G. On Strain Rate and Temperature Dependent Mechanical Properties and Constitutive Models for Additively Manufactured Polylactic Acid (PLA) Materials. Thin-Walled Structures 2022, 179, 109624. [CrossRef]

- Pepelnjak, T.; Karimi, A.; Maček, A.; Mole, N. Altering the Elastic Properties of 3D Printed Poly-Lactic Acid (PLA) Parts by Compressive Cyclic Loading. Materials 2020, 13. [CrossRef]

- Chen, W.; Guo, C.; Zuo, X.; Zhao, J.; Peng, Y.; Wang, Y. Experimental and Numerical Investigation of 3D Printing PLA Origami Tubes under Quasi-Static Uniaxial Compression. Polymers 2022, 14. [CrossRef]

- Qin, D.; Sang, L.; Zhang, Z.; Lai, S.; Zhao, Y. Compression Performance and Deformation Behavior of 3D-Printed PLA-Based Lattice Structures. Polymers 2022, 14. [CrossRef]

- Liu, T.; Liu, L.; Zeng, C.; Liu, Y.; Leng, J. 4D Printed Anisotropic Structures with Tailored Mechanical Behaviors and Shape Memory Effects. Composites Science and Technology 2020, 186, 107935. [CrossRef]

- Mercado-Colmenero, J.M.; Rubio-Paramio, M.A.; la Rubia-Garcia, M.D.; Lozano-Arjona, D.; Martin-Doñate, C. A Numerical and Experimental Study of the Compression Uniaxial Properties of PLA Manufactured with FDM Technology Based on Product Specifications. The International Journal of Advanced Manufacturing Technology 2019, 103, 1893–1909. [CrossRef]

- Peng, X.; Liu, G.; Li, J.; Wu, H.; Jia, W.; Jiang, S. Compression Property and Energy Absorption Capacity of 4D-Printed Deformable Honeycomb Structure. Composite Structures 2023, 325, 117591. [CrossRef]

- Cadete, M.S.; Gomes, T.E.P.; Gonçalves, I.; Neto, V. Influence of 3D-Printing Deposition Parameters on Crystallinity and Morphing Properties of PLA-Based Materials. Progress in Additive Manufacturing 2024. [CrossRef]

- Barletta, M.; Gisario, A.; Mehrpouya, M. 4D Printing of Shape Memory Polylactic Acid (PLA) Components: Investigating the Role of the Operational Parameters in Fused Deposition Modelling (FDM). Journal of Manufacturing Processes 2021, 61, 473–480. [CrossRef]

- Brischetto, S.; Torre, R. Tensile and Compressive Behavior in the Experimental Tests for PLA Specimens Produced via Fused Deposition Modelling Technique. Journal of Composites Science 2020, 4. [CrossRef]

- Cláudio, R.A.; Dupont, J.; Baptista, R.; Leite, M.; Reis, L. Behaviour Evaluation of 3D Printed Polylactic Acid under Compression. Journal of Materials Research and Technology 2022, 21, 4052–4066. [CrossRef]

- JI, Q.; Wei, J.; YI, J.; Zhang, L.; Ma, J.; Wang, Z. Study on the Static and Dynamic Mechanical Properties and Constitutive Models of 3D Printed PLA and PLA-Cu Materials. Materials Today Communications 2024, 39, 108690. [CrossRef]

- Hosseini, S.A.; Torabizadeh, M.; Eisazadeh, H. Experimental Study of the Effect of Strain Rate on the Mechanical Behavior of Assorted Thermoplastic Polymers. Journal of Materials Engineering and Performance 2023. [CrossRef]

- Xu, P.; Lan, X.; Zeng, C.; Zhang, X.; Zhao, H.; Leng, J.; Liu, Y. Compression Behavior of 4D Printed Metamaterials with Various Poisson’s Ratios. International Journal of Mechanical Sciences 2024, 264, 108819. [CrossRef]

- Rajkumar, A.R.; Shanmugam, K. Additive Manufacturing-Enabled Shape Transformations via FFF 4D Printing. Journal of Materials Research 2018, 33, 4362–4376. [CrossRef]

- Balasubramanian, M.; Saravanan, R.; Shanmugam, V. Impact of Strain Rate on Mechanical Properties of Polylatic Acid Fabricated by Fusion Deposition Modeling. Polymers for Advanced Technologies 2024, 35, e6335. [CrossRef]

- Bergström, J.S.; Boyce, M.C. Constitutive Modeling of the Large Strain Time-Dependent Behavior of Elastomers. Journal of the Mechanics and Physics of Solids 1998, 46, 931–954. [CrossRef]

- Qi, H.J.; Boyce, M.C. Constitutive Model for Stretch-Induced Softening of the Stress–Stretch Behavior of Elastomeric Materials. Journal of the Mechanics and Physics of Solids 2004, 52, 2187–2205. [CrossRef]

- Qi, H.J.; Nguyen, T.D.; Castro, F.; Yakacki, C.M.; Shandas, R. Finite Deformation Thermo-Mechanical Behavior of Thermally Induced Shape Memory Polymers. Journal of the Mechanics and Physics of Solids 2008, 56, 1730–1751. [CrossRef]

- Bodaghi, M.; Damanpack, A.R.; Liao, W.H. Triple Shape Memory Polymers by 4D Printing. Smart Materials and Structures 2018, 27, 065010. [CrossRef]

- Garg, M.; Mulliken, A.D.; Boyce, M.C. Temperature Rise in Polymeric Materials During High Rate Deformation. Journal of Applied Mechanics 2008, 75, 011009. [CrossRef]

- Ames, N.M.; Srivastava, V.; Chester, S.A.; Anand, L. A Thermo-Mechanically Coupled Theory for Large Deformations of Amorphous Polymers. Part II: Applications. International Journal of Plasticity 2009, 25, 1495–1539. [CrossRef]

- Okereke, M.I.; Buckley, C.P.; Siviour, C.R. Compression of Polypropylene across a Wide Range of Strain Rates. Mechanics of Time-Dependent Materials 2012, 16, 361–379. [CrossRef]

- Hao, P.; Spronk, S.W.F.; Paepegem, W.V.; Gilabert, F.A. Hydraulic-Based Testing and Material Modelling to Investigate Uniaxial Compression of Thermoset and Thermoplastic Polymers in Quasistatic-to-Dynamic Regime. Materials & Design 2022, 224, 111367. [CrossRef]

- Bodaghi, M.; Damanpack, A.R.; Liao, W.H. Self-Expanding/Shrinking Structures by 4D Printing. Smart Materials and Structures 2016, 25, 105034. [CrossRef]

- Van Manen, T.; Janbaz, S.; Jansen, K.M.B.; Zadpoor, A.A. 4D Printing of Reconfigurable Metamaterials and Devices. Commun Mater 2021, 2, 56. [CrossRef]

- Staszczak, M.; Nabavian Kalat, M.; Golasiński, K.M.; Urbański, L.; Takeda, K.; Matsui, R.; Pieczyska, E.A. Characterization of Polyurethane Shape Memory Polymer and Determination of Shape Fixity and Shape Recovery in Subsequent Thermomechanical Cycles. Polymers 2022, 14, 4775. [CrossRef]

- Miehe, C.; Göktepe, S.; Méndez Diez, J. Finite Viscoplasticity of Amorphous Glassy Polymers in the Logarithmic Strain Space. International Journal of Solids and Structures 2009, 46, 181–202. [CrossRef]

- Boyce, M.C.; Arruda, E.M.; Jayachandran, R. The Large Strain Compression, Tension, and Simple Shear of Polycarbonate. Polymer Engineering and Science 1994, 34, 716–725.

- Wiersma, J.; Sain, T. A Coupled Viscoplastic-Damage Constitutive Model for Semicrystalline Polymers. Mechanics of Materials 2023, 176, 104527. [CrossRef]

| Parameter | Value |

|---|---|

| Nozzle diameter | 0.4 mm |

| Layer height | 0.1 mm |

| Infill | 100 % |

| Printing speed | 40 mm/s |

| Printing bed temperature | °C |

| Production time | 35 min |

| G’ (MPa) | G’’ (MPa) | G’/G’’ (-) | Tg (°C) |

|---|---|---|---|

| 1045 | 1.2 | >100 | 65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).