Submitted:

26 April 2024

Posted:

27 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

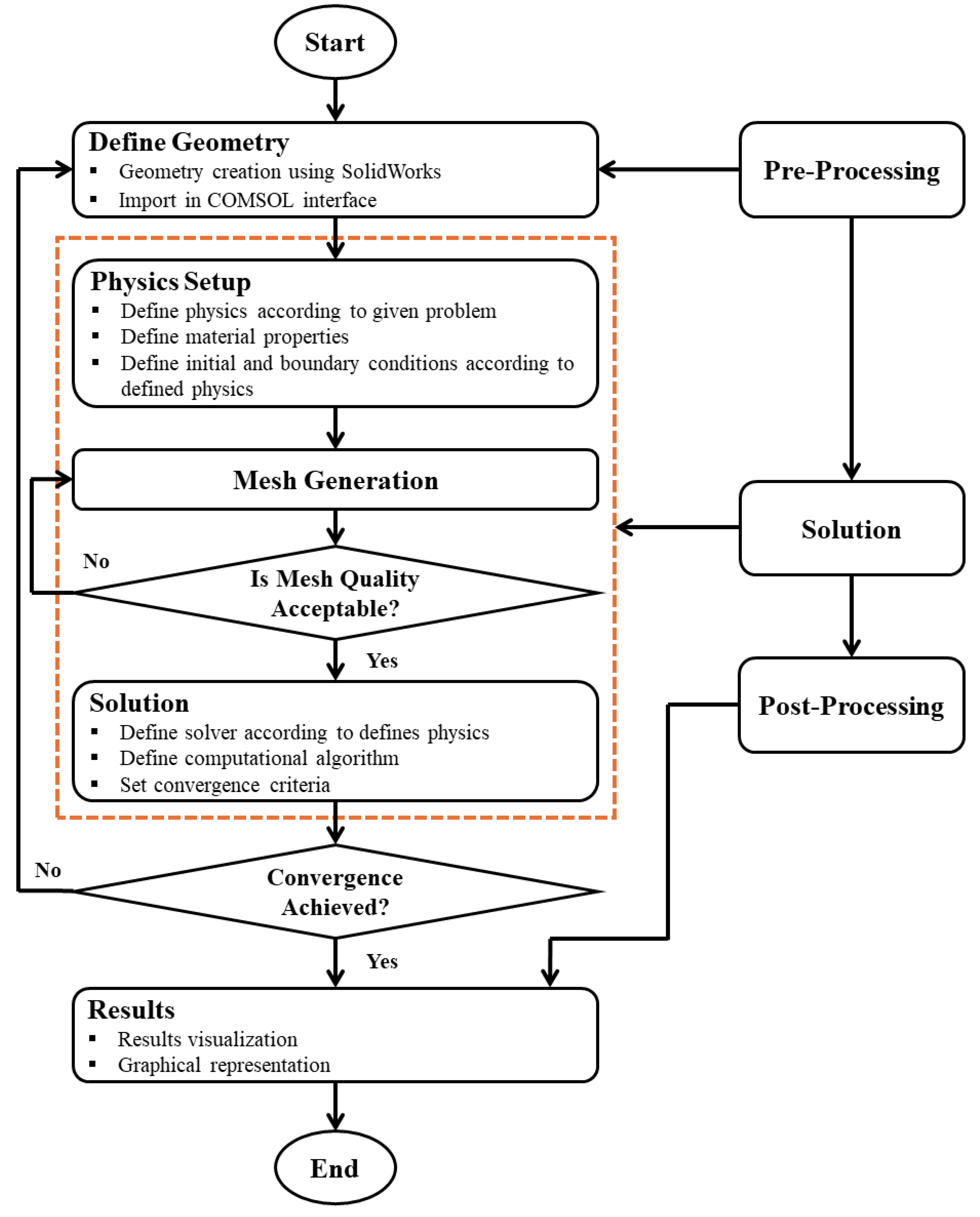

2. Materials and Methods

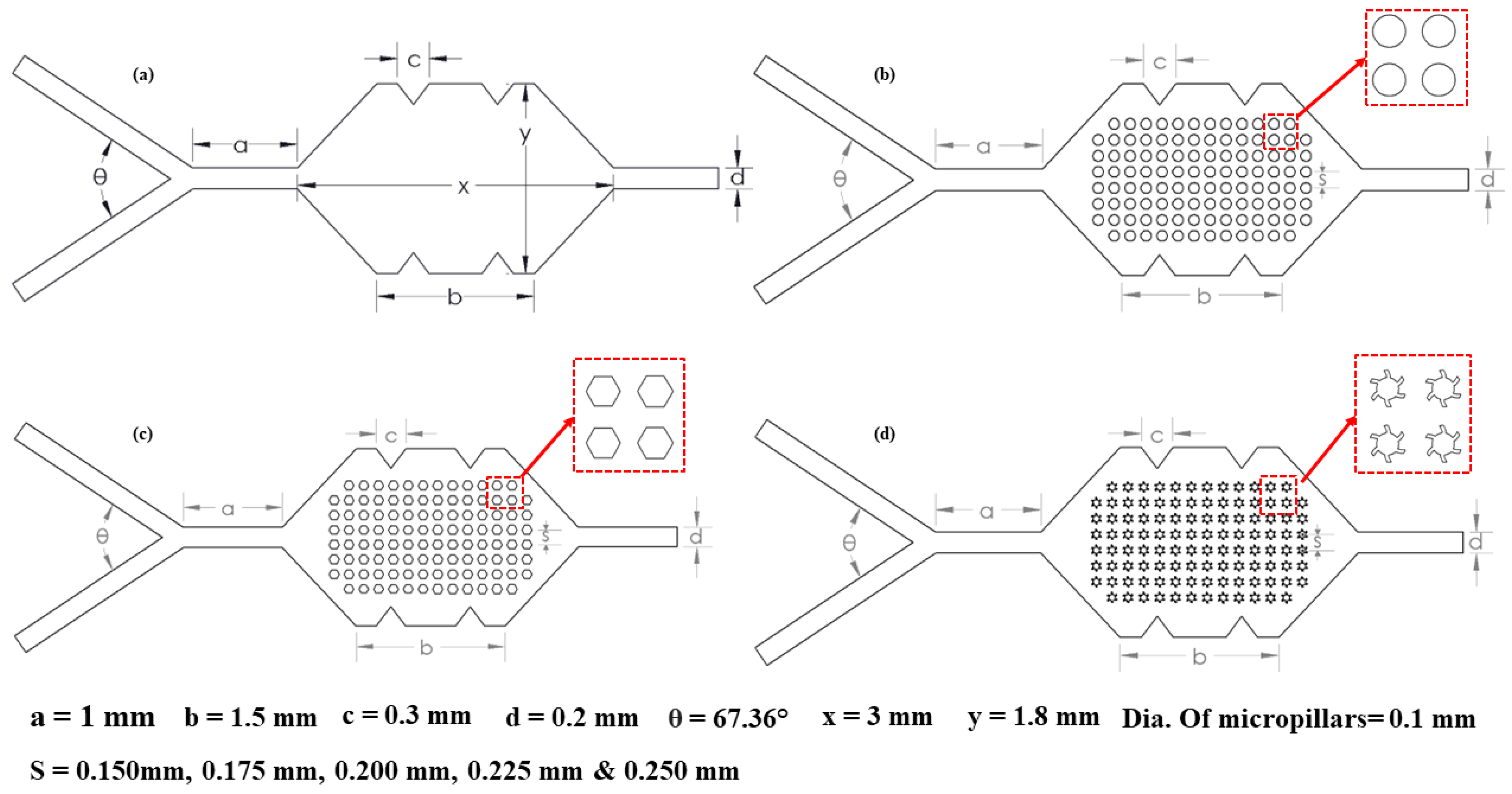

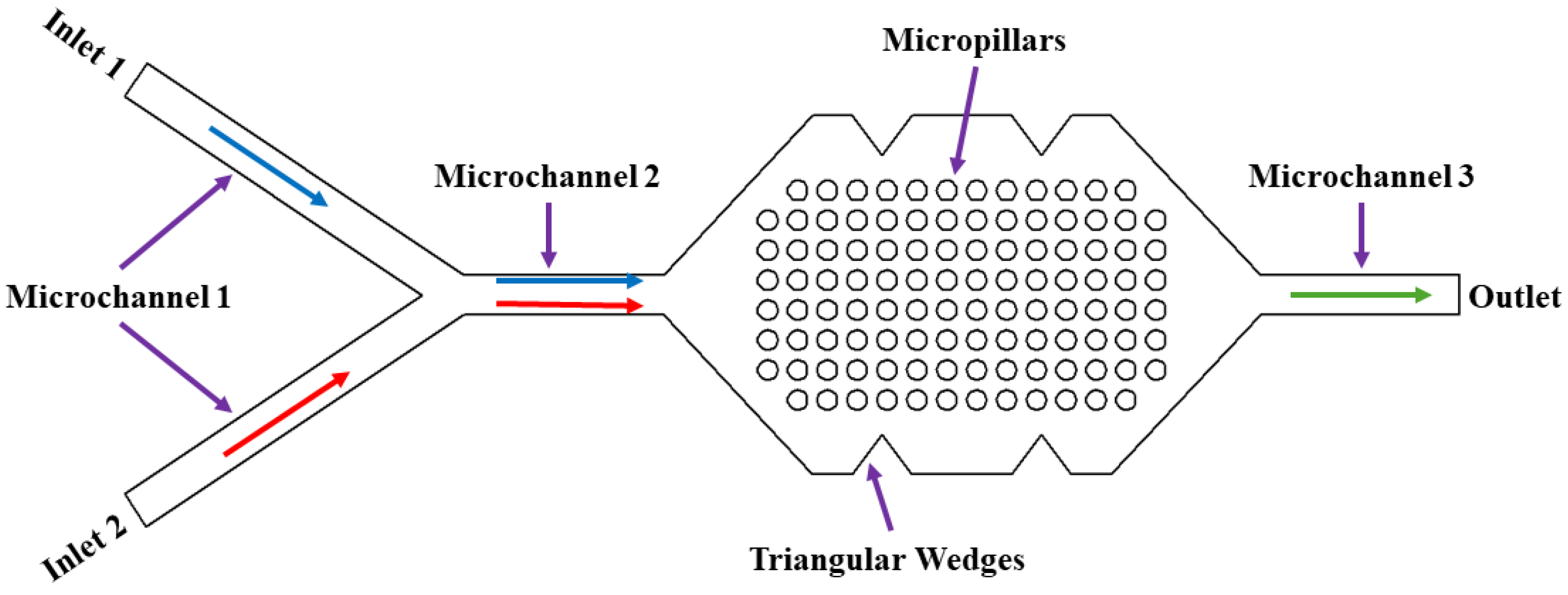

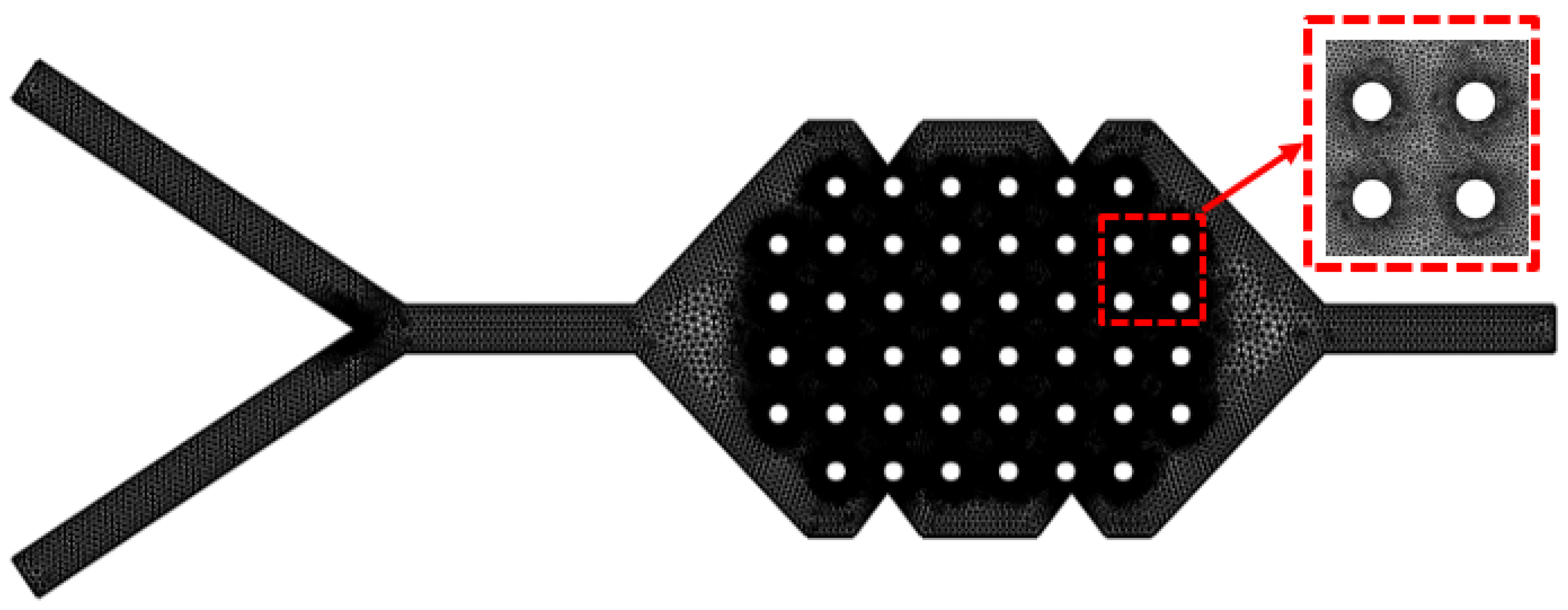

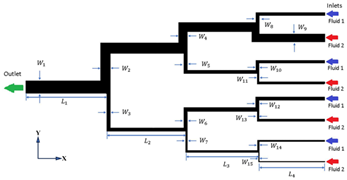

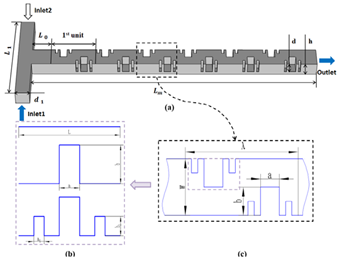

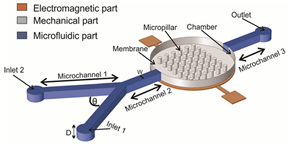

2.1. Micro-Mixer Design and Performance Parameters

2.2. Computational Domain and Meshing

2.3. Mathematical Modeling

2.3.1. Mass and Momentum Conservation

2.3.2. Thermoviscous Acoustic Model

2.3.3. Laminar Model

2.3.4. Transport Diluted Species Model

2.4. Numerical Scheme and Boundary Conditions

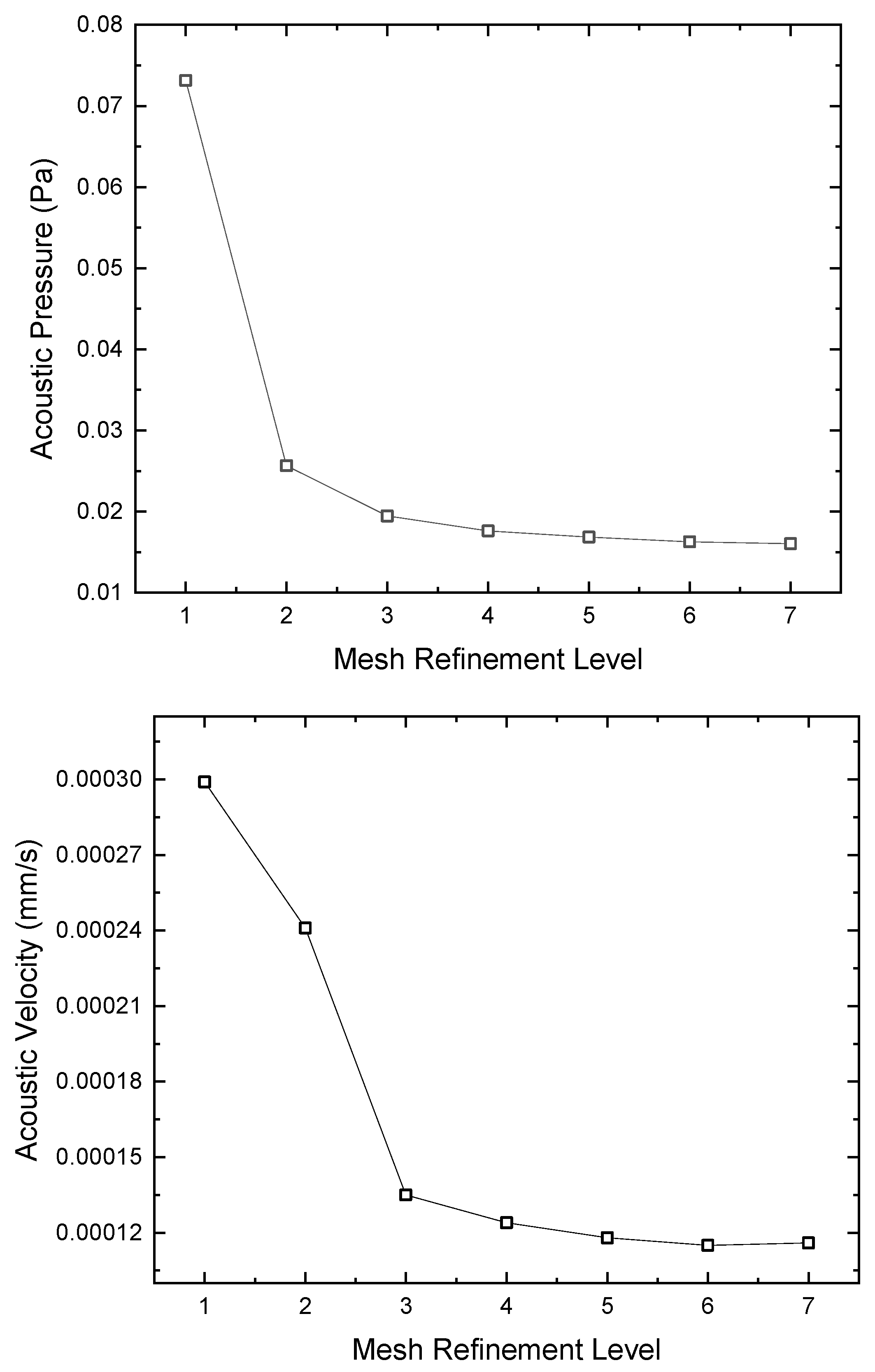

3. Mesh Independence Study

4. Results and Discussion

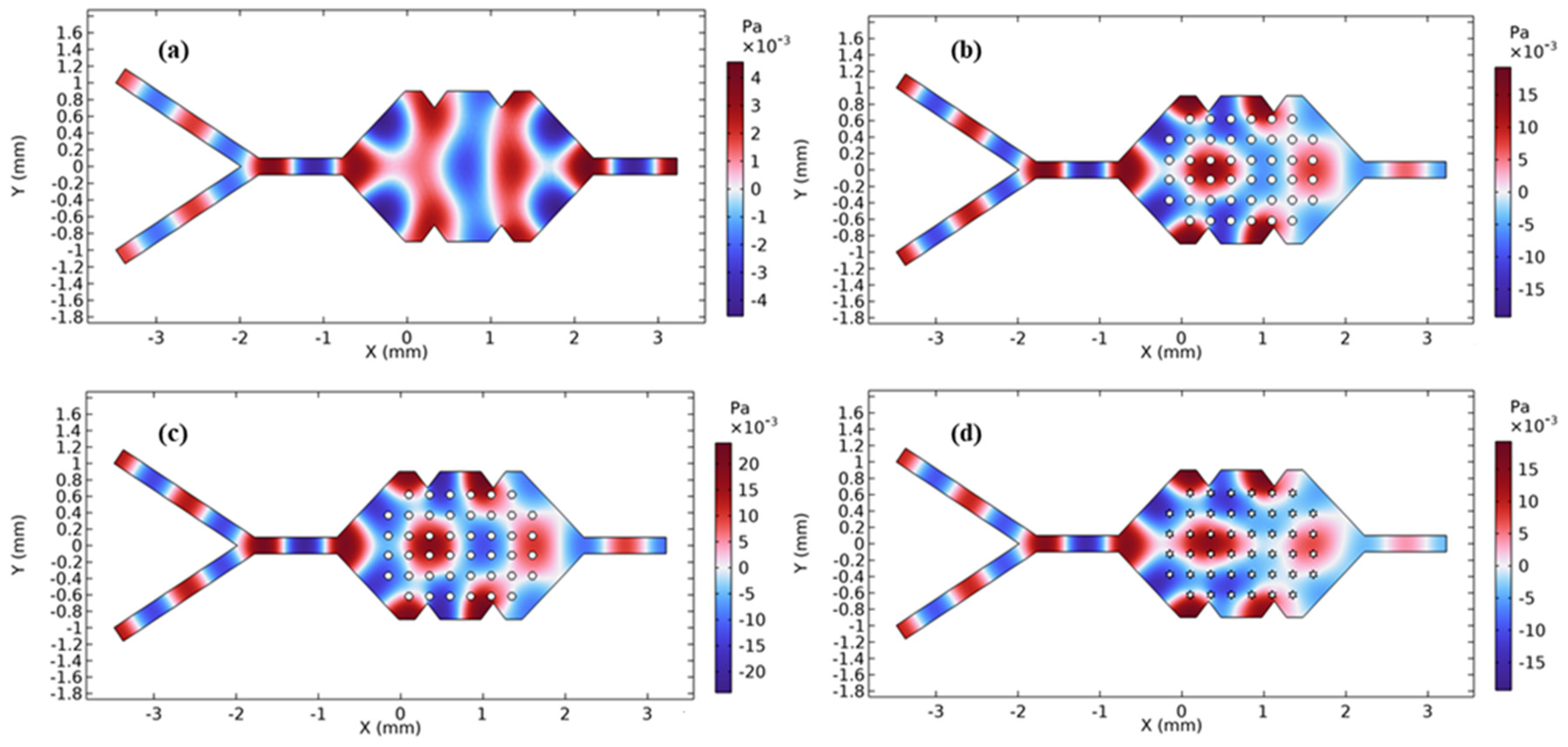

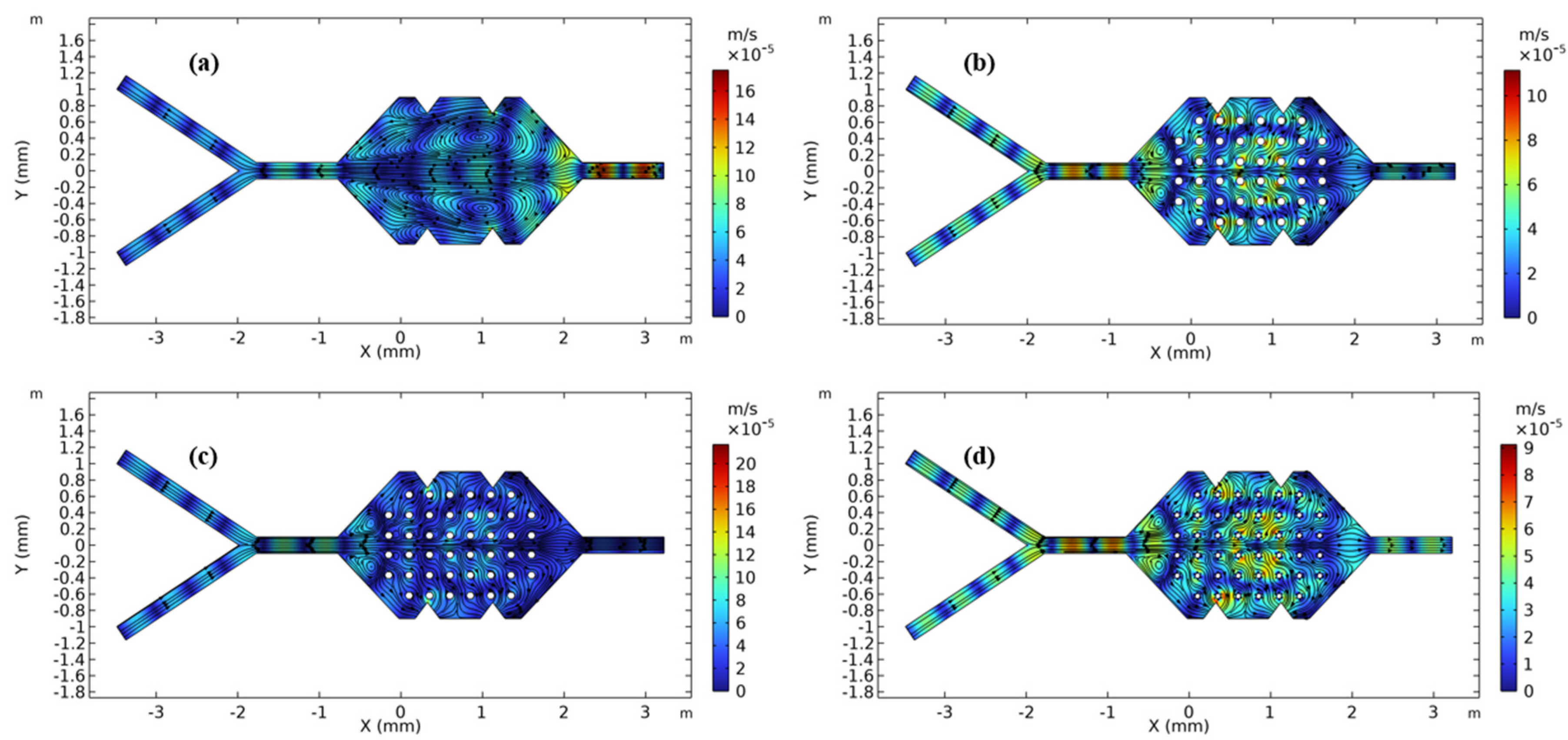

4.1. Acoustic Field

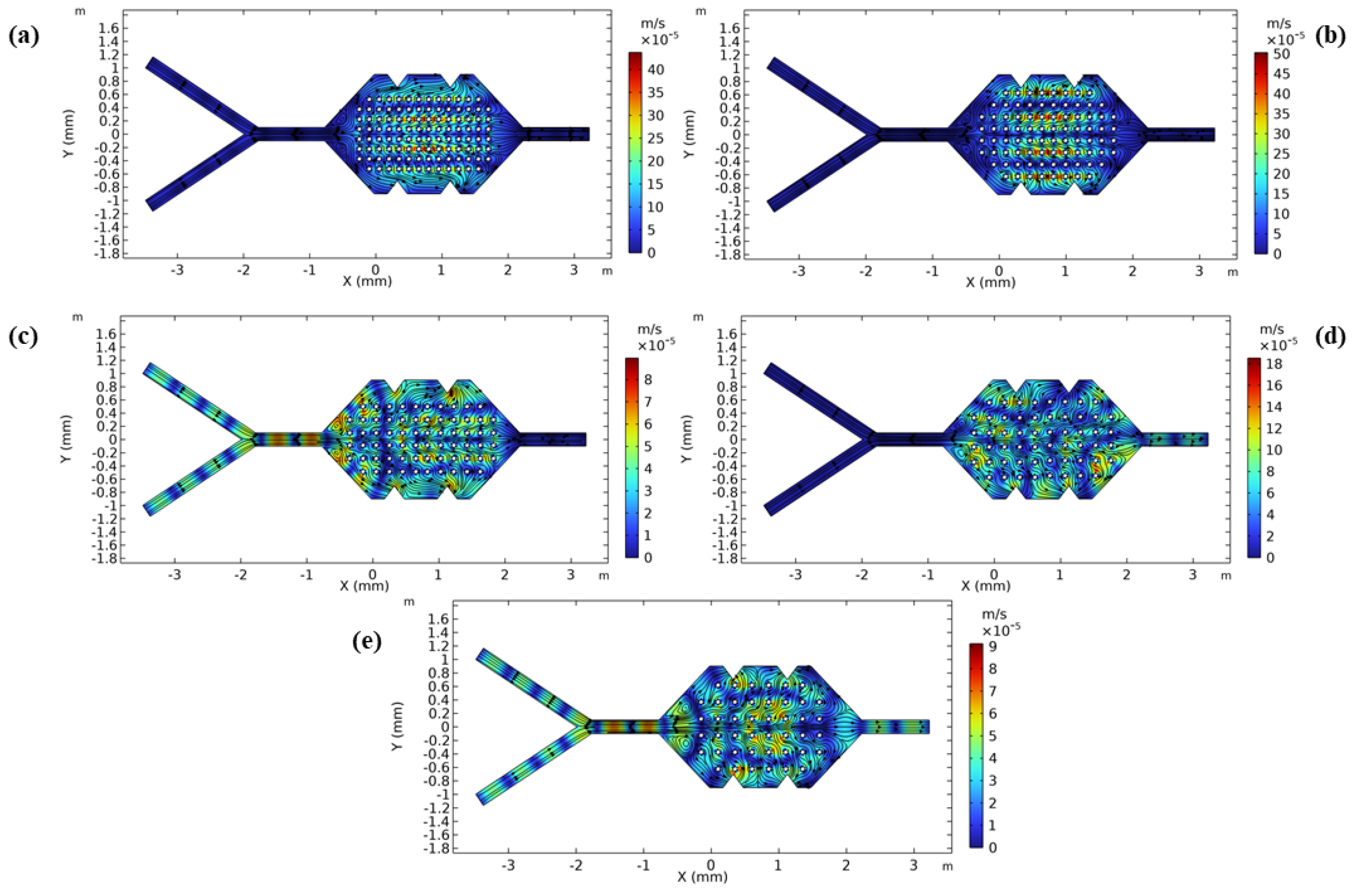

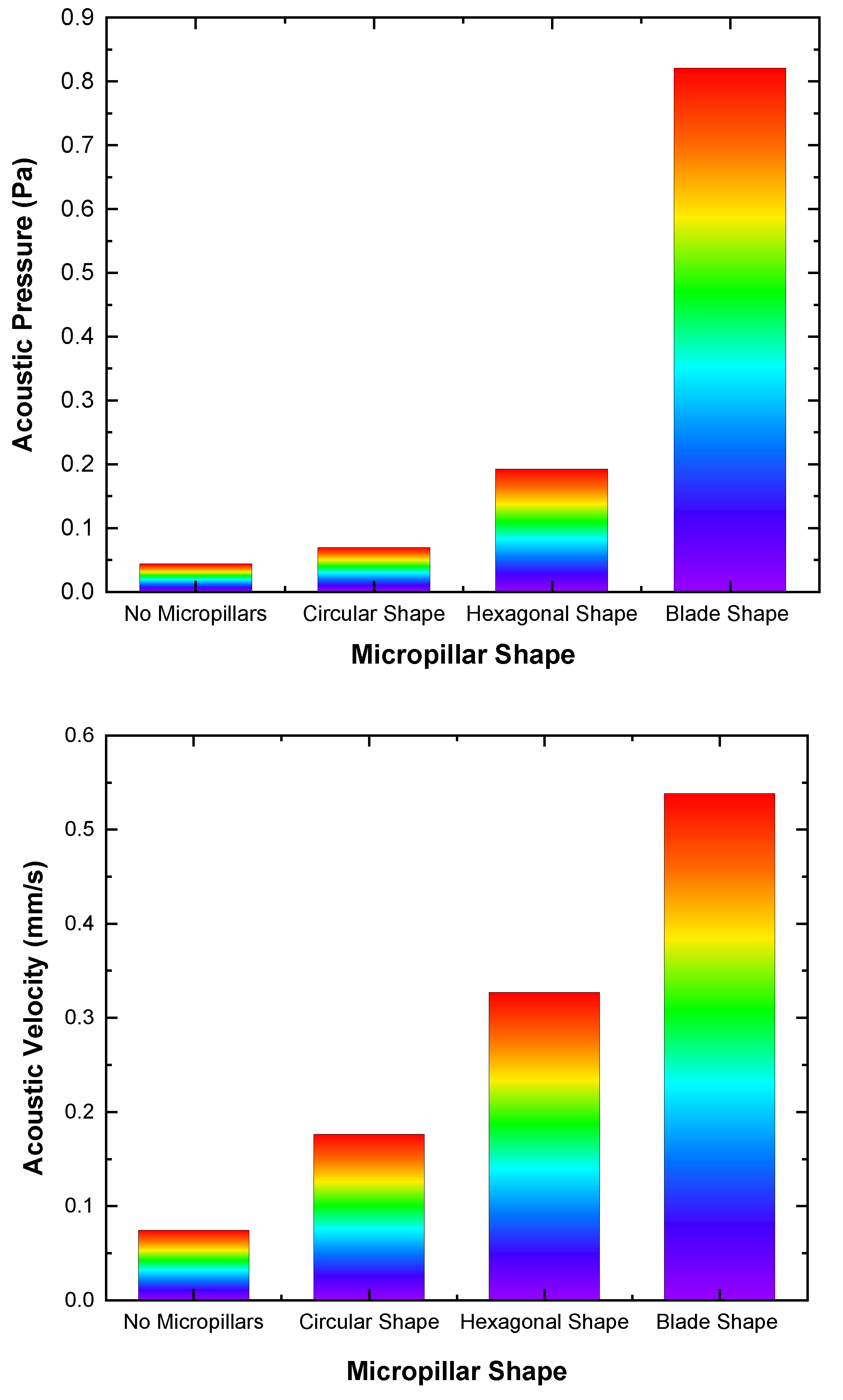

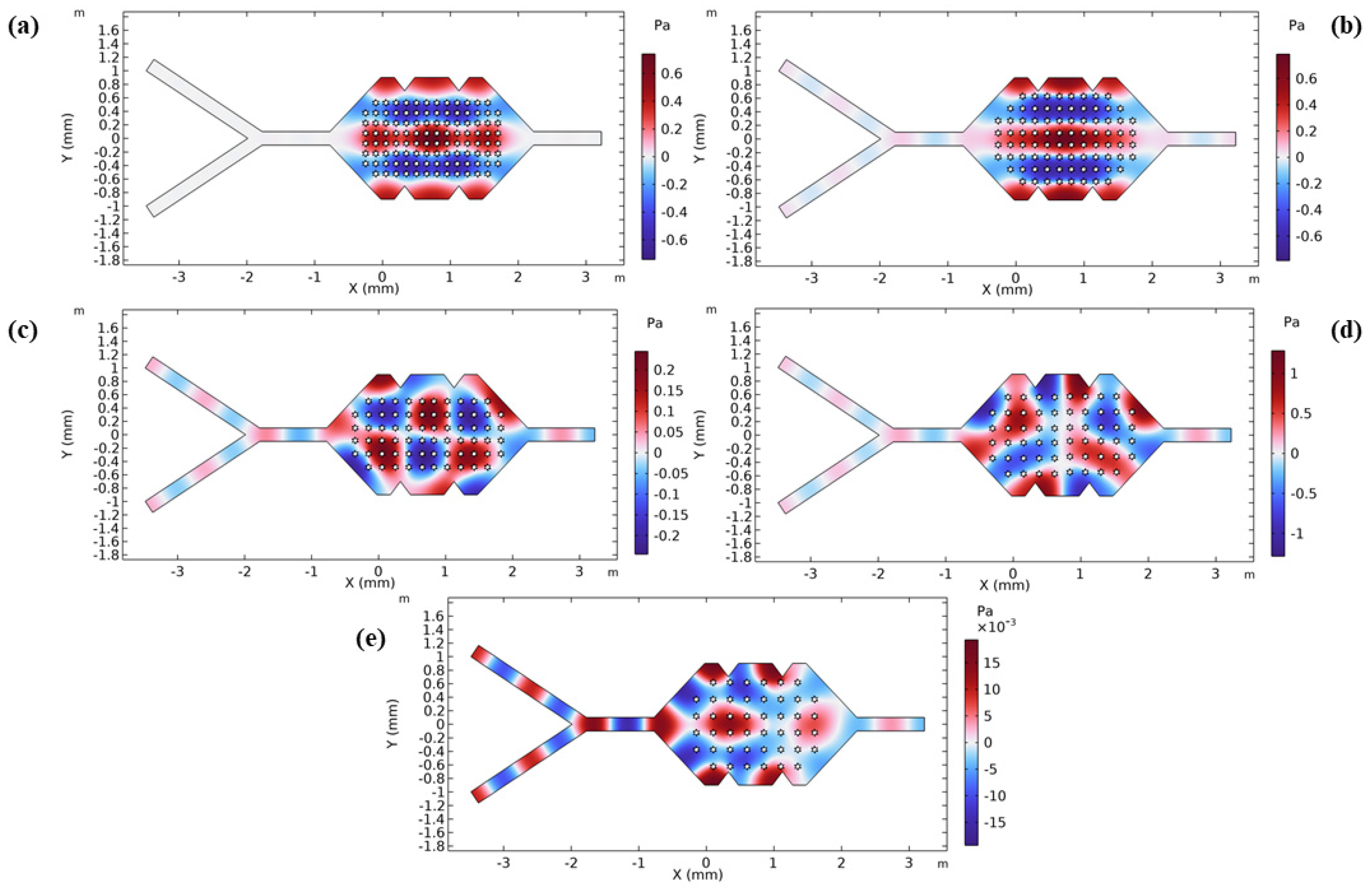

4.1.1. Effect of Micropillar Shapes

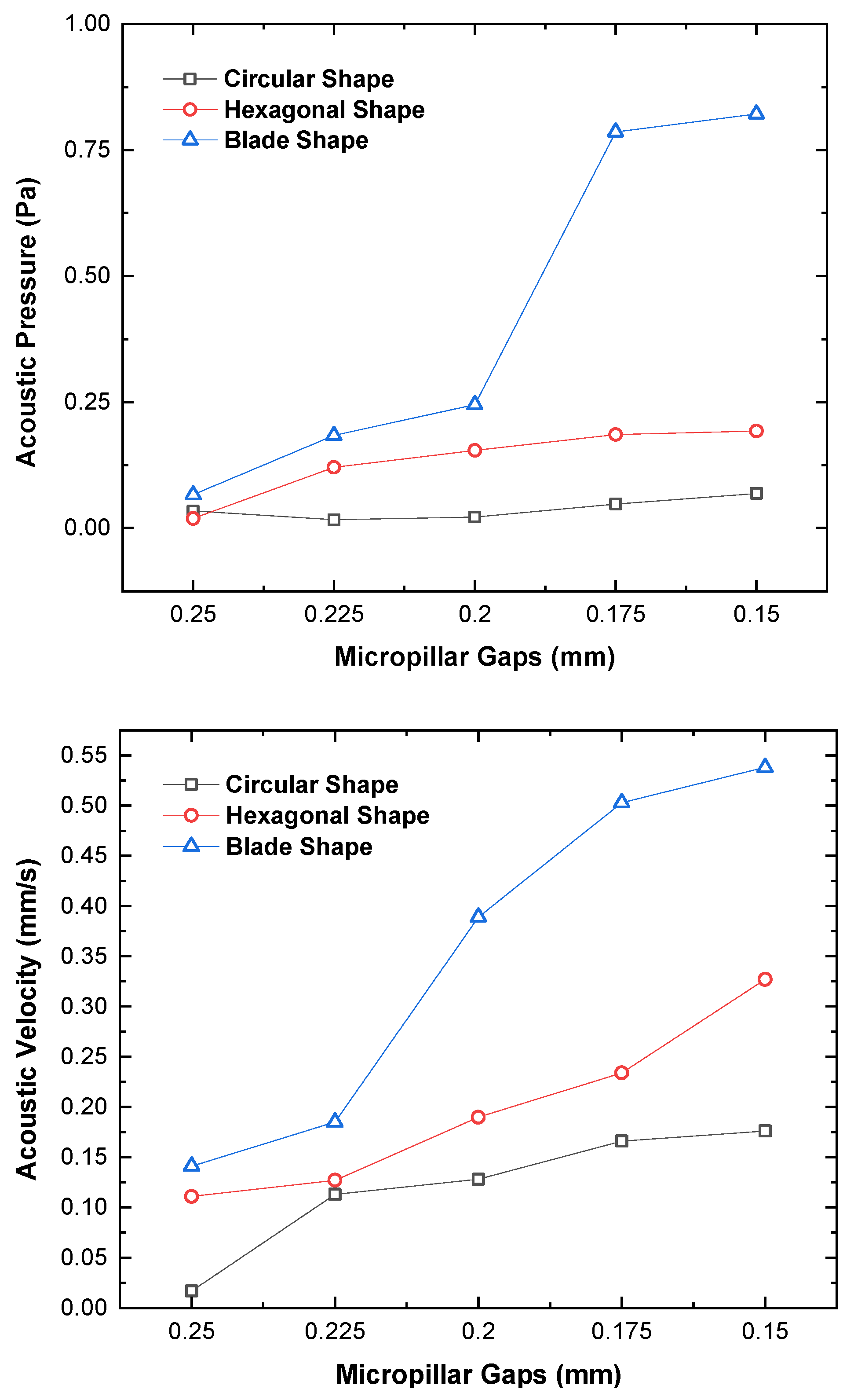

4.1.2. Effect of Micropillars Gaps

4.2. Fluid Mixing

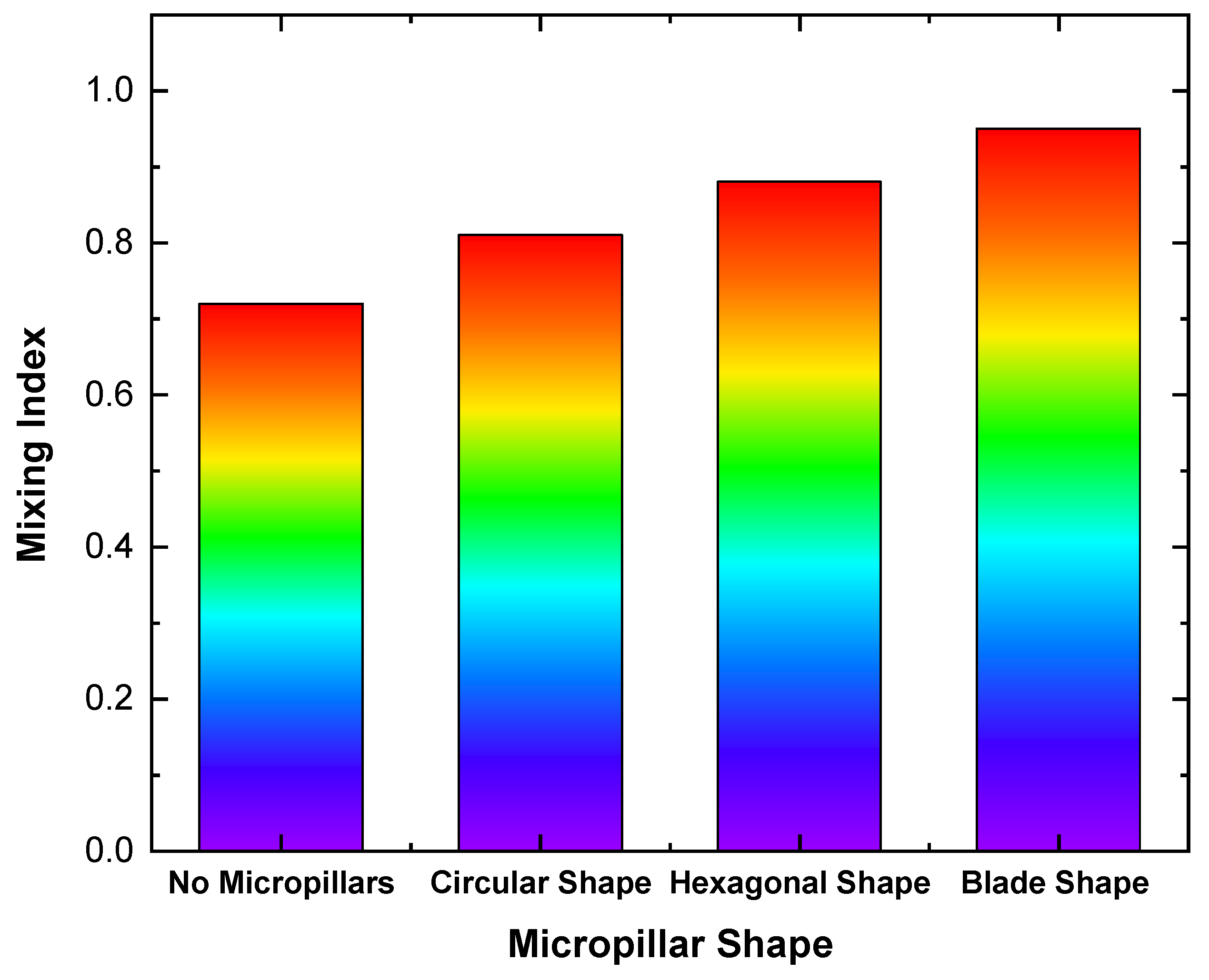

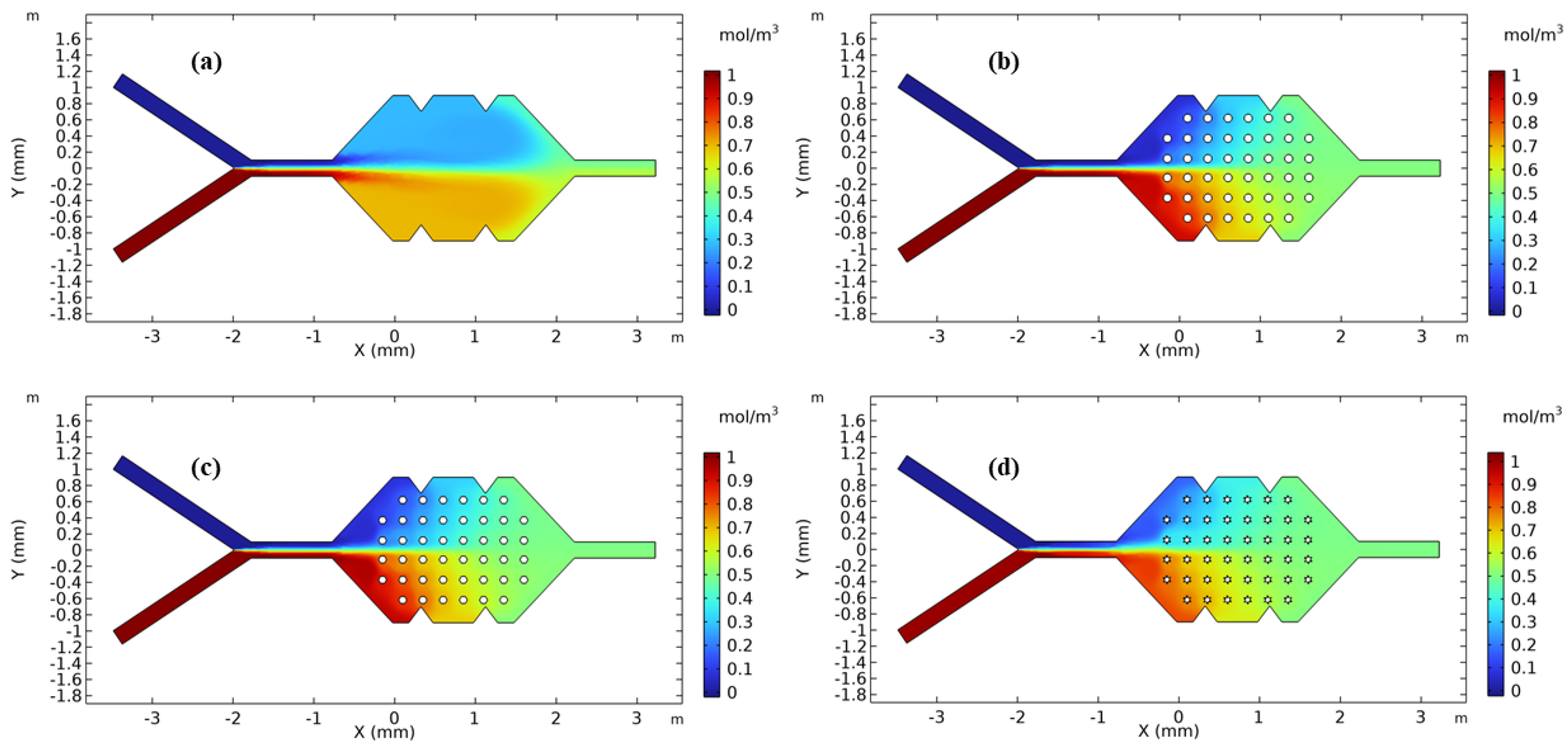

4.2.1. Effect of Micropillar Shapes

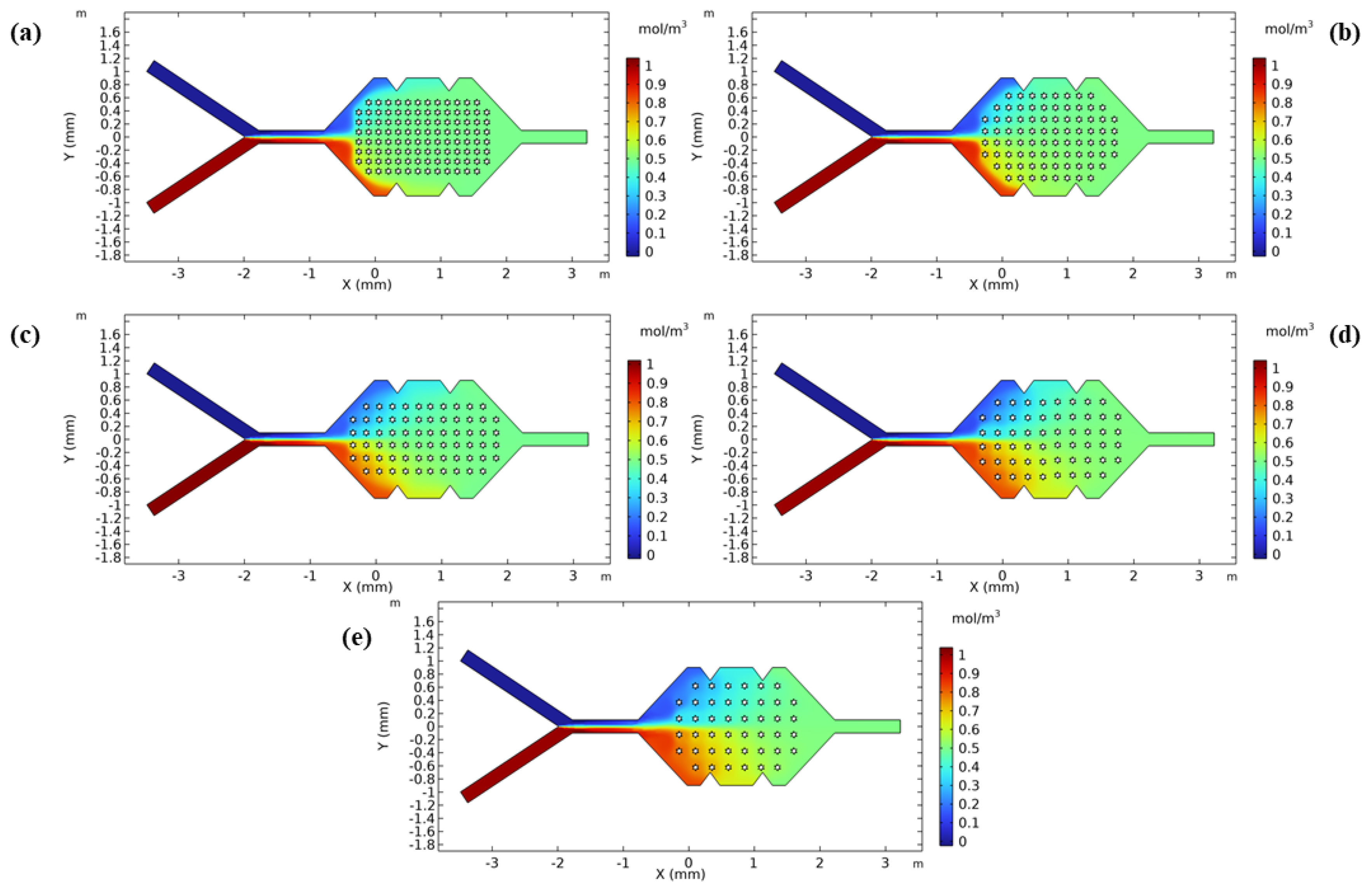

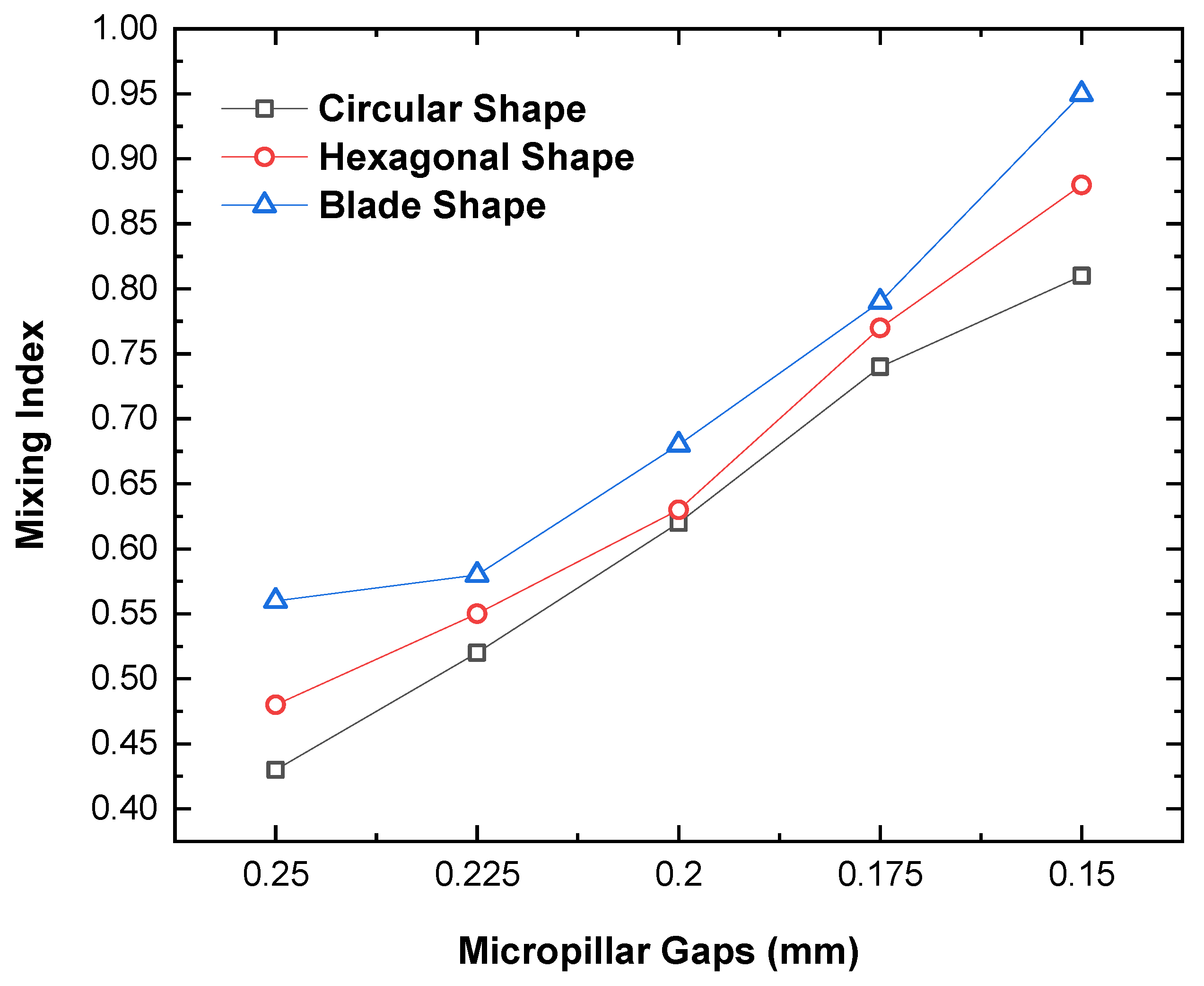

4.2.2. Effect of Micropillar Gaps

5. Conclusions

- The performance of microfluidics micro-mixer is greatly affected by the inclusion of micropillars compared to the case with no micropillars. The presence of micropillars in the microfluidics chamber increases the micro vortices as well as strengthens the acoustic field.

- Similarly, shapes of micropillars are also impacted on flow characteristics as well as mixing performance of microfluidics micro-mixer. Various micropillars shapes such as circular, hexagonal and blade were investigated and compared to the case with no micropillars. The inclusion of blade shape micropillars delivers the best outcomes compared to other shapes.

- The performance of microfluidics micro-mixer was also investigated with different micropillars gaps and found that the mixing performance increased with the decreasing of micropillars gaps. The reason behind this increment in performance is due to larger surface areas and more boundaries to generate higher micro vortices as well as strengthening the acoustic field near the micropillars walls. The maximum performance achieved with micropillar gap of 0.150 mm.

- The maximum and minimum magnitude values of 0.95 and 0.72 of mixing index are achieved respectively with the inclusion of blade shape micropillars and 0.150 mm micropillar gap.

- Based on the current research work, further work is required for the optimization of hybrid microfluidics micro-mixer based on various micropillars arrangements. In addition, acoustic structure analysis with different materials and geometrical parameters is also required to examine the structural stability and structural strength of micropillars.

Author Contributions

Funding

References

- M. Juraeva and D. J. Kang, “Mixing performance of a cross-channel split-and-recombine micro-mixer combined with mixing cell,” Micromachines, vol. 11, no. 7, 2020. [CrossRef]

- T. Wan, B. Wang, Q. Han, J. Chen, B. Li, and S. Wei, “A review of superhydrophobic shape-memory polymers: Preparation, activation, and applications,” Appl. Mater. Today, vol. 29, no. July, p. 101665, 2022. [CrossRef]

- S. Prakash and S. Kumar, “Fabrication of microchannels: A review,” Proc. Inst. Mech. Eng. Part B J. Eng. Manuf., vol. 229, no. 8, pp. 1273–1288, 2015. [CrossRef]

- D. Bahrami, A. A. Nadooshan, and M. Bayareh, “Effect of non-uniform magnetic field on mixing index of a sinusoidal micromixer,” Korean J. Chem. Eng., vol. 39, no. 2, pp. 316–327, 2022. [CrossRef]

- B. Lee et al., “Characterization of passive microfluidic mixer with a three-dimensional zig-zag channel for cryo-EM sampling,” Chem. Eng. Sci., vol. 281, no. May, p. 119161, 2023. [CrossRef]

- E. Tripathi, P. K. Patowari, and S. Pati, “Numerical investigation of mixing performance in spiral micromixers based on Dean flows and chaotic advection,” Chem. Eng. Process. - Process Intensif., vol. 169, no. July, p. 108609, 2021. [CrossRef]

- C. Bai, W. Zhou, S. Yu, T. Zheng, and C. Wang, “A surface acoustic wave-assisted micromixer with active temperature control,” Sensors Actuators A Phys., vol. 346, no. August, p. 113833, 2022. [CrossRef]

- C. Kumar et al., “Modeling of mass transfer enhancement in a magnetofluidic micromixer,” Phys. Fluids, vol. 31, no. 6, 2019. [CrossRef]

- M. Rahimi, B. Aghel, B. Hatamifar, M. Akbari, and A. A. Alsairafi, “CFD modeling of mixing intensification assisted with ultrasound wave in a T-type microreactor,” Chem. Eng. Process. Process Intensif., vol. 86, pp. 36–46, 2014. [CrossRef]

- H. Jalili, M. Raad, and D. A. Fallah, “Numerical study on the mixing quality of an electroosmotic micromixer under periodic potential,” Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci., vol. 234, no. 11, pp. 2113–2125, 2020. [CrossRef]

- Y. Gong and X. Cheng, “Numerical investigation of electroosmotic mixing in a contraction–expansion microchannel,” Chem. Eng. Process. - Process Intensif., vol. 192, no. February, p. 109492, 2023. [CrossRef]

- S. Xiong, X. Chen, H. Chen, Y. Chen, and W. Zhang, “Numerical study on an electroosmotic micromixer with rhombic structure,” J. Dispers. Sci. Technol., vol. 42, no. 9, pp. 1331–1337, 2021. [CrossRef]

- B. Mondal, S. K. Mehta, S. Pati, and P. K. Patowari, “Numerical analysis of electroosmotic mixing in a heterogeneous charged micromixer with obstacles,” Chem. Eng. Process. - Process Intensif., vol. 168, no. July, p. 108585, 2021. [CrossRef]

- K. N. Vasista, S. K. Mehta, and S. Pati, “Electroosmotic mixing in a microchannel with heterogeneous slip dependent zeta potential,” Chem. Eng. Process. - Process Intensif., vol. 176, no. April, p. 108940, 2022. [CrossRef]

- L. Tata Rao, S. Goel, S. Kumar Dubey, and A. Javed, “Performance Investigation of T-Shaped Micromixer with Different Obstacles,” J. Phys. Conf. Ser., vol. 1276, no. 1, 2019. [CrossRef]

- A. Farahinia and W. J. Zhang, “Numerical investigation into the mixing performance of micro T-mixers with different patterns of obstacles,” J. Brazilian Soc. Mech. Sci. Eng., vol. 41, no. 11, 2019. [CrossRef]

- A. Xia et al., “Numerical and Experimental Investigation on a ‘Tai Chi’-Shaped Planar Passive Micromixer,” Micromachines, vol. 14, no. 7, 2023. [CrossRef]

- Y. Jiang and Y. Zhang, “High performance micromixers by 3D printing based on split-and-recombine modules and twisted-architecture microchannel,” Proc. 5th Int. Conf. Intell. Hum. Syst. Integr. (IHSI 2022) Integr. People Intell. Syst. Febr. 22–24, 2022, Venice, Italy, vol. 22, no. Ihsi 2022, 2022. [CrossRef]

- Z. Wang, X. Yan, Q. Zhou, Q. Wang, D. Zhao, and H. Wu, “A Directly Moldable, Highly Compact, and Easy-for-Integration 3D Micromixer with Extraordinary Mixing Performance,” Anal. Chem., vol. 95, no. 23, pp. 8850–8858, 2023. [CrossRef]

- Y. Shao et al., “Cross-channel microfluidic device for dynamic control of concentration and velocity by the electroosmotic drive,” Chem. Eng. Sci., vol. 281, no. July, p. 119139, 2023. [CrossRef]

- K. Ward and Z. H. Fan, “Mixing in microfluidic devices and enhancement methods,” J. Micromechanics Microengineering, vol. 25, no. 9, 2015. [CrossRef]

- J. B. You et al., “PDMS-based turbulent microfluidic mixer,” Lab Chip, vol. 15, no. 7, pp. 1727–1735, 2015. [CrossRef]

- X. Chen and H. Lv, “New insights into the micromixer with Cantor fractal obstacles through genetic algorithm,” Sci. Rep., vol. 12, no. 1, pp. 1–17, 2022. [CrossRef]

- M. Xiong, J. Yang, X. Ding, H. Li, and H. Zhang, “Topology optimization design of micromixer based on principle of Tesla valve: An experimental and numerical study,” Chem. Eng. Process. - Process Intensif., vol. 193, no. August, p. 109560, 2023. [CrossRef]

- Z. Chen, Z. Pei, X. Zhao, J. Zhang, J. Wei, and N. Hao, “Acoustic microreactors for chemical engineering,” Chem. Eng. J., vol. 433, no. P2, p. 133258, 2022. [CrossRef]

- H. Ahmed, J. Park, G. Destgeer, M. Afzal, and H. J. Sung, “Surface acoustic wave-based micromixing enhancement using a single interdigital transducer,” Appl. Phys. Lett., vol. 114, no. 4, 2019. [CrossRef]

- H. Lim, S. M. Back, H. Choi, and J. Nam, “Acoustic mixing in a dome-shaped chamber-based SAW (DC-SAW) device,” Lab Chip, vol. 20, no. 1, pp. 120–125, 2020. [CrossRef]

- X. Li, J. Huffman, N. Ranganathan, Z. He, and P. Li, “Acoustofluidic enzyme-linked immunosorbent assay (ELISA) platform enabled by coupled acoustic streaming,” Anal. Chim. Acta, vol. 1079, pp. 129–138, 2019. [CrossRef]

- “Microfluidic Mixing,” SpringerReference, no. 2, pp. 1–13, 2011. [CrossRef]

- G. Gharib et al., “Biomedical Applications of Microfluidic Devices: A Review,” Biosensors, vol. 12, no. 11, 2022. [CrossRef]

- Francesko, V. F. Cardoso, and S. Lanceros-Méndez, Lab-on-a-chip technology and microfluidics. 2019. [CrossRef]

- M. A. Khan, M. Suhaib, and M. A. Ansari, “Investigations on fluid flow and mixing in fractal tree like biomimetic microchannel based on Murray’s law,” Chem. Eng. Process. - Process Intensif., vol. 194, no. October, p. 109564, 2023. [CrossRef]

- F. Liu et al., “An inverted micro-mixer based on a magnetically-actuated cilium made of Fe doped PDMS,” Smart Mater. Struct., vol. 25, no. 9, 2016. [CrossRef]

- W. Kim, B. Cha, J. S. Jeon, and J. Park, “Acoustofluidic control of chemical concentration within picoliter droplets in a disposable microfluidic chip,” Sensors Actuators B Chem., vol. 393, no. January, p. 134132, 2023. [CrossRef]

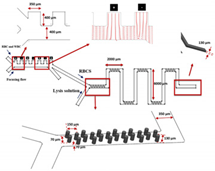

- E. Jalilvand, A. Shamloo, and M. H. Gangaraj, “Computational study of an integrated microfluidic device for active separation of RBCs and cell lysis,” Chem. Eng. Process. - Process Intensif., vol. 174, no. March, p. 108891, 2022. [CrossRef]

- R. E. Pawinanto, J. Yunas, and A. M. Hashim, “Design optimization of active microfluidic mixer incorporating micropillar on flexible membrane,” Microsyst. Technol., vol. 25, no. 4, pp. 1203–1209, 2019. [CrossRef]

- H. Bruus, “Acoustofluidics 1: Governing equations in microfluidics,” Lab Chip, vol. 11, no. 22, pp. 3742–3751, 2011. [CrossRef]

- H. Bruus, Theoretical Microfluidics, no. January 2008. 1997. [CrossRef]

- H. Bruus, “Governing equations in microfluidics,” pp. 1–28. [CrossRef]

- “Chapter 18. Theory,” vol. 0, pp. 1–52, 2002, [Online]. Available: http://www.ce.utexas.edu/prof/Novoselac/classes/ARE372/handouts/CFD_theory.pdf.

- J.M. Ottino, The Kinematics of Mixing: Stretching, Chaos and Transport, in: Cambridge Texts in Applied Mathematics, Cambridge University Press, 2004. [Online]. Available: https://books.google.lt/books?id=8OLVcbRoNSgC&lpg=PP1&hl=lt&pg=PP1#v=onepage&q&f=false.

- Barman and A. Bandopadhyay, “Mixing intensification in an acoustofluidic micromixer aided with micro-pillars,” Chem. Eng. Process. - Process Intensif., vol. 194, no. November, p. 109604, 2023. [CrossRef]

| Year | Goal | Microchannel Type | Microfluidic Type | Microchannel Design | References |

|---|---|---|---|---|---|

| 2023 | Development and characterization of 3D zig-zag microchannel. | 3D Zig-Zag microchannel | Passive |  |

[5] |

| 2023 | Investigate impact of geometrical parameters and applied voltage on fluid mixing and fluid flow behavior experimentally and numerically. | Cross channel | Active |  |

[20] |

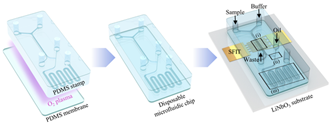

| 2023 | Introduced acoustic fluid approach to control chemical concentration within picolitre droplet in disposable microfluidic chip. | T-Shape | Hybrid (Active & Passive) |  |

[34] |

| 2023 | Investigation of fluid flow mixing in fractal tree. | Fractal Tree | Passive |  |

[32] |

| 2023 | Topology optimization of micromixers based on tesla principle valve. | Tesla based shape | Passive |  |

[24] |

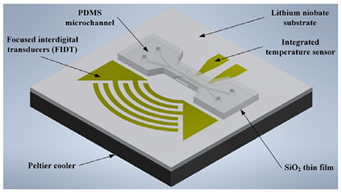

| 2022 | Development and analysis of microfluidics system with thermal control unit to reduce thermal affect due to acoustic actuation. | Double Y-Shape | Active |  |

[7] |

| 2022 | Introduced novel type microfluidic microchannel design for sequential RBC’s separation and lysis. | Y-Shape and Zig-Zag Shape | Passive |  |

[35] |

| 2022 | Investigation of different operational parameters by combining fractal principle with multi objective genetic algorithm and multi objective optimization of cantor fractal baffle micromixers. | Cantor fractal baffle shape micromixers | Passive |  |

[23] |

| 2019 | Design and optimization of active based microchannel incorporated with Micropillars. | Microchannel with Micropillars | Hybrid (Active & Passive) |  |

[36] |

| Properties | Water | Ethanol |

| Viscous dynamic viscosity | 890 µPas | 1200 µPas |

| Specific heat capacity | 4180 J/kg·K | 2570 J/kg·K |

| Density | 997 kg/m3 | 789 kg/m3 |

| Speed of sound | 1497 m/s | 1144 m/s |

| Compressibility | 4.47 × 10−10 1/Pa | 1.1 × 10−9 1/Pa |

| Specific heat capacity ratio | 1.012 | 1.13 |

| Thermal conductivity | 0.61 W/m·K | 0.614 W/m·K |

| Thermal expansion coefficient | 2.74 × 10−4 1/K | 1.09 × 10−3 1/K |

| Thermal diffusivity | 1.464 × 10−7 m2/s | 7 × 10−8 m2/s |

| Bulk dynamic viscosity | 2.47 mPas | 1.2 mPas |

| Mesh Refinement Level | Number of Elements | Number of nodes | Acoustic Pressure (Pmax) | Acoustic Velocity (Vmax) |

| 1 | 5616 | 3769 | 0.07314 | 0.000299 |

| 2 | 10080 | 6421 | 0.02564 | 0.000241 |

| 3 | 14592 | 9121 | 0.01944 | 0.000208 |

| 4 | 27332 | 16371 | 0.01761 | 0.000154 |

| 5 | 30012 | 17821 | 0.01685 | 0.000124 |

| 6 | 41856 | 24287 | 0.01626 | 0.000115 |

| 7 | 48062 | 27876 | 0.01605 | 0.000119 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).