Submitted:

17 April 2024

Posted:

18 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methodology

2.1. Materials

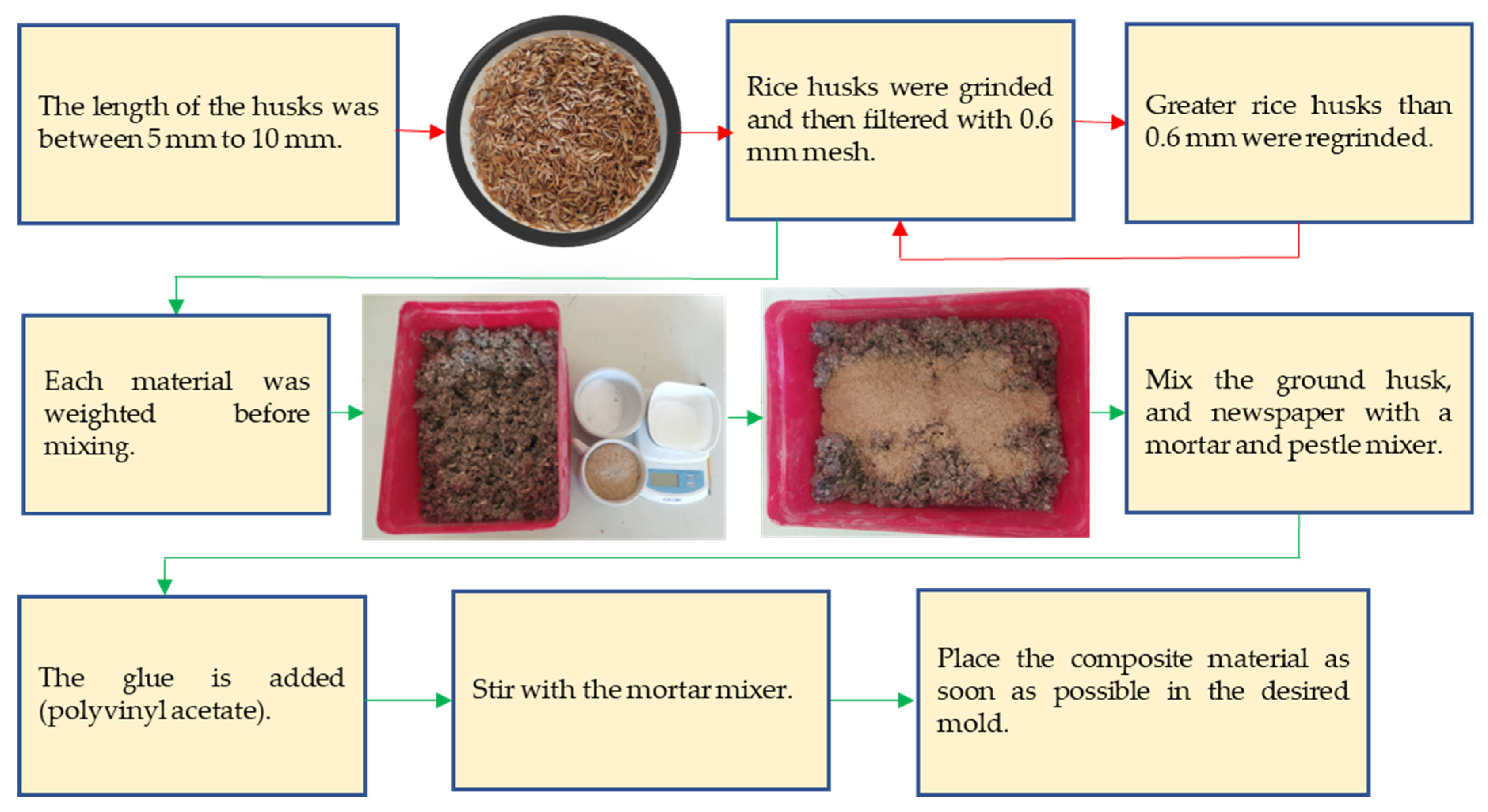

2.2. Methodology for Composite Samples

2.3. Water Absorption

- Mh = mass of the sample after exposure to moisture.

- Ms = mass of the dry sample

2.4. Density Test

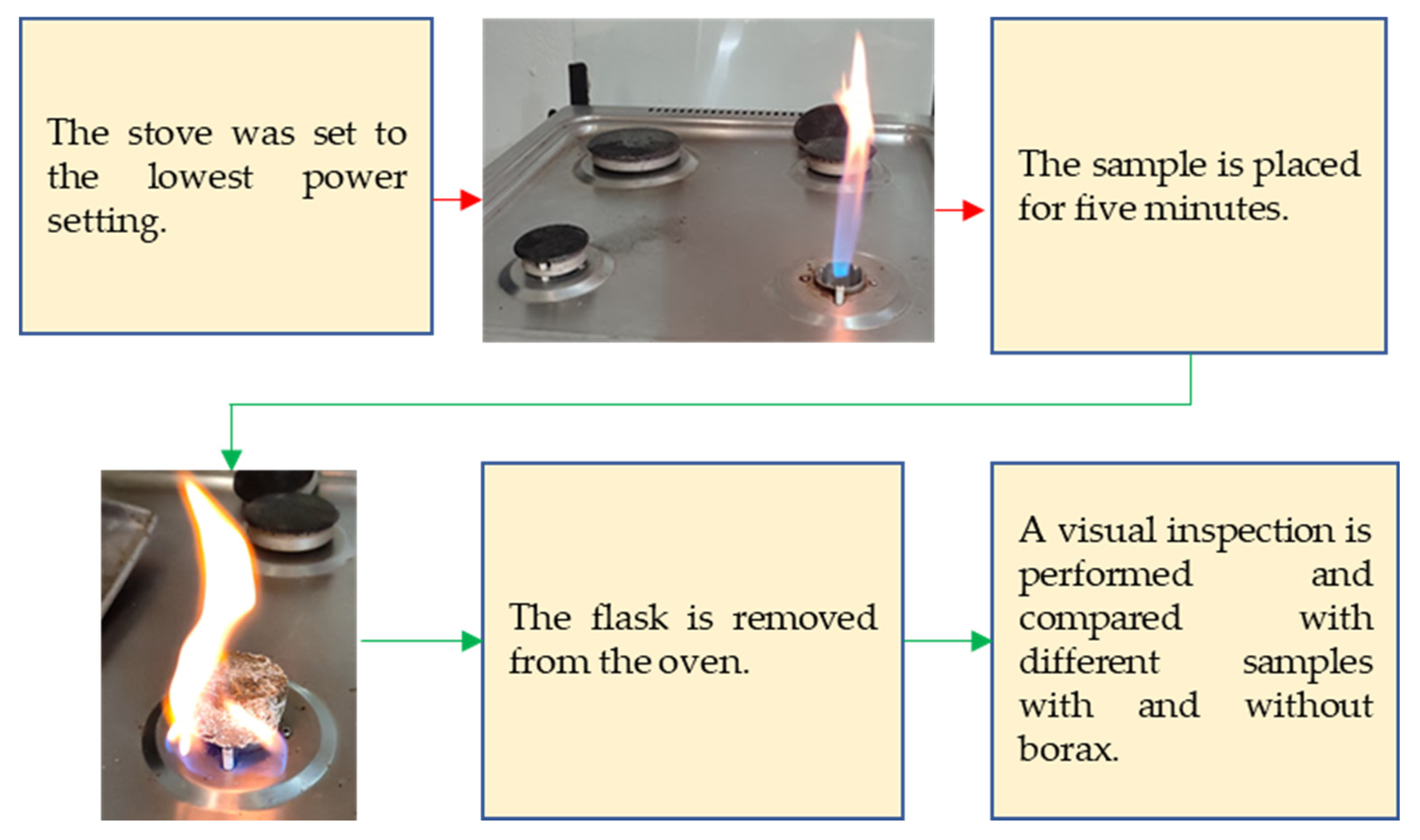

2.5. Flammability Test

2.6. Fungi Growth Test

3. Results and Discussion

3.1. Water Absorption

3.2. Density Test

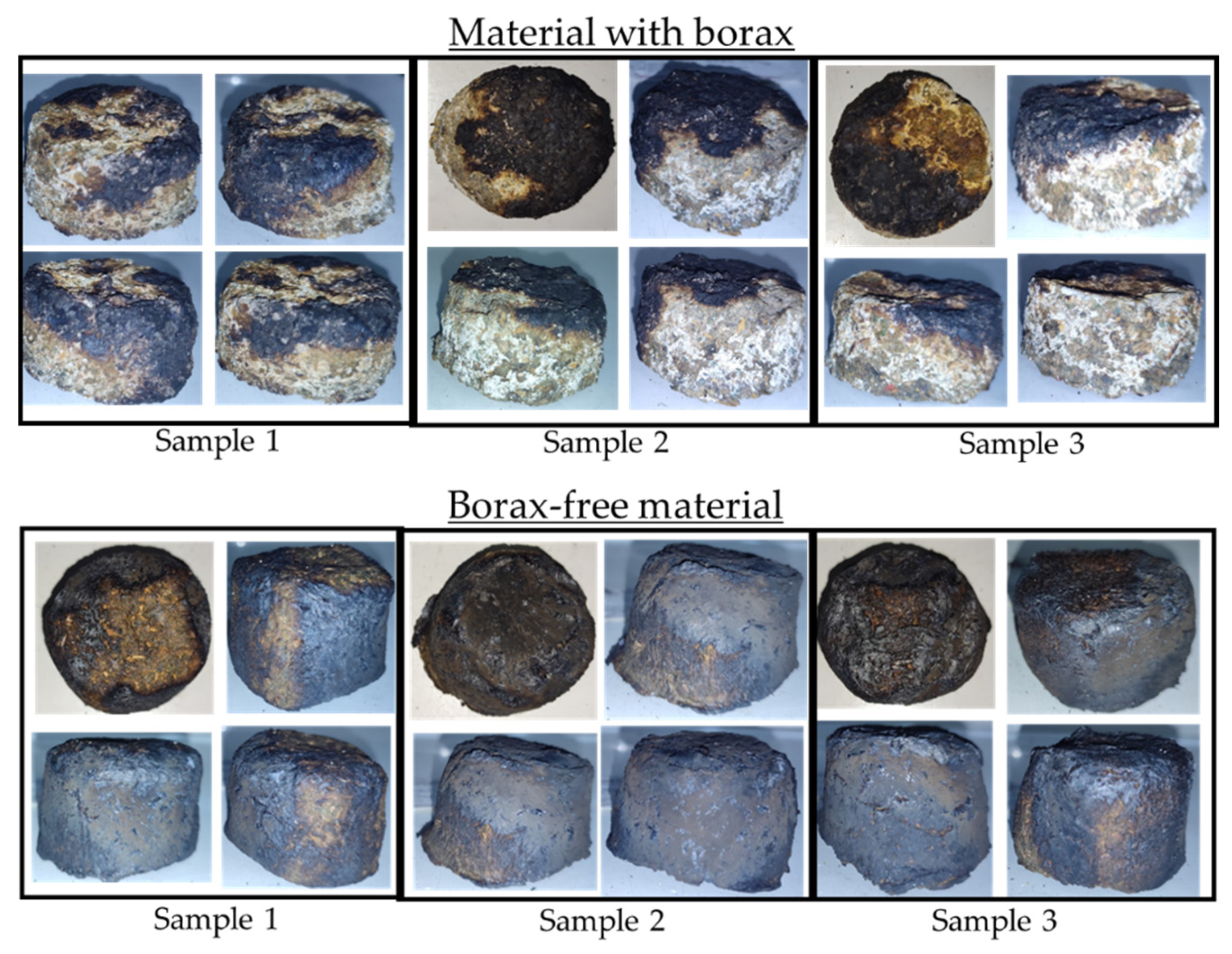

3.3. Flammability Test

3.4. Fungi Growth Test

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Plant Fibre Based Bio-Composites: Sustainable and Renewable Green Materials. Renewable and Sustainable Energy Reviews 2017, 79, 558–584. [CrossRef]

- Takagi, H. Review of Functional Properties of Natural Fiber-Reinforced Polymer Composites: Thermal Insulation, Biodegradation and Vibration Damping Properties. Advanced Composite Materials 2019, 28, 525–543. [CrossRef]

- Ben Hadj Tahar, D.; Triki, Z.; Guendouz, M.; Tahraoui, H.; Zamouche, M.; Kebir, M.; Zhang, J.; Amrane, A. Characterization and Thermal Evaluation of a Novel Bio-Based Natural Insulation Material from Posidonia Oceanica Waste: A Sustainable Solution for Building Insulation in Algeria. ChemEngineering 2024, 8, 18. [CrossRef]

- Pop, M.A.; Croitoru, C.; Matei, S.; Zaharia, S.-M.; Coșniță, M.; Spîrchez, C. Thermal and Sound Insulation Properties of Organic Biocomposite Mixtures. Polymers (Basel) 2024, 16, 672. [CrossRef]

- Cengel, Y.A.; Ghajar, A.J. Heat and Mass Transfer: Fundamentals and Applications; 6th ed.; McGraw-Hill Professional: New York, 2020;

- Bergman, T.L.; Lavine, A.S.; Incropera, F.P.; DeWitt, D.P. Introduction to Heat Transfer; John Wiley & Sons, 2011; ISBN 0470501960.

- Quintaliani, C.; Merli, F.; Fiorini, C.V.; Corradi, M.; Speranzini, E.; Buratti, C. Vegetal Fiber Additives in Mortars: Experimental Characterization of Thermal and Acoustic Properties. Sustainability 2022, 14, 1260. [CrossRef]

- Sharif Hossain, A.B.M.; Ibrahim, N.A.; AlEissa, M.S. Nano-Cellulose Derived Bioplastic Biomaterial Data for Vehicle Bio-Bumper from Banana Peel Waste Biomass. Data Brief 2016, 8, 286–294. [CrossRef]

- Palumbo, M.; Lacasta, A.M.; Navarro, A.; Giraldo, M.P.; Lesar, B. Improvement of Fire Reaction and Mould Growth Resistance of a New Bio-Based Thermal Insulation Material. Constr Build Mater 2017, 139, 531–539. [CrossRef]

- Almalkawi, A.T.; Soroushian, P. Aerated Cement Slurry and Controlling Fungal Growth of Low-Cost Biomass-Based Insulation Materials. Sci Rep 2019, 9, 19237. [CrossRef]

- Lopez Hurtado, P.; Rouilly, A.; Raynaud, C.; Vandenbossche, V. The Properties of Cellulose Insulation Applied via the Wet Spray Process. Build Environ 2016, 107, 43–51. [CrossRef]

- Lopez Hurtado, P.; Rouilly, A.; Vandenbossche, V.; Raynaud, C. A Review on the Properties of Cellulose Fibre Insulation. Build Environ 2016, 96, 170–177. [CrossRef]

- Day, M.; Wiles, D.M. Combustibility of Loose Fiber Fill Cellulose Insulation: The Role of Borax and Boric Acid. Journal of Thermal Insulation 1978, 2, 30–39. [CrossRef]

- Sprague, R.W.; Shen, K.K. The Use of Boron Products in Cellulose Insulation. Journal of Thermal Insulation 1979, 2, 161–174. [CrossRef]

- Zhang, Y.; Bai, M.; Zhang, A.; Zhang, X.; Dong, Y.; Kang, H.; Zhang, Q.; Li, J. A Facile and Small-Molecule Regulated Borate Network Gelation to Improve the Mildew Proof, Fire-Retardant of Bamboo. Ind Crops Prod 2023, 197, 116602. [CrossRef]

- Soytürk, E.E.; Kartal, S.N.; Terzi, E.; Önses, M.S.; Şarkdemir, K.; Çelik, N. Evaluation of Wood Treated with Paraloid B72® and Boric Acid: Thermal Behavior, Water Absorption and Mold Resistance. European Journal of Wood and Wood Products 2023, 81, 923–934. [CrossRef]

- Liu, T. Improvements in the Physical Properties and Decay Resistance of Bamboo Materials via Modification with Boric Acid and Borax. Bioresources 2022, 18, 100–110. [CrossRef]

- Dylewski, R.; Adamczyk, J. Economic and Environmental Benefits of Thermal Insulation of Building External Walls. Build Environ 2011, 46, 2615–2623. [CrossRef]

- Jelle, B.P. Traditional, State-of-the-Art and Future Thermal Building Insulation Materials and Solutions – Properties, Requirements and Possibilities. Energy Build 2011, 43, 2549–2563. [CrossRef]

- Marín-Calvo, N.; González-Serrud, S.; James-Rivas, A. Thermal Insulation Material Produced from Recycled Materials for Building Applications: Cellulose and Rice Husk-Based Material. Front Built Environ 2023, 9. [CrossRef]

- Al-Homoud, M.S. The Effectiveness of Thermal Insulation in Different Types of Buildings in Hot Climates. Journal of Thermal Envelope and Building Science 2004, 27, 235–247. [CrossRef]

- Hassan, T.; Jamshaid, H.; Mishra, R.; Khan, M.Q.; Petru, M.; Novak, J.; Choteborsky, R.; Hromasova, M. Acoustic, Mechanical and Thermal Properties of Green Composites Reinforced with Natural Fibers Waste. Polymers (Basel) 2020, 12, 654. [CrossRef]

- Korjenic, A.; Petránek, V.; Zach, J.; Hroudová, J. Development and Performance Evaluation of Natural Thermal-Insulation Materials Composed of Renewable Resources. Energy Build 2011, 43, 2518–2523. [CrossRef]

- Shekar, H.S.S.; Ramachandra, M. Green Composites: A Review. Mater Today Proc 2018, 5, 2518–2526. [CrossRef]

- Rabbat, C.; Awad, S.; Villot, A.; Rollet, D.; Andrès, Y. Sustainability of Biomass-Based Insulation Materials in Buildings: Current Status in France, End-of-Life Projections and Energy Recovery Potentials. Renewable and Sustainable Energy Reviews 2022, 156, 111962. [CrossRef]

- Füchsl, S.; Rheude, F.; Röder, H. Life Cycle Assessment (LCA) of Thermal Insulation Materials: A Critical Review. Cleaner Materials 2022, 5, 100119. [CrossRef]

- Almusaed, A.; Almssad, A.; Alasadi, A.; Yitmen, I.; Al-Samaraee, S. Assessing the Role and Efficiency of Thermal Insulation by the “BIO-GREEN PANEL” in Enhancing Sustainability in a Built Environment. Sustainability 2023, 15, 10418. [CrossRef]

- Bozsaky, D. Nature-Based Thermal Insulation Materials From Renewable Resources – A State-Of-The-Art Review. Slovak Journal of Civil Engineering 2019, 27, 52–59. [CrossRef]

- Yarbrough, D.W.; Wilkes, K.E. Thermal Properties and Use of Cellulosic Insulation Produced from Recycled Paper; Oak Ridge National Lab.(ORNL), Oak Ridge, TN (United States), 1996;

- La Mantia, F.P.; Morreale, M. Green Composites: A Brief Review. Compos Part A Appl Sci Manuf 2011, 42, 579–588. [CrossRef]

- Li, M.; Pu, Y.; Thomas, V.M.; Yoo, C.G.; Ozcan, S.; Deng, Y.; Nelson, K.; Ragauskas, A.J. Recent Advancements of Plant-Based Natural Fiber–Reinforced Composites and Their Applications. Compos B Eng 2020, 200, 108254. [CrossRef]

- Abu-Jdayil, B.; Mourad, A.-H.; Hittini, W.; Hassan, M.; Hameedi, S. Traditional, State-of-the-Art and Renewable Thermal Building Insulation Materials: An Overview. Constr Build Mater 2019, 214, 709–735. [CrossRef]

- Lavrykov, S.A.; Ramarao, B. V. Thermal Properties of Copy Paper Sheets. Drying Technology 2012, 30, 297–311. [CrossRef]

- Liuzzi, S.; Rubino, C.; Martellotta, F.; Stefanizzi, P. Sustainable Materials from Waste Paper: Thermal and Acoustical Characterization. Applied Sciences 2023, 13, 4710. [CrossRef]

- Mathews, J.M.; Vivek, B.; Charde, M. Thermal Insulation Panels for Buildings Using Recycled Cardboard: Experimental Characterization and Optimum Selection. Energy Build 2023, 281, 112747. [CrossRef]

- Hasan, K.M.F.; Horváth, P.G.; Bak, M.; Alpár, T. A State-of-the-Art Review on Coir Fiber-Reinforced Biocomposites. RSC Adv 2021, 11, 10548–10571. [CrossRef]

- Balador, Z.; Gjerde, M.; Isaacs, N.; Imani, M. Thermal and Acoustic Building Insulations from Agricultural Wastes. Handbook of Ecomaterials; Torres Martínez, LM, Oxana Vasilievna, K., Boris Ildusovich, K., Eds 2018, 1–20.

- Chikhi, M.; Agoudjil, B.; Boudenne, A.; Gherabli, A. Experimental Investigation of New Biocomposite with Low Cost for Thermal Insulation. Energy Build 2013, 66, 267–273. [CrossRef]

- Benallel, A.; Tilioua, A.; Ettakni, M.; Ouakarrouch, M.; Garoum, M.; Ahmed Alaoui Hamdi, M. Design and Thermophysical Characterization of New Thermal Insulation Panels Based on Cardboard Waste and Vegetable Fibers. Sustainable Energy Technologies and Assessments 2021, 48, 101639. [CrossRef]

- Kwon, Y.C.; Yarbrough, D.W. A Comparison of Korean Cellulose Insulation with Cellulose Insulation Manufactured in the United States of America. Journal of Thermal Envelope and Building Science 2004, 27, 185–197. [CrossRef]

- Benallel, A.; Tilioua, A.; Garoum, M. Development of Thermal Insulation Panels Bio-Composite Containing Cardboard and Date Palm Fibers. J Clean Prod 2024, 434, 139995. [CrossRef]

- Dahal, R.K.; Acharya, B.; Dutta, A. The Interaction Effect of the Design Parameters on the Water Absorption of the Hemp-Reinforced Biocarbon-Filled Bio-Epoxy Composites. Int J Mol Sci 2023, 24, 6093. [CrossRef]

- Xiong, H.; Yuan, K.; Xu, J.; Wen, M. Pore Structure, Adsorption, and Water Absorption of Expanded Perlite Mortar in External Thermal Insulation Composite System during Aging. Cem Concr Compos 2021, 116, 103900. [CrossRef]

- Penjumras, P.; Rahman, R.A.; Talib, R.A.; Abdan, K. Mechanical Properties and Water Absorption Behaviour of Durian Rind Cellulose Reinforced Poly (Lactic Acid) Biocomposites. Int J Adv Sci Eng Inf Technol 2015, 5, 343–349. [CrossRef]

- Nor Arman, N.S.; Chen, R.S.; Ahmad, S. Review of State-of-the-Art Studies on the Water Absorption Capacity of Agricultural Fiber-Reinforced Polymer Composites for Sustainable Construction. Constr Build Mater 2021, 302, 124174. [CrossRef]

- Muthuraj, R.; Lacoste, C.; Lacroix, P.; Bergeret, A. Sustainable Thermal Insulation Biocomposites from Rice Husk, Wheat Husk, Wood Fibers and Textile Waste Fibers: Elaboration and Performances Evaluation. Ind Crops Prod 2019, 135, 238–245. [CrossRef]

- Guo, Y.; Ruan, K.; Gu, J. Controllable Thermal Conductivity in Composites by Constructing Thermal Conduction Networks. Materials Today Physics 2021, 20, 100449. [CrossRef]

- Barbieri, V.; Lassinantti Gualtieri, M.; Siligardi, C. Wheat Husk: A Renewable Resource for Bio-Based Building Materials. Constr Build Mater 2020, 251, 118909. [CrossRef]

- Trobiani Di Canto, J.A.; Malfait, W.J.; Wernery, J. Turning Waste into Insulation – A New Sustainable Thermal Insulation Board Based on Wheat Bran and Banana Peels. Build Environ 2023, 244, 110740. [CrossRef]

- Rojas, C.; Cea, M.; Iriarte, A.; Valdés, G.; Navia, R.; Cárdenas-R, J.P. Thermal Insulation Materials Based on Agricultural Residual Wheat Straw and Corn Husk Biomass, for Application in Sustainable Buildings. Sustainable Materials and Technologies 2019, 20, e00102. [CrossRef]

- Hung Anh, L.D.; Pásztory, Z. An Overview of Factors Influencing Thermal Conductivity of Building Insulation Materials. Journal of Building Engineering 2021, 44, 102604. [CrossRef]

- Koru, M. Determination of Thermal Conductivity of Closed-Cell Insulation Materials That Depend on Temperature and Density. Arab J Sci Eng 2016, 41, 4337–4346. [CrossRef]

- Day, M.; Suprunchuk, T.; Wiles, D.M. The Fire Properties of Cellulose Insulation. Journal of Thermal Insulation 1981, 4, 157–170. [CrossRef]

- Sejdinović, B. Modern Thermal Insulation and Sound Insulation Materials. In; 2023; pp. 218–233. [CrossRef]

- Pedroso, M.; de Brito, J.; Silvestre, J.D. Characterization of Eco-Efficient Acoustic Insulation Materials (Traditional and Innovative). Constr Build Mater 2017, 140, 221–228. [CrossRef]

- Day, M.; Suprunchuk, T.; Wiles, D.M. A Combustibility Study of Cellulose Insulation. Journal of Thermal Insulation 1980, 3, 260–271. [CrossRef]

- Herrera, J. Assessment of Fungal Growth on Sodium Polyborate-Treated Cellulose Insulation. J Occup Environ Hyg 2005, 2, 626–632. [CrossRef]

- Vidal, J.; Ponce, D.; Mija, A.; Rymarczyk, M.; Castell, P. Sustainable Composites from Nature to Construction: Hemp and Linseed Reinforced Biocomposites Based on Bio-Based Epoxy Resins. Materials 2023, 16, 1283. [CrossRef]

- Rocha, M.; Gomes, B.; Aguiar, A.; Landesmann, A.; Hasparyk, N.P.; Toledo Filho, R. Fire Reaction Properties of Bio-based Aggregates Used in Thermally Insulated Building Components. Fire Mater 2024, 48, 62–78. [CrossRef]

- Ahmed, A.; Qayoum, A.; Mir, F.Q. Spectroscopic Studies of Renewable Insulation Materials for Energy Saving in Building Sector. Journal of Building Engineering 2021, 44, 103300. [CrossRef]

- Carlos Javier, R.H.; Karin, R.N.; Juan Pablo, C.-R. Valorization of Wheat Crop Waste in Araucanía, Chile: Development of Prototype of Thermal Insulation Material for Blowing Technique and Geographical Analysis. Buildings 2023, 13, 1152. [CrossRef]

- Maraveas, C. Production of Sustainable and Biodegradable Polymers from Agricultural Waste. Polymers (Basel) 2020, 12, 1127. [CrossRef]

- Pal, R.K.; Goyal, P.; Sehgal, S. Effect of Cellulose Fibre Based Insulation on Thermal Performance of Buildings. Mater Today Proc 2021, 45, 5778–5781. [CrossRef]

- Gonzalez-Serrud, S.; Saavedra, D.; Marin, N. Caracterización Mecánica y Térmica de Un Compuesto a Base de Celulosa. In Proceedings of the Congreso Iberoamericano de Ingeniería Mecánica-CIBIM 2022; Universidad Nacional de Educación a Distancia (España), 2022.

- Chen, Z.; Xu, Y.; Shivkumar, S. Microstructure and Tensile Properties of Various Varieties of Rice Husk. J Sci Food Agric 2018, 98, 1061–1070. [CrossRef]

- ASTM International Standard Test Method for Water Absorption by Immersion of Thermal Insulation Materials - ASTM C1763.

- ASTM International Standard Test Method for Dimensions and Density of Preformed Block and Board–Type Thermal Insulation - ASTM C303.

- Mercier, D.; Dutil, Y.; Rousse, D.; Pronovost, F.; Boudreau, D.; Hudon, N.; Castonguay, M. Los Aislamientos Térmicos Naturales: Construcción Ecológica y Eficiencia Energética. Ponencia presentada en el Coloquio Universitario Franco-Québécois, Saguenay 2011.

- Muktha, K.; Keerthi Gowda, B.S. Investigation of Water Absorption and Fire Resistance of Untreated Banana Fibre Reinforced Polyester Composites. Mater Today Proc 2017, 4, 8307–8312. [CrossRef]

- Hwang, J.; Park, D.; Rie, D. Manufacture and Combustion Characteristics of Cellulose Flame-Retardant Plate through the Hot-Press Method. Polymers (Basel) 2023, 15, 4736. [CrossRef]

- Guo, Y.; He, S.; Zuo, X.; Xue, Y.; Chen, Z.; Chang, C.-C.; Weil, E.; Rafailovich, M. Incorporation of Cellulose with Adsorbed Phosphates into Poly (Lactic Acid) for Enhanced Mechanical and Flame Retardant Properties. Polym Degrad Stab 2017, 144, 24–32. [CrossRef]

- Feldsine, P.T.; Lienau, A.H.; Leung, S.C.; Mui, L.A. Enumeration of Total Yeasts and Molds in Foods by the SimPlate® Yeast and Mold–Color Indicator Method and Conventional Culture Methods: Collaborative Study. J AOAC Int 2003, 86, 296–313.

- Feldsine, P.T.; Lienau, A.H.; Leung, S.C.; Mui, L.A. Enumeration of Total Yeasts and Molds in Foods by the SimPlate® Yeast and Mold–Color Indicator Method and Conventional Culture Methods: Collaborative Study. J AOAC Int 2003, 86, 296–313. [CrossRef]

- Noor, S.; Yao, T.; Muhammad, K.; Yahya, N. Thermal Insulation Improvement in Wall Using Recycled Cellulose as An Alternative and Its Physical Properties. Journal of Advanced Research in Engineering Knowledge 2019, 9, 26–31.

- Kumar, R.; Singh, V.; Bansal, A.; Singla, A.K.; Singla, J.; Gupta, S.; Rajput, A.; Singh, J.; Khanna, N. Experimental Research on the Physical and Mechanical Properties of Rice Straw-Rice Straw Ash Composite Materials. International Journal on Interactive Design and Manufacturing (IJIDeM) 2024, 18, 721–731. [CrossRef]

- Erica-Aislamiento-Estanqueidad AISLAMIENTO TERMICO CONDUCTIVIDAD | CALOR ESPECIFICO | TRANSFERENCIA DE CALOR.

- Wu, M.; Yu, G.; Chen, W.; Dong, S.; Wang, Y.; Liu, C.; Li, B. A Pulp Foam with Highly Improved Physical Strength, Fire-Resistance and Antibiosis by Incorporation of Chitosan and CPAM. Carbohydr Polym 2022, 278, 118963. [CrossRef]

| Shredded newsprint | Rice husk | ||||

|---|---|---|---|---|---|

| Element | # at | [wt.%] | Element | # at | [wt.%] |

| Hydrogen | 1 | 4.962 | Hydrogen | 1 | 3.289 |

| Carbon | 6 | 65.516 | Carbon | 6 | 20.048 |

| Oxygen | 8 | 27.363 | Oxygen | 8 | 42.807 |

| Aluminium | 13 | 1.400 | Nitrogen | 13 | 0.567 |

| Calcium | 20 | 0.759 | Silicium | 14 | 33.289 |

| Polyvinyl acetate-based glue (Grip Bond 2) | Borax (20 Mule Team Borax) | ||||

| Hydrogen | 1 | 5.670 | Hydrogen | 1 | 25.436 |

| Carbon | 6 | 63.329 | Boron | 5 | 10.079 |

| Oxygen | 8 | 31.001 | Oxygen | 8 | 52.792 |

| Sodium | 11 | 11.692 | |||

| Dry mass (g) | Wet mass (g) | Water absorption (%) | |

|---|---|---|---|

| S1 | 23.98 | 39.72 | 65.63 |

| S2 | 33.76 | 58.67 | 73.77 |

| S3 | 31.00 | 51.08 | 64.79 |

| Average | 68.06 ± 4.96 |

| Mass (grams) | Volume 1 (mL) | Volume 2 (mL) | Density (g/mL) | |

|---|---|---|---|---|

| S1 | 38.19 | 200 | 260 | 0.64 |

| S2 | 34.68 | 200 | 248 | 0.72 |

| S3 | 27.59 | 200 | 245 | 0.61 |

| Average | 0.66 ± 0.06 |

| Material with borax | P | C | D | Fungi and yeast count (UFC/mL) |

|---|---|---|---|---|

| Sample 1 | 0 | <1 | 1 | <1 * |

| Sample 2 | 0 | <1 | 10-1 | <1* |

| Sample 3 | 0 | <1 | 10-2 | <1* |

| Borax-free material | ||||

| Sample 1 | 84 | <738 | 1 | < 730 ** |

| Sample 2 | 84 | <738 | 10-1 | <7380 ** |

| Sample 3 | 84 | <738 | 10-2 | <73 800 ** |

| No. of positive wells (P) Most Probable Number of Colony Forming Units per plate (C) Dilution Factor (D) Colony Forming Unit (CFU) | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).