Submitted:

12 April 2024

Posted:

15 April 2024

You are already at the latest version

Abstract

Keywords:

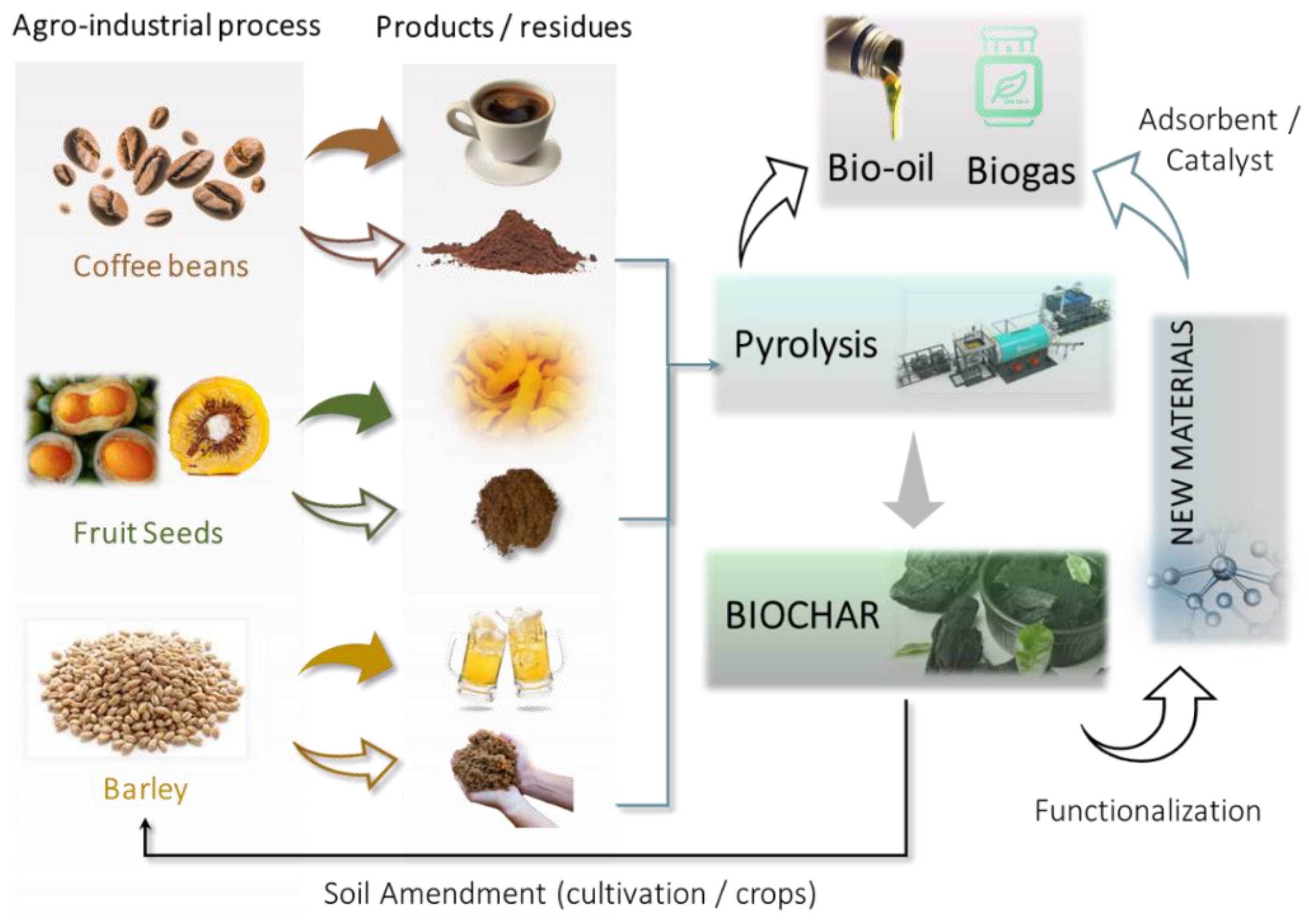

1. Introduction

2. Prospective Study on Biochar Research

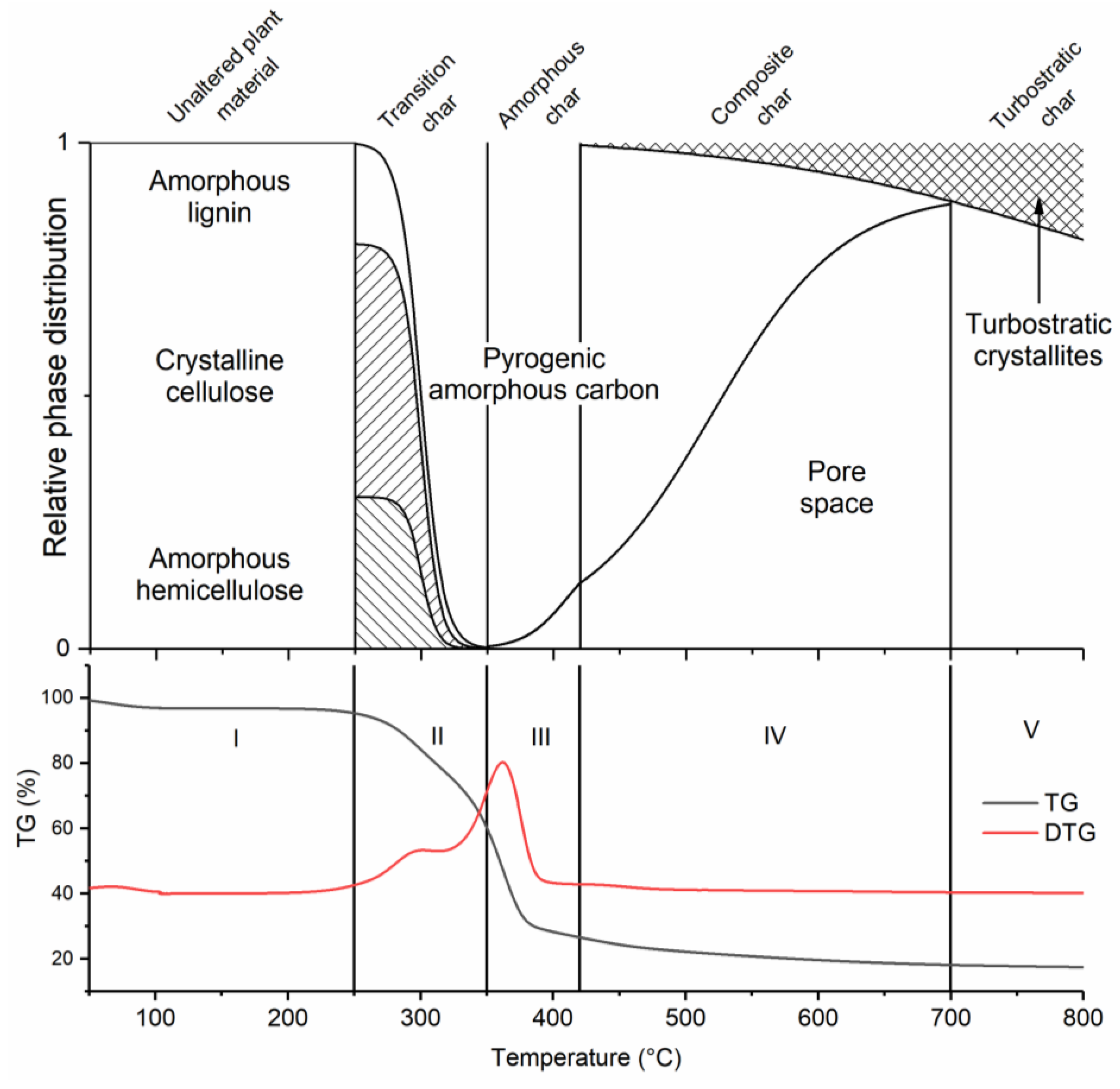

3. Lignocellulosic Biomass in Thermochemical Conversion

4. Biochar Production

- Flash pyrolysis: operates at high temperatures (above 800 ºC) with an even shorter residence time than fast pyrolysis (< 0.5 s) and heating ramp > 1000 ºC min–1[39].

5. Physicochemical Characterization of Biochar

5.1. Main Standard Biochar Characterization

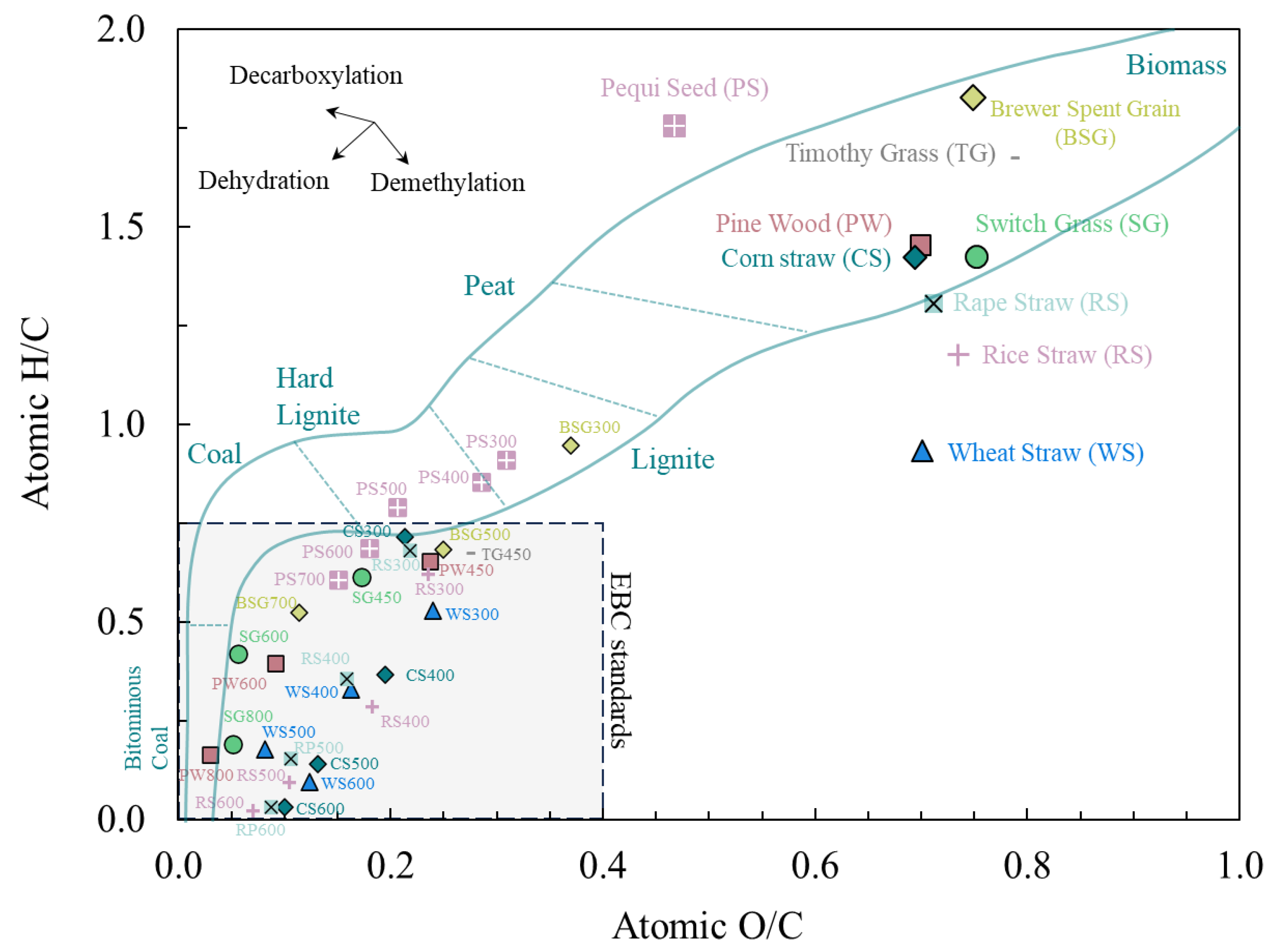

5.2. Atomic H/C and O/C Ratios

5.3. Calorific Value

5.4. Spectroscopic Analysis

5.4.1. Fourier Transform Infrared (FTIR) Spectroscopy

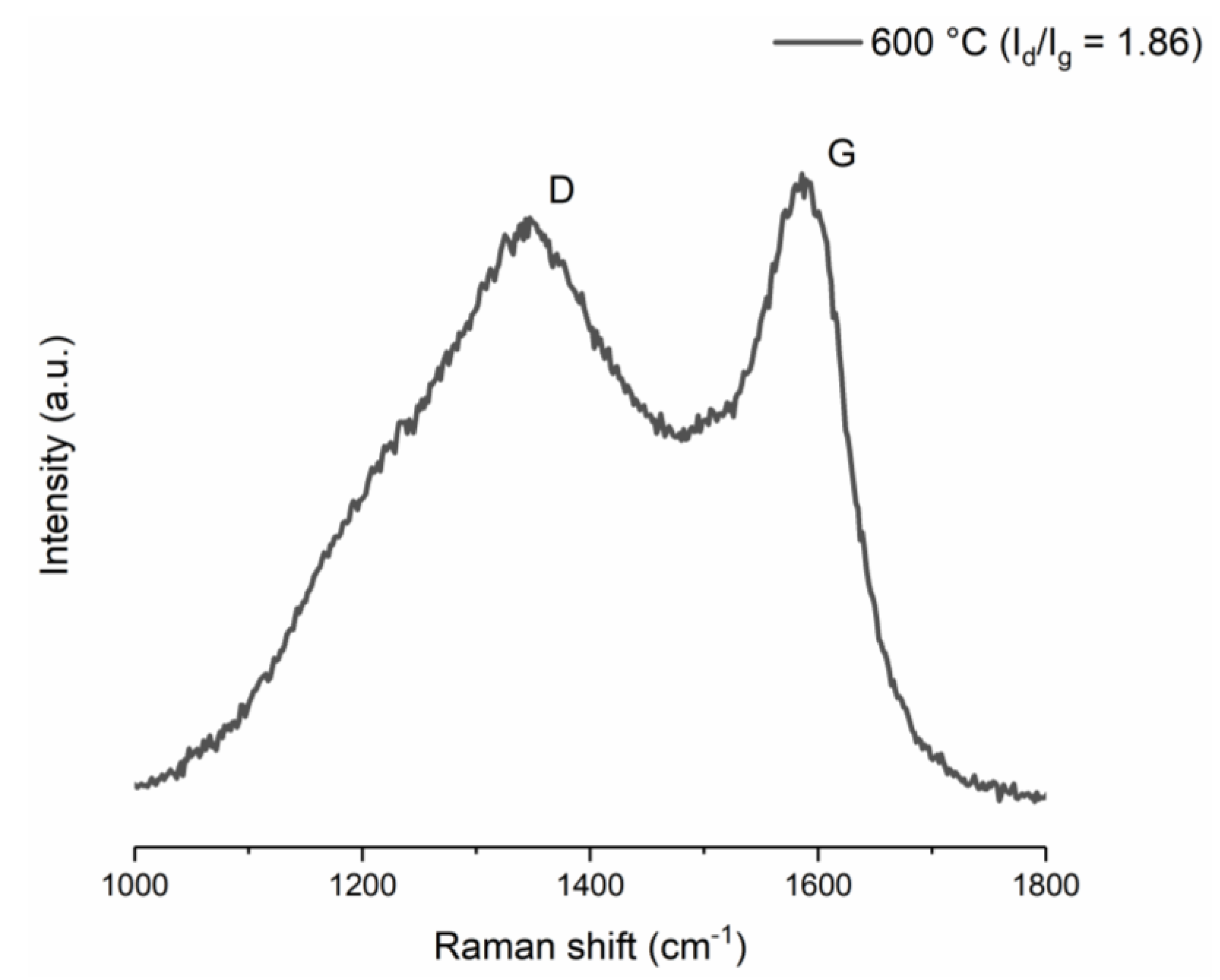

5.4.2. Raman Spectroscopy

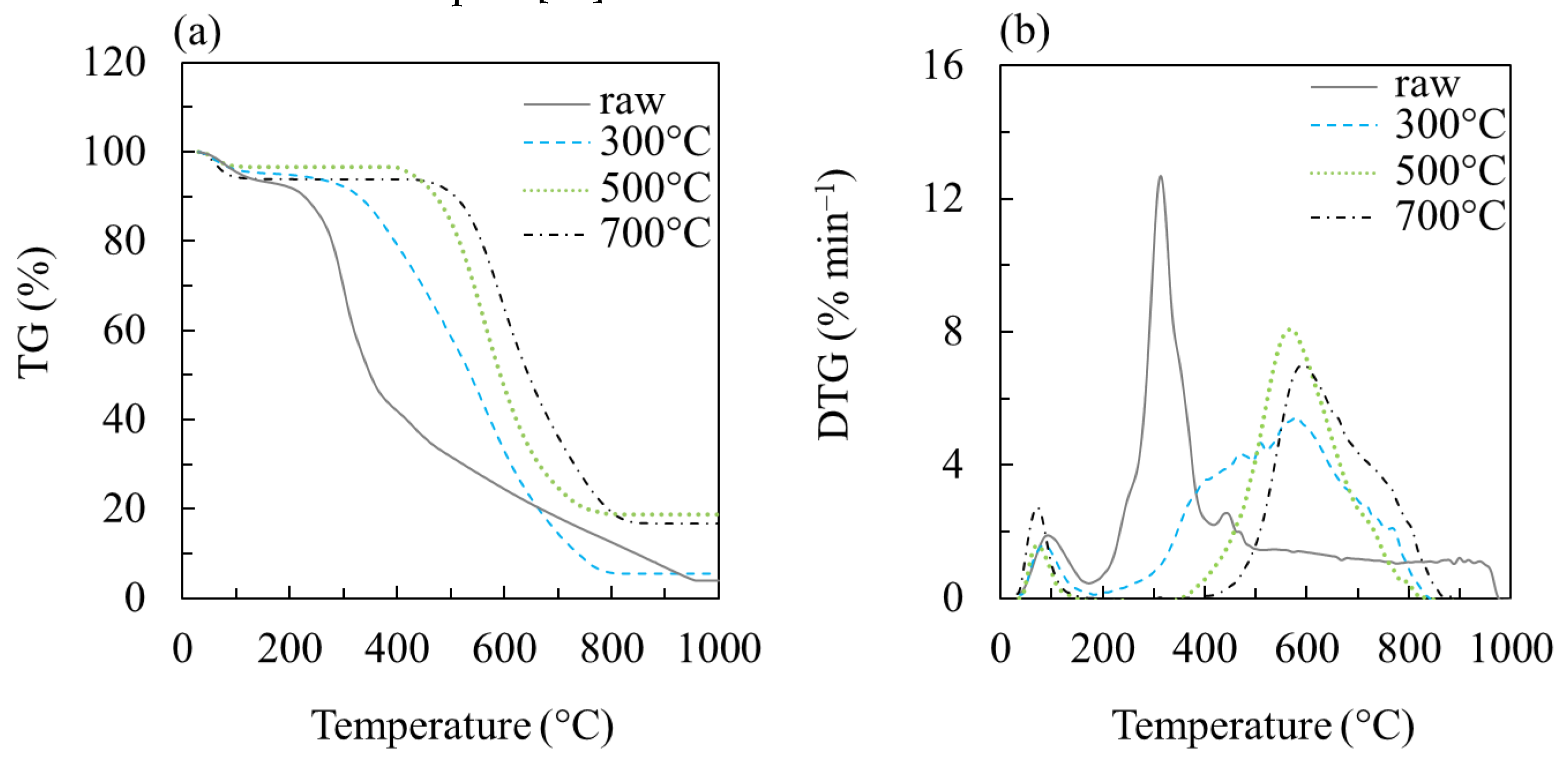

5.5. Thermogravimetric Analysis (TGA)

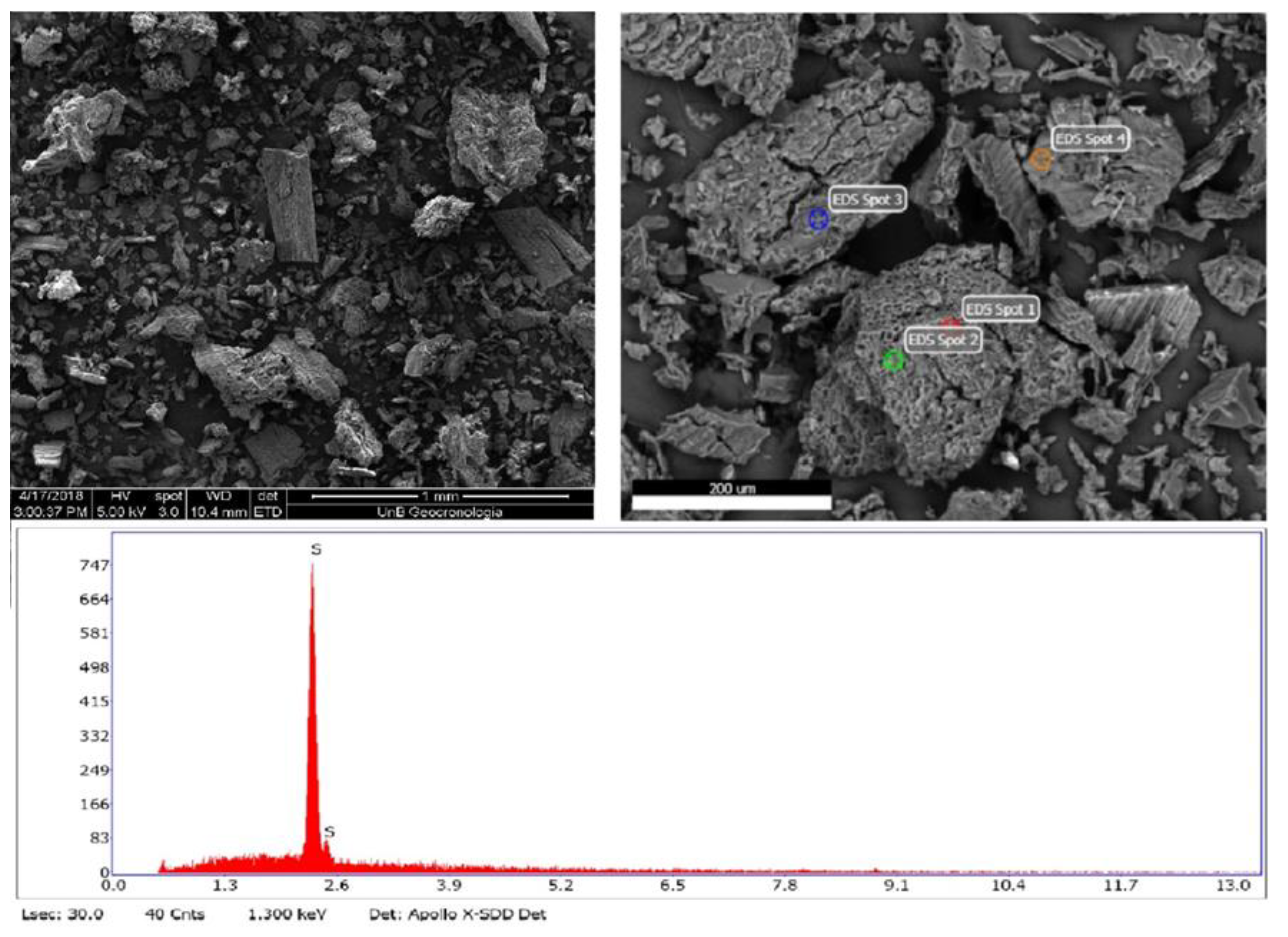

5.6. Scanning Electron Microscopy (SEM)

5.7. Böehm Titration—Functional Group Identification and Acidity Analysis

5.8. Solid-State Nuclear Magnetic Resonance (ssNMR)

5.9. X-ray Photoelectron Spectroscopy (XPS)

6. Biochar Application

6.1. Soil Amendment

6.2. Catalysis

6.3. Biofuel

6.4. Wastewater Treatment

5. Multi-Criteria Decision Analysis

7.1. MCDM Criteria Selection, Analytical Technique, and Optimization

7. Conclusions and Perspectives

Acknowledgments

References

- Sieradzka M, Kirczuk C, Kalemba-Rec I, Mlonka-Mędrala A, Magdziarz A. Pyrolysis of Biomass Wastes into Carbon Materials. Energies 2022;15:1941. [CrossRef]

- Menezes LNB, Silveira EA, Mazzoni JVS, Evaristo RBW, Rodrigues JS, Lamas GC, et al. Alternative valuation pathways for primary, secondary, and tertiary sewage sludge: biochar and bio-oil production for sustainable energy. Biomass Convers Biorefinery 2022. [CrossRef]

- Glushkov D, Nyashina G, Shvets A, Pereira A, Ramanathan A. Current Status of the Pyrolysis and Gasification Mechanism of Biomass. Energies 2021;14:7541. [CrossRef]

- Xie Y, Wang L, Li H, Westholm LJ, Carvalho L, Thorin E, et al. A critical review on production, modification and utilization of biochar. J Anal Appl Pyrolysis 2022;161:105405. [CrossRef]

- Al-Rumaihi A, Shahbaz M, Mckay G, Mackey H, Al-Ansari T. A review of pyrolysis technologies and feedstock: A blending approach for plastic and biomass towards optimum biochar yield. Renew Sustain Energy Rev 2022;167:112715. [CrossRef]

- Tran H-T, Bolan NS, Lin C, Binh QA, Nguyen M-K, Luu TA, et al. Succession of biochar addition for soil amendment and contaminants remediation during co-composting: A state of art review. J Environ Manage 2023;342:118191. [CrossRef]

- Mosa A, Mansour MM, Soliman E, El-Ghamry A, El Alfy M, El Kenawy AM. Biochar as a Soil Amendment for Restraining Greenhouse Gases Emission and Improving Soil Carbon Sink: Current Situation and Ways Forward. Sustainability 2023;15:1206. [CrossRef]

- Zhou S, Jiang Z, Shen J, Yao Q, Yang X, Li X, et al. Biochar-amended compost as a promising soil amendment for enhancing plant productivity: A meta-analysis study. Sci Total Environ 2023;879:163067. [CrossRef]

- Mbugua Nyambura S, Li C, Li H, Xu J, Wang J, Zhu X, et al. Microwave co-pyrolysis of kitchen food waste and rice straw: Effects of susceptor on thermal, surface, and fuel properties of biochar. Fuel 2023;352:129093. [CrossRef]

- Zhang C, Wang M, Chen W-HH, Zhang Y, Pétrissans A, Pétrissans M, et al. Superhydrophobic and superlipophilic biochar produced from microalga torrefaction and modification for upgrading fuel properties. Biochar 2023;5:18. [CrossRef]

- Cueva Zepeda L, Griffin G, Shah K, Al-Waili I, Parthasarathy R. Energy potential, flow characteristics and stability of water and alcohol-based rice-straw biochar slurry fuel. Renew Energy 2023;207:60–72. [CrossRef]

- Liu W, Zhang X, Ren H, Hu X, Yang X, Liu H. Co-production of spirosiloxane and biochar adsorbent from wheat straw by a low-cost and environment-friendly method. J Environ Manage 2023;338:117851. [CrossRef]

- Liang H, Wang W, Liu H, Deng X, Zhang D, Zou Y, et al. Porous MgO-modified biochar adsorbents fabricated by the activation of Mg(NO3)2 for phosphate removal: Synergistic enhancement of porosity and active sites. Chemosphere 2023;324:138320. [CrossRef]

- Li H, Tang M, Huang X, Wang L, Liu Q, Lu S. An efficient biochar adsorbent for CO2 capture: Combined experimental and theoretical study on the promotion mechanism of N-doping. Chem Eng J 2023;466:143095. [CrossRef]

- Qin X, Cheng S, Xing B, Qu X, Shi C, Meng W, et al. Preparation of pyrolysis products by catalytic pyrolysis of poplar: Application of biochar in antibiotic wastewater treatment. Chemosphere 2023;338:139519. [CrossRef]

- Fseha YH, Shaheen J, Sizirici B. Phenol contaminated municipal wastewater treatment using date palm frond biochar: Optimization using response surface methodology. Emerg Contam 2023;9:100202. [CrossRef]

- Ajibade FO, Yin W-X, Guadie A, Ajibade TF, Liu Y, Kumwimba MN, et al. Impact of biochar amendment on antibiotic removal and ARGs accumulation in constructed wetlands for low C/N wastewater treatment. Chem Eng J 2023;459:141541. [CrossRef]

- Silveira EA, Macedo LA, Candelier K, Rousset P, Commandré J-M. Assessment of catalytic torrefaction promoted by biomass potassium impregnation through performance indexes. Fuel 2021;304:121353. [CrossRef]

- Silveira EA, Luz S, Candelier K, Macedo LA, Rousset P. An assessment of biomass torrefaction severity indexes. Fuel 2021;288:119631. [CrossRef]

- Thengane SK, Kung KS, Gomez-Barea A, Ghoniem AF. Advances in biomass torrefaction: Parameters, models, reactors, applications, deployment, and market. Prog Energy Combust Sci 2022;93:101040. [CrossRef]

- Chen WH, Lin BJ, Lin YY, Chu YS, Ubando AT, Show PL, et al. Progress in biomass torrefaction: Principles, applications and challenges. Prog Energy Combust Sci 2021;82. [CrossRef]

- Muzyka R, Misztal E, Hrabak J, Banks SW, Sajdak M. Various biomass pyrolysis conditions influence the porosity and pore size distribution of biochar. Energy 2023;263:126128. [CrossRef]

- Premchand P, Demichelis F, Chiaramonti D, Bensaid S, Fino D. Biochar production from slow pyrolysis of biomass under CO2 atmosphere: A review on the effect of CO2 medium on biochar production, characterisation, and environmental applications. J Environ Chem Eng 2023;11:110009. [CrossRef]

- Brown TR, Wright MM, Brown RC. Estimating profitability of two biochar production scenarios: slow pyrolysis vs fast pyrolysis. Biofuels, Bioprod Biorefining 2011;5:54–68. [CrossRef]

- Lamas GC, S. Chaves B, Oliveira PP, Barbosa T, Gonzales T da S, Ghesti GF, et al. Effect of torrefaction on steam-enhanced co-gasification of an urban forest and landfill waste blend: H2 production and CO2 emissions mitigation. Int J Hydrogen Energy 2023. [CrossRef]

- Ghesti GF, Silveira EA, Guimarães MG, Evaristo RBWW, Costa M. Towards a sustainable waste-to-energy pathway to pequi biomass residues: Biochar, syngas, and biodiesel analysis. Waste Manag 2022;143:144–56. [CrossRef]

- Rodrigues MI, Silveira EA. Visualização da dinâmica de liberação de voláteis durante o tratamento térmico de materiais lignocelulósicos. 27o Congr. Iniciação Científica da UnB e 18o Congr. Iniciação Científica do DF, 2021.

- Rodrigues JP, Ghesti GF, Silveira EA, Lamas GC, Ferreira R, Costa M. Waste-to-hydrogen via CO2/Steam-enhanced gasification of spent coffee ground. Clean Chem Eng 2022;4:100082. [CrossRef]

- Collard F-XX, Blin J. A review on pyrolysis of biomass constituents: Mechanisms and composition of the products obtained from the conversion of cellulose, hemicelluloses and lignin. Renew Sustain Energy Rev 2014;38:594–608. [CrossRef]

- Lehmann, J. Bio-energy in the black. Front Ecol Environ 2007;5:381–7. [CrossRef]

- Evaristo RBW, Ferreira R, Petrocchi Rodrigues J, Sabino Rodrigues J, Ghesti GF, Silveira EA, et al. Multiparameter-analysis of CO2/Steam-enhanced gasification and pyrolysis for syngas and biochar production from low-cost feedstock. Energy Convers Manag X 2021;12:100138. [CrossRef]

- Chin LH, Abdullah AZ, Hameed BH. Sugar cane bagasse as solid catalyst for synthesis of methyl esters from palm fatty acid distillate. Chem Eng J 2012;183:104–7. [CrossRef]

- Niju S, Ajieth Kanna SK, Ramalingam V, Satheesh Kumar M, Balajii M. Sugarcane bagasse derived biochar – a potential heterogeneous catalyst for transesterification process. Energy Sources, Part A Recover Util Environ Eff 2019:1–12. [CrossRef]

- Quintella, CM. A REVISTA CADERNOS DE PROSPECÇÃO E OS NÍVEIS DE MATURIDADE DE TECNOLOGIAS (TRL). Cad Prospecção 2017;10:1. [CrossRef]

- NASA. Technology Readiness Level. NASA 2012.

- Conte P, Schmidt H-P, Cimò G. Research and Application of Biochar in Europe. Agric. Envioronmental Appl. Biochar Adv. Barrirers, 2016, p. 409–22. [CrossRef]

- Novotny EH, Maia CMB de F, Carvalho MT de M, Madari BE. BIOCHAR: PYROGENIC CARBON FOR AGRICULTURAL USE - A CRITICAL REVIEW. Rev Bras Ciência Do Solo 2015;39:321–44. [CrossRef]

- Zhang X, Luo Y, Müller K, Chen J, Lin Q, Xu J, et al. Research and Application of Biochar in China. Agric. Envioronmental Appl. Biochar Adv. Barrirers, 2016, p. 377–407. [CrossRef]

- He Z, Uchimiya SM, Guo M. Production and Characterization of Biochar from Agricultural By-Products: Overview and Use of Cotton Biomass Residues. Agric. Envioronmental Appl. Biochar Adv. Barrirers, 2016, p. 63–86. [CrossRef]

- Zheng W, Holm N, Spokas KA. Research and Application of Biochar in North America. Agric. Envioronmental Appl. Biochar Adv. Barrirers, 2016, p. 475–94. [CrossRef]

- Lee J, Kim K-H, Kwon EE. Biochar as a Catalyst. Renew Sustain Energy Rev 2017;77:70–9. [CrossRef]

- Karakaya F, Kobu B. New product development process: An investigation of success and failure in high-technology and non-high-technology firms. J Bus Ventur 1994;9:49–66. [CrossRef]

- Ranzi E, Corbetta M, Manenti F, Pierucci S. Kinetic modeling of the thermal degradation and combustion of biomass. Chem Eng Sci 2014;110:2–12. [CrossRef]

- Ranzi E, Debiagi PEA, Frassoldati A. Mathematical Modeling of Fast Biomass Pyrolysis and Bio-Oil Formation. Note I: Kinetic Mechanism of Biomass Pyrolysis. ACS Sustain Chem Eng 2017;5:2867–81. [CrossRef]

- Braga RM, Costa TR, Freitas JCO, Barros JMF, Melo DMA, Melo MAF. Pyrolysis kinetics of elephant grass pretreated biomasses. J Therm Anal Calorim 2014. [CrossRef]

- Van de Velden M, Baeyens J, Brems A, Janssens B, Dewil R. Fundamentals, kinetics and endothermicity of the biomass pyrolysis reaction. Renew Energy 2010;35:232–42. [CrossRef]

- Corbetta M, Frassoldati A, Bennadji H, Smith K, Serapiglia MJ, Gauthier G, et al. Pyrolysis of Centimeter-Scale Woody Biomass Particles: Kinetic Modeling and Experimental Validation. Energy & Fuels 2014;28:3884–98. [CrossRef]

- Padilla ERD, Santos LRO, Silva DA da, Barros JL de, Belini GB, Yamaji FM, et al. Eucalyptus Bark Charcoal: the Influence of Carbonization Temperature in Thermal Behavior. Mater Res 2019;22. [CrossRef]

- Kambo HS, Dutta A. A comparative review of biochar and hydrochar in terms of production, physico-chemical properties and applications. Renew Sustain Energy Rev 2015;45:359–78. [CrossRef]

- EBC. European Biochar Certificate - Guidelines for a Sustainable Production of Biochar. 2012.

- Keiluweit M, Nico PS, Johnson MG, Kleber M. Dynamic Molecular Structure of Plant Biomass-Derived Black Carbon (Biochar). Environ Sci Technol 2010;44:1247–53. [CrossRef]

- Srinivasan P, Sarmah AK, Smernik R, Das O, Farid M, Gao W. A feasibility study of agricultural and sewage biomass as biochar, bioenergy and biocomposite feedstock: Production, characterization and potential applications. Sci Total Environ 2015;512–513:495–505. [CrossRef]

- Rawat J, Saxena J, Sanwal P. Biochar: A Sustainable Approach for Improving Plant Growth and Soil Properties. Biochar - An Imp. Amend. Soil Environ., IntechOpen; 2019. [CrossRef]

- Ghesti GF, Rodrigues JP, Brasil AC de M, Guimarães MG, Evaristo RBW. Caracterização e Aplicação de Biomassa em Tecnologias de Conversão Termoquímica . Brasília, DF: Editora UnB; 2021.

- Steiner, C. Considerations in Biochar Characterization. Agric. Envioronmental Appl. Biochar Adv. Barrirers, 2016, p. 87–100. [CrossRef]

- Ronsse F, van Hecke S, Dickinson D, Prins W. Production and characterization of slow pyrolysis biochar: influence of feedstock type and pyrolysis conditions. GCB Bioenergy 2013;5:104–15. [CrossRef]

- Zhang X, Zhang P, Yuan X, Li Y, Han L. Effect of pyrolysis temperature and correlation analysis on the yield and physicochemical properties of crop residue biochar. Bioresour Technol 2020;296:122318. [CrossRef]

- Maia CMBF, Madari BE, Novotny EH. Advances in Biochar Research in Brazil. Dyn Soil, Dyn Plant 2011;5:53–8.

- NREL. National Renewable Energy Laboratory - Biomass Compositional Analysis Laboratory Procedures. 2020.

- IBI. International Biochar Initiative - Standarized Product Definition and Product Testing Guidelines for Biochar That Is Used in Soil. 2015.

- EBC. European Biochar Certificate - Comparison of European Biochar Certificate Verson 4.8 and IBI Biochar Standards Version 2.0. 2014.

- ASTM International. ASTM D1762-84 Standard Test Mehod for Chemical Analysis of Wood Charcoal. 2013.

- Klasson, KT. Biochar characterization and a method for estimating biochar quality from proximate analysis results. Biomass and Bioenergy 2017;96:50–8. [CrossRef]

- Xiao X, Chen Z, Chen B. H/C atomic ratio as a smart linkage between pyrolytic temperatures, aromatic clusters and sorption properties of biochars derived from diverse precursory materials. Sci Rep 2016;6:22644. [CrossRef]

- Spokas, KA. Review of the stability of biochar in soils: predictability of O:C molar ratios. Carbon Manag 2010;1:289–303. [CrossRef]

- Nanda S, Mohanty P, Pant KK, Naik S, Kozinski JA, Dalai AK. Characterization of North American Lignocellulosic Biomass and Biochars in Terms of their Candidacy for Alternate Renewable Fuels. BioEnergy Res 2013;6:663–77. [CrossRef]

- Kim P, Johnson A, Edmunds CW, Radosevich M, Vogt F, Rials TG, et al. Surface Functionality and Carbon Structures in Lignocellulosic-Derived Biochars Produced by Fast Pyrolysis. Energy & Fuels 2011;25:4693–703. [CrossRef]

- Silveira EA, Santanna Chaves B, Macedo L, Ghesti GF, Evaristo RBW, Cruz Lamas G, et al. A hybrid optimization approach towards energy recovery from torrefied waste blends. Renew Energy 2023. [CrossRef]

- Ivanovski M, Goricanec D, Krope J, Urbancl D. Torrefaction pretreatment of lignocellulosic biomass for sustainable solid biofuel production. Energy 2022;240:122483. [CrossRef]

- McKendry, P. Energy production from biomass (part 1): overview of biomass. Bioresour Technol 2002;83:37–46. [CrossRef]

- González Martínez M, Couce AA, Dupont C, Da D, Perez S, Thiéry S, et al. Torrefaction of cellulose, hemicelluloses and lignin extracted from woody and agricultural biomass in TGA-GC/MS: Linking production profiles of volatile species to biomass type and macromolecular composition The production of volatile species in torrefact 2021. [CrossRef]

- Worasuwannarak N, Sonobe T, Tanthapanichakoon W. Pyrolysis behaviors of rice straw, rice husk, and corncob by TG-MS technique. J Anal Appl Pyrolysis 2007;78:265–71. [CrossRef]

- Biagini E, Barontini F, Tognotti L. Devolatilization of Biomass Fuels and Biomass Components Studied by TG/FTIR Technique. Ind Eng Chem Res 2006;45:4486–93. [CrossRef]

- Miranda MR da S, Veras CAG, Ghesti GF. Charcoal production from waste pequi seeds for heat and power generation. Waste Manag 2020;103:177–86. [CrossRef]

- Berthomieu C, Hienerwadel R. Fourier transform infrared (FTIR) spectroscopy. Photosynth Res 2009;101:157–70. [CrossRef]

- Singh B, Fang Y, Johnston CT. A Fourier-Transform Infrared Study of Biochar Aging in Soils. Soil Sci Soc Am J 2016;80:613–22. [CrossRef]

- Ray, A. Characterization of Biochars from Various Agricultural By-Products Using FTIR Spectroscopy, SEM focused with image Processing. Int J Agric Environ Biotechnol 2020;13:423–30. [CrossRef]

- Janu R, Mrlik V, Ribitsch D, Hofman J, Sedláček P, Bielská L, et al. Biochar surface functional groups as affected by biomass feedstock, biochar composition and pyrolysis temperature. Carbon Resour Convers 2021;4:36–46. [CrossRef]

- Huang J, Glæsner N, Triolo JM, Bekiaris G, Bruun S, Liu F. Application of Fourier transform mid-infrared photoacoustic spectroscopy for rapid assessment of phosphorus availability in digestates and digestate-amended soils. Sci Total Environ 2022;832:155040. [CrossRef]

- Mukome FND, Kilcoyne ALD, Parikh SJ. Alteration of Biochar Carbon Chemistry during Soil Incubations: SR-FTIR and NEXAFS Investigation. Soil Sci Soc Am J 2014;78:1632–40. [CrossRef]

- Igalavithana AD, Mandal S, Niazi NK, Vithanage M, Parikh SJ, Mukome FND, et al. Advances and future directions of biochar characterization methods and applications. Crit Rev Environ Sci Technol 2017;47:2275–330. [CrossRef]

- Orlando A, Franceschini F, Muscas C, Pidkova S, Bartoli M, Rovere M, et al. A Comprehensive Review on Raman Spectroscopy Applications. Chemosensors 2021;9:262. [CrossRef]

- Wu H, Yip K, Tian F, Xie Z, Li C-Z. Evolution of Char Structure during the Steam Gasification of Biochars Produced from the Pyrolysis of Various Mallee Biomass Components. Ind Eng Chem Res 2009;48:10431–8. [CrossRef]

- Bokobza L, Bruneel J-L, Couzi M. Raman Spectra of Carbon-Based Materials (from Graphite to Carbon Black) and of Some Silicone Composites. C 2015;1:77–94. [CrossRef]

- Ferrari AC, Robertson J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys Rev B 2000;61:14095–107. [CrossRef]

- Elkhalifa S, Parthasarathy P, Mackey HR, Al-Ansari T, Elhassan O, Mansour S, et al. Biochar development from thermal TGA studies of individual food waste vegetables and their blended systems. Biomass Convers Biorefinery 2022:1–18. [CrossRef]

- Zaefferer, S. A critical review of orientation microscopy in SEM and TEM. Cryst Res Technol 2011;46:607–28. [CrossRef]

- Dinh V-P, Nguyen D-K, Luu T-T, Nguyen Q-H, Tuyen LA, Phong DD, et al. Adsorption of Pb(II) from aqueous solution by pomelo fruit peel-derived biochar. Mater Chem Phys 2022;285:126105. [CrossRef]

- Anas AK, Mutiara R, Musawwa MM, Taftazani A. Influence of Mixing Time and Mass Ratio of Precursor on Preparation of Magnetic Biochar Derived from Cassava Peel (Manihot utilissima). EKSAKTA J Sci Data Anal 2022:10–6. [CrossRef]

- Boehm, HP. Some aspects of the surface chemistry of carbon blacks and other carbons. Carbon N Y 1994;32:759–69. [CrossRef]

- Goertzen SL, Thériault KD, Oickle AM, Tarasuk AC, Andreas HA. Standardization of the Boehm titration. Part I. CO2 expulsion and endpoint determination. Carbon N Y 2010;48:1252–61. [CrossRef]

- Zhao W, Fernando LD, Kirui A, Deligey F, Wang T. Solid-state NMR of plant and fungal cell walls: A critical review. Solid State Nucl Magn Reson 2020;107:101660. [CrossRef]

- Yang M, Liu Z, Zhang J, Zhu X, Xie W, Lan H, et al. Simultaneous quantification of cellulose and pectin in tobacco using a robust solid-state NMR method. Carbohydr Res 2022;521:108676. [CrossRef]

- Morgan, DJ. Comments on the XPS Analysis of Carbon Materials. C 2021;7:51. [CrossRef]

- Bagus PS, Ilton ES, Nelin CJ. The interpretation of XPS spectra: Insights into materials properties. Surf Sci Rep 2013;68:273–304. [CrossRef]

- Chen J, Wang P, Ding L, Yu T, Leng S, Chen J, et al. The comparison study of multiple biochar stability assessment methods. J Anal Appl Pyrolysis 2021;156:105070. [CrossRef]

- Sato MK, de Lima HV, Costa AN, Rodrigues S, Pedroso AJS, de Freitas Maia CMB. Biochar from Acai agroindustry waste: Study of pyrolysis conditions. Waste Manag 2019;96:158–67. [CrossRef]

- Ramos R, Abdelkader-Fernández VK, Matos R, Peixoto AF, Fernandes DM. Metal-Supported Biochar Catalysts for Sustainable Biorefinery, Electrocatalysis, and Energy Storage Applications: A Review. Catalysts 2022;12:207. [CrossRef]

- Wang S, Li H, Wu M. Advances in metal/ biochar catalysts for biomass hydro-upgrading: A review. J Clean Prod 2021;303:126825. [CrossRef]

- Yan Q, Wan C, Liu J, Gao J, Yu F, Zhang J, et al. Iron nanoparticles in situ encapsulated in biochar-based carbon as an effective catalyst for the conversion of biomass-derived syngas to liquid hydrocarbons. Green Chem 2013;15:1631. [CrossRef]

- Dehkhoda AM, West AH, Ellis N. Biochar based solid acid catalyst for biodiesel production. Appl Catal A Gen 2010;382:197–204. [CrossRef]

- Yusuff AS, Thompson-Yusuff KA, Porwal J. Sulfonated biochar catalyst derived from eucalyptus tree shed bark: synthesis, characterization and its evaluation in oleic acid esterification. RSC Adv 2022;12:10237–48. [CrossRef]

- Zhang L, Yao Z, Zhao L, Li Z, Yi W, Kang K, et al. Synthesis and characterization of different activated biochar catalysts for removal of biomass pyrolysis tar. Energy 2021;232:120927. [CrossRef]

- Taghavi S, Norouzi O, Tavasoli A, Di Maria F, Signoretto M, Menegazzo F, et al. Catalytic conversion of Venice lagoon brown marine algae for producing hydrogen-rich gas and valuable biochemical using algal biochar and Ni/SBA-15 catalyst. Int J Hydrogen Energy 2018;43:19918–29. [CrossRef]

- Zhao C, Shao B, Yan M, Liu Z, Liang Q, He Q, et al. Activation of peroxymonosulfate by biochar-based catalysts and applications in the degradation of organic contaminants: A review. Chem Eng J 2021;416:128829. [CrossRef]

- Cao M, Lu M, Yin H, Zhu Q, Xing K, Ji J. Effect of hemicellulose extraction pretreatment on sulfonated corncob biochar for catalytic biodiesel production. J Environ Chem Eng 2023;11:109058. [CrossRef]

- da Luz Corrêa AP, da Silva PMM, Gonçalves MA, Bastos RRC, da Rocha Filho GN, da Conceição LRV. Study of the activity and stability of sulfonated carbon catalyst from agroindustrial waste in biodiesel production: Influence of pyrolysis temperature on functionalization. Arab J Chem 2023;16:104964. [CrossRef]

- Azman NS, Khairuddin N, Tengku Azmi TSM, Seenivasagam S, Hassan MA. Application of Biochar from Woodchip as Catalyst Support for Biodiesel Production. Catalysts 2023;13:489. [CrossRef]

- Daimary N, Eldiehy KSH, Boruah P, Deka D, Bora U, Kakati BK. Potato peels as a sustainable source for biochar, bio-oil and a green heterogeneous catalyst for biodiesel production. J Environ Chem Eng 2022;10:107108. [CrossRef]

- Su G, Ong HC, Mohd Zulkifli NW, Ibrahim S, Chen WH, Chong CT, et al. Valorization of animal manure via pyrolysis for bioenergy: A review. J Clean Prod 2022;343:130965. [CrossRef]

- Li Y, Gupta R, Zhang Q, You S. Review of biochar production via crop residue pyrolysis: Development and perspectives. Bioresour Technol 2023;369:128423. [CrossRef]

- Macedo LA, Silveira EA, Rousset P, Valette J, Commandré J-M. Synergistic effect of biomass potassium content and oxidative atmosphere: Impact on torrefaction severity and released condensables. Energy 2022;254:124472. [CrossRef]

- Silveira EA, Macedo LA, Rousset P, Candelier K, Galvão LGO, Chaves BS, et al. A potassium responsive numerical path to model catalytic torrefaction kinetics. Energy 2022;239:122208. [CrossRef]

- Selvarajoo A, Wong YL, Khoo KS, Chen W-H, Show PL. Biochar production via pyrolysis of citrus peel fruit waste as a potential usage as solid biofuel. Chemosphere 2022;294:133671. [CrossRef]

- de Almeida SGC, Tarelho LAC, Hauschild T, Costa MAM, Dussán KJ. Biochar production from sugarcane biomass using slow pyrolysis: Characterization of the solid fraction. Chem Eng Process - Process Intensif 2022;179:109054. [CrossRef]

- Selvarajoo A, Oochit D. Effect of pyrolysis temperature on product yields of palm fibre and its biochar characteristics. Mater Sci Energy Technol 2020;3:575–83. [CrossRef]

- Lee K-T, Cheng C-L, Lee D-S, Chen W-H, Vo D-VN, Ding L, et al. Spent coffee grounds biochar from torrefaction as a potential adsorbent for spilled diesel oil recovery and as an alternative fuel. Energy 2022;239:122467. [CrossRef]

- Ning X, Liang W, Wang G, Xu R, Wang P, Zhang J, et al. Effect of pyrolysis temperature on blast furnace injection performance of biochar. Fuel 2022;313:122648. [CrossRef]

- Khairy M, Amer M, Ibrahim M, Ookawara S, Sekiguchi H, Elwardany A. The influence of torrefaction on the biochar characteristics produced from sesame stalks and bean husk. Biomass Convers Biorefinery 2023:1–22. [CrossRef]

- Sharma AK, Ghodke P, Sharma PK, Manna S, Pugazhendhi A, Matsakas L, et al. Holistic utilization of Chlorella pyrenoidosa microalgae for extraction of renewable fuels and value-added biochar through in situ transesterification and pyrolysis reaction process. Biomass Convers Biorefinery 2022:1–14. [CrossRef]

- Tu R, Sun Y, Wu Y, Fan X, Cheng S, Jiang E, et al. The fuel properties and adsorption capacities of torrefied camellia shell obtained via different steam-torrefaction reactors. Energy 2022;238:121969. [CrossRef]

- Su G, Mohd Zulkifli NW, Ong HC, Ibrahim S, Bu Q, Zhu R. Pyrolysis of oil palm wastes for bioenergy in Malaysia: A review. Renew Sustain Energy Rev 2022;164:112554. [CrossRef]

- Sun J, Norouzi O, Mašek O. A state-of-the-art review on algae pyrolysis for bioenergy and biochar production. Bioresour Technol 2022;346:126258. [CrossRef]

- Bataillou G, Lee C, Monnier V, Gerges T, Sabac A, Vollaire C, et al. Cedar Wood-Based Biochar: Properties, Characterization, and Applications as Anodes in Microbial Fuel Cell. Appl Biochem Biotechnol 2022;194:4169–86. [CrossRef]

- Cai W, Tong X, Yan X, Li H, Li Y, Gao X, et al. Direct carbon solid oxide fuel cells powered by rice husk biochar. Int J Energy Res 2022;46:4965–74. [CrossRef]

- Osman AI, Fawzy S, Farghali M, El-Azazy M, Elgarahy AM, Fahim RA, et al. Biochar for agronomy, animal farming, anaerobic digestion, composting, water treatment, soil remediation, construction, energy storage, and carbon sequestration: a review. Environ Chem Lett 2022;20:2385–485. [CrossRef]

- Qiu B, Shao Q, Shi J, Yang C, Chu H. Application of biochar for the adsorption of organic pollutants from wastewater: Modification strategies, mechanisms and challenges. Sep Purif Technol 2022;300:121925. [CrossRef]

- AJALA OA, AKINNAWO SO, BAMISAYE A, ADEDIPE DT, ADESINA MO, OKON-AKAN OA, et al. Adsorptive removal of antibiotic pollutants from wastewater using biomass/biochar-based adsorbents. RSC Adv 2023;13:4678–712. [CrossRef]

- Rangabhashiyam S, Lins PV dos S, Oliveira LMT de M, Sepulveda P, Ighalo JO, Rajapaksha AU, et al. Sewage sludge-derived biochar for the adsorptive removal of wastewater pollutants: A critical review. Environ Pollut 2022;293:118581. [CrossRef]

- Foong SY, Chan YH, Chin BLF, Lock SSM, Yee CY, Yiin CL, et al. Production of biochar from rice straw and its application for wastewater remediation − An overview. Bioresour Technol 2022;360:127588. [CrossRef]

- Alsawy T, Rashad E, El-Qelish M, Mohammed RH. A comprehensive review on the chemical regeneration of biochar adsorbent for sustainable wastewater treatment. Npj Clean Water 2022;5:29. [CrossRef]

- Sutar S, Patil P, Jadhav J. Recent advances in biochar technology for textile dyes wastewater remediation: A review. Environ Res 2022;209:112841. [CrossRef]

- Zeghioud H, Fryda L, Djelal H, Assadi A, Kane A. A comprehensive review of biochar in removal of organic pollutants from wastewater: Characterization, toxicity, activation/functionalization and influencing treatment factors. J Water Process Eng 2022;47:102801. [CrossRef]

- Kasera N, Kolar P, Hall SG. Nitrogen-doped biochars as adsorbents for mitigation of heavy metals and organics from water: a review. Biochar 2022;4:17. [CrossRef]

- Choi Y-K, Choi T-R, Gurav R, Bhatia SK, Park Y-L, Kim HJ, et al. Adsorption behavior of tetracycline onto Spirulina sp. (microalgae)-derived biochars produced at different temperatures. Sci Total Environ 2020;710:136282. [CrossRef]

- Xu J, Zhang Y, Li B, Fan S, Xu H, Guan D-X. Improved adsorption properties of tetracycline on KOH/KMnO4 modified biochar derived from wheat straw. Chemosphere 2022;296:133981. [CrossRef]

- Nguyen T-B, Nguyen T-K-T, Chen W-H, Chen C-W, Bui X-T, Patel AK, et al. Hydrothermal and pyrolytic conversion of sunflower seed husk into novel porous biochar for efficient adsorption of tetracycline. Bioresour Technol 2023;373:128711. [CrossRef]

- Yu KL, Lee XJ, Ong HC, Chen W-H, Chang J-S, Lin C-S, et al. Adsorptive removal of cationic methylene blue and anionic Congo red dyes using wet-torrefied microalgal biochar: Equilibrium, kinetic and mechanism modeling. Environ Pollut 2021;272:115986. [CrossRef]

- Yu KL, Chen W-H, Sheen H-K, Chang J-S, Lin C-S, Ong HC, et al. Production of microalgal biochar and reducing sugar using wet torrefaction with microwave-assisted heating and acid hydrolysis pretreatment. Renew Energy 2020;156:349–60. [CrossRef]

- Wei X, Huang S, Yang J, Liu P, Li X, Xue R, et al. Adsorption of methylene blue on activated carbons prepared from penicillin mycelial residues via torrefaction and hydrothermal pretreatment. Biomass Convers Biorefinery 2023:1–13. [CrossRef]

- Li Z, Xing B, Ding Y, Li Y, Wang S. A high-performance biochar produced from bamboo pyrolysis with in-situ nitrogen doping and activation for adsorption of phenol and methylene blue. Chinese J Chem Eng 2020;28:2872–80. [CrossRef]

- Zhengfeng S, Ming C, Geming W, Quanrong D, Shenggao W, Yuan G. Synthesis, characterization and removal performance of Cr (Ⅵ) by orange peel-based activated porous biochar from water. Chem Eng Res Des 2023;193:1–12. [CrossRef]

- Chen W-H, Hoang AT, Nižetić S, Pandey A, Cheng CK, Luque R, et al. Biomass-derived biochar: From production to application in removing heavy metal-contaminated water. Process Saf Environ Prot 2022;160:704–33. [CrossRef]

- Xu D, Sun T, Jia H, Sun Y, Zhu X. The performance and mechanism of Cr(VI) adsorption by biochar derived from Potamogeton crispus at different pyrolysis temperatures. J Anal Appl Pyrolysis 2022;167:105662. [CrossRef]

- Zhu Q, Gao H, Sun Y, Xiang Y, Liang X, Ivanets A, et al. Highly efficient adsorption of chromium on N, S-codoped porous carbon materials derived from paper sludge. Sci Total Environ 2022;834:155312. [CrossRef]

- Vlachokostas C, Michailidou A V., Achillas C. Multi-Criteria Decision Analysis towards promoting Waste-to-Energy Management Strategies: A critical review. Renew Sustain Energy Rev 2021;138:110563. [CrossRef]

- Khan I, Kabir Z. Waste-to-energy generation technologies and the developing economies: A multi-criteria analysis for sustainability assessment. Renew Energy 2020;150:320–33. [CrossRef]

- Cutz L, Haro P, Santana D, Johnsson F. Assessment of biomass energy sources and technologies: The case of Central America. Renew Sustain Energy Rev 2016;58:1411–31. [CrossRef]

- Almanaseer N, Dunlop C, Friesen K, Nestico-Semianiw E, Abbassi B. Multi-criteria analysis of waste-to-energy technologies in developed and developing countries. Environ Res Eng Manag 2020;76:32–43. [CrossRef]

- Mpanang’ombe W, Tilley E, Zabaleta I, Zurbrügg C. A biowaste treatment technology assessment in Malawi. Recycling 2018;3:1–14. [CrossRef]

- Thengane, SK. Assessment of Different Technologies for Managing Yard Waste Using Analytic Hierarchy Process. Process Integr Optim Sustain 2019;3:255–72. [CrossRef]

- Ferreira AF, Ribau JP, Costa M. A decision support method for biochars characterization from carbonization of grape pomace. Biomass and Bioenergy 2021;145. [CrossRef]

- Silveira EA, Santanna MS, Barbosa Souto NP, Lamas GC, Galvão LGO, Luz SM, et al. Urban lignocellulosic waste as biofuel: thermal improvement and torrefaction kinetics. J Therm Anal Calorim 2023;148:197–212. [CrossRef]

- Petrova T, Naydenova I, Ribau J, Ferreira AF. Biochar from Agro-Forest Residue: Application Perspective Based on Decision Support Analysis. Appl Sci 2023;13. [CrossRef]

- Carlsen L, Bruggemann R. The 17 United Nations’ sustainable development goals: a status by 2020. Int J Sustain Dev World Ecol 2022;29:219–29. [CrossRef]

| Search | Keywords | Boolean Operator | Keywords | Boolean Operator | Keywords | Results |

|---|---|---|---|---|---|---|

| 1 | biochar | AND | - | - | - | 29.645 |

| 2 | biochar | AND | pyrolys* | - | - | 11.417 |

| 3 | biochar | AND | gasificat* | - | - | 1.570 |

| 4 | biochar | AND | Soil | - | - | 13.954 |

| 5 | biochar | AND | catalys* | - | - | 2.504 |

| 6 | biochar | AND | Water | - | - | 12.264 |

| 7* | biochar | AND | Water | AND | treatment | 4.783 |

| 8 | biochar | AND | wastewater | - | - | 3.486 |

| 9 | #7 | OR | #8 | - | - | 6.901 |

| Properties | |

|---|---|

| Specific surface area (SSA) | High values of SSA are indicators of adsorption capabilities |

| Porosity | High values of porosity are indicators of adsorption capabilities |

| Pore volume/distribution | Pore volume and distribution are significant criteria for the adsorption/desorption capability and selectivity |

| Surface functional Group | The superficial composition of biochar delimitates the application and adsorption capabilities |

| Water holding capability | High water holding capability values indicate water retention and delimitate the applications on plant stress remediation |

| Ion exchange capability | Indicative of efficiency on remediation of soil nutrient leaching |

| Elemental composition | The elemental composition is an indicator of stability and possible remediation applications |

| High heating value (HHV) | Indication of combustion energy production. The greater the value, the better |

| Feedstock / Biochar | %C | %H | %O | H/C* | O/C* | |

| Pinewood | [66] | |||||

| PW | 48.90 | 6.20 | 42.50 | 1.51 | 0.65 | |

| PW450 | 75.50 | 3.70 | 17.00 | 0.58 | 0.17 | |

| Timothy grass | ||||||

| TG | 43.40 | 6.10 | 45.40 | 1.68 | 0.79 | |

| TG450 | 63.70 | 3.60 | 23.10 | 0.67 | 0.27 | |

| Wheat straw | ||||||

| WS | 44.10 | 6.00 | 45.00 | 1.62 | 0.77 | |

| WS450 | 64.80 | 3.10 | 23.00 | 0.57 | 0.27 | |

| Pinewood-2 | [67] | |||||

| PW-2 | 48.50 | 5.92 | 45.16 | 1.45 | 0.70 | |

| PW450-2 | 71.80 | 3.94 | 22.66 | 0.65 | 0.24 | |

| PW600-2 | 84.66 | 2.81 | 10.25 | 0.40 | 0.09 | |

| PW800-2 | 89.7 | 1.24 | 3.61 | 0.16 | 0.03 | |

| Switchgrass | ||||||

| SW | 45.58 | 5.45 | 45.65 | 1.43 | 0.75 | |

| SW450 | 66.54 | 3.43 | 15.31 | 0.61 | 0.17 | |

| SW600 | 71.52 | 2.53 | 5.39 | 0.42 | 0.06 | |

| SW800 | 71.62 | 1.16 | 4.85 | 0.19 | 0.05 | |

| Wheat straw-2 | [57] | |||||

| WS-2 | 45.53 | 3.56 | 42.53 | 0.93 | 0.70 | |

| WS300-2 | 61.48 | 2.73 | 19.61 | 0.53 | 0.24 | |

| WS400-2 | 64.18 | 1.78 | 13.93 | 0.33 | 0.16 | |

| WS500-2 | 67.39 | 1.01 | 7.35 | 0.18 | 0.08 | |

| WS600-2 | 65.34 | 0.52 | 10.77 | 0.09 | 0.12 | |

| Corn straw | ||||||

| CS | 44.53 | 5.31 | 41.18 | 1.42 | 0.69 | |

| CS300 | 61.2 | 3.68 | 17.39 | 0.72 | 0.21 | |

| CS400 | 63.36 | 1.96 | 16.46 | 0.37 | 0.20 | |

| CS500 | 65.08 | 0.77 | 11.36 | 0.14 | 0.13 | |

| CS600 | 67.48 | 0.18 | 8.98 | 0.03 | 0.10 | |

| Rape straw | 44.63 | 4.89 | 42.34 | 1.31 | 0.71 | |

| RP | ||||||

| RP300 | 61.80 | 3.54 | 17.95 | 0.68 | 0.22 | |

| RP400 | 63.74 | 1.91 | 13.48 | 0.36 | 0.16 | |

| RP500 | 66.96 | 0.87 | 9.46 | 0.15 | 0.11 | |

| RP600 | 67.85 | 0.18 | 7.89 | 0.03 | 0.09 | |

| Rice straw | ||||||

| RS | 42.12 | 4.16 | 41.22 | 1.18 | 0.73 | |

| RS300 | 56.49 | 2.95 | 17.73 | 0.62 | 0.24 | |

| RS400 | 56.42 | 1.35 | 13.71 | 0.29 | 0.18 | |

| RS500 | 59.59 | 0.47 | 8.27 | 0.09 | 0.10 | |

| RS600 | 61.30 | 0.12 | 5.71 | 0.02 | 0.07 | |

| Brewers’ spent grain | [31] | |||||

| BSG | 44.72 | 6.86 | 44.66 | 1.83 | 0.75 | |

| BSG300 | 63.28 | 5.03 | 31.20 | 0.95 | 0.37 | |

| BSG500 | 71.67 | 4.11 | 23.84 | 0.68 | 0.25 | |

| BSG700 | 83.17 | 3.66 | 12.62 | 0.52 | 0.11 |

| Band position (cm–1) | Component | Ref. |

| 480, 592, 652 | Aromatic deforming rings, C-C stretching | [66] |

| 782, 840, 885 | C-H, aromatic hydrogen | |

| 1097 | C-O-C symmetric stretching | |

| 1618 | Aromatic C-C ring stretching | |

| 1709 | Phenyl ring substitution overtones | |

| 2950 | Alkyl/aliphatic C-H stretching | |

| 3544 | -OH stretching | |

| 3642 | -OH stretching, alcohols, phenols |

| Source Biomass | Biochar Preparation Conditions | Optimum Biochar Characteristics and Combustibility Properties | Ref. |

|---|---|---|---|

| Orange peel | Pyrolysis Atmosphere: N2 Temp.: 500 °C HR: 5 °C min–1 Time: 60 min |

Biochar O/C – 0.12; Biochar H/C – 0.66; HHV–25.73 MJ kg–1; Energy yield – 47.52%; Fuel Ratio – 5.87; Thermal stability – 0.85. | [114] |

| Sugarcane bagasse | Pyrolysis Atmosphere: N2 Temp.: 600 °C HR: 10 °C min–1 Time: 30 min |

Biochar O/C – 0.3; H/C – 0.2; HHV–29.99 MJ kg–1; Biochar yield – 21.75%; Fuel Ratio – 3.21; Energy yield – 36.32%. | [115] |

| Palm fiber | Pyrolysis Atmosphere: N2 Temp.: 700 °C HR: 5 °C min–1 Time: 120 min |

Biochar O/C – 0.23; Biochar SSA – 0.272 m2 g–1; HHV – 26.77 MJ kg–1; Biochar yield – 28.37%; Energy yield – 45.72%. | [116] |

| Spent coffee grounds | Torrefaction Atmosphere: N2 Temp.: 300 °C Time: 30min |

Biochar O/C – 0.39; Biochar H/C – 0.10; Biochar SSA – 0.524 m2 g–1; HHV- 30.32 MJ kg–1; Biochar yield – 62%. | [117] |

| Poplar wood | Pyrolysis Atmosphere: N2 Temp.: 600 °C HR: 5–20 °C min–1 |

Biochar O/C – 0.06; Biochar H/C – 0.025; HHV- 32.73 MJ kg–1; Biochar yield – 24.3 %; Fuel Ratio – 6.86; Combustibility Index – 1.9 s–1 °C–2; Comprehensive combustion characteristic index – 3.3 s–2 °C–3. | [118] |

| Sewage sludge | Pyrolysis Atmosphere: N2 Temp.: 450 °C HR: 10 °C min–1 Time: 30min |

Biochar O/C – 0.19; Biochar H/C – 0.74; HHV–13.58 MJ kg-1; Biochar yield – 57.90%; Fuel Ratio – 0.86; Energy yield – 42.04%; Combustion index – 0.59 106 %–2 s–2 °C–3. | [2] |

| Sesame stalks | Torrefaction Atmosphere: N2 Temp.: 275 °C Time: 30min |

Biochar O/C – 0.64; Biochar H/C – 1.25; HHV–20.5 MJ kg–1; Biochar yield – 76.25%; Fuel Ratio – 0.52; Energy yield – 86.16%; Bulk density – 290.01 kg m–3. | [119] |

| Microalgae - Chlorella pyrenoidosa | Pyrolysis Atmosphere: N2 Temp.: 400–600 °C HR: 10 °C min–1 Time: 30min |

Biochar O/C – 0.23; Biochar H/C – 0.055; HHV–17.15 MJ kg–1; Biochar yield – 51.23%; Fuel Ratio – 1.72. | [120] |

| Camellia shell | Steam-torrefaction Atmosphere: N2 Temp.: 280 °C Time: 30min |

Biochar O/C – 0.36; Biochar H/C – 0.07; Biochar SSA – 28.66 m2 g–1; HHV–24.76 MJ kg–1; Biochar yield – 50.45%; Fuel Ratio – 1.04. | [121] |

| Biomass | Process | Contam. | Biochar Properties and Adsorption Data | Ref. |

|---|---|---|---|---|

| Microalgae (Spirulina sp.) | Pyrolysis Atmosphere: N2 Temp.: 750 °C Time: 120min |

Tetracycline (TC) | O/C–0.138; H/C–1.38; SSA–2.63 m2 g-1; Desorption efficiency–61 %; Highest TG adsorption at 147.9 mg g–1 (TC 100 mg L–1; dosage 0,1 g L–1; pH 6). |

[135] |

| Wheat Straw | Pyrolysis Atmosphere: N2Temp.: 500 °C Time: 120 min Activation: KMnO4/KOH |

O/C–0.225; H/C–0.007; SSA–1524.6 m2 g–1; Pore volume–0.85 cm3 g-1; Raman ID/IG before adsorption–2.58; Desorption efficiency (NaOH solution)–7%; Highest TG adsorption at 584.19 mg g–1 at 318 K (TC 10–200 mg L–1; pH 3–10); No co-existing ions effect | [136] | |

| Sunflower Seed Husk | Pyrolysis Atmosphere: N2 Temp.: 700 °C Time: 120 min Activation: KMnO4/KOH/ZnCl2 |

O/C–0.1; H/C–0.014; SSA–1578.3 m2 g–1; Pore volume–1.138 cm3 g–1; Raman ID/IG before adsorption–0.585; Desorption efficiency–97.61%; Highest TG adsorption at 673.0 mg g–1 at 298 K for 24h (TC 1–20 mg L–1; pH 3.0–11.0); Highest TG adsorption with ions at 583.1 (K+), 539.8 (Mg2+) and 555.9 (Ca2+). | [137] | |

| Microalgae - Chlorella sp. GD | Wet Torrefaction (Water vapor) and Microwave Torref. (2450MHz, 800W) Temp.: 160–170 °C Time: 5–10min |

Methylene Blue (MB) | O/C between (0.462–0.506); SSA–2.66 m2 g–1; Pore volume 0.00043 cm3 g–1; Maximum removal of 85.47% MB; Highest MB adsorption at 113 mg g–1 (optimum pH 2–8). | [138,139] |

| Penicillin mycelial residues | Torrefaction Atmosphere: N2 Temp.: 260 °C HR.: 5 °C min–1 Time: 45 min Impregnation: KOH |

O/C–0.08; H/C–0.021; SSA – 1809.74 m2 g-1; Pore volume 1.02 cm3 g–1; Raman ID/IG before adsorption – 1.21; Highest MB adsorption at 620 mg g–1. | [140] | |

| Bamboo particles | Pyrolysis Atmosphere: N2 Temp.: 700 °C HR.: 10 °C min–1 Time: 120 min Impregnation: KHCO3/ Urea |

O/C–0.081; SSA–1693 m2 g–1; Biochar total pore volume 0.90 cm3 g–1; Raman ID/IG before adsorption – 1.10; Highest MB adsorption at 499 mg g–1. | [141] | |

| Orange peel | Pyrolysis Atmosphere: N2 Temp.: 400 °C HR.: 5 °C min–1 Time: 180 min Activation: KOH |

Cr(III)/Cr(IV) | Cr(IV) synthetic solution; O/C–0.100; SSA–998 m2 g–1; Biochar total pore volume–1.24 cm3 g–1; Raman ID/IG before adsorption–1.03; Highest Cr(IV) adsorption at 285.5 mg g–1 (pH – 2, Dosage 0,2 g L–1, C0 100 mg L–1, T = 25 °C, contact time = 40 h). | [142] |

| Vegetal waste – Rice Husk/ Polyethylene | Co-pyrolysis Atmosphere: N2 Temp.: 390 °C Time: 35 min |

Cr(III) synthetic solution; O/C 0.089; Biochar SSA <5.0 m2 g–1; Adsorption capacity–9.23 mg g–1 (final pH 4–5). |

[143] | |

| Algae - Potamogeton crispus | Pyrolysis Atmosphere: N2 Temp.: 300 °C HR.: 5 °C min–1 Time: 120 min |

Cr(IV) synthetic solution; O/– 0.53; H/C–0.09; SSA–0.42 m2 g–1; Pore volume–0.002 cm3 g–1; Raman ID/IG before adsorption–1.83; Highest Cr(IV) adsorption at 34.37 mg g–1 (pH–2, Dosage 2 g L–1, C0 100 mg L–1 and T = 25 °C.). | [144] | |

| Paper sludge waste | Pyrolysis Atmosphere: N2 Temp.: 350–550 °C HR.: 5 °C min–1 Time: 120 min Activation (KOH) Temp.: 105 °C Time: 150 min / Pyrolysis Atmosphere: N2 Temp.: 800 °C Time: 120 min Impregnation: NH4Cl |

Cr(IV) synthetic solution; O/C–0.383; H/C–0.059; SSA–3336.7 m2 g–1; Pore volume–2.10 cm3 g–1; Raman ID/IG before adsorption–0.95; Highest Cr(IV) adsorption at 356.25 mg g–1 (99% removal under 30 min.). | [145] |

| App. | Biomass | Properties/Criteria | Analytical Technique | MCDM | Ref. |

|---|---|---|---|---|---|

| Biofuel | Grape pomace | Biochar yield, Carbon (%), HHV, Kinetics Combustion parameters (Ea) |

Proximate analysis Calorific analysis Ultimate analysis TG/DTG |

Pareto Dominance Analysis / Metric distance based on compromise programming |

[152] |

| Grape pomace, cherry stones, peach stones, colza, sunflower husks, and softwood |

Moisture%, Ash, HHV, Kinetics Combustion parameters (Ea) |

Proximate analysis Calorific analysis TG/DTG |

Pareto Dominance Analysis / Metric distance based on compromise programming |

[154] | |

| Fruit seeds | Carbon enhancement index (CEI), HHV and its enhancement factor (EF) and energy-mass coefficient index (EMCI) | Calorific analysis Ultimate analysis |

Pareto Dominance Analysis / Metric distance based on compromise programming |

[26] | |

| Spent coffee ground Brew spent grains |

O/C and H/C, HHV and its enhancement factor (EF), energy yield (EY) |

Calorific analysis Ultimate analysis |

Pareto Dominance Analysis / Metric distance based on compromise programming |

[31] | |

| Pruning trees | FC, ash, HHV, O/C and H/C | Proximate analysis Calorific analysis Ultimate analysis |

Pareto Dominance Analysis / Metric distance based on compromise programming |

[68] | |

| Catalyst | Grape pomace, cherry stones, peach stones, colza, sunflower husks, and softwood |

K, Ca, P (%), Carbon (%), Specific surface area (m2 g–1) |

EDS Ultimate analysis Brunauer– Emmett–Teller (BET) method |

Pareto Dominance Analysis / Metric distance based on compromise programming |

[154] |

| Soil Amendment | Fruit seeds | O/C and H/C, Carbon enhancement index (CEI), K, N, P(%) |

EDS Ultimate analysis |

Pareto Dominance Analysis / Metric distance based on compromise programming |

[26] |

| Grape pomace | Biochar yield, Carbon content, O/C and H/C, N, P, Mg, K |

EDS Ultimate analysis |

Pareto Dominance Analysis / Metric distance based on compromise programming |

[152] | |

| Soil Amendment / CO2 sequestration / Supercapacitor development |

Grape pomace, cherry stones, peach stones, colza, sunflower husks, and softwood |

K, Ca, P (%) / Carbon (%) / Specific surface area, Bulk density, electric conductivity, pH |

EDS Ultimate analysis Brunauer– Emmett–Teller (BET) method Biochar pH, Electrical Conductivity and Liming Potential |

Pareto Dominance Analysis / Metric distance based on compromise programming |

[154] |

| Wastewater treatment |

Spirulina sp. Wheat straw Sunflower seed husk Chlorella sp. Penicillin mycelia Bamboo particles Orange peel Rice husk Paper sludge |

O/C SSA Pore volume Raman ID/IG Surface composition Adsorption capability |

Ultimate analysis Physicochemical analysis Surface analysis Molecular/structural analysis |

- | [81,135,136,137,138,140,141,142,143,144,145] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).