Submitted:

12 April 2024

Posted:

12 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Panel Identification

2.2. Panel Selection

2.3. Study Design

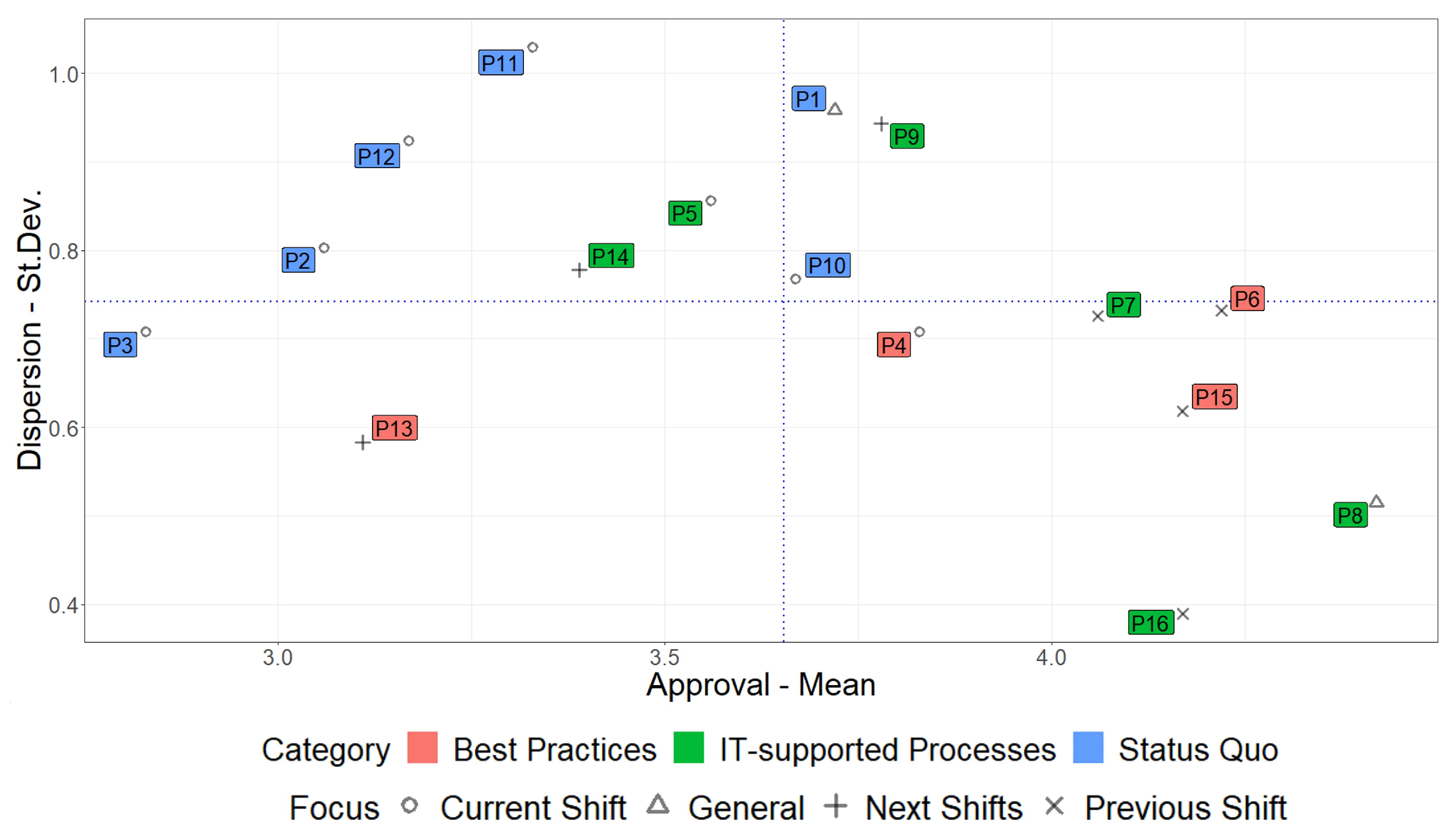

- Status quo: How well are operations at terminals supported by modern TOS solutions? What does the current situation look like?

- Best practices: What are common opinions of what operations should look like? In case of challenges during operations, what are appropriate countermeasures?

- IT-supported processes: How can modern IT solutions improve terminal operations in general and operational best practices specifically?

- Previous shifts: The proposition addresses the analysis of terminal operations during previous shifts based on recorded information.

- Current shift: The proposition focuses on terminal operations in real-time.

- Next shifts: The proposition describes shift planning including workload forecasting for the next few days.

- General: The proposition covers several of the aforementioned time ranges or does not have a clear temporal focus.

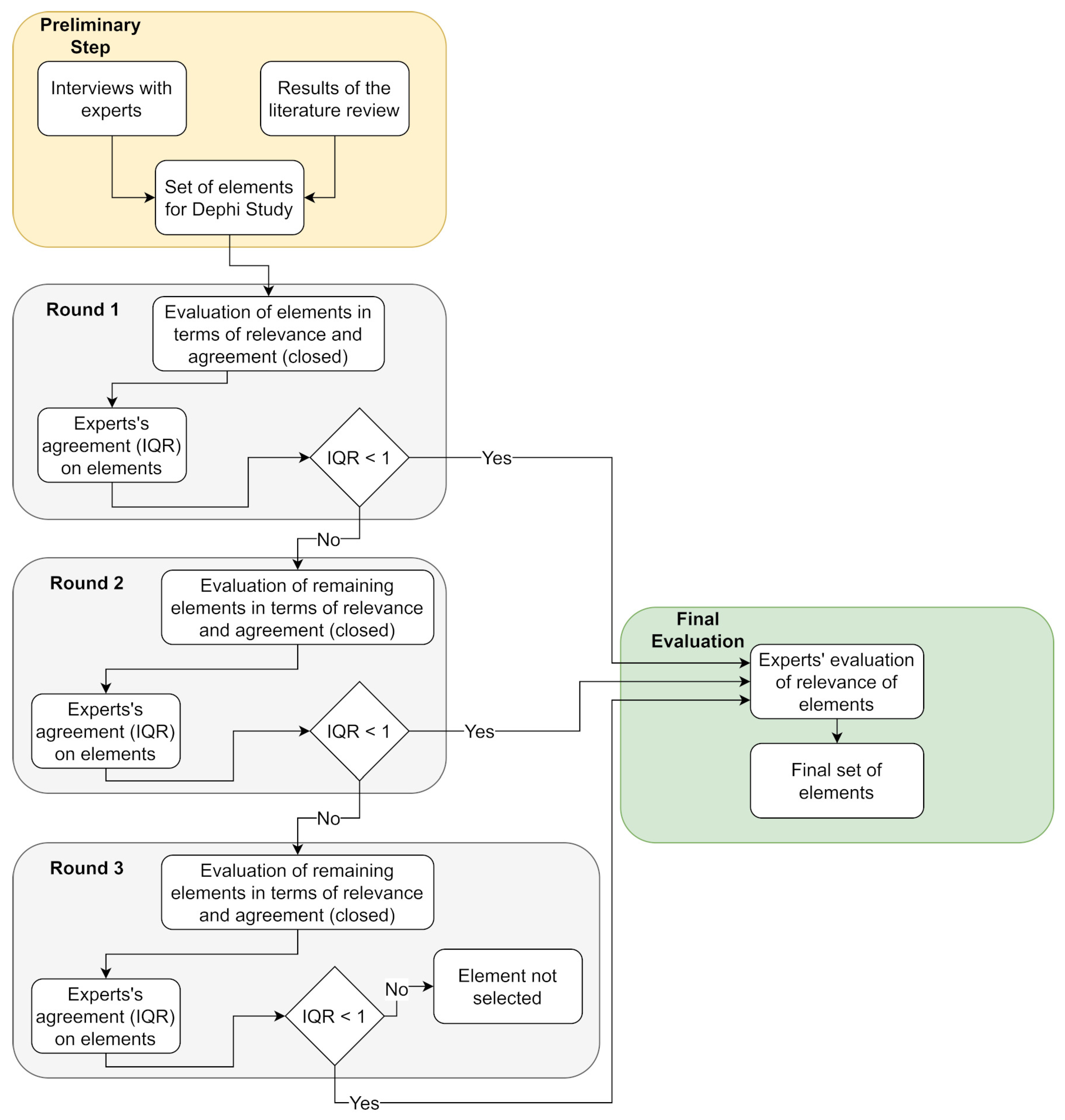

2.4. Rounds

3. Results

4. Discussion

4.1. Outlook

4.2. Limitations

4.3. Conclusion

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AI | Artificial Intelligence |

| AGV | Automated Guided Vehicle |

| CT | Container Terminal |

| DT | Digital Twin |

| ECS | Equipment Control System |

| IoT | Internet of Things |

| ML | Machine Learning |

| RL | Reinforcement Learning |

| TOS | Terminal Operating System |

References

- UNCTAD. Review of Maritime Transport 2021: Challenges faced by seafarers in view of the COVID-19 crisis; Review of maritime transport / United Nations Conference on Trade and Development, Geneva, United Nations Publications: New York, USA, 2021. [Google Scholar]

- UNCTAD. Review of Maritime Transport 2022: Navigating stormy waters; Vol. 2022, Review of maritime transport / United Nations Conference on Trade and Development, Geneva, United Nations: Geneva, 2022. [Google Scholar]

- UNCTAD. Digitalizing the Port Call Process; Vol. 13, Transport and Trade Facilitation, United Nations: New York, 2020. [Google Scholar] [CrossRef]

- Lange, A.K.; Grafelmann, M. Digitalization of Maritime Logistics Systems. In Arctic Maritime Logistics: The Potentials and Challenges of the Northern Sea Route; Ilin, I., Devezas, T., Jahn, C., Eds.; Springer International Publishing: Cham, 2022; pp. 95–116. [Google Scholar] [CrossRef]

- Kim, A.; Park, H.J.; Park, J.H.; Cho, S.W. Rescheduling Strategy for Berth Planning in Container Terminals: An Empirical Study from Korea. Journal of Marine Science and Engineering 2021, 9. [Google Scholar] [CrossRef]

- Voss, A.; Guckenbiehl, G.; Schütt, H.; Buer, T. An online storage strategy with dynamic bay reservations for container terminals. 2016 IEEE Symposium Series on Computational Intelligence (SSCI). IEEE, 2016, pp. 1–8. [CrossRef]

- Raeesi, R.; Sahebjamnia, N.; Mansouri, S.A. The synergistic effect of operational research and big data analytics in greening container terminal operations: A review and future directions. European Journal of Operational Research 2023, 310, 943–973. [Google Scholar] [CrossRef]

- Jing Gao, Yuhui Sun, R.R.; Chow, C. Understanding data governance requirements in IoT adoption for smart ports – a gap analysis. Maritime Policy & Management. [CrossRef]

- PIANC. Masterplans for the development of existing ports: MarCom Working Group Report N° 158, 2014.

- He, B.; Bai, K.J. Digital twin-based sustainable intelligent manufacturing: a review. Advances in Manufacturing 2021, 9, 1. [Google Scholar]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. Transdisciplinary Perspectives on Complex Systems.

- Negri, E.; Fumagalli, L.; Macchi, M. A Review of the Roles of Digital Twin in CPS-based Production Systems. Procedia Manufacturing 2017, 11, 939–948. [Google Scholar]

- Szpytko, J.; Duarte, Y.S. Digital Twins Model for Cranes Operating in Container Terminal. IFAC-PapersOnLine 2019, 52, 25–30. [Google Scholar] [CrossRef]

- Szpytko, J.; Salgado Duarte, Y. A digital twins concept model for integrated maintenance: a case study for crane operation. Journal of Intelligent Manufacturing 2021, 32, 1863–1881. [Google Scholar] [CrossRef]

- Jakovlev, S.; Eglynas, T.; Voznak, M.; Partila, P.; Tovarek, J.; Jusis, M.; Pocevicius, E.; Purlaura, Z. Development of an Intelligent Digital Twins Framework for Secure Container Terminal Operations. ITMS 2021 - 2021 62nd International Scientific Conference on Information Technology and Management Science of Riga Technical University, Proceedings, 2021. [CrossRef]

- Li, Y.; Chang, D.; Gao, Y.; Zou, Y.; Bao, C. Automated Container Terminal Production Operation and Optimization via an AdaBoost-Based Digital Twin Framework. Journal of Advanced Transportation 2021, 2021. [Google Scholar] [CrossRef]

- Saanen, Y.A. Modeling Techniques in Planning of Terminals: The Quantitative Approach. In Handbook of Terminal Planning; Böse, J.W., Ed.; Springer International Publishing: Cham, 2020; pp. 49–71. [Google Scholar] [CrossRef]

- Yang, A.; Liu, Y.; Xin, C.; Chen, Q.; Wang, L. Towards intuitive visualisation goals for the operation optimisation of automated container terminal based on digital twin technology. Maritime Policy & Management. [CrossRef]

- Lou, P.; Zhong, Y.; Hu, J.; Fan, C.; Chen, X. Digital-Twin-Driven AGV Scheduling and Routing in Automated Container Terminals. Mathematics 2023, 11. [Google Scholar] [CrossRef]

- Gao, Y.; Chen, C.H.; Chang, D.; Chen, S.; Song, X.T. Machine Learning and Digital Twin-Based Path Planning for AGVs at Automated Container Terminals. Advances in Transdisciplinary Engineering, 2022, Vol. 28, p. 423 – 432. Cited by. [CrossRef]

- Zhang, Y.; Bao, X.; Zhang, L.; Chen, L.; Tang, X.; Zhang, Z.; Zheng, Y. Digital Twin Enhanced Reinforcement Learning for Integrated Scheduling in Automated Container Terminals*. 2023 IEEE 19th International Conference on Automation Science and Engineering (CASE). IEEE, 2023, pp. 1–6. [CrossRef]

- Wang, K.; Hu, Q.; Zhou, M.; Zun, Z.; Qian, X. Multi-aspect applications and development challenges of digital twin-driven management in global smart ports. Case Studies on Transport Policy 2021, 9, 1298–1312. [Google Scholar]

- Ding, Y.; Zhang, Z.; Chen, K.; Ding, H.; Voss, S.; Heilig, L.; Chen, Y.; Chen, X.; others. Real-Time Monitoring and Optimal Resource Allocation for Automated Container Terminals: A Digital Twin Application at the Yangshan Port. Journal of Advanced Transportation 2023, 2023. [Google Scholar] [CrossRef]

- Bozzo, R.; Derito, A.; Nurchi, R.; Ackroyd, N. MOCONT: a new system for container terminal monitoring and control. ITSC 2001. 2001 IEEE Intelligent Transportation Systems. Proceedings (Cat. No.01TH8585), 2001, pp. 1090–1094. [CrossRef]

- Boer, C.A.; Saanen, Y.A. Using simulation and emulation throughout the life cycle of a container terminal. 2017 Winter Simulation Conference (WSC), 2017, pp. 3126–3137. [CrossRef]

- Kastner, M.; Grasse, O.; Jahn, C. Container Flow Generation for Maritime Container Terminals. Dynamics in Logistics; Freitag, M., Kinra, A., Kotzab, H., Megow, N., Eds.; Springer International Publishing: Cham, 2022; pp. 133–143. [Google Scholar] [CrossRef]

- Schnabel, D. Pavements for Container Terminals. In Handbook of terminal planning; Böse, J.W., Ed.; Operations research, computer science interfaces series; Springer: Cham, CH, 2020; pp. 155–172. [Google Scholar] [CrossRef]

- Huang, C.; Bai, Y.; Lu, L. Hazard Analysis and Quantitative Risk Assessment of Port Operation for Dangerous Goods Container. IOP Conference Series: Materials Science and Engineering 2020, 780, 072027. [Google Scholar] [CrossRef]

- Tsolakis, N.; Zissis, D.; Papaefthimiou, S.; Korfiatis, N. Towards AI driven environmental sustainability: an application of automated logistics in container port terminals. International Journal of Production Research 2022, 60, 4508–4528. [Google Scholar]

- Sauer, P.; Seuring, S. Extending the reach of multi-tier sustainable supply chain management – Insights from mineral supply chains. International Journal of Production Economics 2019, 217, 31–43. [Google Scholar]

- Ekström, T.; Hilletofth, P.; Skoglund, P. Towards a purchasing portfolio model for defence procurement – A Delphi study of Swedish defence authorities. International Journal of Production Economics 2021, 233. [Google Scholar]

- Goodman, C. The Delphi technique: a critique. Journal of Advanced Nursing 1987, 6, 729–734. [Google Scholar]

- Linstone, H.; Turoff, M. The delphi method; Addison-Wesley, 1975.

- Okoli, C.; Pawlowski, S. The Delphi method as a research tool: An example, design considerations and applications. Information and Management 2004, 1, 15–29. [Google Scholar]

- Dohale, V.; Gunasekaran, A.; Akarte, M.; Verma, P. An integrated Delphi-MCDM-Bayesian Network framework for production system selection. International Journal of Production Economics 2021, 242. [Google Scholar]

- Kembro, J.; Näslund, D.; Olhager, J. Information sharing across multiple supply chain tiers: A Delphi study on antecedents. International Journal of Production Economics 2017, 193, 77–86. [Google Scholar]

- Landeta, J. Current validity of the Delphi method in social sciences. Technological Forecasting and Social Change 2006, 5, 467–482. [Google Scholar]

- Hasson, F.; Keeney, S. Enhancing rigour in the Delphi technique research. Technological Forecasting and Social Change 2011, 9, 1695–1704. [Google Scholar]

- Culot, G.; Orzes, G.; Sartor, M.; Nassimbeni, G. The future of manufacturing: A Delphi-based scenario analysis on Industry 4.0. Technological Forecasting and Social Change 2020, 157. [Google Scholar]

- Diamond, I.; Grant, R.; C, R.; Feldman, B.M.; Pencharz, P.B.; Ling, S.C.; Moore, A.M.; Wales, P.W. Defining consensus: A systematic review recommends methodologic criteria for reporting of Delphi studies. Journal of Clinical Epidemiology 2014, 67, 401–409. [Google Scholar]

- Blair, J.; Czaja, R.; Blair, E. Designing surveys: A guide to decisions and procedures; SAGE Publications, Inc, 2013.

- von der Gracht, H. Consensus measurement in Delphi studies. Review and implications for future quality assurance. Technological Forecasting and Social Change 2012, 8, 1525–1536. [Google Scholar]

- Gbededo, M.; Liyanage, K. Descriptive framework for simulation-aided sustainability decision-making: A Delphi study. Sustainable Production and Consumption 2020, 22, 45–57. [Google Scholar]

- Moeuf, A.; Lamouri, S.; Pellerin, R.; Tamayo-Giraldo, S.; Tobon-Valencia, E.; Eburdy, R. Identification of critical success factors, risks and opportunities of Industry 4.0 in SMEs. International Journal of Production Research 2020, 5, 1384–1400. [Google Scholar]

- Saporiti, N.; Cannas, V.; Pozzi, R.; Rossi, T. Challenges and countermeasures for digital twin implementation in manufacturing plants: A Delphi study. International Journal of Production Economics 2023, 261, 1–13. [Google Scholar] [CrossRef]

- Chen, Z.; Pak, M. A Delphi analysis on green performance evaluation indices for ports in China. Maritime Policy & Management 2017, 44, 537–550. [Google Scholar] [CrossRef]

| Code | Region | Employer | Shortened CV / Research Focus |

| 1 | Eastern Europe | CT Operator |

|

| 2 | Northern America | Labour Organisation |

|

| 3 | Northern America | Port Consultant |

|

| 4 | Northern Europe | CT Operator |

|

| 5 | Northern Europe | Port Consultant |

|

| 6 | South America | CT Operator |

|

| 7 | South America | CT Operator |

|

| 8 | Southern Asia | CT Operator |

|

| 9 | Southern Asia | TOS Provider |

|

| 10 | Southern Europe | Academia |

|

| 11 | Southern Europe | CT Operator |

|

| 12 | Western Asia | CT Operator |

|

| 13 | Western Europe | Academia |

|

| 14 | Western Europe | CT Operator |

|

| 15 | Western Europe | Port Consultant |

|

| 16 | Western Europe | Port Consultant |

|

| 17 | Western Europe | TOS Provider |

|

| No. | Category | Focus | Proposition |

| P1 | Status quo | General | Today’s TOS solutions consider the entire picture of terminal operations. This includes the terminal equipment as well as the ships, trains, and external trucks which visit the terminal. |

| P2 | Status quo | Current shift | Today’s TOS solutions are excellent in workload balancing – they take both internal and external vehicles into account. This successfully prevents waiting queues in front of cranes inside the terminal. |

| P3 | Status quo | Current shift | A modern TOS solution requires little to no manual intervention from the equipment operators or from the operations control room. Most to all processes are automated. |

| P4 | Best practices | Current shift | Centralising the control over container handling processes in a TOS solution (and thus limiting the degrees of freedom for the equipment operators) is essential for higher efficiency. |

| P5 | IT-supported processes | Current shift | A configurable 3-D visualisation of terminal operations in the control room enables the office staff to make smarter decisions and thus adds value to terminal operations. |

| P6 | Best practices | Previous shifts | When terminal operations do not meet the required performance indicators, it is crucial to examine the root cause in retrospect and to discuss the insights with the whole team. |

| P7 | IT-supported processes | Previous shifts | To find the root cause of poor operations, it is crucial to have proper visualisation tools to display the operational data in retrospect. Modern TOS solutions need to have a visual playback mode. |

| P8 | IT-supported processes | General | It is crucial not to tamper with the productive system when trying out new TOS add-ons or checking the effect of changes in the TOS configuration on terminal operations. A terminal needs a realistic emulation environment to digitally test changes under various productive scenarios. |

| P9 | IT-supported processes | Next shifts | Terminal operations can be improved by developing automated what-if analyses in daily decision-making processes. These analyses could, e.g., take the shape of ad-hoc simulation studies with short execution times. |

| P10 | Status quo | Current shift | Today’s TOS solutions lack the ability to properly account for the expected developments in the next hours, such as vessel schedules, planned maintenance tasks, shift changes, and similar. |

| P11 | Status quo | Current shift | Today’s TOS solutions support IMO container-specific handling processes and monitoring tasks well. The open tasks, such as applying dangerous goods labels to the containers as a service, are well communicated to the workforce. |

| P12 | Status quo | Current shift | Today’s TOS solutions support reefer-specific processes and monitoring tasks appropriately. The open tasks, such as plugging in and unplugging reefers, are well communicated to the workforce. |

| P13 | Best practices | Next shifts | To effectively plan the upcoming shifts, an Excel sheet with information on vessel arrivals and their call sizes is sufficient |

| P14 | IT-supported processes | Next shifts | When planning upcoming shifts, the planners need to consider many aspects. Only ad-hoc simulation studies which use terminal emulation can sufficiently account for the complexity of this task. |

| P15 | Best practices | Previous shifts | It is necessary to frequently check the adequacy of shift plans in retrospect. Especially when terminal performance indicators are missed within a shift, it is crucial to discuss this with the shift planning team. |

| P16 | IT-supported processes | Previous shifts | To find the root cause of poor shift plans, it is crucial to have proper visualisation tools to display the operational data in retrospect. Modern TOS solutions need to have a visual playback mode. |

| Prop. No. | Round 1 | Round 2 | Round 3 | Final Result | ||||||||||

| Mean | St.Dev. | IQR | IQR Pass | Mean | St.Dev. | IQR | IQR Pass | Mean | St.Dev. | IQR | IQR Pass | Mean | St.Dev. | |

| P1 | 3.72 | 0.96 | 0.75 | ✓ | 3.72 | 0.96 | ||||||||

| P2 | 3.11 | 1.13 | 2.00 | ✗ | 3.06 | 0.80 | 0.00 | ✓ | 3.06 | 0.80 | ||||

| P3 | 2.83 | 0.71 | 1.00 | ✗ | 2.83 | 0.71 | 1.00 | ✓ | 2.83 | 0.71 | ||||

| P4 | 3.50 | 0.86 | 1.00 | ✗ | 3.83 | 0.71 | 0.00 | ✓ | 3.83 | 0.71 | ||||

| P5 | 3.83 | 0.99 | 1.75 | ✗ | 3.56 | 0.86 | 0.75 | ✓ | 3.56 | 0.86 | ||||

| P6 | 4.44 | 0.62 | 1.00 | ✗ | 4.22 | 0.73 | 1.00 | ✓ | 4.22 | 0.73 | ||||

| P7 | 4.06 | 0.73 | 0.75 | ✓ | 4.06 | 0.73 | ||||||||

| P8 | 4.56 | 0.51 | 1.00 | ✗ | 4.00 | 1.08 | 1.75 | ✗ | 4.42 | 0.51 | 1.00 | ✓ | 4.42 | 0.51 |

| P9 | 4.22 | 0.73 | 1.00 | ✗ | 3.78 | 0.94 | 0.75 | ✓ | 3.78 | 0.94 | ||||

| P10 | 3.50 | 0.92 | 1.00 | ✗ | 3.67 | 0.77 | 1.00 | ✓ | 3.67 | 0.77 | ||||

| P11 | 3.44 | 0.78 | 1.00 | ✗ | 3.17 | 0.92 | 1.00 | ✓ | 3.17 | 0.92 | ||||

| P12 | 3.44 | 0.86 | 1.00 | ✗ | 3.33 | 1.03 | 1.00 | ✓ | 3.33 | 1.03 | ||||

| P13 | 1.89 | 0.58 | 0.00 | ✓ | 1.89 | 0.58 | ||||||||

| P14 | 3.67 | 0.84 | 1.00 | ✗ | 3.39 | 0.78 | 1.00 | ✓ | 3.39 | 0.78 | ||||

| P15 | 4.17 | 0.62 | 0.75 | ✓ | 4.17 | 0.62 | ||||||||

| P16 | 4.33 | 0.69 | 1.00 | ✗ | 3.94 | 0.80 | 1.75 | ✗ | 4.17 | 0.39 | 0.00 | ✓ | 4.17 | 0.39 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).