Submitted:

01 April 2024

Posted:

10 April 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Indentation Size Effect (ISE) Models

2.1. Meyer Model

2.2. Hays and Kendall (H-K) Model

2.3. Proportional Specimen Resistance (PSR) Model

2.4. Modified Proportional Specimen Resistance (MPSR) Model

2.5. Elastic Plastic Deformation (EPD) Model

2.6. Exponential (EXP) Model

2.7. Hou-Jennet(H-J) Model

2.8. Nix-Gao (N-G) Model

2.9. Nix-Gao-Feng (N-G-Fs) Model

2.10. Nix-Gao-Huangs (N-G-Hs) Model

2.11. Nix-Gao-Haušild (N-G-H) Model

2.12. Nix–Gao-Abu Al-Rub (N-G-A) Model

2.13. Nix–Gao-Qius (N-G-Qs) Model

2.14. Nix–Gao-Yuan-Chen (N-G-YC) Model

2.15. Nix–Gao-Lius (N-G-Ls) Model

2.16. Li-Zhang -Hans (L-Z-Hs) Model

3. Collection of Experimental and Simulated Results

4. Comparative Study of Indentation Size Effect Models

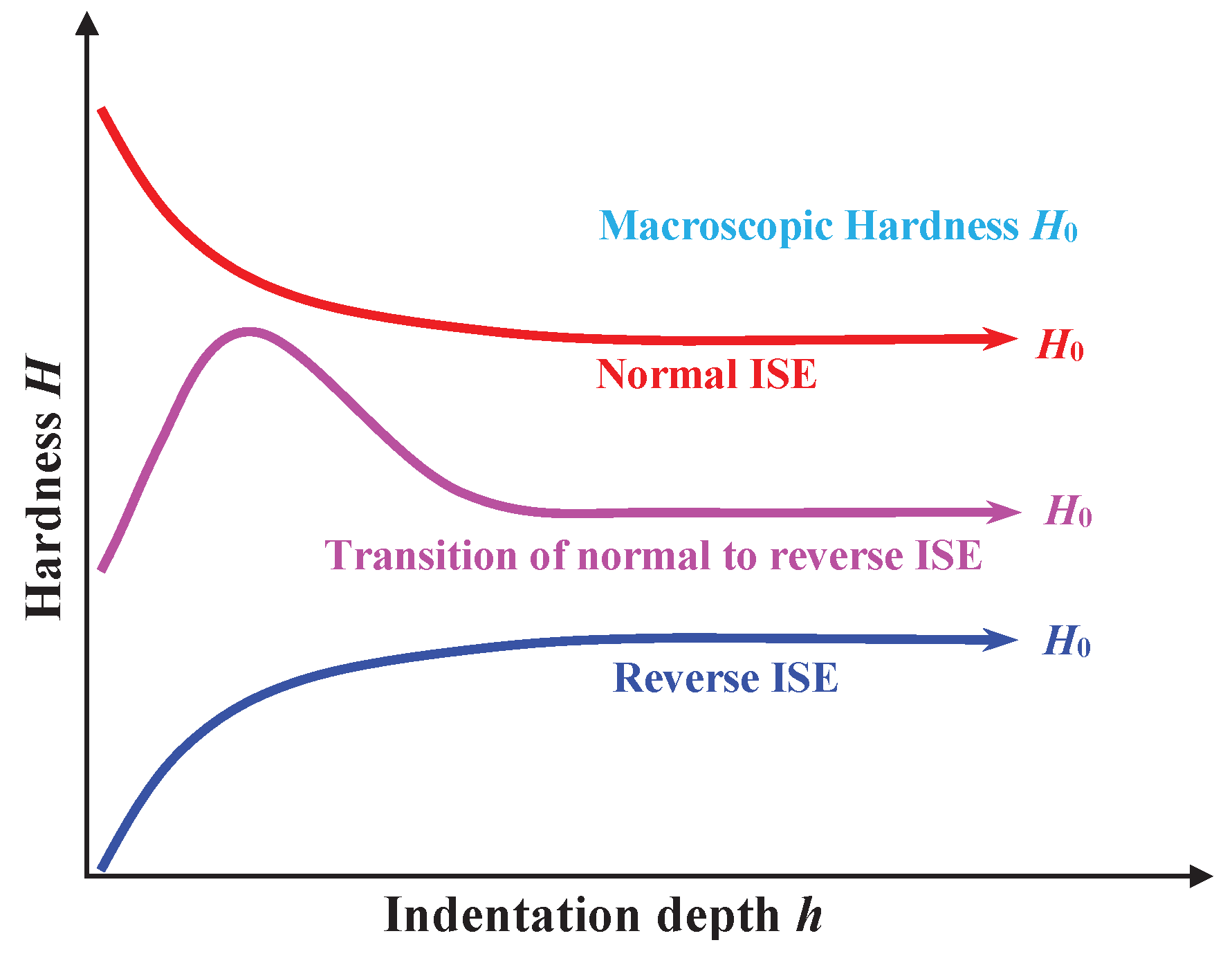

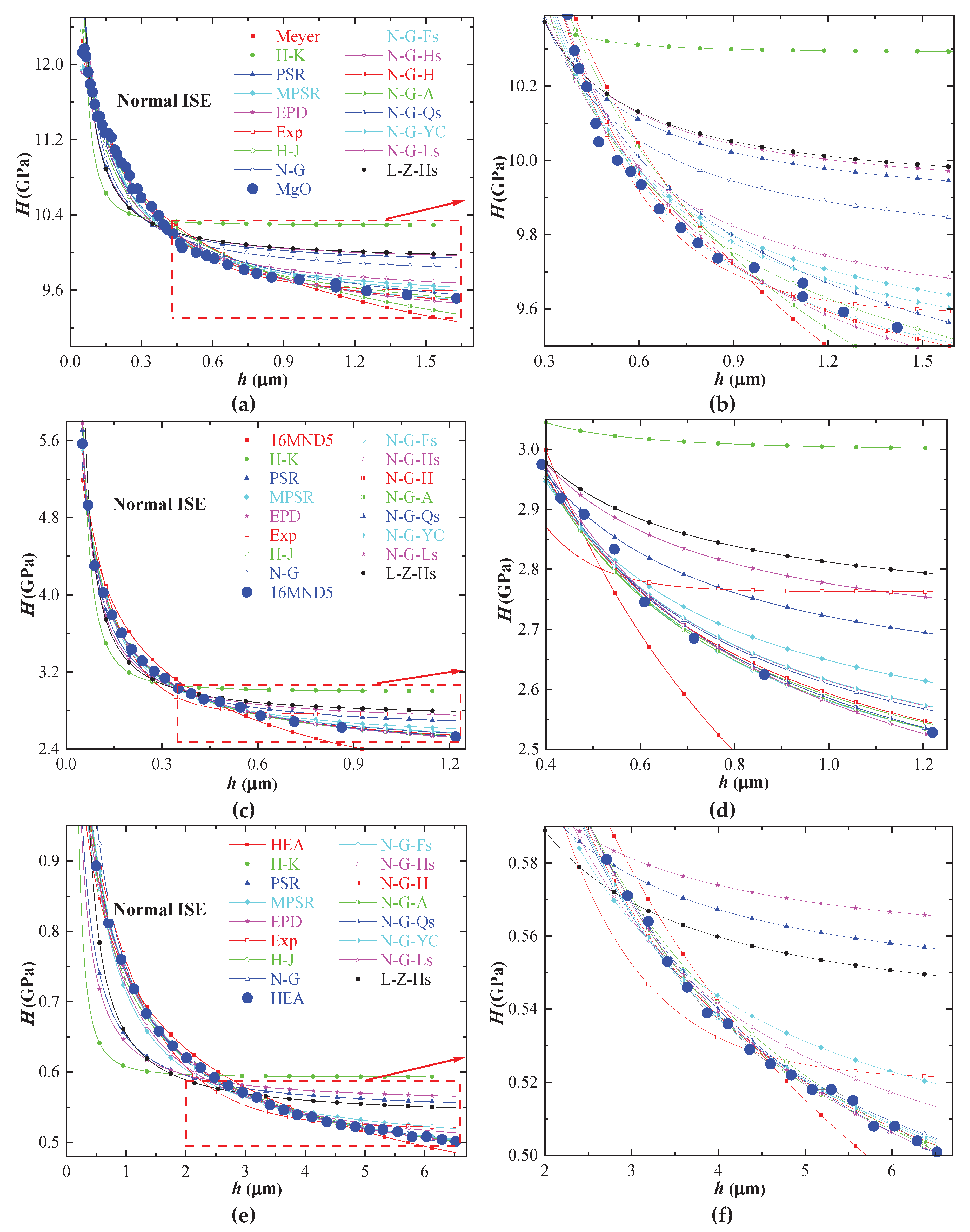

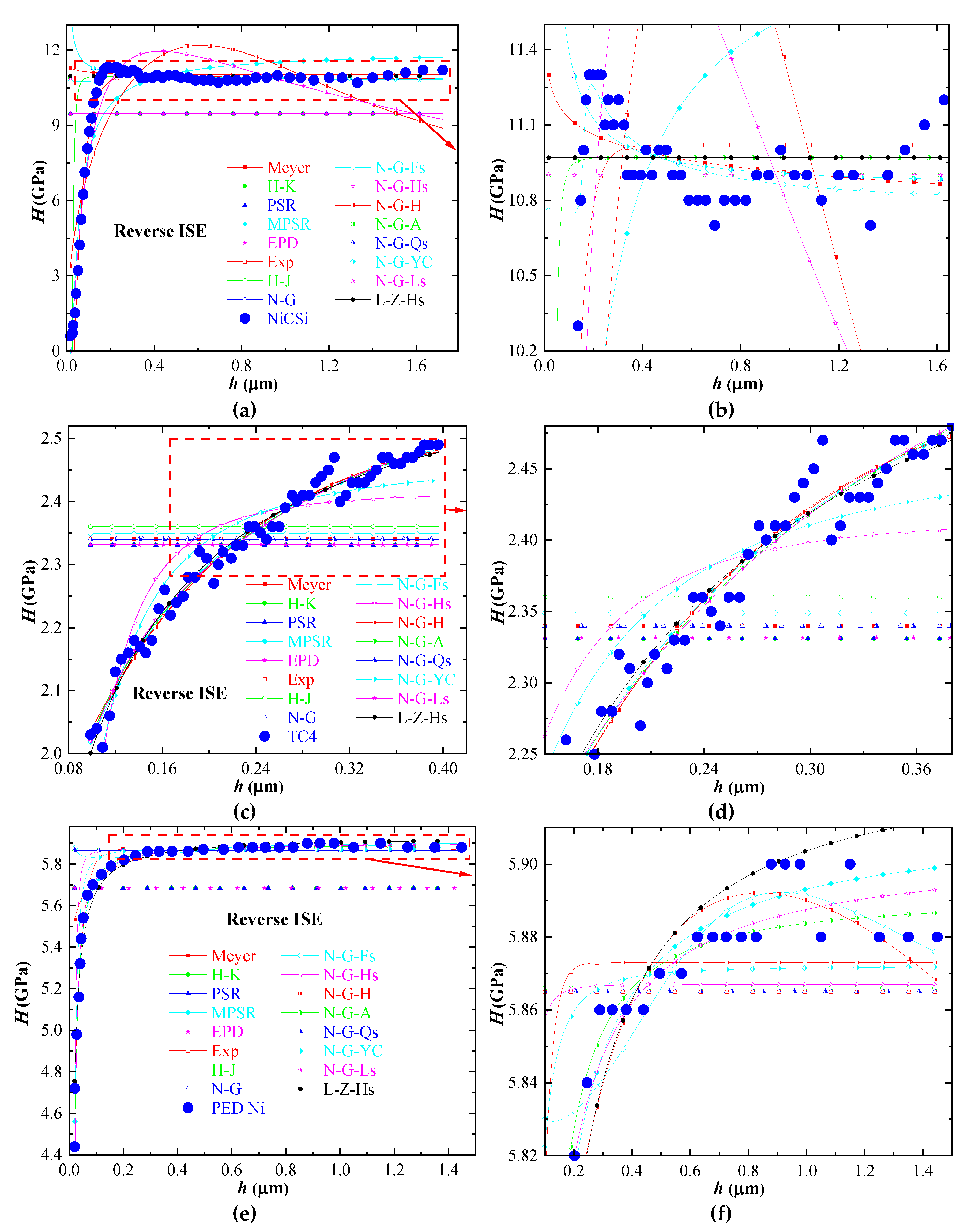

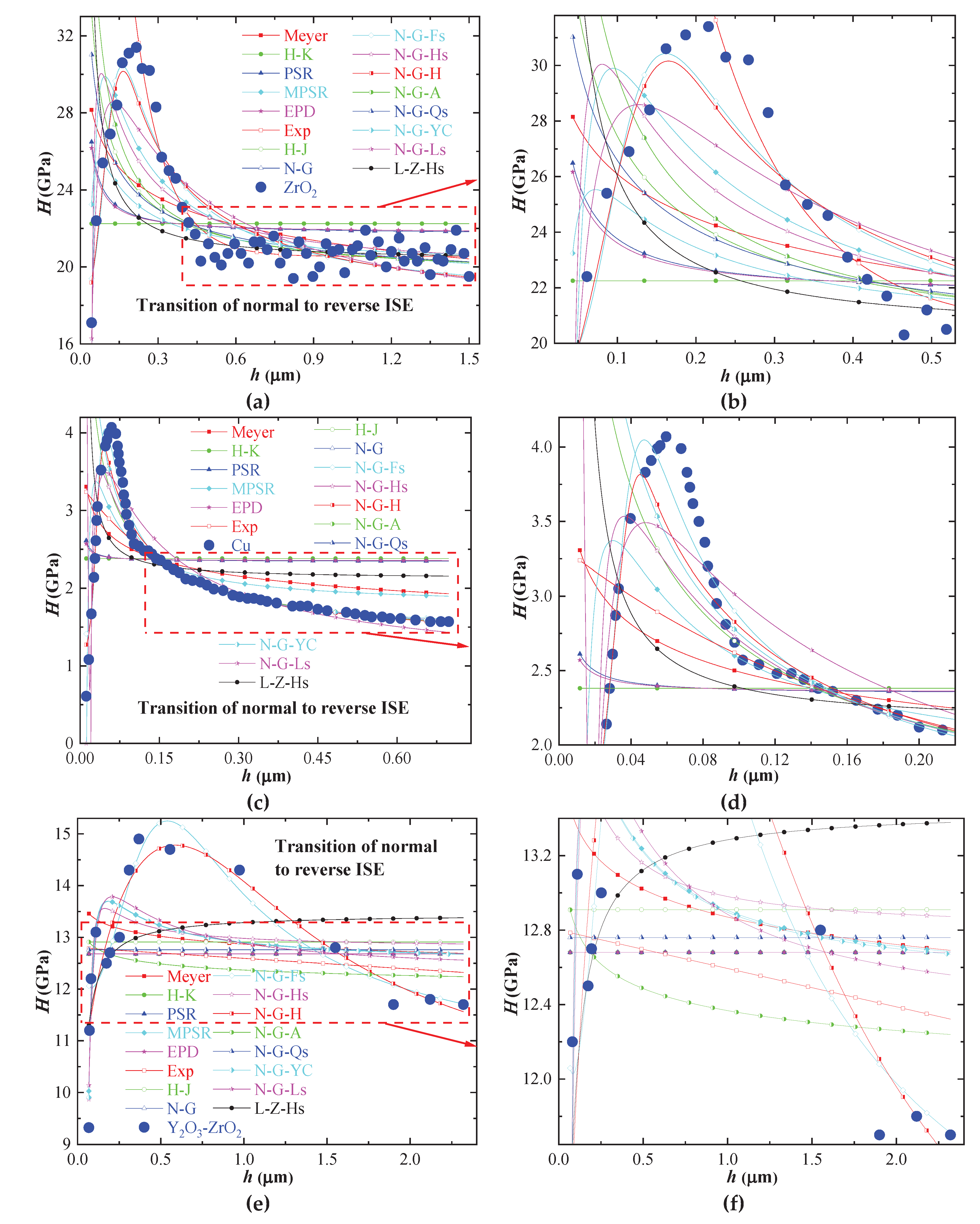

4.1. Qualitative Comparison

4.2. Quantitative Comparison

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Renjo, M.M.; Ćurković, L.; Štefančić, S.; Ćorić, D. Indentation size effect of Y-TZP dental ceramics. Dent. Mater. 2014, 30, e371–e376. [Google Scholar] [CrossRef] [PubMed]

- Čech, J.; Haušild, P.; Karlík, M.; Čapek, J.; Průša, F. Indentation Size Effect in CoCrFeMnNi HEA Prepared by Various Techniques. Materials 2021, 14, 7246. [Google Scholar] [CrossRef] [PubMed]

- Golovin, Y.I.; Gusev, A.A.; Golovin, D.Y.; Matveev, S.M.; Vasyukova, I.A. Multiscale Mechanical Performance of Wood: From Nano- to Macro-Scale across Structure Hierarchy and Size Effects. Nanomaterials 2022, 12, 1139. [Google Scholar] [CrossRef] [PubMed]

- Luo, Q.; Kitchen, M. Microhardness, Indentation Size Effect and Real Hardness of Plastically Deformed Austenitic Hadfield Steel. Materials 2023, 16, 1117. [Google Scholar] [CrossRef] [PubMed]

- Muslić, M.; Orešković, L.; Rede, V.; Maksimović, V. Indentation Size Effect of Composite A356 + 6%FA Subjected to ECAP. Metals 2022, 12, 821. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Yaghoobi, M. Chapter 1 - Introduction: Size effects in materials. In Size Effects in Plasticity, Voyiadjis, G.Z., Yaghoobi, M., Eds.; Academic Press: 2019; pp. 1–79.

- Ma, Y.; Song, Y.; Zhang, T. Revealing Nanoindentation Size-Dependent Creep Behavior in a La-Based Metallic Glassy Film. Nanomaterials 2019, 9, 1712. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Zhang, W.; Dong, Z.; Wang, Z.; Li, D.; Zhang, J. Study on Size Effect in Indentation Tests. Coatings 2022, 12, 1962. [Google Scholar] [CrossRef]

- Šolc, M.; Blaško, P.; Petrík, J.; Palfy, P.; Girmanová, L. The Indentation Size Effect (ISE) of Ag–Cu Alloys. Crystals 2023, 13, 91. [Google Scholar] [CrossRef]

- Petrík, J.; Blaško, P.; Markulík, S.; Šolc, M.; Palfy, P. The Indentation Size Effect (ISE) of Metals. Crystals 2022, 12, 795. [Google Scholar] [CrossRef]

- Chakraborty, R.; Dey, A.; Mukhopadhyay, A.K.; Joshi, K.D.; Rav, A.; Mandal, A.K.; Bysakh, S.; Biswas, S.K.; Gupta, S.C. Indentation size effect of alumina ceramic shocked at 12GPa. Int. J. Refract. Met. Hard Mater. 2012, 33, 22–32. [Google Scholar] [CrossRef]

- Li, H.; Ghosh, A.; Han, Y.; Bradt, R. The frictional component of the indentation size effect in low load microhardness testing. J. Mater. Res. 1993, 8, 1028–1032. [Google Scholar] [CrossRef]

- Iost, A.; Bigot, R. Indentation size effect: reality or artefact? J. Mater. Sci. 1996, 31, 3573–3577. [Google Scholar] [CrossRef]

- Gong, J.; Wu, J.; Guan, Z. Analysis of the indentation size effect on the apparent hardness for ceramics. Mater. Lett. 1999, 38, 197–201. [Google Scholar] [CrossRef]

- Gao, Y.X.; Fan, H. A micro-mechanism based analysis for size-dependent indentation hardness. J. Mater. Sci. 2002, 37, 4493–4498. [Google Scholar] [CrossRef]

- Dey, A.; Mukhopadhyay, A.K.; Gangadharan, S.; Sinha, M.K.; Basu, D. Weibull modulus of nano-hardness and elastic modulus of hydroxyapatite coating. J. Mater. Sci. 2009, 44, 4911–4918. [Google Scholar] [CrossRef]

- Liu, W.; Chen, L.; Cheng, Y.; Yu, L.; Yi, X.; Gao, H.; Duan, H. Model of nanoindentation size effect incorporating the role of elastic deformation. J. Mech. Phys. Solids 2019, 126, 245–255. [Google Scholar] [CrossRef]

- Chauniyal, A.; Dehm, G.; Janisch, R. On the role of pre-existing defects in influencing hardness in nanoscale indentations — Insights from atomistic simulations. J. Mech. Phys. Solids 2021, 154, 104511. [Google Scholar] [CrossRef]

- Hays, C.; Kendall, E. An analysis of Knoop microhardness. Metallography 1973, 6, 275–282. [Google Scholar] [CrossRef]

- Li, H.; Bradt, R.C. The effect of indentation-induced cracking on the apparent microhardness. J. Mater. Sci. 1996, 31, 1065–1070. [Google Scholar] [CrossRef]

- Bull, S.J.; Page, T.F.; Yoffe, E.H. An explanation of the indentation size effect in ceramics. Philos. Mag. Lett. 1989, 59, 281–288. [Google Scholar] [CrossRef]

- Ruiz-Moreno, A.; Hähner, P.; Kurpaska, L.; Jagielski, J.; Spätig, P.; Trebala, M.; Hannula, S.-P.; Merino, S.; de Diego, G.; Namburi, H.; et al. Round Robin into Best Practices for the Determination of Indentation Size Effects. Nanomaterials 2020, 10, 130. [Google Scholar] [CrossRef] [PubMed]

- Hou, X.; Jennett, N.M. Application of a modified slip-distance theory to the indentation of single-crystal and polycrystalline copper to model the interactions between indentation size and structure size effects. Acta Mater. 2012, 60, 4128–4135. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Swadener, J.; George, E.; Pharr, G. The correlation of the indentation size effect measured with indenters of various shapes. J. Mech. Phys. Solids 2002, 50, 681–694. [Google Scholar] [CrossRef]

- Feng, G.; Nix, W.D. Indentation size effect in MgO. Scr. Mater. 2004, 51, 599–603. [Google Scholar] [CrossRef]

- Durst, K.; Backes, B.; Göken, M. Indentation size effect in metallic materials: Correcting for the size of the plastic zone. Scr. Mater. 2005, 52, 1093–1097. [Google Scholar] [CrossRef]

- Huang, Y.; Zhang, F.; Hwang, K.; Nix, W.; Pharr, G.; Feng, G. A model of size effects in nano-indentation. J. Mech. Phys. Solids 2006, 54, 1668–1686. [Google Scholar] [CrossRef]

- Haušild, P. On the breakdown of the Nix-Gao model for indentation size effect. Philos. Mag. 2021, 101, 420–434. [Google Scholar] [CrossRef]

- Abu Al-Rub, R.K. Prediction of micro and nanoindentation size effect from conical or pyramidal indentation. Mech. Mater. 2007, 39, 787–802. [Google Scholar] [CrossRef]

- Qiu, X.; Huang, Y.; Nix, W.; Hwang, K.; Gao, H. Effect of intrinsic lattice resistance in strain gradient plasticity. Acta Mater. 2001, 49, 3949–3958. [Google Scholar] [CrossRef]

- Yuan, H.; Chen, J. Identification of the intrinsic material length in gradient plasticity theory from micro-indentation tests. Int. J. Solids Struct. 2001, 38, 8171–8187. [Google Scholar] [CrossRef]

- Maiti, P.; Bhattacharya, M.; Das, P.S.; Devi, P.S.; Mukhopadhyay, A.K. Indentation size effect and energy balance issues in nanomechanical behavior of ZTA ceramics. Ceram. Int. 2018, 44, 9753–9772. [Google Scholar] [CrossRef]

- Alao, A.-R.; Azhari, M.A.M. Investigation of indentation size effect and R-curve behaviour of Li2O–SiO2 and Li2O–2SiO2 glass ceramics. J. Mech. Behav. Biomed. Mater. 2021, 124, 104842. [Google Scholar] [CrossRef] [PubMed]

- Kathavate, V.; Kumar, B.P.; Singh, I.; Prasad, K.E. Analysis of indentation size effect (ISE) in nanoindentation hardness in polycrystalline PMN-PT piezoceramics with different domain configurations. Ceram. Int. 2021, 47, 11870–11877. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, B.; Long, X.; Deng, H.; Xiao, X.; Jiang, C. Revealing the hardening mechanisms of ion-irradiated nanostructured multilayers/substrate systems: A theoretical model. Int. J. Plast. 2021, 138, 102925. [Google Scholar] [CrossRef]

- Xiao, X.; Terentyev, D.; Chen, Q.; Yu, L.; Chen, L.; Bakaev, A.; Duan, H. The depth dependent hardness of bicrystals with dislocation transmission through grain boundaries: A theoretical model. Int. J. Plast. 2017, 90, 212–230. [Google Scholar] [CrossRef]

- Zhang, C.; Voyiadjis, G.Z. Rate-dependent size effects and material length scales in nanoindentation near the grain boundary for a bicrystal FCC metal. Mater. Sci. Eng. A 2016, 659, 55–62. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Zhang, C. The mechanical behavior during nanoindentation near the grain boundary in a bicrystal FCC metal. Mater. Sci. Eng. A 2015, 621, 218–228. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Znemah, R.A.; Wood, P.; Gunputh, U.; Zhang, C. Effect of element wall thickness on the homogeneity and isotropy of hardness in SLM IN718 using nanoindentation. Mech. Res. Commun. 2021, 114, 103568. [Google Scholar] [CrossRef]

- Li, X.; Zhang, W.; Han, M.; Xie, F.; Li, D.; Zhang, J.; Long, B. Indentation size effect: an improved mechanistic model incorporating surface undulation and indenter tip irregularity. J. Mater. Res. Technol. 2023, 23, 143–153. [Google Scholar] [CrossRef]

- Liu, M. Study on mechanics problem in the indentation testing. Tianjin University, Tianjin, China, 2007.

- Liu, X.; Wang, R.; Ren, A.; Jiang, J.; Xu, C.; Huang, P.; Qian, W.; Wu, Y.; Zhang, C. Evaluation of radiation hardening in ion-irradiated Fe based alloys by nanoindentation. J. Nucl. Mater. 2013, 444, 1–6. [Google Scholar] [CrossRef]

- Wang, L.; Asempah, I.; Li, X.; Zang, S.-Q.; Zhou, Y.-F.; Ding, J.; Jin, L. Indentation size effect in aqueous electrophoretic deposition zirconia dental ceramic. J. Mater. Res. 2019, 34, 555–562. [Google Scholar] [CrossRef]

- Yang, R.; Zhang, Q.; Xiao, P.; Wang, J.; Bai, Y. Two opposite size effects of hardness at real nano-scale and their distinct origins. Sci. Rep. 2017, 7, 16053. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Dai, C.; Shen, Y.; Mao, W. Elasto-plastic characteristics and mechanical properties of as-sprayed 8mol% yttria-stabilized zirconia coating under nano-scales measured by nanoindentation. Appl. Surf. Sci. 2014, 309, 271–277. [Google Scholar] [CrossRef]

- Seekala, H.; Bathini, L.; Wasekar, N.P.; Krishnaswamy, H.; Phani, P.S. A unified approach to quantify the material and geometrical effects in indentation size effect. J. Mater. Res. 2023, 38, 1740–1755. [Google Scholar] [CrossRef]

- Pharr, G.M.; Herbert, E.G.; Gao, Y. The Indentation Size Effect: A Critical Examination of Experimental Observations and Mechanistic Interpretations. Annu. Rev. Mater. Res. 2010, 40, 271–292. [Google Scholar] [CrossRef]

- Ma, X.; Higgins, W.; Liang, Z.; Zhao, D.; Pharr, G.M.; Xie, K.Y. Exploring the origins of the indentation size effect at submicron scales. Proc. Natl. Acad. Sci. USA 2021, 118, e2025657118. [Google Scholar] [CrossRef] [PubMed]

| Type of ISE | No. | Material | Data bulk | Data sources |

|---|---|---|---|---|

| Normal ISE | 1 | MgO | 41 | [26] |

| 2 | 16MND5 | 19 | [17] | |

| 3 | HEA | 29 | [29] | |

| Reverse ISE | 4 | NiCSi | 57 | [42] |

| 5 | TC4 | 58 | [41] | |

| 6 | PED Ni | 32 | [47] | |

| Transition of normal to reverse ISE | 7 | ZrO2 | 59 | [44] |

| 8 | Cu | 64 | [45] | |

| 9 | Y2O3-ZrO2 | 15 | [46] |

| Model | Parameter | Normal ISE | Reverse ISE | Transition of normal to reverse ISE | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MgO | 16MND5 | HEA | NiCSi | TC4 | PED Ni | ZrO2 | Cu | Y2O3-ZrO2 | ||

| Meyer | m0 | 8.063E-02 | 2.651E-01 | 2.257E-01 | 1.580E-11 | 2.221E-14 | 2.220E-14 | 9.056E-02 | 1.314E-01 | 1.661E-02 |

| m1 | 9.639E+00 | 2.352E+00 | 7.408E-01 | 9.467E+00 | 2.340E+00 | 5.865E+00 | 2.118E+01 | 1.841E+00 | 1.287E+01 | |

| H-K | k2 | 1.029E+01 | 2.997E+00 | 5.927E-01 | 9.467E+00 | 2.331E+00 | 5.683E+00 | 2.225E+01 | 2.381E+00 | 1.268E+01 |

| k3 | 7.630E-03 | 7.652E-03 | 1.493E-02 | 3.973E-14 | 1.628E-13 | 1.626E-12 | 3.771E-12 | 3.653E-12 | 1.391E-11 | |

| PSR | b0 | 9.844E+00 | 2.563E+00 | 5.395E-01 | 9.467E+00 | 2.331E+00 | 5.683E+00 | 2.169E+01 | 2.343E+00 | 1.268E+01 |

| b1 | 1.597E-01 | 1.586E-01 | 1.110E-01 | 2.770E-14 | 1.317E-11 | 3.611E-09 | 2.072E-01 | 3.111E-03 | 8.098E-10 | |

| MPSR | g0 | 9.422E+00 | 2.443E+00 | 4.805E-01 | 1.198E+01 | 2.703E+00 | 5.912E+00 | 1.882E+01 | 1.763E+00 | 1.250E+01 |

| g1 | 3.502E-01 | 2.079E-01 | 2.585E-01 | -4.535E-01 | -9.325E-02 | -1.595E-04 | 2.091E+00 | 9.640E-02 | 4.476E-01 | |

| g2 | -1.133E-02 | -2.643E-03 | -2.527E-02 | 4.208E-03 | 2.534E-03 | -1.869E-02 | -9.867E-02 | -1.444E-03 | -4.187E-02 | |

| EPD | e0 | 3.143E+00 | 1.627E+00 | 7.431E-01 | 3.077E+00 | 1.527E+00 | 2.384E+00 | 4.664E+00 | 1.533E+00 | 3.561E+00 |

| e1 | 2.356E-02 | 3.925E-02 | 5.782E-02 | 5.445E-12 | 2.275E-14 | 3.682E-14 | 1.950E-02 | 8.139E-04 | 3.512E-12 | |

| EXP | r1 | 3.018E+00 | 4.024E+00 | 6.453E-01 | -2.426E+01 | -1.027E+00 | -2.377E+00 | 7.590E+01 | 1.804E+00 | 2.699E+02 |

| r2 | 3.685E+00 | 9.041E+00 | 1.004E+00 | 2.302E+01 | 7.165E+00 | 3.617E+01 | 8.536E+00 | 5.288E+00 | 7.642E-04 | |

| r3 | 9.586E+00 | 2.763E+00 | 5.206E-01 | 1.102E+01 | 2.542E+00 | 5.873E+00 | 2.054E+01 | 1.542E+00 | -2.571E+02 | |

| H-J | j0 | 8.821E+00 | 4.150E-01 | 3.544E-01 | 4.168E+00 | 4.838E-02 | 2.410E-01 | 1.521E+01 | 8.493E-01 | 6.014E-01 |

| j1 | 7.819E-01 | 1.140E+00 | 1.402E-01 | 1.068E-12 | 2.443E-14 | 2.220E-14 | 1.334E+01 | 3.302E-01 | 2.220E-14 | |

| j2 | 2.337E-14 | 3.589E+00 | 2.266E-14 | 4.532E+01 | 5.344E+00 | 3.164E+01 | 1.651E+01 | 3.290E-02 | 1.515E+02 | |

| N-G | H0 | 9.719E+00 | 2.351E+00 | 4.461E-01 | 1.085E+01 | 2.340E+00 | 5.865E+00 | 1.939E+01 | 1.280E+00 | 1.276E+01 |

| h0 | 4.216E-02 | 2.316E-01 | 1.821E+00 | 1.026E-02 | 2.220E-14 | 2.220E-14 | 1.338E-01 | 3.613E-01 | 2.220E-14 | |

| N-G-Fs | H0 | 9.242E+00 | 2.309E+00 | 4.516E-01 | 1.076E+01 | 2.349E+00 | 5.801E+00 | 1.794E+01 | 1.391E+00 | 1.005E+01 |

| h0 | 4.607E-02 | 1.176E-01 | 7.597E-01 | 9.346E-03 | 1.097E-13 | 1.940E-02 | 1.388E-01 | 1.058E-01 | 3.835E-01 | |

| h1 | 8.170E-02 | 1.249E-01 | 4.369E-01 | 1.039E-02 | 1.043E+00 | 2.606E-01 | 3.447E-02 | 7.292E-03 | 1.622E-01 | |

| r0 | 7.189E-01 | 2.731E-01 | 5.481E-01 | 1.594E+06 | 1.416E+02 | 3.497E+00 | 8.178E+00 | 3.544E+01 | 3.109E+00 | |

| N-G-Hs | H0 | 9.495E+00 | 2.362E+00 | 4.651E-01 | 1.090E+01 | 2.417E+00 | 5.867E+00 | 1.960E+01 | 1.286E+00 | 1.279E+01 |

| h0 | 6.329E-02 | 2.248E-01 | 1.421E+00 | 4.431E-14 | 7.455E-07 | 7.385E-08 | 1.629E-01 | 3.586E-01 | 3.024E-02 | |

| hnano | 6.487E-02 | 1.982E-08 | 1.893E-01 | 2.220E-14 | 4.093E+01 | 1.161E+01 | 8.047E-02 | 3.646E-02 | 1.628E-01 | |

| N-G-H | H0 | 9.204E+00 | 2.295E+00 | 4.406E-01 | 5.834E-02 | 6.391E-01 | 1.571E-01 | 1.739E+01 | 1.236E+00 | 8.682E+00 |

| h0 | 1.035E-01 | 4.700E+01 | 1.967E+00 | 3.993E+04 | 1.349E+01 | 1.414E+04 | 3.807E-01 | 4.120E-01 | 1.795E+00 | |

| h1 | 1.198E-01 | 1.695E+02 | 3.633E-01 | 3.641E-01 | 4.807E-01 | 9.558E+00 | 1.315E-03 | 1.896E-08 | 4.193E-01 | |

| n | 9.735E-01 | 4.901E-02 | 8.645E-01 | 1.847E+00 | 1.473E+00 | 1.045E+00 | 3.286E+00 | 5.415E+00 | 1.688E+00 | |

| N-G-A | H0 | 4.784E+00 | 2.265E+00 | 4.877E-01 | 1.097E+01 | 3.007E+00 | 5.891E+00 | 1.939E+01 | 1.280E+00 | 1.104E+01 |

| Hy | 3.825E+00 | 2.257E-14 | 3.343E-01 | 5.967E+04 | 3.189E+00 | 2.460E+03 | 0.000E+00 | 0.000E+00 | 1.050E+01 | |

| h0 | 1.038E-07 | 2.371E-01 | 6.968E+00 | 4.902E-03 | 2.257E+00 | 1.684E-04 | 1.338E-01 | 3.613E-01 | 1.492E-09 | |

| β | 1.475E-01 | 1.822E+00 | 9.192E+00 | 7.944E+00 | 8.292E-01 | 2.702E+00 | 0.000E+00 | 0.000E+00 | 1.536E-01 | |

| N-G-Qs | H0 | 8.855E+00 | 1.741E-02 | 1.804E-01 | 1.085E+01 | 2.340E+00 | 5.865E+00 | 1.807E+01 | 1.280E+00 | 1.276E+01 |

| h0 | 2.952E+00 | 3.802E-01 | 9.892E-02 | 1.026E-02 | 2.220E-14 | 2.220E-14 | 6.023E+00 | 3.613E-01 | 2.220E-14 | |

| σ0 | 1.016E-02 | 2.725E+03 | 5.598E+00 | 0.000E+00 | 0.000E+00 | 0.000E+00 | 2.219E-02 | 0.000E+00 | 0.000E+00 | |

| N-G-YC | H0 | 9.359E+00 | 2.363E+00 | 4.408E-01 | 1.085E+01 | 2.466E+00 | 5.872E+00 | 2.007E+01 | 1.280E+00 | 1.248E+01 |

| h0 | 8.538E-02 | 2.244E-01 | 2.011E+00 | 1.026E-02 | 2.337E-14 | 2.337E-14 | 8.916E-02 | 3.613E-01 | 7.457E-02 | |

| h3 | 5.199E-02 | 1.025E-04 | 4.287E-01 | 0.000E+00 | 6.322E-02 | 1.296E-02 | 5.670E-02 | 0.000E+00 | 8.235E-02 | |

| N-G-Ls | H0 | 9.087E+00 | 2.227E+00 | 4.290E-01 | 1.215E+00 | 2.534E+00 | 5.905E+00 | 1.649E+01 | 8.363E-01 | 1.227E+01 |

| h0 | 7.354E+01 | 4.284E+00 | 1.024E+01 | 2.374E+01 | 3.728E+01 | 4.508E+02 | 5.995E-01 | 1.672E+05 | 2.691E+01 | |

| c | 4.424E-03 | 2.970E-02 | 1.694E-02 | 6.971E-02 | 1.410E-01 | 8.128E-03 | 1.079E-02 | 1.363E+05 | 1.012E-02 | |

| d | 6.967E-02 | 4.037E-01 | 1.344E-01 | 2.353E-01 | 9.211E-01 | 1.121E+00 | 7.524E-01 | 4.612E+06 | 1.241E+00 | |

| f | 3.199E+01 | 2.160E+00 | 4.007E+00 | 8.769E-01 | 1.121E+00 | 3.633E+00 | 3.753E-01 | 3.401E+01 | 1.044E+00 | |

| m | 2.000E+00 | 2.000E+00 | 2.000E+00 | 2.000E+00 | 2.000E+00 | 2.000E+00 | 2.000E+00 | 2.000E+00 | 2.000E+00 | |

| ξ | 6.030E-03 | 2.498E-02 | 1.346E-02 | 1.817E-02 | 4.861E-02 | 3.544E-03 | 3.368E-12 | 6.148E+01 | 8.113E-03 | |

| L-Z-Hs | H0 | 9.895E+00 | 2.709E+00 | 5.329E-01 | 1.097E+01 | 2.675E+00 | 5.931E+00 | 2.026E+01 | 2.122E+00 | 1.345E+01 |

| δ | -6.993E-03 | -1.848E-02 | -9.721E-02 | 2.221E-14 | 1.544E-02 | 2.315E-03 | -1.177E-02 | -5.695E-03 | 6.193E-03 | |

| m | 2.000E+00 | 2.000E+00 | 2.000E+00 | 2.000E+00 | 2.000E+00 | 2.000E+00 | 2.000E+00 | 2.000E+00 | 2.000E+00 | |

| Model | Normal ISE | Reverse ISE | Transition of normalto reverse ISE | Mean DC | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| MgO | 16MND5 | HEA | NiCSi | TC4 | PED Ni | ZrO2 | Cu | Y2O3-ZrO2 | ||

| Meyer | 0.9863 | 0.9623 | 0.9940 | 0.0000 | 0.0000 | 0.0000 | 0.3087 | 0.2138 | 0.1120 | 0.3975 |

| H-K | 0.6088 | 0.8641 | 0.5672 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.0000 | 0.2267 |

| PSR | 0.8595 | 0.9875 | 0.8354 | 0.0000 | 0.0000 | 0.0000 | 0.0587 | 0.0033 | 0.0000 | 0.3049 |

| MPSR | 0.9803 | 0.9955 | 0.9854 | 0.9209 | 0.9783 | 0.9853 | 0.6786 | 0.5455 | 0.5512 | 0.8468 |

| EPD | 0.8472 | 0.9753 | 0.7910 | 0.0000 | 0.0000 | 0.0000 | 0.0535 | 0.0027 | 0.0000 | 0.2966 |

| EXP | 0.9961 | 0.9732 | 0.9904 | 0.9864 m | 0.9766 | 0.9902 | 0.8691 | 0.9275 | 0.0147 | 0.8582 |

| H-J | 0.9937 | 0.9991 | 0.9936 | 0.8636 | 0.0502 | 0.7699 | 0.7944 | 0.8870 | 0.1019 | 0.7170 |

| N-G | 0.8882 | 0.9895 | 0.9988 | 0.9314 | 0.0505 | 0.8761 | 0.8391 | 0.9403 | 0.0759 | 0.7322 |

| N-G-Fs | 0.9977 m | 0.9993 m | 0.9991 | 0.8708 | 0.9789 m | 0.8082 | 0.8400 | 0.9900 m | 0.8029 | 0.9208 m |

| N-G-Hs | 0.9710 | 0.9971 | 0.9917 | 0.8636 | 0.7920 | 0.9528 | 0.7141 | 0.9144 | 0.3963 | 0.8437 |

| N-G-H | 0.9965 | 0.9983 | 0.9998 m | 0.7414 | 0.9771 | 0.9443 | 0.8278 | 0.9900 m | 0.8098 m | 0.9206 |

| N-G-A | 0.9884 | 0.9987 | 0.9978 | 0.9624 | 0.9777 | 0.9952 m | 0.8391 | 0.9403 | 0.2496 | 0.8832 |

| N-G-Qs | 0.9704 | 0.9983 | 0.9934 | 0.9314 | 0.0505 | 0.8761 | 0.8925 | 0.9403 | 0.0759 | 0.7476 |

| N-G-YC | 0.9853 | 0.9971 | 0.9993 | 0.9314 | 0.8977 | 0.9835 | 0.9183 m | 0.9403 | 0.5586 | 0.9124 |

| N-G-Ls | 0.9956 | 0.9986 | 0.9998 m | 0.9265 | 0.9773 | 0.9266 | 0.7489 | 0.8580 | 0.5672 | 0.8887 |

| L-Z-Hs | 0.8195 | 0.9546 | 0.8555 | 0.9854 | 0.9741 | 0.9860 | 0.8508 | 0.1935 | 0.2686 | 0.7653 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).