Submitted:

20 March 2024

Posted:

20 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

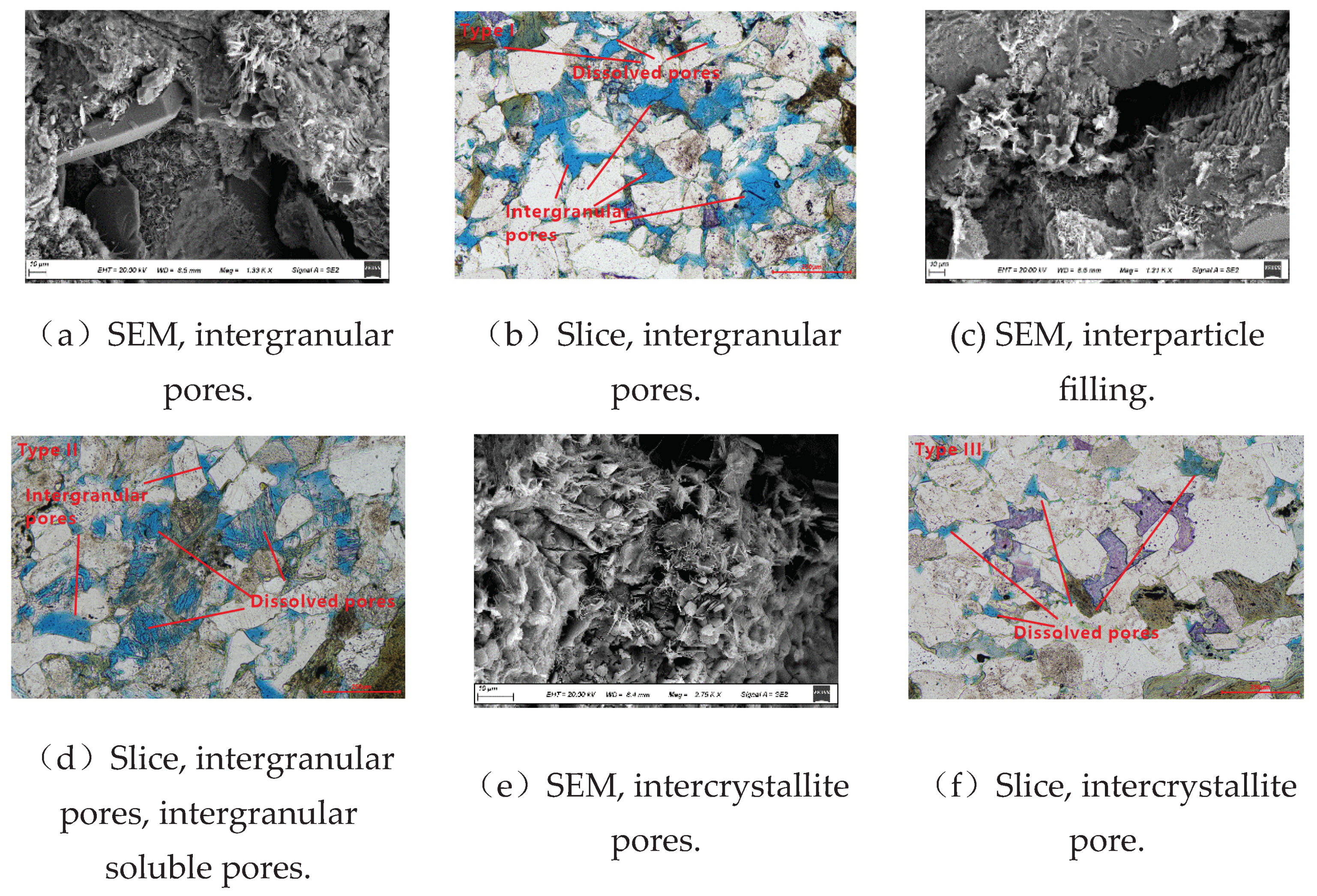

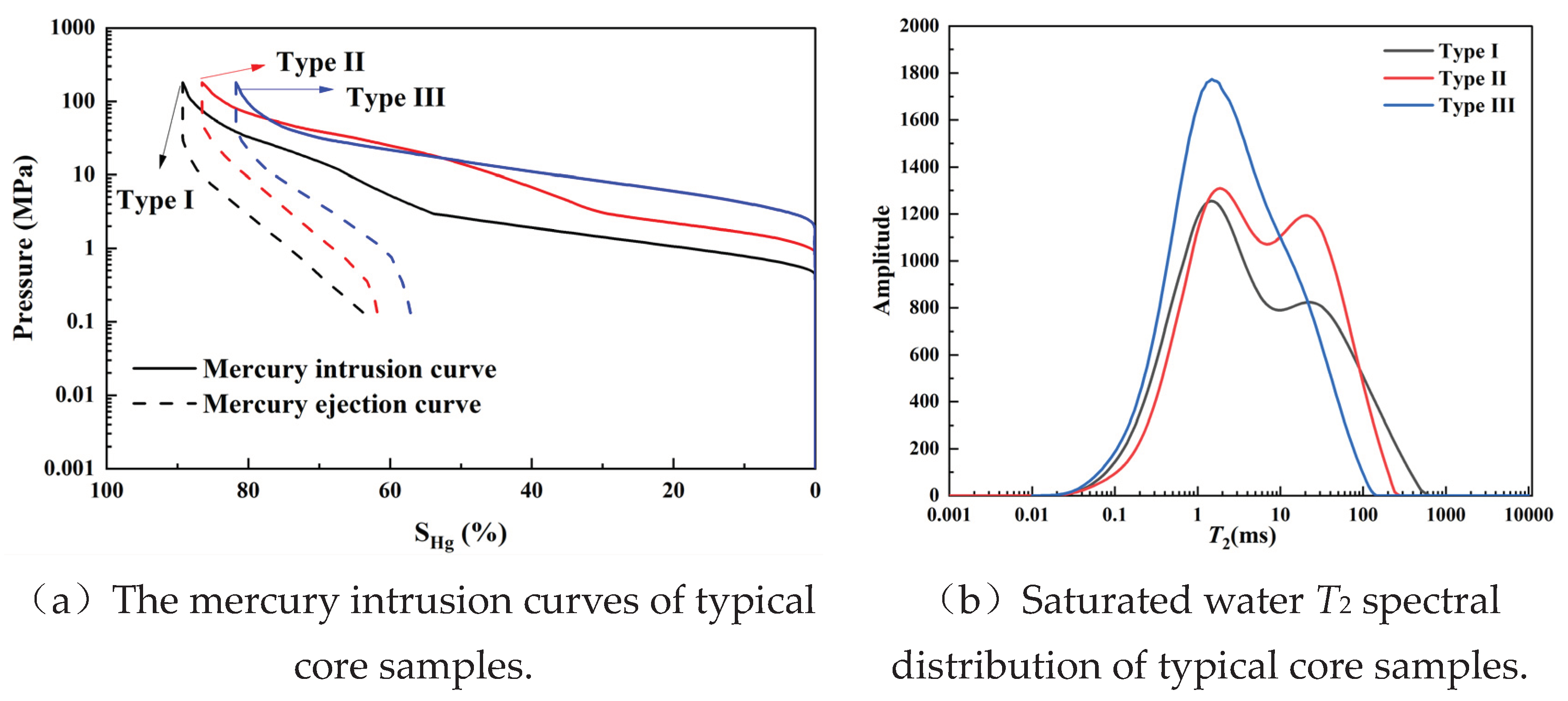

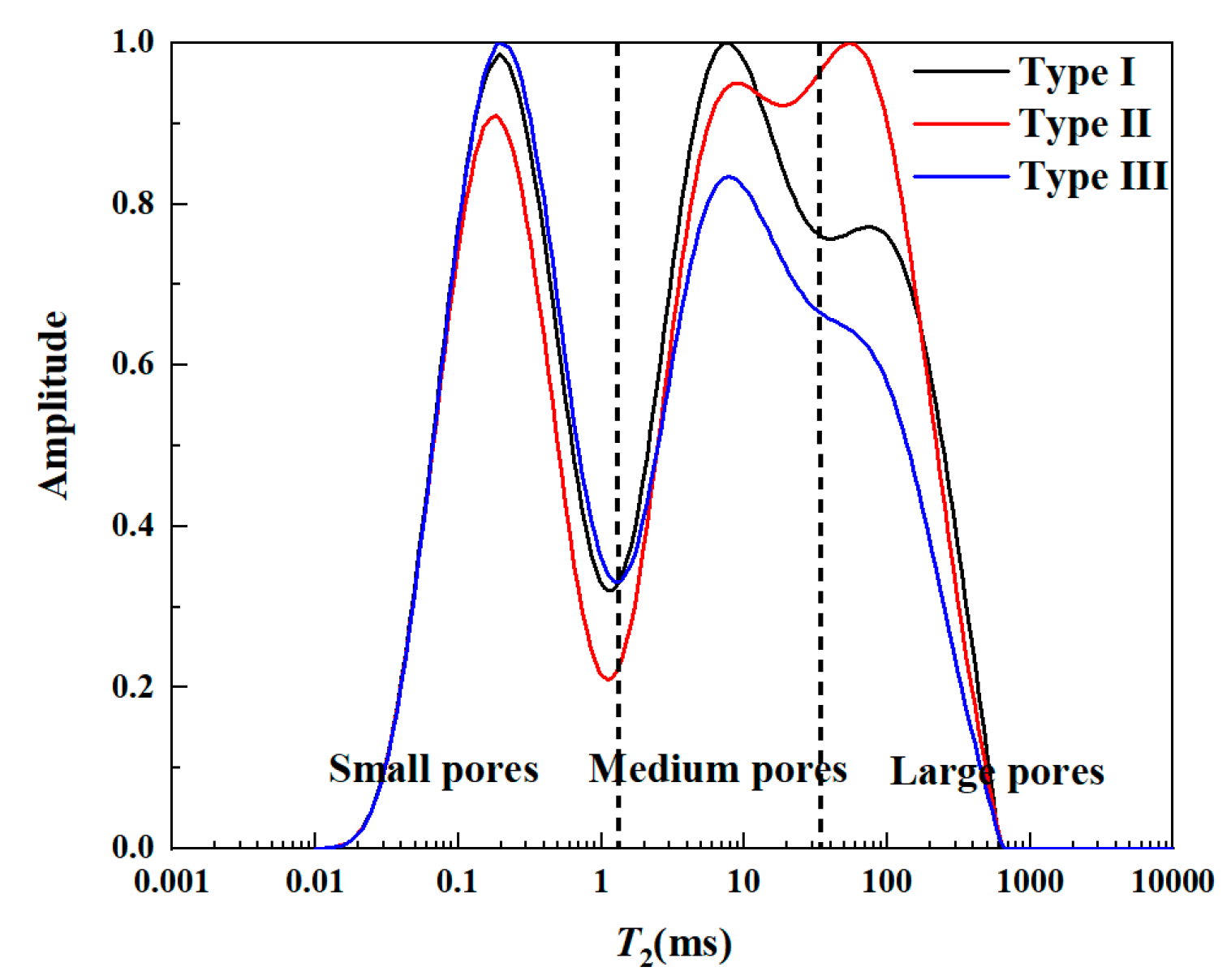

2. Microscopic Pore Structure Characteristics of Typical Tight Sandstone

3. Experimental Section

3.1. Experimental Principles

3.2. Experimental materials

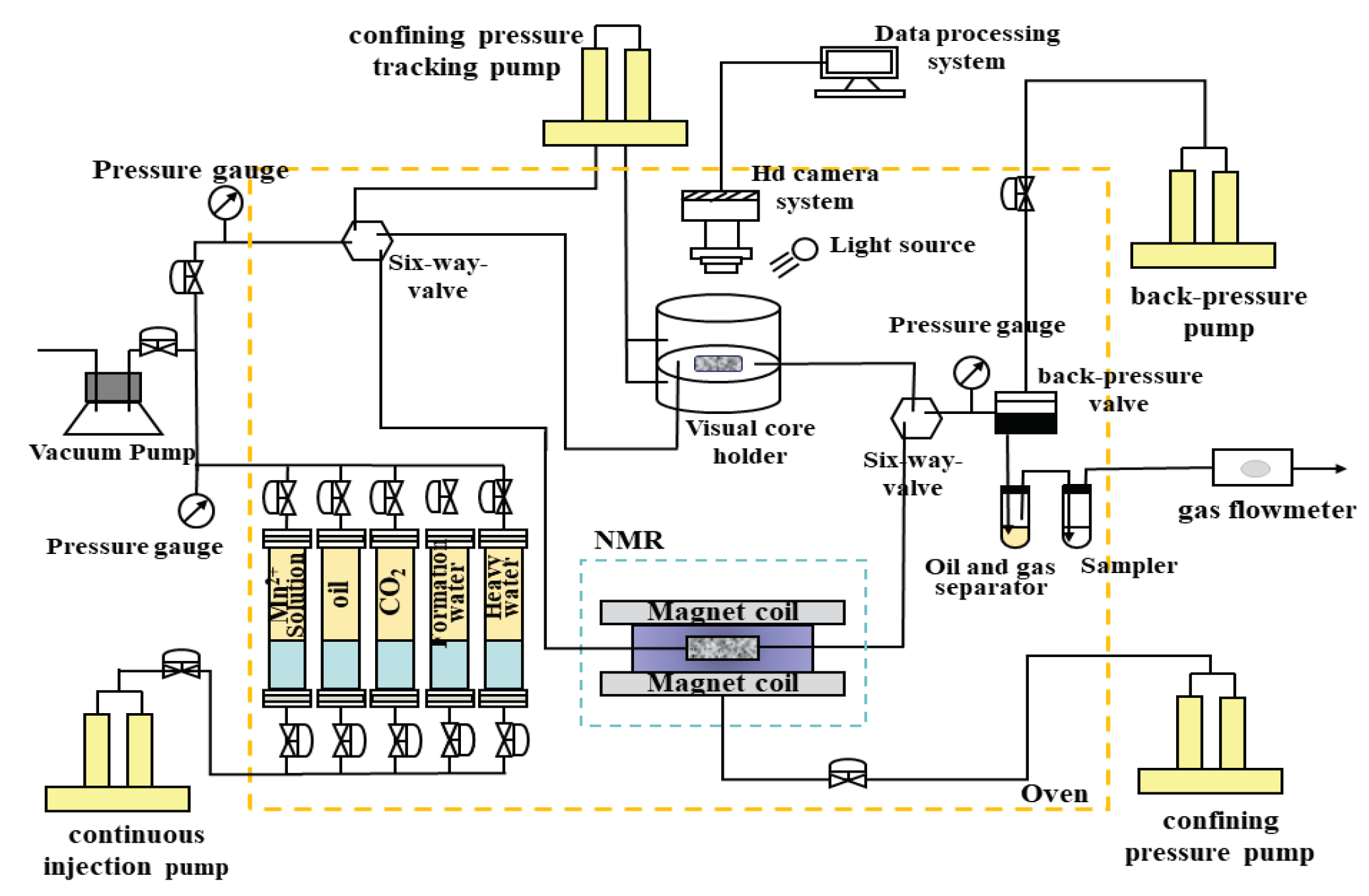

3.3. Experimental Apparatus

3.4. Experimental Procedure

- Plunger sample displacement experiment.

- Core preparation. The core was washed with a mixture of benzene and ethanol in a ratio of 3:1 for seven days using an oil washing apparatus. Following this, the cores were heated to 105°C in a thermostat and maintained at that temperature for 48 hours without any changes. After drying, permeability and porosity of the cores should be calculated.

- Reconstruction of oil-water distribution. The core was saturated with simulated formation water with 0.01 mL/min low rate, it consisted of CaCl2 water with a salinity level of 25000 mg/L. The flooding process was halted when the liquid output reached 4-5PV. We use Mn2+ solution to minimize the hydrogen signal with 4-5PV. Subsequently, using 0.01mL/min rate of the configured simulated oil was injected into the core. The flooding process was halted again when the discharge reached 4-5PV, and the liquid at the outlet was confirmed to be 100% simulated oil. Finally, an NMR T2 spectral was performed on the core.

- D2O flooding experiment. In the D2O flooding experiment, 0.01mL/min rate of the D2O injected is into the core at the inlet end. Reaching 2PV, the displacement is stopped, it is recorded about the oil production and the D2O injection, and it must be performed T2 spectrum sampling at the before and end of the displacement.

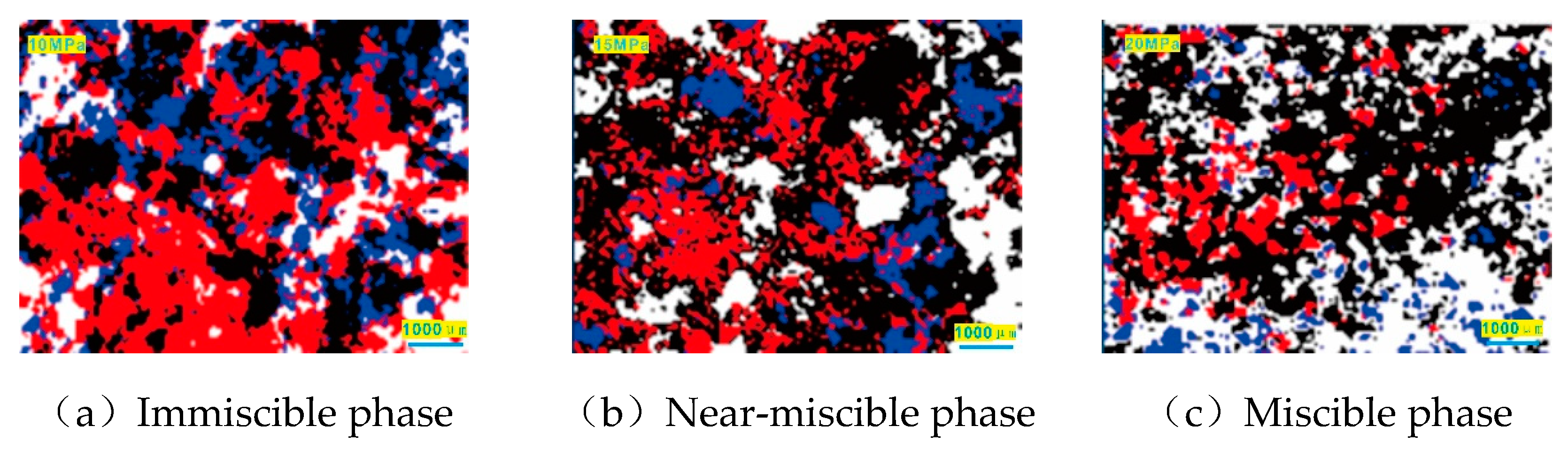

- CO2 flooding Experiment. After the D2O flooding experiment, the CO2 flooding experiment was initiated. The intermediate vessel containing CO2 was first pressurized to the experimental pressure of 10MPa. By adjusting the pressure return valve, the backpressure was adjusted to 0.1 MPa below the injection pressure. The CO2 injected rate is 0.1 mL/min to the inlet end, and the valve at the injection end was opened. The flooding process was stopped with 2PV injection volume. t is recorded about the oil production and the CO2 injection, and NMR T2 spectrum always recorded.

- During the whole experiment, the annular pressure remains constant at 25MPa throughout the experiment, with the temperature set at 60℃. After completing the flooding process (2)-(4), the pressure is adjusted to 15MPa and 20MPa respectively for subsequent flooding experiments. Following each experiment, the core is replaced before continuing with steps (2)-(5).

- Micro-visualization experiments.

- Preparation of real core model. The core sample is extracted from the area adjacent to the plunger in the displacement experiment. It is then carefully cut and polished using professional equipment to create a visual model with dimensions of 50mm×25mm×5mm (length × width × thickness). The model is then glued together for visualization purposes, and its porosity and permeability are measured.

- The visualization of flooding experiments follows the same steps as those used in plunger-like flooding experiments, with some differences in experimental subjects. The microscopic visualization of the flooding is studied using real core flakes, while the sample substitution is carried out using a standard core sample with a diameter of 2.5 cm.

- During the visualization of the flooding process, the annular pressure is regulated by an annular pressure tracking pump, which maintains a constant pressure that is always higher 0.5 MPa than the injection pressure.

4. Results and Discussion

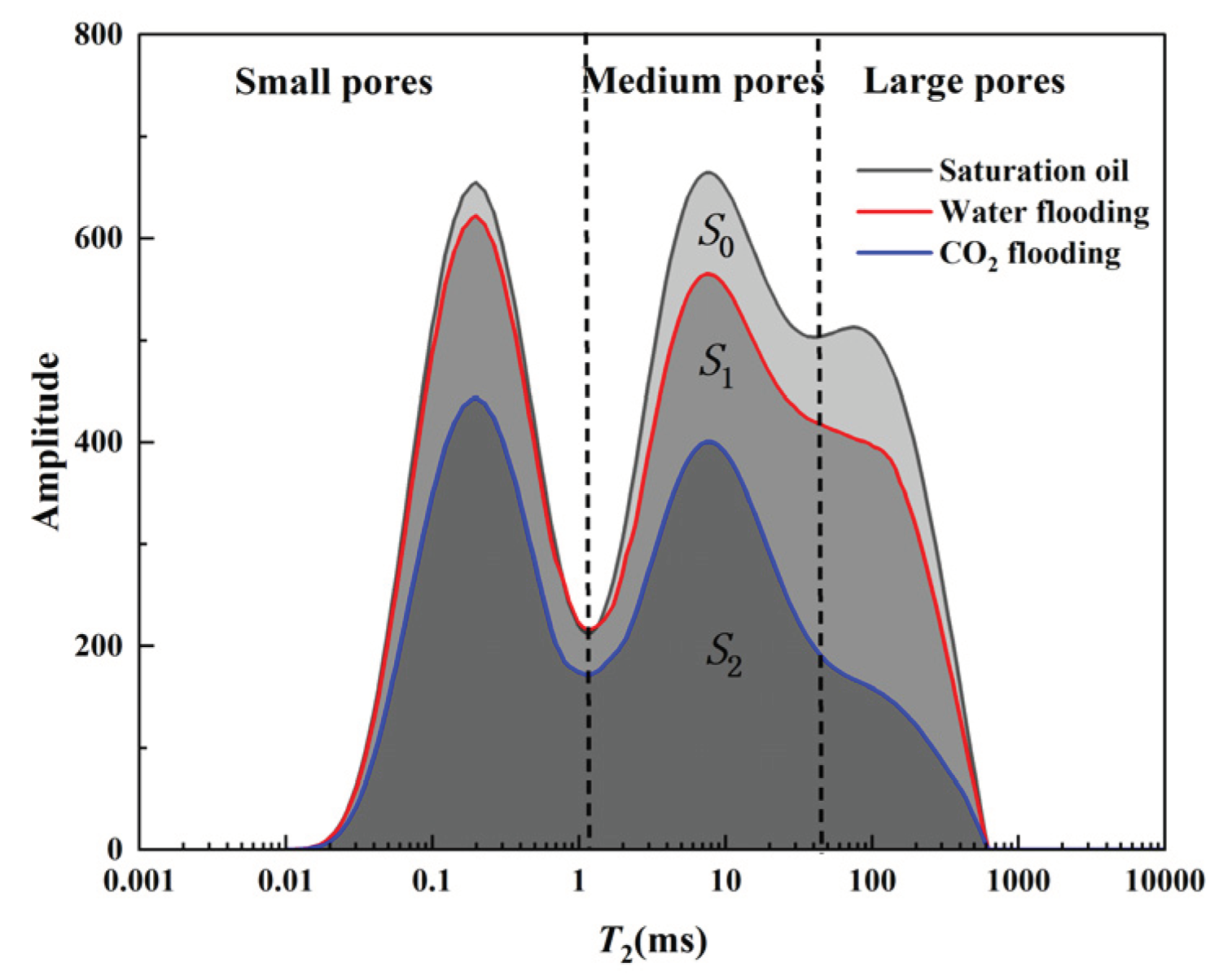

4.1. Saturated Oil T2 Spectrum of Typical Core Samples

4.2. Oil Utilization Characteristics of Heavy Water Flooding

4.2.1. Recovery of D2O Flooding for Different Types of Samples

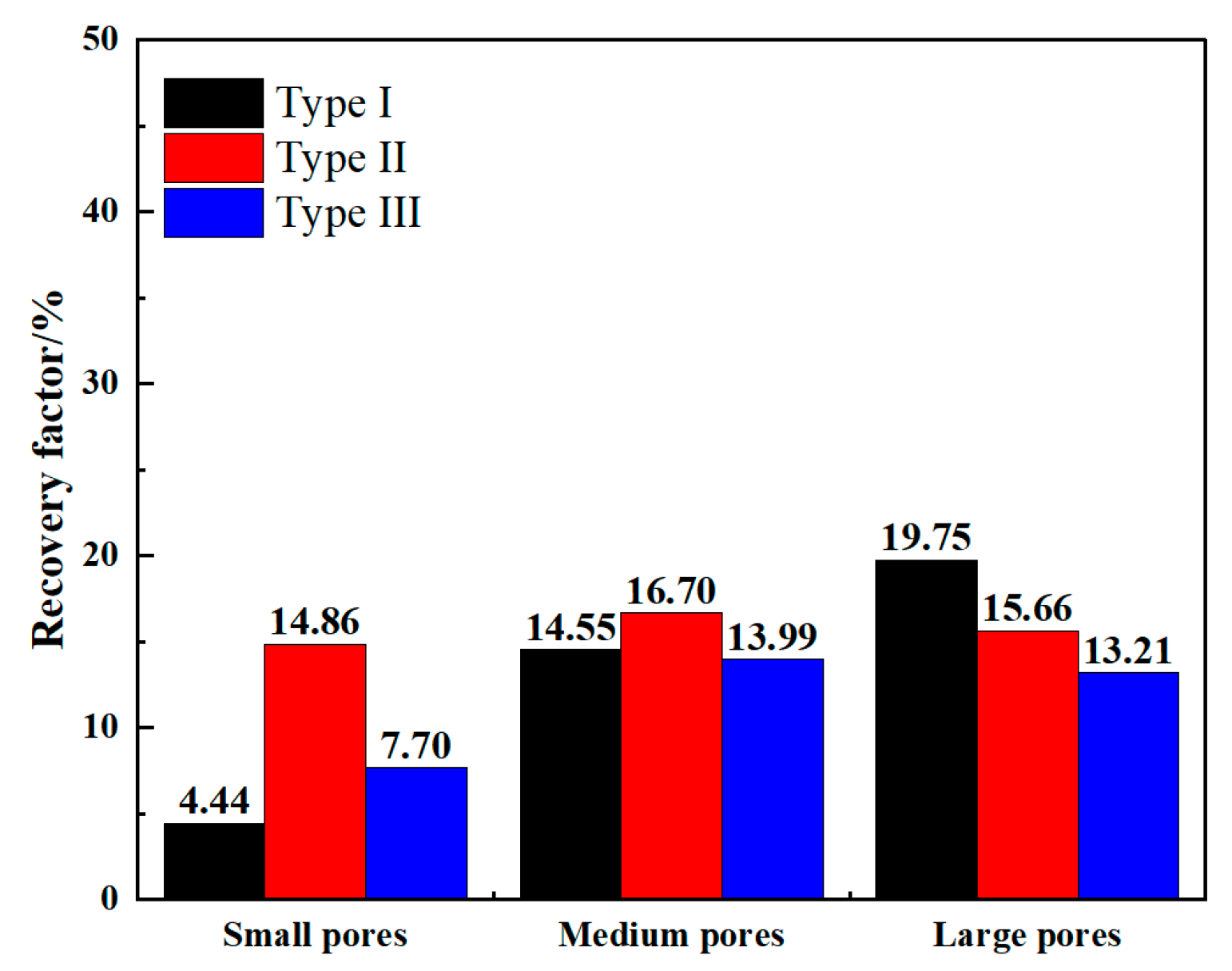

4.2.2. Microporous Oil Utilization Characteristics of D2O Flooding

4.3. Oil Utilization Characteristics of CO2 Flooding after Water Flooding

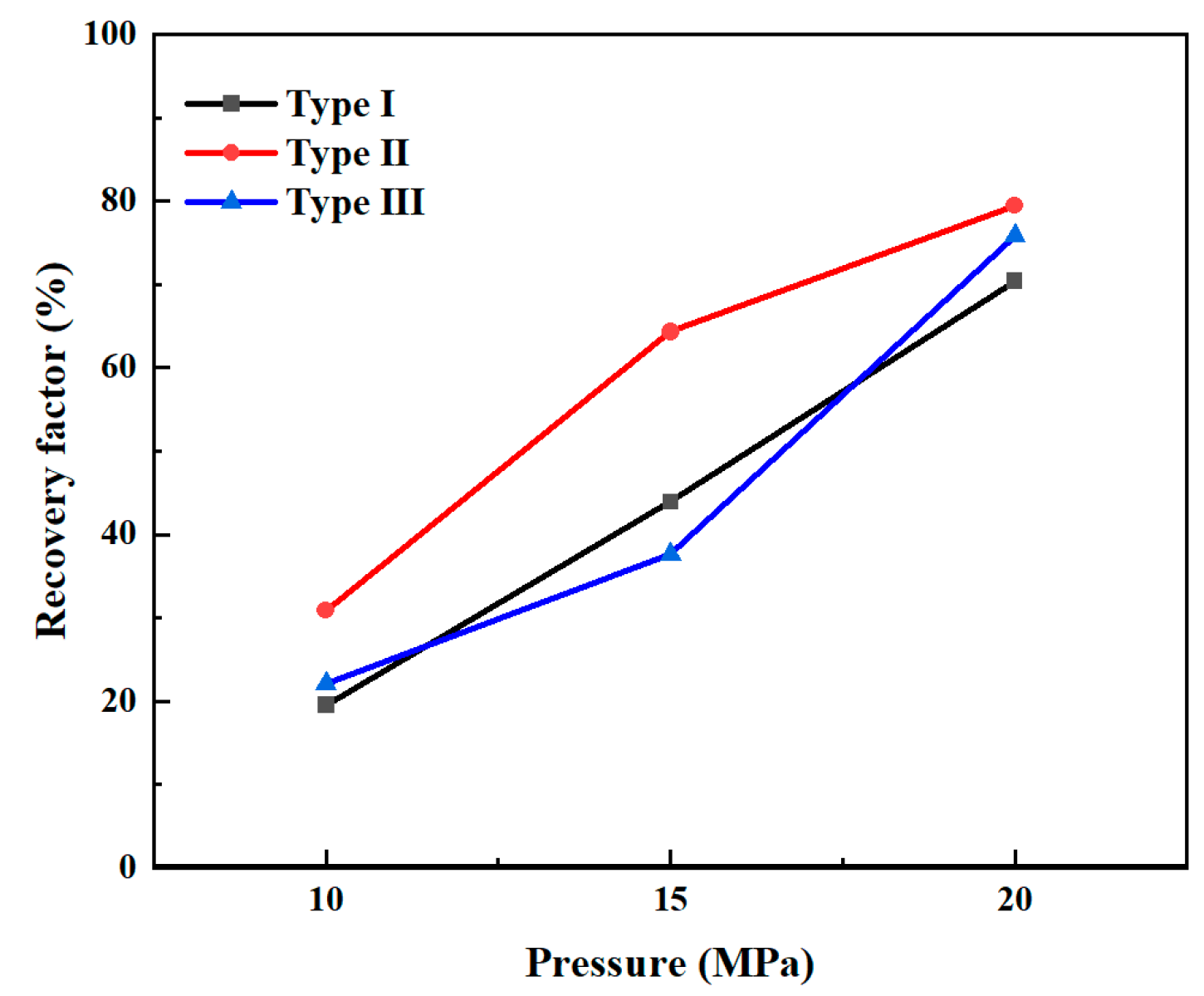

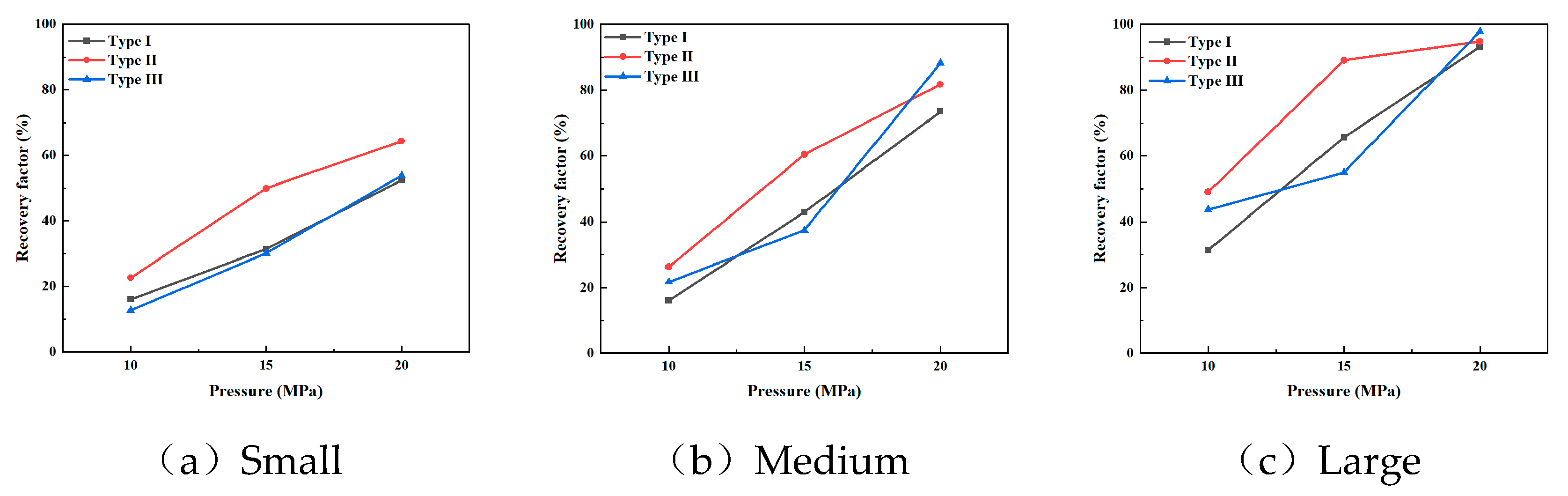

4.3.1. Recovery of CO2 Flooding after D2O Flooding for Different Types of Samples

4.3.2. Microporous Oil Utilization Characteristics of CO2 Flooding

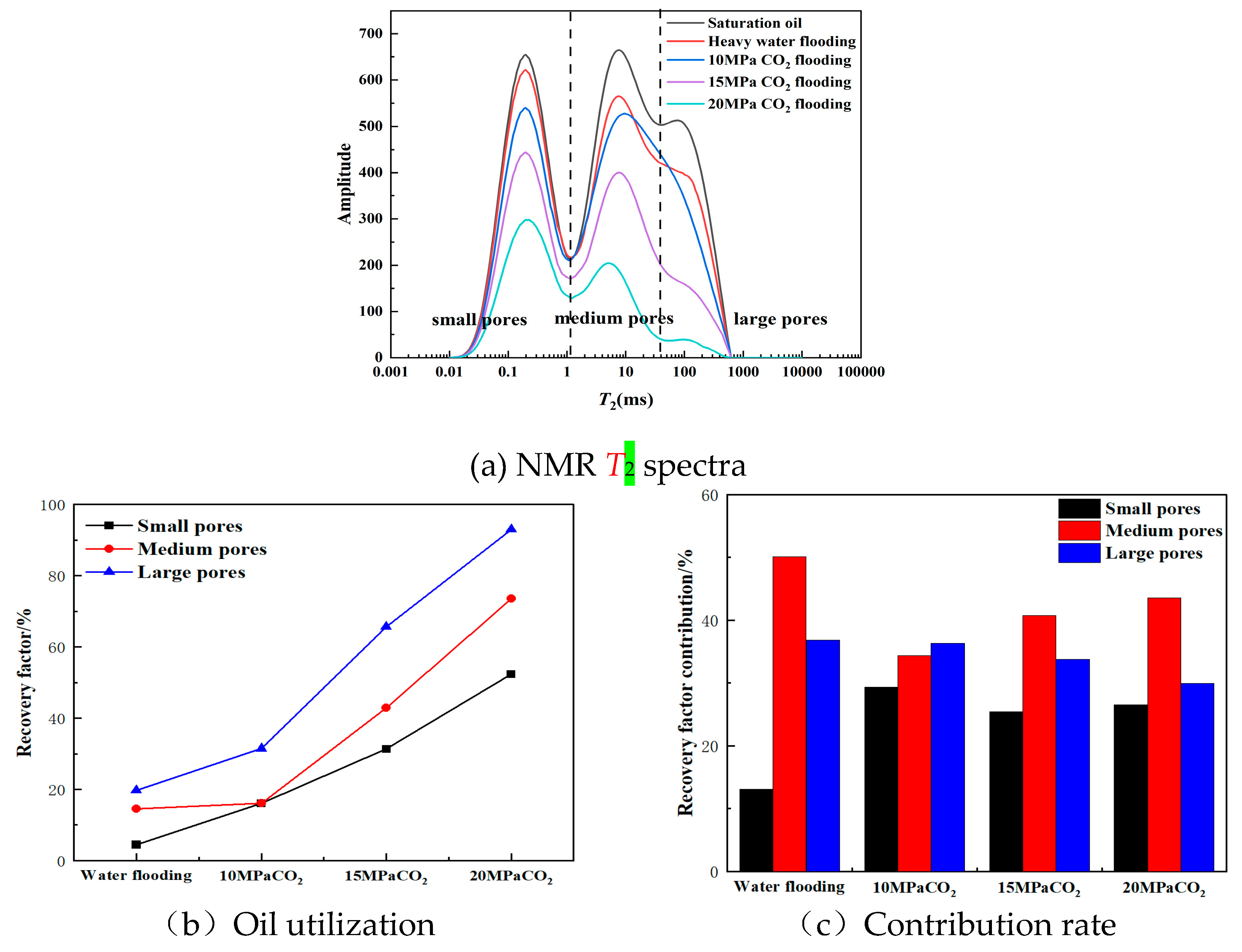

4.3.2.1. Oil Utilization Characteristics of Type I Samples

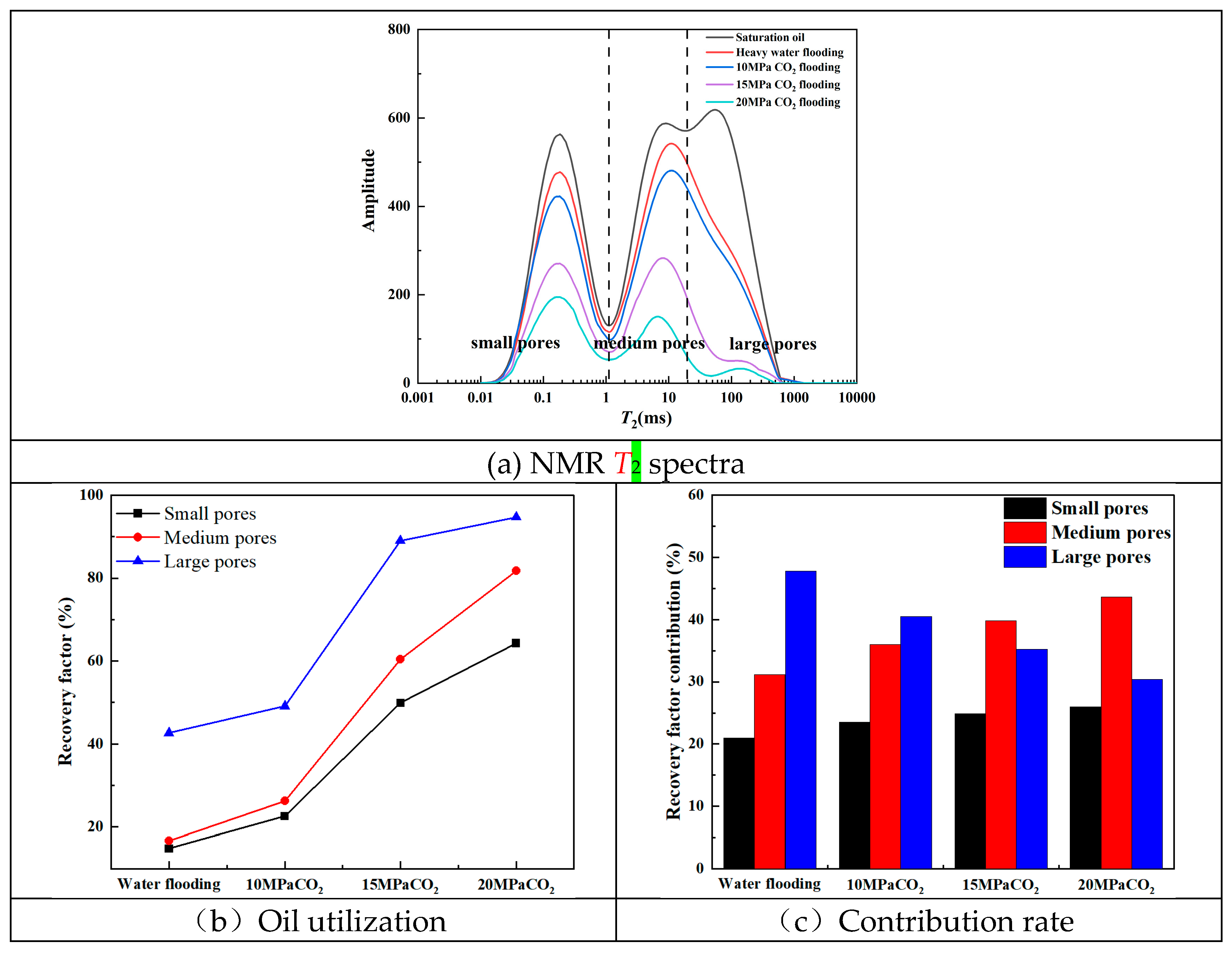

4.3.2.2. Oil Utilization Characteristics of Type II Samples

4.3.2.3. Oil Utilization Characteristics of Type III Samples

4.4. Microscopic Residual Oil Characteristics

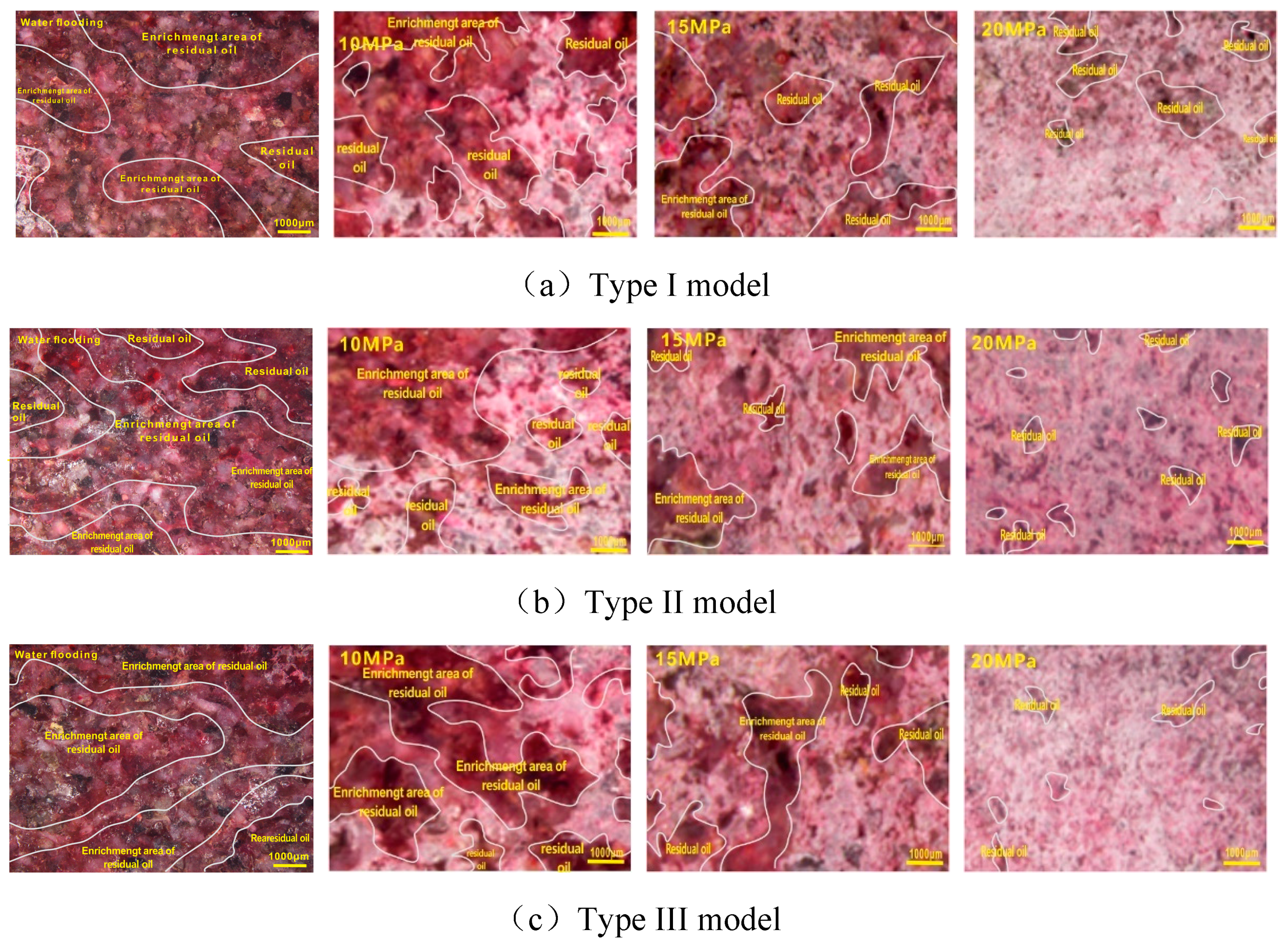

4.4.1. Residual Oil Distribution Regularity

4.4.2. Typology of Microscopic Residual Oils

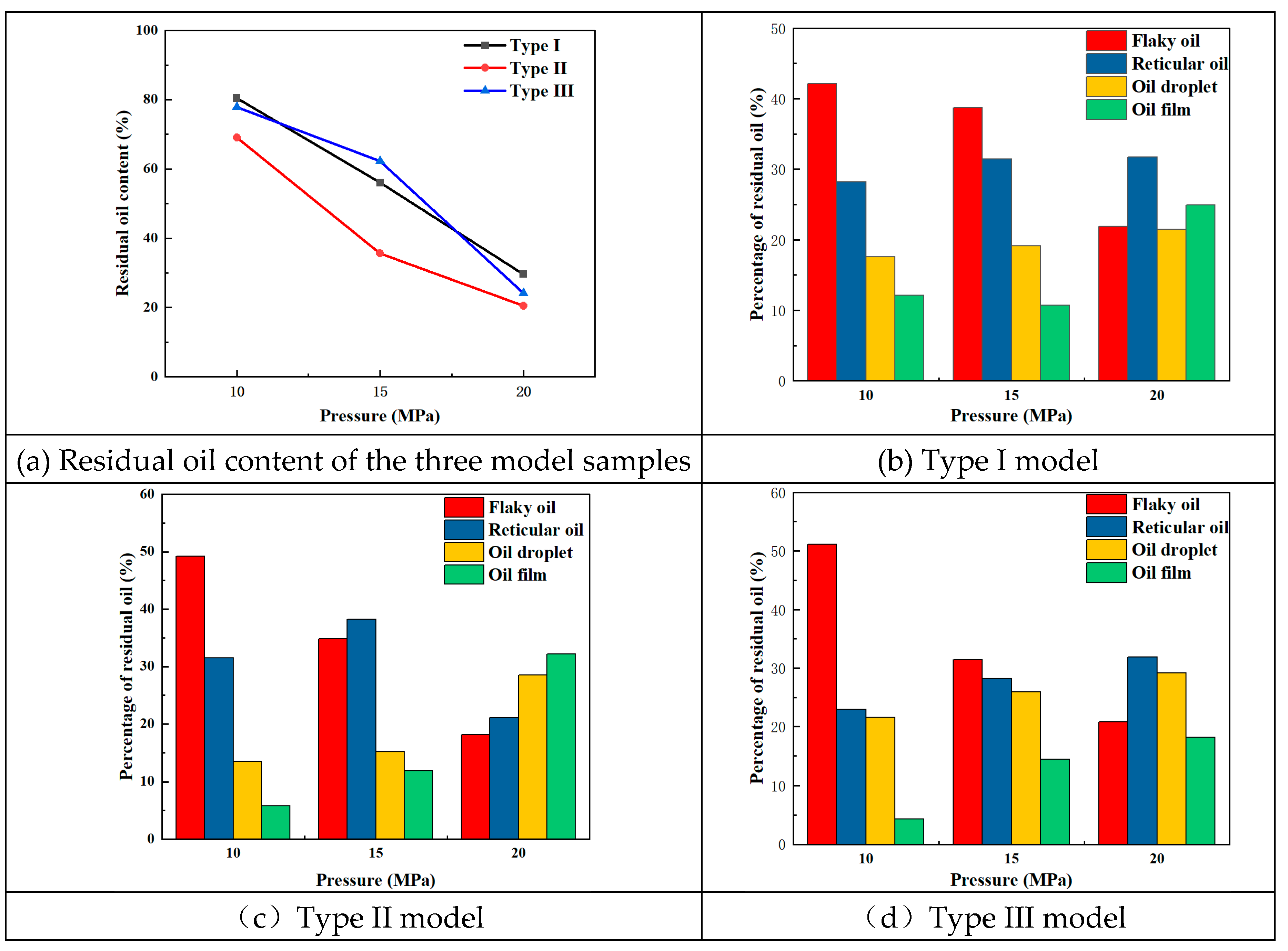

4.4.3. Differential Characterization of Different Types of Samples

5. Conclusion

- During water flooding, the oil recovery of type I, II, and III samples decreased progressively. The oil recovery of type I core was the highest at 18.12%. Produced oil in large pores and some medium pores is considerable, and the contribution from the small pores is relatively small for Type I and type III samples.

- The CO2 flooding after water flooding, the CO2 flooding significantly increases the oil recovery for all three-sample types. Type II core samples exhibited the highest oil recovery, while type I cores had the lowest oil recovery in both immiscible and miscible flooding. In near-miscible phases, type III cores had the lowest oil recovery. Notably, from immiscible to near-miscible flooding, type II cores demonstrated the most significant improvement in recovery. On the other hand, from near-miscible flooding to miscible flooding, type III cores experienced the most substantial recovery enhancement.

- As pressure increases, in the near-miscible phase, produced oil in type I and II samples primarily from large pores. Upon reaching the miscible phase, the recovered oil is predominantly from medium pores. In the immiscible phase, recovered oil for type III samples mainly from medium and large pores. In the near-miscible phase, produced oil is mainly from medium and small pores. The near-miscible phase flooding after water flooding is more suitable for Type I and II samples, while the miscible phase flooding is more suitable for type III samples.

- Examination of the microscopic distribution of residual oil reveals that in immiscible phase flooding after water flooding, the oil recovery among the three core types exhibits marginal disparities, with the maximum recovery of 68.11% achieved in the near-miscible phase flooding of the type II model after water flooding. The highest recovery of 74.57% is observed in the miscible phase flooding of the type III model after water flooding. The characteristics of residual oil are well-established. With escalating pressure, the proportion of flaky residual oil diminishes, while that of droplet and oil film formations gradually increases. Reticular residual oils predominate in type II samples during the near-miscible phase.

Acknowledgments

Notes

References

- Caineng, Z.; Zhang, G.; Zhi, Y.; Shizhen, T.; Lianhua, H.; Rukai, Z.; Xuanjun, Y.; Qiquan, R.; Denghua, L.; Zhiping, W. Concepts, characteristics, potential and technology of unconventional hydrocarbons: On unconventional petroleum geology. Petroleum Exploration and Development 2013, 40, 413–428. [Google Scholar]

- Longde, S.; Caineng, Z.; Ailin, J.; Yunsheng, W.; Rukai, Z.; Songtao, W.; Zhi, G. Development characteristics and orientation of tight oil and gas in China. Petroleum Exploration and Development 2019, 46, 1073–1087. [Google Scholar]

- Kokkinos, N.C.; Nkagbu, D.C.; Marmanis, D.I.; et al. Evolution of Unconventional Hydrocarbons: Past, Present, Future and Environmental FootPrint[J]. Journal of Engineering Science & Technology Review 2022, 15, 15–24. [Google Scholar]

- Lin, R.; Yu, Z. H.; Zhao, J. Z.; Dai, C. L.; Sun, Y. P.; Ren, L.; Xie, M. K. Experimental evaluation of tight sandstones reservoir flow characteristics under CO2-Brine-Rock multiphase interactions: A case study in the Chang 6 layer, Ordos Basin, China. Fuel 2022, 309, 122167. [Google Scholar] [CrossRef]

- Gao, H.; Liu, Y.; Zhang, Z.; Niu, B.; Li, H. Impact of Secondary and Tertiary Floods on Microscopic Residual Oil Distribution in Medium-to-High Permeability Cores with NMR Technique. Energy & Fuels 2015, 29, 4721–4729. [Google Scholar]

- Gao, H.; Wang, C.; Cheng, Z.; Li, T.; Dou, L.; Zhao, K.; Xue, J.; Luo, K. Effect of pressure pulse stimulation on imbibition displacement within a tight sandstone reservoir with local variations in porosity. Geoenergy Science and Engineering 2023, 226, 211811. [Google Scholar] [CrossRef]

- Wang, C.; Gao, H.; Qi, Y.; Li, X.; Zhang, R.; Fan, H. Investigation on the Mechanisms of Spontaneous Imbibition at High Pressures for Tight Oil Recovery. ACS omega 2020, 5, 12727–12734. [Google Scholar] [CrossRef]

- Zhang, T.; Tang, M.; Ma, Y.; Zhu, G.; Zhang, Q.; Wu, J.; Xie, Z. Experimental study on CO2/Water flooding mechanism and oil recovery in ultralow - Permeability sandstone with online LF-NMR. Energy 2022, 252, 123948. [Google Scholar] [CrossRef]

- Jiang, Z.; Liu, Z.; Zhao, P.; Chen, Z.; Mao, Z. Evaluation of tight waterflooding reservoirs with complex wettability by NMR data: A case study from Chang 6 and 8 members, Ordos Basin, NW China. Journal of Petroleum Science and Engineering 2022, 213, 110436. [Google Scholar] [CrossRef]

- Chen, M.; Dai, J. C.; Liu, X. J.; Kuang, Y. T.; Wang, Z. T.; Gou, S. C.; Qin, M. J.; Li, M. Effect of displacement rates on fluid distributions and dynamics during water flooding in tight oil sandstone cores from nuclear magnetic resonance (NMR). Journal of Petroleum Science and Engineering 2020, 184, 106588–106588. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X. Z.; Shen, W. J.; Gao, S. S.; Liu, H. X.; Ye, L. Y.; Fang, F. F. Study of the Effect of Movable Water Saturation on Gas Production in Tight Sandstone Gas Reservoirs. Energies 2020, 13, 4645–4645. [Google Scholar] [CrossRef]

- Wang, W.; Li, X. Y.; Wei, Z. K.; Xin, Y. D.; Xiao, R.; Yang, H. X.; Chen, X. L. Effect of CO2-Brine-Rock Interactions on the Pore Structure of the Tight Sandstone during CO2 Flooding: A Case Study of Chang 7 Member of the Triassic Yanchang Formation in the Ordos Basin, China. ACS omega 2023, 8(4), 3998–4009. [Google Scholar] [CrossRef]

- Chen, W.; Maolei, C.; Kai, W.; Yong, W.; Keyi, W.; Hui, G. Full-Scale Experimental Study on the Effect of CO2 Flooding on Storage-Seepage Capacity of Tight Sandstone Reservoirs. ACS omega 2023, 8, 11897–11907. [Google Scholar]

- Ding, J. C.; Yan, C. H.; Wang, G. Z.; He, Y. M.; Zhao, R. H. Competitive adsorption between CO2 and CH4 in tight sandstone and its influence on CO2-injection enhanced gas recovery (EGR). International Journal of Greenhouse Gas Control 2022, 113, 103530. [Google Scholar] [CrossRef]

- Lin, R.; Yu, Z. H.; Zhao, J. Z.; Dai, C. L.; Sun, Y. P.; Ren, L.; Xie, M. K. Experimental evaluation of tight sandstones reservoir flow characteristics under CO2-Brine-Rock multiphase interactions: A case study in the Chang 6 layer, Ordos Basin, China. Fuel 2022, 309, 122167. [Google Scholar] [CrossRef]

- Li, T.; Gao, H.; Ni, J.; Wang, C.; Cheng, Z. L.; Xue, J. J.; Luo, K. Q. Research on the Differential Oil Producing in the Various Scale Pores under Different CO2 Flooding Modes with a Fluid Distribution Pore Classification Method. Energy & Fuels 2023, 37, 3775–3784. [Google Scholar]

- Danchen, L.; Soheil, S.; Zunsheng, J.; Ye, Z. An experimental study of CO2 injection strategies for enhanced oil recovery and geological sequestration in a fractured tight sandstone reservoir. Geoenergy Science and Engineering 2023, 230, 212166. [Google Scholar]

- Ping, Y.; Feng, L.; Kai, Y.; Chunshuo, H.; Chao, R.; Jiangtang, Z.; Xiukun, W.; Quantang, F.; Xinxin, L.; Liangbin, D. Micro-Displacement and Storage Mechanism of CO2 in Tight Sandstone Reservoirs Based on CT Scanning. Energies 2022, 15, 6201. [Google Scholar]

- Yuting, D.; Fengpeng, L.; Jun, N.; Yisheng, L.; Hao, S.; Gongshuai, S. Evaluation of the impact of CO2 geological storage on tight oil reservoir properties. Journal of Petroleum Science and Engineering 2022, 212, 110307. [Google Scholar]

- Xiang, L.; Junjie, X.; Yanqing, W.; Weipeng, Y.; Jun, L. Experimental study of oil recovery from pore of different sizes in tight sandstone reservoirs during CO2 flooding. Journal of Petroleum Science and Engineering 2022, 208, 109740. [Google Scholar]

- Wang, Y.; Shang, Q.; Zhou, L.; Jiao, Z. Utilizing macroscopic areal permeability heterogeneity to enhance the effect of CO2 flooding in tight sandstone reservoirs in the Ordos Basin. Journal of Petroleum Science and Engineering 2021, 196, 107633. [Google Scholar] [CrossRef]

- Peng, H.; Yang, J.; Peng, J. L.; Pu, J. H.; Liu, Q.; Su, J.; Liu, J. Experimental investigation of the mechanism of supercritical CO2 interaction with tight sandstone. Frontiers in Energy Research 2022, 10, 984144. [Google Scholar] [CrossRef]

- Peng, H.; Zhou, L.; Yang, J.; Peng, J.L.; Han, H.F.; Gou, X.H.; Wang, Z.Y. Influence of Supercritical CO2 on the Formation Sensitivity of Tight Sandstone. Frontiers in Energy Research 2022, 10, 922941. [Google Scholar] [CrossRef]

- Xue, J., Gao, H., Wen, X., Wang, M., Cheng, Z., Wang, C., ... & Zhang, N. (2023). Microscopic Production Characteristics of Huff-n-Puff after CO2 Flooding in Tight Oil Sandstone Reservoirs. Energy & Fuels, 37(17), 12994–13010. [CrossRef]

- Wang, Q.; Wang, L.; Glover, P. W. J.; Lorinczi, P. Effect of a Pore Throat Microstructure on Miscible CO2 Soaking Alternating Gas Flooding of Tight Sandstone Reservoirs. Energy & Fuels 2020, 34, 9450–9462. [Google Scholar]

- Wang, Q.; Yang, S.; Glover, P. W. J.; Lorinczi, P.; Qian, K.; Wang, L. Effect of Pore-Throat Microstructures on Formation Damage during Miscible CO2 Flooding of Tight Sandstone Reservoirs. Energy & Fuels 2020, 34, 4338–4352. [Google Scholar]

- Liu, X.; Kang, Y.; You, L.; et al. Experimental Evaluation of Spontaneous Imbibitions and Water Injection in Tight Sandstone Oil Reservoirs. Arabian Journal for Science and Engineering volume 2019, 44, 10525–10535. [Google Scholar] [CrossRef]

- Jinghong, H.; Haopeng, Z.; Du, C.; Yuan, Z. An analytical model for shut-in time optimization after hydraulic fracturing in shale oil reservoirs with imbibition experiments. Journal of Petroleum Science and Engineering 2022, 210, 110055. [Google Scholar]

- Liu, H.; Luo, Y.; Meng, Y.; Xiao, G.; Zhao, Y.; Zhou, S.; Shao, L. Effects of pore structure on the moveable oil saturation in water-driven tight oil sandstone reservoirs. Journal of Petroleum Science and Engineering 2021, 207, 109142. [Google Scholar] [CrossRef]

- Zhou, S.; Zhou, Y.; Shi, J.; Zhu, Y.; Xiao, W.; Zhang, R. Micropore structure and water driving characteristics of tight sandstone reservoirs in Ordos Basin. Journal of Petroleum Science and Engineering 2022, 12, 601–612. [Google Scholar] [CrossRef]

- Jiang, Z.; Liu, Z.; Zhao, P.; Chen, Z.; Mao, Z. Evaluation of tight waterflooding reservoirs with complex wettability by NMR data: A case study from Chang 6 and 8 members, Ordos Basin, NW China. Journal of Petroleum Science and Engineering 2022, 213, 110436. [Google Scholar] [CrossRef]

- Li, X.; Xue, J.; Wang, Y.; Yang, W.; Lu, J. Experimental study of oil recovery from pore of different sizes in tight sandstone reservoirs during CO2 flooding. Journal of Petroleum Science and Engineering 2022, 208, 109740. [Google Scholar] [CrossRef]

- Wang, H.; Tian, L.; Chai, X.; Wang, J.; Zhang, K. Effect of pore structure on recovery of CO2 miscible flooding efficiency in low permeability reservoirs. Journal of Petroleum Science and Engineering 2022, 208, 109305. [Google Scholar] [CrossRef]

- Gao, H.; Luo, K. Q.; Xie, Y. G.; Qi, Y.; Li, T.; Cheng, Z. L.; Wang, C. Experimental Investigation of the CO2 Flooding Characteristics of Tight Sandstone Reservoirs Using a High-Temperature and-Pressure Visualization Apparatus. Energy & Fuels 2022, 12544–12554. [Google Scholar]

- Yuxi, Z.; Quan, W.; Haizhu, W.; Bin, W.; Kangjian, T.; Tianyu, W.; Jie, L.; Zhichao, Z.; Shouceng, T.; Sergey, S.; Alexey, C.; Yaniv, E. Laboratory visualization of supercritical CO2 fracturing in tight sandstone using digital image correlation method. Geoenergy Science and Engineering 2023, 225, 211556. [Google Scholar]

- Wang, Y.; Hou, J.; Tang, Y.; Song, Z. Effect of vug filling on oil-displacement efficiency in carbonate fractured-vuggy reservoir by natural bottom-water drive: A conceptual model experiment. Journal of Petroleum Science and Engineering 2018, 174, 1113–1126. [Google Scholar] [CrossRef]

- Al-Obaidi, D. A.; Al-Mudhafar, W. J.; Al-Jawad, M. S. Experimental evaluation of Carbon Dioxide-Assisted Gravity Drainage process ( CO2-AGD ) to improve oil recovery in reservoirs with strong water drive. Fuel 2022, 324, 124409. [Google Scholar] [CrossRef]

- D., K.P.; K., K.L.; Somnath, N. Characterization of heterogeneous petroleum reservoir of Indian Sub-continent: An integrated approach of hydraulic flow unit – Mercury intrusion capillary pressure – Fractal model. Journal of Petroleum Science and Engineering 2021, 205, 108788. [Google Scholar]

- Yang, J.; Hou, J. Experimental study on gas channeling characteristics of nitrogen and foam flooding in 2-D visualized fractured-vuggy model. Journal of Petroleum Science and Engineering 2020, 192, 107334. [Google Scholar] [CrossRef]

- Song, Z.; Li, M.; Zhao, C.; Yang, Y.; Hou, J. Gas injection for enhanced oil recovery in two-dimensional geology-based physical model of Tahe fractured-vuggy carbonate reservoirs: karst fault system. Petroleum Science 2020, 17, 419–433. [Google Scholar] [CrossRef]

- Ting, Z.; Pengfei, X.; Fangfang, L. 3D reconstruction of digital cores based on a model using generative adversarial networks and variational auto-encoders. Journal of Petroleum Science and Engineering 2021, 207, 109151. [Google Scholar]

- Andrés, P.; Luis, R.; Miguel, A.; Nicolás, R. Modelling of 3D viscous fingering: Influence of the mesh on coreflood experiments. Fuel 2020, 287, 119441. [Google Scholar]

- Yan, G.; Yan, W.; Yuan, Y.; Gong, X.; Tang, Z.; Xue, B. Research on the Method of Evaluating the Pore Throat Structure of Rock Microscopically Based on the 3D Pore Network Model of Digital Core. International Journal of Petroleum Technology 2022, 9, 44–53. [Google Scholar] [CrossRef]

- Huang, X.; Zhang, Y.; He, M.; et al. Asphaltene precipitation and reservoir damage characteristics of CO2 flooding in different microscopic structure types in tight light oil reservoirs[J]. Fuel 2022, 312, 122943. [Google Scholar] [CrossRef]

| Parameter type | Type I (16cores) |

Type II (23cores) |

Type III (11cores) |

|||||||||

| Range | Average | Range | Average | Range | Average | |||||||

| Physical | Porosity/% | 9.45-13.58 | 10.96 | 8.19-11.61 | 9.12 | 6.87-10.48 | 8.83 | |||||

| Permeability /10-3μm2 | 0.123-0.381 | 0.138 | 0.047 -0.116 | 0.067 | 0.025 -0.043 | 0.031 | ||||||

| Mercury injection | Maximum mercury saturation/% | 86.24-93.81 | 89.25 | 83.87-89.58 | 85.71 | 67.95-88.14 | 74.62 | |||||

| Median pressure /MPa | 2.85-8.56 | 6.97 | 5.65-10.93 | 8.91 | 18.52-38.14 | 31.84 | ||||||

| Threshold pressure /MPa | 0.29-0.97 | 0.58 | 0.87-2.84 | 1.82 | >3.48 | 3.94 | ||||||

| Pore throat radius /μm | 0.27-2.48 | 1.94 | 0.21-1.30 | 0.57 | 0.06-0.46 | 0.24 | ||||||

| Sorting factor | 1.86-2.95 | 2.53 | 1.45-2.51 | 2.21 | 1.39-2.38 | 1.83 | ||||||

| Casting thin section | Pore throat combination | Medium pore Medium-fine throat | Small pore Medium-fine throat | Fine pore Micro-fine throat | ||||||||

| Pore type | Intergranular pore - solution pore | Intergranular pores -a small amount of corrosion pores | Corrosion pore – a small number of intergranular pores | |||||||||

| Comprehensive reservoir evaluation | Good | Medium | Difference | |||||||||

| Sample type | Core number | Length(cm) | Diameter(cm) | Permeability(mD) | Porosity(%) |

| Type I | 11-1 | 5.75 | 2.52 | 0.158 | 11.784 |

| Type II | 10-2 | 5.35 | 2.53 | 0.0886 | 10.190 |

| Type III | 20-8 | 6.02 | 2.53 | 0.0311 | 8.474 |

| Recovery of CO2 flooding after D2O flooding |

10MPa | 15MPa | 20MPa | |||

| Current (%) |

Increase (%) |

Current (%) |

Increase (%) |

Current (%) |

Increase (%) |

|

| I类 | 19.57 | - | 43.95 | 24.37 | 70.39 | 26.44 |

| II类 | 30.91 | - | 64.33 | 33.42 | 79.46 | 15.13 |

| III类 | 22.12 | - | 37.69 | 15.56 | 75.84 | 38.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).