Submitted:

20 March 2024

Posted:

20 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experimental Equipment and Method

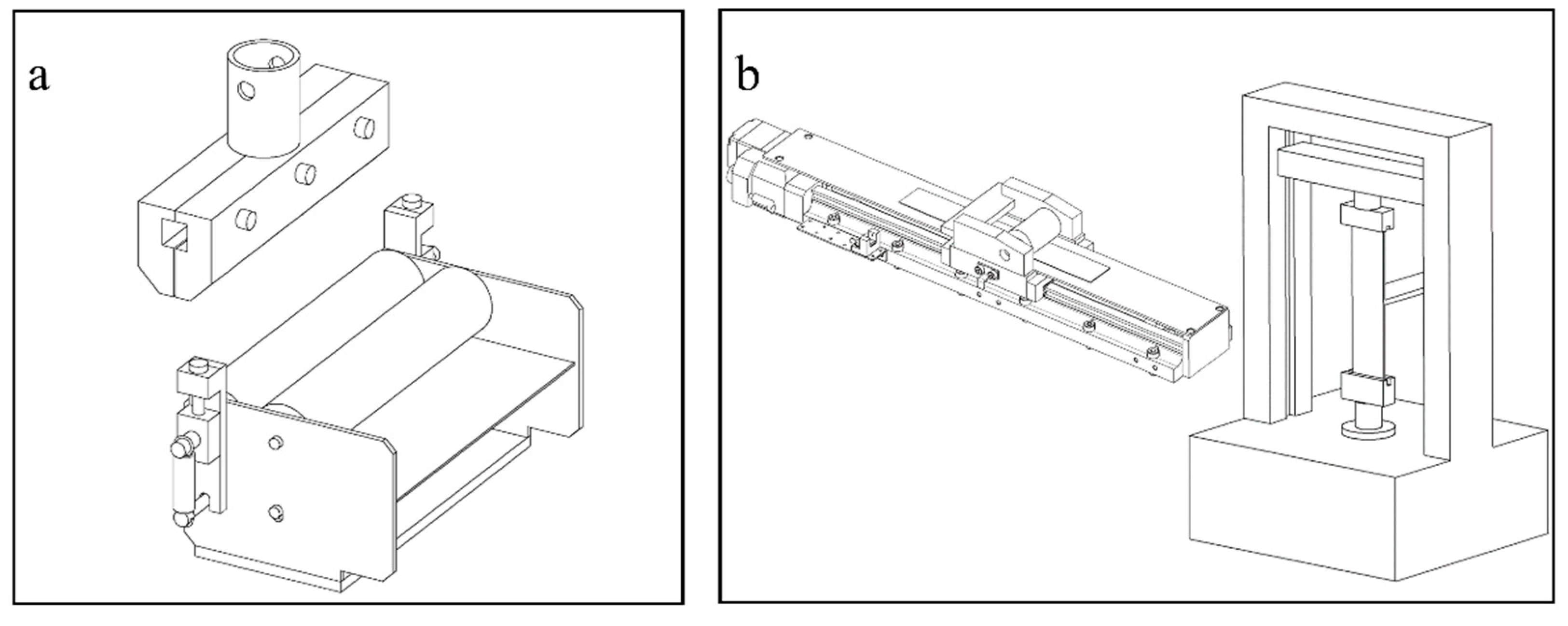

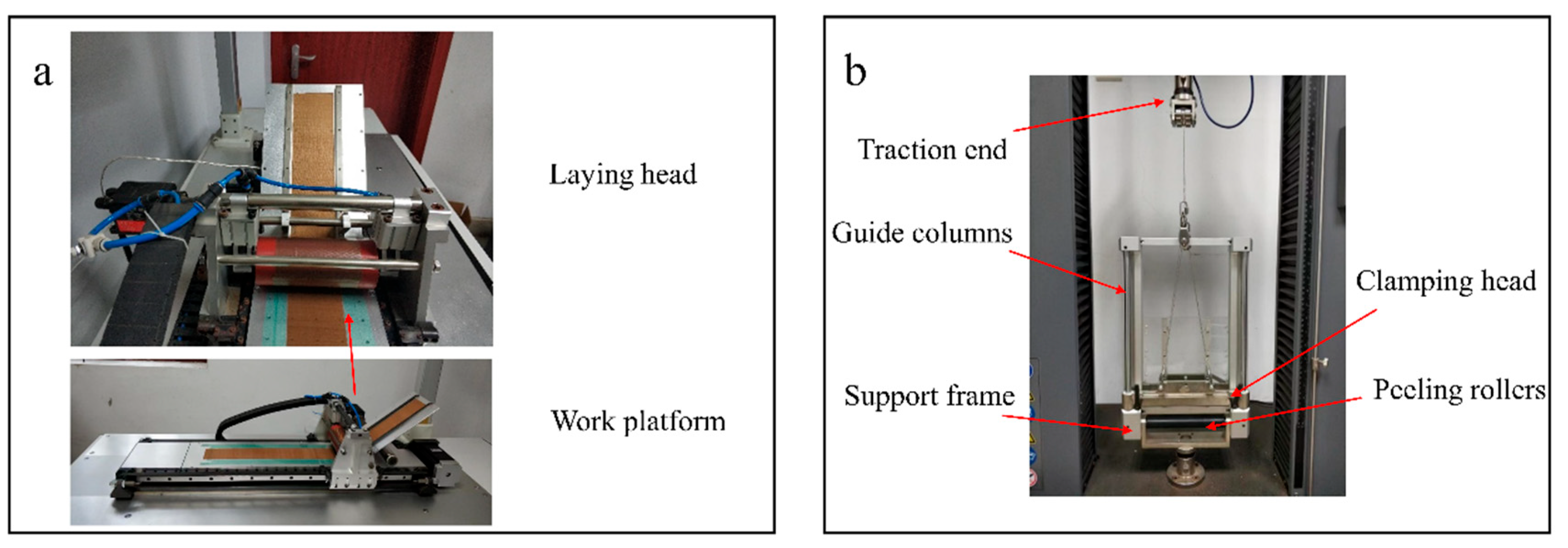

2.1. Experimental Equipment

2.2. Experimental Materials

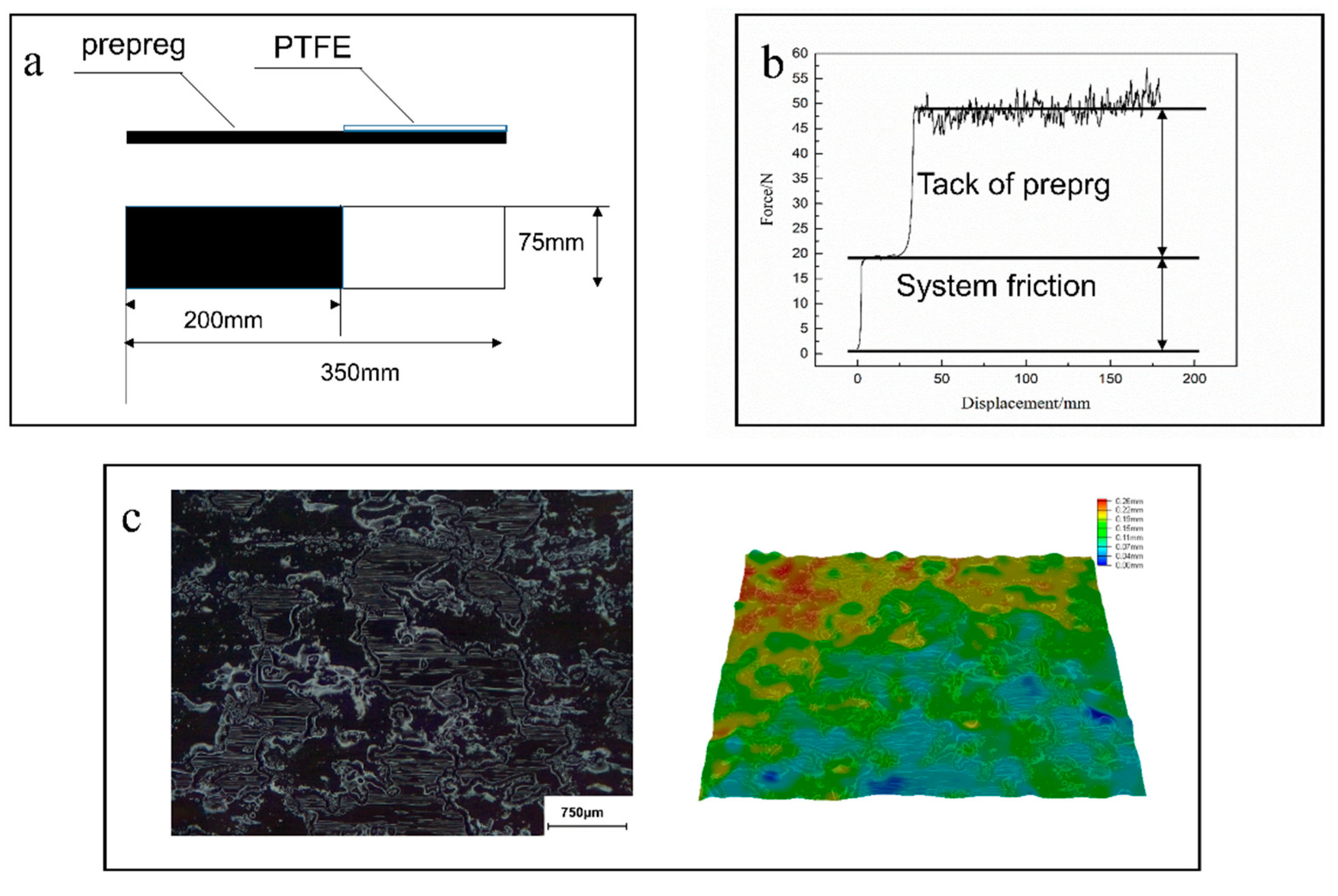

2.3. Experiment Procedure

3. Results Analysis and Discussion

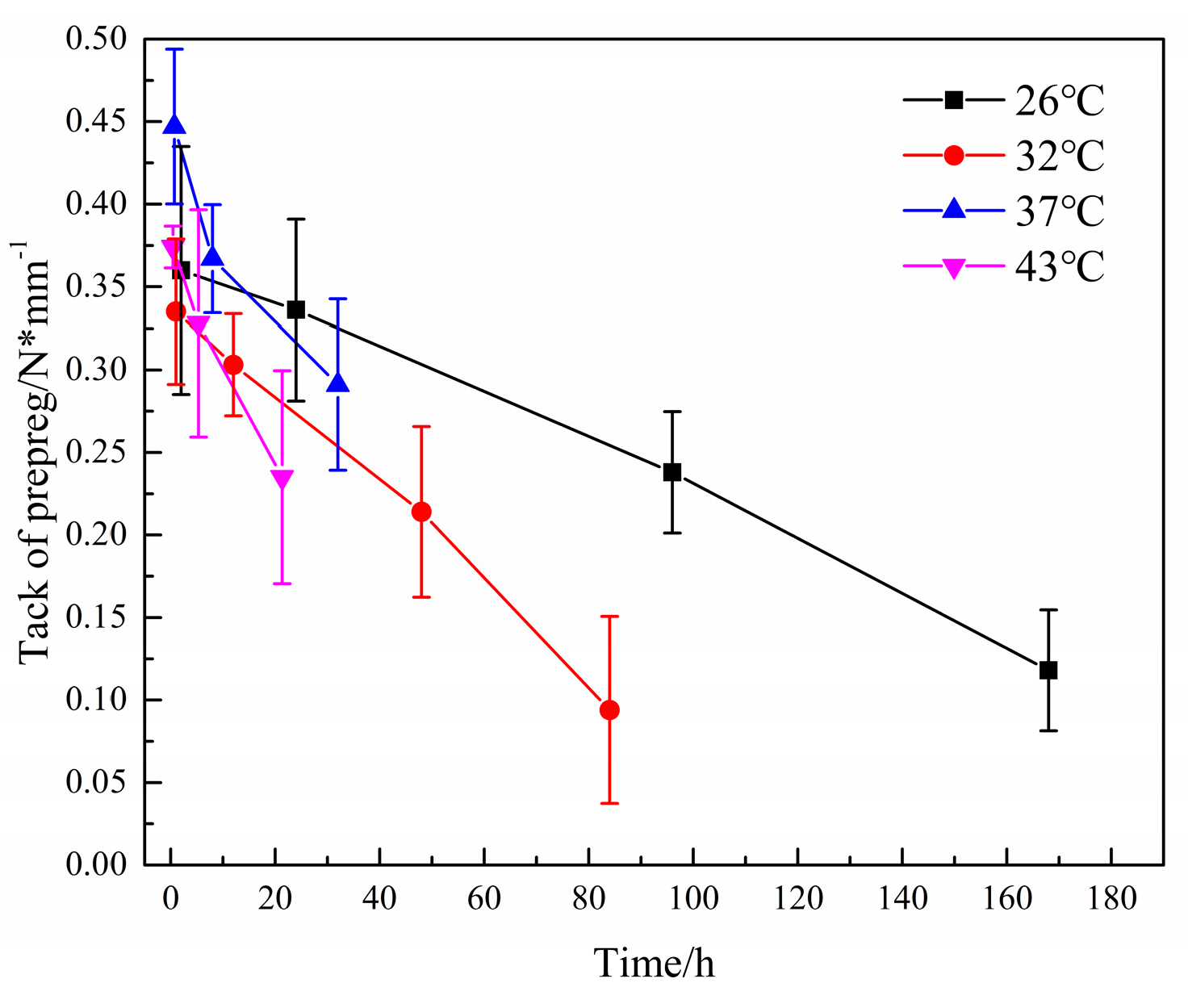

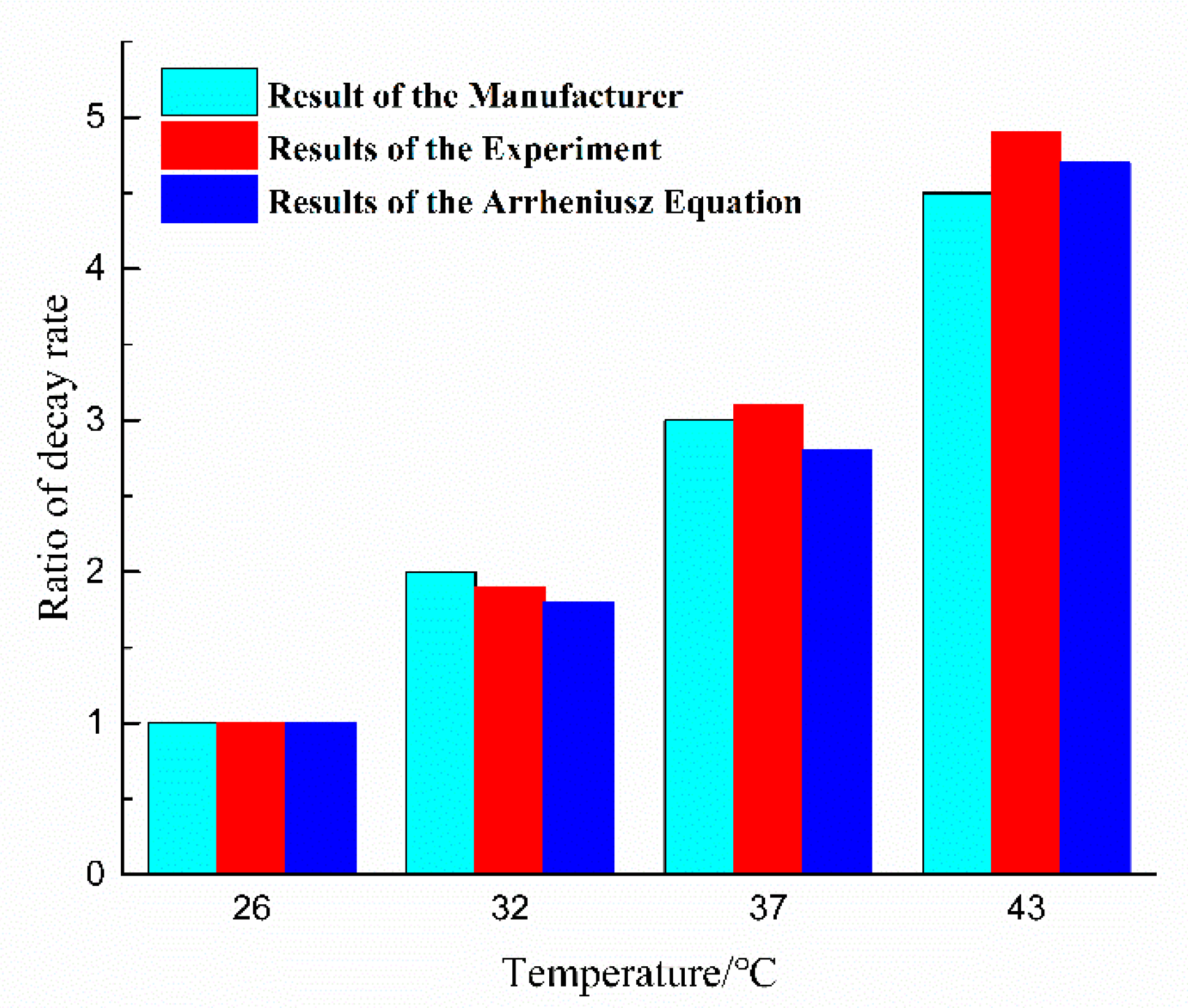

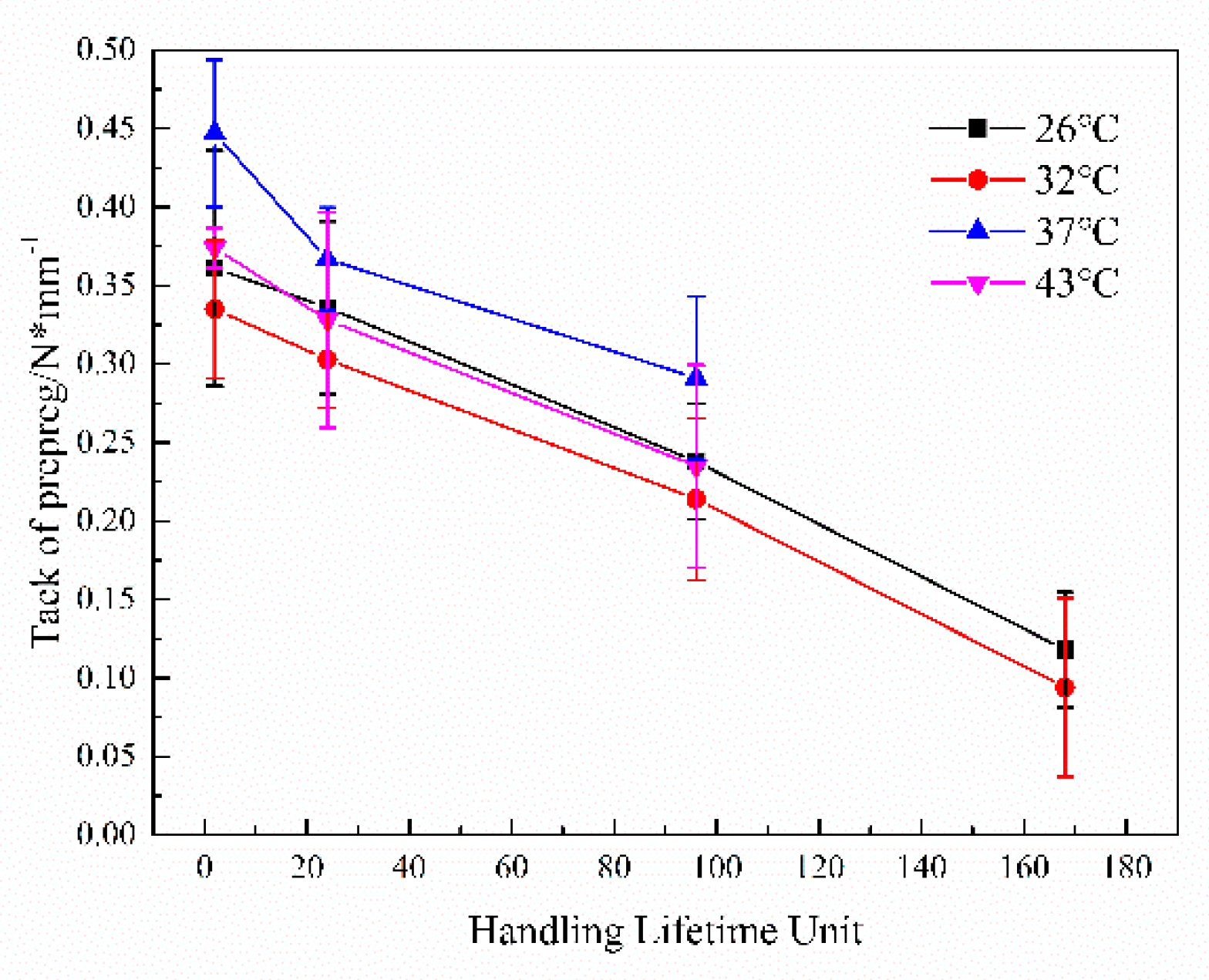

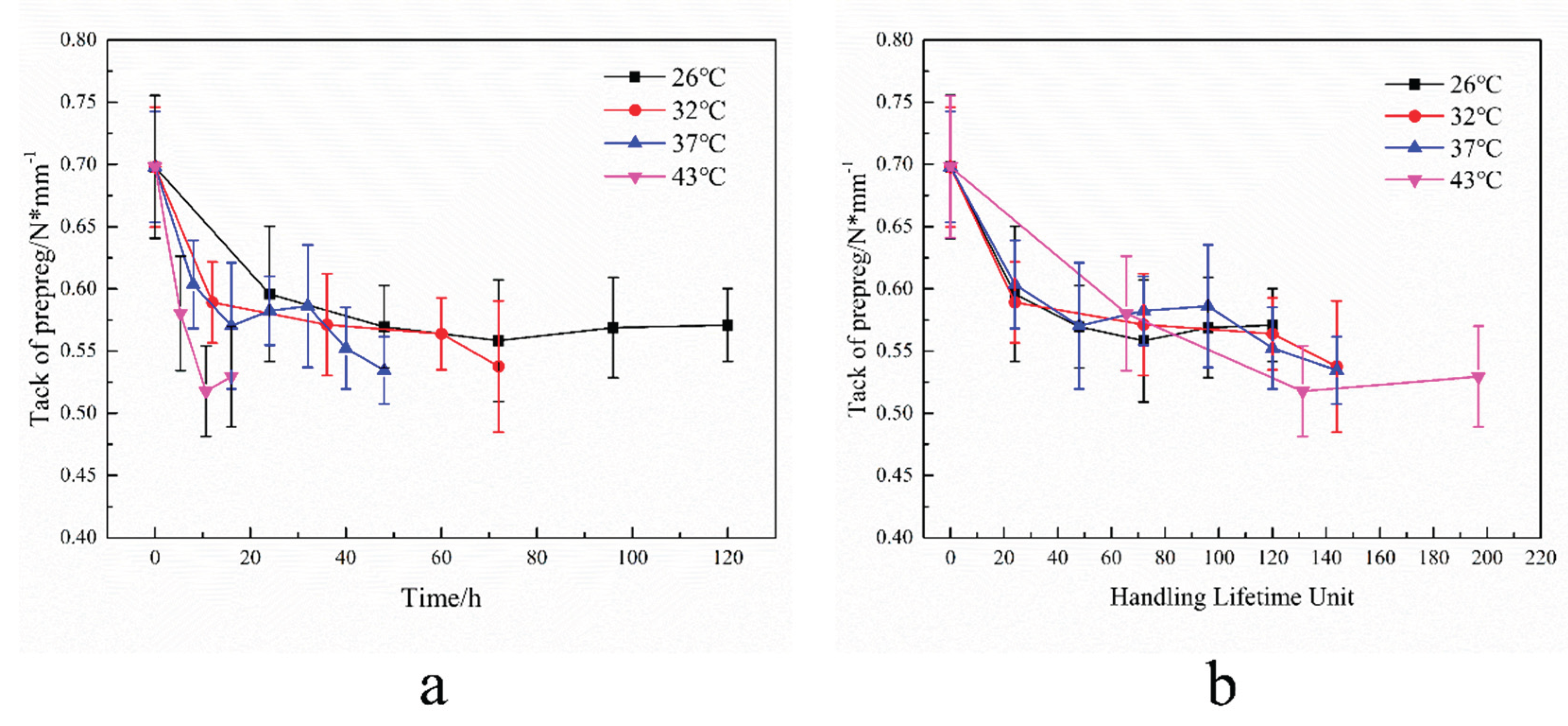

Analysis of Ageing Results

4. Conclusion

References

- Ahn KJ, Seferis JC. Prepreg processing science and engineering. Polym Eng Sci 1993; 33: 1177–1188.

- Molyneux M, Murray P, P. Murray B. Prepreg, tape and fabric technology for advanced composites. Composites 1983; 14: 87–91.

- Pollock L, O’Byrne S, Wild G. Quality assurance of uncured polymer matrix prepregs through the application of non-destructive methods. NDT E Int 2023; 133: 102761.

- Anis Baz Radwan. Experimental Analysis of the Automated Fiber Placement Manufacturing Parameters for High and Low Tack Prepreg Material. University of South Carolina, 2019.

- Rui X, Wang W, Jiaqi S, et al. Two-stage model of prepreg bonding interface formation in automated fiber placement process. J Reinf Plast Compos 2022; 07316844211060247.

- Endruweit A, Choong GYH, Ghose S, et al. Characterisation of tack for uni-directional prepreg tape employing a continuous application-and-peel test method. Compos Part A Appl Sci Manuf 2018; 114: 295–306.

- Endruweit A, Ghose S, Johnson BA, et al. Tack testing to aid optimisation of process parameters for automated material placement in an industrial environment. ICCM Int Conf Compos Mater 2017; 2017-Augus: 20–25.

- Budelmann D, Detampel H, Schmidt C, et al. Interaction of process parameters and material properties with regard to prepreg tack in automated lay-up and draping processes. Compos Part A Appl Sci Manuf 2019; 117: 308–316.

- Lei Z, Xianzhao X, Qian Z, et al. Influence and optimization of parameters of prepreg viscosity during placement. Chinese J Aeronaut 2022; 35: 438–449.

- Endruweit A, Choong GYH, Ghose S, et al. Characterisation of tack for uni-directional prepreg tape employing a continuous application-and-peel test method. Compos Part A Appl Sci Manuf 2018; 114: 295–306.

- Heller K, Böckl B, Ebel C, et al. Influence of prepreg aging and tack on lay-up effects/defects in thermoset automated fiber placement. ECCM18 - 18th Eur Conf Compos Mater 2018; 24–28.

- Amare C, Mantaux O, Gillet A, et al. Innovative test methodology for shelf life extension of carbon fibre prepregs. IOP Conf Ser Mater Sci Eng 2022; 1226: 012101.

- Schmidt C, Weber P, Hocke T, et al. Influence of prepreg material quality on carbon fiber reinforced plastic laminates processed by automated fiber placement. Procedia CIRP 2018; 67: 422–427.

- Olivia de Andrade Raponi, Barbosa LCM, Junior JEB, et al. Effects of the exposition of an autoclave prepreg to the processing environment on its properties, curing cycle and final composite behavior. Int J Adv Manuf Technol 2020; 106: 5129–5136.

- Chadwick CJ, Yang Y, Kalaitzidou K, et al. Processing of post-industrial unidirectional prepreg tapes using SMC equipment. Proc Am Soc Compos - 34th Tech Conf ASC 2019. Epub ahead of print 2019. [CrossRef]

- Sultana S, Asadi A, Colton J, et al. Composites made from CF prepreg trim waste tapes using sheet molding compounds (SMC) technology: Challenges and potential. Compos Part A Appl Sci Manuf 2020; 134: 105906.

- Pati S, Manomaisantiphap S, Goto T, et al. Development of CFRP with polyaniline-based resin using curable dopants employing storage stable prepregs. Appl Compos Mater 2021; 28: 381–394.

- Tao L, Min W, Qi L, et al. The hygrothermal aging process and mechanism of CFRP papered by prepreg that may be stored at room temperature. Polym Degrad Stab; 182. Epub ahead of print 2020. [CrossRef]

- Nandini A, Shute N, Elenchezhian MRP, et al. Dielectric property investigation of degraded pre-preg and performance prediction of the final composite part. Int SAMPE Tech Conf; 2018-May.

- Olivia de Andrade Raponi, Bárbara Righetti de Souza, Junior JEB, et al. Dielectric analysis as a low-complexity methodology for tracking prepreg out-time and its effects on the curing cycle. J Compos Mater 2019; 53: 4035–4042.

- Grunenfelder LK, Nutt SR. Prepreg age monitoring via differential scanning calorimetry. J Reinf Plast Compos 2012; 31: 295–302.

- Rabby MM, Rahman M, Das PP, et al. The effect of room-temperature aging on enthalpy and dielectric property of carbon-fiber/epoxy composite prepreg and the mechanical property of manufactured composite. Int SAMPE Tech Conf 2021; 2021-June: 592–605.

- Raponi O de A, Baldo Junior JE, Leite P de S, et al. Prepreg aging effects on its properties, curing process and final composite behavior characterized by dynamic mechanical analysis. J Reinf Plast Compos 2019; 38: 749–759.

- Jones RW, Ng Y, McClelland JF. Monitoring ambient-temperature aging of a carbon-fiber/epoxy composite prepreg with photoacoustic spectroscopy. Compos Part A Appl Sci Manuf 2008; 39: 965–971.

- Heller K, Hallmannseder M, Colin D, et al. Comparing test methods for the intra-ply shear properties of uncured prepreg tapes. Sci Eng Compos Mater 2020; 27: 89–96.

- Ahn, K J and Seferis, J C and Pelton, T and Wilhelm M. Deformation parameters influencing prepreg tack. SAMPE Q (Society Aerosp Mater Process Eng States); 23:2.

- Voyutskii SS, Vakula VL. The role of diffusion phenomena in polymer-to-polymer adhesion. J Appl Polym Sci 1963; 7: 475–491.

- Crossley RJ, Schubel PJ, De Focatiis DSA. Time-temperature equivalence in the tack and dynamic stiffness of polymer prepreg and its application to automated composites manufacturing. Compos Part A Appl Sci Manuf 2013; 52: 126–133.

- Crossley RJ, Schubel PJ, Warrior NA. The experimental determination of prepreg tack and dynamic stiffness. Compos Part A Appl Sci Manuf 2012; 43: 423–434.

- Wool RP, O’Connor KM. A theory of crack healing in polymers. J Appl Phys 1981; 52: 5953–5963.

- Reference class: other 31. De Gennes P-G. Reptation of a polymer chain in the presence of fixed obstacles. J Chem Phys 2009; 2: 35–42. Show / Hide Editor Save.

- Edwards SF. The statistical mechanics of polymerized material. Proc Phys Soc 1967; 92: 9–16.

- Ahn KJ, Seferis JC, Pelton T, et al. Analysis and characterization of prepreg tack. Polym Compos 1992; 13: 197–206.

- Dubois O, Le Cam JB, Béakou A. Experimental analysis of prepreg tack. Exp Mech 2010; 50: 599–606.

- Wang Y, Mahapatra S, Belnoue JPH, et al. Understanding tack behaviour during prepreg-based composites’ processing. Compos Part A Appl Sci Manuf 2023; 164: 107284.

- Bakhshi N, Hojjati M. An experimental and simulative study on the defects appeared during tow steering in automated fiber placement. Compos Part A Appl Sci Manuf 2018; 113: 122–131.

- Crossley RJ, Schubel PJ, Warrior NA. Experimental determination and control of prepreg tack for automated manufacture. Plast Rubber Compos 2011; 40: 363–368.

- Brooks, John R and Platt PR. 5513537 Method and apparatus to determine composite prepreg tack. 1996.

- Ahn KJ, Peterson L, Seferis JC, et al. Prepreg aging in relation to tack. J Appl Polym Sci 1992; 45: 399–406.

- Krapez J. Room-Temperature Aging of Narmco 5208 Carbon-Epoxy Prepreg. Part. Polymer (Guildf); 72.

- Janković B. Kinetic and reactivity distribution behaviors during curing process of carbon/epoxy composite with thermoplastic interface coatings (T800/3900-2 prepreg) under the nonisothermal conditions. Polym Compos 2018; 39: 201–220.

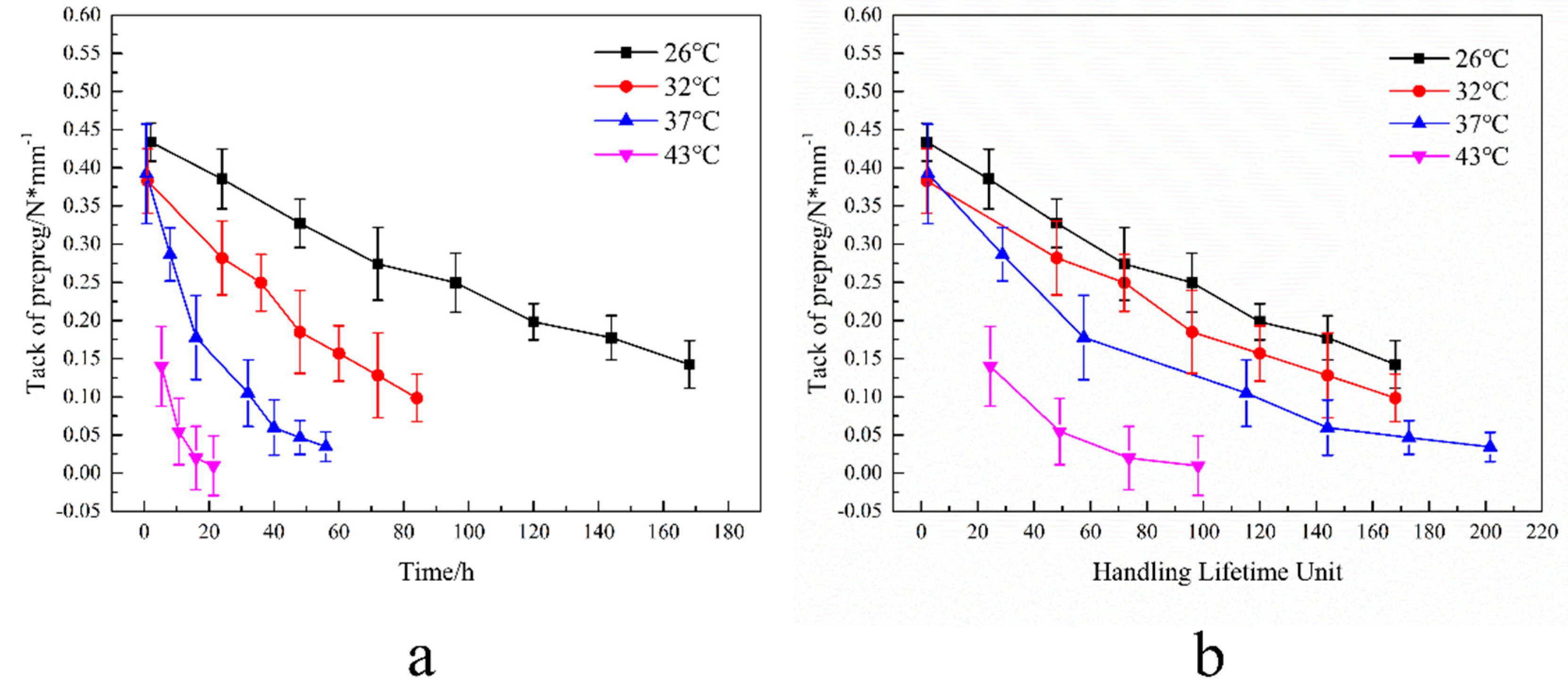

| Temperature | Handling life decay rate ratio |

|---|---|

| <26°C | 1 |

| 26~32°C | 2 |

| 32~37°C | 3 |

| 37~43°C | 4.5 |

| Ageing temperature /°C | 43 | 37 | 32 | 26 |

|---|---|---|---|---|

| Ageing time /Hour | 5.3 | 8 | 12 | 24 |

| 21.3 | 32 | 48 | 96 | |

| 37.3 | 56 | 84 | 168 | |

| 53.3 | 80 | 120 | 240 | |

| 69.3 | 104 | 156 | 312 |

| Temperature | T- type prepreg of R2 |

|---|---|

| 26℃ | 0.996 |

| 32℃ | 0.995 |

| 37℃ | 0.905 |

| 43℃ | 0.989 |

| Temperature | H- type prepreg of R2 | C- type prepreg of R2 |

|---|---|---|

| 26℃ | 0.981 | 0.547 |

| 32℃ | 0.983 | 0.705 |

| 37℃ | 0.900 | 0.707 |

| 43℃ | 0.862 | 0.793 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).