Submitted:

19 March 2024

Posted:

20 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Electric Arc Welding

3. Laser Beam Welding

4. Discussion

5. Conclusions and Future Directions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kah, P.; Shrestha, M.; Martikainen, J. Trends in joining dissimilar metals by welding. Applied Mechanics and Materials 2014, 440, 269-276. [CrossRef]

- Martinsen, K.; Hu, S.J. Hu, Carlson, B.E. Joining of dissimilar materials CIRP Annals – Manufacturing. Technology 2015, 64, 679–699. [CrossRef]

- Soltan, H.; Omar, M. A roadmap for selection of metal welding process: A review and proposals. 2022, Welding in the World, 66, 2639–2675. [CrossRef]

- Maruyama, T. Arc welding technology for dissimilar joints. Welding International 2003, 17, 276–281. [CrossRef]

- Boumerzoug, Z. A review: Welding by laser beam of dissimilar metals, Aspects Min Miner Sci 2021, 8, 916-920. [CrossRef]

- Ekeh, T.D.; Lawal, F.T.; Osoba, L.O.; Amuda, M.O.H. Microstructure and mechanical properties of dissimilar welds of duplex and API steel for offshore applications. International Journal of Materials Technology and Innovation 2023, 3, 2, 80-91. [CrossRef]

- Nabavi, S F.; Farshidianfar, A.; Dalir, H. A comprehensive review on recent laser beam welding process: Geometrical, metallurgical, and mechanical characteristic modeling, Int J Adv Manuf Technol 2023, 129, 4781–4828. [CrossRef]

- Abioye, T.E.; Olugbade, T.O.; Ogedengbe, T.I. Welding of dissimilar metals using gas metal arc and laser welding techniques: A review. Journal of Emerging Trends in Engineering and Applied Sciences 2017, 8, 6, 225-228.

- Mvola, B.; Kah, P.; Martikainen, J. Dissimilar ferrous metal welding using advanced gas metal arc welding processes. Rev. Adv. Mater. Sci. 2014, 38, 125-137.

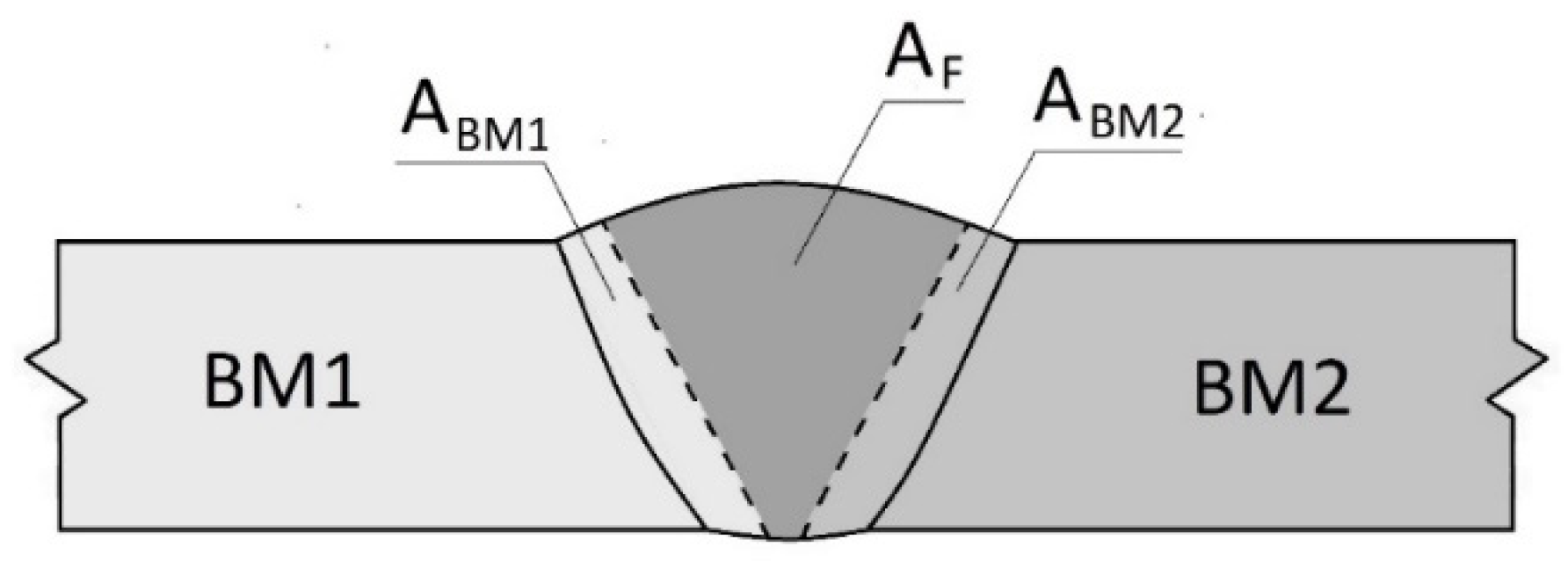

- DuPont, J. N. Dilution in fusion welding, in Metals Handbook,1st ed. Lienert, T. J.; Babu, S. S.; Siewert, T. A.; Acoff, V. L. Eds. ASM, Materials Park, Ohio US, 2011, Volume 06A, pp. 115-121.

- Abioye, T. E.; Ariwoola, O.E.; Ogedengbe, T.I.; Farayibi, P.K.; Gbadeyan, O.O. Effects of welding speed on the microstructure and corrosion behavior of dissimilar gas metal arc weld joints of AISI 304 stainless steel and low carbon steel. Materials Today: Proceedings 2019, 17, 871-877. [CrossRef]

- Mvola, B.; Kah, P.; Martikainen, J.; Suoranta, R. Dissimilar welded joints operating in sub-zero temperature environment. Int J Adv Manuf Technol 2016, 87, 3619–3635. [CrossRef]

- Echezona, N.; Akinlabi, S. A.; Jen, T. C.; Fatoba, O. S.; Hassan, S.; Akinlabi, E. T. Tig welding of dissimilar steel: A review. In Advances in Manufacturing Engineering, Lecture Notes in Mechanical Engineering, M. Awang and S. S. Emamian (Eds.), publisher: Springer Nature, Singapore 2021. [CrossRef]

- Shojaati, M.; Beidokhti, B. Characterization of AISI 304/AISI 409 stainless steel joints using different filler materials. Construction and Building Materials 2017, 147, 608–615. [CrossRef]

- Sun, Y.L; Obasi, G.; Hamelin, C.J.; Vasileiou, A.N.; Flinta, T.F.; Francis, J.A.; Smith, M.C. Characterization and modelling of tempering during multi-pass welding. Journal of Materials Processing Tech. 2019, 270, 118-131. [CrossRef]

- Sun, Y.L Hamelin, C. J.; Vasileiou, A. N.; Xiong, Q.; Flint, T.F.; Obasi, G.; Francis, J.A.; Smith, M.C. Effects of dilution on the hardness and residual stresses in multipass steel weldments. International Journal of Pressure Vessels and Piping 187 (2020) 104154. [CrossRef]

- Hsieh, C.-C.; Lin, Chen, M.-C.; Wu W. Microstructure, recrystallization, and mechanical property evolutions in the heat-affected and fusion zones of the dissimilar stainless steels. Materials Transactions 2007, 48, 11 2898-2902. [CrossRef]

- Hoang, A. T.; Le, V. V.; Nguyen, A. X. ; Nguyen, D. N. A study on the changes in microstructure and mechanical properties of multi-pass welding between 316 stainless steel and low-carbon steel. Journal of Advanced Manufacturing Technology 2018, 12, 2, 25-40.

- Bahador, A.; Hamzah, E.; Mamat, M. F. Effect of filler metals on the mechanical properties of dissimilar welding of stainless steel 316L and carbon steel A516 GR 70. Jurnal Teknologi 2015, 75, 7, 61–65. [CrossRef]

- Vargas, V.H.; Albiter, A.; Domínguez-Aguilar, M.A.; Altamirano, G.; Maldonado, C. Corrosion resistance of dissimilar GTA welds of pipeline steel and super duplex stainless steels in synthetic brine. Corrosion Iournal 2021, 77, 6, 668-680. [CrossRef]

- Wang, J.; Lu. M.-x.; Zhang, L.; Chang, W.; Xu, Li-ning; Hu, L.-h. Effect of welding process on the microstructure and properties of dissimilar weld joints between low alloy steel and duplex stainless steel. International Journal of Minerals, Metallurgy and Materials 2012, 19, 6, 518-524. [CrossRef]

- Ming, H.; Zhang, Z.; Wang, J.; E.-H., Han; Wang, P.; Sun, Z. Microstructure of a safe-end dissimilar metal weld joint (SA508-52-316L) prepared by narrow-gap GTAW. Materials Characterization 2017,123, 233–243. [CrossRef]

- Zhang, R.; Wu, Q.; Wang, L.; Zeng, C.; Wang, X. Study on A-TIG welding of Q245R/321 dissimilar steel. IOP Conf. Series: Earth and Environmental Science 2019, 310 042011. [CrossRef]

- Yılmaz, R.; Tümer, M. Microstructural studies and impact toughness of dissimilar weldments between AISI 316 L and AH36 steels by FCAW. Int J Adv Manuf Technol 2013, 67, 1433-1447. [CrossRef]

- Afriansyah, Arifin A. A. Dissimilar metal welding using Shielded metal arc welding: A Review. Technology Reports of Kansai University 2020, 64, 04, 1935-1948.

- Bahandari, D.; Chhibberb, R.; Arorac, N.; Mehtad, R. Investigation of TiO2–SiO2–CaO–CaF2 based electrode coatings on weld metal chemistry and mechanical behaviour of bimetallic welds. Journal of Manufacturing Processes 2016, 23, 61-74. [CrossRef]

- Pratiwi, D.K.; Arifin, A.; Gunawan; Mardhi, A.; Afriansyah Investigation of welding parameters of dissimilar weld of SS316 and ASTM A36 joint using a grey-based Taguchi Optimization Approach J. Manuf. Mater. Process. 2023, 7, 39. [CrossRef]

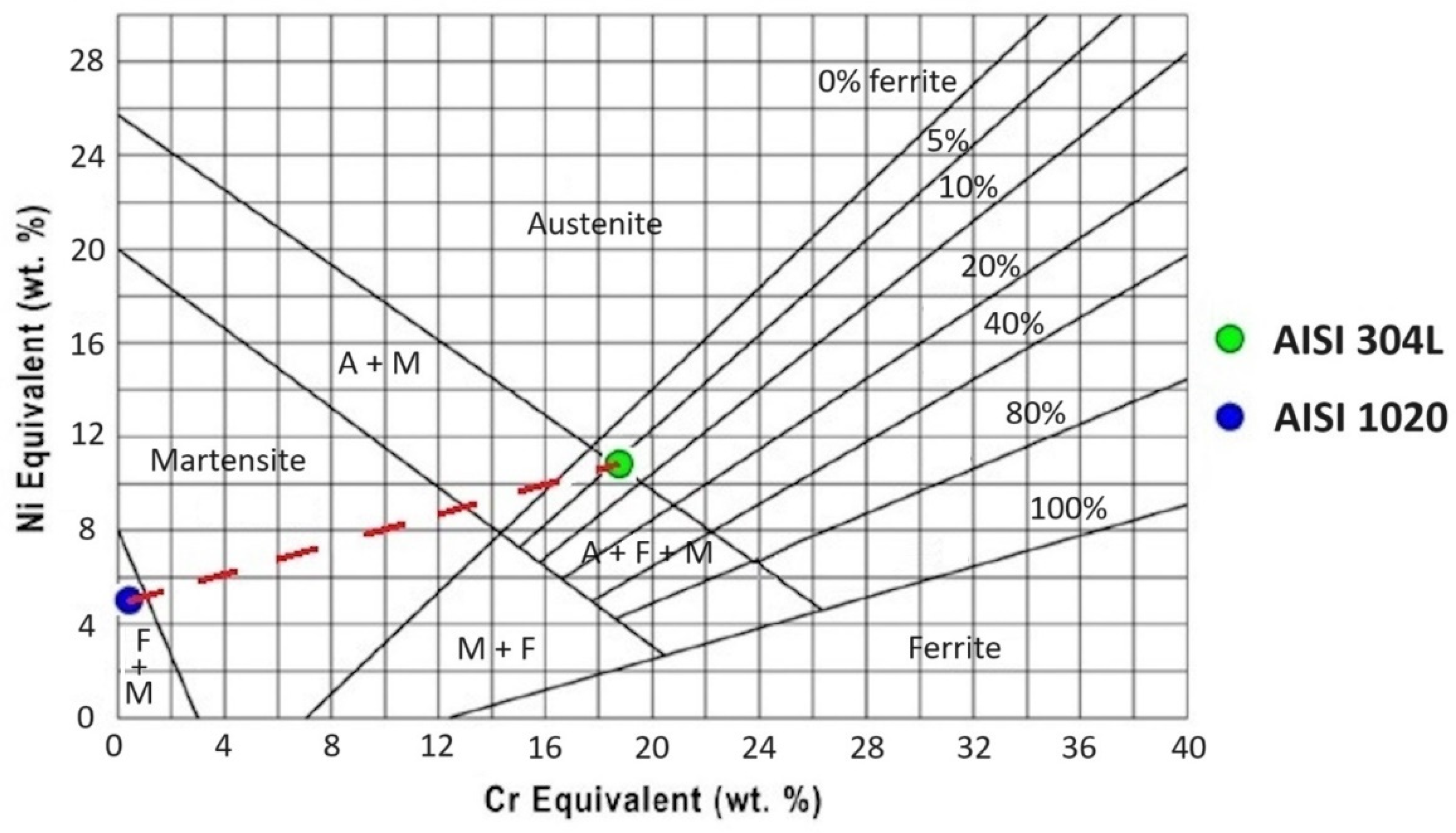

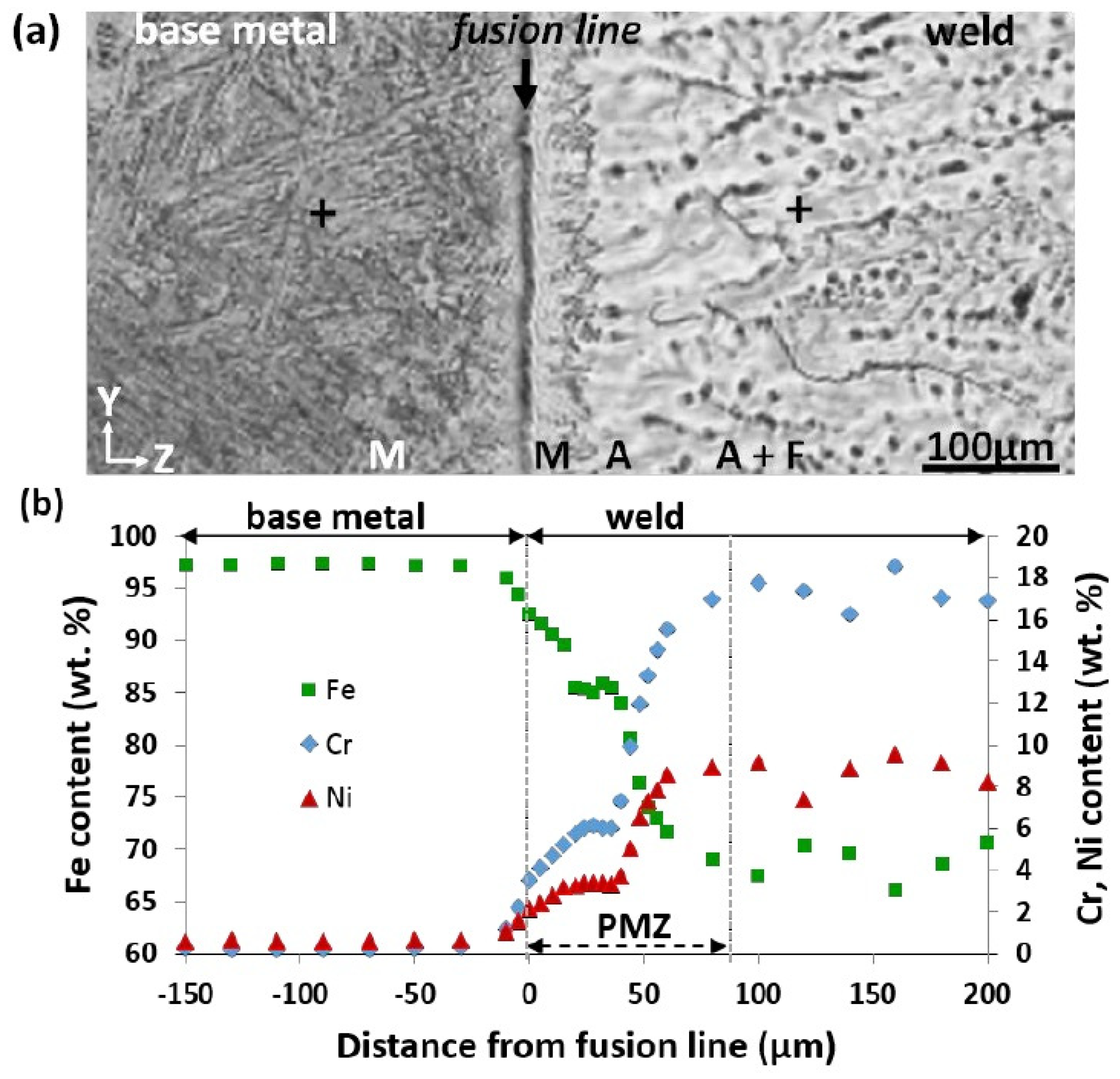

- Mas, F.; Tassin, C.; Roch, F.; Yescas, M.; Todeschini, P.; Bréchet, Y. Growth morphologies and primary solidification modes in a dissimilar weld between a low-alloy steel and an austenitic stainless steel. Metals 2018, 8, 284 :. [CrossRef]

- Nivas, R.; Singh, P.K.; Das, G.; Das, S.K.; Kumar, S.; Mahato, B.; Sivaprasad, K.; Ghosh, M. A comparative study on microstructure and mechanical properties near interface for dissimilar materials during conventional V-grooveand narrow gap welding. Journal of Manufacturing Processes 2017, 25, 274–283. [CrossRef]

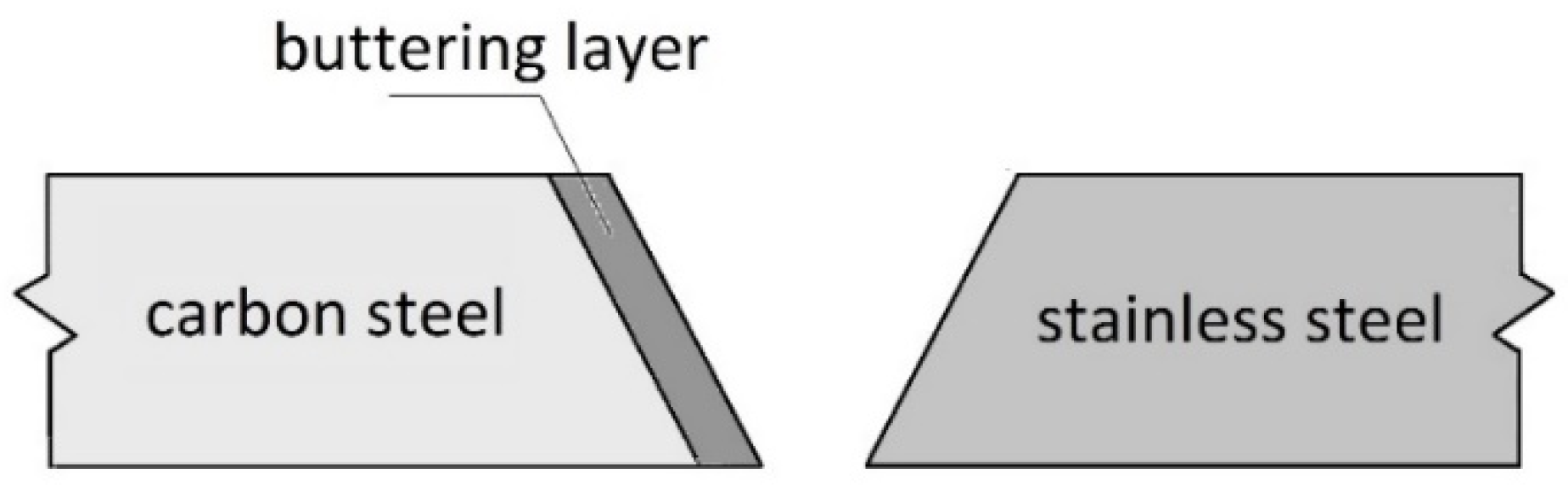

- Asadollahi, A.; Bahrami, A.; Shamanian, M. The effects of filler metal and butter layer on the microstructure and mechanical properties of API 5L X65/AISI 304L joint. Journal of Materials Research and Technology 2023, 23, 4148-4166. [CrossRef]

- Ghosh, P. S.; Sen, A.; Chattopadhyaya, S.; Sharma, S.; Singh, J.; Li, C.; Królczyk, G.; Rajkumar, S. Progressive developments and challenges in dissimilar laser welding of steel to various other light alloys (Al/Ti/Mg): A comprehensive review. Heliyon 2022, 8, e11710. [CrossRef]

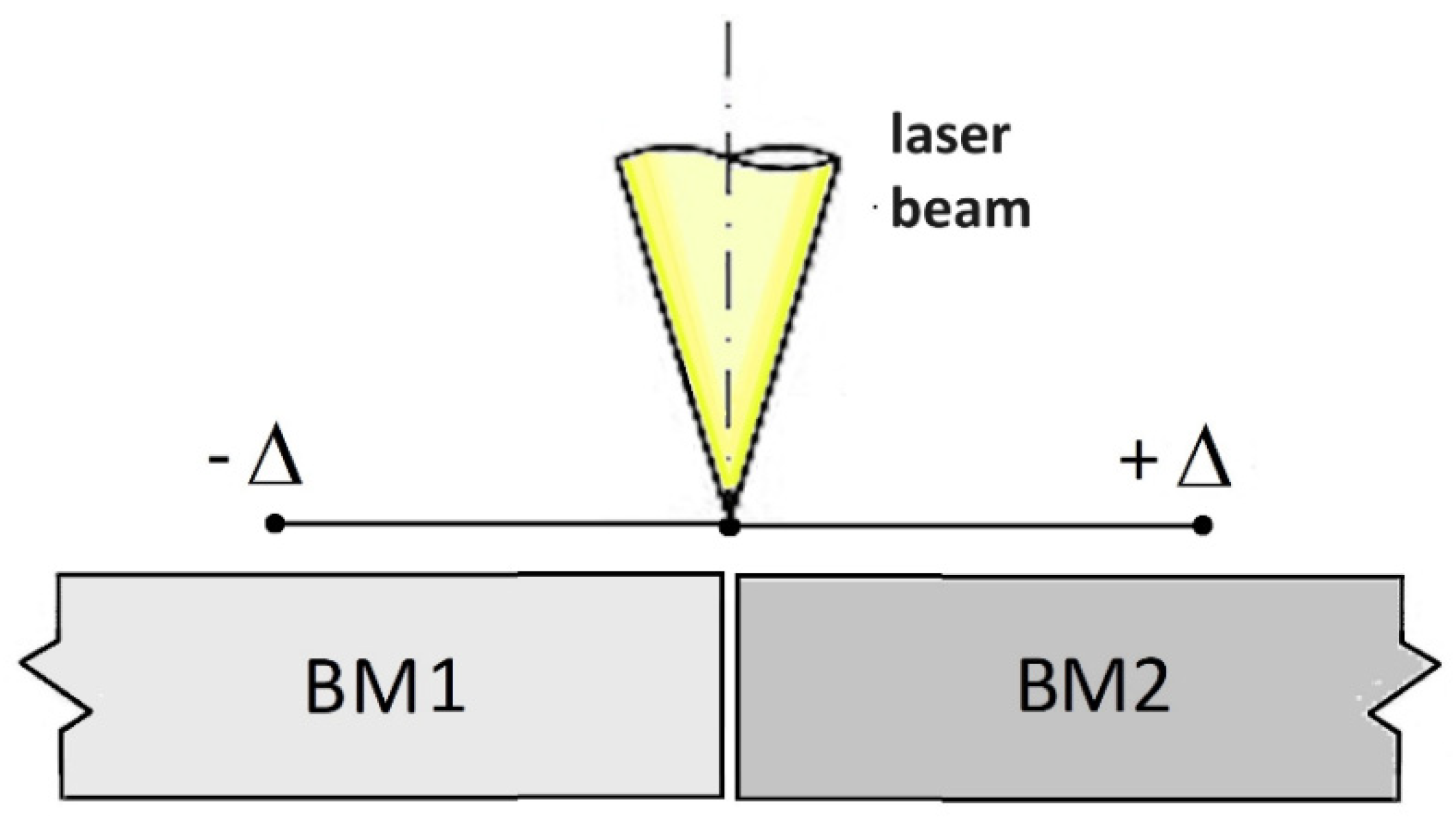

- Anawa, E.M.; Olabi, A.G. Optimization of tensile strength of ferritic/austenitic laser-welded components, Optics and Lasers in Engineering 2008, 46, 571–577. [CrossRef]

- Casalino, G.; Guglielmi, P.; Lorusso, V.D.; Mortello, M.; Peyrec, P.; Sorgente, D. Laser offset welding of AZ31B magnesium alloy to 316 stainless steel. Journal of Materials Processing Technology 2017, 242, 49–59. [CrossRef]

- Pereira, A. B.; Cabrinha, A.; Rocha, F.; Marques, P.; Fernandes, F. A. O.; Alves de Sousa, R. J. Dissimilar metals laser welding between DP1000 steel and aluminum alloy 1050. Metals 2019, 9, 102. [CrossRef]

- Zhang, M.; Chen, G; Zhou, Y.; Liao, S. Optimization of deep penetration laser welding of thick stainless steel with a 10 kW fiber laser. Materials and Design 2014, 53, 568–576. [CrossRef]

- Stanciu, E. M.; Pascu, A.; Tierean, M. H.; Roata, I. C.; Voiculescu, I.; Hulka, I.; Croitoru, C. Dissimilar laser welding of AISI 321 and AISI 1010. Technical Gazette 2018, 25, 2, 344-349. [CrossRef]

- Scutelnicu, E.; Iordachescu, M.; Rusu, C. C.; Mihailescu, D.; Ocaña, J. L. Metallurgical and mechanical characterization of low carbon steel - stainless steel dissimilar joints made by laser autogenous welding. Metals 2021, 11, 810. [CrossRef]

- Venkatakrishna, A.; Lakshminarayanan, A.; Vasantharaja, P.; Vasudevan, M. Decisive impact of filler-free joining processes on the Microstructural evolution, tensile and impact properties of 9Cr-1Mo-V-Nb to 316 L(N) dissimilar joints. Proceedings of the Institution of Mechanical Engineers, Part C: Journal of Mechanical Engineering Science. 2022, 236, 5, 2408-2427. [CrossRef]

- Danielewski, H.; Skrzypczyk, A.; Tofil, S.; Witkowski, G.; Rutkowski, S. Numerical Simulation of Laser Welding Dissimilar Low Carbon and Austenitic Steel Joint. Open Eng. 2020, 10. 491–498. [CrossRef]

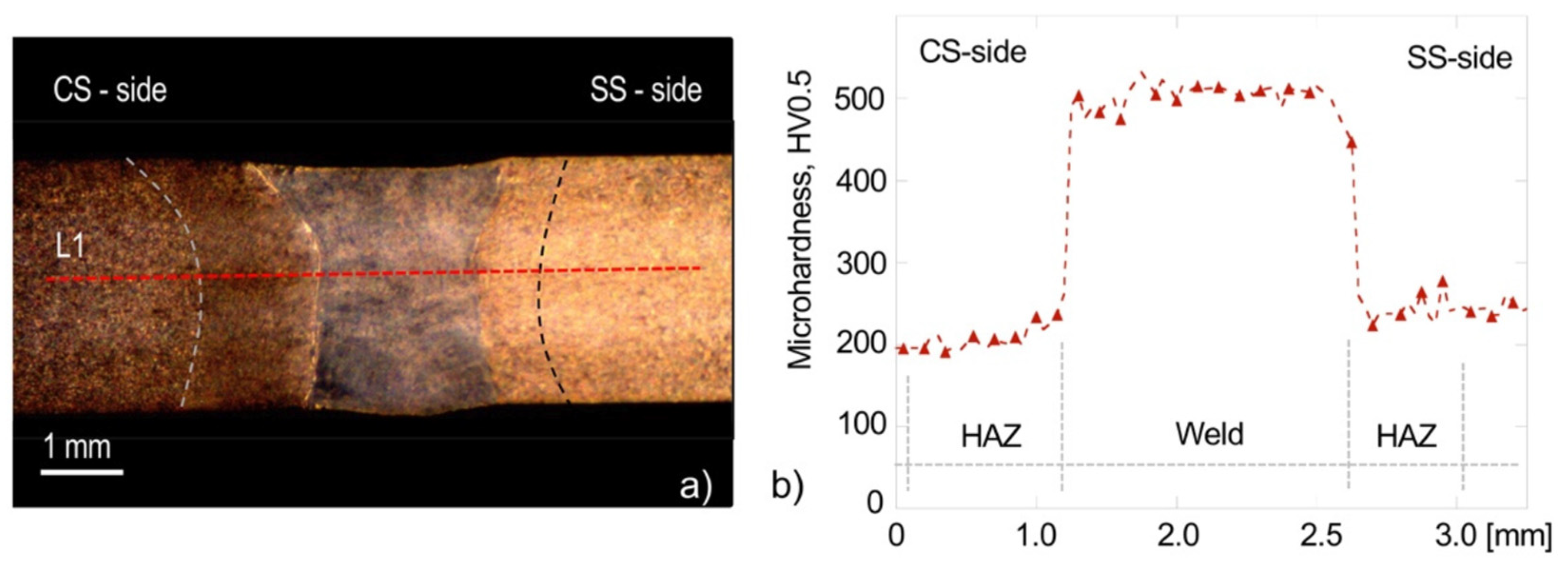

- Hamada, A.; Ghosh, S.; Ali, M.; Jaskari, M.; Järvenpää. A. Studying the strengthening mechanisms and mechanical properties of dissimilar laser-welded butt joints of medium-Mn stainless steel and automotive high-strength carbon steel. Materials Science & Engineering A 2022, 856, 143936. [CrossRef]

- Hamada, A.; Khosravifard, A.; Ali, M.; Ghosh, S.; Jaskari, M.; Hietala, M.; Järvenpää, A.; Newishy, M. Micromechanical analysis and finite element modelling of laser-welded 5-mm-thick dissimilar joints between 316L stainless steel and low-alloyed ultra-high-strength steel. Materials Science & Engineering A 2023, 882, 145442. [CrossRef]

- Prabakaran, M.P.; Kannan, G.R. Optimization of laser welding process parameters in dissimilar joint of stainless steel AISI316/AISI1018 low carbon steel to attain the maximum level of mechanical properties through PWHT. Optics and Laser Technology 2019, 112, 314–322. [CrossRef]

- Prabakaran, M.P.; Kannan, G.R. Effects of post-weld heat treatment on dissimilar laser welded joints of austenitic stainless steel to low carbon steel. International Journal of Pressure Vessels and Piping 2021, 191, 104322. [CrossRef]

- Liu, F.; Zhou, X.; Chen, X.; Gong, X.; Wu, L.; Chen, B.; Chen, K.; Tan, C. Melt flowing behaviors and microstructure evolution during laser offset welding of dissimilar metals between AH36 and 304 steels. Optics & Laser Technology 2022, 151, 10802. [CrossRef]

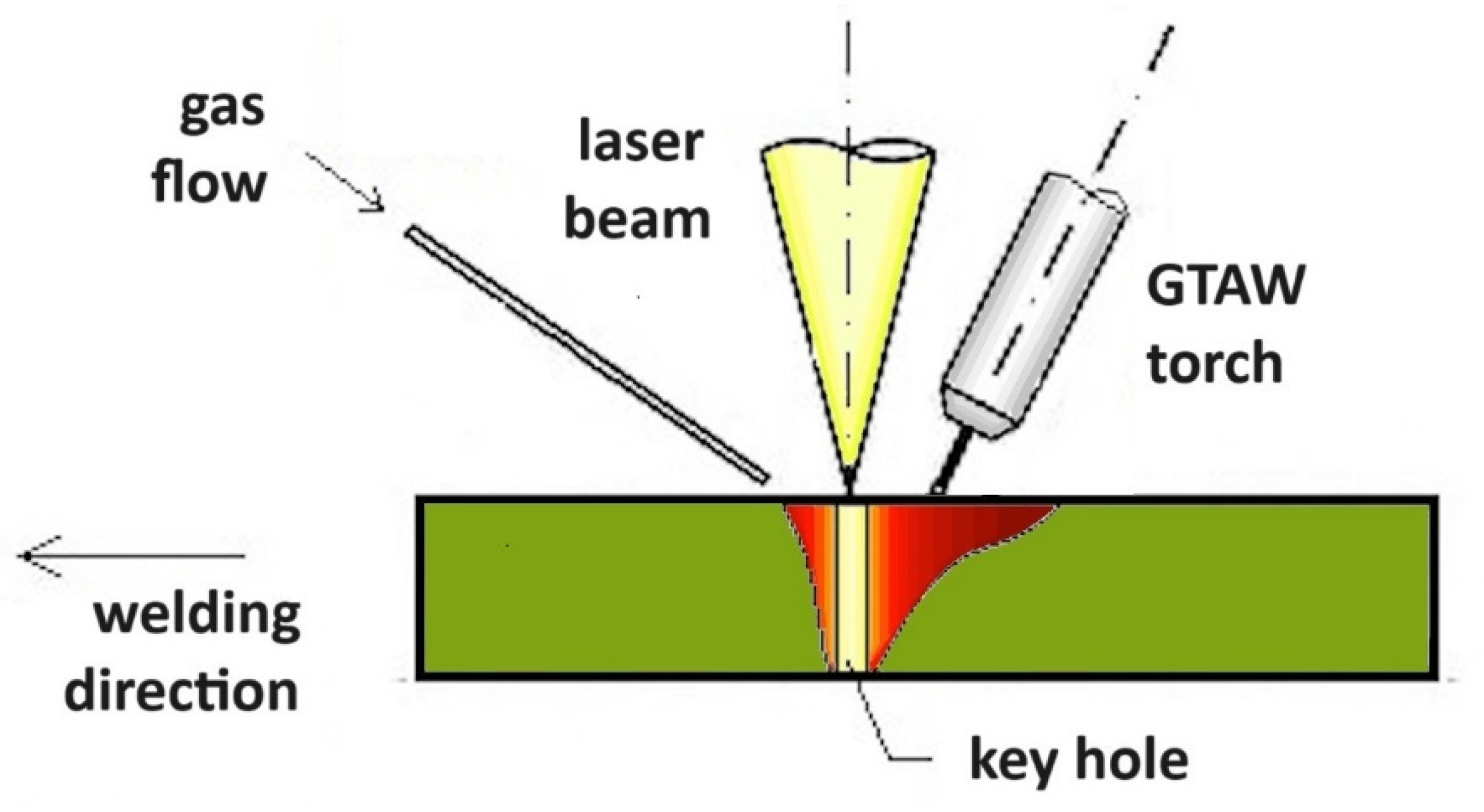

- Li, G.; Zhang, C.; Gao, M.; Zeng, X. Role of arc mode in laser-metal active gas arc hybrid welding of mild steel. Materials and Design 2014, 61, 239-250. [CrossRef]

- Russo Spena, P.; Angelastro, A.; Casalino, G. Hybrid laser arc welding of dissimilar TWIP and DP high strength steel weld. Journal of Manufacturing Processes 2019, 39 233–240. [CrossRef]

- Zhang, X.; Mi, G.; Wang, C. Microstructure and performance of hybrid laser-arc welded high-strength low alloy steel and austenitic stainless steel dissimilar joint. Optics and Laser Technology 2020, 122 105878. [CrossRef]

- Missori, S.; Sili, A. Prediction of weld metal microstructure in laser beam welded clad steel. Metallurgist, 2018, 62, 84-92. [CrossRef]

- Salminen, A. The filler wire - laser beam interaction during laser welding with low alloyed steel filler wire. Mechanika. 2010, 4, 84, 67-74.

- Hansen, K. S.; Olsen, F. O.; Kristiansen, M.; Madsen, O. Joining of multiple sheets in a butt-joint configuration using single pass laser welding with multiple spots. J. Laser Appl. 2015, 27, 032011. [CrossRef]

- Kristiansen, M.; Hansen, K. S.: Langbak, A.; Johansen, S. B.; Krempin, S. B.; Hornum, M. D. Single pass laser welding with multiple spots to join four sheets in a butt-joint configuration. Physics Procedia 2017, 89, 205-213. [CrossRef]

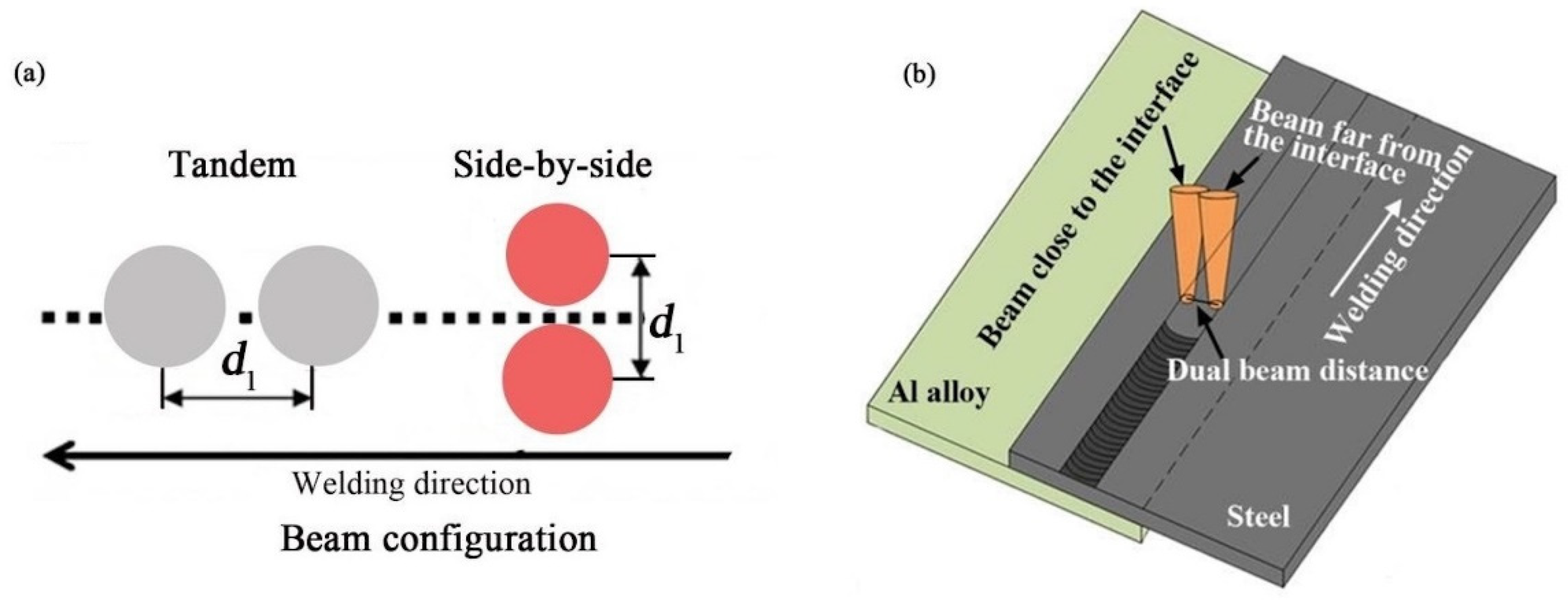

- Cui, L.; Chen, H.; Chen, B.; He, D. Welding of dissimilar steel/Al Joints using dual-beam lasers with side-by-side configuration. Metals 2018, 8, 1017. [CrossRef]

- Xu, S.; Thermal stress analysis of dissimilar welding joints by finite element method. Procedia Engineering 2011, 15, 3860 – 3864. [CrossRef]

- Bharthi, A. D.; Babu, D. H. Structural and Thermal Analysis of Dissimilar Metal Welding of 1020 Mild Steel and 304 Stainless Steel. International Journal of Scientific Engineering and Technology Research 2015, 04, 09, 1761-1771. [CrossRef]

- An, G.; Park, J.; Lim, W.; Park, H.; Han, I. Characteristics of welding residual stress distribution in dissimilar weld joints. Metals 2022, 12, 405. [CrossRef]

- Dokme, F.; Kulekci, M.K.; Esme, U. Microstructural and mechanical characterization of dissimilar metal welding of Inconel 625 and AISI 316L, Metals 2018, 8, 797. [CrossRef]

- Ramkumar, T.; Selvakumarb, M.; Narayanasamyc, P.; Ayisha Begamd, A.; Mathavand, P.; Arun Rajd, A. Studies on the structural property, mechanical relationships and corrosion behaviour of Inconel 718 and SS 316L dissimilar joints by TIG welding without using activated flux, J. of Manuf. Proc. 2017, 30, 290-298. [CrossRef]

- Shankar, V.; Gill, T.P.S.; Mannan, S.L.; Sundaresan, S. Solidification Cracking in Austenitic Stainless SteelWelds. Sadhana Acad. Proc. Eng. Sci. 2003, 28, 359–382. [CrossRef]

- Manitsas, D.; Andersson, J. Hot Cracking Mechanisms in Welding Metallurgy: A Review of Theoretical Approaches. In Proceendings of the ICEAF-V, Chios Island, Greece, 22–28 June 2018. [CrossRef]

- Fei, Z.; Pan, Z.; Cuiuri, D.; Li, H.; Van Duin, S.; Yu, Z. Microstructural characterization and mechanical properties of K-TIG welded SAF2205/AISI316L dissimilar joint. Journal of Manufacturing Processes, 2019, 45, 340-355. [CrossRef]

- Landowski, M.; ´Swierczynska, A.; Rogalski, G.; Fydrych, D. Autogenous fiber laser welding of 316L austenitic and 2304 lean duplex stainless steels. Materials 2020, 13, 2930. [CrossRef]

- Alali, M.; Abass, M. H.; Abbas, W. S.; Shehabd, A A. Effect of nickel powder buffering layer on microstructure and hardness properties of high carbon steel / stainless steel arc stud welding. Materials Research 2020, 23, 1, e20190567. [CrossRef]

- Giudice, F.; Sili, A. Weld metal microstructure prediction in laser beam welding of austenitic stainless steel. Appl. Sci. 2021, 11, 1463. [CrossRef]

- Tandon, V.; Patil, A. P.; Kowshik, S. Impact of filler electrodes on welding properties of dissimilar welded 316L/201 austenitic stainless steels. Eng. Proc. 2023, 59, 90. [CrossRef]

- Wu, C.; Li, S.; Zhang, C.; Wang, X. Microstructural evolution in 316LN austenitic stainless steel during solidification process under different cooling rates. J Mater Sci 2016, 51, 2529–2539. [CrossRef]

- Zhai, R.; Zhang, H.; Xu, B.; Liu, S.; Xie, B.; Sun, M. Elimination of δ-ferrite in N50 steel and its effect on cryogenic mechanical properties. Cryogenics 2022, 126 103522. [CrossRef]

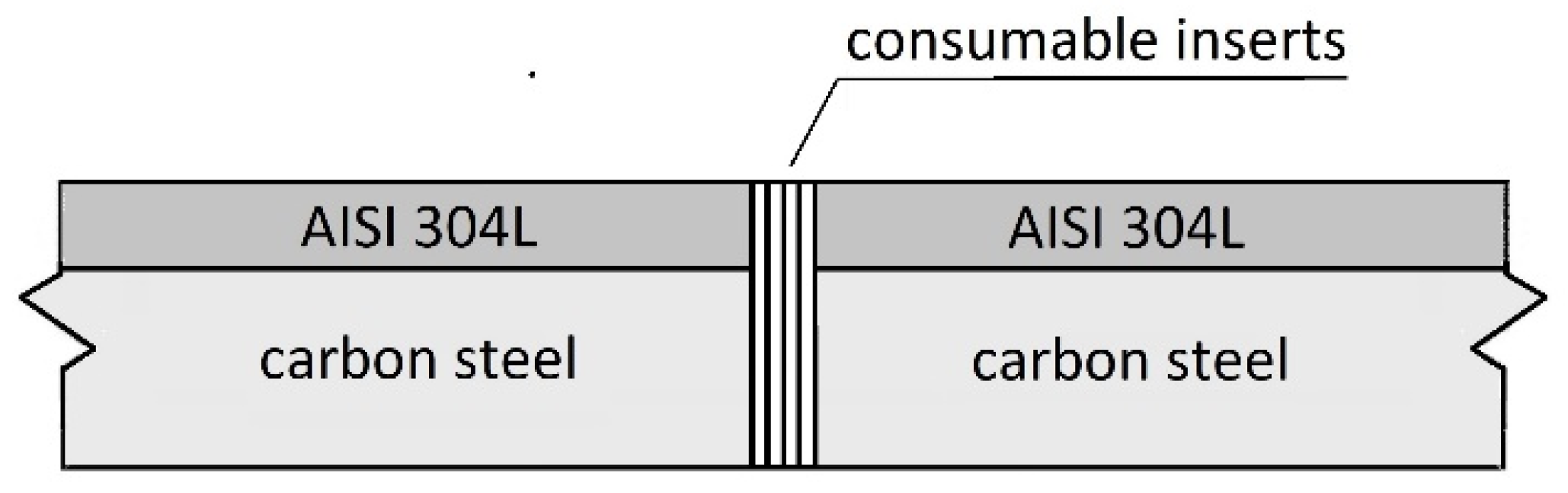

- Bunaziv, I.; Olden, V.; Akselsen, O.M. Metallurgical Aspects in the Welding of Clad Pipelines—A Global Outlook. Appl. Sci. 2019, 9, 3118. [CrossRef]

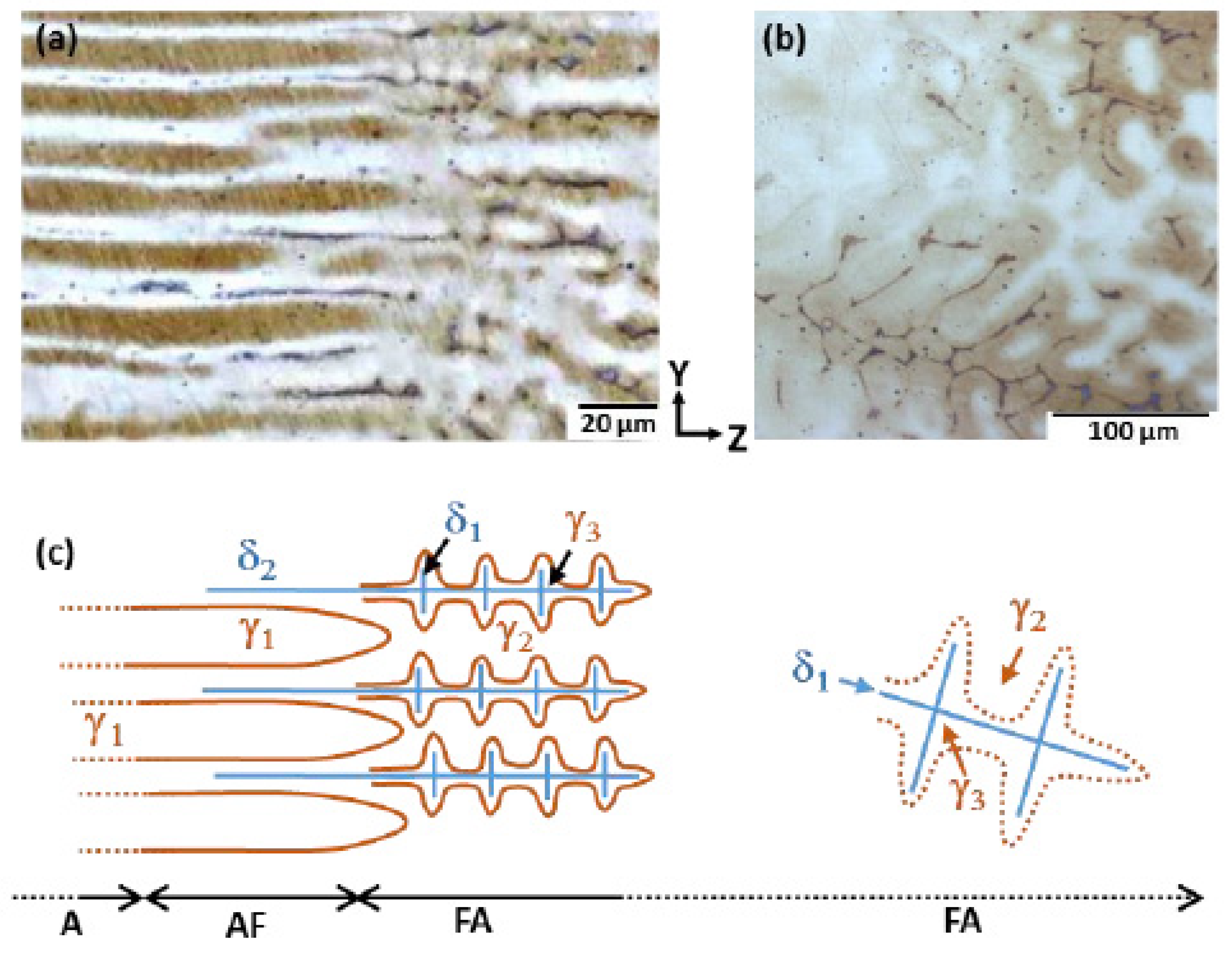

- Valiente Bermejo, M.A.: Reagent selection in austenitic stainless steel solidification modes characterization. Weld. J. 2012, 91,133s–139s.

- Yu, P.; Thompson, K.J.; MCCarthy, J.; Kou, S. Microstructure evolution and solidification cracking in austenitic stainless steel. Welds. Weld. J. 2018, 97, 301s–314s. [CrossRef]

- Zhou, C.; Dia, P.; Wu, H.; He, M.; Liu, X.; Chu, P. K. Effect of the ferrite morphology on hydrogen embrittlement of MAG welded 304 austenitic stainless steel. Applied Surface Science 2022, 606, 154866. [CrossRef]

- Wang, Q.; Chen, S.; Rong, L. Properties of heavy-section AISI 316 stainless steel casting. Metall Mater Trans 2020, A 51, 2998–3008 . [CrossRef]

- Weman, K. The weldability of steel (chap. 14) in Welding processes handbook, Woodhead Publishing Ltd, Cambridge, 2003, pp. 149-150.

- Tandon, V., Thombre, M.A., Patil, A.P. et al. Effect of Heat Input on the Microstructural, mechanical, and corrosion properties of dissimilar weldment of conventional austenitic stainless steel and low-nickel stainless steel. Metallogr. Microstruct. Anal. 2020, 9, 668–677. [CrossRef]

- Vitek, J.M.; David, S.A.; Hinman, C.R. Improved Ferrite Number Prediction Model That Accounts for Cooling Rate Effects—Part 2: Model Results. Weld. J. 2003, 82, 43s–50s.

- DuPont, J. N. Fundamentals of weld solidification, in Metals Handbook, 1st ed. Lienert, T. J.; Babu, S. S.; Siewert, T. A.; Acoff, V. L. Eds. ASM, Materials Park, Ohio US, 2011, Volume 06A, pp. 96-114.

- Ghosh, A., Misra, D., Acharyya, S.K.: Experimental and numerical investigation on laser welding of 2205 duplex stainless steel. Lasers Manuf. Mater. Process. 2019, 6, 228–246. [CrossRef]

- Kik, T. Heat source models in numerical simulations of laser welding. Materials 2020, 13, 2653. [CrossRef]

- Giudice, F.; Missori, S.; Sili, A. Parameterized multipoint-line analytical modeling of a mobile heat source for thermal field prediction in laser beam welding. Int. J. Adv. Manuf. Technol. 2021, 112, 1339–1358. [CrossRef]

- Giudice, F.; Sili, A. Validation of a theoretical model for laser welding thermal field by multi-physics numerical simulation. Metals 2023, 13, 2020. [CrossRef]

- Gajjar, P. K.; Khatri, B. C.; Siddhpura, A.; Siddhpura, M. A. Sensitization and desensitization (healing) in austenitic stainless steel: A Critical Review. Trans Indian Inst Met 2022, 75, 1411-1427. [CrossRef]

- Ramdan, R. D.; Kariem, M. A.; Neswan, O.; Wiriawan, F., Suratman, R.; Widyanto, B.; Wirawan, R. Mechanical properties and microstructure at stainless steel HAZ from dissimilar metal welding after heat treatment processes. IOP Conf. Series: Materials Science and Engineering 2019, 553, 012034. [CrossRef]

- Dai, P.; Li, S.; Wu, L.; Wang, Y.; Feng, G. Dean Deng A new numerical model to predict welding-induced sensitization in SUS304 austenitic stainless steel joint. Journal of Materials Research and Technology 2022, 17, 234e243. [CrossRef]

- Winarto, W.; Anis, M.; Riastuti, R.; Suarjana, I.N. Study the effect of welding position and plate thickness to the mechanical and microstructural properties of the TIG dissimilar metal welded between carbon steel ASTM A36 and stainless steel 304 plates. Material Science Forum 2020, 1000, 364–372. [CrossRef]

- DuPont, J. N. Microstructural evolution and high temperature failure of ferritic to austenitic dissimilar welds. International Materials Reviews 2012, 57, 4, 208-231. [CrossRef]

- Nimko, M. O. Influence of welding parameters on decarburization in heat affected zone of dissimilar weldments after post weld heat treatment. Archives of Materials Science Engineering 2021, 112, 1, 23-31 https://doi.org/10.5604/01.3001.0015.5929.

- Britto, J. G.; Sulbihar, A. D.; Dinesh, K. L.; Jeya, J.; Durai R. R. B.; Sriram V. Microstructural studies of P91 and SS304L dissimilar welding. Materials Today: Proceedings 2021, 47, 4571-4577. [CrossRef]

| Composition ranges1, 2 | Solidification modes | Sequence of transformations |

|---|---|---|

| Creq/Nieq > 2.0 | F (ferritic) | L → L + δ → δ |

| 1.5 < Creq/Nieq < 2.0 | FA (ferritic-austenitic) | L → L + δ → L + δ + γ → δ + γ |

| 1.37 < Creq/Nieq <1.5 | AF (austenitic-ferritic) | L → L + γ → L + δ + γ → γ + δ |

| Creq/Nieq < 1.37 | A (austenitic) | L → L + γ → γ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).