Submitted:

14 March 2024

Posted:

14 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Material and Methods

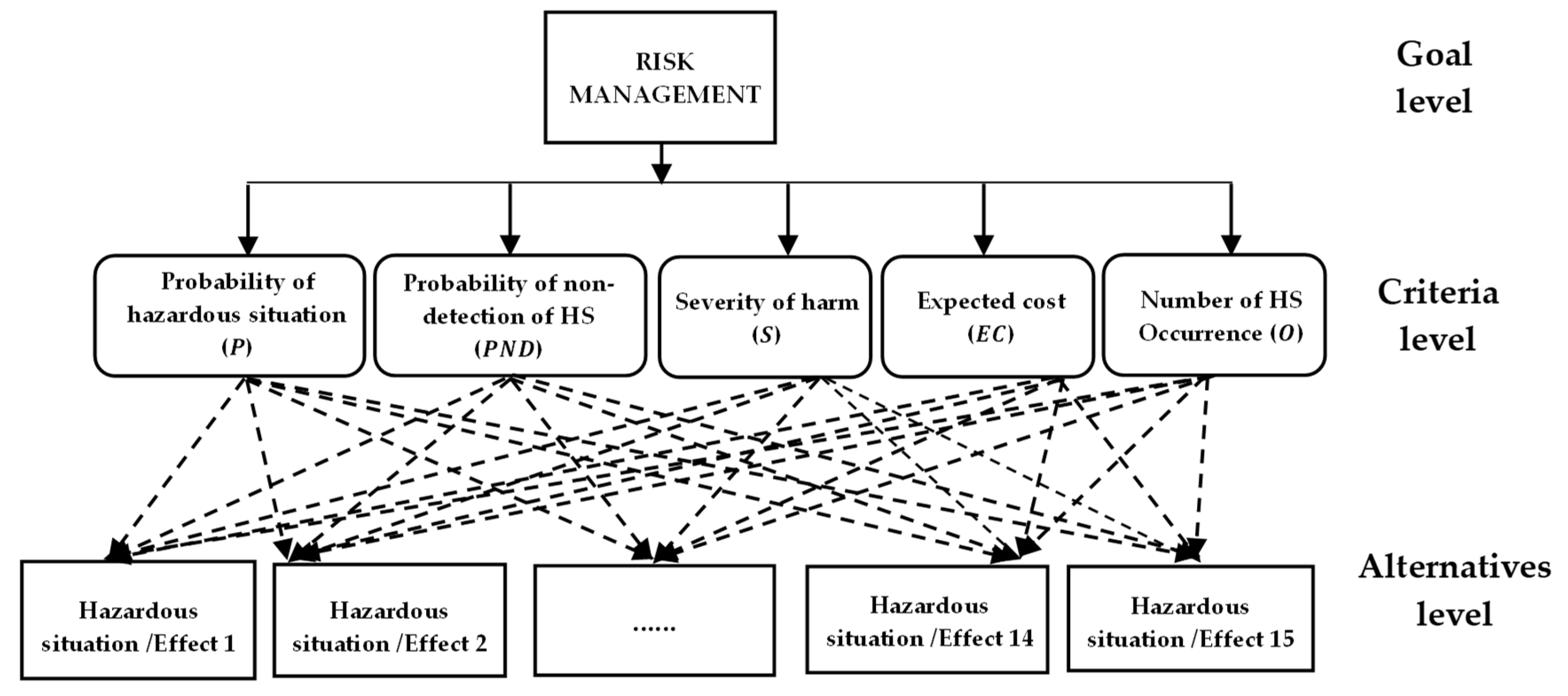

2.1. Machinery Safety Analysis

2.2. Estimation of Expected Cost Using the AHP Method

- The calculation of the normalized comparison matrix was performed.

- The average weights (priorities) for each element were determined.

- Calculated maximum eigenvalue ().

- Calculated specific coherence indices () and coherence ratio () to verify the consistency of the comparison matrix.

- The priority vector for each HS/E combination (Table 9 part (b)) represents the priority or weight of the relevant element compared to the other elements;

- The maximum eigenvalue represents the value ;

- The consistent index is equal to ;

- The coherence ratio is equal to .

- We filled the diagonal with units and mirrored the values in the lower half of the matrix to the upper half to make it symmetric.

- We have normalized the matrix.

- We calculated the average weights (priorities) for each criterion.

- We verified the consistency of the matrix by calculating the consistency ratio ().

- The maximum eigenvector is ;

- Consistent index is equal to ;

- The coherence ratio is equal to .

- Probability of HS: ;

- Severity of Harm: ;

- Number of HS occurrences: ;

- Probability of non-detection of HS: .

- The most important are the expected costs: ;

2.3. Sensitivity analysis

- The chance of failure (Probability of HS): ;

- Severity of Harm: ;

- Number of HS occurrences: ;

- The chance of not detecting an undesirable event: ;

- Expected costs: .

- The largest eigenvector is ;

- The consistency index is ;

- The consistency ratio is .

- Severity of harm: ;

- The chance of failure (undesirable event): ;

- Number of HS Occurrences: ;

- Expected costs: ;

- The chance of not detecting an undesirable event: .

- The largest eigenvector: ;

- Consistency index: ;

- Consistency ratio: .

3. Results of the Evaluation of the Effectiveness and Efficiency of the Proposed Measures

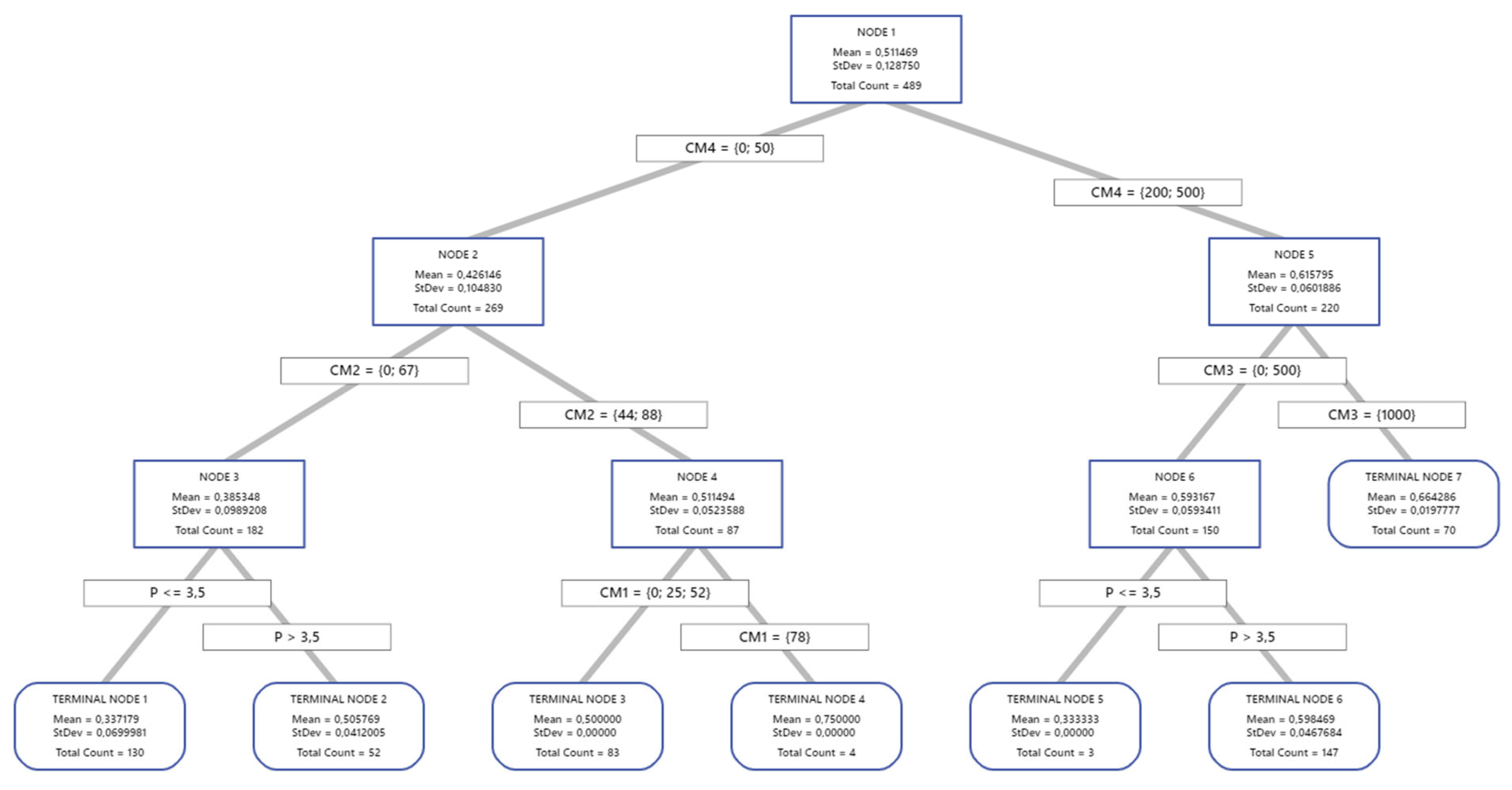

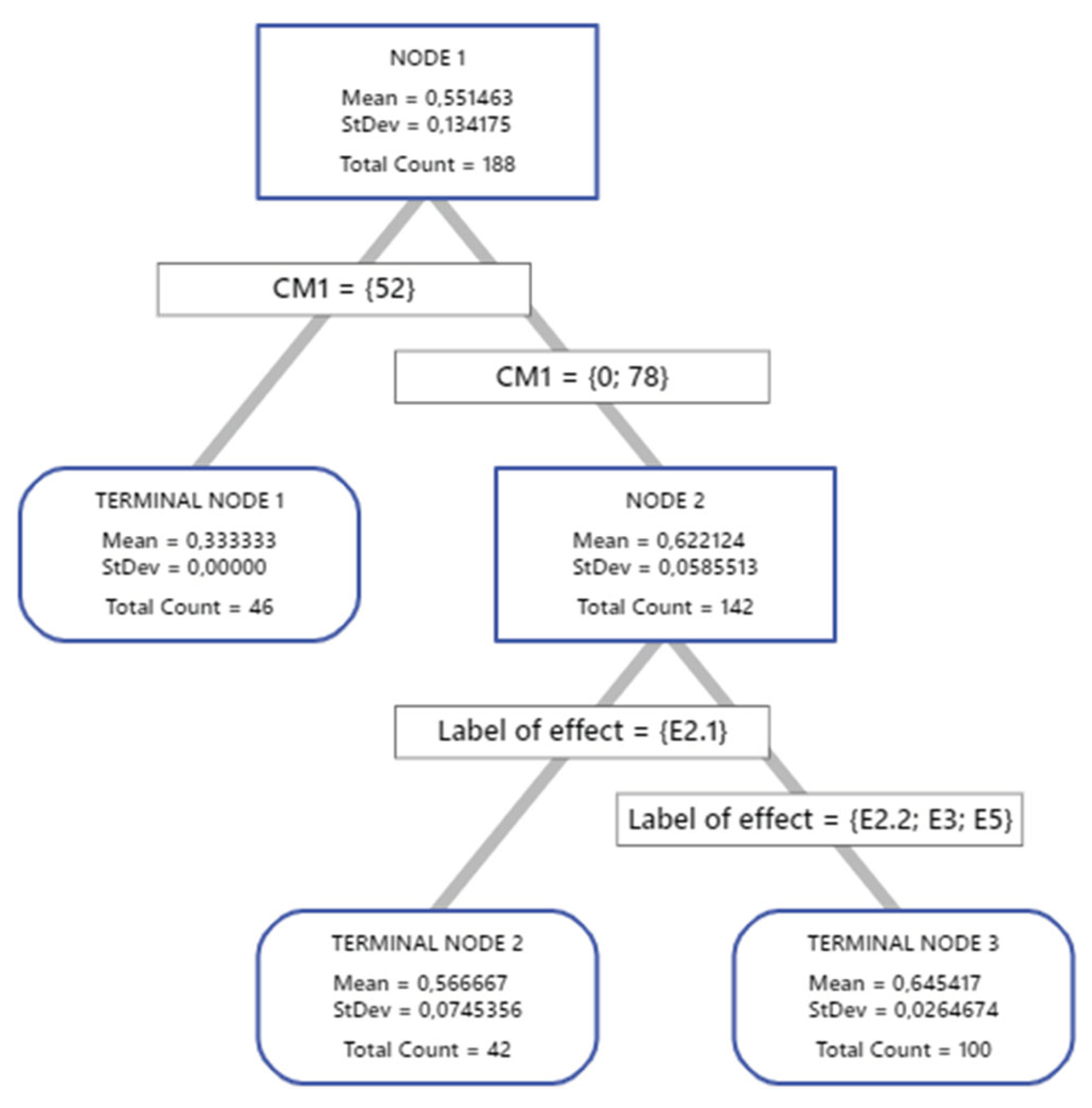

3.1. Applying the CART Method for Assessing Effectiveness of

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Badri, A.; Boudreau-Trudel, B.; Souissi, A.S. Occupational health and safety in the industry 4.0 era: A cause for major concern? Saf. Sci. 2018, 109, 403–411. [Google Scholar] [CrossRef]

- Vogl, G.W.; Weiss, B.A.; Helu, M. A review of diagnostic and prognostic capabilities and best practices for manufacturing. J. Intell. Manuf. 2019, 30, 79–95. [Google Scholar] [CrossRef] [PubMed]

- Jocelyn, S.; Chinniah, Y.; Ouali, M-S. ; Yacout, S. Application of logical analysis of data to machinery related accident prevention based on scarce data. Reliab. Eng. Syst. Saf. 2017, 159, 223–236. [Google Scholar] [CrossRef]

- Lee, D. The Effect of Safety Management and Sustainable Activities on Sustainable Performance: Focusing on Suppliers. Sustainability 2018, 10, 4796. [Google Scholar] [CrossRef]

- Xue, Y.; Fan, Y.; Xie, X. Relation between senior managers’ safety leadership and safety behavior in the Chinese petrochemical industry. J. Loss Prev. Process Ind. 2020, 65, 104142. [Google Scholar] [CrossRef]

- Roger, I.; Flin, R.; Mearns, K.J.; Hetherington, C. Safety Leadership: A View of the Senior Managers' Role. In SPE Offshore Europe Oil and Gas Conference and Exhibition. OnePetro, Aberdeen, UK, 2009. [Google Scholar] [CrossRef]

- Pham, H.; Kim, S.-Y. The effects of sustainable practices and managers’ leadership competences on sustainability performance of construction firms. Sustain. Prod. Consum. 2019, 20, 1–14. [Google Scholar] [CrossRef]

- Anunciação, P.; Dinis, V.; Peñalver, A.; Esteves, F. Functional Safety as a critical success factor to industry 4.0. Procedia Comput. Sci. 2022, 204, 45–53. [Google Scholar] [CrossRef]

- Balážiková, M.; Pačaiová, H.; Tomašková, M. A Proposal for Risk Assessment of Low-Frequency Noise in the Human–Machine–Environment System. Appl. Sci. 2023, 13, 13321. [Google Scholar] [CrossRef]

- Leveson, N. A new accident model for engineering safer systems. Saf. Sci. 2004, 42, 237–270. [Google Scholar] [CrossRef]

- Manuele, F.A. On the practice of safety., 4th ed.; Wiley & Sons: Hoboken, New Jersey, 2003. [Google Scholar]

- Ayyub, B.M. Risk analysis in engineering and economics., 1st ed.; Chapman and Hall/CRC: New York, NY, USA, 2003. [Google Scholar]

- Harms-Ringdahl, L. Safety analysis: principles and practice in occupational safety., 2nd ed.; CRC Press: London, 2001. [Google Scholar]

- Boileau, P.E. Sustainability and prevention in occupational health and safety. Ind Health. 2016, 54, 293–295. [Google Scholar] [CrossRef]

- Nawaz, W.; Linke, P.; Koҫ, M. Safety and sustainability nexus: A review and appraisal. J. Clean. Prod. 2019, 216, 74–87. [Google Scholar] [CrossRef]

- Hogevold, N. M.; Svensson, G.; Wagner, B.; Petzer, D. J.; Klopper, H. B.; Sosa Varela, J. C.; Padin, C.; Ferro, C. Sustainable business models: Corporate reasons, economic effects, social boundaries, environmental actions and organizational challenges in sustainable business practices. Balt. J. Manag. 2014, 9, 357–380. [Google Scholar] [CrossRef]

- Dyllick, T.; Muff, K. Clarifying the Meaning of Sustainable Business: Introducing a Typology From Business-as-Usual to True Business Sustainability. Organ. Environ. 2016, 29, 156–174. [Google Scholar] [CrossRef]

- Bayram, M.; Ünğan, M.C.; Ardıç, K. The relationships between OHS prevention costs, safety performance, employee satisfaction and accident costs. Int. J. Occup. Saf. Ergon. 2016, 23, 285–296. [Google Scholar] [CrossRef]

- Jallon, R.; Imbeau, D.; Marcellis-Warin, N. Development of an indirect-cost calculation model suitable for workplace use. J. Saf. Res. 2011, 42, 149–164. [Google Scholar] [CrossRef] [PubMed]

- Šolc, M.; Blaško, P.; Girmanová, L.; Kliment, J. The Development Trend of the Occupational Health and Safety in the Context of ISO 45001:2018. Standards 2022, 2, 294–305. [Google Scholar] [CrossRef]

- Kineber, A.F.; Antwi-Afari, M.F.; Elghaish, F.; Zamil, A.M.A.; Alhusban, M.; Qaralleh, T.J.O. Benefits of Implementing Occupational Health and Safety Management Systems for the Sustainable Construction Industry: A Systematic Literature Review. Sustainability 2023, 15, 12697. [Google Scholar] [CrossRef]

- Botti, L.; Melloni, R.; Oliva, M. Learn from the Past and Act for the Future: A Holistic and Participative Approach for Improving Occupational Health and Safety in Industry. Saf. Sci. 2022, 145, 105475. [Google Scholar] [CrossRef]

- Fonseca, L.; Carvalho, F. The Reporting of SDGs by Quality, Environmental, and Occupational Health and Safety-Certified Organizations. Sustainability 2019, 11, 5797. [Google Scholar] [CrossRef]

- Möller, N.; Hansson, S. O.; Peterson, M. Safety is more than the antonym of risk. J. Appl. Philos. 2006, 23, 419–432. [Google Scholar] [CrossRef]

- Aven, T.; Renn, O. On risk defined as an event where the outcome is uncertain. J. Risk Res. 2009, 12, 1–11. [Google Scholar] [CrossRef]

- Kóča, F.; Pačaiová, H.; Turisová, R.; Sütőová, A.; Darvaši, P. The Methodology for Assessing the Applicability of CSR into Supplier Management Systems. Sustainability 2023, 15, 13240. [Google Scholar] [CrossRef]

- Tsalis, T.A.; Stylianou, M.S.; Nikolaou, I.E. Evaluating the quality of corporate social responsibility reports: The case of occupational health and safety disclosures. Saf. Sci. 2018, 109, 313–323. [Google Scholar] [CrossRef]

- Standard ISO 12100. Safety of Machinery - General Principles for Design–Risk Assessment and Risk Reduction; ISO: Geneva, Switzerland, 2010. [Google Scholar]

- European Parliament and of the Council. Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on Machinery and Amending Directive 95/16/EC (Recast); European Parliament and of the Council: Brussels, Belgium, 2006. [Google Scholar]

- Dudek, E.; Kozłowski, M. The concept of risk tolerability matrix determination for aeronautical data and information chain. J. KONBiN 2017, 43, 69–94. [Google Scholar] [CrossRef]

- Tanasić, Z.; Kecman, B.; Janjić, G. QFD METHOD-A MODEL FOR PRODUCT IMPROVEMENT AND DEVELOPMENT. Ann. Fac. Eng. Hunedoara 2021, 19, 75–80. [Google Scholar]

- Braglia, M. MAFMA: Multi-attribute failure mode analysis. Int. J. Qual. Reliab. Manag. 2000, 17, 1017–1033. [Google Scholar] [CrossRef]

- Robinson, L.S.; Sarkies, M.; Brown, T.; O’Brien, L. Direct, indirect and intangible costs of acute hand and wrist injuries: a systematic review. Injury 2016, 47, 2614–2626. [Google Scholar] [CrossRef]

- Leal, J.E. AHP-express: A simplified version of the analytical hierarchy process method. MethodsX 2020, 7, 100748. [Google Scholar] [CrossRef] [PubMed]

- Saaty, T.L. The Analytical Hierarchy Process: Planning, Priority Setting, Resource Allocation; McGraw-Hill: New York, NY, USA, 1980. [Google Scholar]

- Saaty, T.L. How to make a decision: the analytic hierarchy process. Eur. J. Oper. Res. 1990, 48, 9–26. [Google Scholar] [CrossRef]

- Munier, N.; Hontoria, E. Uses and Limitations of the AHP Method. A Non-Mathematical and Rational Analysis. In Management for Professionals; Springer: Berlin, Germany, 2021. [Google Scholar]

- Min, H.; Melachrinoudis, E. The relocation of a hybrid manufacturing/distribution facility from supply chain perspectives: a case study. Omega 1999, 27, 75–85. [Google Scholar] [CrossRef]

- Ajslev, J.Z.N.; Møller, J.L.; Andersen, M.F.; Pirzadeh, P.; Lingard, H. The Hierarchy of Controls as an Approach to Visualize the Impact of Occupational Safety and Health Coordination. Int. J. Environ. Res. Public Health 2022, 19, 2731. [Google Scholar] [CrossRef] [PubMed]

- Jian, Z.; Zhaowei, W.; Changsong, Q. Study on the key quality parameter decision for multi-process by CART method. In 2010 International Conference on Computer Application and System Modeling, 2010. [Google Scholar] [CrossRef]

| Verbal Evaluation | ) Corresponding to the Occurrence of Once Per: | Score |

|---|---|---|

| Very unlikely | > 3 years | 1 |

| Unlikely | 1 - 3 years | 2 |

| Possible | 6 months to a year | 3 |

| Likely | 1 month to six months | 4 |

| Very likely | < 1 month | 5 |

| Verbal Evaluation | Severity of that Harm (𝑺) | Score |

|---|---|---|

| Negligible | A near miss with little potential for injury, or an injury that does not require treatment. | 1 |

| Minor | Injury requires treatment at the workplace but without incapacity for work. Examples include a scratch, minor cut,bruise, such as one requiring first aid. | 2 |

| Moderate | Injury requiring medical treatment by a medical professional. An example is a more serious cut or sprain. Work can usually only be carried out after medical treatment. | 3 |

| Major | Possible injury with prolonged incapacity for work. | 4 |

| Severe | Serious injury with long-term incapacity for work or death. | 5 |

| ) | |||||||

|---|---|---|---|---|---|---|---|

| Negligible 1 |

Minor 2 |

Moderate 3 |

Major 4 |

Severe 5 |

|||

| ) | Very unlikely 1 |

1 | 2 | 3 | 4 | 5 | |

| Unlikely 2 |

2 | 4 | 6 | 8 | 10 | ||

| Possible 3 |

3 | 6 | 9 | 12 | 15 | ||

| Likely 4 |

4 | 8 | 12 | 16 | 20 | ||

| Very likely 5 |

5 | 10 | 15 | 20 | 25 | ||

| Risk assessment - Risk category | |||||||

| LOW Score: 1 - 3 |

Low or acceptable risk. Proceed with due care and attention, following instructions and procedures. | ||||||

| MEDIUM Score: 4 - 7 |

Moderate or tolerable risk. Task must be carried out according to training and in accordance with safety procedures. Any appropriate control measures must be in place before the task/activity commences. | ||||||

| HIGH Score: 8 - 14 |

High or undesirable risk. Management consideration and authorization is required for its tolerance. Where possible the task should be reassessed to take account of the associated risks and additional control measures put in place to reduce the risk (if feasible). | ||||||

| STOP Score: 15 - 20 |

Very high or unacceptable risk. This role must not be continued. Further action needs to be reviewed or implemented immediately. These measures should be reconsidered. | ||||||

| STOP - STOP Score: 25 |

A strongly unacceptable risk. Operation must be stopped immediately. Redesign of the machine must be considered. | ||||||

| Process | Activity | Type of Hazard | Hazardous Situation (HS) | Possible Consequences |

Risk | |||

|---|---|---|---|---|---|---|---|---|

| P | S | R | Category | |||||

| Manufacturing: Cartoon maker | Material handling; Shutdown and start-up | Mechanical | kinetic energy (occurrence in the zone of product movement on the machine conveyor, movement of packaging machine parts) |

ejection, crushing | 4 | 4 | 16 | STOP |

| compressed air (activity in the vicinity of compressed air pipelines) |

ejection, crushing, abrasion | 3 | 4 | 12 | H | |||

| Electrical | electric arc (arc flash zone) |

burn, death | 3 | 5 | 15 | STOP | ||

| inappropriate contact (contact with live parts of electrical wiring) |

burn, death | 2 | 5 | 10 | H | |||

| Radiation hazard | optical radiation (exposure to optical radiation when checking product labelling) |

discomfort, fatigue, damage to eyes | 3 | 4 | 12 | H | ||

| high frequency el. magnetic radiation (activity in the zone of wireless transmission of production data). | discomfort, fatigue (in the case of a pacemaker, even death) | 3 | 4 | 12 | H | |||

| Material and substances | air pollution (environmental pollution by dusty waste) |

over sensitization, infection | 3 | 4 | 12 | H | ||

| combustible materials (combustible dust in the workplace) |

over sensitization | 3 | 5 | 15 | STOP | |||

| fire, explosion, | 3 | 5 | 15 | STOP | ||||

| Machinery | Number | Machinery | Number |

|---|---|---|---|

| APS Inline Pre-Made Pouches | 7 | Automatic labelling system | 10 |

| FUT Urostomy product | 2 | Extruder | 21 |

| Ostomy pouches | 1 | Material handling system | 1 |

| Cutter | 2 | Mixer | 1 |

| Folding machine | 2 | Cartoon maker | 2 |

| ) | ) | |

|---|---|---|

| air pollution | 41 | |

| combustible materials | 74 | |

| compressed air | 92 | |

| electric arc | 76 | |

| falling objects (e.g. tools and materials) | 52 | |

| high frequency electromagnetic radiation | 9 | |

| inappropriate contact | 87 | |

| instability (loose parts) | 39 | |

| kinetic energy | 8 | |

| optical radiation | 15 | |

| Total sum | 489 |

| Identifiable by Human Senses | Automatic Detection | Detection after Occurrence (Corrective Measures) | Detection before Occurrence (Preventive Measures) | Score | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Yes | Partially | No | Directly | Indirectly | No | Yes | No | Yes | No | |

| o | 1 | 1 | ||||||||

| o | o | 1 | 1 | |||||||

| o | 2 | o | 2 | |||||||

| o | 2 | o | o | 2 | ||||||

| o | 3 | o | o | 3 | ||||||

| o | 3 | o | o | 3 | ||||||

| o | 4 | o | o | 4 | ||||||

| o | 4 | o | o | 4 | ||||||

| o | 4 | o | o | 4 | ||||||

| o | 5 | o | o | o | 5 | |||||

| o | 5 | o | o | o | 5 | |||||

| o | 5 | o | o | o | 5 | |||||

| o | 5 | o | o | o | 5 | |||||

| Process | Type of hazard | Potential harm | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CAUSE | 41 | operation | Material/ substance | air pollution | over sensitization, infection | 3 | 4 | 3 | 36 | E1 | EFFECT | |

| 15 | maintenance | Material/ substance | combustible materials | local fire | 4 | 5 | 4 | 80 | E2.1 | |||

| 4 | explosion | 4 | 5 | 5 | 100 | E2.2 | ||||||

| 12 | operation | over sensitization | 3 | 5 | 4 | 60 | E2.3 | |||||

| 43 | fire, explosion | 2 | 5 | 5 | 50 | E2.4 | ||||||

| 92 | operation | Mechanical | compressed air | ejection, crushing, abrasion | 3 | 4 | 3 | 36 | E3 | |||

| 31 | maintenance | Electrical | electric arc | burn, death | 3 | 5 | 5 | 75 | E4.1 | |||

| 45 | operation | burn, death | 2 | 5 | 4 | 40 | E4.2 | |||||

| 52 | maintenance | Mechanical | falling objects (e.g. tools and materials) | crushing, contusion, throwing | 4 | 4 | 4 | 64 | E5 | |||

| 9 | operation | Radiation | high frequency electromagnetic radiation | discomfort, fatigue (in the case of a pacemaker, even death) | 3 | 4 | 5 | 60 | E6 | |||

| 32 | operation | Electrical | inappropriate contact | burn, death | 2 | 5 | 3 | 30 | E7.1 | |||

| 51 | maintenance | Mechanical | impact, crushing, ejection | 4 | 3 | 2 | 24 | E7.2 | ||||

| 39 | maintenance | Mechanical | instability (loose parts) | impact, crushing | 5 | 3 | 4 | 60 | E8 | |||

| 8 | operation | Mechanical | kinetic energy | ejection, crushing | 4 | 4 | 3 | 48 | E9 | |||

| 15 | operation | Radiation | optical radiation | discomfort, fatigue, damage to eyes | 3 | 4 | 5 | 60 | E10 | |||

| Total | 489 | x | x | x | x | x | x | x | 823 | x |

| E1 | E2.1 | E2.2 | E2.3 | E2.4 | E3 | E4.1 | E4.2 | E5 | E6 | E7.1 | E7.2 | E8 | E9 | E10 | Local | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| E1 | X | 0,2 | 0,2 | 0,2 | 0,2 | 0,25 | 0,33 | 2,00 | 0,25 | 1 | 1 | 2 | 0,33 | 0,25 | 5 | 0,027 |

| E2.1 | 5 | X | 1 | 4 | 4 | 4 | 4 | 8 | 2 | 4 | 5 | 2 | 6 | 2 | 5 | 0,157 |

| E2.2 | 5 | 1 | X | 4 | 4 | 4 | 4 | 8 | 2 | 4 | 5 | 2 | 6 | 2 | 5 | 0,157 |

| E2.3 | 5 | 0,25 | 0,25 | X | 1 | 2 | 1 | 4 | 0,33 | 0,5 | 4 | 3 | 2 | 2 | 3 | 0,069 |

| E2.4 | 5 | 0,25 | 0,25 | 1 | X | 2 | 1 | 4 | 0,33 | 0,5 | 4 | 3 | 2 | 2 | 3 | 0,069 |

| E3 | 4 | 0,25 | 0,25 | 0,5 | 0,5 | X | 2 | 6 | 0,33 | 4 | 0,5 | 5 | 1 | 0,33 | 3 | 0,056 |

| E4.1 | 3 | 0,25 | 0,25 | 1 | 1 | 0,5 | X | 6 | 0,33 | 4 | 2 | 0,25 | 1 | 0,33 | 2 | 0,049 |

| E4.2 | 0,5 | 0,13 | 0,13 | 0,25 | 0,25 | 0,17 | 0,17 | X | 0,13 | 0,5 | 0,2 | 1 | 0,2 | 0,13 | 0,5 | 0,013 |

| E5 | 4 | 0,5 | 0,5 | 3 | 3 | 3 | 3 | 8 | X | 6 | 3 | 6 | 3 | 1 | 4 | 0,115 |

| E6 | 2 | 0,25 | 0,25 | 2 | 2 | 0,25 | 0,25 | 2 | 0,17 | X | 0,33 | 2 | 0,33 | 0,17 | 3 | 0,039 |

| E7.1 | 2 | 0,2 | 0,2 | 0,25 | 0,25 | 2 | 0,5 | 5 | 0,33 | 3 | X | 5 | 1 | 0,33 | 2 | 0,046 |

| E7.2 | 0,5 | 0,5 | 0,5 | 0,33 | 0,33 | 0,2 | 4 | 1 | 0,17 | 0,5 | 0,2 | X | 0,2 | 0,13 | 1 | 0,033 |

| E8 | 3 | 0,17 | 0,17 | 0,5 | 0,5 | 1 | 1 | 5 | 0,33 | 3 | 1 | 5 | X | 0,33 | 4 | 0,049 |

| E9 | 4 | 0,5 | 0,5 | 0,5 | 0,5 | 3 | 3 | 8 | 1 | 6 | 3 | 8 | 3 | X | 5 | 0,101 |

| E10 | 0,2 | 0,2 | 0,2 | 0,33 | 0,33 | 0,33 | 0,5 | 2 | 0,25 | 0,33 | 0,5 | 1 | 0,25 | 0,2 | X | 0,020 |

| (a) | (b) | |||||||||||||||

| Criteria | Priority | |||||

|---|---|---|---|---|---|---|

| x | 3 | 1 | 1 | 0,50 | 0,2084 | |

| 0,33 | x | 0,50 | 0,33 | 0,50 | 0,0889 | |

| 1 | 2 | x | 0,50 | 1 | 0,1802 | |

| 1 | 3 | 2 | x | 2 | 0,3048 | |

| 2 | 2 | 1 | 0,50 | x | 0,2177 | |

| (a) | (b) | |||||

| Alternative | Probability of HS ) | 0,2084 | Severity ) | 0,1802 | ) | 0,0889 | Expected cost ) | 0,3048 | Occurrence count (O) | 0,2177 | Evaluation | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| E1 | 3 | 0,061 | 0,013 | 4 | 0,062 | 0,011 | 3 | 0,051 | 0,005 | 0,027 | 0,008 | 41 | 0,084 | 0,018 | 0,055 |

| E2.1 | 4 | 0,082 | 0,017 | 5 | 0,077 | 0,014 | 4 | 0,068 | 0,006 | 0,157 | 0,047 | 15 | 0,031 | 0,007 | 0,091 |

| E2.2 | 4 | 0,082 | 0,017 | 5 | 0,077 | 0,014 | 5 | 0,085 | 0,008 | 0,157 | 0,047 | 4 | 0,008 | 0,002 | 0,087 |

| E2.3 | 3 | 0,061 | 0,013 | 5 | 0,077 | 0,014 | 4 | 0,068 | 0,006 | 0,069 | 0,021 | 12 | 0,025 | 0,005 | 0,059 |

| E2.4 | 2 | 0,041 | 0,009 | 5 | 0,077 | 0,014 | 5 | 0,085 | 0,008 | 0,069 | 0,021 | 43 | 0,088 | 0,019 | 0,070 |

| E3 | 3 | 0,061 | 0,013 | 4 | 0,062 | 0,011 | 3 | 0,051 | 0,005 | 0,056 | 0,017 | 92 | 0,188 | 0,041 | 0,086 |

| E4.1 | 3 | 0,061 | 0,013 | 5 | 0,077 | 0,014 | 5 | 0,085 | 0,008 | 0,049 | 0,015 | 31 | 0,063 | 0,014 | 0,063 |

| E4.2 | 2 | 0,041 | 0,009 | 5 | 0,077 | 0,014 | 4 | 0,068 | 0,006 | 0,013 | 0,004 | 45 | 0,092 | 0,020 | 0,052 |

| E5 | 4 | 0,082 | 0,017 | 4 | 0,062 | 0,011 | 4 | 0,068 | 0,006 | 0,115 | 0,035 | 52 | 0,106 | 0,023 | 0,092 |

| E6 | 3 | 0,061 | 0,013 | 4 | 0,062 | 0,011 | 5 | 0,085 | 0,008 | 0,039 | 0,012 | 9 | 0,018 | 0,004 | 0,048 |

| E7.1 | 2 | 0,041 | 0,009 | 5 | 0,077 | 0,014 | 3 | 0,051 | 0,005 | 0,046 | 0,014 | 32 | 0,065 | 0,014 | 0,055 |

| E7.2 | 4 | 0,082 | 0,017 | 3 | 0,046 | 0,008 | 2 | 0,034 | 0,003 | 0,033 | 0,011 | 51 | 0,104 | 0,023 | 0,062 |

| E8 | 5 | 0,102 | 0,021 | 3 | 0,046 | 0,008 | 4 | 0,068 | 0,006 | 0,049 | 0,015 | 39 | 0,080 | 0,017 | 0,068 |

| E9 | 4 | 0,082 | 0,017 | 4 | 0,062 | 0,011 | 3 | 0,051 | 0,005 | 0,101 | 0,031 | 8 | 0,016 | 0,004 | 0,067 |

| E10 | 3 | 0,061 | 0,013 | 4 | 0,062 | 0,011 | 5 | 0,085 | 0,008 | 0,020 | 0,006 | 15 | 0,031 | 0,007 | 0,044 |

| Total | 49 | 1 | 0,2084 | 65 | 1 | 0,1802 | 59 | 1 | 0,0889 | 1 | 0,3048 | 489 | 1 | 0,2177 | 1 |

| Occurrence. | |||||||||||||||

| Criteria | Priority | |||||

|---|---|---|---|---|---|---|

| x | 3 | 1 | 0,33 | 0,33 | 0,127 | |

| 0,33 | x | 0,50 | 0,33 | 0,33 | 0,078 | |

| 2 | 2 | x | 0,33 | 0,33 | 0,145 | |

| 3 | 3 | 3 | x | 0,50 | 0,279 | |

| 3 | 3 | 3 | 2 | x | 0,369 | |

| (a) | (b) | |||||

| Criteria | Priority | ||||||

|---|---|---|---|---|---|---|---|

| x | 3 | 0,33 | 3 | 3 | 0,258 | ||

| 0,33 | x | 0,33 | 0,5 | 0,33 | 0,078 | ||

| 3 | 3 | x | 0,33 | 3 | 0,395 | ||

| 0,33 | 2 | 0,33 | x | 0,50 | 0,109 | ||

| 0,33 | 3 | 0,33 | 2 | x | 0,16 | ||

| (a) | (b) | ||||||

| Alternative | Evaluation - Variant A | Order of events Variant A | Evaluation - Variant B | Order of events Variant B | Evaluation - Variant C | Order of events Variant C | Risk | |

|---|---|---|---|---|---|---|---|---|

| E1 | 0,055 | 11 | 0,059 | 7 | 0,057 | 11 | 36 | 9 |

| E2.1 | 0,091 | 2 | 0,082 | 3 | 0,076 | 4 | 80 | 2 |

| E2.2 | 0,087 | 3 | 0,075 | 4 | 0,079 | 2 | 100 | 1 |

| E2.3 | 0,059 | 10 | 0,053 | 10 | 0,060 | 9 | 60 | 5 |

| E2.4 | 0,070 | 5 | 0,075 | 4 | 0,072 | 6 | 75 | 3 |

| E3 | 0,086 | 4 | 0,106 | 1 | 0,077 | 3 | 36 | 9 |

| E4.1 | 0,063 | 8 | 0,063 | 6 | 0,071 | 7 | 75 | 3 |

| E4.2 | 0,052 | 12 | 0,059 | 7 | 0,059 | 10 | 50 | 6 |

| E5 | 0,092 | 1 | 0,096 | 2 | 0,082 | 1 | 64 | 4 |

| E6 | 0,048 | 13 | 0,041 | 11 | 0,061 | 8 | 60 | 5 |

| E7.1 | 0,055 | 11 | 0,057 | 9 | 0,052 | 12 | 40 | 8 |

| E7.2 | 0,062 | 9 | 0,068 | 5 | 0,059 | 10 | 60 | 5 |

| E8 | 0,068 | 6 | 0,068 | 5 | 0,075 | 5 | 75 | 3 |

| E9 | 0,067 | 7 | 0,058 | 8 | 0,060 | 9 | 48 | 7 |

| E10 | 0,044 | 14 | 0,040 | 12 | 0,061 | 8 | 60 | 5 |

| Total | 1 | x | 1 | x | 1 | x | x | x |

| Measures | Hierarchy of control [39] | |

|---|---|---|

| M1 | LOTO - safety padlock | Isolate people from the hazard |

| M2 | Emergency stop button (ESB) | Isolate people from the hazard |

| M3 | Guard | Elimination |

| M4 | Education - training | Administration |

| M5 | Automated ventilation system | Engineering |

| M6 | PPE (personal protective equipment) | PPE (personal protective equipment) |

| M7 | Periodic maintenance - inspections | Engineering |

| Measures | |||

|---|---|---|---|

| Min (Eur) | Max (Eur) | ||

| LOTO - Safety padlock | 25 | 78 | |

| E - STOP | 44 | 88 | |

| Guard | 500 | 1000 | |

| Education - training | 50 | 500 | |

| Automated ventilation system | 600 | 1000 | |

| Statistics | Training | Test |

|---|---|---|

| R-squared | 86,75% | 84,08% |

| RMSE | 0,0469 | 0,0514 |

| MSE | 0,0022 | 0,0026 |

| MAD | 0,0120 | 0,0137 |

| MAPE | 0,0231 | 0,0279 |

| Terminal Node | Number of HS events | Criterion | Total Cost | |

|---|---|---|---|---|

| 4 | 4 | 75% | CM1 = {78}; CM2 = {44; 88}; CM4 = {0; 50} | {122; 216} |

| 7 | 70 | 66,43% | CM3 = {1000}; CM4 = {200; 500} | {1200; 1500} |

| 6 | 147 | 59,85 | P> 3.5; CM3 = {0; 500}; CM4 = {200; 500}; | {200; 1000} |

| 2 | 52 | 50,58% | P > 3.5; CM2 = {0; 67}; CM4 = {0; 50} | {0; 117} |

| 3 | 83 | 50% | CM1 = {0; 25; 52}; CM2 = {44; 88}; CM4 = {0; 50} | {44; 190} |

| 1 | 130 | 33,72% | P <= 3.5; CM2 = {0; 67}; CM4 = {0; 50}; | {0; 117} |

| 5 | 3 | 33,33% | P <= 3.5; CM3 = {0; 500}; CM4 = {200; 500} | {200;1000} |

| Statistics | Training | Test |

|---|---|---|

| R-squared | 91,04% | 89,97% |

| RMSE | 0,0402 | 0,0425 |

| MSE | 0,0016 | 0,0018 |

| MAD | 0,0245 | 0,0250 |

| MAPE | 0,0444 | 0,0451 |

| Terminal Node | Reduction of the criticality of the event | Events in the node | Priorities under Variant A | Priorities under Variant B | Priorities under Variant C | (i = 1 to 5) | in Eur | Total cost in EUR | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 3 | 64,54% | 100 | E2.2 | 3 | 3 | 4 | 2 | M4, M5 | 1500 | 4500 |

| E3 | 46 | 4 | 1 | 3 | M1, M2, M3, M4 | 1366 | 62836 | |||

| E5 | 51 | 1 | 2 | 1 | M1, M2, M4 | 666 | 33966 | |||

| 2 | 56,66% | 42 | E2.1 | 42 | 2 | 3 | 4 | M4, M5 | 1500 | 63000 |

| 1 | 33,33% | 46 | E3 | 46 | 4 | 1 | 3 | M1, M2, M3 | 619 | 28474 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).