Submitted:

01 March 2024

Posted:

04 March 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

- -

- -

2. Materials and Methods

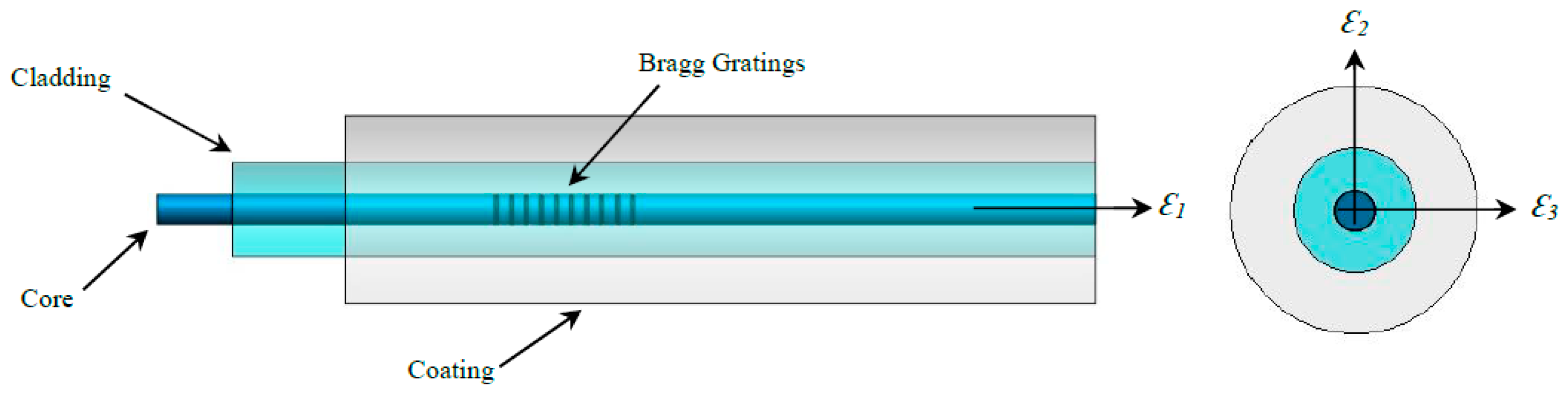

2.1. Coating Material of FBGS

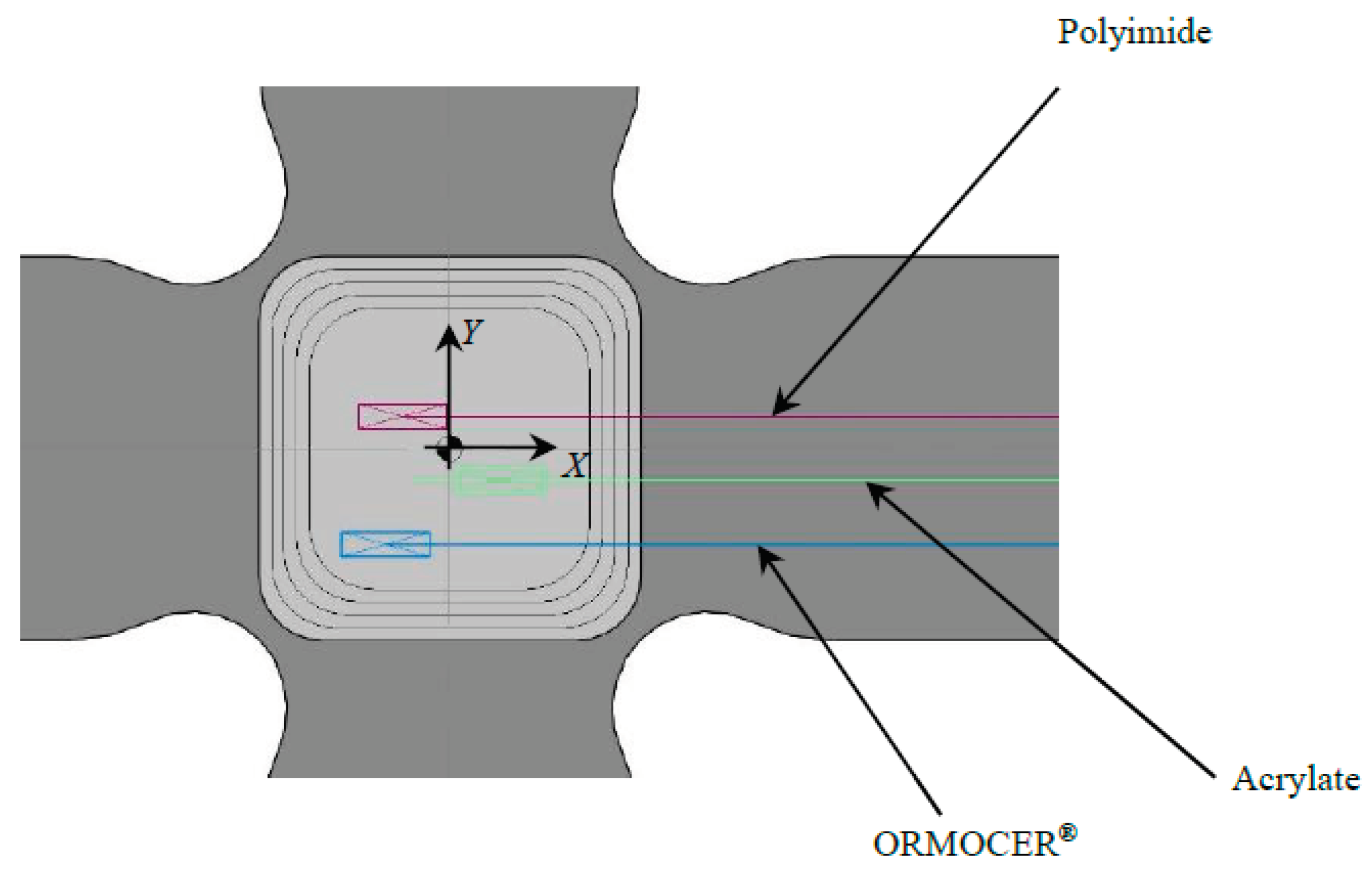

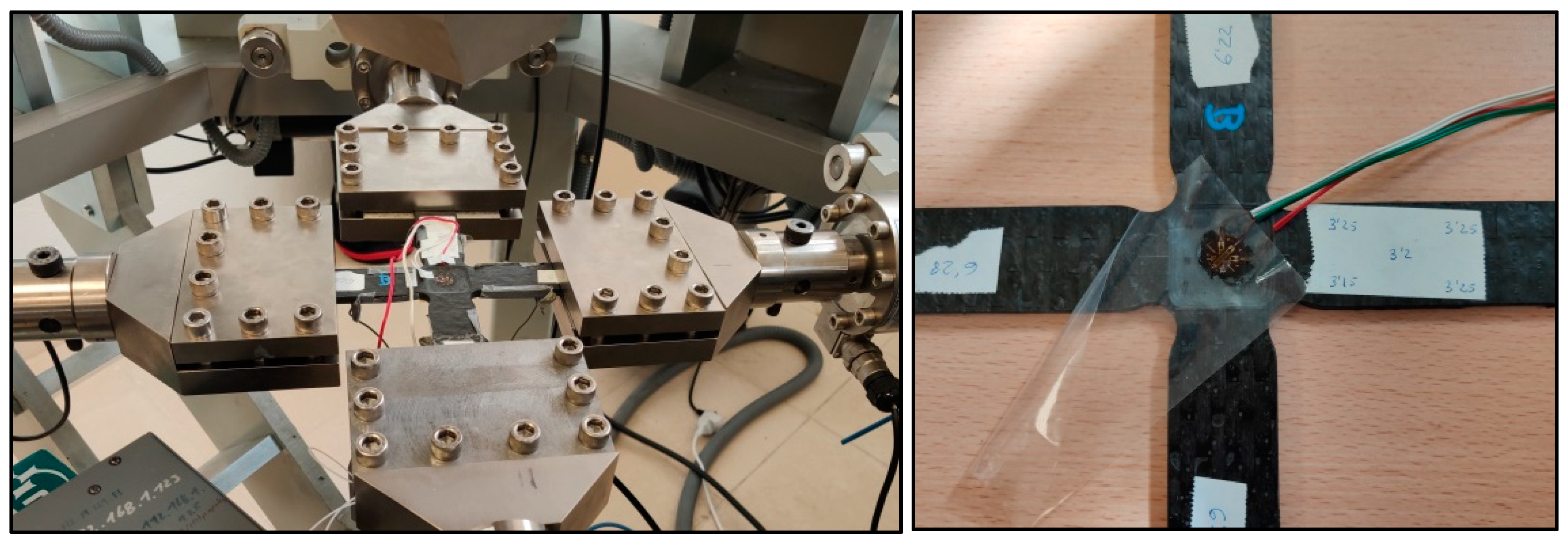

2.2. Experimental Setup

2.3. Strain–Optic Theory

3. Experimental Results

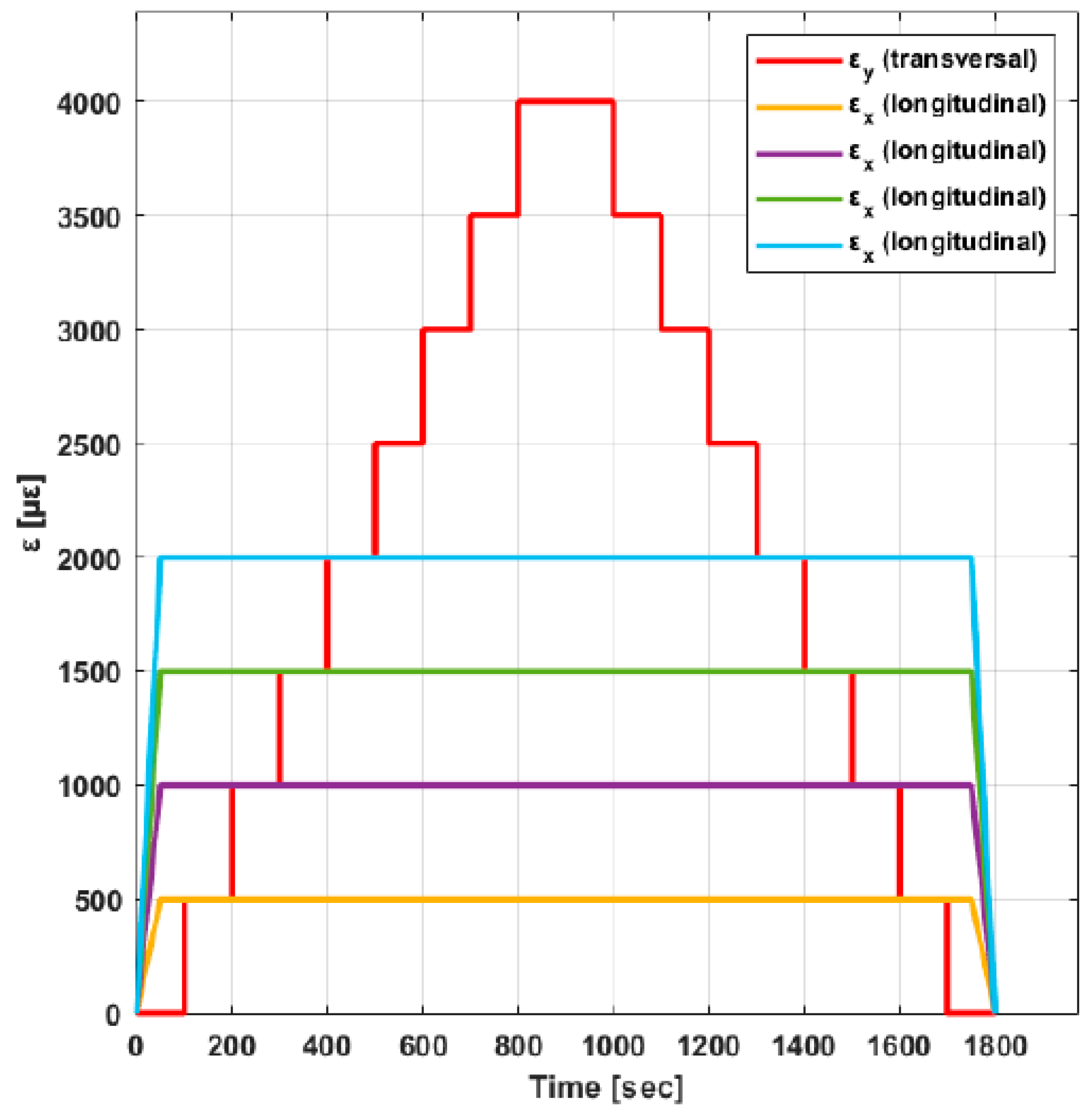

3.1. Testing Plan

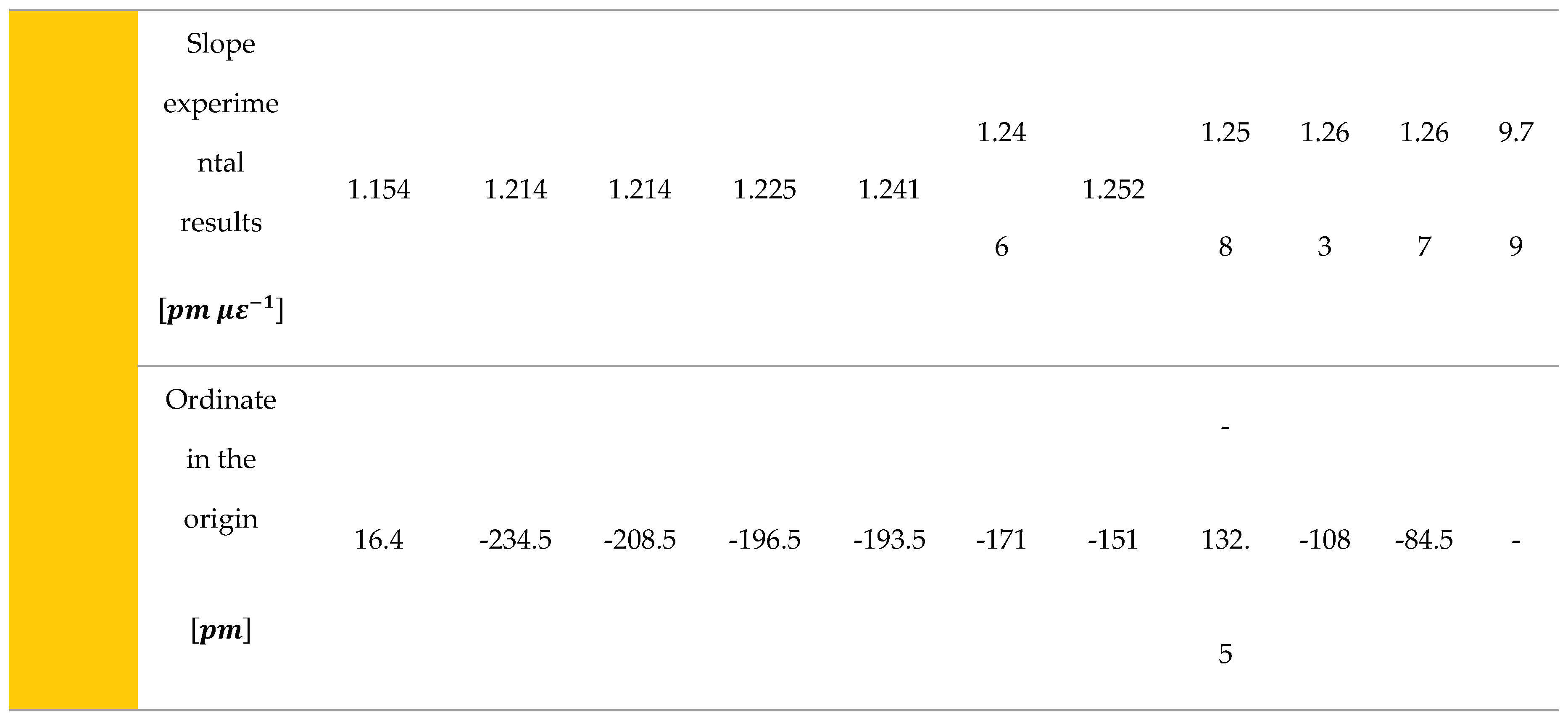

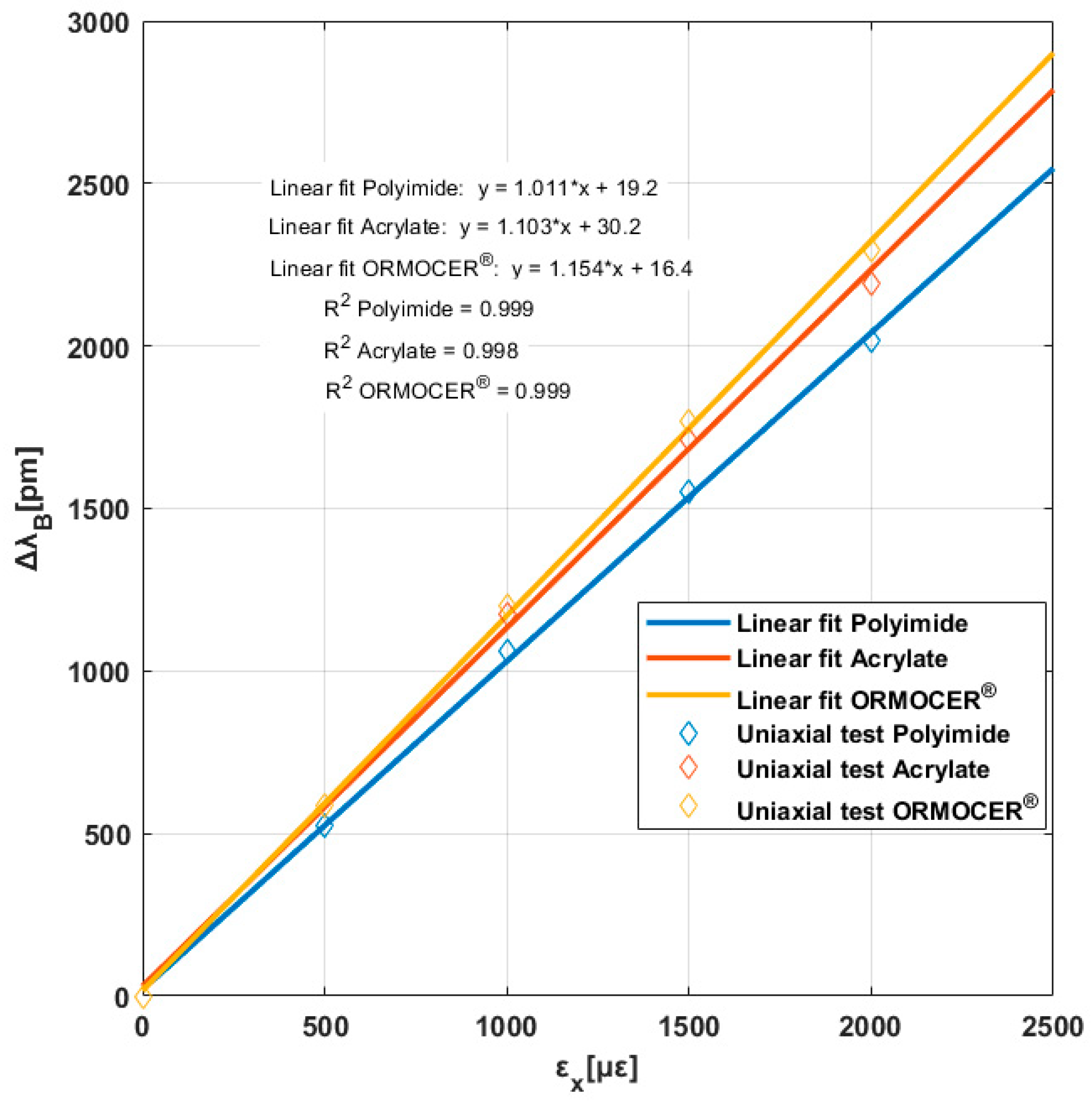

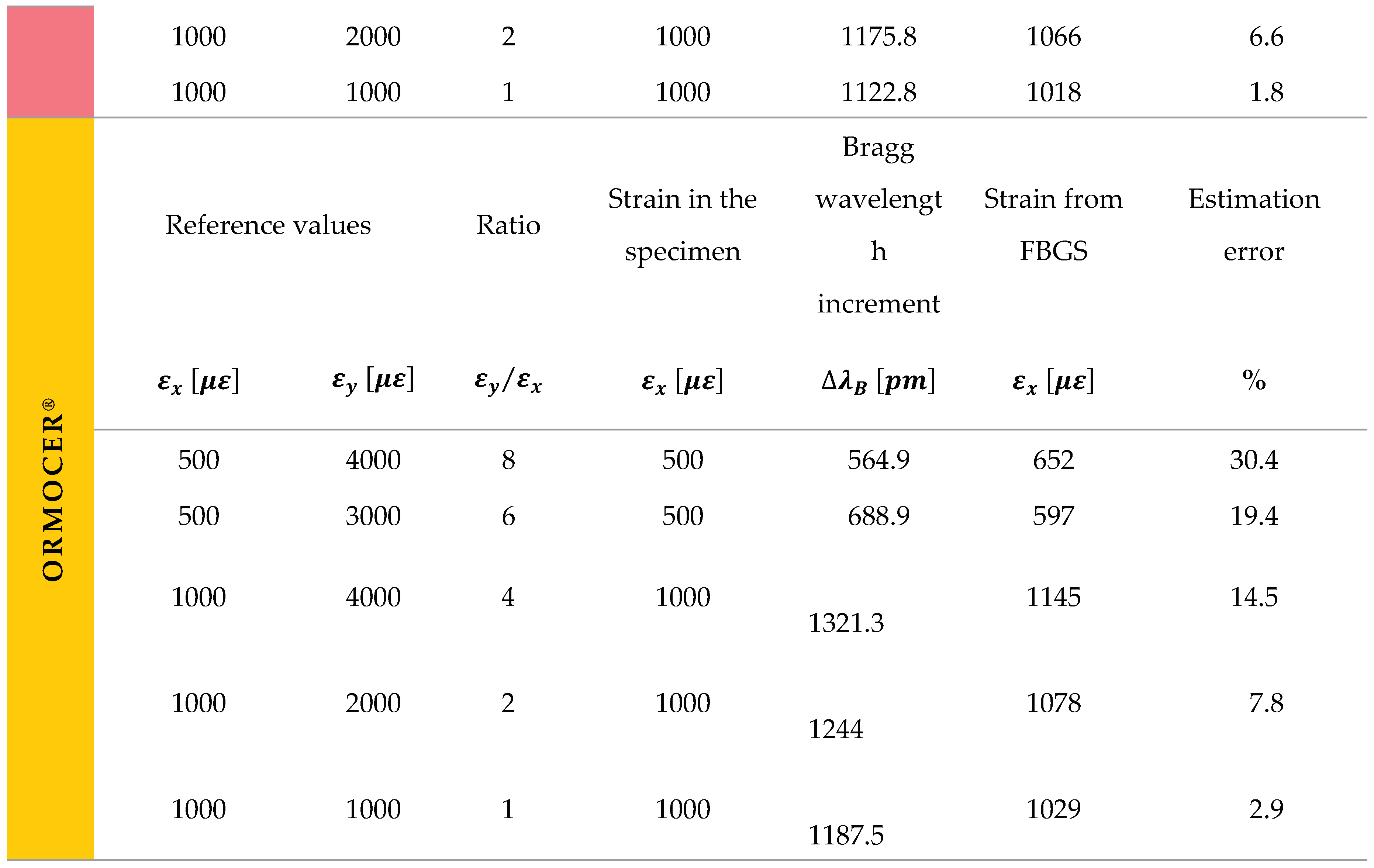

3.2. Biaxial Tests

4. Conclusions

- -

- It will present a fixed value for each longitudinal strain value.

- -

- It will present negative values for each longitudinal strain value.

- -

- It will have low proportions .

- -

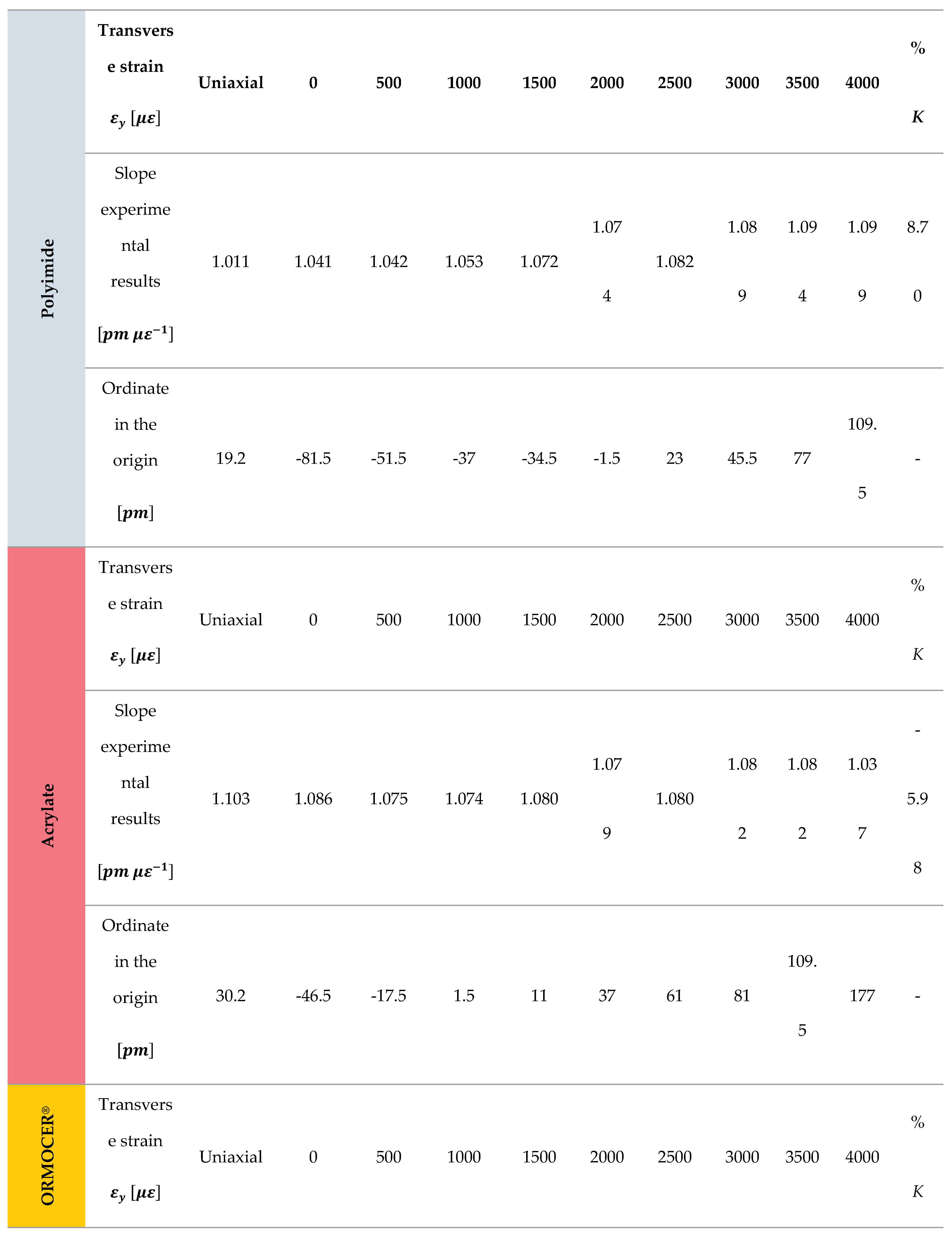

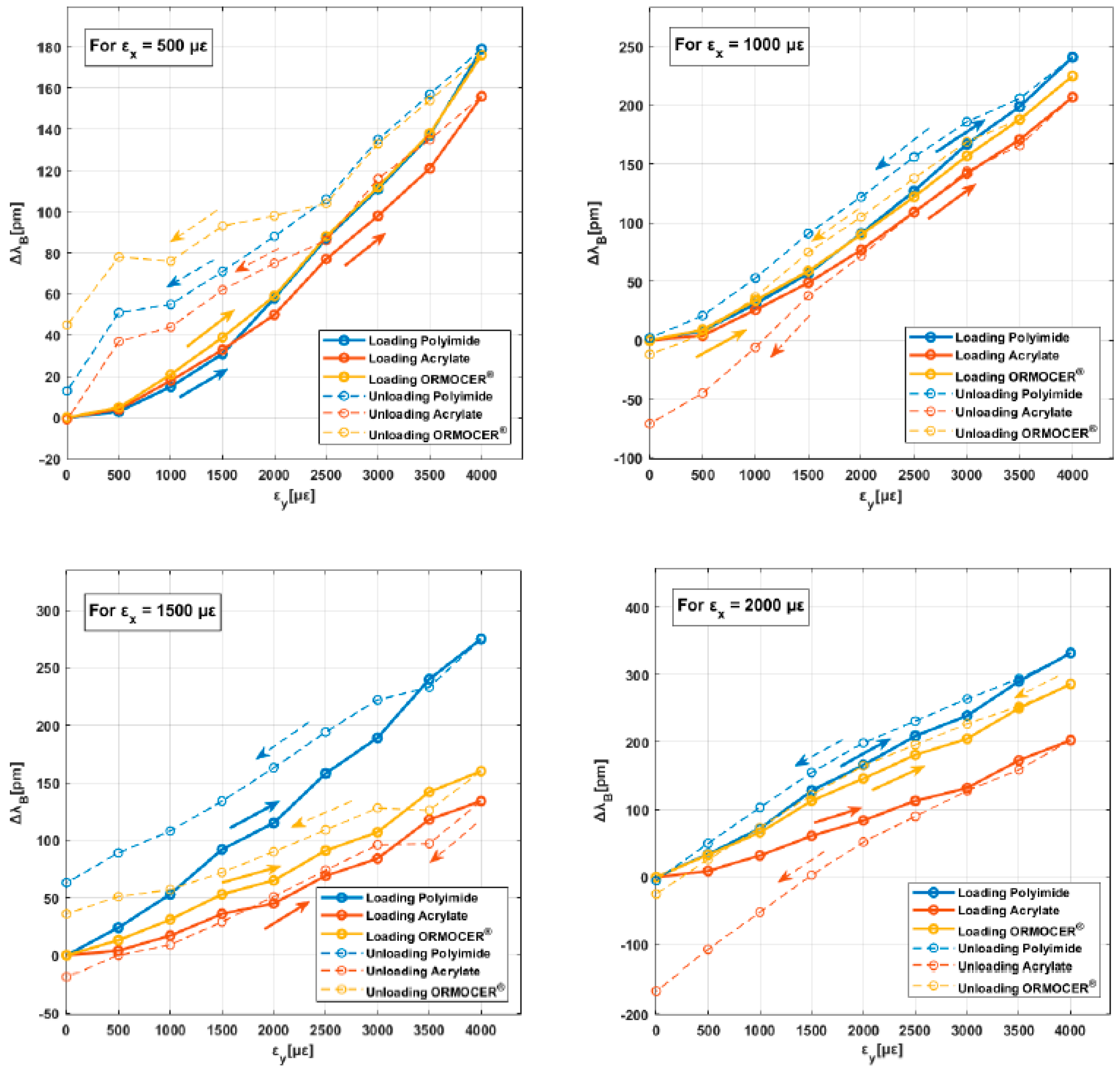

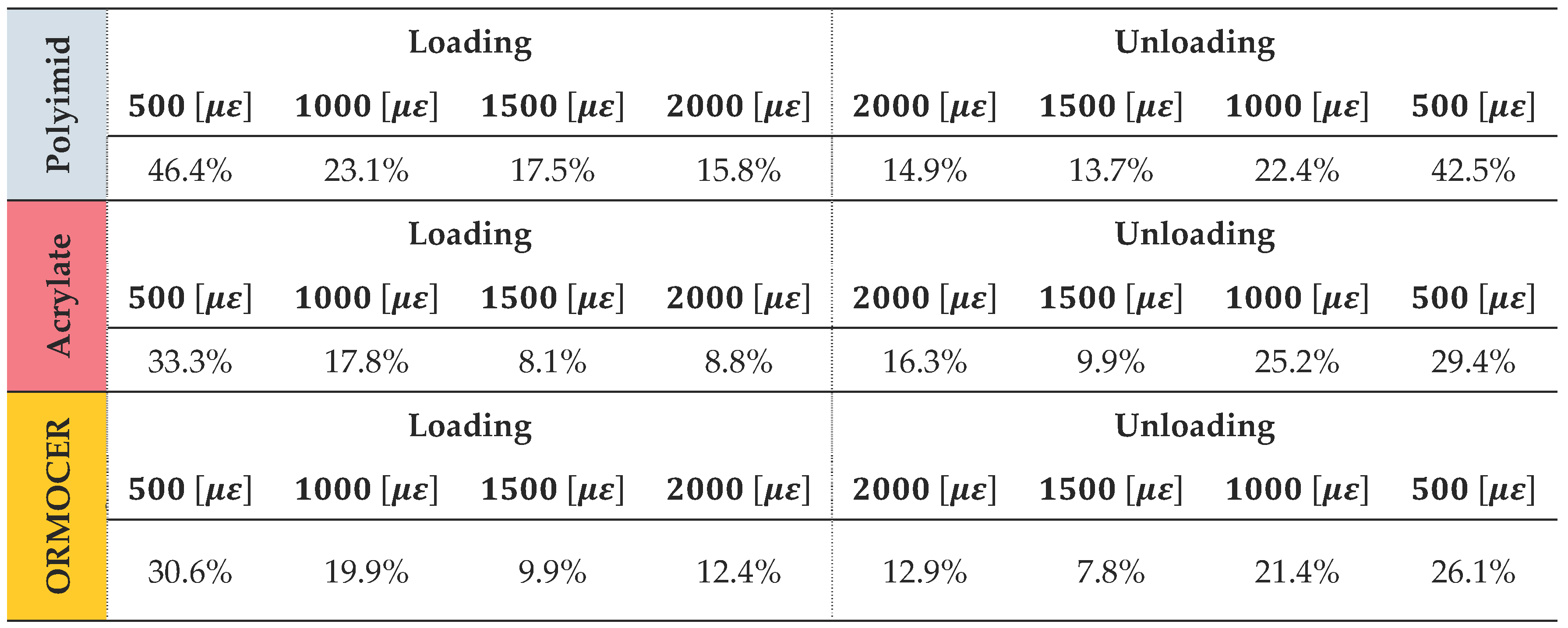

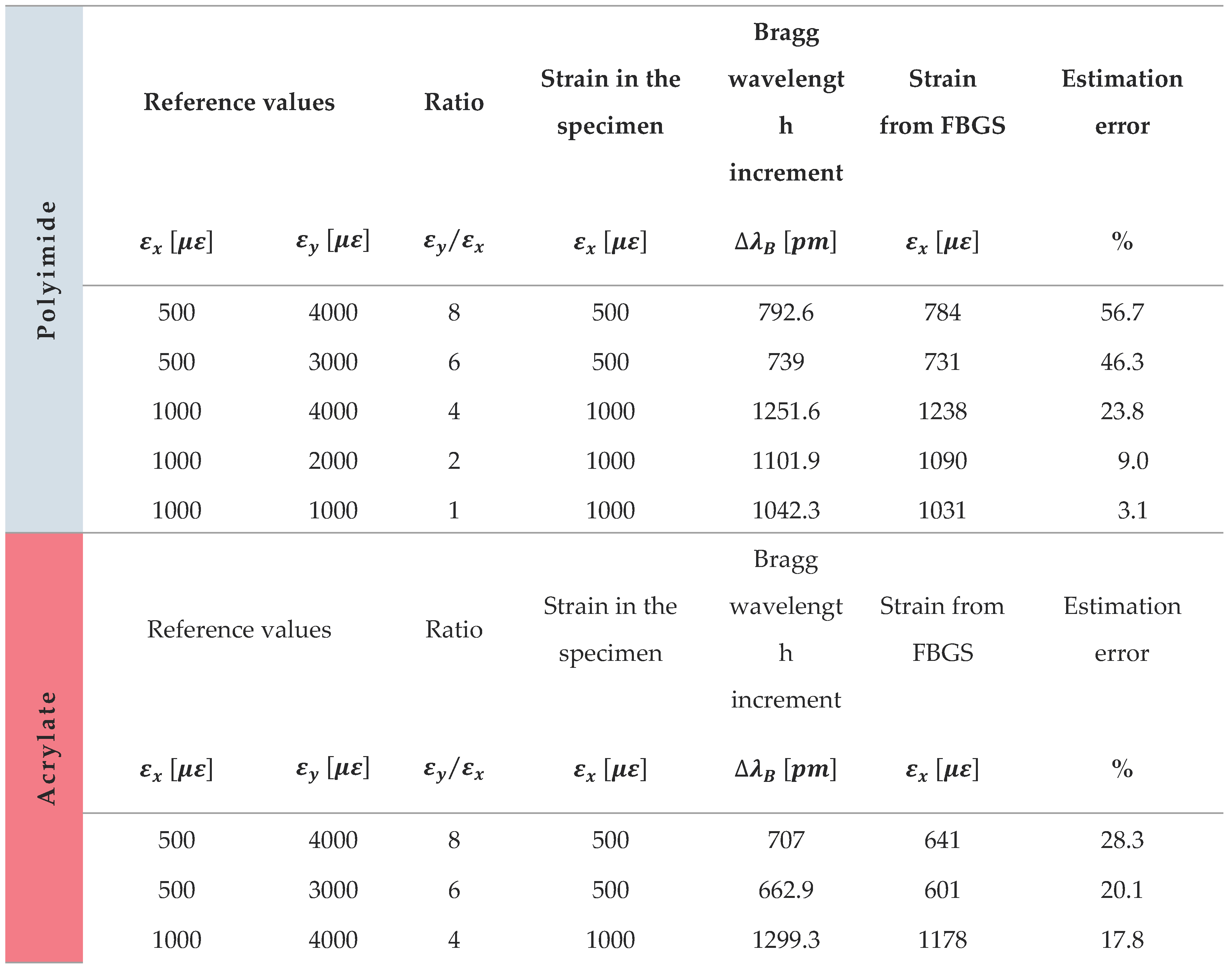

- The response of the sensor to longitudinal strain is significantly influenced by the transverse strain and by the coating material. The influence of transverse strain affects three fundamental parameters of the sensor: the output or response of the sensor and two derived values such as the sensor's (strain sensitivity) and the interpreted value. The influence of transverse strain on the response of the sensor can reach values of up to 46% increase in the signal with respect to the defined reference state (the one with a ratio). This extreme case is observed in a polyimide coated sensor subjected to a ratio. For lower ratios, the influence decreases. It is also observed that the influence on the sensor's output signal is lower in acrylate and ORMOCER® coatings that exhibit very similar behaviors, around 30%.

- -

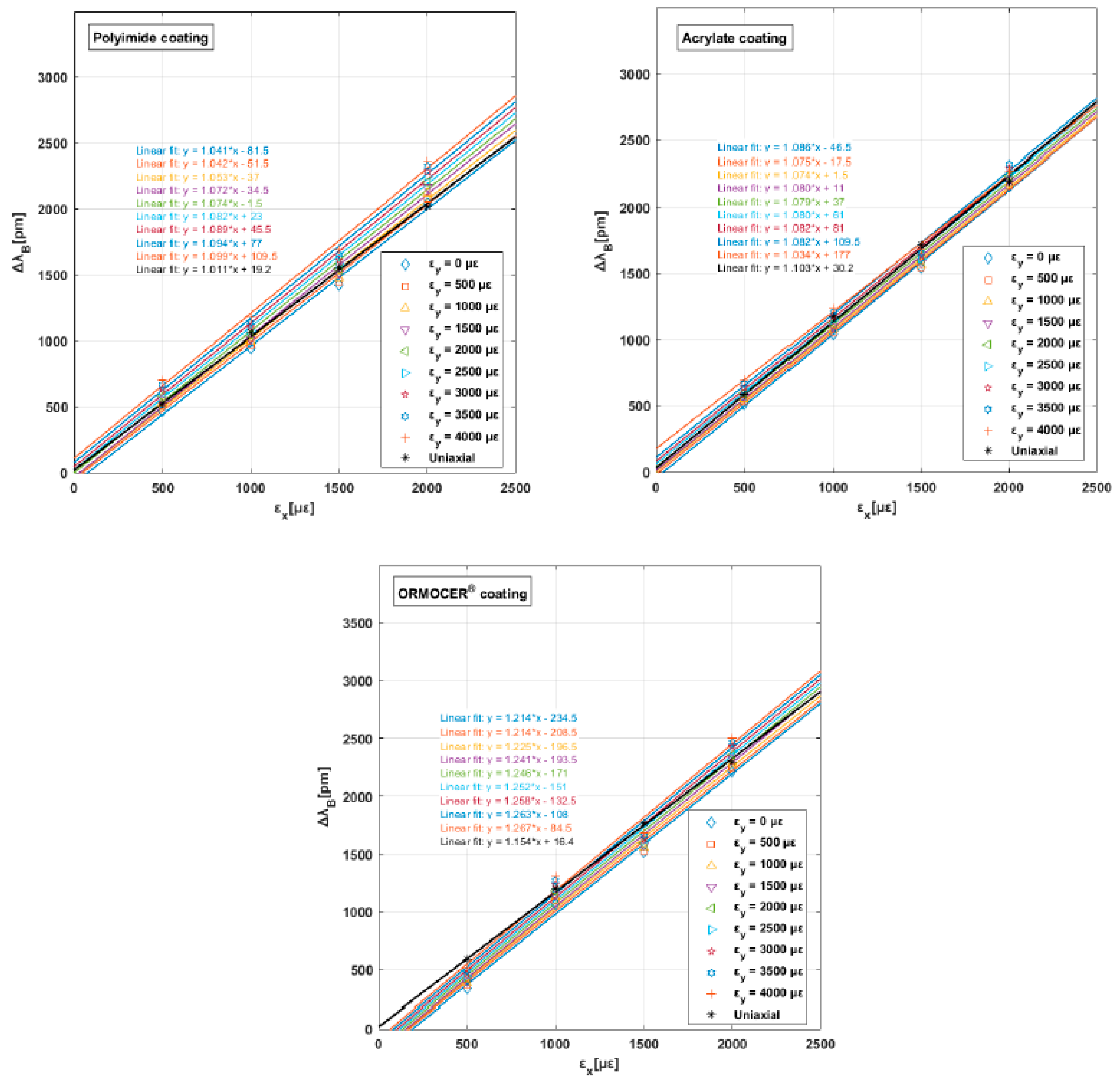

- Regarding the magnitudes derived from sensor (strain sensitivity) and interpreted, the influence can reach a 10% increase in the most extreme case for polyimide and ORMOCER® coatings. On the other hand, for the acrylate coating, a decrease of 6% in the sensor's value (strain sensitivity) is observed. This phenomenon may be due to the mechanical nature of the coating material (Table 1).

- -

- A significant hysteresis effect has been observed in the loading and unloading cycles in the acrylate coating, being higher than 150pm for one of the cases, which is logical due to the less rigid nature (Table 1) of this polymer.

- -

- Based on the results obtained, the standardized sensor characterization procedure should be reconsidered, for those sensors working for multiaxial stress states with high ratios where the sensor's (strain sensitivity) could lead to an erroneous interpretation of the results in terms of interpreted .

Acknowledgements

References

- Frövel, M. (2006). Sensores de fibra óptica tipo redes de Bragg embebidos en material compuesto para medir deformaciones y temperaturas criogénicas. (Doctoral Thesis). Universidad Politécnica de Madrid. Madrid (España).

- Bertrán, G. (2013): Y el A350 XWB voló…. AVION REVUE Internacional, 373, 22-25.

- González-Gallego, M. (2014). Comportamiento multiaxial de laminados de material compuesto reforzado con fibra de carbono a partir de ensayos uniaxiales. (Master Thesis). Universidad de Castilla-La Mancha. Ciudad Real (España).

- Infographic-A350-Family. Available online: https://www.airbus.com/sites/g/files/jlcbta136/files/2021-10/Infographic-A350-Family (accessed on 07 November 2023).

- AERO—Boeing787fromtheGroundUp. Available online: http://www.boeing.com/commercial/aeromagazine/articles/qtr_4_06/article_04_2.html (accessed on 07 November 2023).

- Teng, H. et al (2023). Carbon Fiber Composites for Large-Scale Wind Turbine Blades: Applicability Study and Comprehensive Evaluation in China. Marine Science and Engineering, 11, 624, pp. 1-22. [CrossRef]

- Leon Mishnaevsky Jr. et al (2023). Materials for Wind Turbine Blades: An Overview. Materials, 10, 1285, pp. 1-24. [CrossRef]

- Yentl Swolfs (2017). Perspective for Fibre-Hybrid Composites in Wind Energy Applications. Materials, 10, 1281, pp. 1-17. [CrossRef]

- Fiberships-Final_Brochurehttp. Available online: https://www.fibreship.eu/wp-content/uploads/2020/06/Fibreship-Final-BROCHURE.pdf (accessed on 07 November 2023).

- M. Saravanan et al (2021). A review on navy ship parts by advanced composite material. Materialstoday: Proceedings, Volume 45, Part 7, pp. 6072-6077. [CrossRef]

- A. P. Mouritz et al (2001). Review of advanced composite structures for naval ships and submarines. Composite Structures, Volume 53, Issue 1, pp. 21-42. [CrossRef]

- George Edward Street et al (2021). Impact Resistance of Fibre Reinforced Composite Railway Freight Tank Wagons. Journal of Composites Science, 5, 152, pp. 1-22. [CrossRef]

- Sakdirat Kaewunruen et al (2017): Composites for Timber-Replacement Bearers in Railway Switches and Crossings. Infrastructures, 2, 13, pp. 1-16.

- M. Robinson et al (2017). Application of Composites in rail vehicles. 21st International Conference on Composite Materials, pp. 1-13.

- Adil Wazeer et al (2022). Composites for electric vehicles and automotive sector: A review. Green Energy and Intelligent Transportation, 2, 100043, pp. 1-23. [CrossRef]

- 16. Gonzalo Marmol et al (2021). Automotive and construction applications of fiber reinforced composites. Fiber Reinforced Composites, 2021, pp. 785-819.

- Andrey E. Krauclis et al (2021). Composite Material Recycling Technology-State-of-the-Art and Sustainable Development for the 2020s. Journal of Composites Science, 5, 28, pp. 1-33. [CrossRef]

- Beatrice Colombo et al (2021). Recycling of Waste Fiber-Reinforced Plastic Composites: A Patent-Based Analysis. Recycling, 6, 72, pp. 1-18. [CrossRef]

- Aniello Smarrazzo et al (2022). Failure Propagation Controlling for Frangible Composite Canister Design. Applied Sciences, 12, 12220, pp. 1-15. [CrossRef]

- Aniello Riccio et al (2023). Delamination Effect on the Buckling Behaviour of Carbon-Epoxi Composite Typical Aeronautical Panels. Applied Sciences, 13, 4358, pp. 1-18. [CrossRef]

- S. Z. H. Shah et al (2019). Impact resistance and damage tolerance of fiber reinforced composites: A review. Composite Structures, 217, pp. 100-121. [CrossRef]

- Matthieu Nicol et al (2023). Automated crack detection in laminated composites by optical flow measurements. Composites Part B: Engineering, Volume 255, pp. [CrossRef]

- Josué Pacheco-Chérrez et al (2021). Experimental Detection and Measurement of Crack-Type Damage Features in Composite Thin-Wall Beams Using Modal Analysis. Sensors, 21, 8102, pp. 1-23. [CrossRef]

- Wim J. C. Verhagen. et al (2023). Condition-Based Maintenance in Aviation: Chellenges and Opportunities. Aerospace, 10, 762, pp. 1-23.

- Güemes, A. et al (2020). Structural Health Monitoring for Advanced Composite Structures: A Review. Journal of Composites Science, 4, 13, pp. 1-15. [CrossRef]

- Senthilkumar et al (2020). Nondestructive health monitoring techniques for composite materials: A review. Polymers and Polymer Composites, Vol. 29 (5), pp. 528-540.

- Félix Terroba et al (2018). Structural health and usage monitoring of an unmanned turbojet target drone. Structural Health Monitoring, pp. 1-16. [CrossRef]

- Fernández-López et al (2017). Sensor integration and data explotation of Structural Health Monitoring Network integrated on a Unmananned Aerial Vehicle (UAV), vol 2, nº 2, pp. 94-99. [CrossRef]

- Yingtao Liu et al (2010). Condition based structural health monitoring and prognosis of composite structures under uniaxial and biaxial loading. Journal of Nondestructive Evaluation, 3, 29, pp. 181-188. [CrossRef]

- Güemes, A. (2014). Fiber Optics Strain Sensors. NATO-STO Lecture Series, pp. 1-26, STO-EN-AVT-220-03.

- Stephen J. Mihailov (2012). Fiber Bragg Grating Sensors for Harsh Environments. Sensors, 12, pp. 1898-1918. [CrossRef]

- Ji-Ying Huang et al (2017). FBGs written in specialty fiber for high pressure/high temperature measurement. Optics Express, Vol. 25, nº 15, pp. 17936-17947. [CrossRef]

- Bruno da Silva Falcão et al (2023). Strain measurement with multiplexed FBG sensor arrays: An experimental investigation. Heliyon, 9 e18652, pp. 1-15. [CrossRef]

- Adriana Morana et al (2022). Radiation Effects on Fiber Bragg Gratings: Vulnerability and Hardening Studies. Sensors, 22, 8175, pp. 1-33. [CrossRef]

- Bal, H. K. et al (2010). Fibre Bragg grating transverse strain sensing using reflections at twice the Bragg wavelength. Measurement Science and Technology Vol. 21, 094004. [CrossRef]

- Lai, M. et al (2013). On the Effects of the Lateral Strains on the Fiber Bragg Grating Response. Sensors,13, 2631-2644. [CrossRef]

- Gouws, A. et al (2020). Transverse strain measurements in polymer-embedded, polarization-maintaining Fiber Bragg Gratings. Engineering Research Express Vol. 2, 045016. [CrossRef]

- Wachtarczyk, K. et al (2022). In-Plane Strain Measurement in Composite Structures with Fiber Bragg Grating Written in Side-Hole Elliptical Core Optical Fiber. Materials Vol. 15(1), 77. [CrossRef]

- J. L. Martínez Vicente et al (2023). Study of the transverse strain effect on the Fiber Bragg Grating Sensor (FBGS) response with polyimide coating under experimental biaxial tests. Composite Structures, 326 (2023) 117621, pp. 1-12. [CrossRef]

- FiSens. Available online: https://fisens.com/sensor-configurator#start (accessed on 10 November 2023).

- Smart fibres. Available online: https://www.smartfibres.com/files/pdf/SmartFBG.pdf (accessed on 10 November 2023).

- FBGS. Available online: https://fbgs.com/technology/ormocer-coating/ (accessed on 10 November 2023).

- Janani, R. et al (2023). From acrylates to silicones: A review of common optical fibre coatings used for normal to harsh environments. Progress in Organic Coatings, 180, 107557. [CrossRef]

- Nath, D. K. et al (1991). Polyimide Coated Embedded Optical Fiber Sensors. Structures Sensing and Control, SPIE, vol. 1489, pp. 17-32.

- Gloge, D. (1975). Optical-Fiber Packaging and Its Influence on Fiber Straightness and Loss. The Bell System Technical Journal, vol. 54, Issue 2, pp. 245-262, USA. [CrossRef]

- Wolter, H. et al (1992). Multifunctional (meth) acrylate alkoxysilanes - A new type of reactive compounds. Mater. Res. Soc. Symp. Proc., vol. 271, pp. 719-724. [CrossRef]

- Rose, K. et al (1992). Multifunctional acrylate alkoxysilanes for polymeric materials. Mater. Res. Soc. Symp. Proc., vol. 271, pp. 731-736. [CrossRef]

- Schuster, K. et al (2010). Innovative fiber coating systems based on organic modified ceramics. Proc. SPIE, vol. 7598, pp. 75980H-1–75980H-8.

- Pak, Y. E. (1992). Longitudinal Shear Transfer in Fiber Optic Sensors. Smart Materials and Structures, vol. 1, pp. 57-62. [CrossRef]

- Sirkis, J. S. et al (1993). Longitudinal The Role of Local Interaction Mechanics in Fiber Optic Smart Structures. J. Intell. Mat. Systems & Struct., vol. 4, pp. 260-271.

- Roberts, S. S. et al (1991). Mechanical Properties of Composites Materials Containing Embedded Fiber Optic Sensors. Fiber Optic Smart Structures and Skins IV, SPIE, vol. 1588, pp. 326-341.

- Paul, C. A. et al (1993). Static Test Study of Composites with Embedded Optical Fibers using Fractional Factorial Methods. Soc. Exper. Mechanism (SEM) Conf., Michigan, USA.

- Mishra, V. et al (2016). Improvement in temperature sensitivity of FBG by coating of different materials. Optik 127, pp. 825-828. [CrossRef]

- Sampath, U. et al (2018). Polymer-coated FBG sensor for simultaneous temperature and strain monitoring in composite materials under cryogenic conditions. Applied Optics, vol. 57, No. 3, pp. 492-497. [CrossRef]

- Yanchao Liu et al (2019). Temperature characteristics of FBG sensors with different coatings for High Temperature Superconductor Application. IEEE 3rd International Electrical and Energy Conference (CIEEC), pp. 1546-1550.

- Weisbrich, M. et al (2020). Comparison of different fiber coatings for distributed strain measurement in cementitious matrices. Journal of Sensors and Sensor Systems, 9, pp. 189-197. [CrossRef]

- Measures, R. M. (2001). Structural Monitoring with Fiber Optic Technology. Academic Press, USA. [CrossRef]

- Luyckx, G. et al (2011). Strain Measurements of Composite Laminates with Embedded Fibre Bragg Gratings: Criticism and Opportunities for Research. Sensors, 11, pp. 384-408. [CrossRef]

- Kim, K. (1993). A Model of Embedded Fiber Optic Fabry-Perot Temperature and Strain Sensors. (Doctoral Thesis). Stanford University. Stanford, California (Estados Unidos). [CrossRef]

- ASTM D3039/D3039M-08. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International.

- ASTM D3518/D3518M-18. Standard Test Method for In-Plane Shear Response of Polymer Matrix Composite Materials by Tensile Test of a ±45° Laminate. ASTM International.

- ASTM D2344/D2344M-22. Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates. ASTM International.

- ASTM D695-15. Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International.

- Serna, M. C. et al (2011). Failure envelope under biaxial tensile loading for chopped glass-reinforced polyester composites. Composites Science and Technology, Elsevier.

- Serna, M.C. et al (2013). Failure strain and stress fields of a chopped glass-reinforced polyester under biaxial loading. Composite Structures, 103, 27-33.

- Van Steenkiste, R. J. et al (1997). Strain and Temperature Measurement with Fiber Optic Sensors. Technomic Publishing Company.

- Lekhnitskii, S. (1977). Theory of Elasticity of an Anisotropic Body. Moscow: MIR Publishers.

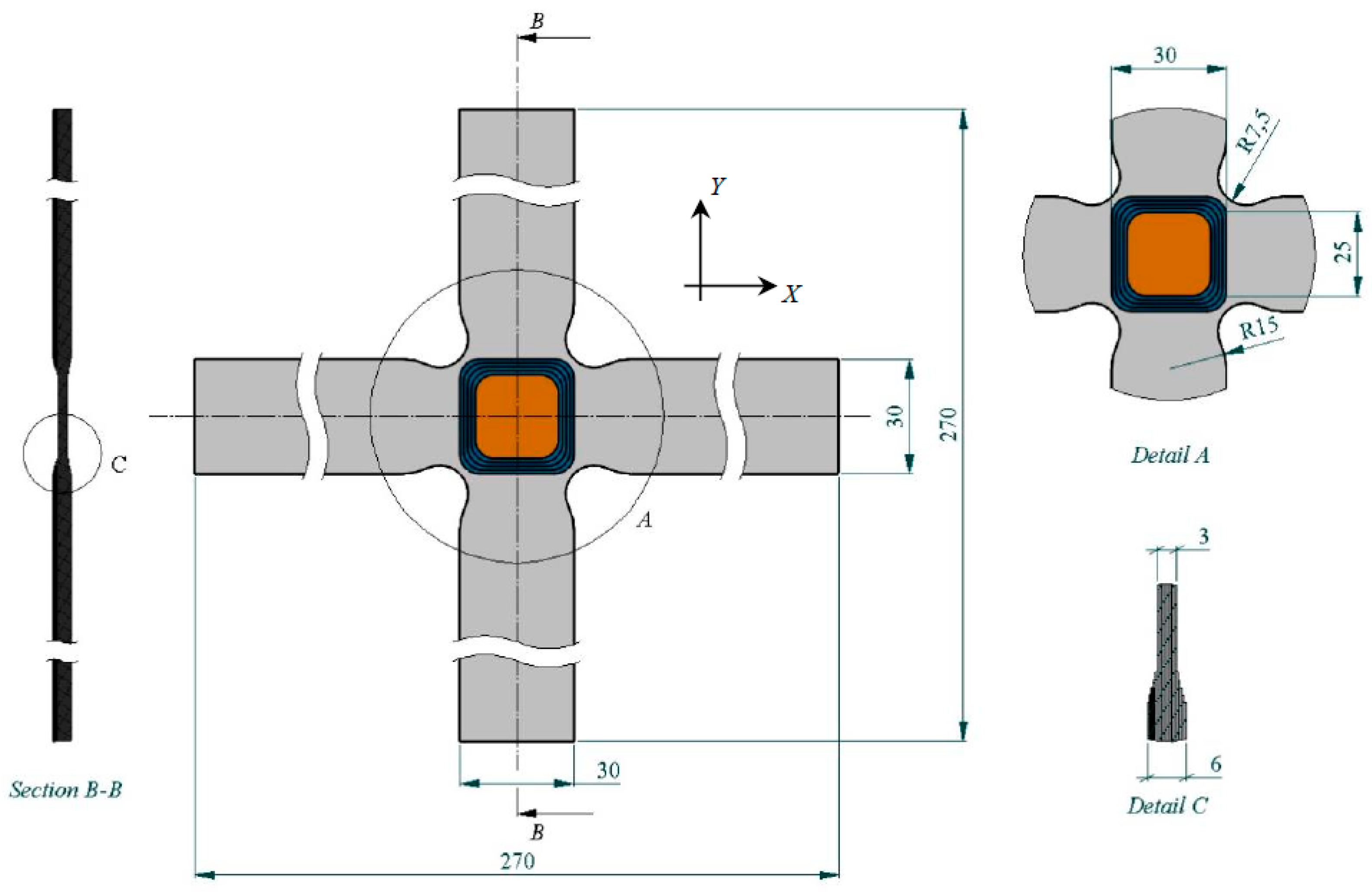

| Properties | Units | Polyimide | Acrylate | ORMOCER® |

|---|---|---|---|---|

| Young’s modulus () | 2.40 | 0.60 | 2.00 | |

| Density | 1.43 | [1.14–1.20] | Not available | |

| Temperature glass transition | > 400 | ≈ 105 | 250 | |

| Temperature of fusion | Not available | [160–200] | Not available | |

| Vicat Softening Temperature (VST) | 220 | Not available | Not available | |

| Operative range of temperature | [-190–350] | [-55–85] | [-180–200] | |

| Core diameter | 9 | 9 | 6 | |

| Cladding diameter | 125 | 125 | 125 | |

| Coating diameter | 160 | 250 | 200 |

| Coatings | X | Y |

|---|---|---|

| Polyimide | -3.7 | 2.5 |

| Acrylate | 4 | -2.5 |

| ORMOCER® | -5 | -7.5 |

| Properties | Units | Polyimide | Acrylate | ORMOCER® |

|---|---|---|---|---|

| Pre-installation | nm | 1535.004 | 1562.028 | 1546.816 |

| Post-installation | nm | 1534.624 | 1561.634 | 1546.578 |

| Properties | Units | Values |

|---|---|---|

| Young’s modulus () | 73.1 | |

| Poisson’s ratio () | 0.16 | |

| Shear modulus () | 31.5 | |

| Thermal expansion coefficient () | 0.5 | |

| Index of refraction () | 1.449 | |

| Pockel constant () | 0.113 | |

| Pockel constant () | 0.252 | |

| Thermooptic coefficient () | 0.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).