Submitted:

28 February 2024

Posted:

29 February 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

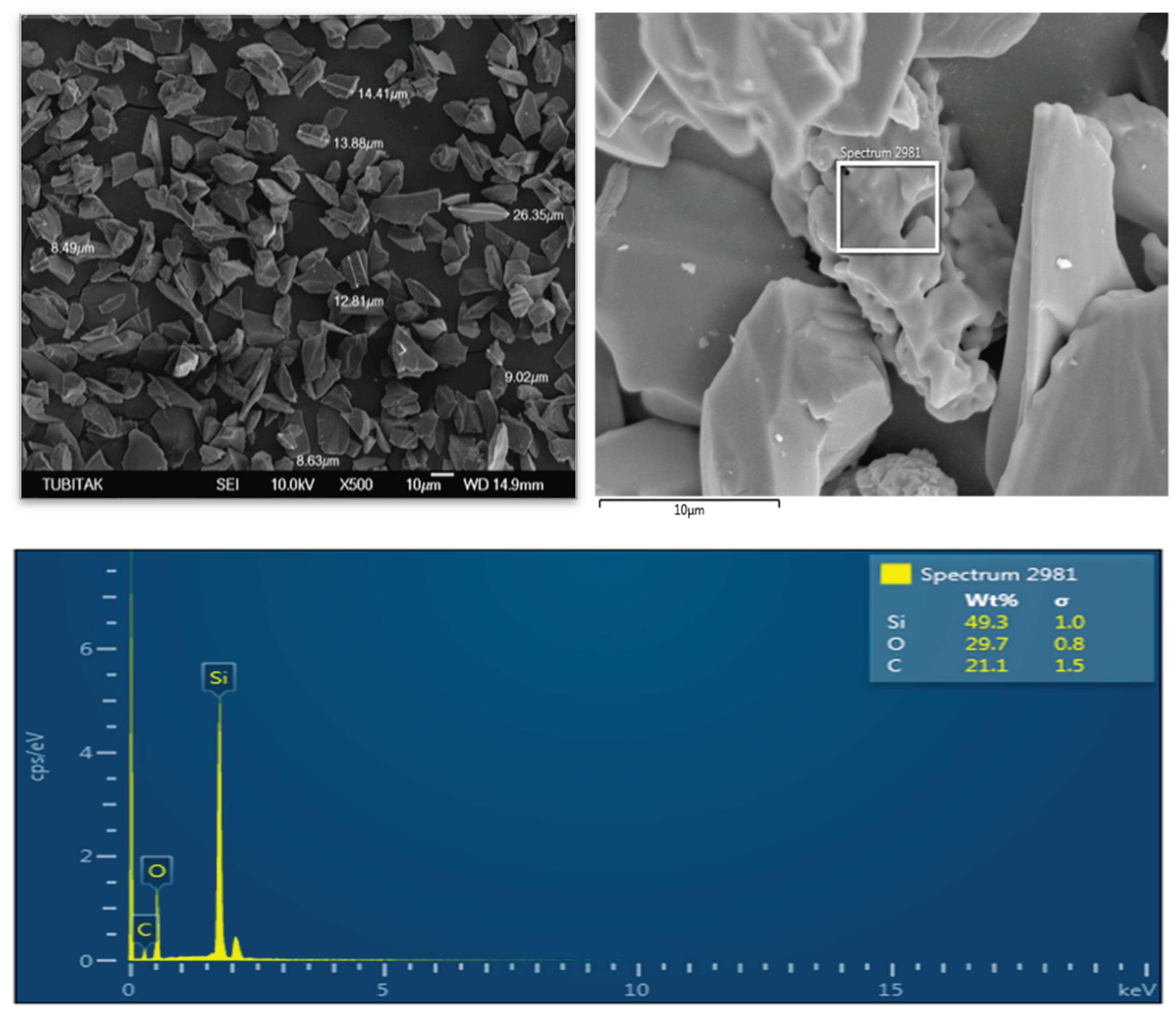

2.1. Materials

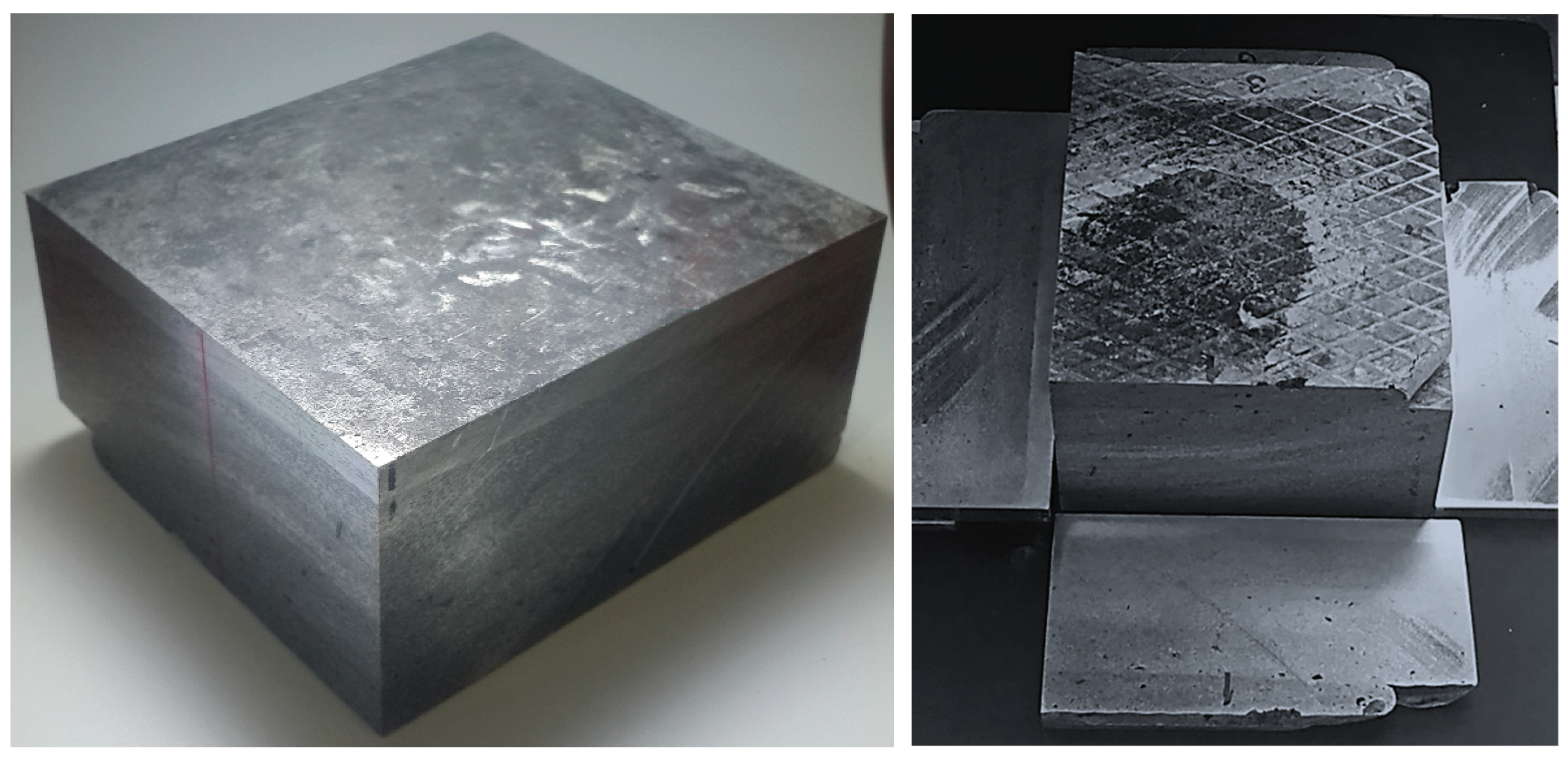

2.2. Preparation of FG-7075/SiCp

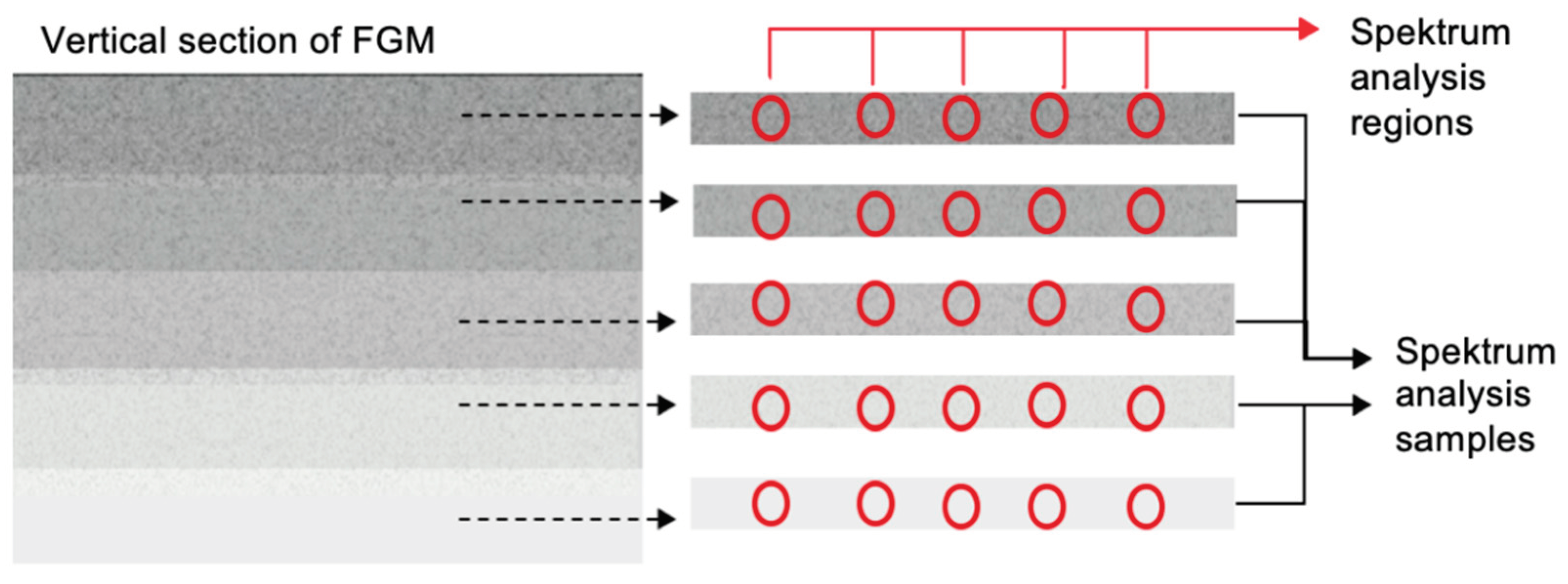

2.3. Microstructural Characterisation

3. Results and Discussion

Effect of Direct Semi-Solid Stirring and Sequential Squeeze Casting

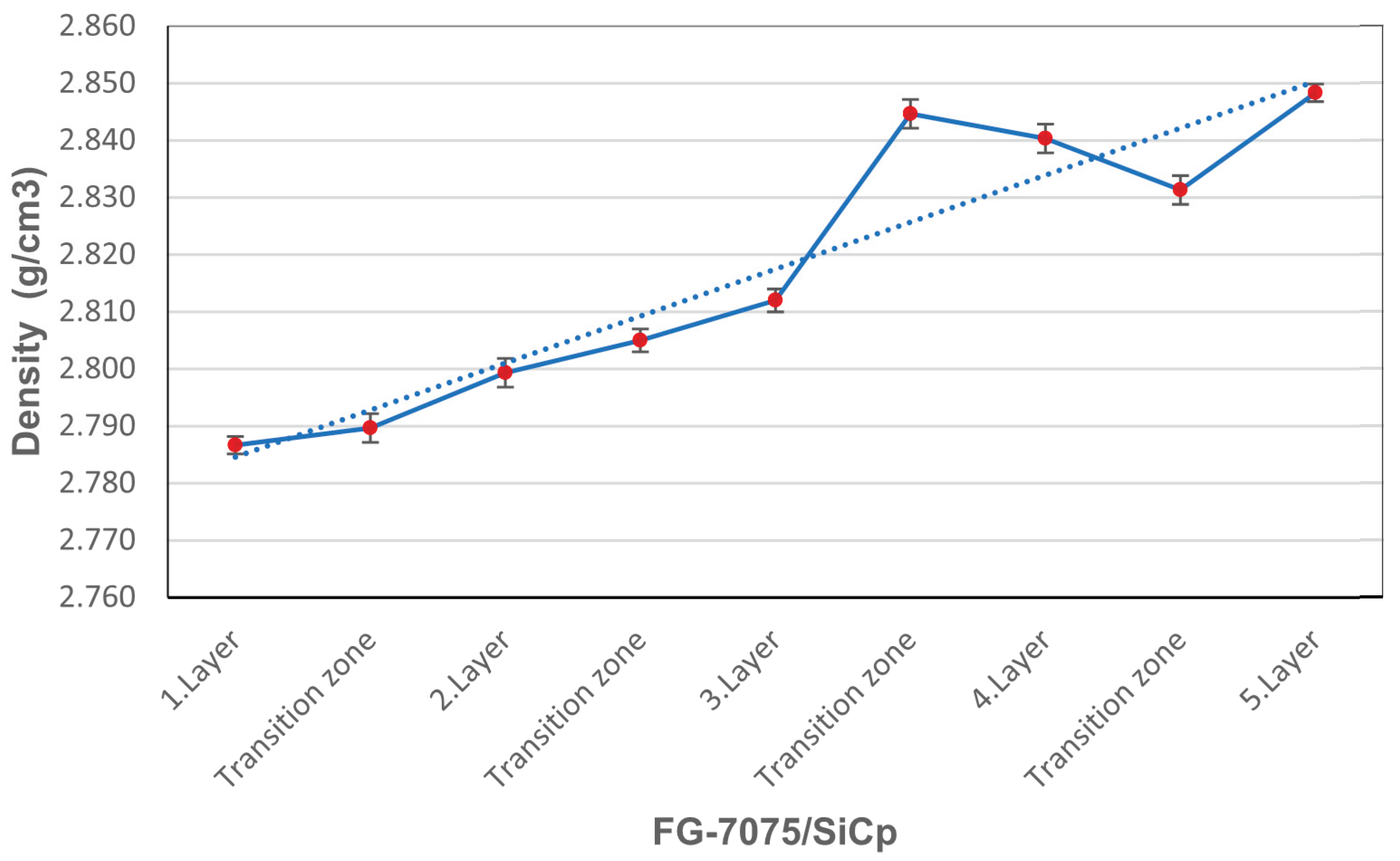

| SiCp% | Measured Density (g/cm³) |

Theoretical Density (g/cm³) |

Porosity (%) |

|---|---|---|---|

| 0% | 2.787 | 2.81 | 1.06 |

| 0-5% | 2.790 | --- | --- |

| 5% | 2.799 | 2.83 | 1.413 |

| 5-10% | 2.805 | --- | |

| 10% | 2.812 | 2.85 | 1.403 |

| 10-15% | 2.845 | --- | --- |

| 15% | 2.840 | 2.87 | 1.045 |

| 15-20% | 2.831 | --- | --- |

| 20% | 2.848 | 2.89 | 1.73 |

4. Conclusions

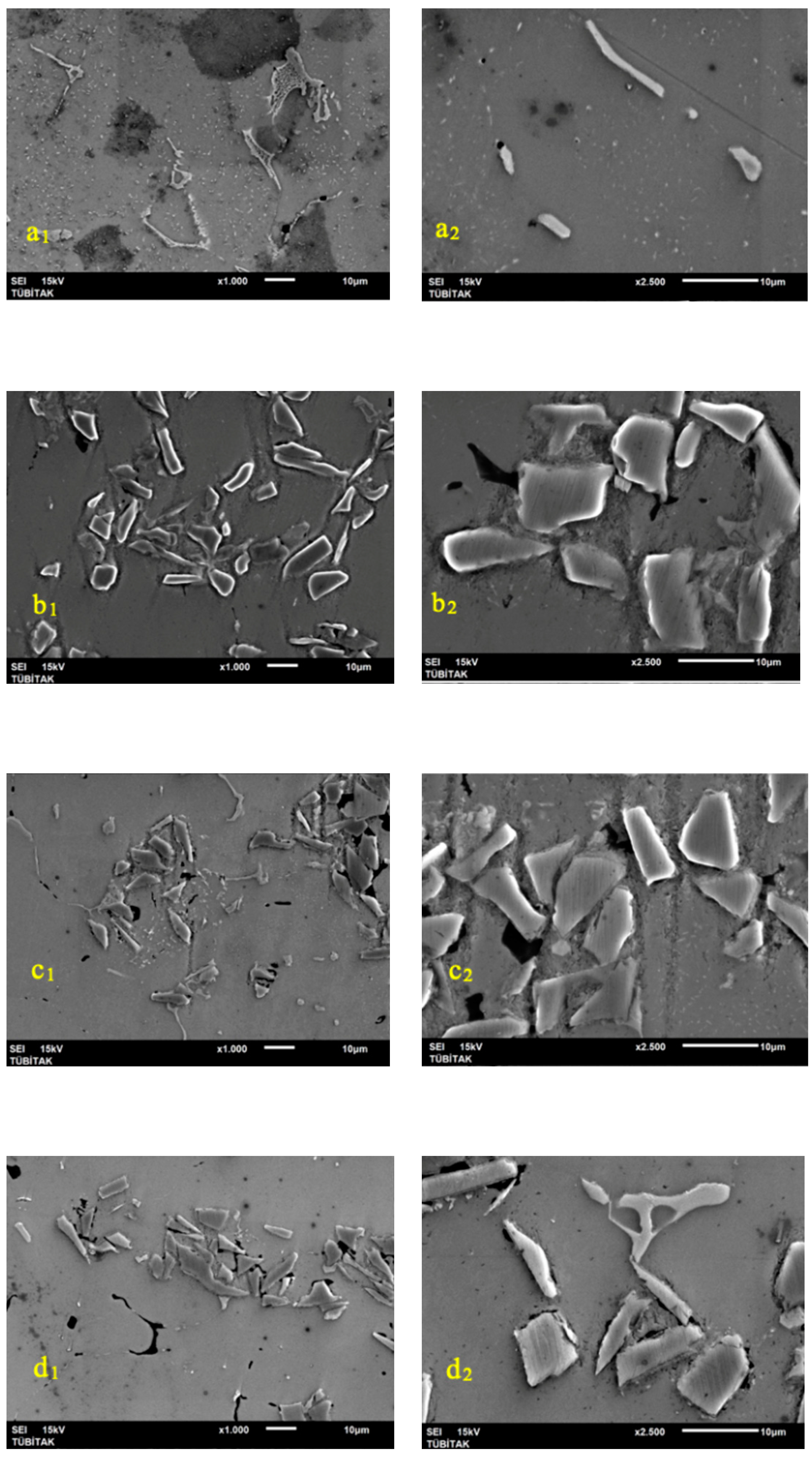

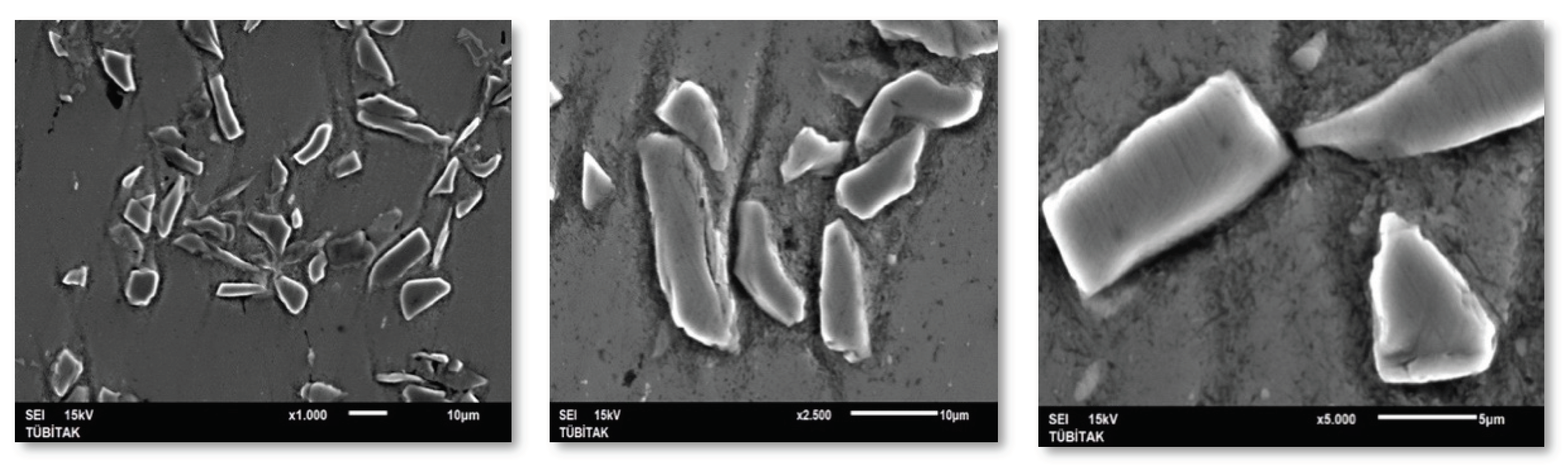

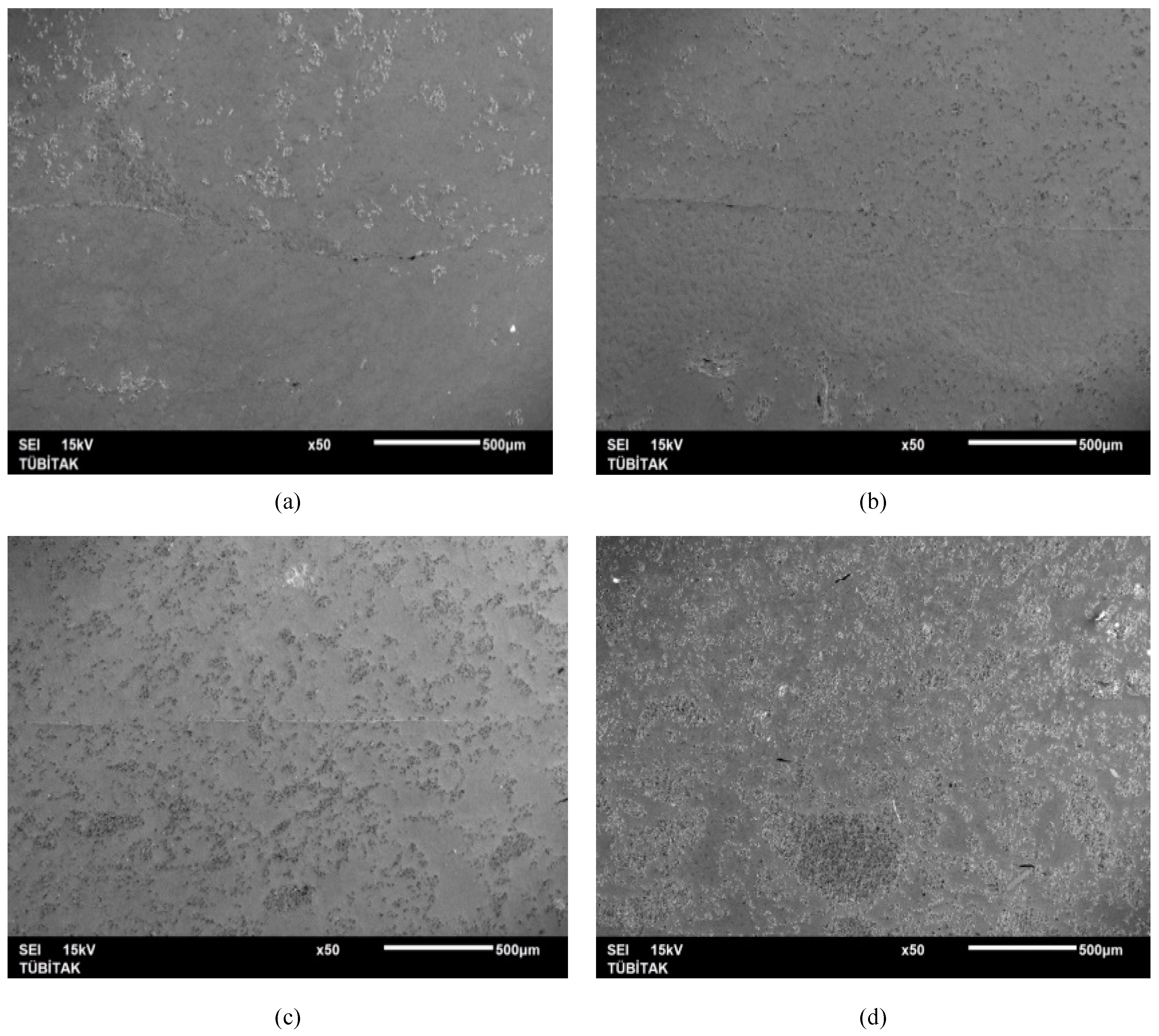

- Semi-solid mixing was found to be an effective and efficient method of achieving homogeneous dispersion of SiCp in AA7075 Al alloy. This process prevented the movement of SiCp to the surface, precipitation and largely eliminated agglomeration of SiCp particles during mixing.

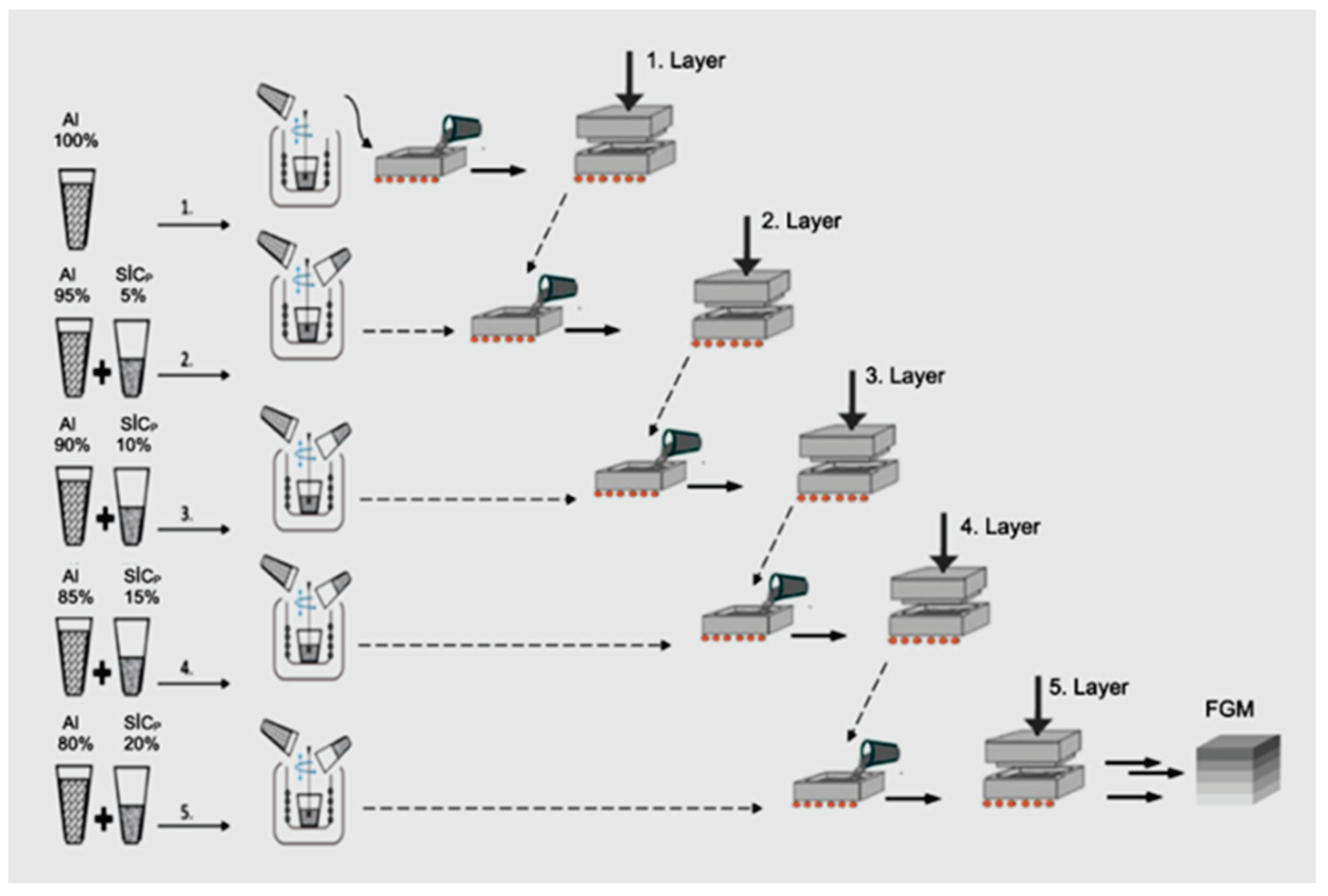

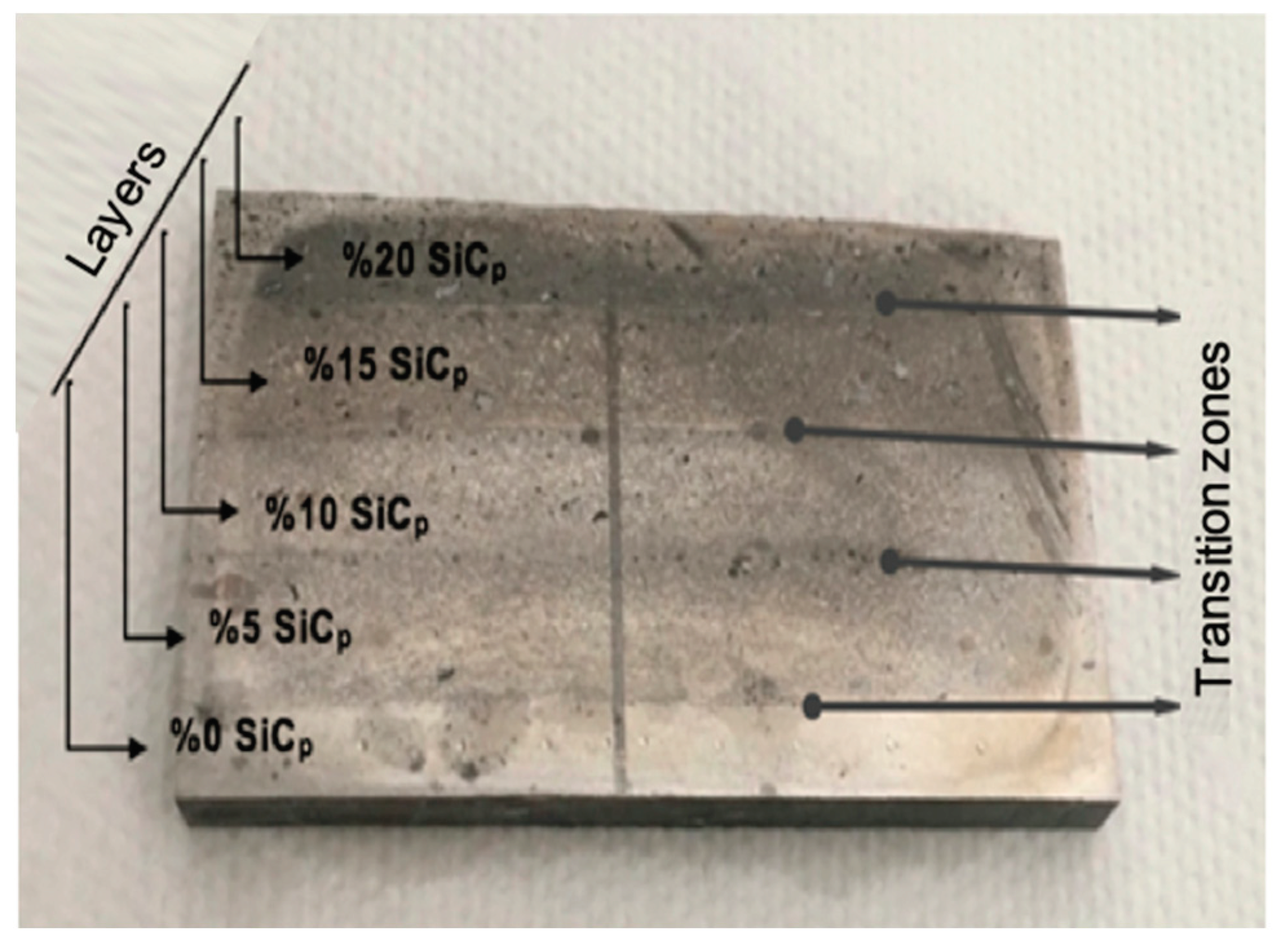

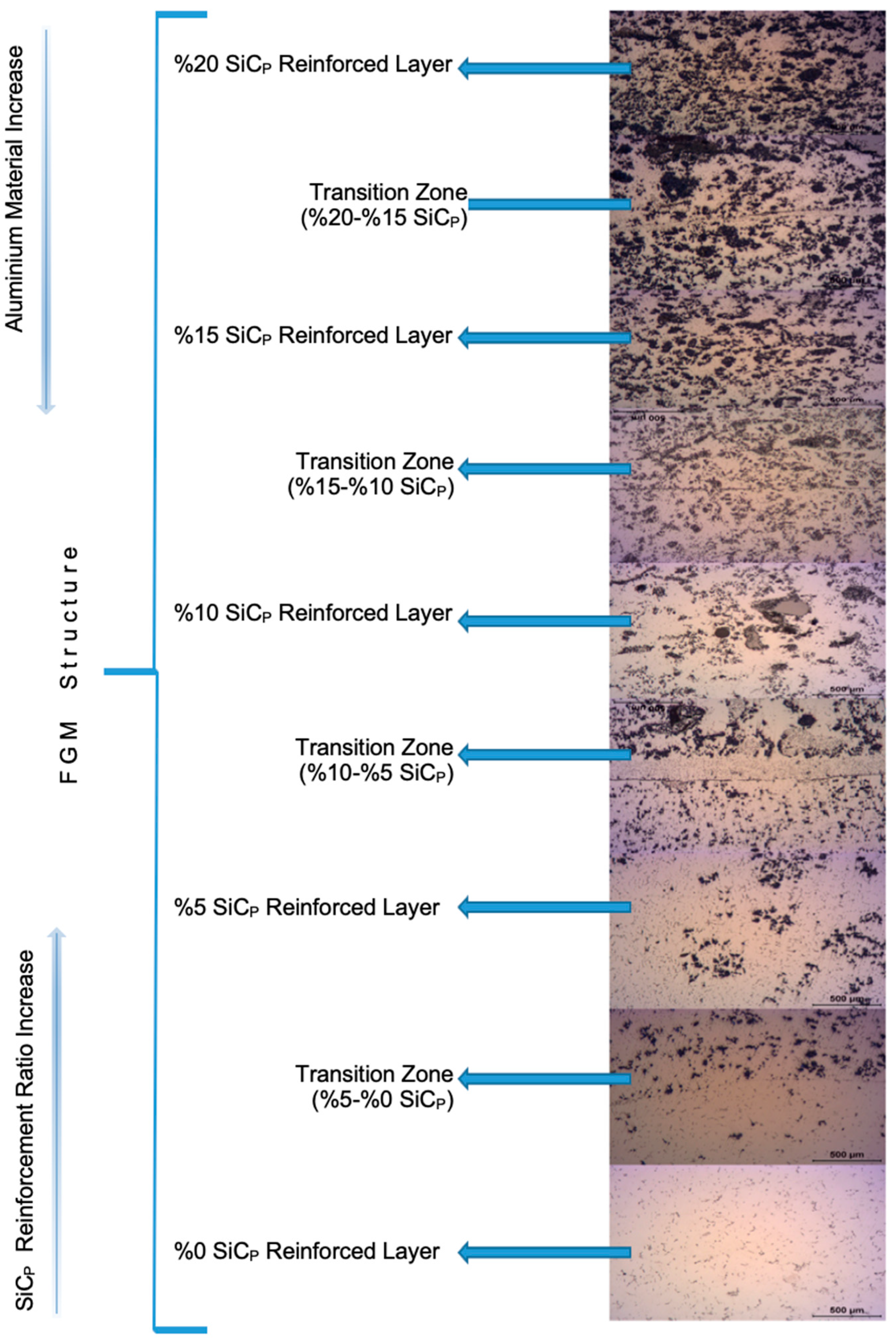

- Semi-solid mixing and sequential squeeze casting were used together in order to produce functionally graded metal matrix composite, and the production of FG-AA7075/SiCp composite was successfully achieved by casting the composite mixture with five different reinforcement ratios and solidifying it under pressure in each layer.

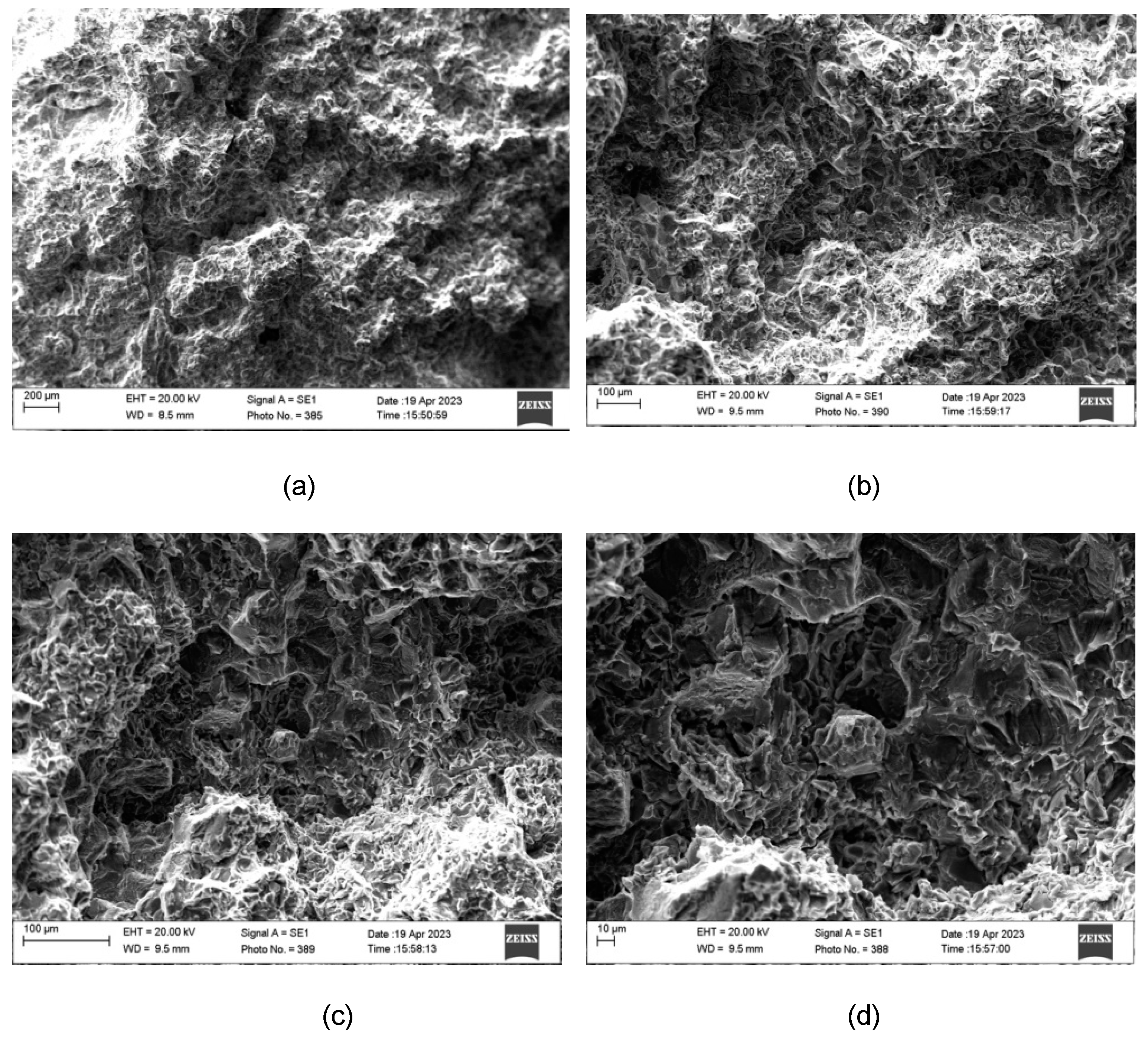

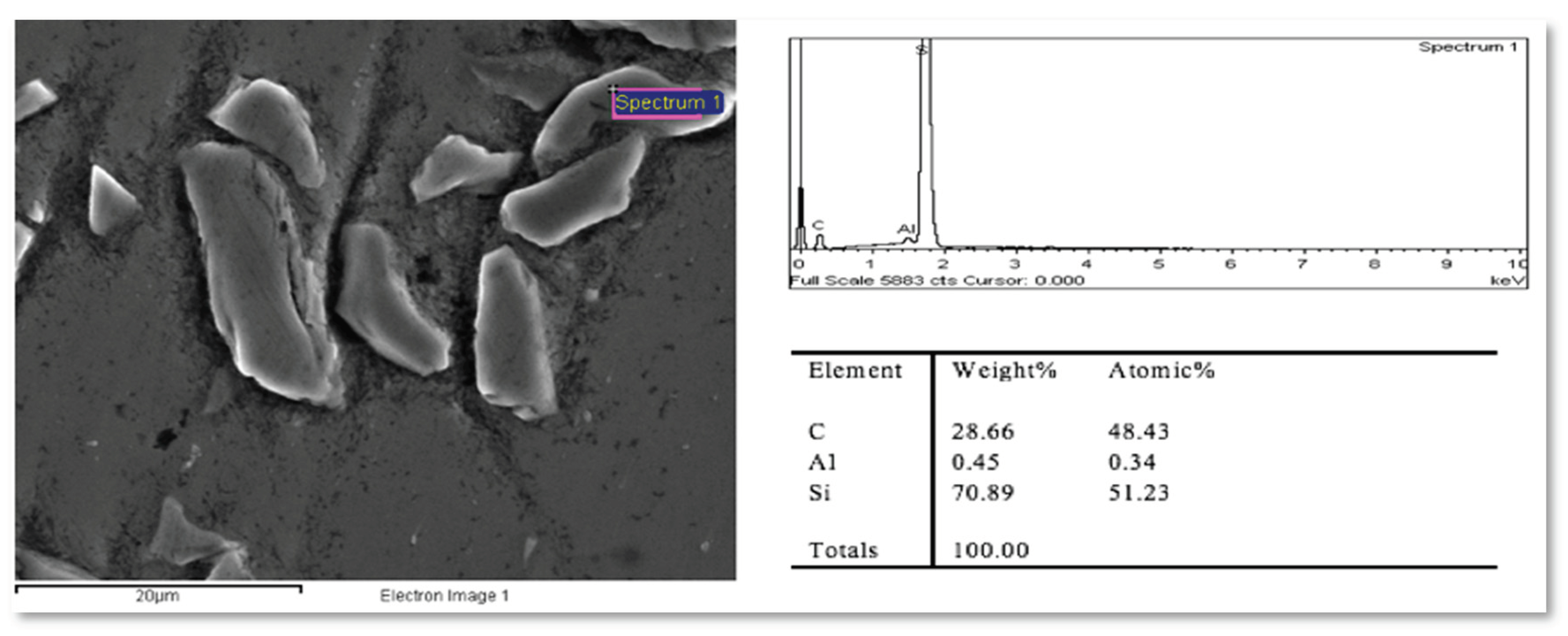

- The addition of 5-20 wt% SiCp to AA7075 Al by using the semi-solid mixing method resulted in an increase in density with increasing reinforcement ratio. The SEM results revealed a good interfacial bonding between SiCp and Al-matrix. This was an important finding due to the addition of SiCs at different ratios, indicating a cost-effective incorporation of the particles.

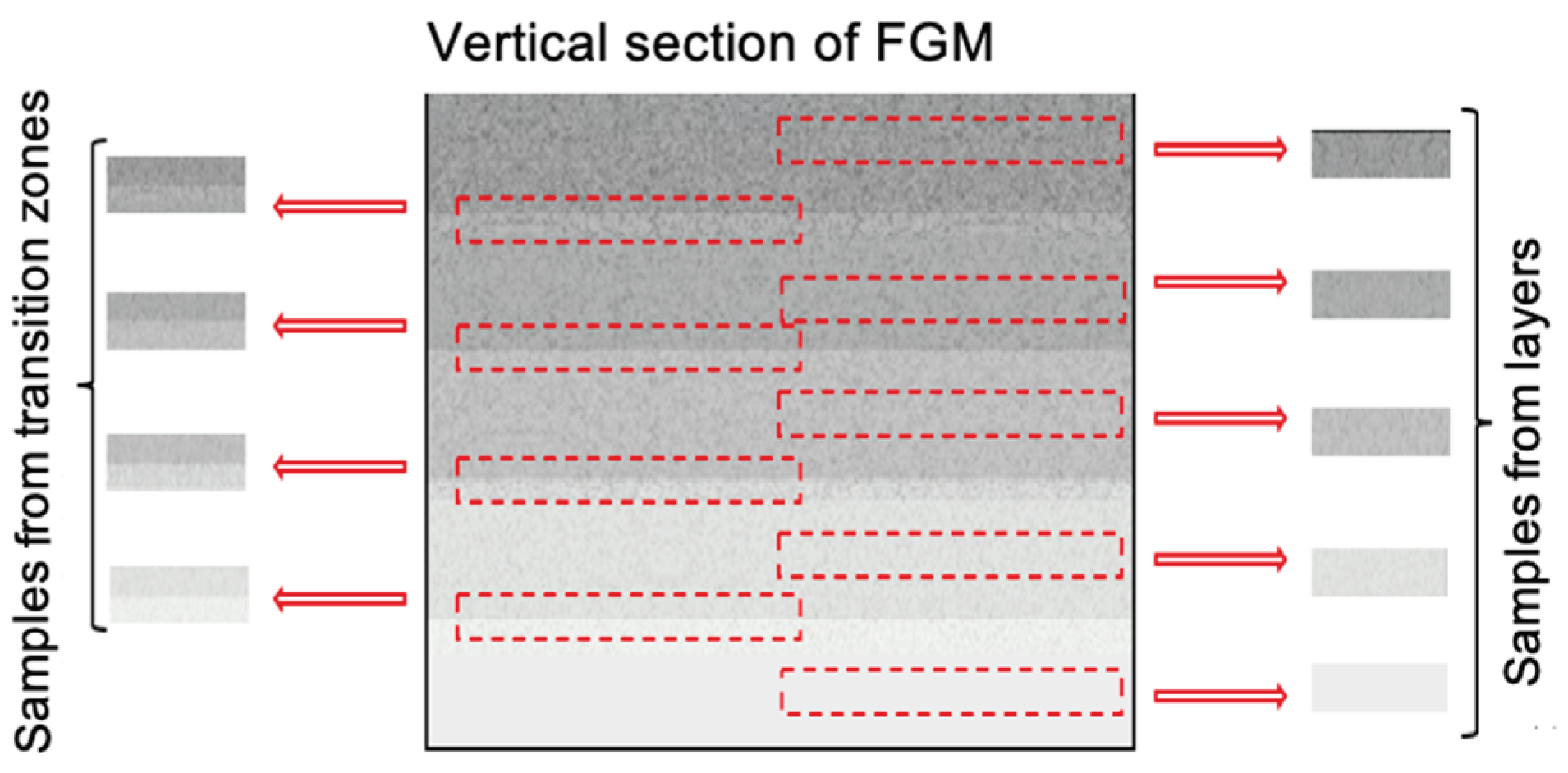

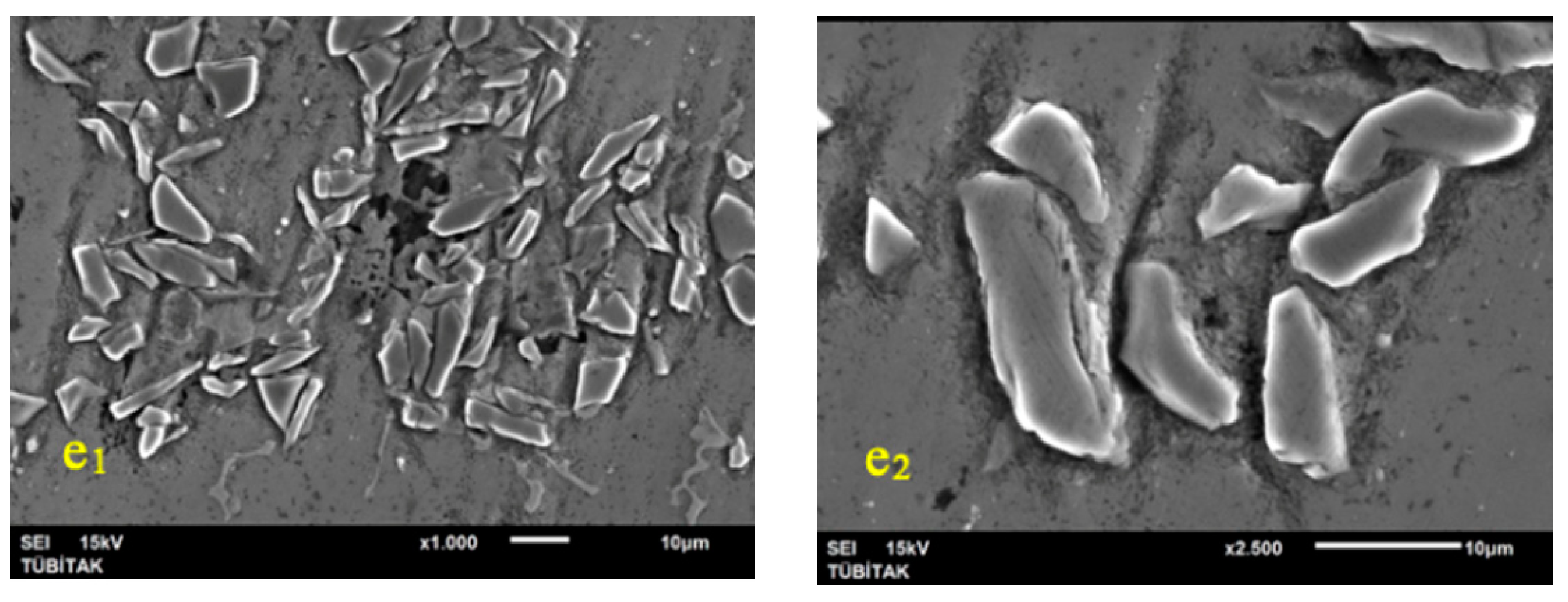

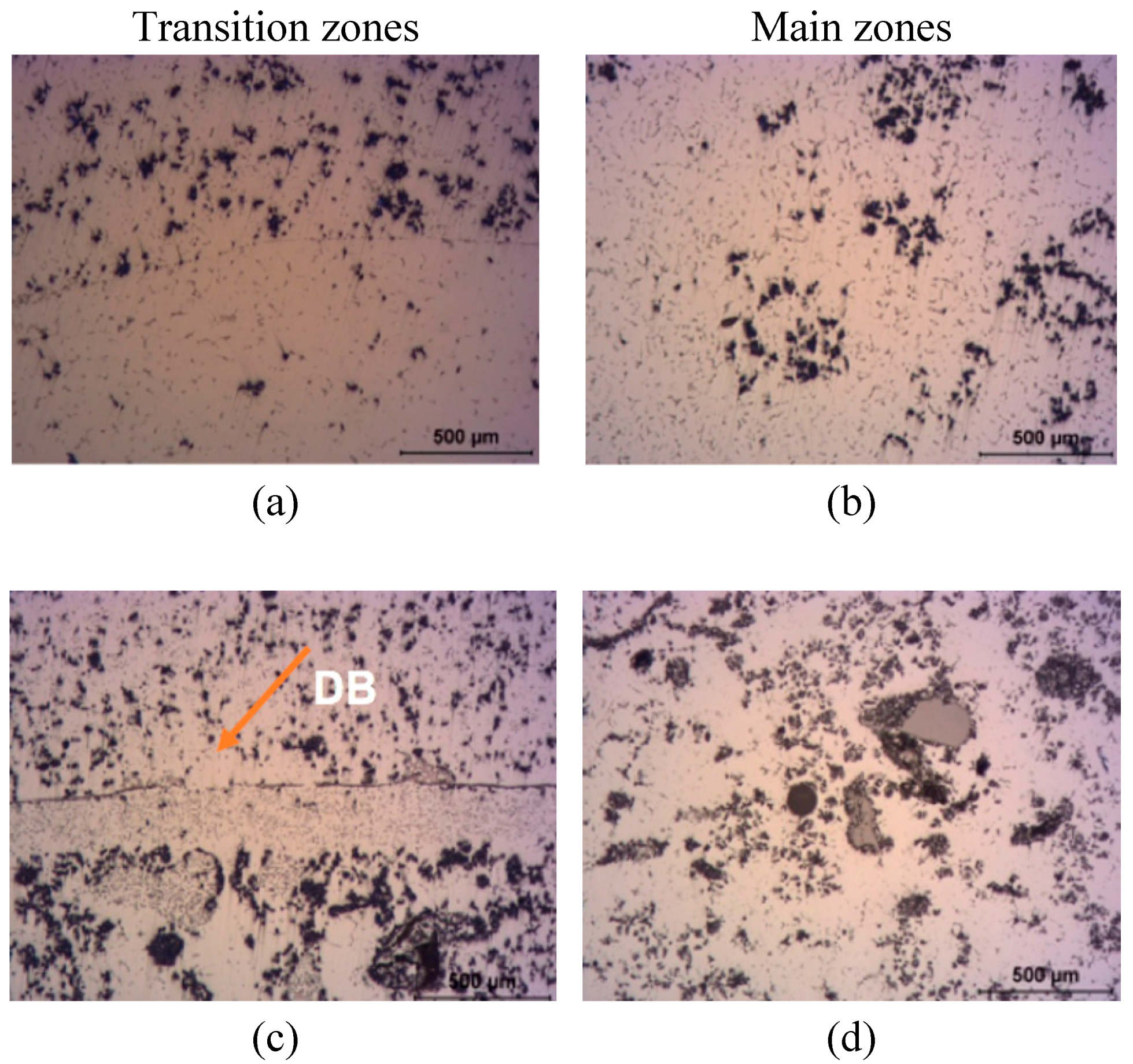

- It was observed that the composite mixture poured in liquid form onto the solidified first layer formed a partial melting and combined with the layer underneath by forming a transition zone under pressure.

- The densities at the intermediate transition zones of the two high reinforcement layers were generally measured higher than the layers before and after the transition zone. These results indicate that partial melting occurred in this zone during production and that two layers were locally diffused with each other.

- Porosity was found to be within the range of 1%-1.7% over the entire cross section. This value is lower than the porosity value obtained when the particle reinforced composites were produced by other methods. It was observed that the sequential application of the squeeze casting method was effective in achieving this result.

Funding

Acknowledgments

References

- Kawasaki, A., & Watanabe, R. (1997). Concept and P/M fabrication of functionally gradient materials. Ceramics international, 23(1), 73-83. [CrossRef]

- Khor, K. A., &Gu, Y. W. (2000). Thermal properties of plasma-sprayed functionally graded thermal barrier coatings. Thin Solid Films, 372(1-2), 104-113. [CrossRef]

- Kieback, B., Neubrand, A., & Riedel, H.(2003). Processing techniques for functionally graded materials. Materials Science and Engineering: A, 362(1-2), 81-106. [CrossRef]

- Koizumi, M. F. G. M. (1997). FGM activities in Japan. Composites Part B: Engineering, 28(1-2), 1-4. [CrossRef]

- Ghosh, K. B., Mukhopadhyay, J., & Basu, R.N. (2016). Functionally graded doped lanthanum cobalt ferrite and ceria-based composite interlayers for advancing the performance stability in solid oxide fuel cell. Journal of Power Sources, 328, 15-27. [CrossRef]

- Vaidya, R. U., Castro, R. G., Peters, M. I., Gallegos, D. E., & Petrovic, J. J. (2002). Use of plasma spraying in the manufacture of continuously graded and layered/graded molybdenum disilicide/alumina composites. Journal of thermal spray technology, 11(3), 409-414. [CrossRef]

- Woolley, R. J., & Skinner, S. J. (2014). Functionally graded composite La2NiO4+ δ and La4Ni3O10− δ solid oxide fuel cell cathodes. Solid State Ionics, 255, 1-5. [CrossRef]

- Marin, L. (2005). Numerical solution of the Cauchy problem for steady-state heat transfer in two-dimensional functionally graded materials. International Journal of Solids and Structures,42(15), 4338-4351. [CrossRef]

- Kim, J. I., Kim, W. J., Choi, D. J., Park, J. Y., & Ryu, W. S. (2005). Design of a C/SiC functionally graded coating for the oxidation protection of C/C composites. Carbon,43(8), 1749-1757. [CrossRef]

- Limarga, A. M., Widjaja, S., & Yip, T. H. (2005). Mechanical properties and oxidation resistance of plasma-sprayed multilayered Al2O3/ZrO2 thermal barrier coatings. Surface and Coatings Technology, 197(1), 93-102. [CrossRef]

- Negahdari, Z., Willert-Porada, M., & Scherm, F. (2010). Development of novel functionally graded Al2O3-lanthanum hexaaluminate ceramics for thermal barrier coatings. In Materials Science Forum, 631, 97-102. [CrossRef]

- 12. Udupa, G., Rao, S. S., & Gangadharan, K. V. (2014). Functionally graded composite materials: an overview. Procedia Materials Science, 5, 1291-1299. [CrossRef]

- Zhang, L. X., Zhang, B., Sun, Z., Pan, X. Y., Shi, J. M., & Feng, J. C. (2020). Preparation of graded double-layer materials for brazing C/C composite and TC4. Journal of Alloys and Compounds,823, 153-169. [CrossRef]

- Torres, Y., Trueba, P., Pavón, J. J., Chicardi, E., Kamm, P., García-Moreno, F., & Rodríguez-Ortiz, J. A. (2016). Design, processing and characterization of titanium with radial graded porosity for bone implants. Materials & Design, 110, 179-187. [CrossRef]

- Woodward, B., & Kashtalyan, M. (2012). Performance of functionally graded plates under localised transverse loading. Composite Structures, 94(7), 2254-2262. [CrossRef]

- Taskin, N.U., Taskin, V. Continuous composite metal foam production and method and device for stirringparticle reinforced composite metal. European Patent No. 3083105.European Patent Office. 2017.

- Andilab, B.; Emadi, P.; Ravindran, C. Casting and Characterization of A319 Aluminum Alloy Reinforced with Graphene Using Hybrid Semi-Solid Stirring and Ultrasonic Processing. Materials 2022, 15, 7232. [CrossRef]

- Kunimine, T., Sato, H., Miura-Fujiwara, E., & Watanabe, Y. (2016). New Processing Routes for Functionally Graded Materials and Structures through Combinations of Powder Metallurgy and Casting. InTech. [CrossRef]

- Shi, Z., Ochiai, S., Hojo, M. et al. (2001).The oxidation of SiC particles and its interfacial characteristics in Al-matrix composite. Journal of Materials. Science 36, 2441–2449. [CrossRef]

- Prabhu, T. R. (2017). Processing and properties evaluation of functionally continuous graded 7075 Al alloy/SiC composites. Archives of Civil and Mechanical Engineering, 17(1), 20-31. [CrossRef]

- Cornie, J.A., Moon, H.K., Flemings, M.C., Masounave, J., Hamel, F.G. (1990). Proceedings of The International Conference On Fabrication of Particulates Reinforced Metal Composites, Montreal, Quebec. Canada. Asm International, USA, 63-78.

- Lei, M., & Ledbetter, H. (1994). Elastic constants of SiC p/Al: Measurements and modeling. Metallurgical and Materials Transactions A,25(12), 2832-2835. [CrossRef]

- Rajan, T. P. D., Pillai, R. M., & Pai, B. C. (2010). Characterization of centrifugal cast functionally graded aluminum-silicon carbide metal matrix composites. Materials characterization, 61(10), 923-928. [CrossRef]

| Density | 2,81 | g/cm3 |

| Elastic Modulus | 71-72 | GPa |

| Specific Heat (273-373 K) | 0,97 | |

| Linear Expansion Coefficient (293-373 K) | 23x10-6 | /°K |

| Thermal Conductivity (373-673 K) | 130 | W/m°K |

| Resistivity (293 K) | 0,049x10-6 | Ωm |

| Weight % | Si | Fe | Cu | Mg | Mn | Cr | Zn | Ti |

|---|---|---|---|---|---|---|---|---|

| Minimum | - | - | 1,2 | 2,1 | - | 0,18 | 5,1 | - |

| Maximum | 0,4 | 0,5 | 2 | 2,9 | 0,3 | 0,28 | 6,1 | 0,2 |

| Heat Treatment | Tensile Strength (Rm MPa) |

Yield Strength (Rp 0,2/MPa) |

Elongation(%) | Hardness (Brinell) |

|---|---|---|---|---|

| T0 | 225 | 105 | 17 | 60 |

| T6 | 530-570 | 460-505 | 10 | 150 |

| Particle Type | Particle Type Size (μm) | Density (gr/ cm3) |

Tensile Strength (GPa) |

Elastic Modulus (GPa) |

|---|---|---|---|---|

| SiC | 15- 340 | 3,2 | 3 | 480 |

| Products | Particle Size | SiC% | Free C % | Si % | SO2 % | Fe2O3 % |

|---|---|---|---|---|---|---|

| SiC | F240- F800 | 99,5 | 0,10 | 0,10 | 0,10 | 0,05 |

| Condition | SiC Addition (wt%) | Application (within a 5-layer FDM) |

|---|---|---|

| AA7075 | - | 1st layer |

| AA7075 + 5 % SiC | 5 | 2nd layer |

| AA7075 + 10 % SiC | 10 | 3rd layer |

| AA7075 + 15 % SiC | 15 | 4th layer |

| AA7075 + 20% SiC | 20 | 5th layer |

| Si | Fe | Cu | Ti | Mn | Mg | Cr | Zn | Al | |

|---|---|---|---|---|---|---|---|---|---|

| 1st Layer | 0,061 | 0,025 | 0,516 | 0,0555 | 0,0287 | 1,57 | 0,257 | 4,00 | 93,4 |

| 2nd Layer | 2,420 | 0,639 | 1,210 | 0,0489 | 0,0817 | 2,69 | 0,159 | 4,57 | 88,1 |

| 3rd Layer | 6,420 | 0,831 | 1,450 | 0,0343 | 0,1670 | 2,80 | 0,241 | 4,79 | 83,1 |

| 4th Layer | 14,32 | 0,798 | 1,690 | 0,0360 | 0,0441 | 2,38 | 0,200 | 5,50 | 74,8 |

| 5th Layer | 20,84 | 1,030 | 1,600 | 0,0344 | 0,0253 | 2,01 | 0,190 | 4,94 | 68,7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).