Submitted:

23 February 2024

Posted:

26 February 2024

You are already at the latest version

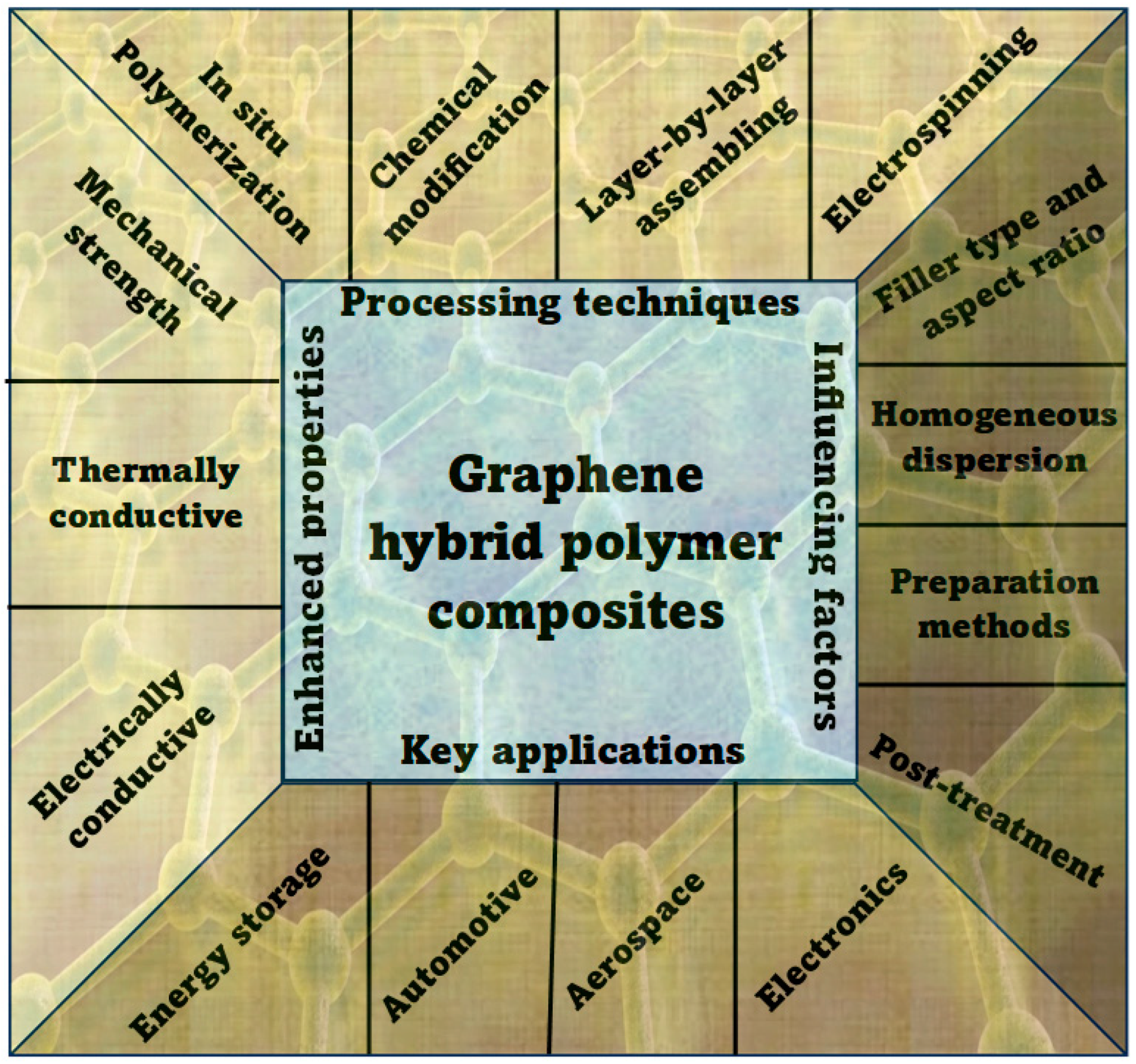

Abstract

Keywords:

1. Introduction

2. Processing Techniques

2.1. Old Preparation Methods for Graphene and Hybrid Polymer Composites

2.1.1. Mechanical Mixing

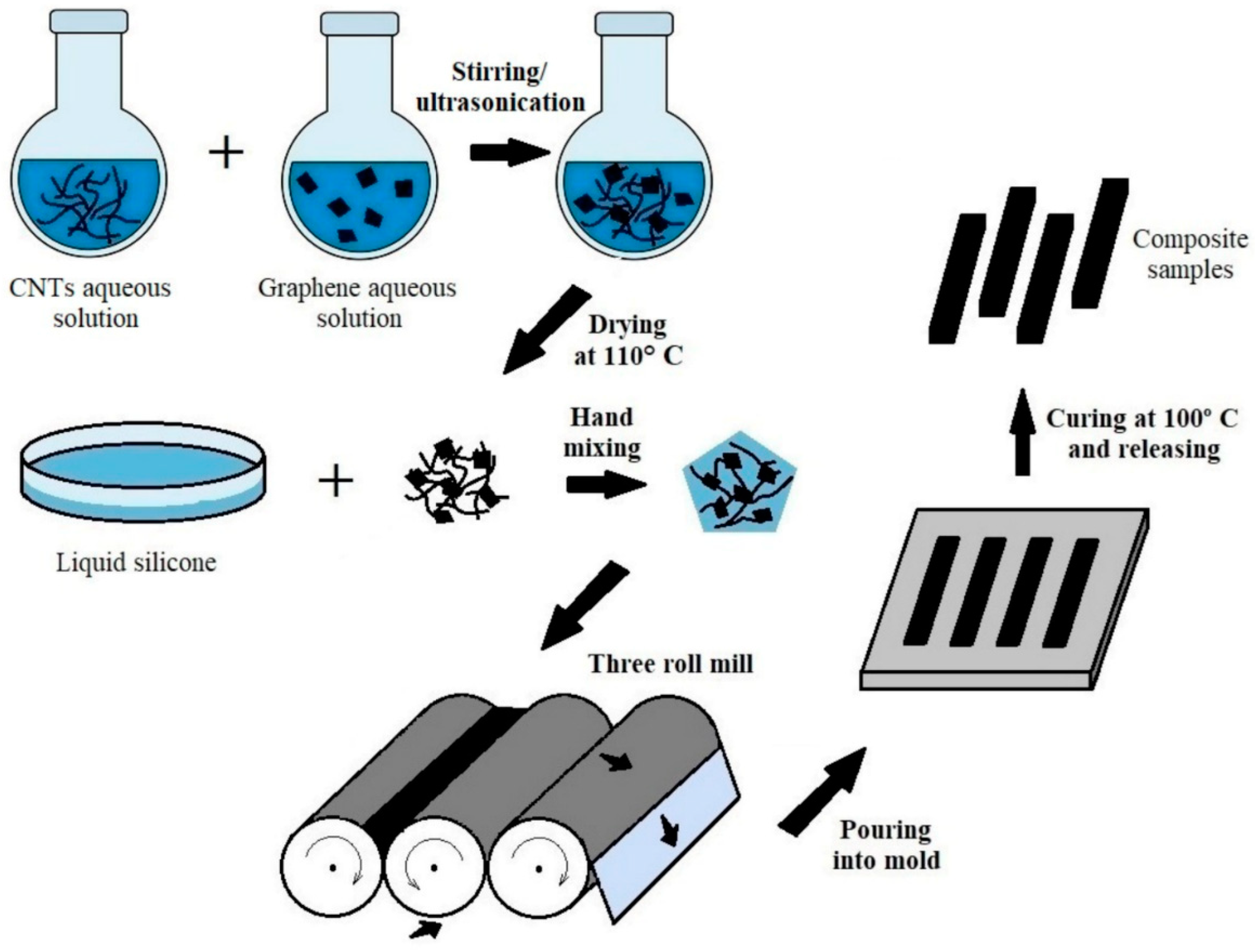

2.1.2. Solution Mixing

2.2. Recent Preparation Methods for Graphene and Hybrid Polymer Composites

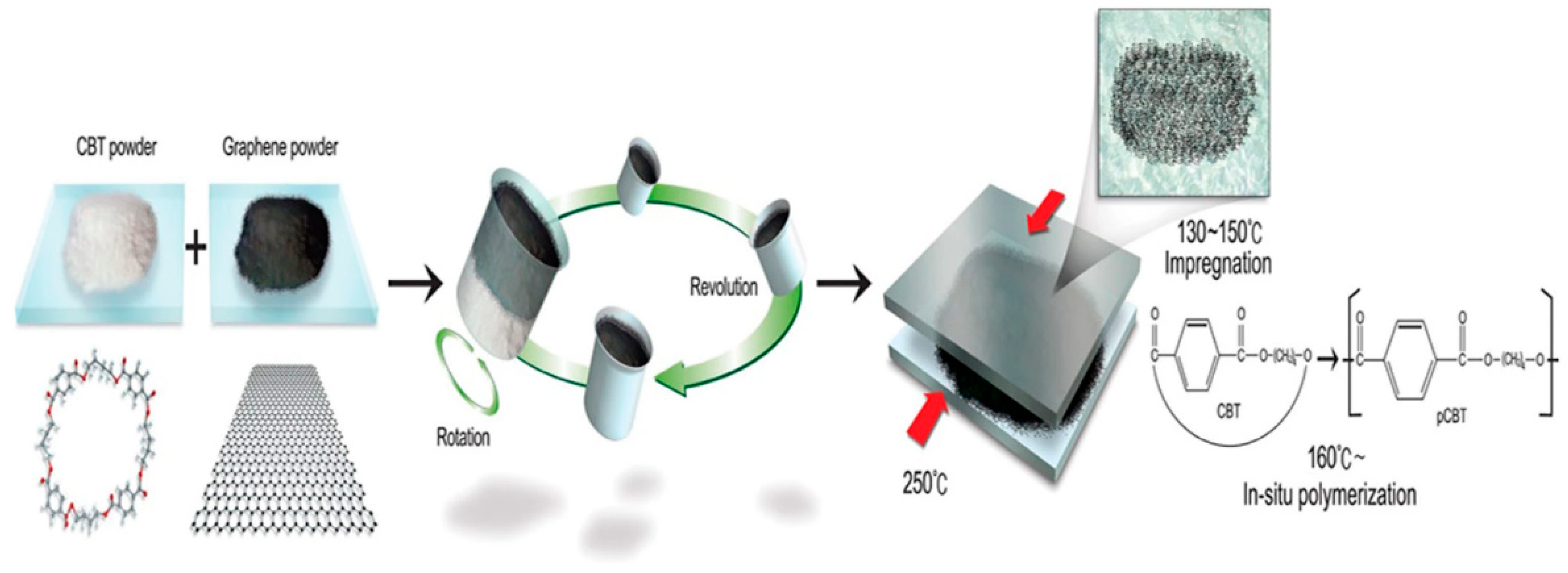

2.2.1. In-situ Polymerization

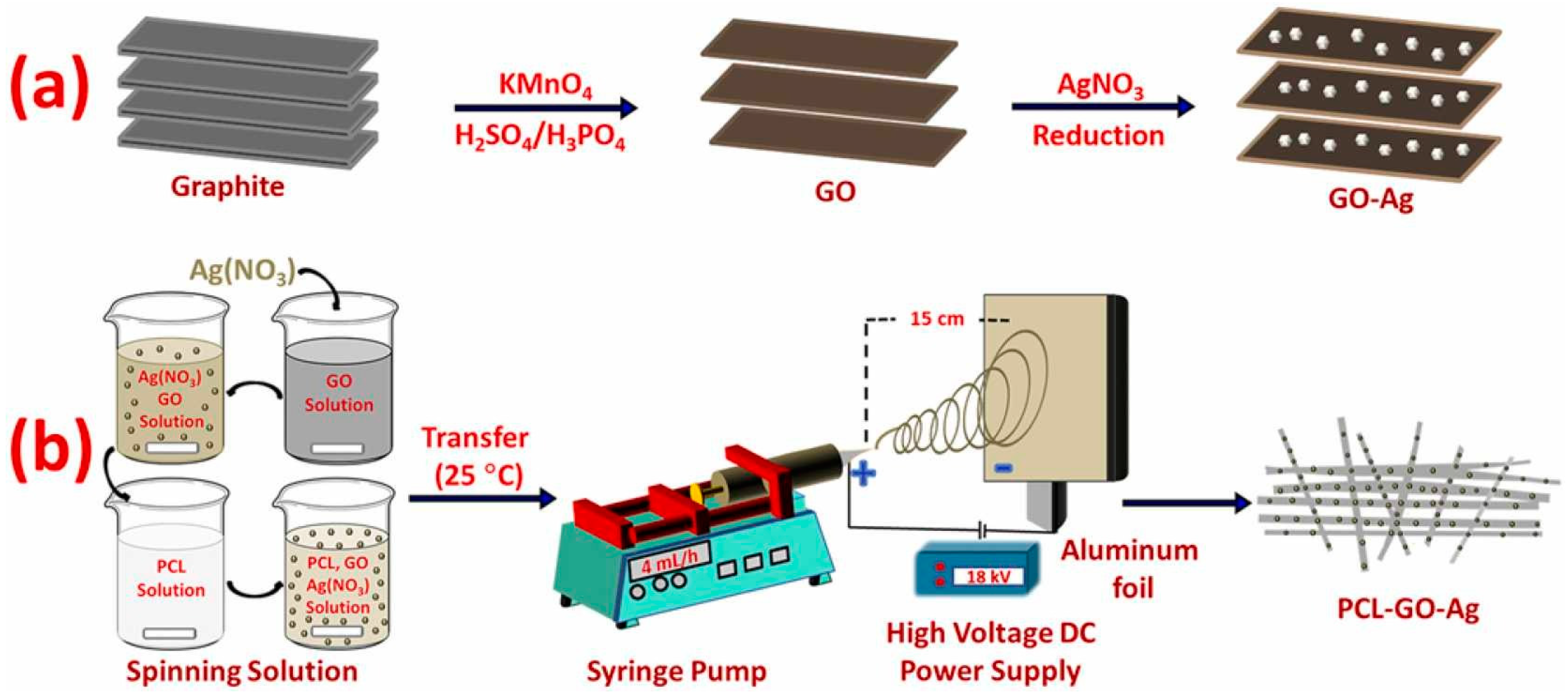

2.2.2. Electrospinning

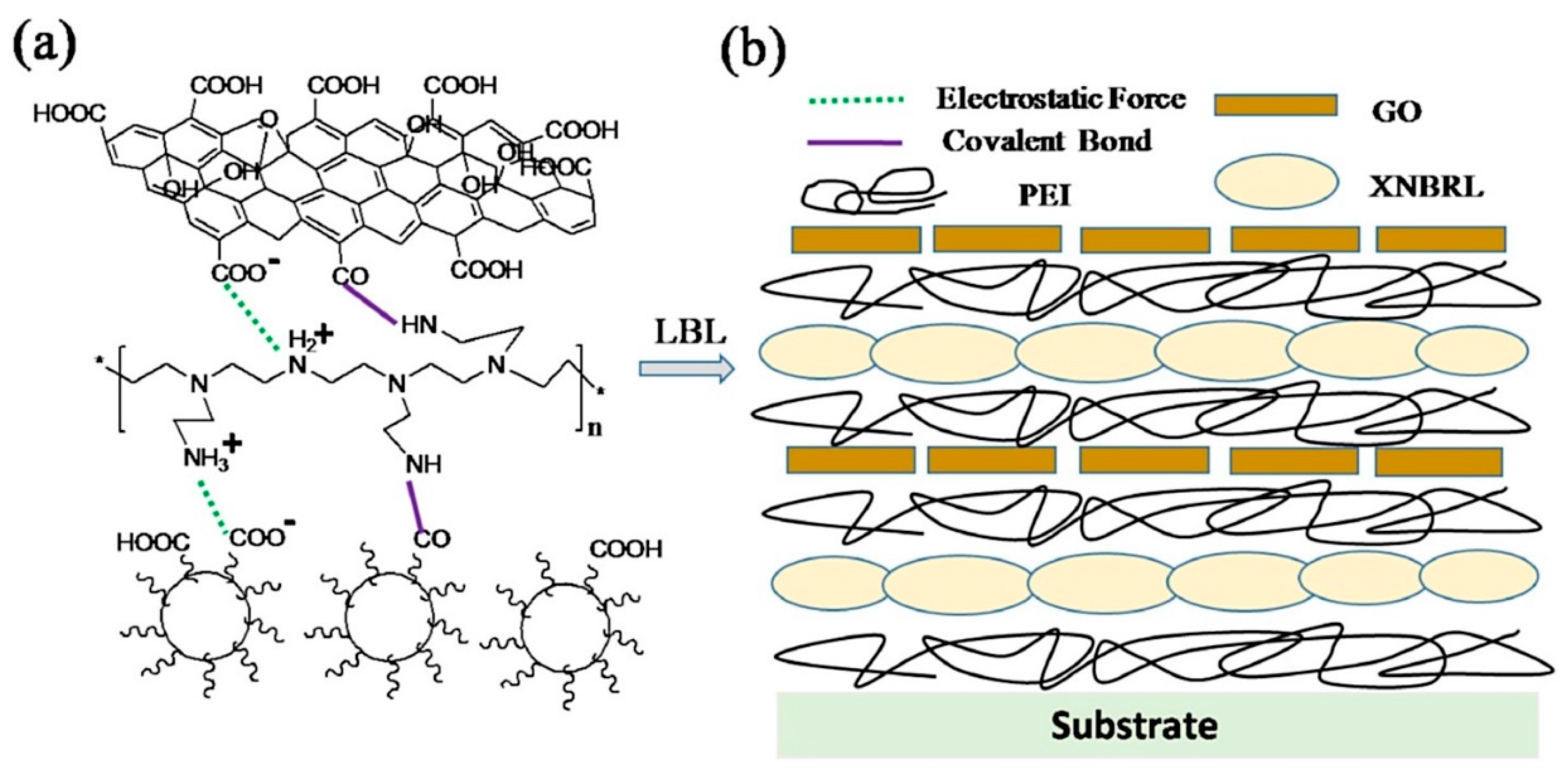

2.2.3. Layer-by-Layer Assembly

2.2.4. Chemical Modification

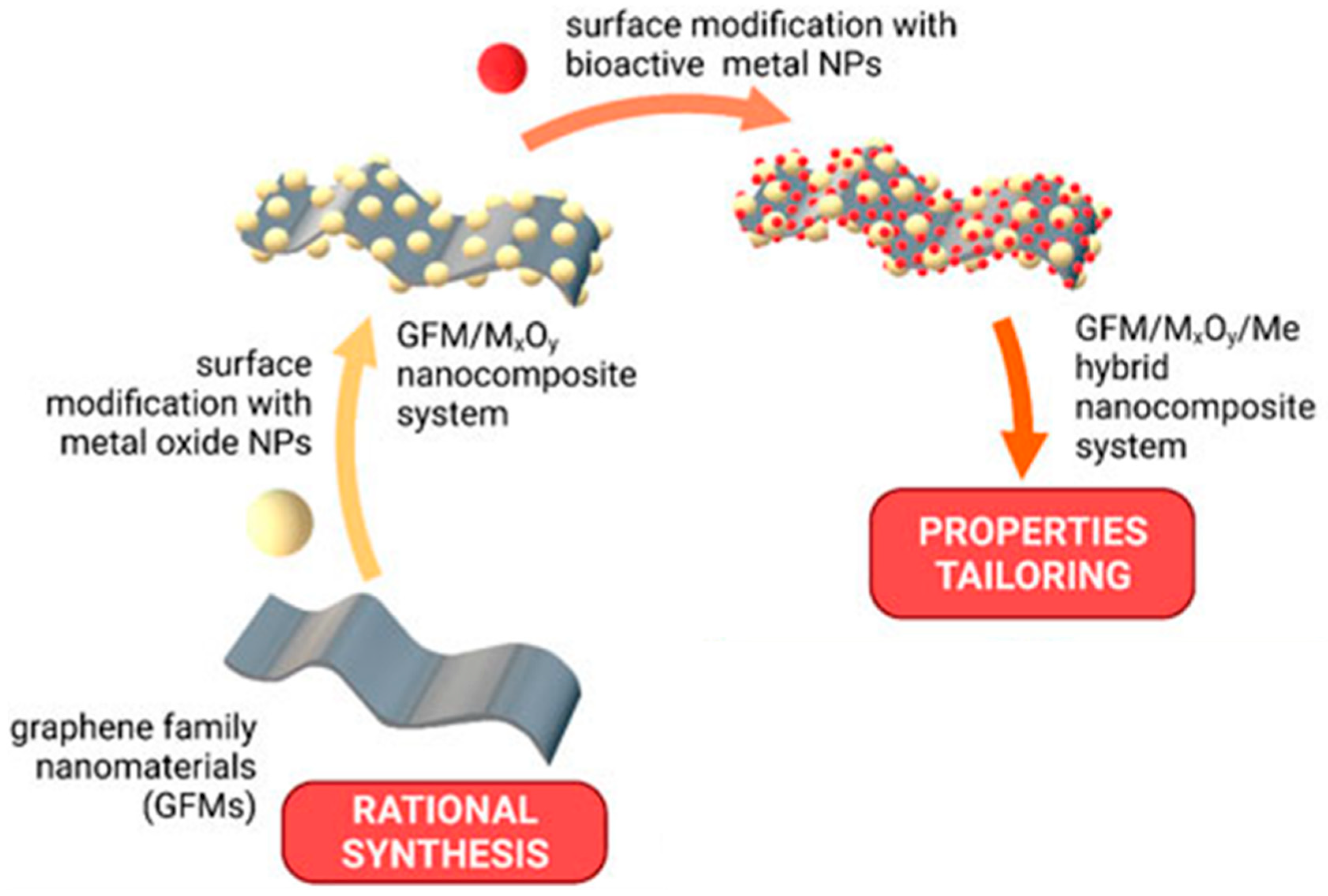

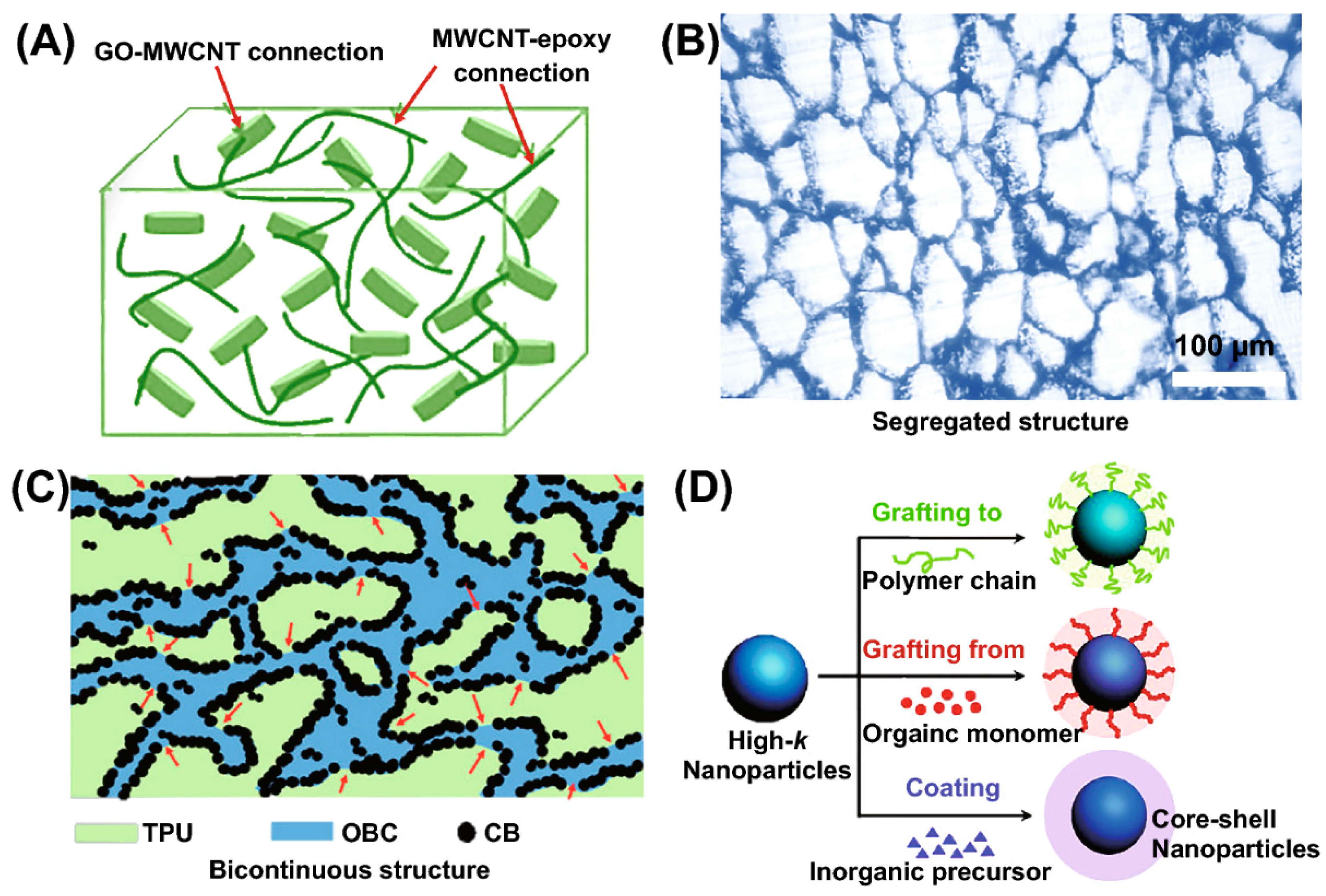

3. Graphene-Based Hybrid Polymer Composites

4. Mechanical and Structural Properties

5. Thermal Properties

6. Electrical Properties

7. Property Influencing Factors

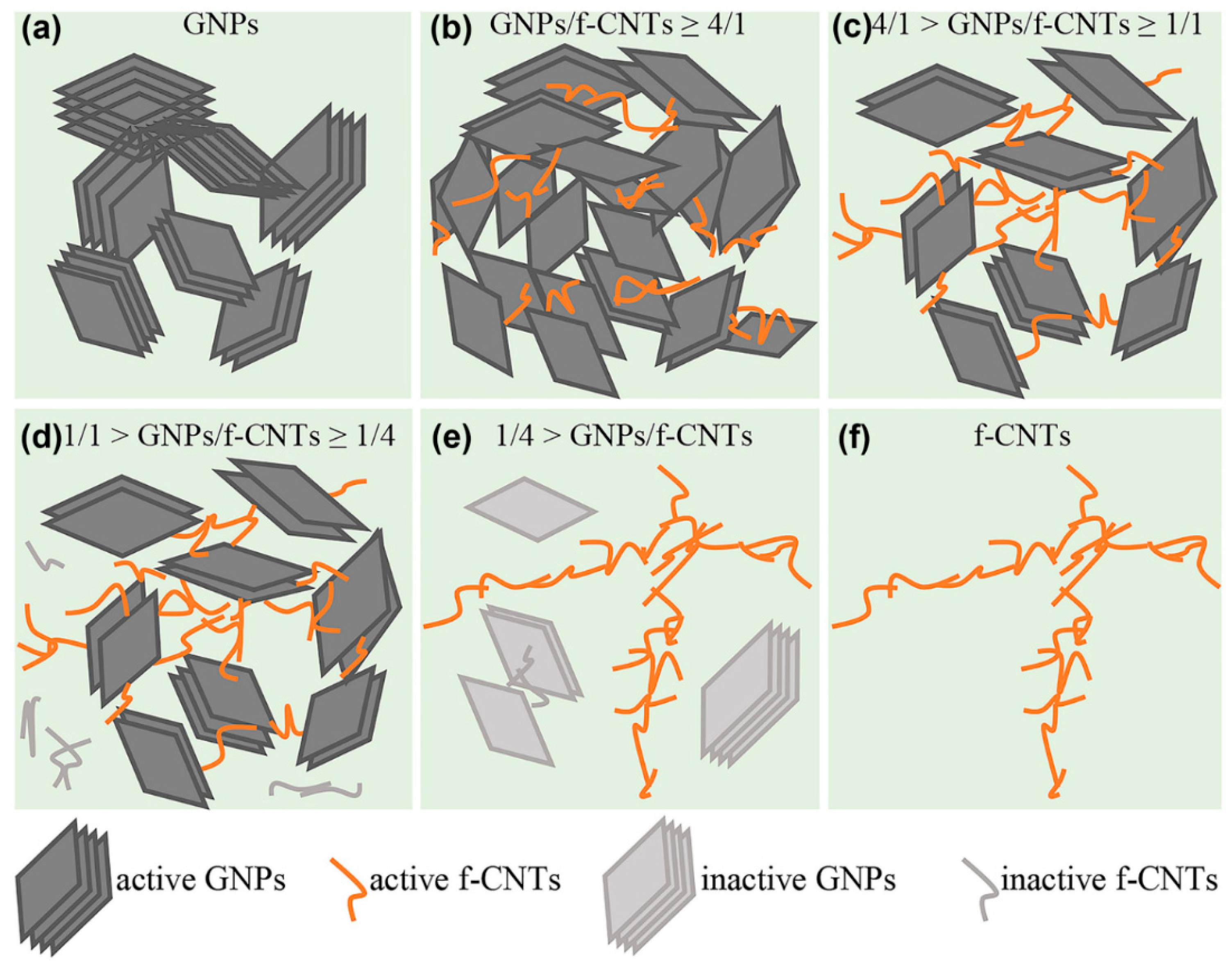

7.1. Filler Type and Aspect Ratio

7.2. Filler-Matrix Compatibility

7.3. Homogeneity of Dispersion

7.4. Processing techniques

7.5. Post-Treatment and Functionalization

8. Applications

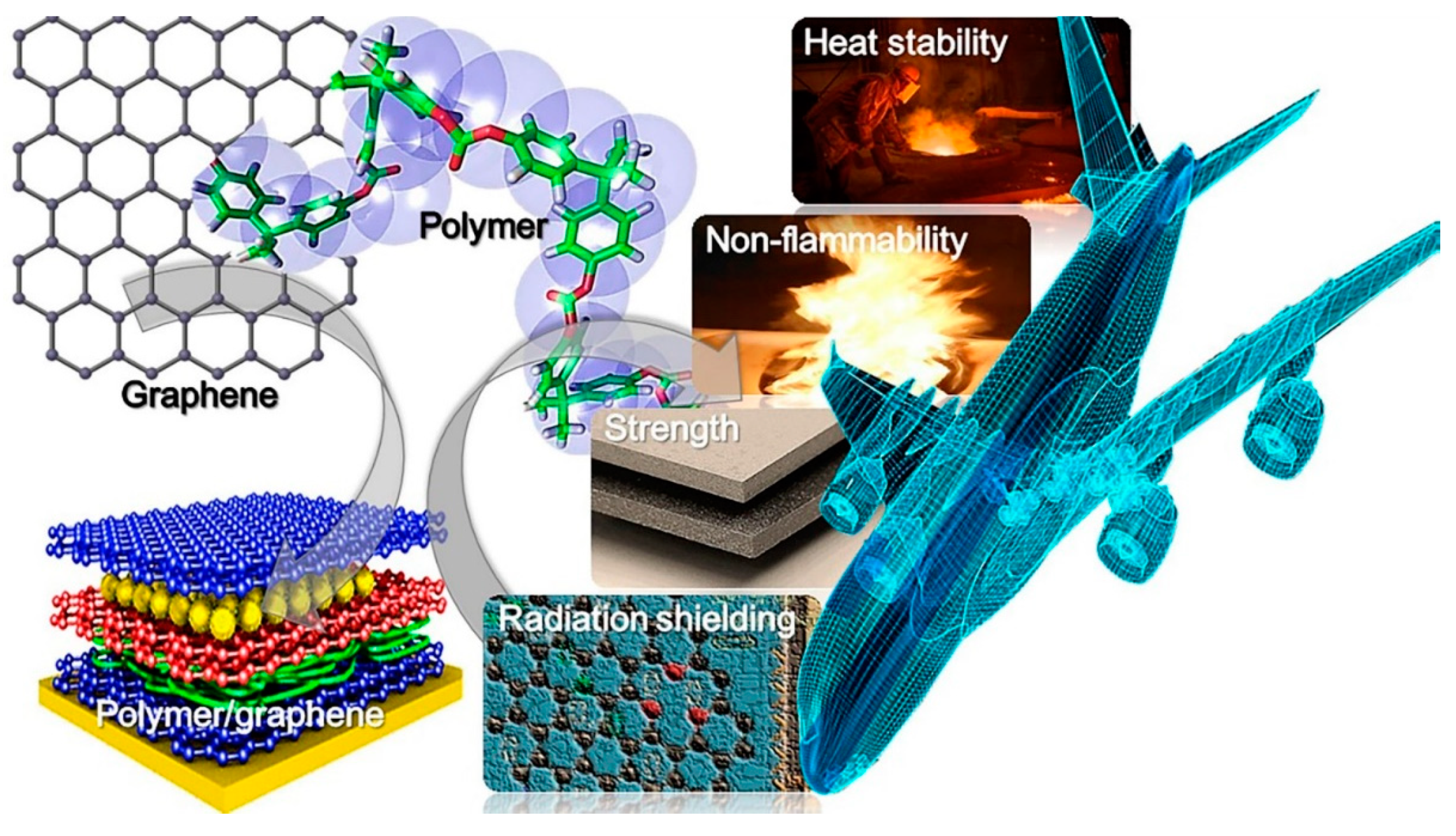

8.1. Aerospace Evolution: Lightweight Structural Components for Enhanced Performance

8.2. Advanced Electronics: High-Performance Conductive Materials and Flexible Circuits

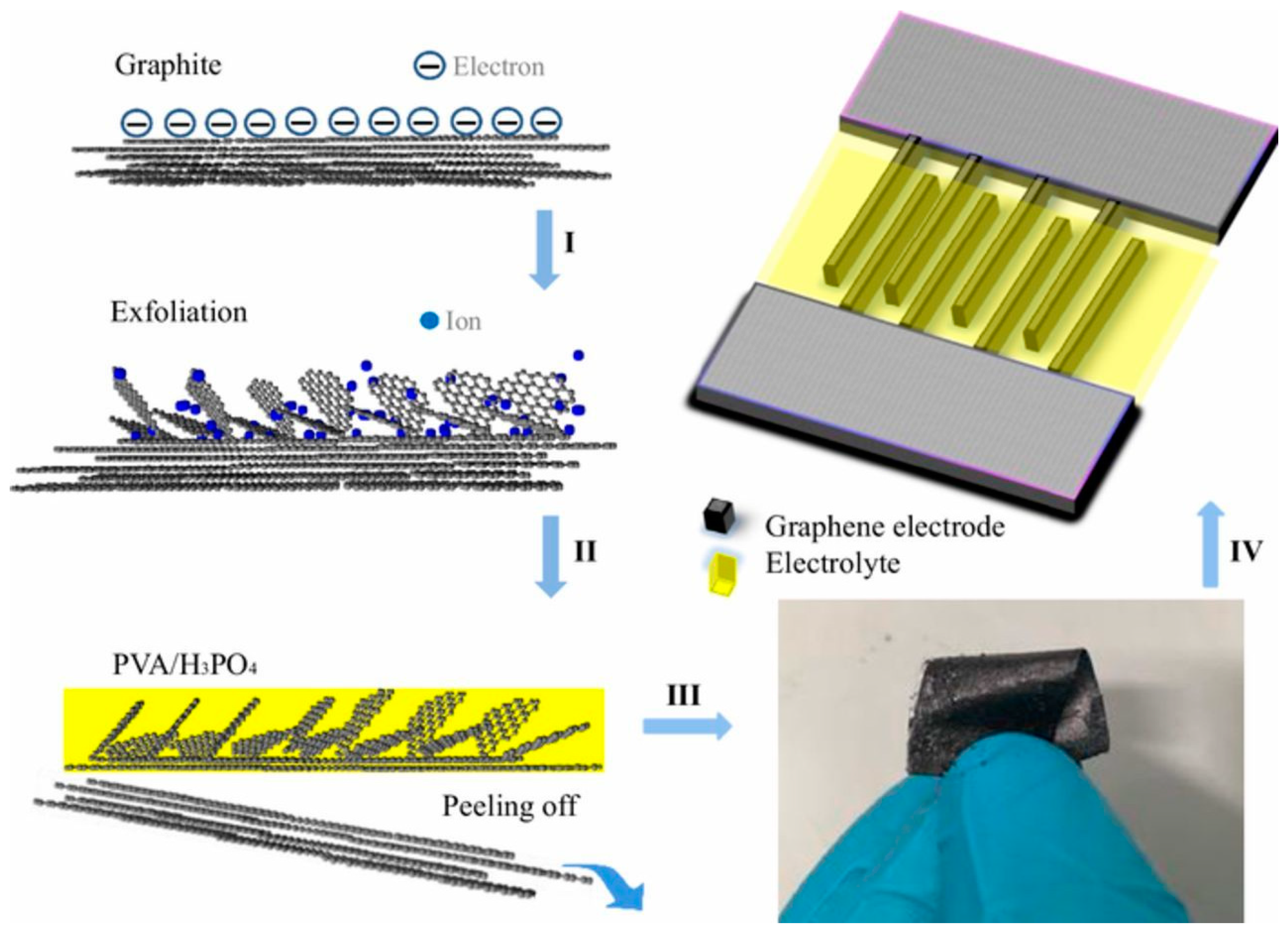

8.3. Energy Storage Revolution: Efficient Batteries and Supercapacitor

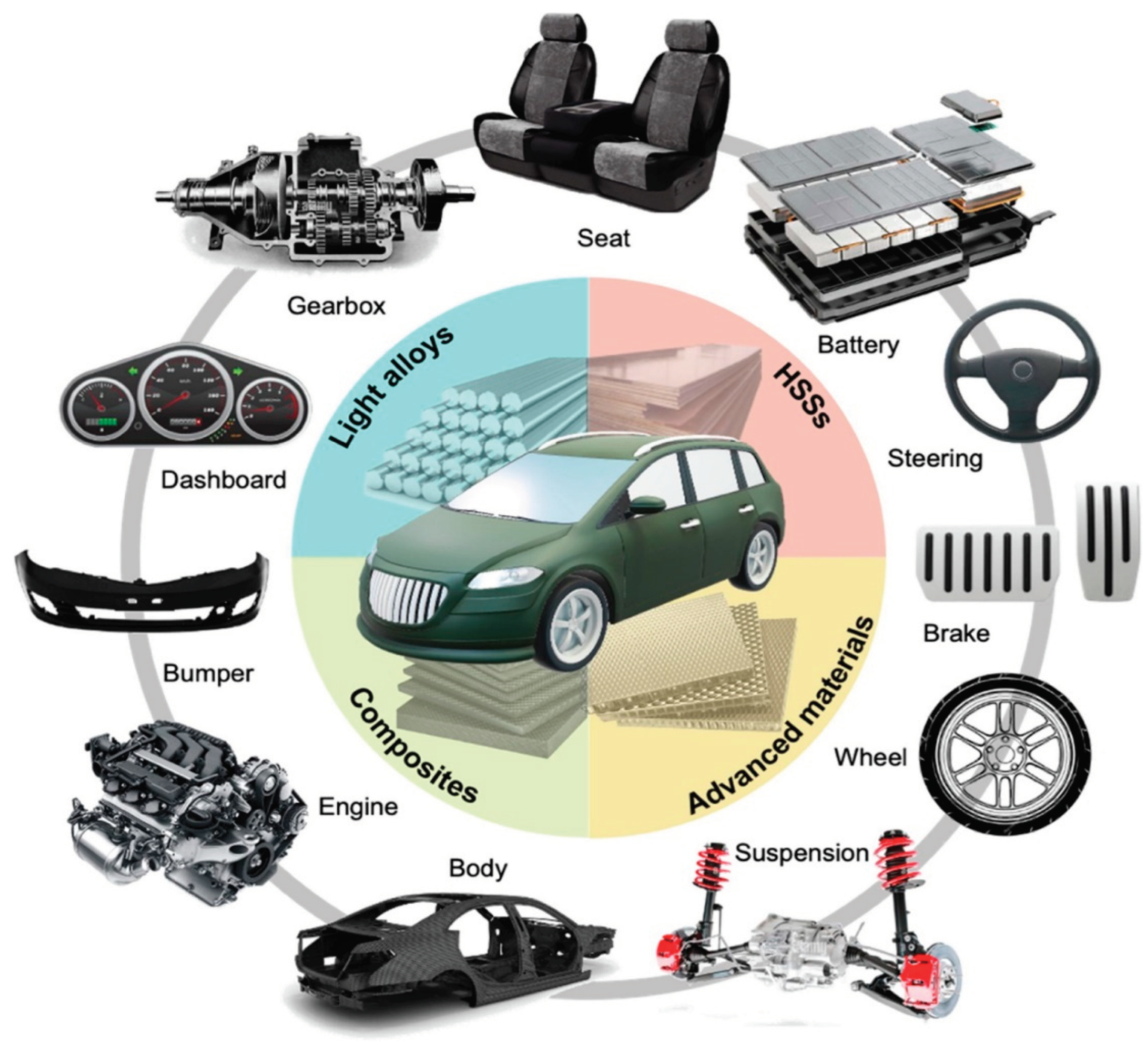

8.4. Transportation Innovation: Lightweight Automotive Components for Enhanced Efficiency

9. Conclusions

10. Future Perspectives

Author Contributions

Data Availability Statement

Conflicts of Interest

References

- Paniagua, S.A.; Kim, Y.; Henry, K.; Kumar, R.; Perry, J.W.; Marder, S.R. Surface-initiated polymerization from barium titanate nanoparticles for hybrid dielectric capacitors. ACS Appl. Mater. Interfaces 2014, 6, 3477–3482. [Google Scholar] [CrossRef] [PubMed]

- Dyachkova, T.P.; Khan, Y.A.; Burakova, E.A.; Galunin, E.V.; Shigabaeva, G.N.; Stolbov, D.N.; Titov, G.A.; Chapaksov, N.A.; Tkachev, A.G. Characteristics of Epoxy Composites Containing Carbon Nanotubes/Graphene Mixtures. Polymers 2023, 15, 1476. [Google Scholar] [CrossRef] [PubMed]

- Singh, P.; Singari, R.M.; Mishra, R.; Bajwa, G. A review on recent development on polymeric hybrid composite and analysis of their enhanced mechanical performance. Mater. Today: Proc. 2022, 56, 3692–3701. [Google Scholar] [CrossRef]

- Sinha, A.K.; Narang, H.K.; Bhattacharya, S. Mechanical properties of hybrid polymer composites: a review. J. Braz. Soc. Mech. Sci. 2020, 42, 1–13. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Puttegowda, M.; Thyavihalli Girijappa, Y.G.; Rangappa, S.M.; Siengchin, S. Effect of natural filler materials on fiber reinforced hybrid polymer composites: An Overview. J. Nat. Fibers 2022, 19, 4132–4147. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, K.; Dixit, A.R. A review on the mechanical properties of polymer composites reinforced by carbon nanotubes and graphene. Carbon Lett. 2021, 31, 149–165. [Google Scholar] [CrossRef]

- Luo, X.; Yang, G.; Schubert, D.W. Electrically conductive polymer composite containing hybrid graphene nanoplatelets and carbon nanotubes: synergistic effect and tunable conductivity anisotropy. Adv. Compos. Hybrid Mater. 2022, 1–13. [Google Scholar] [CrossRef]

- Abu-Okail, M.; Alsaleh, N.A.; Farouk, W.; Elsheikh, A.; Abu-Oqail, A.; Abdelraouf, Y.A.; Ghafaar, M.A. Effect of dispersion of alumina nanoparticles and graphene nanoplatelets on microstructural and mechanical characteristics of hybrid carbon/glass fibers reinforced polymer composite. J. Mater. Res. Technol. 2021, 14, 2624–2637. [Google Scholar] [CrossRef]

- Trache, D.; Thakur, V.K.; Boukherroub, R. Cellulose nanocrystals/graphene hybrids—a promising new class of materials for advanced applications. Nanomaterials 2020, 10, 1523. [Google Scholar] [CrossRef]

- Liu, C.; Wu, W.; Drummer, D.; Wang, Y.; Chen, Q.; Liu, X.; Schneider, K. Significantly enhanced thermal conductivity of polymer composites via establishing double-percolated expanded graphite/multi-layer graphene hybrid filler network. Eur. Polym. J. 2021, 160, 110768. [Google Scholar] [CrossRef]

- Latif, U.; Dickert, F.L. Graphene hybrid materials in gas sensing applications. Sensors 2015, 15, 30504–30524. [Google Scholar] [CrossRef]

- Gao, Y. Graphene and polymer composites for supercapacitor applications: a review. Nanoscale Res. Lett. 2017, 12, 387. [Google Scholar] [CrossRef]

- Kobyliukh, A.; Olszowska, K.; Szeluga, U.; Pusz, S. Iron oxides/graphene hybrid structures–Preparation, modification, and application as fillers of polymer composites. Adv. Colloid Interface Sci. 2020, 285, 102285. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, K.; Dixit, A.R. Carbon nanotube-and graphene-reinforced multiphase polymeric composites: review on their properties and applications. J. Mater. Sci. 2020, 55, 2682–2724. [Google Scholar] [CrossRef]

- Krusenbaum, A.; Grätz, S.; Tigineh, G.T.; Borchardt, L.; Kim, J.G. The mechanochemical synthesis of polymers. Chem. Soc. Rev. 2022, 51, 2873–2905. [Google Scholar] [CrossRef] [PubMed]

- Delogu, F.; Gorrasi, G.; Sorrentino, A. Fabrication of polymer nanocomposites via ball milling: Present status and future perspectives. Prog. Mater. Sci. 2017, 86, 75–126. [Google Scholar] [CrossRef]

- Baláž, P.; Achimovičová, M.; Baláž, M.; Billik, P.; Cherkezova-Zheleva, Z.; Criado, J.M.; Delogu, F.; Dutková, E.; Gaffet, E.; Gotor, F.J. Hallmarks of mechanochemistry: from nanoparticles to technology. Chem. Soc. Rev. 2013, 42, 7571–7637. [Google Scholar] [CrossRef] [PubMed]

- Jing, J.; Xiong, Y.; Shi, S.; Pei, H.; Chen, Y.; Lambin, P. Facile fabrication of lightweight porous FDM-Printed polyethylene/graphene nanocomposites with enhanced interfacial strength for electromagnetic interference shielding. Compos. Sci. Technol. 2021, 207, 108732. [Google Scholar] [CrossRef]

- Awasthi, G.P.; Kumar, D.; Shrestha, B.K.; Kim, J.; Kim, K.-S.; Park, C.H.; Kim, C.S. Layer–Structured partially reduced graphene oxide sheathed mesoporous MoS2 particles for energy storage applications. J. Colloid Interface Sci. 2018, 518, 234–241. [Google Scholar] [CrossRef] [PubMed]

- Ke, K.; Wang, Y.; Liu, X.-Q.; Cao, J.; Luo, Y.; Yang, W.; Xie, B.-H.; Yang, M.-B. A comparison of melt and solution mixing on the dispersion of carbon nanotubes in a poly (vinylidene fluoride) matrix. Compos. B. Eng. 2012, 43, 1425–1432. [Google Scholar] [CrossRef]

- Dunlop, M.J.; Bissessur, R. Nanocomposites based on graphene analogous materials and conducting polymers: a review. J. Mater. Sci. 2020, 55, 6721–6753. [Google Scholar] [CrossRef]

- Rafiee, M.A.; Rafiee, J.; Wang, Z.; Song, H.; Yu, Z.-Z.; Koratkar, N. Enhanced mechanical properties of nanocomposites at low graphene content. ACS nano 2009, 3, 3884–3890. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.; Kumar, V.; Yokozeki, T.; Goto, T.; Takahashi, T.; Koyanagi, J.; Wu, L.; Wang, R. Highly conductive graphene oxide/polyaniline hybrid polymer nanocomposites with simultaneously improved mechanical properties. Compos. Part A Appl. Sci. Manuf. 2016, 82, 100–107. [Google Scholar] [CrossRef]

- Ren, Y.; Zhang, Y.; Guo, H.; Lv, R.; Bai, S.-L. A double mixing process to greatly enhance thermal conductivity of graphene filled polyamide 6 composites. Compos. Part A Appl. Sci. Manuf. 2019, 126, 105578. [Google Scholar] [CrossRef]

- Barshutina, M.N.; Volkov, V.S.; Arsenin, A.V.; Yakubovsky, D.I.; Melezhik, A.V.; Blokhin, A.N.; Tkachev, A.G.; Lopachev, A.V.; Kondrashov, V.A. Biocompatible, electroconductive, and highly stretchable hybrid silicone composites based on few-layer graphene and CNTs. Nanomaterials 2021, 11, 1143. [Google Scholar] [CrossRef] [PubMed]

- Tarhini, A.; Tehrani-Bagha, A. Advances in preparation methods and conductivity properties of graphene-based polymer composites. Appl. Compos. Mater. 2023, 1–26. [Google Scholar] [CrossRef]

- Cromer, B.M.; Scheel, S.; Luinstra, G.A.; Coughlin, E.B.; Lesser, A.J. In-situ polymerization of isotactic polypropylene-nanographite nanocomposites. Polymer 2015, 80, 275–281. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhu, B.; Cai, X.; Yuan, X.; Zhao, S.; Yu, J.; Qiao, K.; Qin, R. Rapid in situ polymerization of polyacrylonitrile/graphene oxide nanocomposites as precursors for high-strength carbon nanofibers. ACS Appl. Mater. Interfaces 2021, 13, 16846–16858. [Google Scholar] [CrossRef]

- Gu, A.; Wu, J.; Shen, L.; Zhang, X.; Bao, N. High-strength GO/PA66 nanocomposite fibers via in situ precipitation and polymerization. Polymers 2021, 13, 1688. [Google Scholar] [CrossRef]

- Noh, Y.J.; Joh, H.-I.; Yu, J.; Hwang, S.H.; Lee, S.; Lee, C.H.; Kim, S.Y.; Youn, J.R. Ultra-high dispersion of graphene in polymer composite via solvent freefabrication and functionalization. Sci. Rep. 2015, 5, 9141. [Google Scholar] [CrossRef]

- Abdali, H.; Ajji, A. Preparation of electrospun nanocomposite nanofibers of polyaniline/poly (methyl methacrylate) with amino-functionalized graphene. Polymers 2017, 9, 453. [Google Scholar] [CrossRef]

- Huang, Z.-M.; Zhang, Y.-Z.; Kotaki, M.; Ramakrishna, S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos. Sci. Technol. 2003, 63, 2223–2253. [Google Scholar] [CrossRef]

- Gu, B.K.; Shin, M.K.; Sohn, K.W.; Kim, S.I.; Kim, S.J.; Kim, S.-K.; Lee, H.; Park, J.S. Direct fabrication of twisted nanofibers by electrospinning. Appl. Phys. Lett. 2007, 90, 263902. [Google Scholar] [CrossRef]

- Subramani, S.; Rajiv, S. Electrospun based polythioaniline/polyvinylalcohol/graphene oxide composite nanofibers for supercapacitor application. Ionics 2021, 27, 2203–2218. [Google Scholar] [CrossRef]

- Sarıipek, F.B.; Sevgi, F.; Dursun, S. Preparation of poly (ε-caprolactone) nanofibrous mats incorporating graphene oxide-silver nanoparticle hybrid composite by electrospinning method for potential antibacterial applications. Colloids Surf. A Physicochem. Eng. Asp. 2022, 653, 129969. [Google Scholar] [CrossRef]

- Sheng, K.; Bai, H.; Sun, Y.; Li, C.; Shi, G. Layer-by-layer assembly of graphene/polyaniline multilayer films and their application for electrochromic devices. Polymer 2011, 52, 5567–5572. [Google Scholar] [CrossRef]

- Xia, F.; Hu, X.; Sun, Y.; Luo, W.; Huang, Y. Layer-by-layer assembled MoO 2–graphene thin film as a high-capacity and binder-free anode for lithium-ion batteries. Nanoscale 2012, 4, 4707–4711. [Google Scholar] [CrossRef]

- Wang, L.; Wang, W.; Fu, Y.; Wang, J.; Lvov, Y.; Liu, J.; Lu, Y.; Zhang, L. Enhanced electrical and mechanical properties of rubber/graphene film through layer-by-layer electrostatic assembly. Compos. B. Eng. 2016, 90, 457–464. [Google Scholar] [CrossRef]

- Song, N.; Gao, Z.; Li, X. Tailoring nanocomposite interfaces with graphene to achieve high strength and toughness. Sci. Adv. 2020, 6, eaba7016. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Tang, J.; Gooding, J.J. Strategies for chemical modification of graphene and applications of chemically modified graphene. J. Mater. Chem. 2012, 22, 12435–12452. [Google Scholar] [CrossRef]

- Jakubczak, M.; Jastrzębska, A.M. A review on development of ceramic-graphene based nanohybrid composite systems in biological applications. Front. Chem. 2021, 9, 685014. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Zhou, H.; Deng, H.; Ji, W.; Tian, K.; Ma, Z.; Zhang, K.; Fu, Q. "Toolbox" for the processing of functional polymer composites. Nanomicro. Lett. 2022, 14, 35. [Google Scholar] [CrossRef] [PubMed]

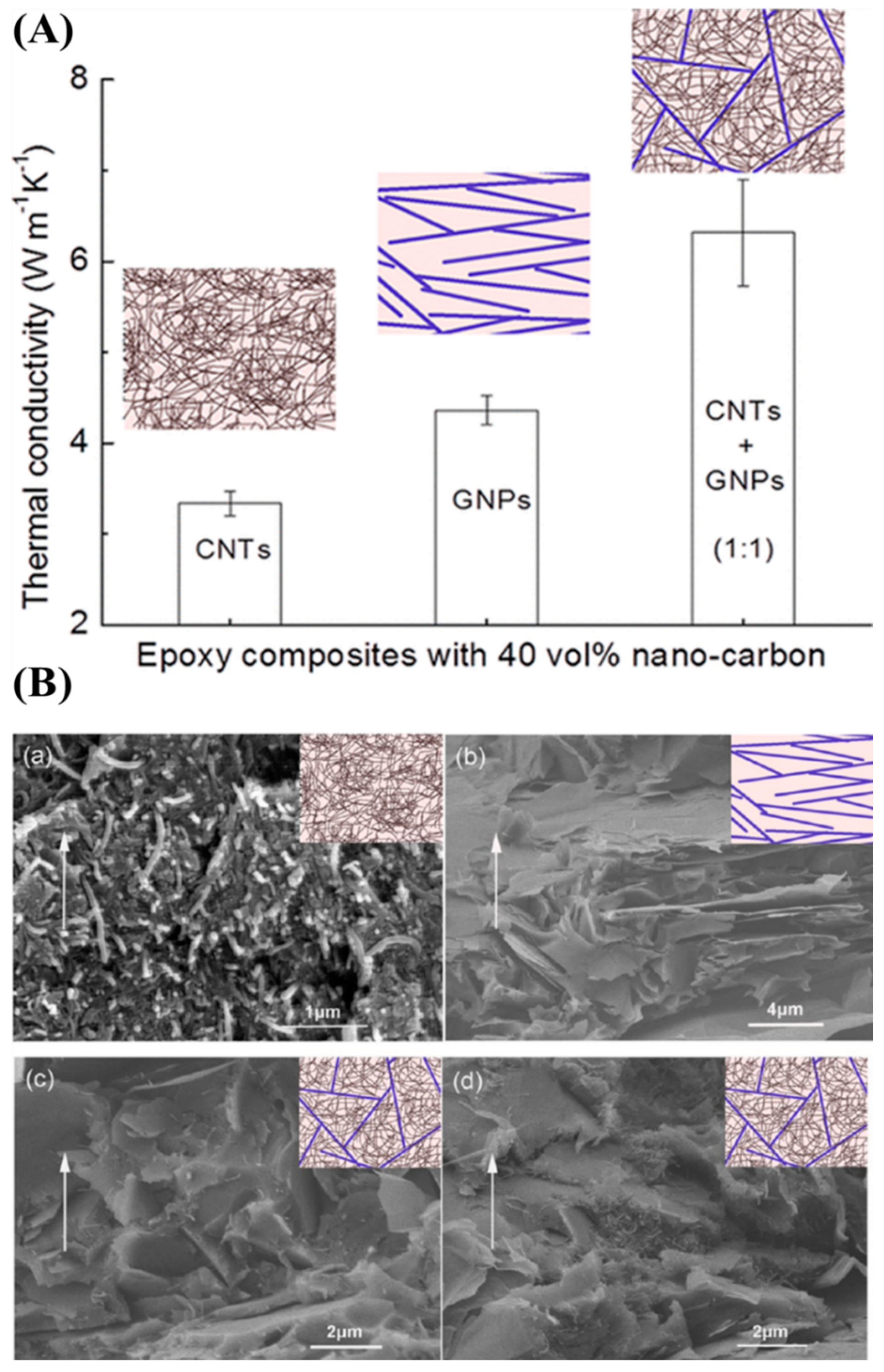

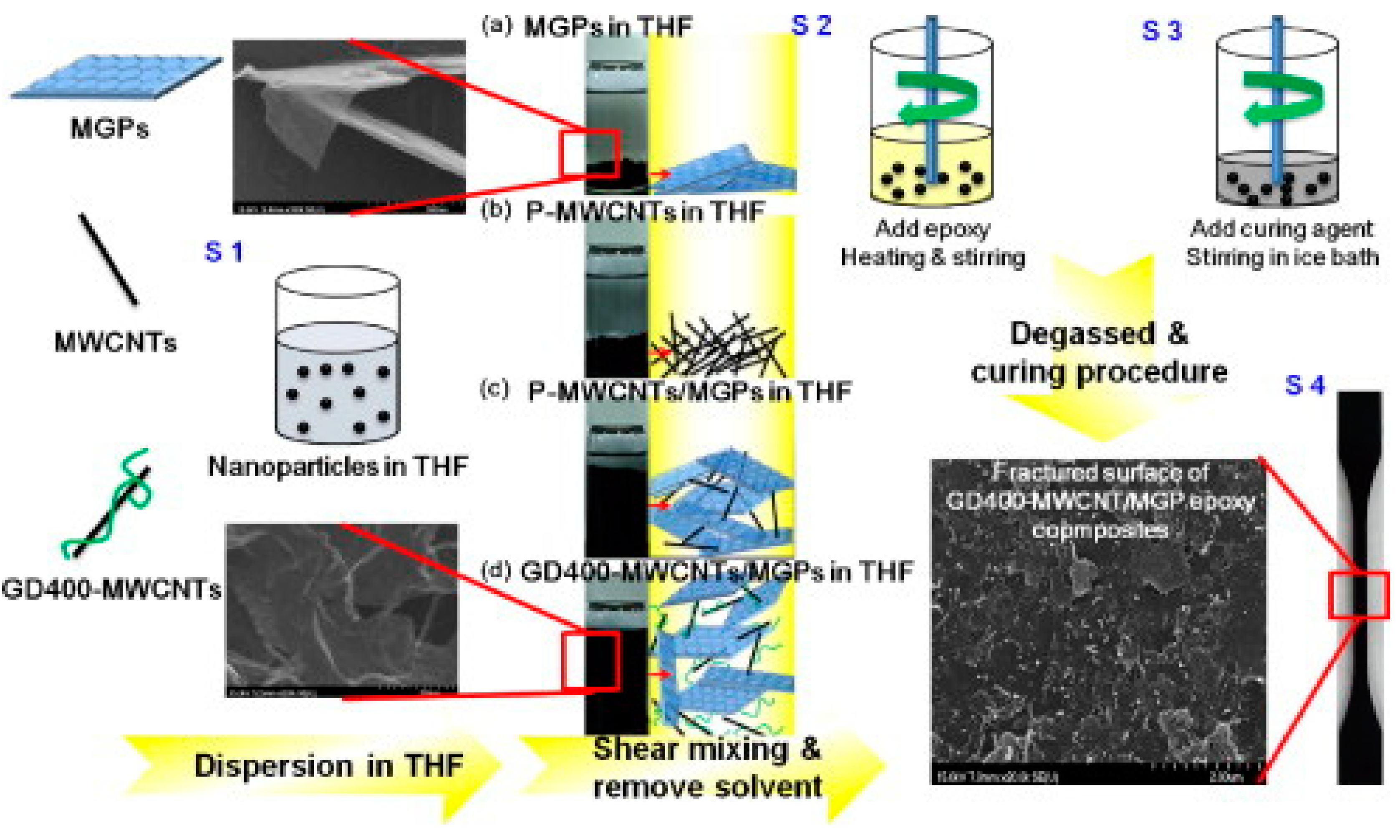

- Huang, X.; Zhi, C.; Jiang, P. Toward effective synergetic effects from graphene nanoplatelets and carbon nanotubes on thermal conductivity of ultrahigh volume fraction nanocarbon epoxy composites. J. Phys. Chem. C 2012, 116, 23812–23820. [Google Scholar] [CrossRef]

- Yang, S.-Y.; Lin, W.-N.; Huang, Y.-L.; Tien, H.-W.; Wang, J.-Y.; Ma, C.-C.M.; Li, S.-M.; Wang, Y.-S. Synergetic effects of graphene platelets and carbon nanotubes on the mechanical and thermal properties of epoxy composites. Carbon 2011, 49, 793–803. [Google Scholar] [CrossRef]

- Turaka, S.; Bandaru, A.K. Enhancement in Mechanical Properties of Glass/Epoxy Composites by a Hybrid Combination of Multi-Walled Carbon Nanotubes and Graphene Nanoparticles. Polymers 2023, 15, 1189. [Google Scholar] [CrossRef] [PubMed]

- Madarvoni, S.; Sreekanth, R.P. Mechanical Characterization of Graphene—Hexagonal Boron Nitride-Based Kevlar–Carbon Hybrid Fabric Nanocomposites. Polymers 2022, 14, 2559. [Google Scholar] [CrossRef] [PubMed]

- Bafakeeh, O.T.; Shewakh, W.M.; Abu-Oqail, A.; Abd-Elaziem, W.; Abdel Ghafaar, M.; Abu-Okail, M. Synthesis and characterization of hybrid fiber-reinforced polymer by adding ceramic nanoparticles for aeronautical structural applications. Polymers 2021, 13, 4116. [Google Scholar] [CrossRef]

- Valentini, L.; Bon, S.B.; López-Manchado, M.A.; Verdejo, R.; Pappalardo, L.; Bolognini, A.; Alvino, A.; Borsini, S.; Berardo, A.; Pugno, N. Synergistic effect of graphene nanoplatelets and carbon black in multifunctional EPDM nanocomposites. Compos. Sci. Technol. 2016, 128, 123–130. [Google Scholar] [CrossRef]

- Zhao, Y.-H.; Zhang, Y.-F.; Bai, S.-L.; Yuan, X.-W. Carbon fibre/graphene foam/polymer composites with enhanced mechanical and thermal properties. Compos. B. Eng. 2016, 94, 102–108. [Google Scholar] [CrossRef]

- Du, S.-S.; Li, F.; Xiao, H.-M.; Li, Y.-Q.; Hu, N.; Fu, S.-Y. Tensile and flexural properties of graphene oxide coated-short glass fiber reinforced polyethersulfone composites. Compos. B. Eng. 2016, 99, 407–415. [Google Scholar] [CrossRef]

- Jiang, S.; Li, Q.; Wang, J.; He, Z.; Zhao, Y.; Kang, M. Multiscale graphene oxide–carbon fiber reinforcements for advanced polyurethane composites. Compos. Part A Appl. Sci. Manuf. 2016, 87, 1–9. [Google Scholar] [CrossRef]

- Lin, Y.; Liu, S.; Peng, J.; Liu, L. The filler–rubber interface and reinforcement in styrene butadiene rubber composites with graphene/silica hybrids: A quantitative correlation with the constrained region. Compos. Part A Appl. Sci. Manuf. 2016, 86, 19–30. [Google Scholar] [CrossRef]

- Pedrazzoli, D.; Pegoretti, A.; Kalaitzidou, K. Synergistic effect of graphite nanoplatelets and glass fibers in polypropylene composites. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Li, F.; Liu, Y.; Qu, C.-B.; Xiao, H.-M.; Hua, Y.; Sui, G.-X.; Fu, S.-Y. Enhanced mechanical properties of short carbon fiber reinforced polyethersulfone composites by graphene oxide coating. Polymer 2015, 59, 155–165. [Google Scholar] [CrossRef]

- Qian, Y.; Wu, H.; Yuan, D.; Li, X.; Yu, W.; Wang, C. In situ polymerization of polyimide-based nanocomposites via covalent incorporation of functionalized graphene nanosheets for enhancing mechanical, thermal, and electrical properties. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Fang, H.; Zhang, X.; Zhao, Y.; Bai, S.-L. Dense graphene foam and hexagonal boron nitride filled PDMS composites with high thermal conductivity and breakdown strength. Compos. Sci. Technol. 2017, 152, 243–253. [Google Scholar] [CrossRef]

- Hassanzadeh-Aghdam, M.K.; Ansari, R.; Deylami, H.M. Influence of graphene nanoplatelets on thermal transport performance of carbon fiber-polymer hybrid composites: Overall assessment of microstructural aspects. Int. J. Therm. Sci. 2022, 171, 107209. [Google Scholar] [CrossRef]

- Feng, Y.; Li, X.; Zhao, X.; Ye, Y.; Zhou, X.; Liu, H.; Liu, C.; Xie, X. Synergetic improvement in thermal conductivity and flame retardancy of epoxy/silver nanowires composites by incorporating "branch-like" flame-retardant functionalized graphene. ACS Appl. Mater. Interfaces 2018, 10, 21628–21641. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Wu, W.; Chen, Q.; Wang, Y.; Cui, S.; Yang, H. 3D expanded graphite frameworks for dual-functional polymer composites with exceptional thermal conductive and electromagnetic interference shielding capabilities. ACS Appl. Electron. Mater. 2022, 4, 707–717. [Google Scholar] [CrossRef]

- Barani, Z.; Mohammadzadeh, A.; Geremew, A.; Huang, C.Y.; Coleman, D.; Mangolini, L.; Kargar, F.; Balandin, A.A. Thermal properties of the binary-filler hybrid composites with graphene and copper nanoparticles. Adv. Funct. Mater. 2020, 30, 1904008. [Google Scholar] [CrossRef]

- Yao, Y.; Sun, J.; Zeng, X.; Sun, R.; Xu, J.B.; Wong, C.P. Construction of 3D skeleton for polymer composites achieving a high thermal conductivity. Small 2018, 14, 1704044. [Google Scholar] [CrossRef]

- Che, J.; Wu, K.; Lin, Y.; Wang, K.; Fu, Q. Largely improved thermal conductivity of HDPE/expanded graphite/carbon nanotubes ternary composites via filler network-network synergy. Compos. Part A Appl. Sci. Manuf. 2017, 99, 32–40. [Google Scholar] [CrossRef]

- Wu, K.; Xue, Y.; Yang, W.; Chai, S.; Chen, F.; Fu, Q. Largely enhanced thermal and electrical conductivity via constructing double percolated filler network in polypropylene/expanded graphite–multi-wall carbon nanotubes ternary composites. Compos. Sci. Technol. 2016, 130, 28–35. [Google Scholar] [CrossRef]

- Sun, R.; Yao, H.; Zhang, H.-B.; Li, Y.; Mai, Y.-W.; Yu, Z.-Z. Decoration of defect-free graphene nanoplatelets with alumina for thermally conductive and electrically insulating epoxy composites. Compos. Sci. Technol. 2016, 137, 16–23. [Google Scholar] [CrossRef]

- Shao, L.; Shi, L.; Li, X.; Song, N.; Ding, P. Synergistic effect of BN and graphene nanosheets in 3D framework on the enhancement of thermal conductive properties of polymeric composites. Compos. Sci. Technol. 2016, 135, 83–91. [Google Scholar] [CrossRef]

- Yu, J.; Qian, R.; Jiang, P. Enhanced thermal conductivity for PVDF composites with a hybrid functionalized graphene sheet-nanodiamond filler. Fibers Polym. 2013, 14, 1317–1323. [Google Scholar] [CrossRef]

- Kim, H.; Abdala, A.A.; Macosko, C.W. Graphene/polymer nanocomposites. Macromolecules 2010, 43, 6515–6530. [Google Scholar] [CrossRef]

- Mohan, V.B.; Jayaraman, K.; Bhattacharyya, D. Hybridization of graphene-reinforced two polymer nanocomposites. Int. J. Smart Nano Mater. 2016, 7, 179–201. [Google Scholar] [CrossRef]

- Stankovich, S.; Dikin, D.A.; Dommett, G.H.; Kohlhaas, K.M.; Zimney, E.J.; Stach, E.A.; Piner, R.D.; Nguyen, S.T.; Ruoff, R.S. Graphene-based composite materials. Nature 2006, 442, 282–286. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Yao, Q.; Bi, H.; Huang, F.; Wang, Q.; Chen, L. PANI/graphene nanocomposite films with high thermoelectric properties by enhanced molecular ordering. J. Mater. Chem. A 2015, 3, 7086–7092. [Google Scholar] [CrossRef]

- Luong, N.D.; Pahimanolis, N.; Hippi, U.; Korhonen, J.T.; Ruokolainen, J.; Johansson, L.-S.; Nam, J.-D.; Seppälä, J. Graphene/cellulose nanocomposite paper with high electrical and mechanical performances. J. Mater. Chem. 2011, 21, 13991–13998. [Google Scholar] [CrossRef]

- Bose, S.; Kuila, T.; Uddin, M.E.; Kim, N.H.; Lau, A.K.; Lee, J.H. In-situ synthesis and characterization of electrically conductive polypyrrole/graphene nanocomposites. Polymer 2010, 51, 5921–5928. [Google Scholar] [CrossRef]

- Saberi, M.; Ansari, R.; Hassanzadeh-Aghdam, M.K. Predicting the electrical conductivity of short carbon fiber/graphene nanoplatelet/polymer composites. Mater. Chem. Phys. 2023, 309, 128324. [Google Scholar] [CrossRef]

- Imran, K.A.; Shivakumar, K.N. Graphene-modified carbon/epoxy nanocomposites: Electrical, thermal and mechanical properties. J. Compos. Mater. 2019, 53, 93–106. [Google Scholar] [CrossRef]

- Curtin, W. Dimensionality and size effects on the strength of fiber-reinforced composites. Compos. Sci. Technol. 2000, 60, 543–551. [Google Scholar] [CrossRef]

- Chen, J.; Gao, X.; Song, W. Effect of various carbon nanofillers and different filler aspect ratios on the thermal conductivity of epoxy matrix nanocomposites. Results Phys. 2019, 15, 102771. [Google Scholar] [CrossRef]

- Osman, A.; Elhakeem, A.; Kaytbay, S.; Ahmed, A. A comprehensive review on the thermal, electrical, and mechanical properties of graphene-based multifunctional epoxy composites. Adv. Compos. Mater. 2022, 5, 547–605. [Google Scholar] [CrossRef]

- Gong, S.; Cheng, W. One-dimensional nanomaterials for soft electronics. Adv. Electron. Mater. 2017, 3, 1600314. [Google Scholar] [CrossRef]

- Papageorgiou, D.G.; Li, Z.; Liu, M.; Kinloch, I.A.; Young, R.J. Mechanisms of mechanical reinforcement by graphene and carbon nanotubes in polymer nanocomposites. Nanoscale 2020, 12, 2228–2267. [Google Scholar] [CrossRef]

- Markandan, K.; Lai, C.Q. Enhanced mechanical properties of 3D printed graphene-polymer composite lattices at very low graphene concentrations. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105726. [Google Scholar] [CrossRef]

- Fu, S.-Y.; Feng, X.-Q.; Lauke, B.; Mai, Y.-W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos. B. Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Bokobza, L. Elastomer Nanocomposites: Effect of Filler–Matrix and Filler–Filler Interactions. Polymers 2023, 15, 2900. [Google Scholar] [CrossRef]

- Kim, K.J.; Kim, J.; Yu, W.-R.; Youk, J.H.; Lee, J. Improved tensile strength of carbon fibers undergoing catalytic growth of carbon nanotubes on their surface. Carbon 2013, 54, 258–267. [Google Scholar] [CrossRef]

- Nassar, M.M.; Sider, I. Evaluation of novel compatibility strategies for improving the performance of recycled low-density polyethylene based biocomposites. Polymers 2021, 13, 3486. [Google Scholar] [CrossRef]

- Li, M.; Tang, C.; Zhang, L.; Shang, B.; Zheng, S.; Qi, S. A thermally conductive and insulating epoxy polymer composite with hybrid filler of modified copper nanowires and graphene oxide. J. Mater. Sci. Mater. Electron. 2018, 29, 4948–4954. [Google Scholar] [CrossRef]

- Govindaraj, P.; Sokolova, A.; Salim, N.; Juodkazis, S.; Fuss, F.K.; Fox, B.; Hameed, N. Distribution states of graphene in polymer nanocomposites: A review. Compos. B. Eng. 2021, 226, 109353. [Google Scholar] [CrossRef]

- Romasanta, L.J.; Hernández, M.; López-Manchado, M.A.; Verdejo, R. Functionalised graphene sheets as effective high dielectric constant fillers. Nanoscale Res. Lett. 2011, 6, 1–6. [Google Scholar] [CrossRef]

- Vigneshwaran, G.; Shanmugavel, B.P.; Paskaramoorthy, R.; Harish, S. Tensile, impact, and mode-I behaviour of glass fiber-reinforced polymer composite modified by graphene nanoplatelets. Arch. Civ. Mech. Eng. 2020, 20, 1–15. [Google Scholar] [CrossRef]

- Tuichai, W.; Karaphun, A.; Ruttanapun, C. Improved dielectric properties of PVDF polymer composites filled with Ag nanomaterial deposited reduced graphene oxide (rGO) hybrid particles. Mater. Res. Bull. 2022, 145, 111552. [Google Scholar] [CrossRef]

- Swolfs, Y.; McMeeking, R.M.; Verpoest, I.; Gorbatikh, L. The effect of fibre dispersion on initial failure strain and cluster development in unidirectional carbon/glass hybrid composites. Compos. Part A Appl. Sci. Manuf. 2015, 69, 279–287. [Google Scholar] [CrossRef]

- Jalalvand, M.; Czél, G.; Wisnom, M.R. Numerical modelling of the damage modes in UD thin carbon/glass hybrid laminates. Compos. Sci. Technol. 2014, 94, 39–47. [Google Scholar] [CrossRef]

- Zhang, Y.; Park, S.-J. Influence of the nanoscaled hybrid based on nanodiamond@ graphene oxide architecture on the rheological and thermo-physical performances of carboxylated-polymeric composites. Compos. Part A Appl. Sci. Manuf. 2018, 112, 356–364. [Google Scholar] [CrossRef]

- Perumal, S.; Atchudan, R.; Cheong, I.W. Recent studies on dispersion of graphene–polymer composites. Polymers 2021, 13, 2375. [Google Scholar] [CrossRef]

- Huang, Y.Y.; Terentjev, E.M. Dispersion of carbon nanotubes: mixing, sonication, stabilization, and composite properties. Polymers 2012, 4, 275–295. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, G.; Tang, M.; Zhou, L.; Li, J.; Fan, X.; Shi, X.; Qin, J. Synergistic effect of carbon nanotube and graphene nanoplates on the mechanical, electrical and electromagnetic interference shielding properties of polymer composites and polymer composite foams. Chem. Eng. J. 2018, 353, 381–393. [Google Scholar] [CrossRef]

- Chiappone, A.; Roppolo, I.; Naretto, E.; Fantino, E.; Calignano, F.; Sangermano, M.; Pirri, F. Study of graphene oxide-based 3D printable composites: Effect of the in situ reduction. Compos. B. Eng. 2017, 124, 9–15. [Google Scholar] [CrossRef]

- Seretis, G.; Nitodas, S.; Mimigianni, P.; Kouzilos, G.; Manolakos, D.; Provatidis, C. On the post-curing of graphene nanoplatelets reinforced hand lay-up glass fabric/epoxy nanocomposites. Compos. B. Eng. 2018, 140, 133–138. [Google Scholar] [CrossRef]

- Pavan, G.; Singh, K.K. Elevated thermal conditioning effect on flexural strength of GFRP laminates: An experimental and statistical approach. Mater. Today Commun. 2021, 26, 101809. [Google Scholar] [CrossRef]

- Sivasankaraiah, T.; Lokavarapu, B.R.; Rajesh, J.V. post-curing effect on flexural strength of glass epoxy composites. Mater. Today: Proc. 2021, 38, 3320–3331. [Google Scholar] [CrossRef]

- Ahmadi-Moghadam, B.; Sharafimasooleh, M.; Shadlou, S.; Taheri, F. Effect of functionalization of graphene nanoplatelets on the mechanical response of graphene/epoxy composites. Mater. Des. 2015, 66, 142–149. [Google Scholar] [CrossRef]

- Tian, J.; Xu, T.; Tan, Y.; Zhang, Z.; Tang, B.; Sun, Z. Effects of non-covalent functionalized graphene oxide with hyperbranched polyesters on mechanical properties and mechanism of epoxy composites. Materials 2019, 12, 3103. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Lin, Y.-C.; Chung, J.H.; Chiu, H.-Y.; Yeh, N.-L.; Chang, S.-J.; Chan, C.-H.; Shih, C.-C.; Chen, G.-Y. Enhancing Cementitious Composites with Functionalized Graphene Oxide-Based Materials: Surface Chemistry and Mechanisms. Int. J. Mol. Sci. 2023, 24, 10461. [Google Scholar] [CrossRef]

- Sagadevan, S.; Shahid, M.M.; Yiqiang, Z.; Oh, W.-C.; Soga, T.; Anita Lett, J.; Alshahateet, S.F.; Fatimah, I.; Waqar, A.; Paiman, S. Functionalized graphene-based nanocomposites for smart optoelectronic applications. Nanotechnol. Rev. 2021, 10, 605–635. [Google Scholar] [CrossRef]

- Maio, A.; Pibiri, I.; Morreale, M.; Mantia, F.P.L.; Scaffaro, R. An overview of functionalized graphene nanomaterials for advanced applications. Nanomaterials 2021, 11, 1717. [Google Scholar] [CrossRef]

- Das, T.K.; Prusty, S. Graphene-based polymer composites and their applications. Polym. Plast. Technol. Eng. 2013, 52, 319–331. [Google Scholar] [CrossRef]

- Kausar, A.; Rafique, I.; Muhammad, B. Aerospace application of polymer nanocomposite with carbon nanotube, graphite, graphene oxide, and nanoclay. Polym. Plast. Technol. Eng. 2017, 56, 1438–1456. [Google Scholar] [CrossRef]

- Kausar, A.; Ahmad, I.; Eisa, M.; Maaza, M. Graphene Nanocomposites in Space Sector—Fundamentals and Advancements. C 2023, 9, 29. [Google Scholar] [CrossRef]

- Wang, B.; Duan, Y.; Xin, Z.; Yao, X.; Abliz, D.; Ziegmann, G. Fabrication of an enriched graphene surface protection of carbon fiber/epoxy composites for lightning strike via a percolating-assisted resin film infusion method. Compos. Sci. Technol. 2018, 158, 51–60. [Google Scholar] [CrossRef]

- Abadal, S.; Alarcón, E.; Cabellos-Aparicio, A.; Lemme, M.C.; Nemirovsky, M. Graphene-enabled wireless communication for massive multicore architectures. IEEE Commun. Mag. 2013, 51, 137–143. [Google Scholar] [CrossRef]

- Raimondo, M.; Guadagno, L.; Speranza, V.; Bonnaud, L.; Dubois, P.; Lafdi, K. Multifunctional graphene/POSS epoxy resin tailored for aircraft lightning strike protection. Compos. B. Eng. 2018, 140, 44–56. [Google Scholar] [CrossRef]

- Scalia, T.; Bonventre, L.; Terranova, M.L. From Protosolar Space to Space Exploration: The Role of Graphene in Space Technology and Economy. Nanomaterials 2023, 13, 680. [Google Scholar] [CrossRef] [PubMed]

- An, F.; Li, X.; Min, P.; Liu, P.; Jiang, Z.-G.; Yu, Z.-Z. Vertically aligned high-quality graphene foams for anisotropically conductive polymer composites with ultrahigh through-plane thermal conductivities. ACS Appl. Mater. Interfaces 2018, 10, 17383–17392. [Google Scholar] [CrossRef]

- Azadmanjiri, J.; Srivastava, V.K.; Kumar, P.; Nikzad, M.; Wang, J.; Yu, A. Two-and three-dimensional graphene-based hybrid composites for advanced energy storage and conversion devices. J. Mater. Chem. A 2018, 6, 702–734. [Google Scholar] [CrossRef]

- Zalba, B.; Marı́n, J.M.; Cabeza, L.F.; Mehling, H. Review on thermal energy storage with phase change: materials, heat transfer analysis and applications. Appl. Therm. Eng. 2003, 23, 251–283. [Google Scholar] [CrossRef]

- Kwon, Y.-J.; Park, J.-B.; Jeon, Y.-P.; Hong, J.-Y.; Park, H.-S.; Lee, J.-U. A review of polymer composites based on carbon fillers for thermal management applications: design, preparation, and properties. Polymers 2021, 13, 1312. [Google Scholar] [CrossRef] [PubMed]

- Ponnamma, D.; Guo, Q.; Krupa, I.; Al-Maadeed, M.A.S.; Varughese, K.; Thomas, S.; Sadasivuni, K.K. Graphene and graphitic derivative filled polymer composites as potential sensors. Phys. Chem. Chem. Phys. 2015, 17, 3954–3981. [Google Scholar] [CrossRef] [PubMed]

- Zeng, X.; Ye, L.; Yu, S.; Li, H.; Sun, R.; Xu, J.; Wong, C.-P. Artificial nacre-like papers based on non-covalent functionalized boron nitride nanosheets with excellent mechanical and thermally conductive properties. Nanoscale 2015, 7, 6774–6781. [Google Scholar] [CrossRef]

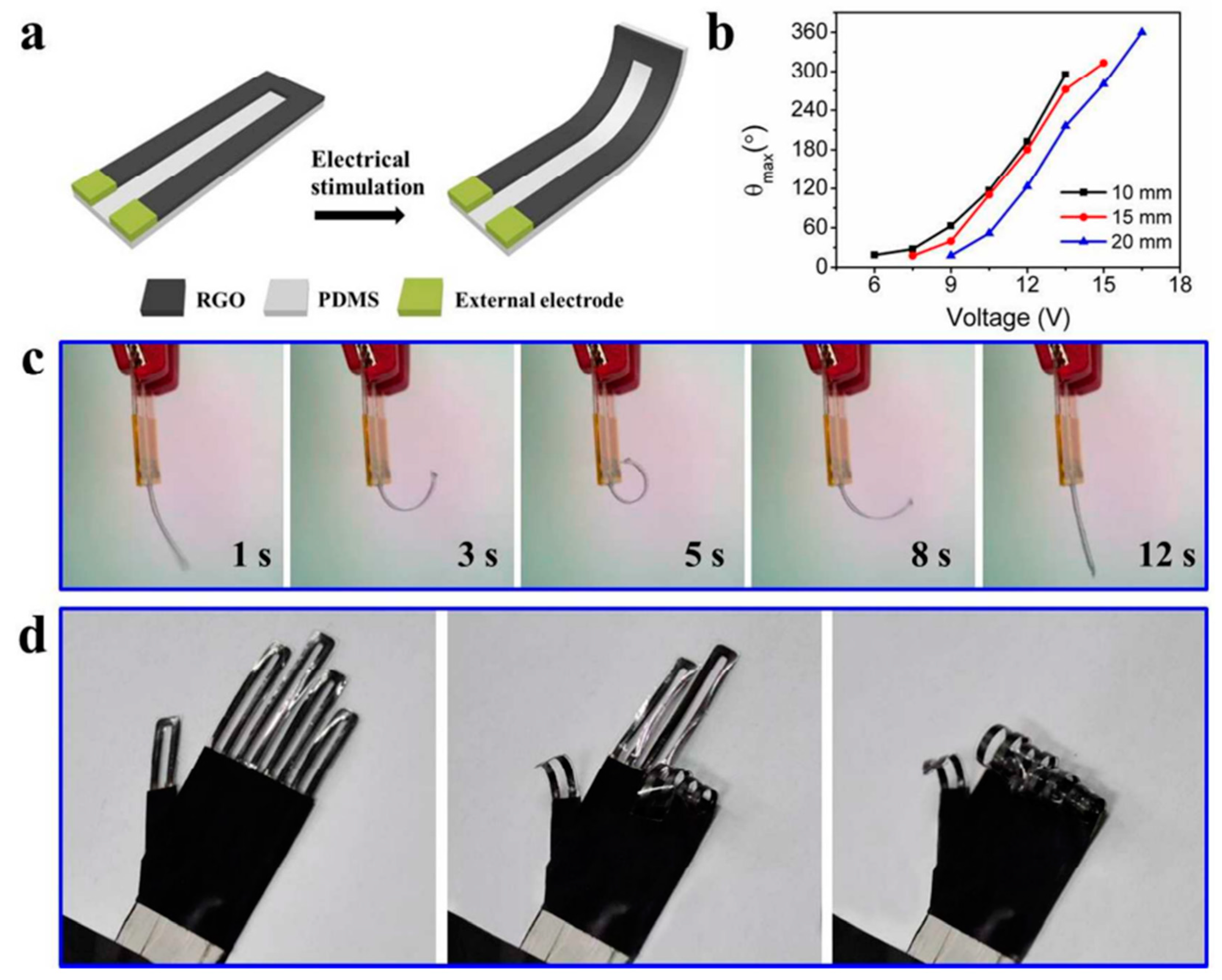

- Le Ferrand, H.; Chabi, S.; Agarwala, S. 3D assembly of graphene nanomaterials for advanced electronics. Adv. Intell. Syst. 2020, 2, 1900151. [Google Scholar] [CrossRef]

- Li, W.; Li, F.; Li, H.; Su, M.; Gao, M.; Li, Y.; Su, D.; Zhang, X.; Song, Y. Flexible circuits and soft actuators by printing assembly of graphene. ACS Appl. Mater. Interfaces 2016, 8, 12369–12376. [Google Scholar] [CrossRef]

- Zhu, J.; Yang, D.; Yin, Z.; Yan, Q.; Zhang, H. Graphene and graphene-based materials for energy storage applications. Small 2014, 10, 3480–3498. [Google Scholar] [CrossRef]

- Ramachandran, T.; Sana, S.S.; Kumar, K.D.; Kumar, Y.A.; Hegazy, H.; Kim, S.C. Asymmetric supercapacitors: Unlocking the energy storage revolution. J. Energy Storage 2023, 73, 109096. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, H.; Zhang, Q.; Liu, Y.; Chen, J.; Guo, Z. Recent advances in 3D graphene architectures and their composites for energy storage applications. Small 2019, 15, 1803858. [Google Scholar] [CrossRef]

- He, D.; Marsden, A.J.; Li, Z.; Zhao, R.; Xue, W.; Bissett, M.A. Fabrication of a graphene-based paper-like electrode for flexible solid-state supercapacitor devices. J. Electrochem. Soc. 2018, 165, A3481. [Google Scholar] [CrossRef]

- Elmarakbi, A.; El-Safty, S.; Martorana, B.; Azoti, W. Nanocomposites for automotive: enhanced graphene-based polymer materials and multi-scale approach. Int. J. Automot. Technol. 2016, 2, 155–166. [Google Scholar]

- Kumar, A.; Sharma, K.; Dixit, A.R. A review of the mechanical and thermal properties of graphene and its hybrid polymer nanocomposites for structural applications. J. Mater. Sci. 2019, 54, 5992–6026. [Google Scholar] [CrossRef]

- Joost, W.J. Reducing vehicle weight and improving US energy efficiency using integrated computational materials engineering. Jom 2012, 64, 1032–1038. [Google Scholar] [CrossRef]

- Amjad, S.; Neelakrishnan, S.; Rudramoorthy, R. Review of design considerations and technological challenges for successful development and deployment of plug-in hybrid electric vehicles. Renew. Sust. Energ. Rev. 2010, 14, 1104–1110. [Google Scholar] [CrossRef]

- Unnikrishnan, V.; Zabihi, O.; Li, Q.; Ahmadi, M.; Ferdowsi, M.R.G.; Kannangara, T.; Blanchard, P.; Kiziltas, A.; Joseph, P.; Naebe, M. Multifunctional PA6 composites using waste glass fiber and green metal organic framework/graphene hybrids. Polym. Compos. 2022, 43, 5877–5893. [Google Scholar] [CrossRef]

- Friedrich, K.; Almajid, A.A. Manufacturing aspects of advanced polymer composites for automotive applications. Appl. Compos. Mater. 2013, 20, 107–128. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 110994. [Google Scholar] [CrossRef]

| Hybrid Filler | Hybrid Filler Content | Matrix | Preparation technique | Young's modulus and enhanced % | Tensile strength and enhanced % |

Ref. |

|---|---|---|---|---|---|---|

| Multi-walled carbon nanotubes/multi-graphene platelets (MWCNTs/MGPs) | 0.1/0.9 wt.% |

Epoxy | Melt-blending | 3350 MPa 22.6% |

64.5 MPa 14.5% |

[44] |

| GNP/Carbon black (CB) | 2/24 wt.% |

Ethylene–propylene–diene terpolymer rubber (EPDM) | Roll milling | 20 MPa ≈198.5% |

19.9 MPa ≈17.06% |

[48] |

| Graphene foam/CF | 0.5/10 wt.% |

PDMS | Chemical vapor deposition (CVD) | 3.05 MPa 185 % |

2.50 MPa 63 % |

[49] |

| GO/Short glass fibers (GF) | 0.5/- wt.% |

Polyether-sulphone (PES) | Extrusion compounding and Injection molding |

7.3 GPa 25.4 % |

119 MPa 10.2 % |

[50] |

| GO/CFGO | 0.1/1 wt.% |

Polyurethane (PU) | Mechanical mix and Electrophoretic deposition |

23.18 MPa - |

62.04 MPa 46.4% |

[51] |

| Reduced graphene oxide/ Silica (rGO/SiO2) | 1/99 30 phr (parts per hundred) |

Styrene butadiene rubber (SBR) | Electrostatic assembly/ Roll mill | 2.7 MPa 170% | 17.34 MPa 1204% |

[52] |

| GNP/GF | 5/10 wt.% |

PP | Melt mixing and injection molding | 4.47 GPa - |

45.4 MPa - |

[53] |

| Short CFs /GO | 12.5/0.5 wt.% |

PES | Solution and melt mixing | 7.79 GPa 31.7% |

119.09 MPa 12.1% |

[54] |

| 3-aminopropyltriethoxysilane -functionalized graphene oxide (APTSi-GO) |

1.5 wt.% |

Polyimide (PI) | In situ polymerization and thermal imidization | - 132% |

- 79% |

[55] |

| Hybrid Filler | Hybrid Filler Content |

Matrix | Preparation method | Thermal conductivity (Wm-1K-1) and %Increase @ pure matrix | Ref. |

|---|---|---|---|---|---|

| GNPs/MWCNT | 20/20 vol% | Epoxy | Melt-blending | 6.31 3055% |

[43] |

| MWCNTs/MGPs | 0.1/0.9 wt.% |

Epoxy | Melt-blending | 0.321 146.9% |

[44] |

| GNP/CB | 2/24 wt.% |

EPDM | Roll milling | 1.2 313.79% |

[48] |

| GF/CF | 0.5/10 wt.% |

PDMS | CVD | 0.55 162 % |

[49] |

| GNP/GF | 20/16 wt.% |

PP | Melt mixing | 5 times increase (pure PP) | [53] |

| APTSi-GO | 1.5 wt.% |

PI | In situ polymerization and thermal imidization | 0.33 100% |

[55] |

| GF + modified hexagonal boron nitride (M-h-BN) | 33.8 wt.% |

PDMS | CVD + Solution mixing | 23.45 12928% |

[56] |

| G/Cu nanoparticles | 40/35 wt.% |

Epoxy | Solution method | 13.5 6650% |

[60] |

| BN + reduced graphene oxide (rGO) | 13.16 vol% | Epoxy | Ice-templated and infiltration | 5.05 2425% |

[61] |

| Expanded graphite (EG)/CNTs | 20/1 wt.% |

High density polyethylene (HDPE) | Melt blending | 3.10 25% |

[62] |

| EG/MWCNT | 15/5 wt.% |

PP | Melting method | 1.52 442.86% |

[63] |

| Al2O3/GNP | 12 wt.% |

Epoxy | Solution mixing | 1.49 677% |

[64] |

| Boron nitride nanosheets (BNNSs)/ Graphene | 1.6/6.8 wt.% |

Polyamide-6 (PA6) | Solution mixing | 0.891 350% |

[65] |

| Functionalized Graphene sheets with nanodiamond filler (FGS/NDs) | 45 wt.% |

Polyvinylidene fluoride (PVDF) | Solution method | 0.66 257.14% |

[66] |

| Hybrid Filler | Hybrid Filler Content |

Matrix | Preparation method | Electrical conductivity | Ref. |

|---|---|---|---|---|---|

| APTSi-GO | 1.5 wt.% | PI | in situ polymerization and thermal imidization | 2.6 × 10−3 Sm-1 | [55] |

| EG/MWCNT | 15/5 wt.% | PP | Melting method | 159.62 Sm-1 | [63] |

| FGS/NDs | 10 wt.% | PVDF | Solution method | 7.1×10−7 Scm-1 | [66] |

| RGO sheets | 10 wt.% | Amine-modified nano-fibrillated cellulose (A-NFC) |

Solution casting | 71.8 Sm-1 | [71] |

| Graphene | 20 wt.% | Polypyrrole (PPy) | In-situ polymerization | 7.930 Scm-1 | [72] |

| GNP/Short CF | 0.02/0.08 vol% | Polymer | Theoretical modeling | 103 Sm-1 | [73] |

| GNP | 1.0 wt.% | Epoxy | 3-roll mill | 2.6 × 10−6 Sm-1 | [74] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).