1. Introduction

Materials are possibly more deep-seated in our everyday life then we realize. Housing, transportation, communication, food production and defense, almost each segment of our daily lives is influenced by one or other way by materials. In history, the development of societies have been reflected by ability to produce or manipulate materials to fill their needs and by the level of their material development. Furthermore, it was discovered that material properties could be altered by adding or combining with other material or by heat treatment to produce superior properties of those basic material [

1]. The demand for the materials is increasing in industries to establish the sector with improved properties, reduced cost and improved sustainability. Composites are developed by using constituent materials namely matrix and reinforcement. The role of matrix is to cover and support the reinforcement materials in their relative positions impart specific mechanical and physical properties. Composites gain importance in various fields such as automotive, aerospace, defence, biomedical, electronic equipment and sports [

2,

3,

4,

5,

6,

7].

In the current scenario, polymers play a major role in many applications due to its some unique properties such as light weight, chemical stability. It can be processed easily and obtained at lower cost gain its importance in many aspects of human life. The properties of the polymers can be altered suitably using fibers, organic/ inorganic particles and nanofillers. These materials have lower density differ from ceramics and metals in terms of strength and stiffness. Polymers can be molded in to complex shapes as it exhibits elastic and ductile behavior [

8]. Polymer matrix composites mainly comprises of epoxy resins as the matrix materials gain importance for structural engineers due to its well balance of mechanical and chemical properties [

9,

10,

11,

12] . Hence in this study, an attempt will be made to study the effect of graphene powder as filler material in larger variations and glass fibre as base material. In this study, we are focusing on mechanical properties and characterization of glass fibre reinforced epoxy polymer composites with variation in filler material as graphene powder in larger constituents.

2. Experimental Details

The approach for manufacturing the composite materials in this study was carried out by hand lay-up process followed up by vacuum bagging process to remove the air trapped between the layers of glass fiber and epoxy matri. The reinforcement material i.e. glass fiber was kept constant at 60% and the filler material i.e. Graphene powder was varied from 2% to 4% by reducing the epoxy matrix to the same amount. A plywood board of dimensions 400x400 mm was taken, on the upper surface plastic tape was placed to ensure it acted as releasing agent. In this work, open mould made from plywood was considered as substitute for metal mold or any other kind of mold because it is cheap, easy to handle and light weight. The required quantities of epoxy, hardener, glass fiber and graphene powder were weighed using an electronic weighing machine and taken in a beaker separately. The mixture of epoxy and hardener was mixed properly using a mechanical stirrer for 5 minutes. While for the second filler added composites, the graphene powder was added to the epoxy at 70°C. The mixture was allowed to cool down at room temperature, at a slower cooling rate by providing partial heat to the mixture. Sonication was done for about 20 minutes at 150V, the hardener was added and stirring was done continuously using mechanical stirrer for 5 minutes. Some quantity of prepared mixture of matrix material was poured in the mold, than a layer of glass fiber mat was placed and again the matrix material was poured. This process was repeated until the required thickness is obtained i.e. 2mm. After the required thickness of composite material was achieved, the upper layer was covered with plastic tape to act as releasing agent, over which the excess trapped air was removed by using a roller. Later vaccum bagging process was carried out. Specimens were cut as per ASTM standards using water jet cutting technique. Tensile test was carried out according to ASTM D3039 standard with Mecmesin multi tester machine (

Figure 1) using dog bone shaped specimen.

3. Results and Discussions

3.1. Tensile Test

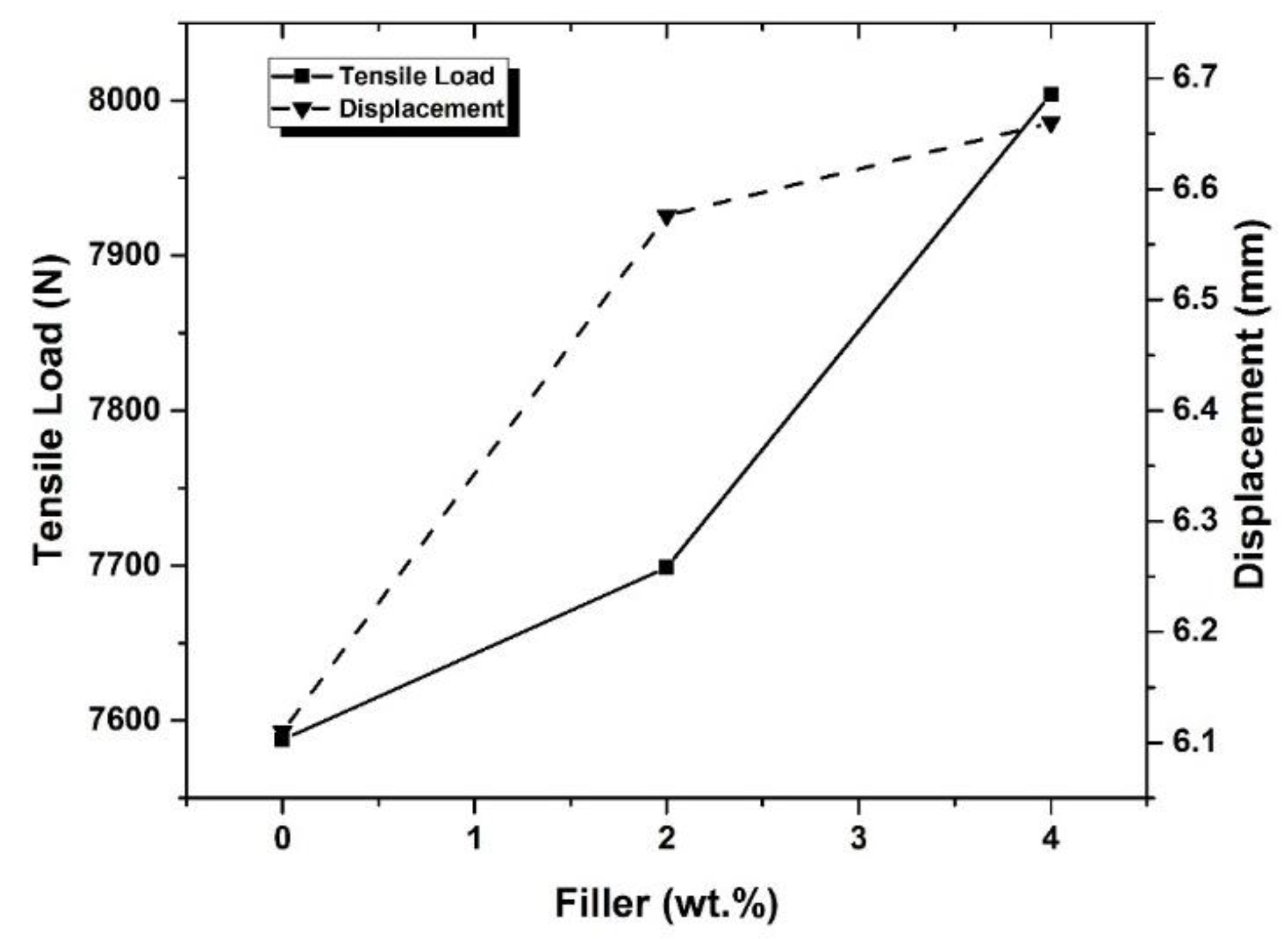

Figure 2 depicts the maximum tensile load v/s maximum displacement for all the combinations of composites. It was observed that the load carrying capacity was increased for increase in Graphene content in the composites. Initially the tensile load obtained for plain composite without graphene powder was 7587.66 N and it increased to 8004 N for the composite with 4 wt. % of Graphene content. The tensile strength of composites depends on interfacial bonding strength between matrix and reinforcement to a larger extent and also on the inherent properties of composite ingredients. It was observed that there is 1.46% tensile load and 7.63% of elongation improvement for composites with 2% filler material, while the composite with 4% filler material showed 5.50% tensile load and 9% elongation improvement. The role of glass fibres in the composite limits the failure and the increase in the filler material content exhibits the upward trend in tensile properties.

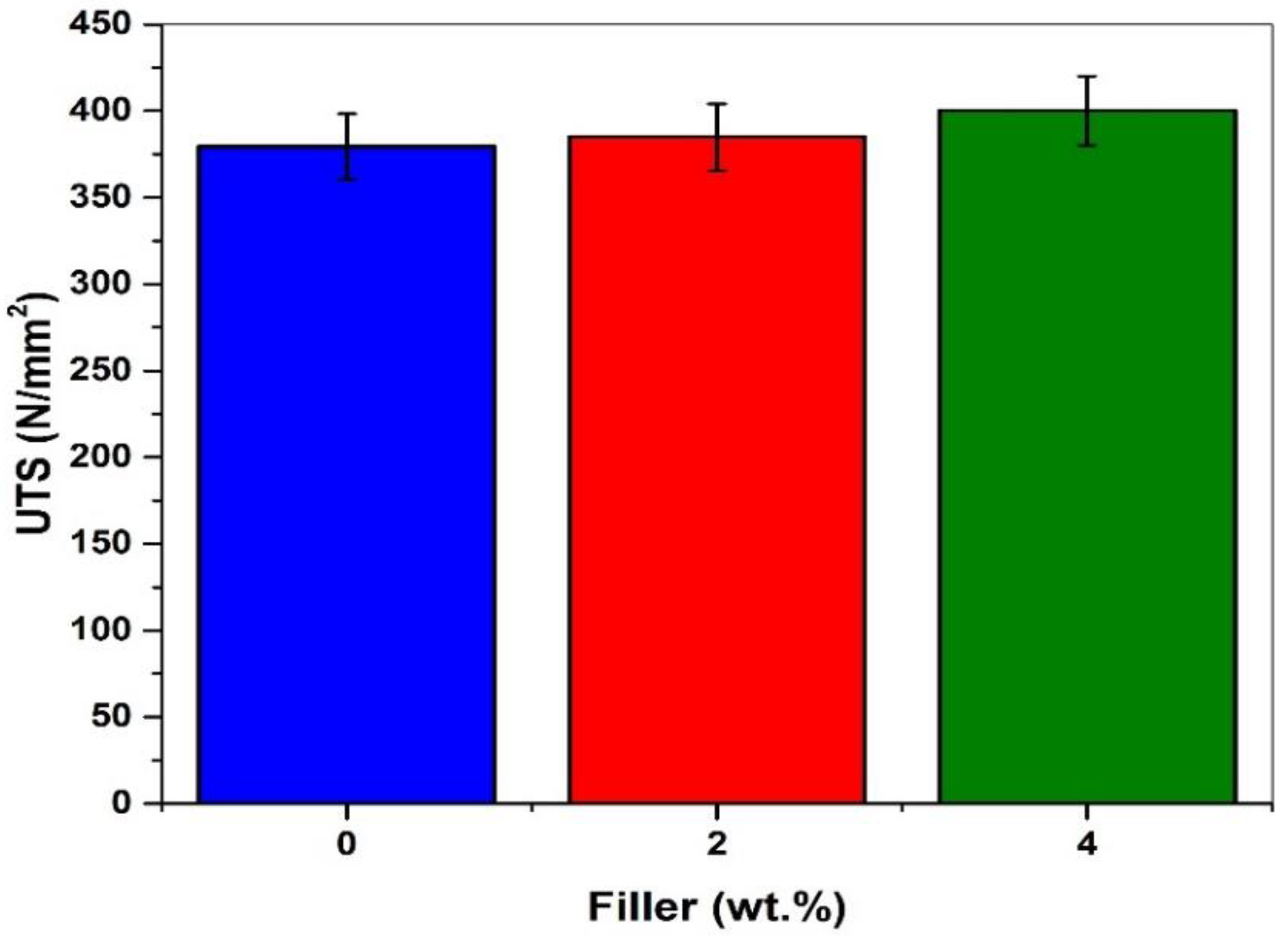

Figure 3 shows the marginal increase in the ultimate tensile strength as a result of increased interfacial bonding between the glass fiber and epoxy matrix due to the addition of Graphene as filler material.

4. Conclusions

The effects of graphene powder reinforcement with different variations in percentage of filler materials have been examined for enhancing the mechanical properties of GFRP composites and their characteristics were studied using a SEM. The GFRP composites were fabricated using Hand lay-up method with and without filler material and specimens for the testing were made as per ASTM standards. From the experimental values it can be observed that the tensile strength and flexural strength of the composite were improved with addition of Graphene powder.

References

- William D. Callister J. Materials Science and Engineering - An Introduction. 2007.

- Roy, S. Comparative analysis of thermo-physical and mechanical properties of PALF/CF/epoxy resin with and without nano TiO2 filler. J Mech Behav Biomed Mater 2023;148:106201. [CrossRef]

- Sharma H, Kumar A, Rana S, Sahoo NG, Jamil M, Kumar R, et al. Critical review on advancements on the fiber-reinforced composites: Role of fiber/matrix modification on the performance of the fibrous composites. J Mater Res Technol 2023;26:2975–3002. [CrossRef]

- Ali Z, Yaqoob S, Yu J, D’Amore A. Critical review on the characterization, preparation, and enhanced mechanical, thermal, and electrical properties of carbon nanotubes and their hybrid filler polymer composites for various applications. Compos Part C Open Access 2024;13:100434. [CrossRef]

- Rashid A Bin, Haque M, Islam SMM, Uddin Labib KMR. Nanotechnology-enhanced fiber-reinforced polymer composites: Recent advancements on processing techniques and applications. Heliyon 2024;10:e24692. [CrossRef]

- Balaji Ayyanar C, Kumar R, Helaili S, B G, RinusubaV, Nalini H E, et al. Experimental and numerical analysis of natural fillers loaded and E-glass reinforced epoxy sandwich composites. J Mater Res Technol 2024;32:1235–44. [CrossRef]

- Demir TN, Yuksel Yilmaz AN, Celik Bedeloglu A. Investigation of mechanical properties of aluminum–glass fiber-reinforced polyester composite joints bonded with structural epoxy adhesives reinforced with silicon dioxide and graphene oxide particles. Int J Adhes Adhes 2023;126:103481. [CrossRef]

- Ahmed KK, Muheddin DQ, Mohammed PA, Ezat GS, Murad AR, Ahmed BY, et al. A brief review on optical properties of polymer Composites: Insights into Light-Matter interaction from classical to quantum transport point of view. Results Phys 2024;56:107239. [CrossRef]

- Yi Hsu C, Mahmoud ZH, Abdullaev S, Abdulrazzaq Mohammed B, Altimari US, Laftah Shaghnab M, et al. Nanocomposites based on Resole/graphene/carbon fibers: A review study. Case Stud Chem Environ Eng 2023;8:100535. [CrossRef]

- Gull N, Khan SM, Munawar MA, Shafiq M, Anjum F, Butt MTZ, et al. Synthesis and characterization of zinc oxide (ZnO) filled glass fiber reinforced polyester composites. Mater Des 2015;67:313–7. [CrossRef]

- Shahnaz T, Hayder G, Shah MA, Ramli MZ, Ismail N, Hua CK, et al. Graphene-based nanoarchitecture as a potent cushioning/filler in polymer composites and their applications. J Mater Res Technol 2024;28:2671–98. [CrossRef]

- Harle, SM. Durability and long-term performance of fiber reinforced polymer (FRP) composites: A review. Structures 2024;60:105881. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).