1. INTRODUCTION:

Concrete is a widely used material in a construction field. It is extremely popular due to its higher load carrying capacity, fire resistance, impermeability, and ease of being molded into any shape. Meanwhile it has some deficiencies which include lower tensile strength, brittleness, limited Fatigue life, low ductility and low deformations, post cracking capacity when they are subjected to large flexural forces. It is also well known fact that due to its brittle failure, concrete is considered extremely vulnerable to flexural loading. Concrete being a brittle material exhibits strong response against compression, but, when the cracks are initiated in it due to flexural loadings, the concrete loses all its loading capacity at once without any prior intimation. Although steel reinforcement is added in concrete to deal with its tensile failure, but on the other addition mild steel makes concrete heavier than plain concrete that is also a matter of great concern for many structural elements, because heavier the structural element higher is the chances of concrete structures losing their stability.

Therefore, in order to control and improve the flexural resistance of concrete different kind of fibers are being preferred to be used as an extra ingredient in order to improve the loading capacity of concrete once the load has been acted on it [

1]. It has also been studied that improvement in the durability, mechanical properties such as compressive and tensile strength of the concrete can be made by using the suitable changes in manufacturing ingredients such as cementitious materials, introducing different kinds of sustainable aggregates and by adding some special kind of admixtures into it. Hence, the use of sustainable and safe concrete has a vital role in the construction field.

The presence and development of micro cracks in the concrete structures is always a matter of a grave concern because these cracks are responsible for the weakness of the concrete particularly in tension and this vulnerability does not only make concrete structures unsafe but also lead to the economic losses as well. Although concrete is not sound enough in tension but this deficiency in concrete can be easily removed by the induction of the fibers in the concrete mix. These fibers can be in the form of glass fibers, carbon fibers, steel fibers, and other similar fibers made from industrial waste or natural products such as coconut fiber. The use of fibers in concrete helps to get its toughness improved and enhances its ability to prevent further growth of the cracks in concrete structures. Moreover, these fibers are also responsible for forces to be uniformly spread at the internal micro cracks; and make concrete lighter in weight as compared to the conventional concrete that’s due to it that fibrous concrete is getting more popularity among the research scholars. Concrete having fibers as another ingredient other than cement, and aggregates such a concrete with fibers is named as the reinforced fiber concrete or fiber reinforced Concrete. Thus, it is the composite material which is formed by the mixture of fibers and the reinforced concrete. Fibers are preferred to be added in concrete so that concrete should gain improvement in its mechanical properties. All types of fibers have a good impact on both fresh and hardened properties of concrete. That’s the reason that extensive research are being made to produce a sustainable concrete with the addition of fibers.

The application of fibers in concrete can be made in the form of an aggregate having extreme variation in its shape, size and its smoothness. Fibers like other ingredients of concrete possess proper shape, size and texture. Not all the fibers in the world are applicable for concrete use. However, the use fibers in concrete have many advantages including environmental and economic. Fibers gets interlocked and entangled around aggregate particles that’s why all types of fibers reduce the workability of the concrete whereas concrete mix becomes extremely cohesive than conventional concrete and less pronounced to the segregation. Furthermore, the fibers are added into a concrete mix with the random capacity hence it improves the concrete in its all parameters and directions. Although it depends upon the type of fiber but it is found that the use of fibers helps the concrete to get post-peak ductility performance, pre-cracks improvement in tensile strength, and impact load resistance of the concrete emphatic strength of the concrete.

In addition, the presence of fibers in a concrete act as a crack arresters resisting the development of cracks in the concrete mixture, cement concrete having extremely low tensile capacity and low impact resistance gets into a strong improved composite which during period of crack resistance improve its ductility and the post tracking behavior which is beneficial for the concrete strength. Hence the use of the study allows us to understand the importance of different types of fibers which are used to improve the compressive strength of the concrete as well as the tensile strength of the concrete.

2. Literature Review

At present, there are number of different laboratory examination that has been done on these fiber reinforced concrete samples in order to measure its effectiveness and the strength values. One of the detailed review studies was carried out by Weli et al., 2020 and, investigated the mechanical properties of the concrete using different fibers and he concluded that there were good results when steel fibers were used in comparison with other fibers. In this study it was observed that the compressive strength of concrete increased from 7 to 19% whereas the splits tensile strength increased from 19 to 48% however the flexural strength increased by more than half which was around 25% but after the usage it moved up to 65% and at last the modulus of elasticity improved from 7% to 25% respectively [

2].

Another research on the use of fibers was conducted by Singh, who induced concrete with 0.33%, 0.65% and 1% of GFRP (Glass Fiber Reinforced Polymers) and CFRP (Carbon Fiber Reinforced Polymers). These two types of fibers are most common now both make concrete strong in tensile strength and carbon Fiber polymers are getting popularity in making of light concrete as well. In this research it was found that due to this addition of GFRP and CCFRP in concrete the Mechanical and hydrological properties of the matrix were affected. Since, it was a comparative study so it revealed that the permeability and porosity of the composite concrete with GFRP were higher than the CFRP. The overall increase in the compressive strength of fibrous concrete was observed and it was recommended that the concrete became more eco-friendly and cost-effective by using the wasted CFRP and GFRP [

3].

A detailed research on fibers was also conducted on concrete sample by Aksar et al., 2023. In this experimental work a total 120 pieces of elements were casted which included 48 cubes, 24 beams, and 48 cylinders. The cylinders were having the diameter of 15 cm and the height of the cylinder was 30 cm, the concrete cubes were casted into 15 x 15 x 15 cm where is the beam work hosted into 15 cross 15 cm and the length of the beam was 56 cm and their testing was done by the single point loading technique and all standards were strictly followed for determining the true results. For normal strength 1:1.5: 2.5 was taken as normal strength proportion NLSP) while for low strength 1:2.6:4.2 was taken as low strength proportion (LSP) for mix. All the samples were brought under testing after 7 days curing and 28 days curing age and their densities were recorded properly before being tested by the help of standard machines. Overall, the result exhibited that the addition of only 0.25% of chopped Carbon fiber reinforce polymer (CCFRP) on to a concrete increased the compressive strength of low strength concrete from 9.5 N/mm2 to 11.2 N/mm2, the overall increment of strength was about 10% in total whereas the 5% increment was there for the normal strength concrete. Meanwhile, the use of 0.25% of CCFRP was exhibited positive response for flexural strength of concrete. It revealed that at this percentage both LSP and NSP represented increase the split tensile strength of concrete from 2.5 MPa to 3.6 MPa , which was about 44% of increment in normal strength proportion (NSP) where as 16.6% for low strength proportion (LSP) concrete mix. Similarly, the same scenario was with the flexural strength of the concrete which improved from 4.5 MPa to 5.4 MPa. Therefore, it was recommended that 0.25% was the ideal percentage to be added in concrete [

4].

Moreover, another research was conducted in which fly ash was added in concrete with the ground granulated blast furnace slag incorporated in place of cement of with the varying percentage. The concrete was modified in order to find the compressive and tensile strength, and durability of the concrete mixture. The proportion was mixed in different percentage which was 0.1%, 0.2%, 0.3% and 0.4% whereas the glass fiber length was around 6 mm and 13 mm. It is also important to underline that the strength and effectiveness of fibers depend upon their length, therefore size of fibers is selected with a proper care. Hence, experiments were made ffter taking length of fibers between 6 mm to 13 mm. The results indicated that the addition of the glass fibers caused improvement in the overall flexural strength of the concrete and also resulted in enhancing the split tensile strength of the concrete as well. The use of 13 mm glass fiber was more effective than the one which was around 6 mm as the main reason of this was that with 13 mm large fibers it gets more area contacted with concrete so overall result was better in terms of greatest strength and durability performance of the concrete structure [

5].

Additionally, the researcher conducted a research using a glass fiber which was 6 to 25 mm long. The application of fibers in the conventional concrete mixes made the concrete more durable and strengthened. The addition of these fibers increases the flexural strength of the concrete and improves the fracture properties of the concrete material. The modulus of elasticity of the glass fiber reinforced concrete increased by 40%. The main purpose of the research was to understand the mechanical and flexural properties of the polymer concrete which was induced using the class fibers [

6].

One of the research which was conducted in 2022, the researcher analyzed the Carbon fiber reinforced polymer grade by taking consideration of the cyclic behavior in reinforcement ratio, aspect ratio, and reinforcement configuration. Moreover, for these analysis, two varying type of concrete specimens were used one of them was 13 concrete share wall which was about 13 in quantity and secondly 11 credit sample with varying from 1.01 to 2.20 were examined under the inverted loadings. The results clearly witnessed that the reduction in aspect ratio would directly encouraged the ductility of the concrete specimen from 13.8% to 36% with an increment of more than 100%. Secondly, the samples which were casted with carbon fiber reinforced polymer showed the increment in the loading capacity for the concrete shear wall [

7].

In addition, the researcher in 2022 Yoo et al., 2022 used carbon fiber reinforced polymers as a the main reinforcement in place of mild steel. The main purpose was to check elevation in temperature along with other properties. It checked the properties of carbon fiber reinforced polymers as a reinforcement in compression members in a carbon fiber reinforced concrete using the reinforced concrete columns. For this purpose 24 short columns was used which were subjected to different temperatures (0, 150, 300 and 450 degree Celsius). And these columns were subjected to centric loading after the cooling process has been done. from this study the conclusion was made that as the temperature increases the compressive strength of the concrete samples which were short columns also increased, what is the increment was from 3 to 15% whereas for and for 300 degree Celsius and 450 degree Celsius the increment was of about 50%. So it was clear that in terms of increment of the temperature the compressive strength of the concrete increased as well [

8].

Another combined research was conducted in 2023 in order to examine the elastic characteristic of the textile based composite materials with carbon nano-tube (CNT) material in the concrete samples. The use of carbon nano-tube (CNT) enhances the axial tensile strength of the concrete as well as makes concrete strong against the bending. It was also determined in this study that CNT raised the tensile modulus of the concrete by 9% [

9,

10].

The detailed study was done in order to examine how wrapping of composite beams may have effect on the flexural strength of beams made from reinforced fibrous concrete and load caused deflection. Nine beams were used in this study with three point loading force mechanism and four point loading mechanism with variation in the shear span to depth ratio. As a result, the ductility and strength of the beam were enhanced significantly by using of glass fiber reinforced polymers (GFRP) wraps [

11,

12].

In one of the research glass fiber reinforced polymer composite beams well in field with hybrid use of glass fiber reinforced polymer on composite beam in presence of hybrid fiber reinforced concrete under the poor point loading and table analyzed experimentally, numerically and analytically in order to make the proper comparison in between them. The variables which were used in experiments included GFRP box profiles and Steel bars, which were in conventional form, hybrid Steel bars and externally wrap class fiber reinforced polymer. As a result it was evaluated that, concrete it improved the overall strength of the concrete and it made the concrete more durable [

13,

14].

A detailed research was also carried out by using a glass fiber in a concrete sample; maximum dosage of the class fiber was found as 1.5% of the weight of the cement used. Five different Binder ratios were used which were in the range from 0.4 to 0.6. As a result, there was an average increase in the compressive strength and flexural strength which was about 13% 28%, respectively. Along with that the concrete with the presence of glass fiber showed less resistance to carbonation attack as compared to the control mix. The addition of fiber added an extra post-cracking flexural strength to the concrete samples. The overall increment of 44% was observed in the flexible strength of the concrete as compared to the control concrete sample [

15].

High performance fiber reinforced lightweight concrete was made up of by making use of polyvinyl alcohol fibers with suitable addition percentage, which exhibited an increment of the flexural strength along with the higher flexural strength ductility in the concrete and improve the toughness of the concrete as a result [

16]. With the addition of the little amount of polyvinyl alcoholic fiber into a concrete sample the mechanical characteristics of the concrete improved significantly as an outcome [

17]. Whereas on the other hand the addition of a metal into a concrete made from glass fibers caused, the fibers having chances to get easily pulled out comparatively more than the chances of being more broken of the fibers, however, the induction of these kinds of chemicals into a concrete did not provide reasonable results and neither improved much of its Mechanical properties [

18].

The induction of the high performance polypropylene fibers into the concrete samples improved all characteristics of concrete such as penetration of chloride in it, water absorption, and carbonation attacks on an ultrasonic pulse velocity of the concrete which make the concrete more strengthened and durable as a result [

19]. In one of the research, the magnesium phosphate cement mortar was added into a glass fiber using the dosage of 1.5%, 2.5% and 3.5%. Optimum of the ideal value of the glass fiber was 2.5% and consequently this addition resulted that the flexural strength of concrete increased dramatically for all of concrete samples [

20]. The compressive strength of the concrete and the split tensile strength of the concrete both were improved by 9 to 13% and 22 to 50% respectively by the induction of the class fibers into a concrete mix [

21]. With an addition of only 2% of the glass fibers into the lime-made mortar, the darkness of the concrete increases and it improves the mechanical particularly compressive and tensile behavior and properties of the concrete mixture [

22].

3. Research Methodology

3.1. Methods and Materials Used

Cement as a binding material, Fine aggregates (FA), Coarse aggregate (CA), water, waste glass a, carbon fibers, and steel fibers were used a fibrous material in order to make the concrete samples. Groundwater was suitable for preparation of concrete as already studied by [

23,

24].

Cement: The cement which was used for the mix was Ordinary Portland Cement (OPC - Grade 43) having a specific gravity equal to 3.15. The initial setting and final setting time of the cement was determined as 20 minutes and 30 minutes, respectively.

The sand used was Lawrencepur. Lawrencepur sand is coarse sand. According to ASTM, sand or fine aggregates are that passes through sieve no. 4 and is retained on sieve no.200. The sand used for casting was passed through sieve no. 4 for larger particles to remove from it.

Coarse Aggregate: The aggregates used in the research were obtained from the field. In addition, normal aggregates of Sargodha source were also used. The size of aggregates was half inch down for normal aggregates and 10 mm down for field aggregates.

Fibers: The fibers which were used in the casting were of different kinds, steel fibers, carbon fibers and glass fibers. Approximately the length of the fiber was 1 inch long and the quantity of the steel fibers is calculated as a certain mass per unit volume which was 0.5% of defined weight of concrete sample.

Design Mix Ratio: The mix ratio used is:- ACI 5200 psi target strength Based on conditions of the materials, the quantities are different. In saturated surface dry condition of the materials, the quantities are:

Cement = 420 kg/m3; Sand = 638 kg/m3

Coarse aggregates = 1237 kg/m3; Water = 197 kg/m3

The mix ratio becomes 1:1.5:3 with water to binder (w/b or w/c) ratio of 0.5.

If materials are in oven dry condition, the quantities are; Cement = 420 kg/m3

Sand = 632 kg/m3

Coarse aggregates = 1228 kg/m3 Water = 197 kg/m3

The mix ratio becomes 1:1.5:2.9 with a water to cement (w/c) ratio of 0.469.

3.2. Experimental Procedure:

The following table presents the samples, which are to be casted. These include cubes of 150 mm and cylinders of size as 200 mm in height and 100 mm diameter.

Table 1.

Concrete Cubes and Concrete Cylinder Specification.

Table 1.

Concrete Cubes and Concrete Cylinder Specification.

Sr. No.

1

|

Shape

Cube

|

Size (mm)

150x150x150

|

No. of samples

60

|

Volume (m3)

3.37x10-3

|

| 2 |

Cylinder |

200x100Ø |

30 |

1.57x10-3

|

Standard procedure was used to pour ingredients in the mixer. The procedure is to pour the fine aggregates first, then cement and then coarse aggregates. Start mixing the mix and pour water. To add fibers in the mix, use a half inch sieve and pour the fibers using it. The fibers should fall vertical on the mix. The

Figure 1 is shown below.

The desired slump of the concrete was 20 mm. The following figure shows the slump test on the concrete. The

Figure 2 below shows the desired outcome in terms of slump.

4. Results and Discussion

In this study the workability and mechanical properties of concrete specifically the compressive strength and split tensile strength were determined. It was a comparative study between various types’ fibers being commonly used in concrete. The compressive strength of concrete was conducted under ultimate compressive testing machine and values were noted down for each sample tested after 3, 7, 14, and 28 days. In total 90 samples were casted out of which 60 were cubes for compressive strength and 30 were cylinders for split tensile strength. All samples were checked having fibers proportion equal to 0.5% for all fibers at once.

- I.

Workability of Concrete

The result exhibited that the workability of concrete kept reducing for various types of fibers. In other word all types of fibers have a negative impact on workability of concrete. Fibers make concrete cohesive and reduce segregation and bleeding effect in concrete. Irrespective of fiber type, concrete experiences continuous declination in its workability as the proportion of fiber increases in concrete.

- II.

Compressive strength of Concrete

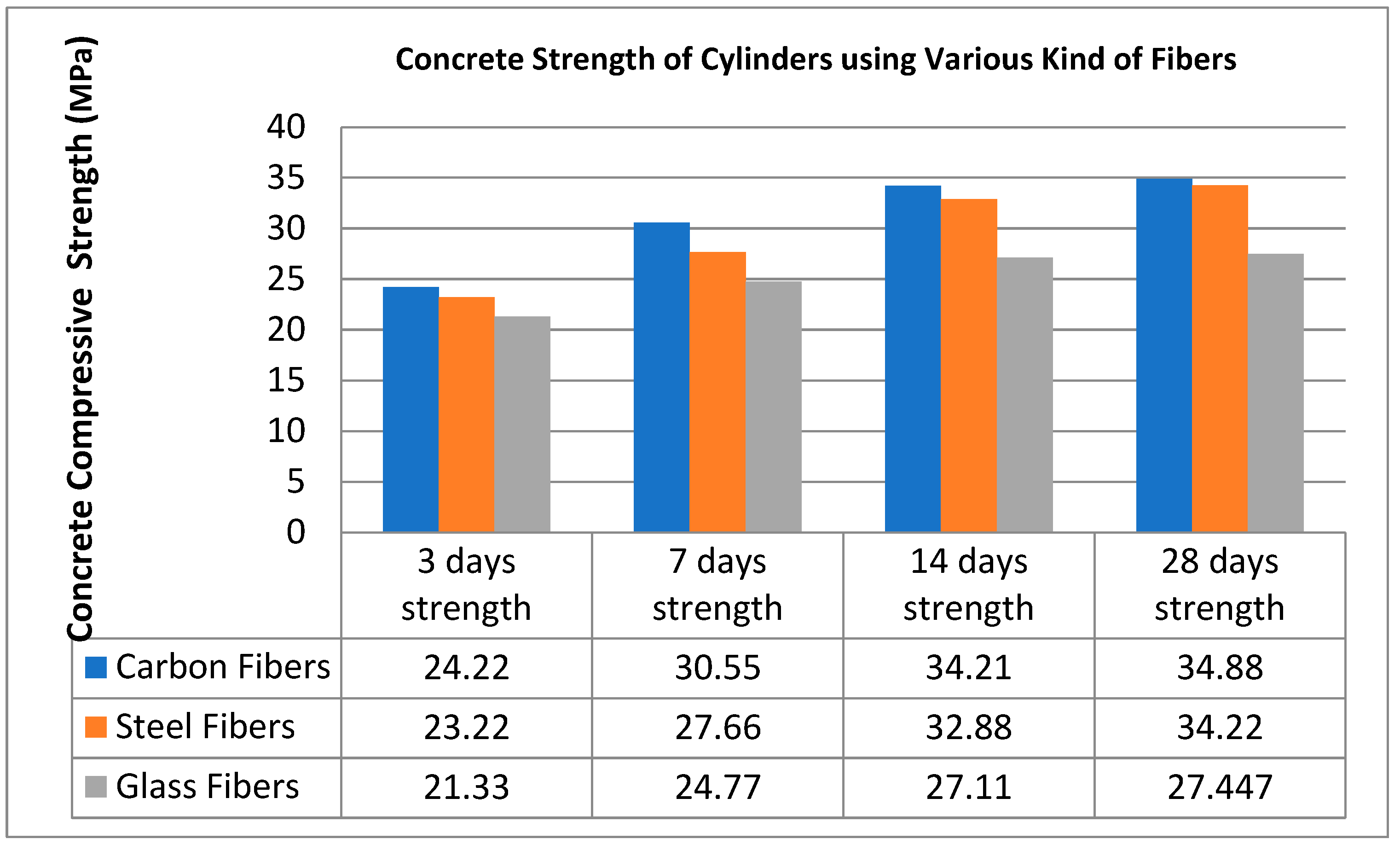

Compressive strength of concrete was checked at 0.5% of each fiber separately after 3, 7, 14, and 28 days curing. The give graph below shows the results of the testing which was done for concrete casted samples.

The results as exhibited in

Figure 3 revealed that the compressive strength of concrete is improved far better with the carbon fibers as compared to any other fiber, and glass fiber was found as a fiber which provides improvement in strength lower than the carbon and steel. The value of full Compressive strength of concrete was found as 37.52 MPa with carbon fiber while with addition of Steel fiber and Glass fiber the strength was reported as 34.22 MPa and 29.335 MPa.

- III.

Compressive strength of Concrete when Cylinder specimen was used

Compressive strength of concrete was checked at 0.5% of each fiber separately after 3, 7, 14, and 28 days curing. The given graph shown in

Figure 4, shows the results of the testing which was done for concrete casted samples.

The given graph shows the concrete cube and concrete cylinder compressive strength and it is noted that the strength of cube is more than cylinders. The concrete with carbon fiber is having the highest compressive strength as compare to others. The 28th day strength for cubes were: with carbon fibers the 37.52 MPa, with steel fiber it is 34.22 MPa and with glass fiber the strength is 29.335 MPa whereas, the 28th day strength for cylinders were: with carbon fibers the 34.88 MPa, with steel fiber it is 34.22 MPa and with glass fiber the strength is 27.447 MPa.

- IV.

Tensile strength of Concrete:

The tensile strength of concrete was checked for concrete specimens. The split tensile test method was followed. Cylinders were prepared for testing tensile strength of concrete. The results elucidated that carbon fibers provide highest strength to concrete to as compared to other fibers. The carbon fiber is also lighter in weight so makes concrete lighter and sustainable. It was reported that after 28 days, the tensile strength of concrete with glass fiber was about 2.88 MPa; with steel fiber it gained strength of about 2.97 MPa; and concrete having carbon fibers as composite material boosted strength to 3.35 MPa. The

Figure 5 illustrates the results of study.

5. Conclusions

The sustainable concrete is the in the high demand due to environment being vulnerable to carbon dioxide emission. The efforts are being made to use innovative industrial waste materials to make concrete stronger and sustainable. Thus, different fibers were added in concrete in order to enhance its mechanical properties and make it eco-friendly. Fibers such as Carbon, Glass, and steel were added in concrete and testing was done. The results spelled out that the specimen which was casted with carbon fibers were having the higher compressive strength as compare to concrete mix which is formed by using steel and glass fibers for both concrete cubes and concrete cylinders. The main reason for higher compressive strength for carbon fiber reinforced concrete is the carbon is toughest material in comparison to steel and glass. Use of carbon fibers in concrete can make the samples higher in load capacity and as a result we can get more strength value. Overall, for cubes the percentage difference for 28th day concrete strength of carbon fibers was 28% approximately as compare to glass fiber reinforced concrete. However, for cylinders the percentage difference is 27% respectively. On the other hand, the higher tensile strength of concrete was also gained with the carbon fiber. It was determined that carbon fiber provided about 16% and 12.8% tensile strength higher than glass and steel fibers respectively. It shows how strong the concrete gets when it is induced with carbon fibers. However, the excess use of concrete with carbon fibers can make the concrete more brittle but at the same time the load-carrying capacity of the concrete sample increases.

References

- Noor, Farah, A.H Tan, Nabilah Abu Bakar, and Nur. “Properties of Concrete with Glass Fibre Reinforced Polymer Waste as Partial Replacement of Fine Aggregate.” Journal of Physics 2521, no. 1 (June 1, 2023): 012015–15. [CrossRef]

- Weli, Sardasht S, Imad Shakir Abbood, Kamalaldin F Hasan, and Mohammed A Jasim. “Effect of Steel Fibers on the Concrete Strength Grade: A Review.” IOP Conference Series: Materials Science and Engineering 888, no. 1 (July 1, 2020): 012043. [CrossRef]

- Singh, Avishreshth, Akhil Charak, Krishna Prapoorna Biligiri, and Venkataraman Pandurangan. “Glass and Carbon Fiber Reinforced Polymer Composite Wastes in Pervious Concrete: Material Characterization and Lifecycle Assessment.” Resources, Conservation and Recycling 182 (July 2022): 106304. [CrossRef]

- Askar, Mand Kamal, Lawend K. Askar, Yaman S.S. Al-Kamaki, and Razaq Ferhadi. “Effects of Chopped CFRP Fiber on Mechanical Properties of Concrete.” Heliyon 9, no. 3 (March 2023): e13832. [CrossRef]

- M.S. Midhun, Gunneswara Rao, and T. Chaitanya Srikrishna. “Mechanical and Fracture Properties of Glass Fiber Reinforced Geopolymer Concrete.” Advances in Concrete Construction 6, no. 1 (February 1, 2018): 29–45. [CrossRef]

- Reis, J.M.L, and A.J.M Ferreira. “Fracture Behavior of Glass Fiber Reinforced Polymer Concrete.” Polymer Testing 22, no. 2 (April 2003): 149–53. [CrossRef]

- Pan, Yingcai, Xuan Wu, Hui Zheng, Gaolin Wu, Siqiang Sun, Hengjian Ye, and Zongke Zhang. “A New Approach to Enhancing Interlaminar Strength and Galvanic Corrosion Resistance of CFRP/Mg Laminates.” Composites Part A: Applied Science and Manufacturing 105 (February 1, 2018): 78–86. [CrossRef]

- Yoo, Sung-Won, and Jinkyo F. Choo. “Behavior of CFRP-Reinforced Concrete Columns at Elevated Temperatures.” Construction and Building Materials 358 (December 2022):129425. [CrossRef]

- Emrah Madenci, Yasin Onuralp Özkılıç, Ceyhun Aksoylu, M. R. M. Asyraf, Agusril Syamsir, Mohd, and Nicolay Mamaev. “Buckling Analysis of CNT-Reinforced Polymer Composite Beam Using Experimental and Analytical Methods.” Materials 16, no. 2 (January 9, 2023): 614–14. [CrossRef]

- Ceyhun Aksoylu, Yasin Onuralp Özkılıç, Emrah Madenci, and Alexander Safonov. “Compressive Behavior of Pultruded GFRP Boxes with Concentric Openings Strengthened by Different Composite Wrappings.” Polymers 14, no. 19 (September 29, 2022): 4095–95. [CrossRef]

- Ozkilic, Y.O. et al. (2022) Effect of the GFRP wrapping on the shear and bending behavior of RC beams with GFRP encasement, Steel and Composite Structures. [CrossRef]

- Emrah Madenci, Yasin Onuralp Özkılıç, Ceyhun Aksoylu, M. R. M. Asyraf, Agusril Syamsir, Abu, and Bobrynina Elizaveta. “Experimental and Analytical Investigation of Flexural Behavior of Carbon Nanotube Reinforced Textile Based Composites.” Materials 16, no. 6 (March 10, 2023): 2222–22. [CrossRef]

- Gemi, Lokman, Emrah Madenci, and Yasin Onuralp Özkılıç. “Experimental, Analytical and Numerical Investigation of Pultruded GFRP Composite Beams Infilled with Hybrid FRP Reinforced Concrete.” Engineering Structures 244 (October 2021): 112790. [CrossRef]

- Arslan, Musa Hakan, Şakir Yazman, Ahmed Abed Hamad, Ceyhun Aksoylu, Yasin Onuralp Özkılıç, and Lokman Gemi. “Shear Strengthening of Reinforced Concrete T-Beams with Anchored and Non-Anchored CFRP Fabrics.” Structures 39 (May 2022): 527–42. [CrossRef]

- Hussain, S M, and Jitendra Singh Yadav. “Mechanical and Durability Performances of Alkali-Resistant Glass Fiber- Reinforced Concrete.” Jordan Journal of Civil Engineering 17, no. 2 (April 1, 2023): 231–46. [CrossRef]

- Arisoy, Bengi, and Hwai-Chung Wu. “Material Characteristics of High Performance Lightweight Concrete Reinforced with PVA.” Construction and Building Materials 22, no. 4 (April 2008): 635–45. [CrossRef]

- Noushini, Amin, Bijan Samali, and Kirk Vessalas. “Effect of Polyvinyl Alcohol (PVA) Fibre on Dynamic and Material Properties of Fibre Reinforced Concrete.” Construction and Building Materials 49 (December 2013): 374–83. [CrossRef]

- Enfedaque, Alejandro, David Cendón, Francisco Gálvez, and Vicente Sánchez-Gálvez. “Analysis of Glass Fiber Reinforced Cement (GRC) Fracture Surfaces.” Construction and Building Materials 24, no. 7 (July 2010): 1302–8. [CrossRef]

- Ramezanianpour, A. A., M. Esmaeili, S. A. Ghahari, and M. H. Najafi. “Laboratory Study on the Effect of Polypropylene Fiber on Durability, and Physical and Mechanical Characteristic of Concrete for Application in Sleepers.” Construction and Building Materials 44 (July 1, 2013): 411–18. [CrossRef]

- Fang, Yuan, Bing Chen, and Sajjad Yousefi Oderji. “Experimental Research on Magnesium Phosphate Cement Mortar Reinforced by Glass Fiber.” Construction and Building Materials 188 (November 1, 2018): 729–36. [CrossRef]

- Choi, Yeol, and Robert L. Yuan. “Experimental Relationship between Splitting Tensile Strength and Compressive Strength of GFRC and PFRC.” Cement and Concre.

- te Research 35, no. 8 (August 2005): 1587–91. [CrossRef]

- Iucolano, F., B. Liguori, and C. Colella. “Fibre-Reinforced Lime-Based Mortars: A Possible Resource for Ancient Masonry Restoration.” Construction and Building Materials 38 (January 2013): 785–89. [CrossRef]

- 24. Jamali, M. Z., Khoso, S., Soomro, Z., Sohu, S., & Abro, A. F. (2022). EVALUATING THE SUITABILITY OF GROUNDWATER IN PAKISTAN: AN ANALYSIS OF WATER QUALITY USING SYNTHETIC POLLUTION INDEX (SPI) AND WATER QUALITY INDEX (WQI). International Journal of Energy, Environment and Economics, 30(3), 311-328.

- Jamali, M. Z., Solangi, G. S., Keerio, M. A., Keerio, J. A., & Bheel, N. (2023). Assessing and mapping the groundwater quality of Taluka Larkana, Sindh, Pakistan, using water quality indices and geospatial tools. International Journal of Environmental Science and Technology, 20(8), 8849-8862. [CrossRef]

- Ahmed, S., Jamali, M. Z., Khoso, S., Azeem, F., & Ansari, A. A. (2022). ASSESSMENT OF GROUNDWATER QUALITY IN RURAL AREAS OF TALUKA DOKRI, SINDH, PAKISTAN, THROUGH PHYSICOCHEMICAL PARAMETERS. International Journal of Energy, Environment and Economics, 30(3), 211-226.

- Jamali, M. Z., Solangi, G. S., & Keerio, M. A. (2020). Assessment of Groundwater Quality of Taluka Larkana, Sindh, Pakistan. International Journal of Scientific & Engineering Research, 11(5), 795-797.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).