Submitted:

20 June 2024

Posted:

21 June 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

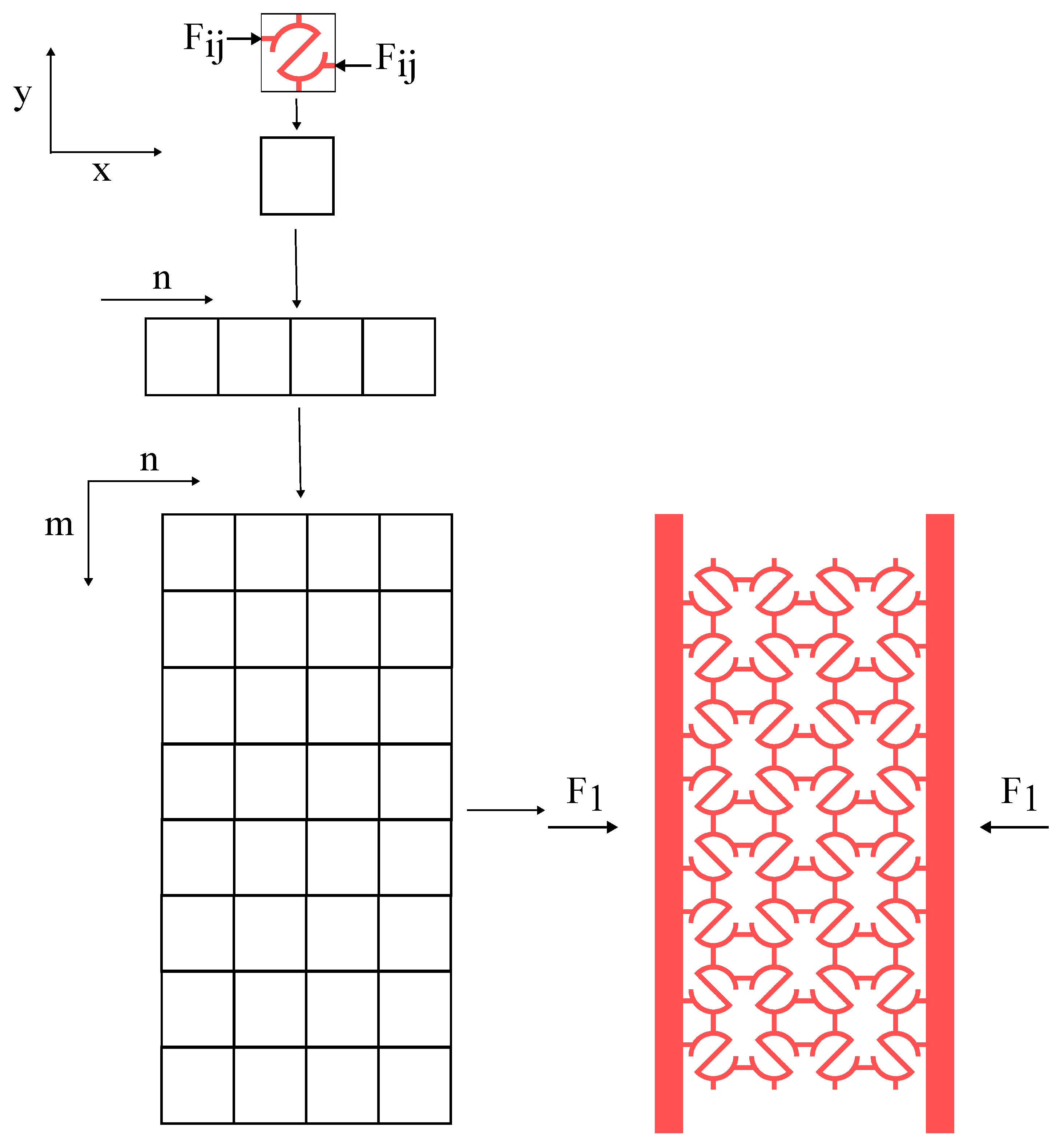

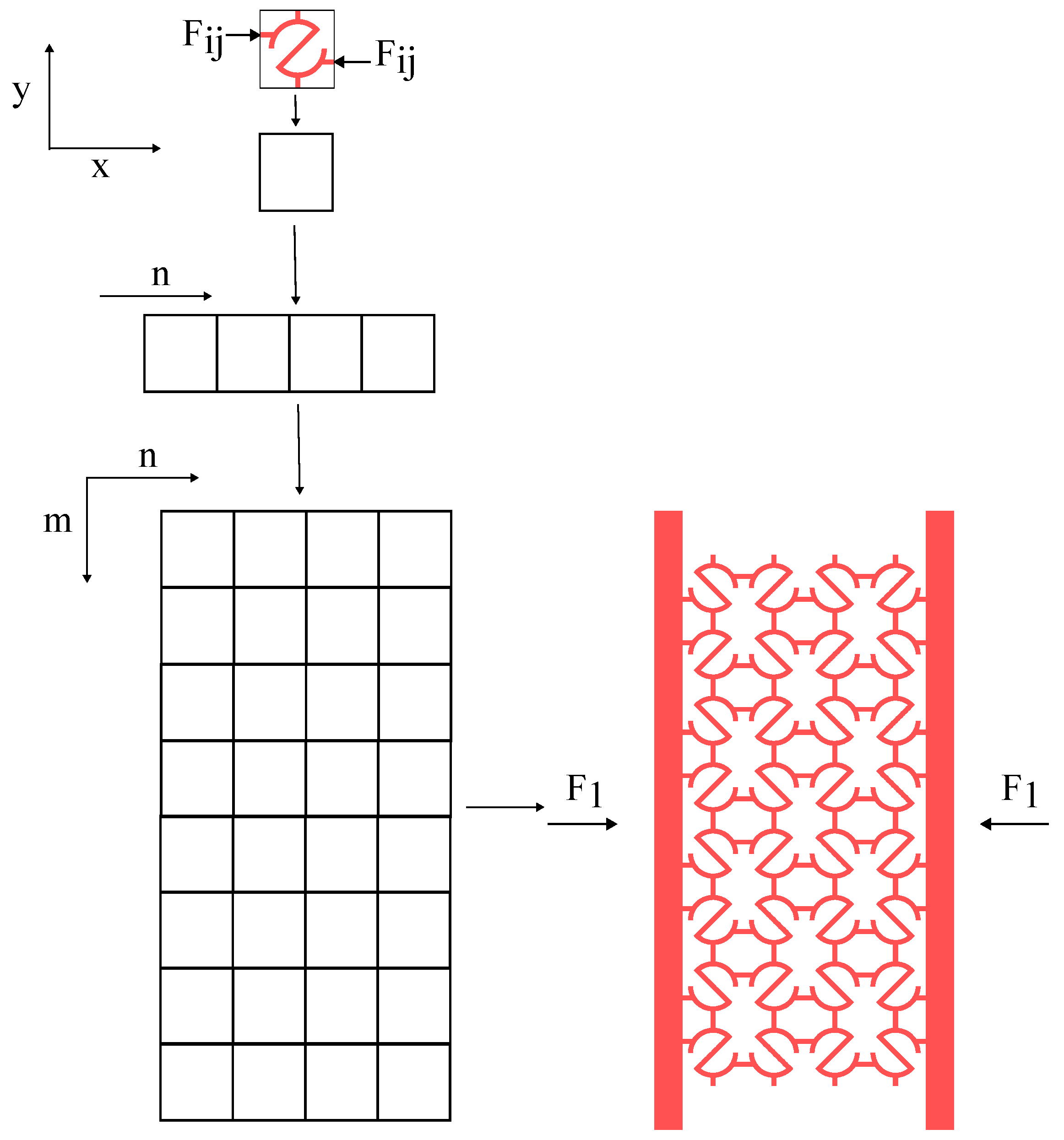

2. Materials and Methods

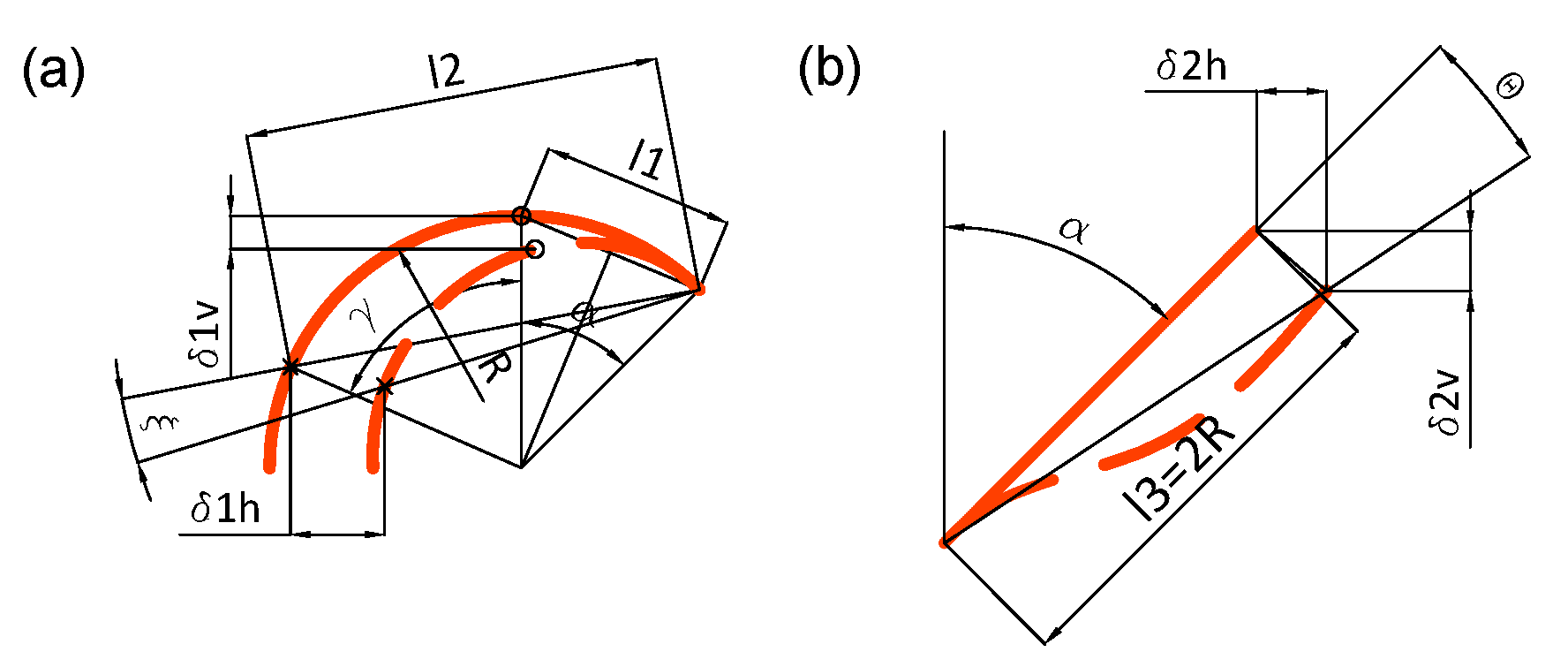

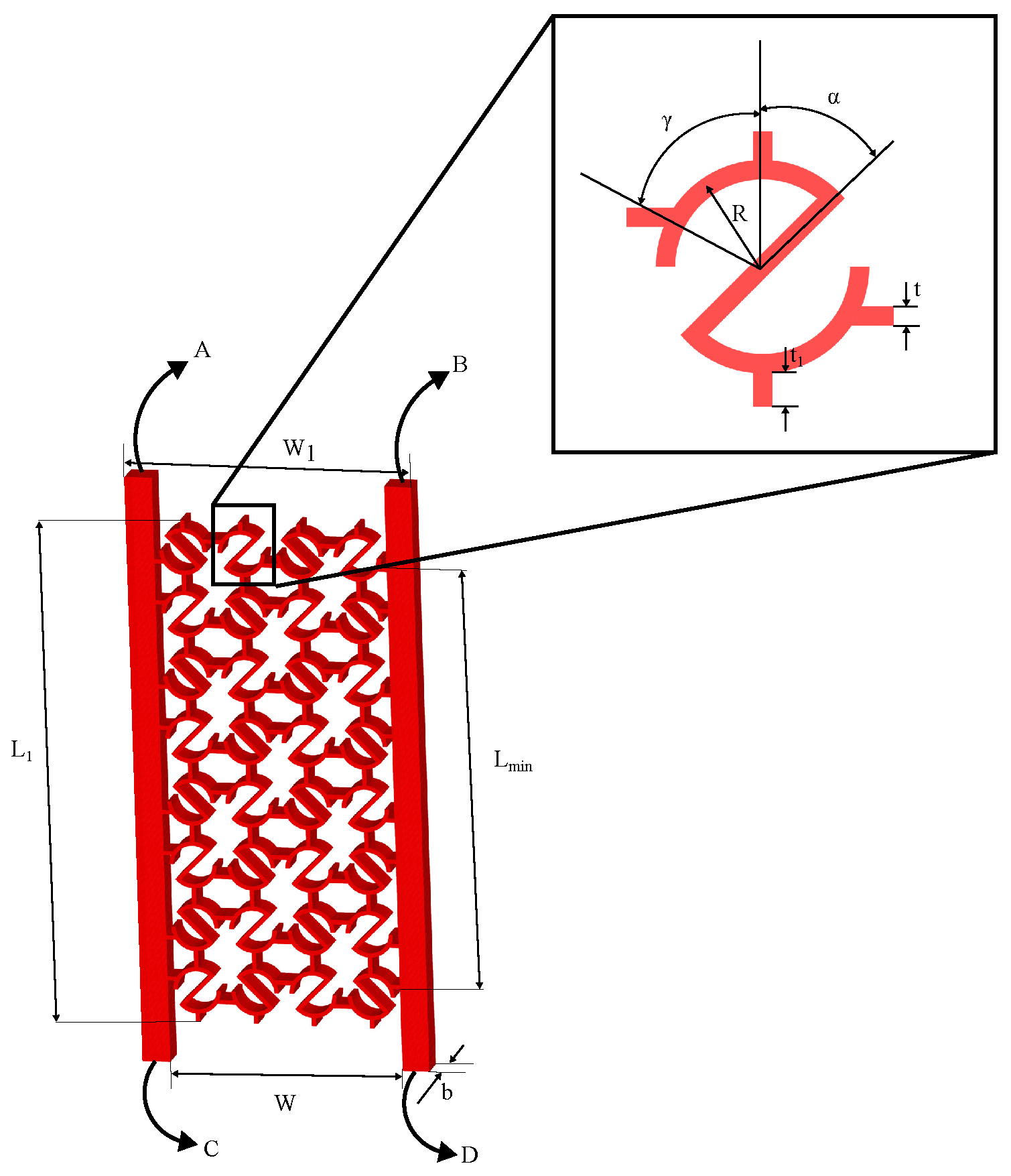

2.1. Material and Geometric Parameters

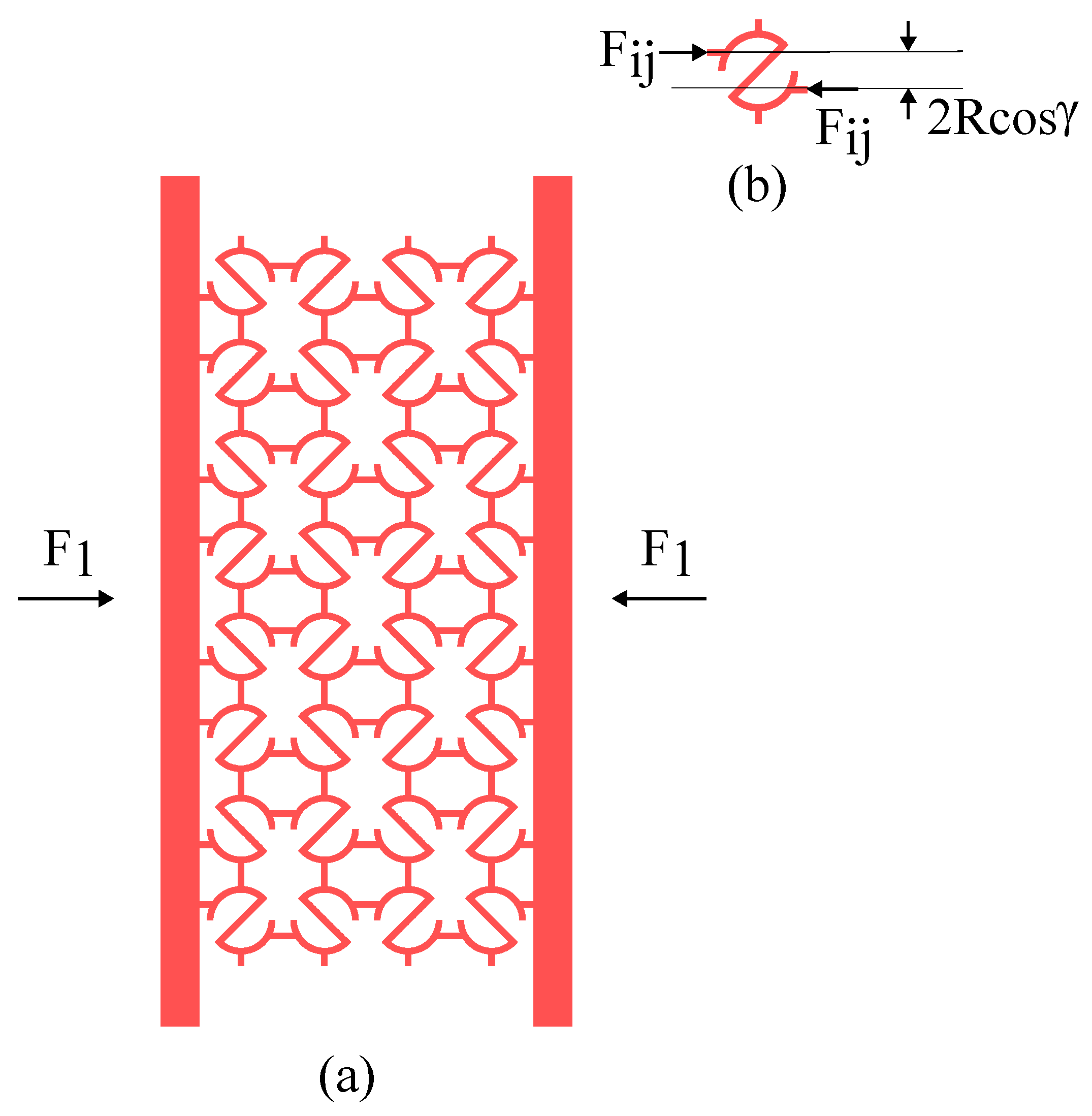

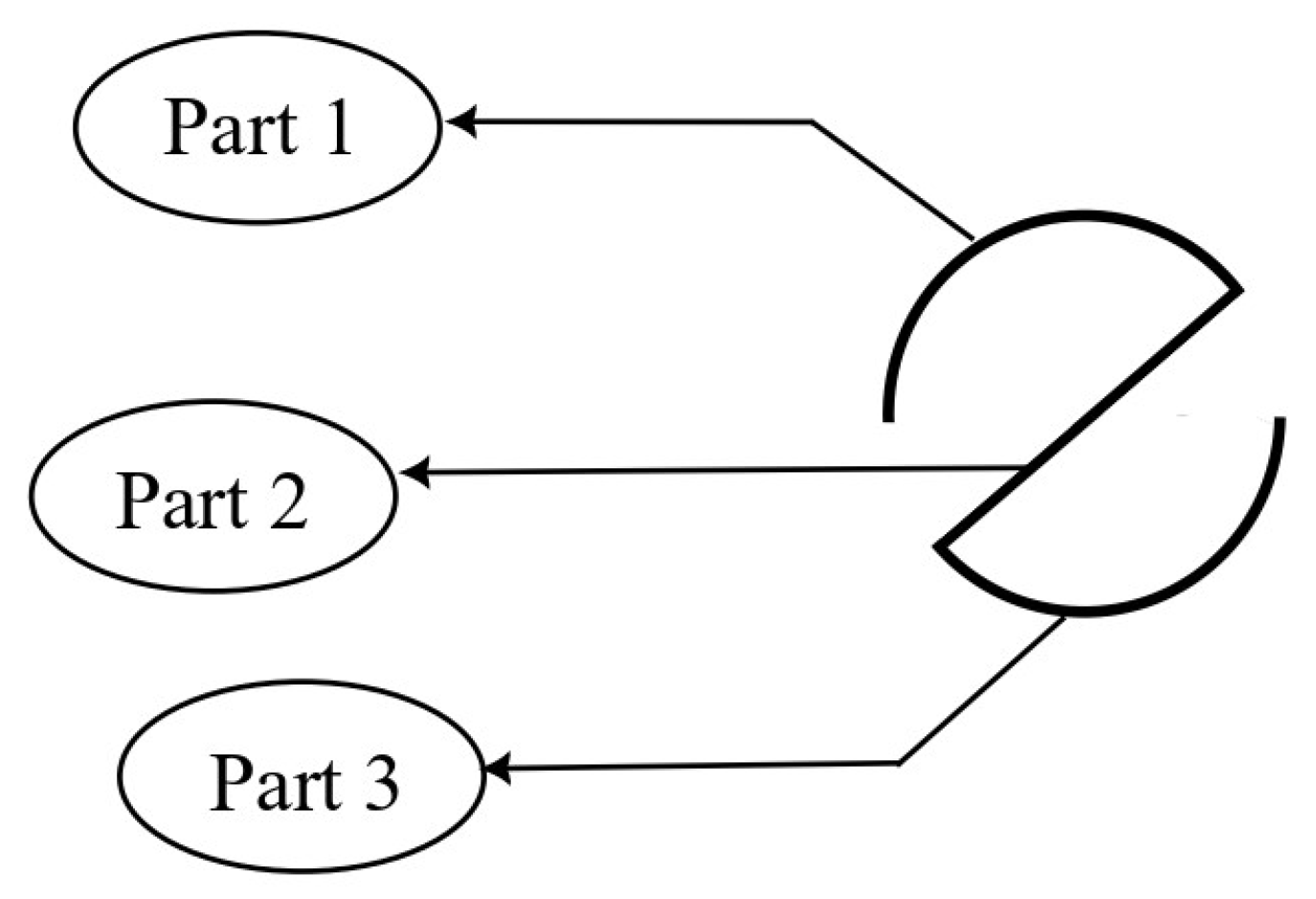

2.2. Analytical Investigation

2.2.1. Total Deflection of RUCE

2.2.2. RUCE to Entire System

2.2.3. Poisson’s Ratio Calculation

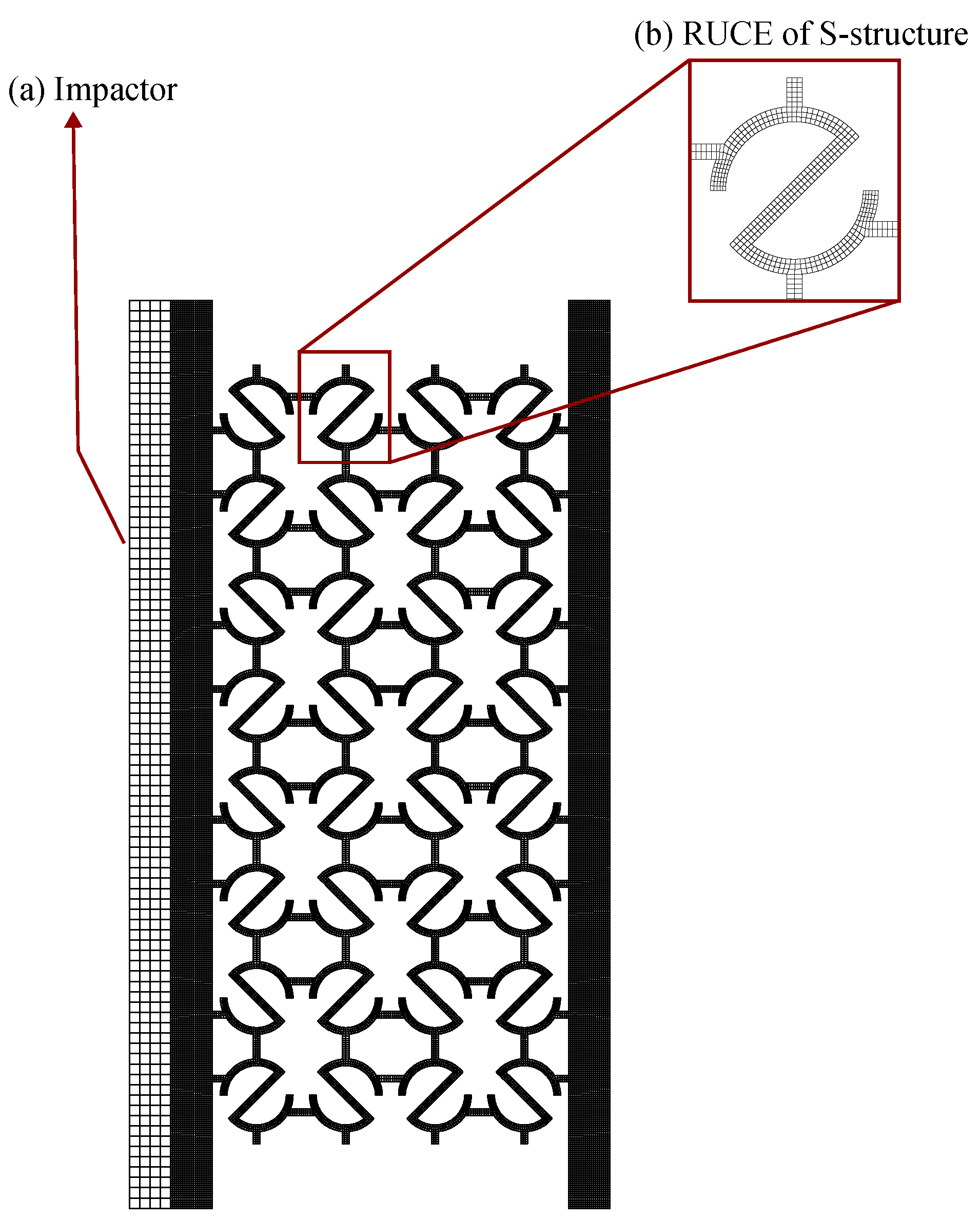

2.3. Numerical Investigation

2.3.1. Finite Element Analysis of all S-structures:

3. Results and Discussion

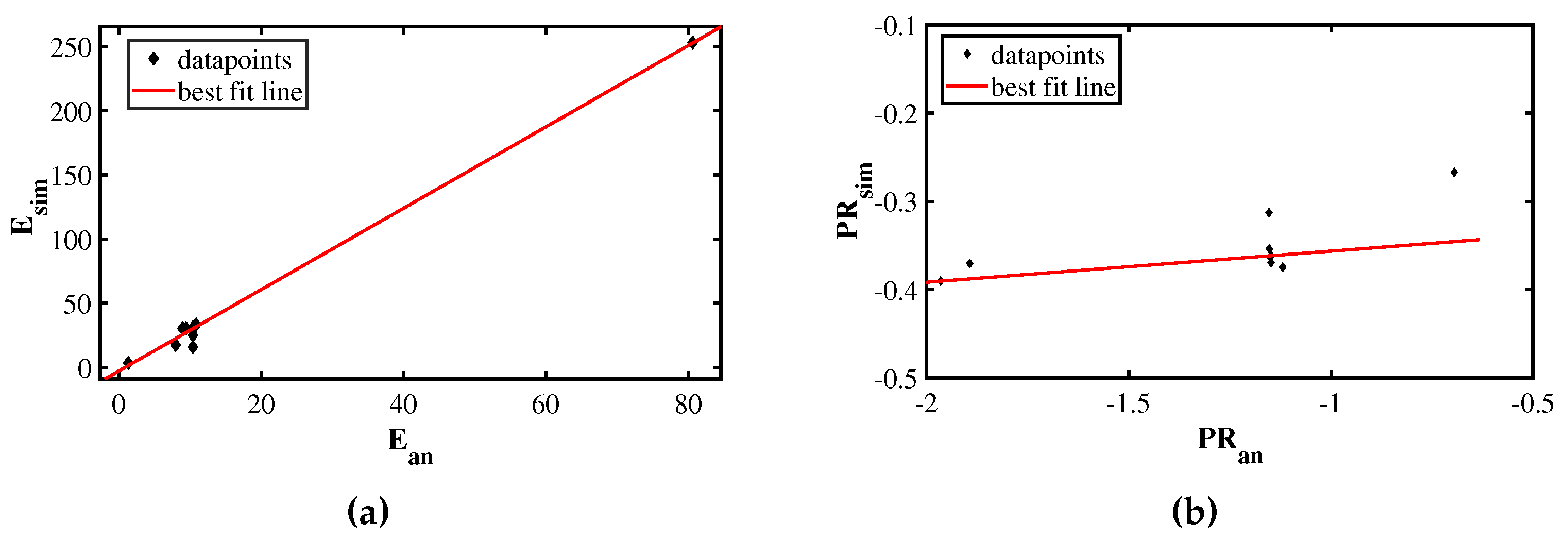

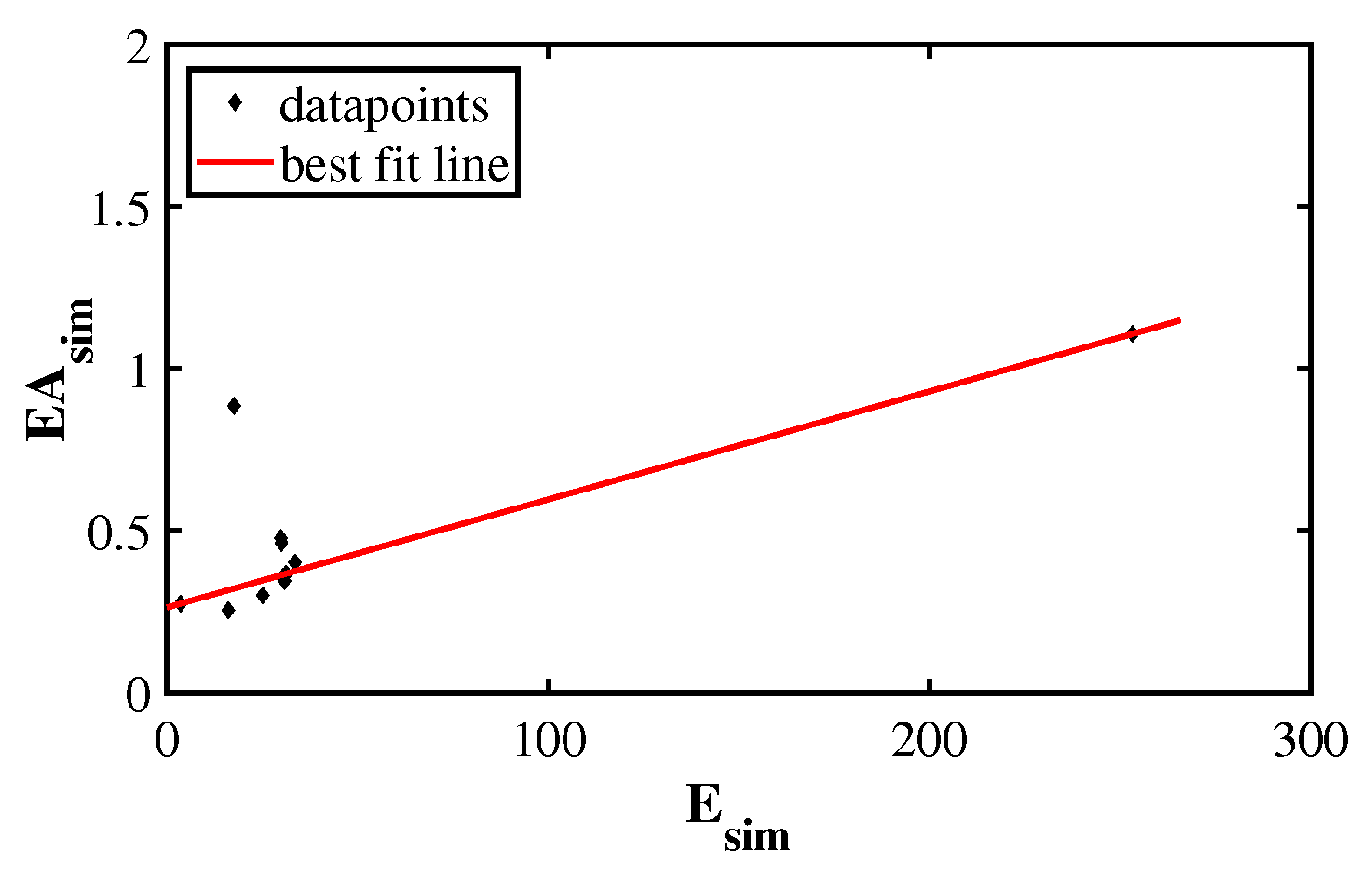

3.1. Comparison of Numerical and Analytical Studies

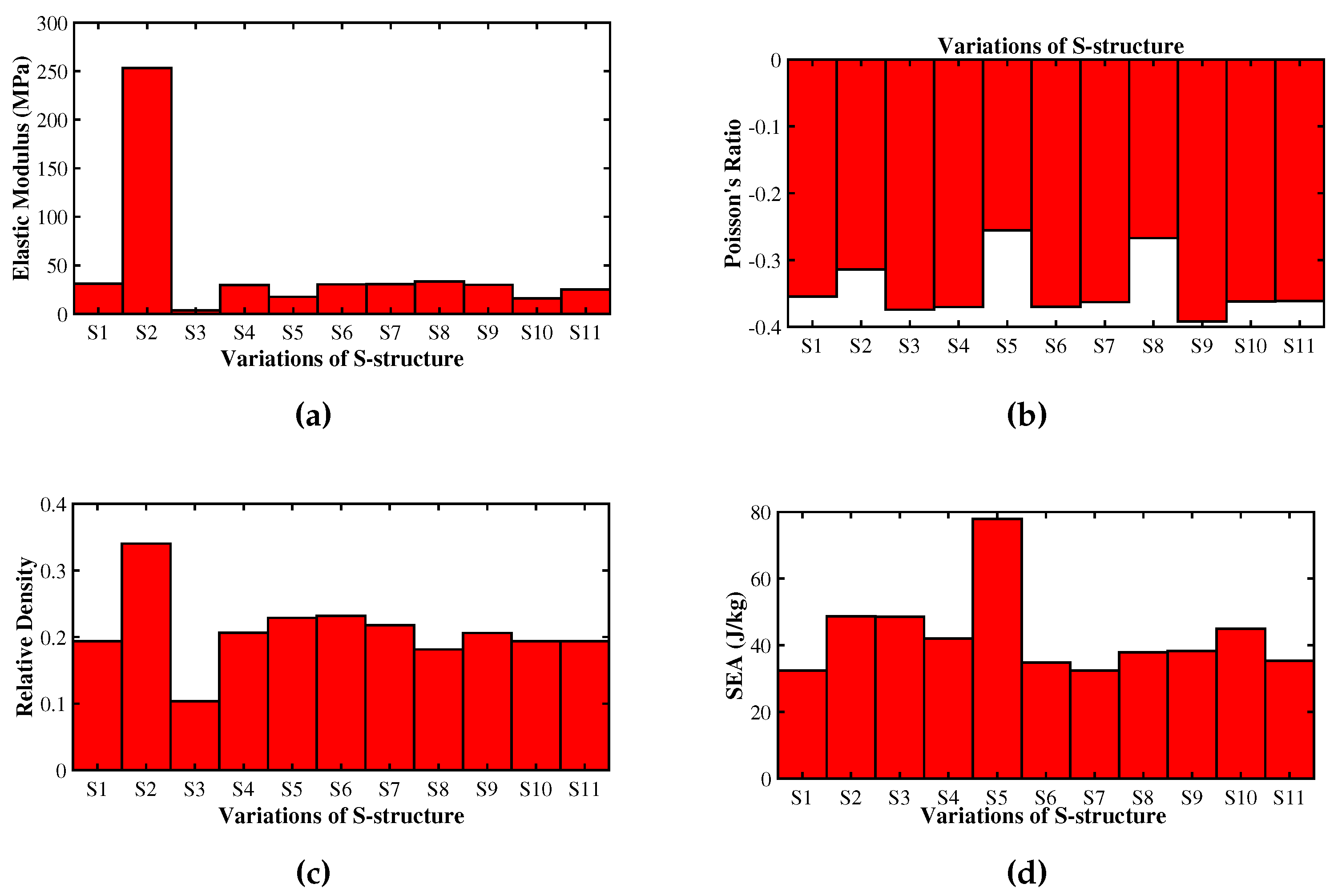

3.2. Parametric Studies

- SEA, elastic modulus, and relative density have increased with a greater thickness of struts (t); however, the NPR effect is decreased.

- Highest SEA and NPR effect is obtained for S-structure with °. With a decrease in , elastic modulus is decreased, and relative density is increased.

- Elastic modulus and NPR effect are almost unaffected by the parameter t1 (connecting strut length); however, with the increase in t1, relative density and SEA have decreased.

- Elastic modulus and energy absorption capacity are decreased with increasing value of ; however, NPR effect and relative density are increased.

- Elastic modulus is increased as the out-of-plane thickness (b) is increased; however, the NPR effect is reduced with an increase in b. SEA capacity is the least for mm, and the relative density remains unchanged.

- SEA for transverse loading condition is maximum for S-structure with °. The next highest value of SEA is obtained for mm. On the other hand, offers the highest elastic modulus among all S-structures, which is expected as increase in strut thickness implies introduction of more mass. The lowest value of SEA and elastic modulus is obtained for the S-structure with mm. So, strut thickness and have the most effect on energy absorption capacity and strength of the S-structure, as can be seen in Figure 8.

- On the other hand, the highest NPR effect is obtained for °, and the highest relative density is obtained for the S-structure with strut thickness, mm.

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| RUCE | Representative Unit Cell Element |

| FBD | Free Body Diagram |

| TB | Timoshenko Beams |

| NPR | Negative Poisson’s Ratio |

Appendix A. Analytical Investigation

Appendix A.1. Brief Description

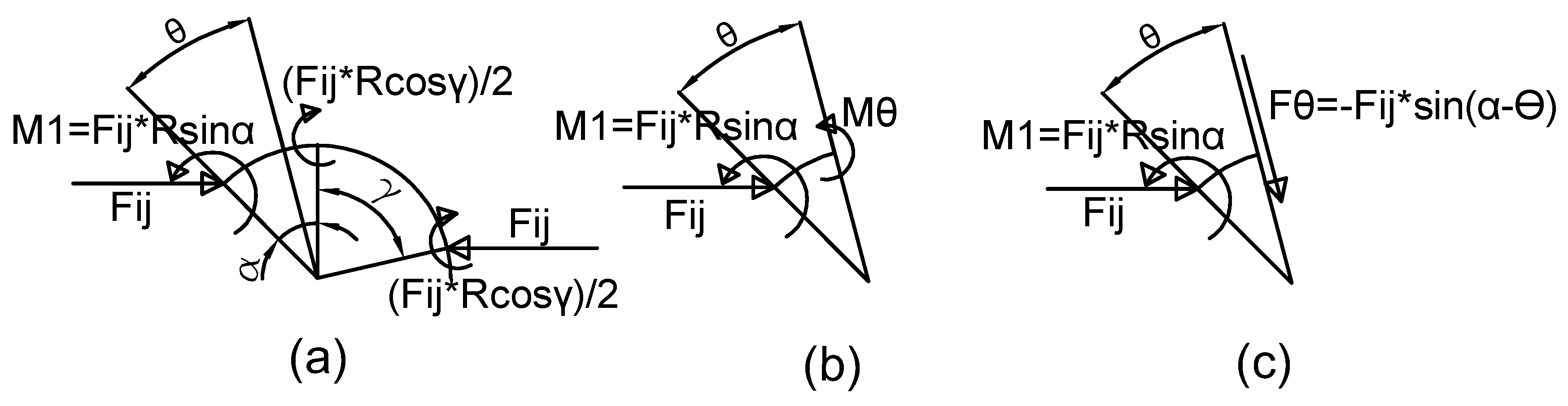

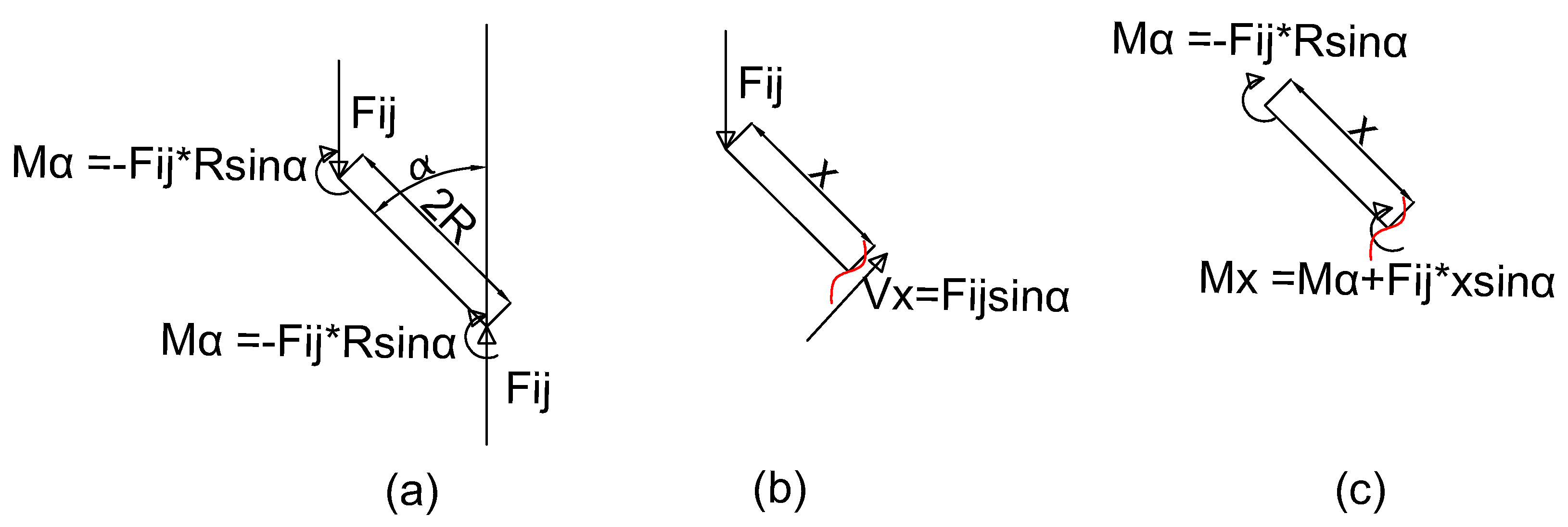

Appendix A.1.1. Shear Force and Bending MOMENT distribution

Appendix A.1.2. Analytical Investigation of Elastic Modulus

References

- Guo, M.F.; Yang, H.; Ma, L. 3D lightweight double arrow-head plate-lattice auxetic structures with enhanced stiffness and energy absorption performance. Composite Structures 2022, 290, 115484. [Google Scholar] [CrossRef]

- Schaedler, T.A.; Carter, W.B. Architected cellular materials. Annual Review of Materials Research 2016, 46, 187–210. [Google Scholar] [CrossRef]

- Francisco, M.B.; Pereira, J.L.J.; Oliver, G.A.; Roque da Silva, L.R.; Cunha Jr, S.S.; Gomes, G.F. A review on the energy absorption response and structural applications of auxetic structures. Mechanics of Advanced Materials and Structures 2022, 29, 5823–5842. [Google Scholar] [CrossRef]

- Li, T.; Liu, F.; Wang, L. Enhancing indentation and impact resistance in auxetic composite materials. Composites Part B: Engineering 2020, 198, 108229. [Google Scholar] [CrossRef]

- Huang, C.; Chen, L. Negative Poisson’s ratio in modern functional materials. Advanced Materials 2016, 28, 8079–8096. [Google Scholar] [CrossRef] [PubMed]

- Lim, T.; Alderson, A.; Alderson, K. Experimental studies on the impact properties of auxetic materials. physica status solidi (b) 2014, 251, 307–313. [Google Scholar] [CrossRef]

- Novak, N.; Plesec, V.; Harih, G.; Cupar, A.; Kaljun, J.; Vesenjak, M. Development, fabrication and mechanical characterisation of auxetic bicycle handlebar grip. Scientific reports 2023, 13, 8158. [Google Scholar] [CrossRef] [PubMed]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Leary, M.; Berto, F.; Du Plessis, A. Metal additive manufacturing in aerospace: A review. Materials & Design 2021, 209, 110008. [Google Scholar]

- Shirzad, M.; Zolfagharian, A.; Bodaghi, M.; Nam, S.Y. Auxetic metamaterials for bone-implanted medical devices: recent advances and new perspectives. European Journal of Mechanics-A/Solids 2022, 104905. [Google Scholar] [CrossRef]

- Lvov, V.A.; Senatov, F.S.; Veveris, A.A.; Skrybykina, V.A.; Díaz Lantada, A. Auxetic metamaterials for biomedical devices: Current Situation, main challenges, and research trends. Materials 2022, 15, 1439. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, D. Mechanical properties of auxetic cellular material consisting of re-entrant hexagonal honeycombs. Materials 2016, 9, 900. [Google Scholar] [CrossRef] [PubMed]

- Ghavidelnia, N.; Bodaghi, M.; Hedayati, R. Idealized 3D auxetic mechanical metamaterial: an analytical, numerical, and experimental study. Materials 2021, 14, 993. [Google Scholar] [CrossRef] [PubMed]

- Xue, Y.; Gao, P.; Zhou, L.; Han, F. An enhanced three-dimensional auxetic lattice structure with improved property. Materials 2020, 13, 1008. [Google Scholar] [CrossRef] [PubMed]

- Liu, R.; Yao, G.; Xu, Z.; Yu, Z.; Zhang, Z.; Han, C.; Li, H.; Jiang, S. Study on quasi-static mechanical properties of novel reentrant structures with multiple energy dissipation. Thin-Walled Structures 2022, 177, 109442. [Google Scholar] [CrossRef]

- Qi, C.; Jiang, F.; Remennikov, A.; Pei, L.Z.; Liu, J.; Wang, J.S.; Liao, X.W.; Yang, S. Quasi-static crushing behavior of novel re-entrant circular auxetic honeycombs. Composites Part B: Engineering 2020, 197, 108117. [Google Scholar] [CrossRef]

- Ben-Yelun, I.; Gómez-Carano, G.; San Millán, F.J.; Sanz, M.Á.; Montáns, F.J.; Saucedo-Mora, L. GAM: General Auxetic Metamaterial with Tunable 3D Auxetic Behavior Using the Same Unit Cell Boundary Connectivity. Materials 2023, 16, 3473. [Google Scholar] [CrossRef]

- Zhang, W.; Yin, H.; Wu, Y.; Jin, Q.; Wu, L.; Wen, G.; Liu, J.; Wu, X. A Novel Auxetic 3D Lattice Structure for Enhancing Energy Absorption. Composite Structures 2023, 117620. [Google Scholar] [CrossRef]

- Mazur, E.; Shishkovsky, I. Additively manufactured hierarchical auxetic mechanical metamaterials. Materials 2022, 15, 5600. [Google Scholar] [CrossRef] [PubMed]

- Tatlıer, M.S.; Öztürk, M.; Baran, T. Linear and non-linear in-plane behaviour of a modified re-entrant core cell. Engineering Structures 2021, 234, 111984. [Google Scholar] [CrossRef]

- Zhang, X.; Hao, H.; Tian, R.; Xue, Q.; Guan, H.; Yang, X. Quasi-static compression and dynamic crushing behaviors of novel hybrid re-entrant auxetic metamaterials with enhanced energy-absorption. Composite Structures 2022, 288, 115399. [Google Scholar] [CrossRef]

- Elipe, J.C.Á.; Lantada, A.D. Comparative study of auxetic geometries by means of computer-aided design and engineering. Smart materials and structures 2012, 21, 105004. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, S.; Scarpa, F.; Wang, J.; Sun, R. In-plane mechanical behavior of novel auxetic hybrid metamaterials. Thin-Walled Structures 2021, 159, 107191. [Google Scholar] [CrossRef]

- Meena, K.; Singamneni, S. Novel hybrid auxetic structures for improved in-plane mechanical properties via additive manufacturing. Mechanics of Materials 2021, 158, 103890. [Google Scholar] [CrossRef]

- Wang, Y.; Zeng, Q.; Wang, J.; Li, Y.; Fang, D. Inverse design of shell-based mechanical metamaterial with customized loading curves based on machine learning and genetic algorithm. Computer Methods in Applied Mechanics and Engineering 2022, 401. [Google Scholar] [CrossRef]

- Cui, J.; Zhang, L.; Gain, A.K. A novel auxetic unit cell for 3D metamaterials of designated negative Poisson’s ratio. International Journal of Mechanical Sciences 2023, 260, 108614. [Google Scholar] [CrossRef]

- Zhang, C.; Lu, F.; Lin, B.; Ling, X.; Zhu, Y. Analysis on the collapse stress of auxetic tubular anti-tetrachiral structures. European Journal of Mechanics-A/Solids 2023, 105167. [Google Scholar] [CrossRef]

- Wang, H.; Lu, Z.; Yang, Z.; Li, X. A novel re-entrant auxetic honeycomb with enhanced in-plane impact resistance. Composite Structures 2019, 208, 758–770. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, L.; Gao, S.; Wu, W.; Xiao, D.; Li, Y. Dynamic response of sandwich beam with star-shaped reentrant honeycomb core subjected to local impulsive loading. Thin-Walled Structures 2021, 161, 107420. [Google Scholar] [CrossRef]

- Usta, F.; Türkmen, H.S.; Scarpa, F. Low-velocity impact resistance of composite sandwich panels with various types of auxetic and non-auxetic core structures. Thin-Walled Structures 2021, 163, 107738. [Google Scholar] [CrossRef]

- An, M.R.; Wang, L.; Liu, H.T.; Ren, F.G. In-plane crushing response of a novel bidirectional re-entrant honeycomb with two plateau stress regions. Thin-Walled Structures 2022, 170, 108530. [Google Scholar] [CrossRef]

- Xu, S.; Beynon, J.H.; Ruan, D.; Lu, G. Experimental study of the out-of-plane dynamic compression of hexagonal honeycombs. Composite Structures 2012, 94, 2326–2336. [Google Scholar] [CrossRef]

- Venkata, S.P.; Balbi, V.; Destrade, M.; Accoto, D.; Zurlo, G. Programmable wrinkling for functionally-graded auxetic circular membranes. Extreme Mechanics Letters 2023, 63, 102045. [Google Scholar] [CrossRef]

- Mukherjee, S.; Adhikari, S. A general analytical framework for the mechanics of heterogeneous hexagonal lattices. Thin-Walled Structures 2021, 167, 108188. [Google Scholar] [CrossRef]

- Mukhopadhyay, T.; Adhikari, S. Effective in-plane elastic properties of auxetic honeycombs with spatial irregularity. Mechanics of Materials 2016, 95, 204–222. [Google Scholar] [CrossRef]

- Liu, W.; Li, H.; Zhang, J.; Bai, Y. In-plane mechanics of a novel cellular structure for multiple morphing applications. Composite Structures 2019, 207, 598–611. [Google Scholar] [CrossRef]

- Guo, M.F.; Yang, H.; Zhou, Y.M.; Ma, L. Mechanical properties of 3D hybrid double arrow-head structure with tunable Poisson’s ratio. Aerospace Science and Technology 2021, 119, 107177. [Google Scholar] [CrossRef]

- Meena, K.; Singamneni, S. A new auxetic structure with significantly reduced stress concentration effects. Materials & Design 2019, 173, 107779. [Google Scholar]

- Nirmal, R.; Patnaik, B.; Jayaganthan, R. FEM simulation of high speed impact behaviour of additively manufactured AlSi10Mg alloy. Journal of Dynamic Behavior of Materials 2021, 1–16. [Google Scholar] [CrossRef]

| Variations | R (in mm) | t (in mm) | t1 (in mm) | b (in mm) | ||

| S1 | 4 | 0.8 | 1.5 | 45 | 75 | 5 |

| S2 | 4 | 1.6 | 1.5 | 45 | 75 | 5 |

| S3 | 4 | 0.4 | 1.5 | 45 | 75 | 5 |

| S4 | 4 | 0.8 | 1.5 | 45 | 62.5 | 5 |

| S5 | 4 | 0.8 | 1.5 | 45 | 50 | 5 |

| S6 | 4 | 0.8 | 0.75 | 45 | 75 | 5 |

| S7 | 4 | 0.8 | 1 | 45 | 75 | 5 |

| S8 | 4 | 0.8 | 1.5 | 30 | 75 | 5 |

| S9 | 4 | 0.8 | 1.5 | 60 | 75 | 5 |

| S10 | 4 | 0.8 | 1.5 | 45 | 75 | 2.5 |

| S11 | 4 | 0.8 | 1.5 | 45 | 75 | 3.75 |

| Material Parameters | Values |

| Density (in kg/) | 2700 |

| Elastic Modulus (in GPa) | 75 |

| Poisson’s Ratio | 0.3 |

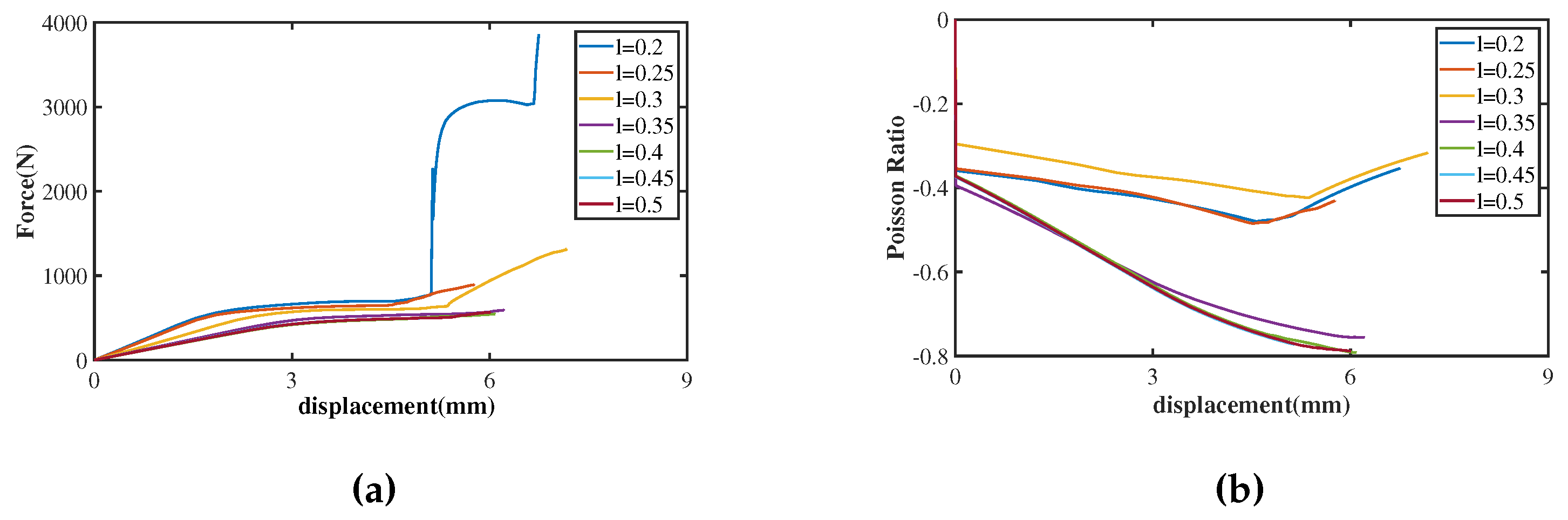

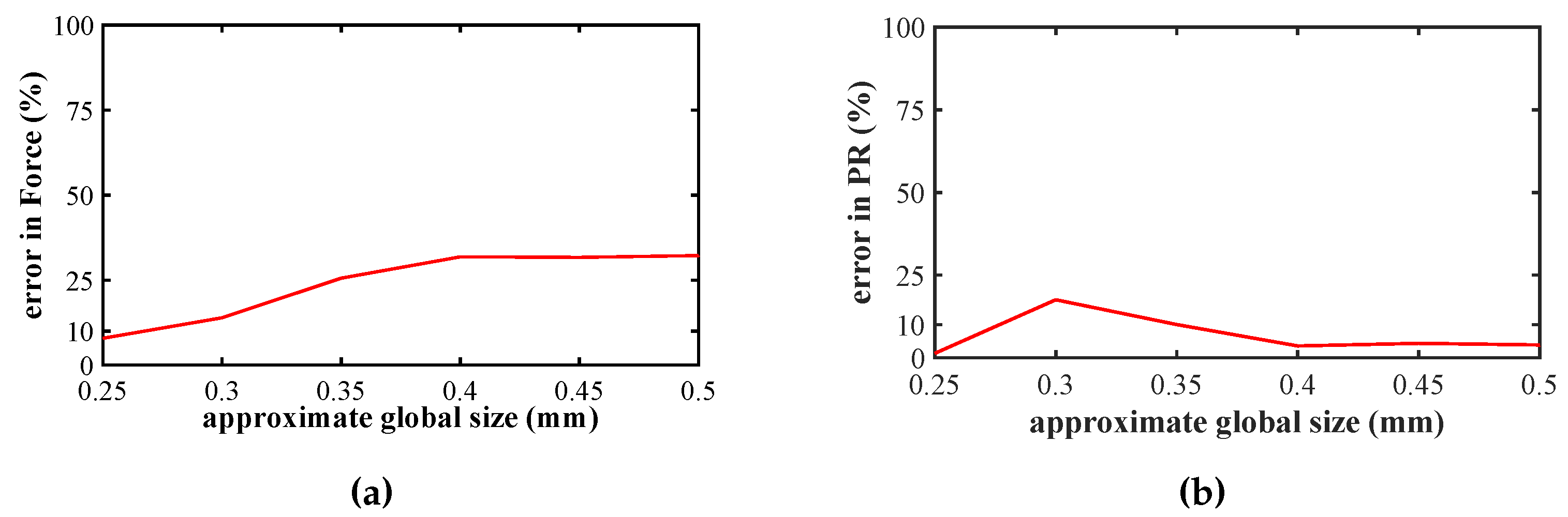

| l (mm) | (N) | NPR(first peak) | Absolute error in (%) | Absolute error in NPR (first peak) (%) | Time (s) | |

| 0.2 | 695.922 | -0.358955 | - | - | 921398 | 221 |

| 0.25 | 641.015 | -0.353701 | 7.89 | 1.46 | 601450 | 334 |

| 0.3 | 599.039 | -0.296 | 13.92 | 17.54 | 245588.2 | 330 |

| 0.35 | 517.979 | -0.394992 | 25.57 | 10.04 | 17926 | 52 |

| 0.4 | 474.29 | -0.371764 | 31.85 | 3.57 | 20280 | 56 |

| 0.45 | 475.383 | -0.374599 | 31.69 | 4.36 | 7742.4 | 32 |

| 0.5 | 471.711 | -0.372856 | 32.22 | 3.87 | 10348 | 41 |

| Various S-structure | W | L | ||

| S1 | 46.001 | 85.678 | 56.001 | 81.122 |

| S2 | 49.092 | 92.285 | 59.092 | 87.135 |

| S3 | 44.455 | 82.374 | 54.455 | 78.026 |

| S4 | 43.223 | 87.463 | 53.223 | 79.337 |

| S5 | 38.965 | 89.057 | 48.965 | 77.743 |

| S6 | 40.001 | 75.178 | 50.001 | 70.622 |

| S7 | 42.001 | 78.678 | 52.001 | 74.122 |

| S8 | 46.001 | 85.678 | 56.001 | 81.122 |

| S9 | 46.001 | 85.677 | 56.001 | 81.123 |

| S10 | 46.001 | 85.678 | 56.001 | 81.122 |

| S11 | 46.001 | 85.678 | 56.001 | 81.122 |

| Various S-structure | E (MPa) | PR (first peak) | EA (J) | SEA (J/kg) |

| S1 | 31.17863 | -0.354618 | 0.37 | 32.37 |

| S2 | 253.188 | -0.313944 | 1.11 | 48.73 |

| S3 | 3.506994 | -0.374515 | 0.28 | 48.55 |

| S4 | 29.77344 | -0.370364 | 0.48 | 42.03 |

| S5 | 17.4955 | -0.255436 | 0.89 | 77.95 |

| S6 | 30.42813 | -0.37018 | 0.36 | 34.81 |

| S7 | 30.72542 | -0.363079 | 0.35 | 32.39 |

| S8 | 33.47418 | -0.267152 | 0.40 | 37.84 |

| S9 | 29.91472 | -0.391942 | 0.46 | 38.32 |

| S10 | 16.00413 | -0.362093 | 0.26 | 44.94 |

| S11 | 25.03883 | -0.361589 | 0.30 | 35.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).