Submitted:

30 January 2024

Posted:

31 January 2024

You are already at the latest version

Abstract

Keywords:

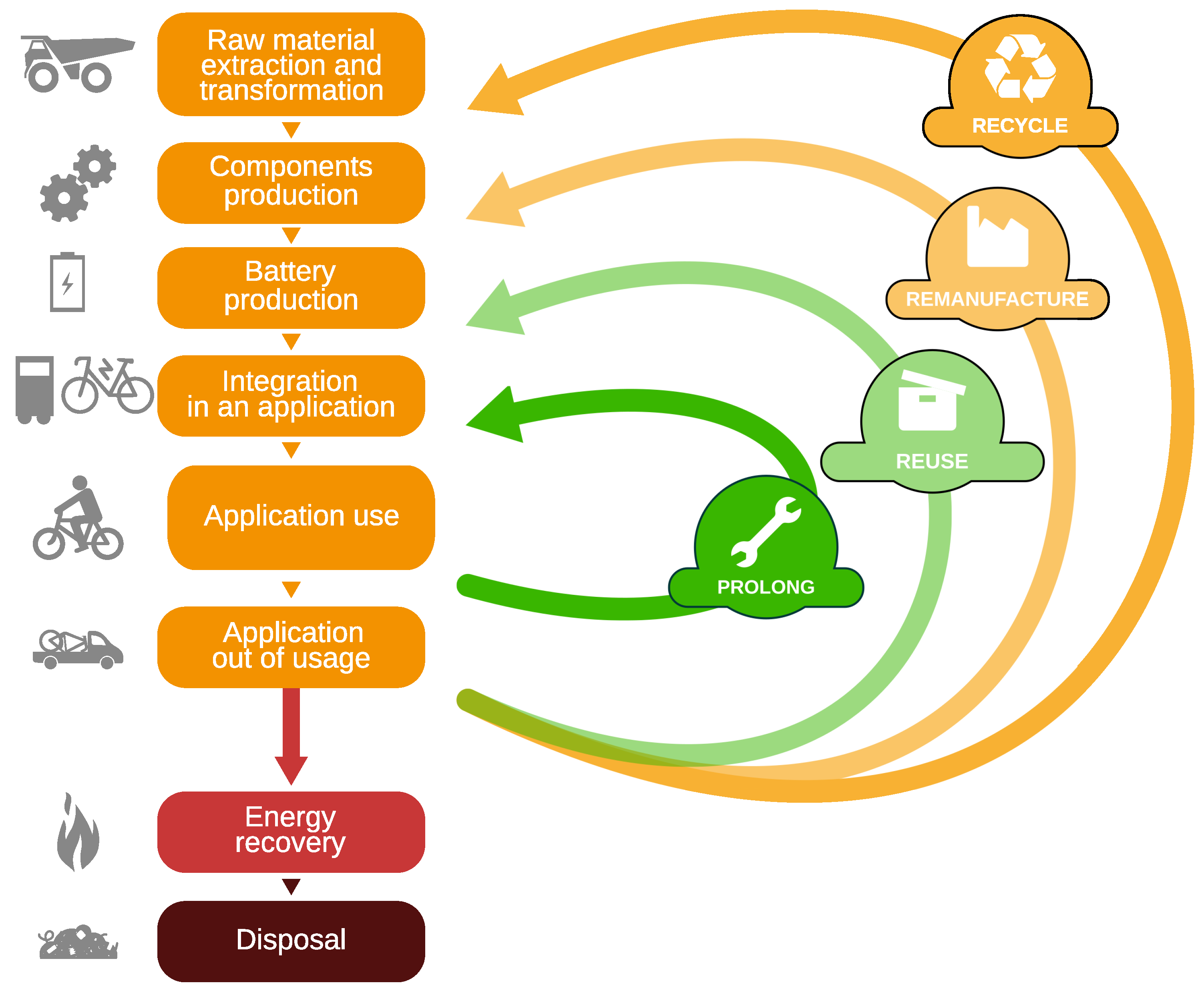

1. Introduction

- to standardise the format for different product types,

- to standardise performance indicators and how they are measured,

- to clearly define the data to be included in the passport,

- to protect intellectual property and confidential information,

- to allow access to the data by repairers, recyclers and consumers.

1.1. Contributions

1.2. Layout

2. Experimental Evaluation of Battery Suitability for Reuse

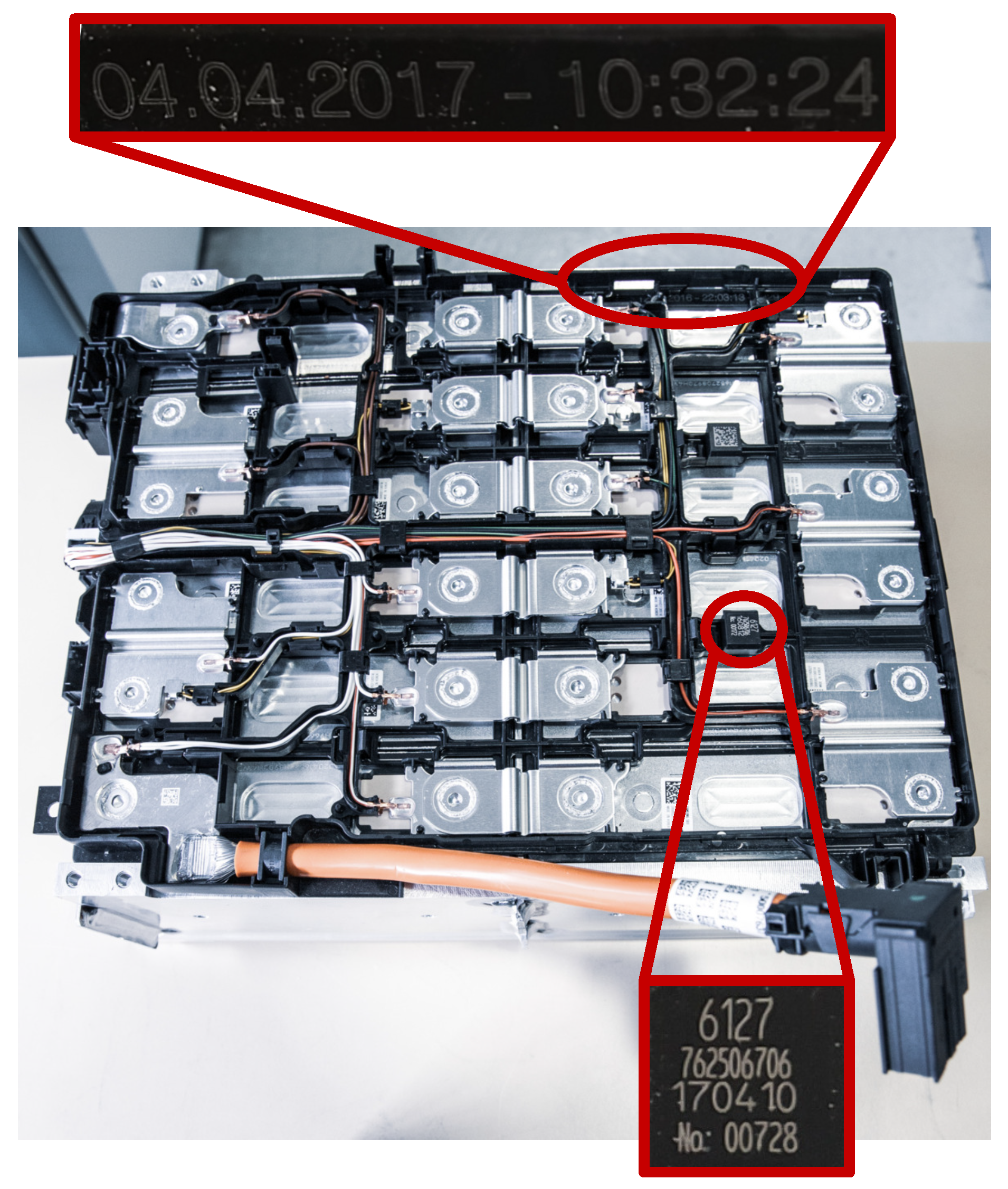

2.1. Visual Inspection of the Battery

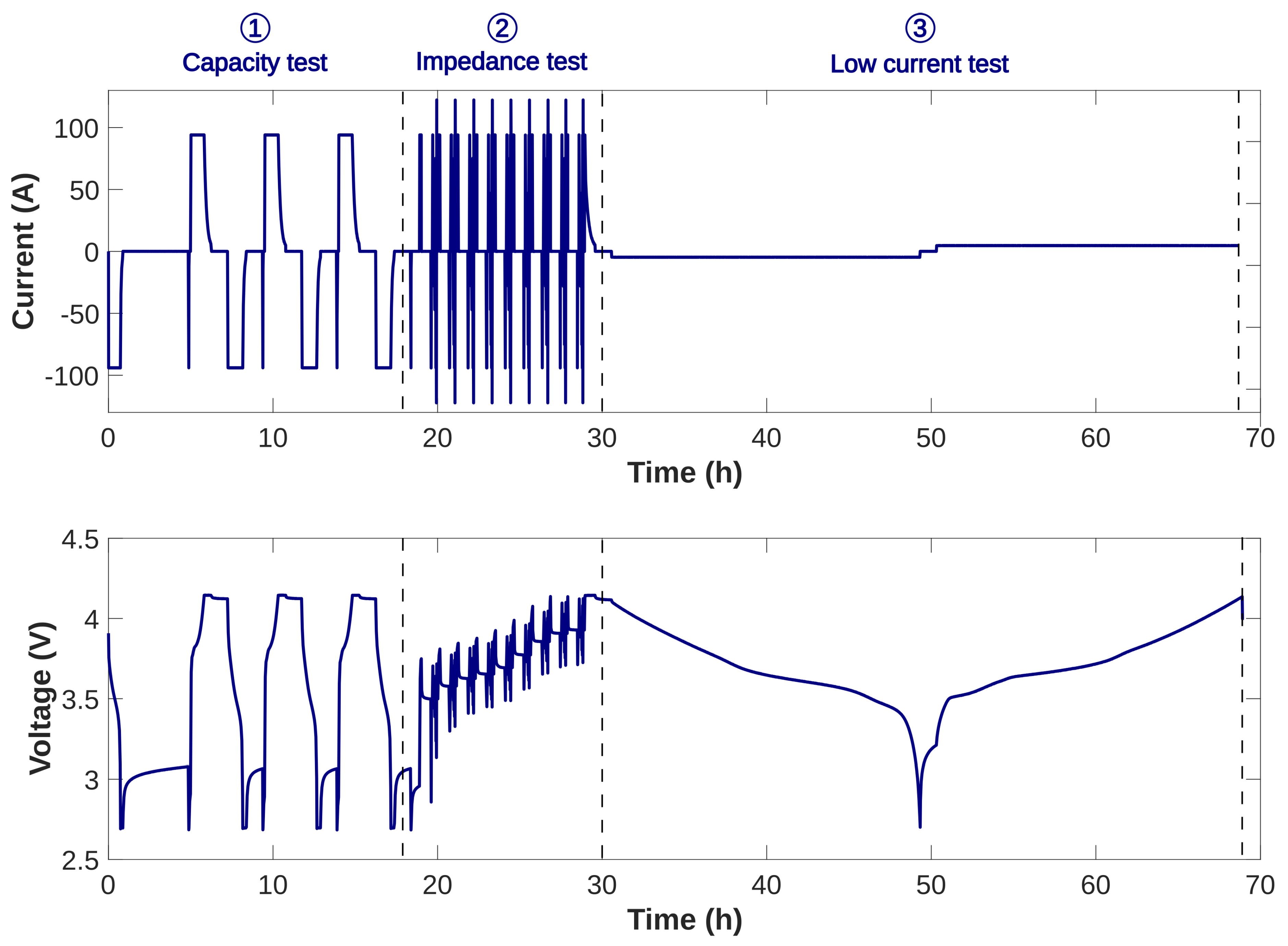

2.2. Experimental Characterisation of the Second Life Module

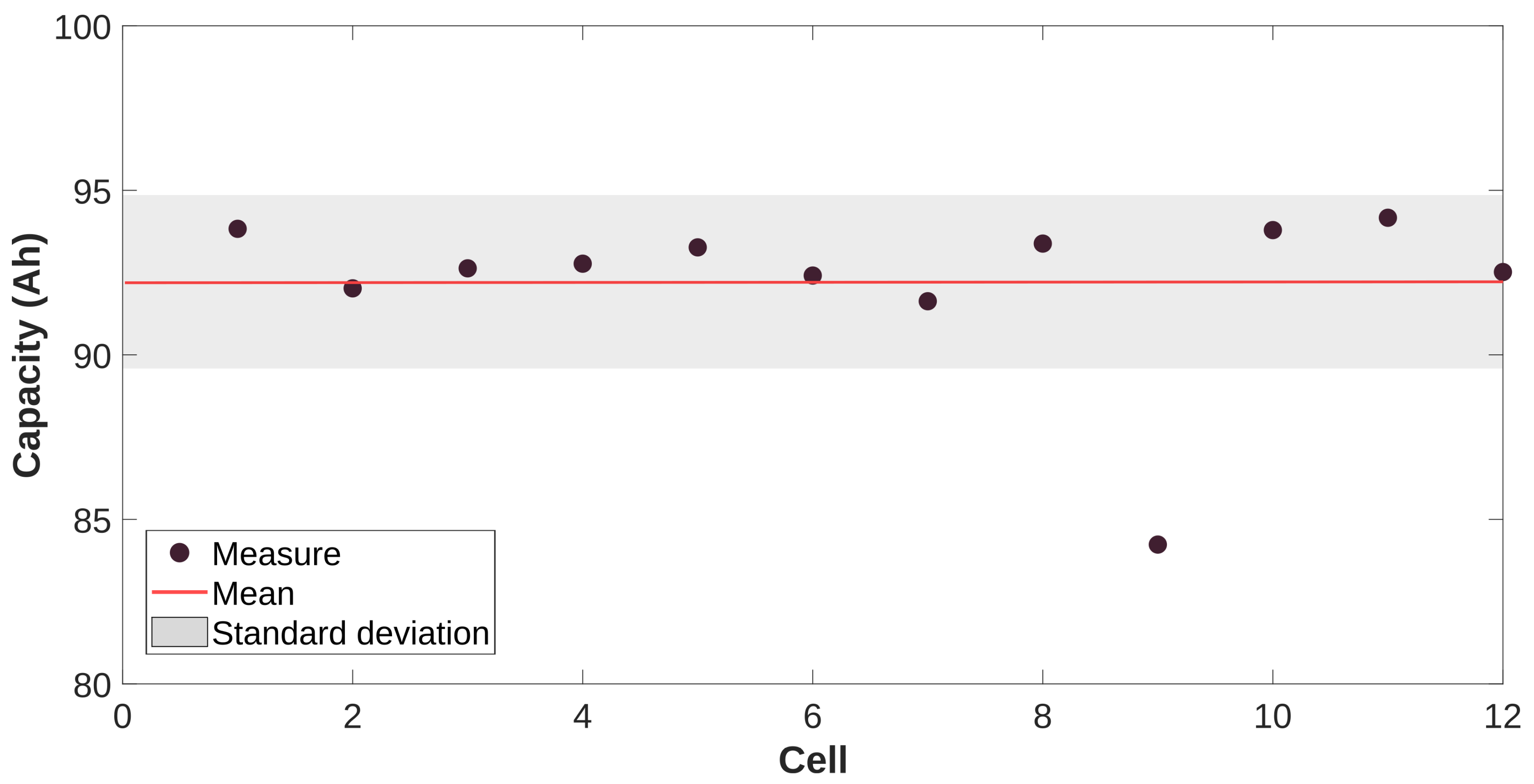

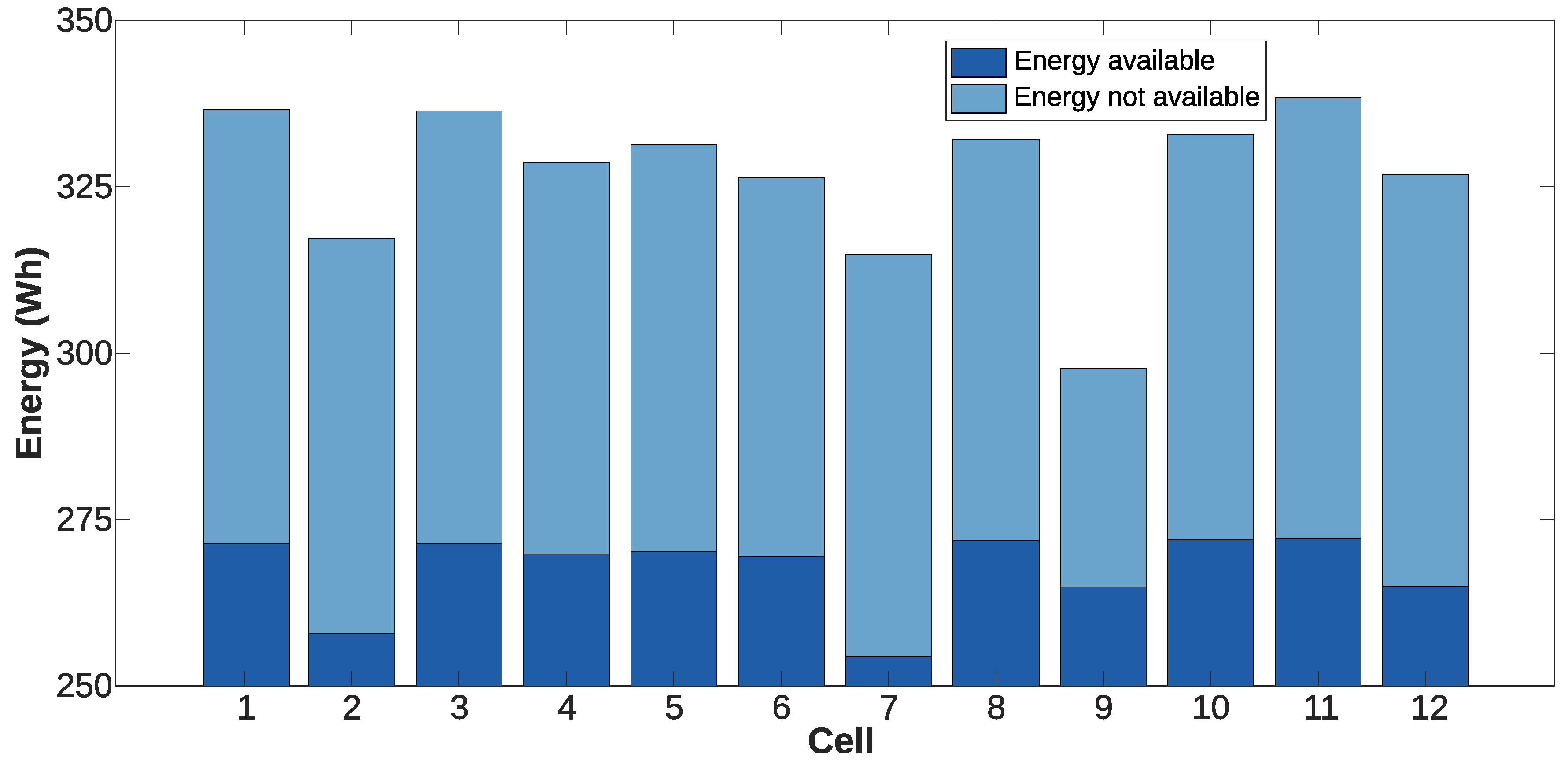

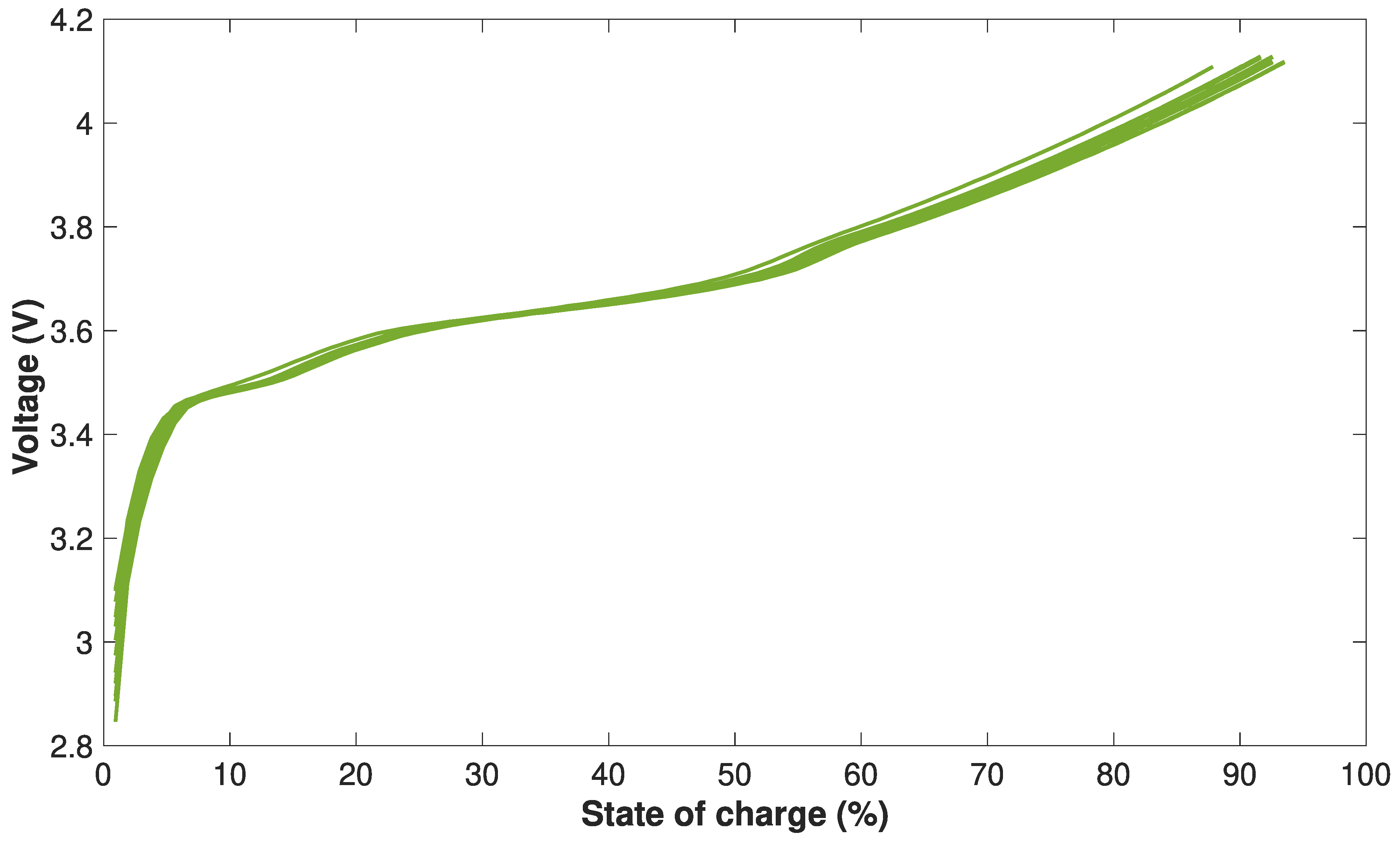

2.3. Capacity Measure and Estimation of Energy

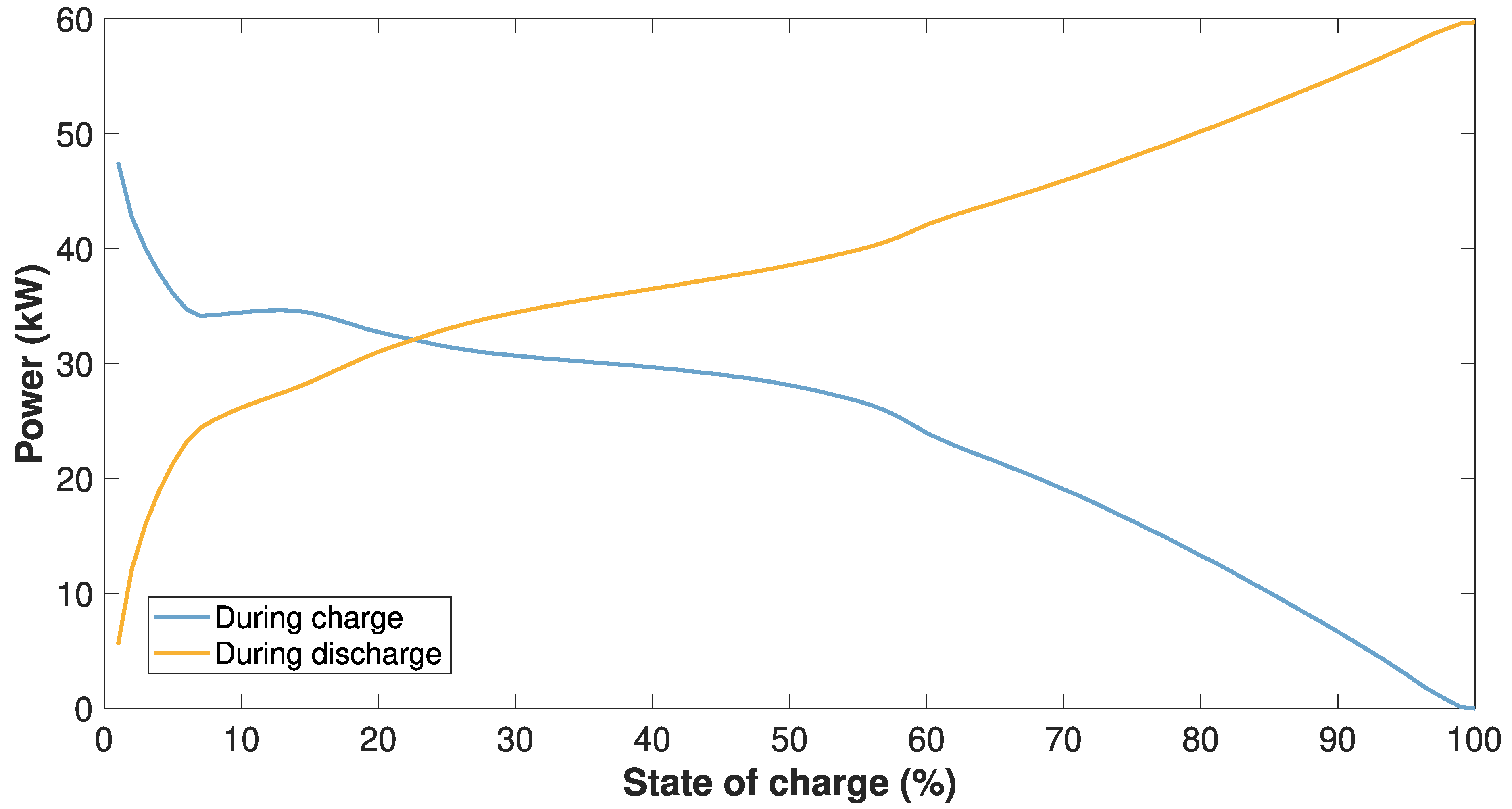

2.4. Resistance and Power

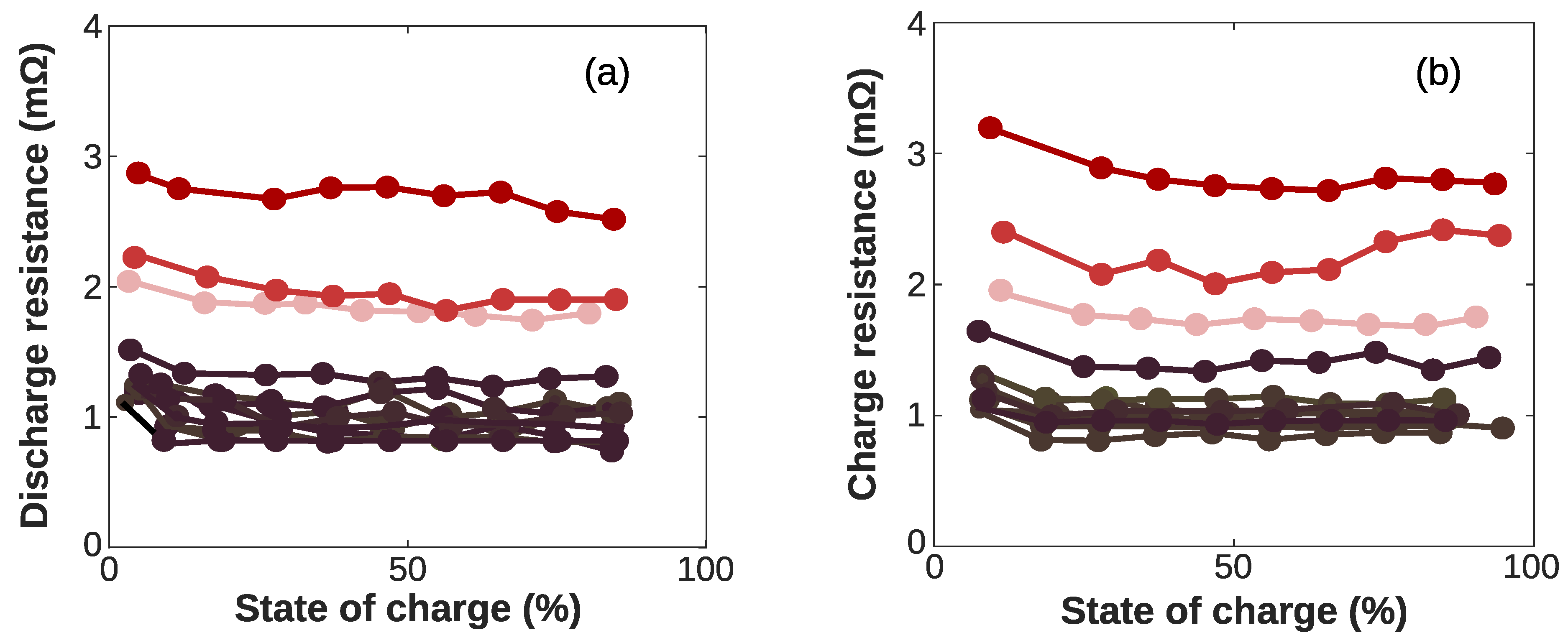

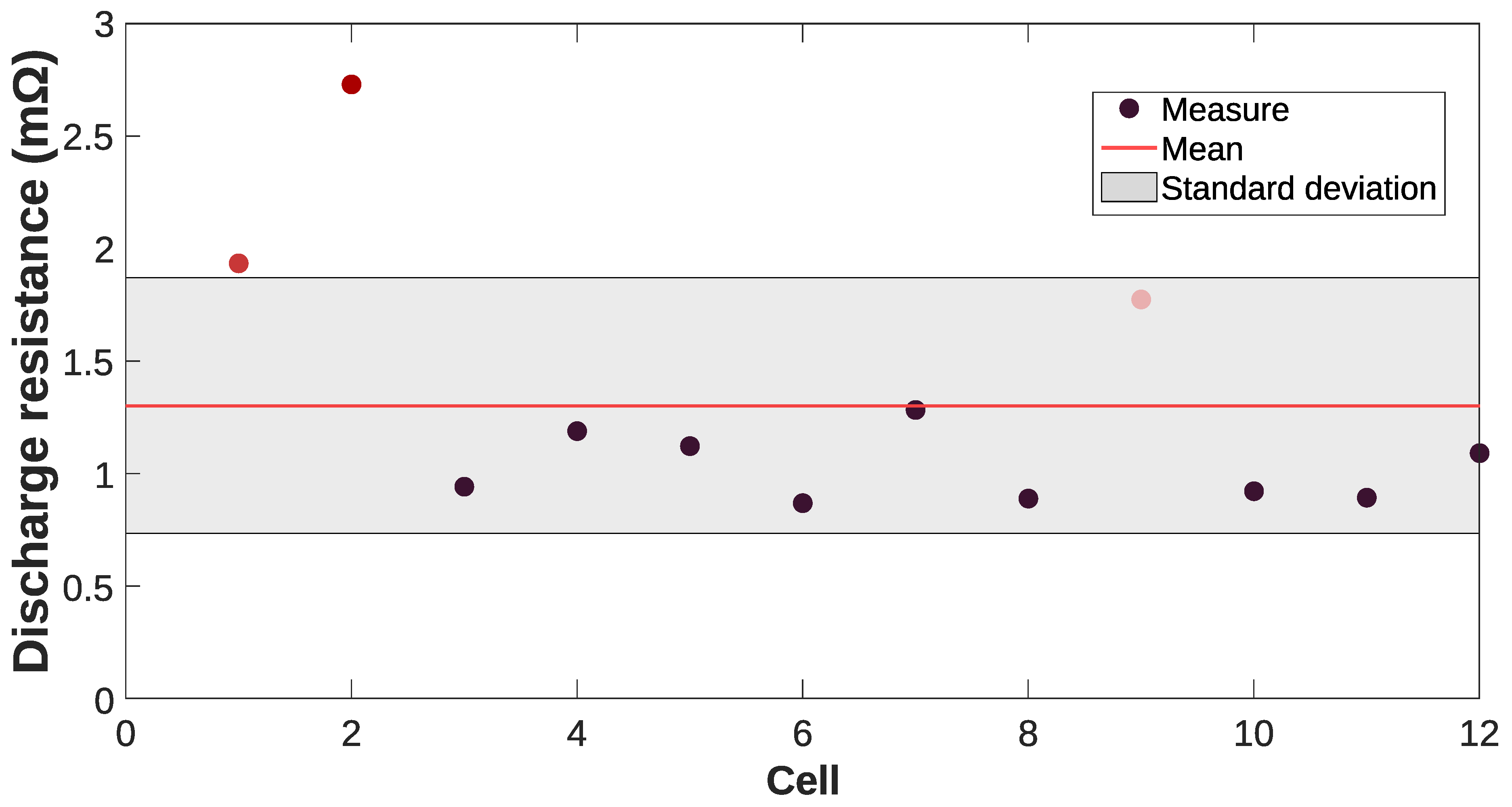

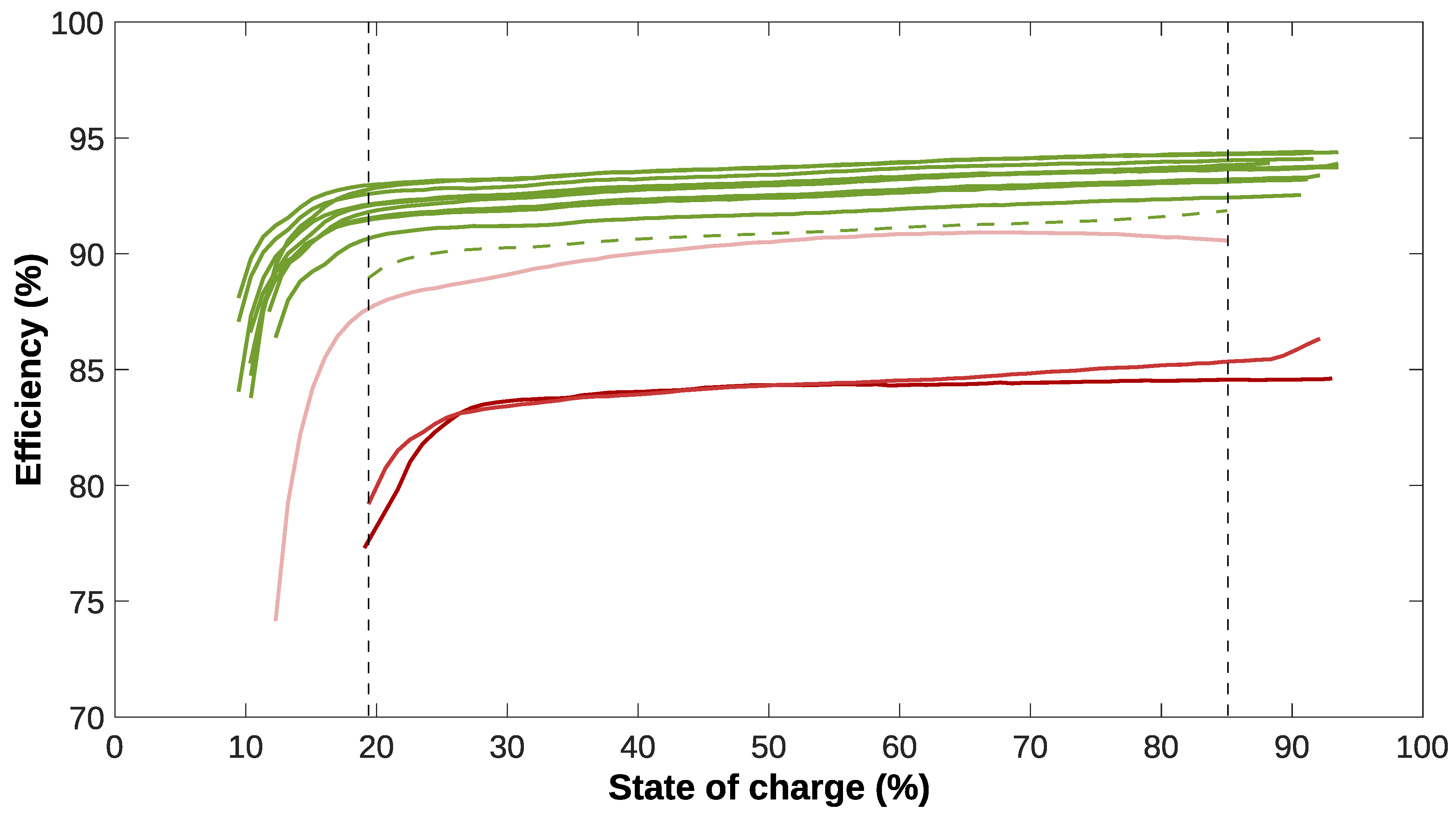

2.5. Efficiency and Energy Losses

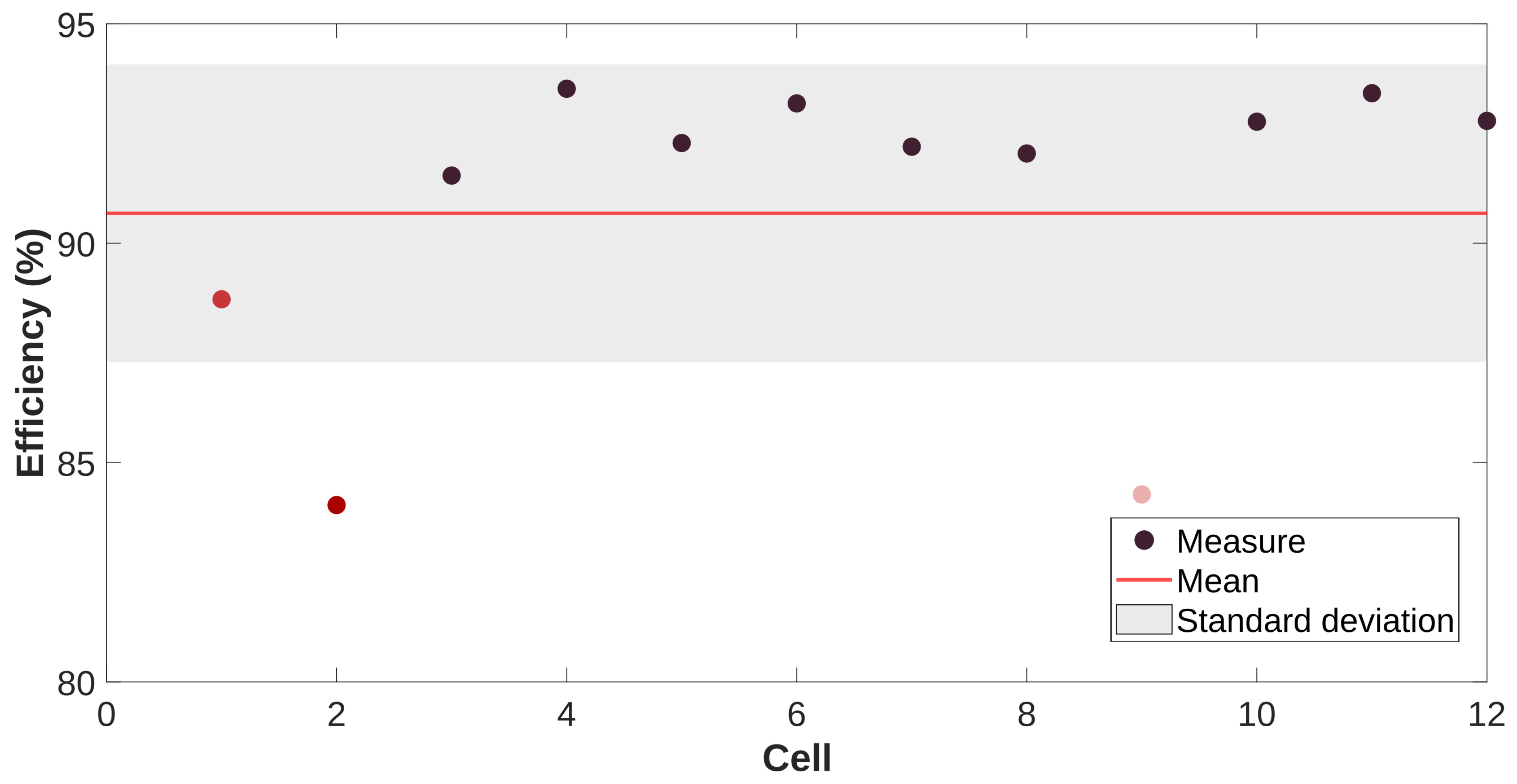

2.6. Performance Dispersion Inside the Module

2.7. Filling the Battery Passport

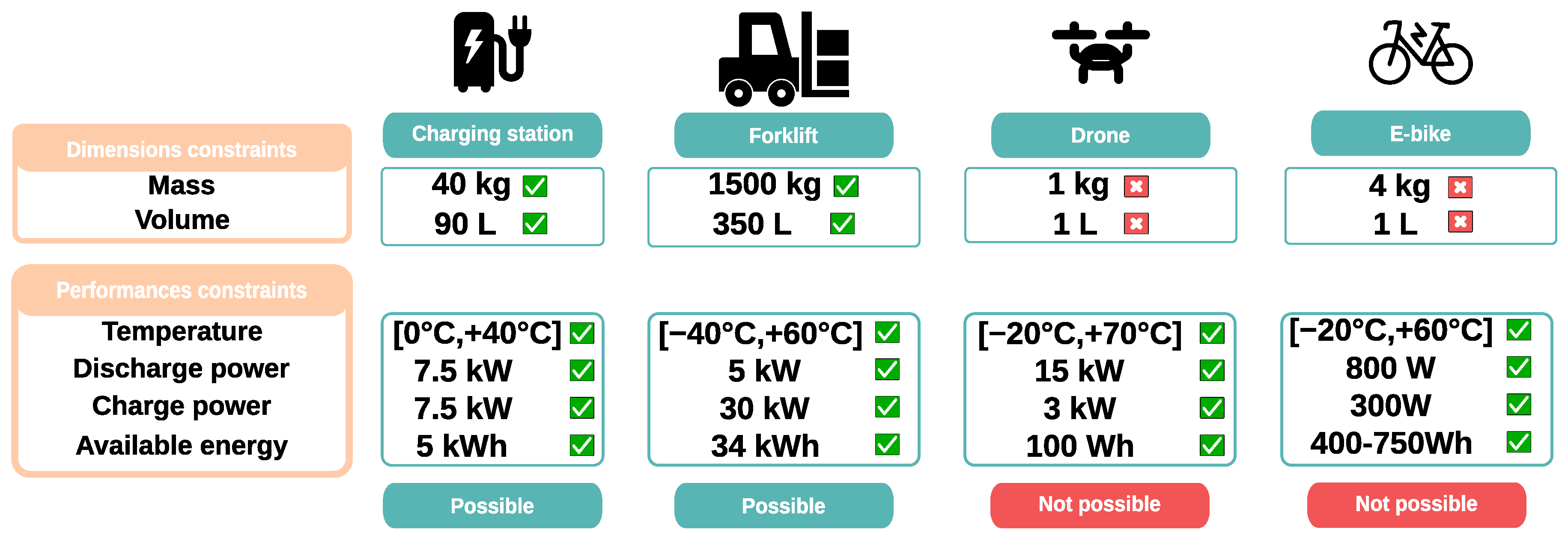

3. Suitability Assessment of the Battery for a Mobile Application

- : the state of health for energy in %,

- : the state of health for charge power in %,

- : the state of health for discharge power in %,

- : the state of health for efficiency in %.

- : the state of health energy in %,

- : the maximal energy available in the battery at the instant t in watt-hours,

- : the end of life performance threshold related to energy available in the battery in watt-hours,

- : the maximal energy available in the battery at the beginning of its life in watt-hours.

- : the state of health charge power criteria in %,

- : the maximal charge power that the battery can receive at the instant t in watt,

- : the end of life performance threshold related to the charge power the battery can receive in watt,

- : the maximal charge power that the battery can receive at the beginning of its life in watt.

- : the state of health discharge power criteria in %,

- : the maximal discharge power that the battery can provide at the instant t in watt,

- : the end of life performance threshold related to the discharge power the battery can provide in watt,

- : the maximal discharge power that the battery can provide at the beginning of its life in watt.

- : the state of health efficiency in %,

- : the mean efficiency of the battery at the instant t in %,

- : the end of life performance threshold related to mean efficiency of the battery in %,

- : the mean efficiency of the battery at the beginning of its life in %.

4. Conclusion and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Equations

Performance Dispersion

- k: the relative dispersion of performance in %,

- : the standard deviation between performance measurements,

- : the average of performance measurements.

Charge Power Capability

- : the charge power capability in watt,

- : the battery open circuit voltage in volts,

- : the battery maximal voltage in volts,

- : the charge resistance of the battery in ohm.

Discharge Power Capability

- : the discharge power capability in watt,

- : the battery open circuit voltage in volts,

- : the battery minimal voltage in volts,

- : the discharge resistance of the battery in ohm.

Efficiency

- : the energy efficiency of a cell as a function of the state of charge in %,

- : the cell voltage during discharge in volts,

- : the cell voltage during charging in volts.

Module Efficiency

- : the module efficiency in %,

- : the sum of all cells voltages during discharge in volts,

- : the sum of all cells voltages during charge in volts.

Energy

- : the energy available in the cell in watt-hours,

- : the time at start of discharge in hours,

- : the time at end of discharge in hours,

- : the voltage measured in volts,

- : the current measured in amperes.

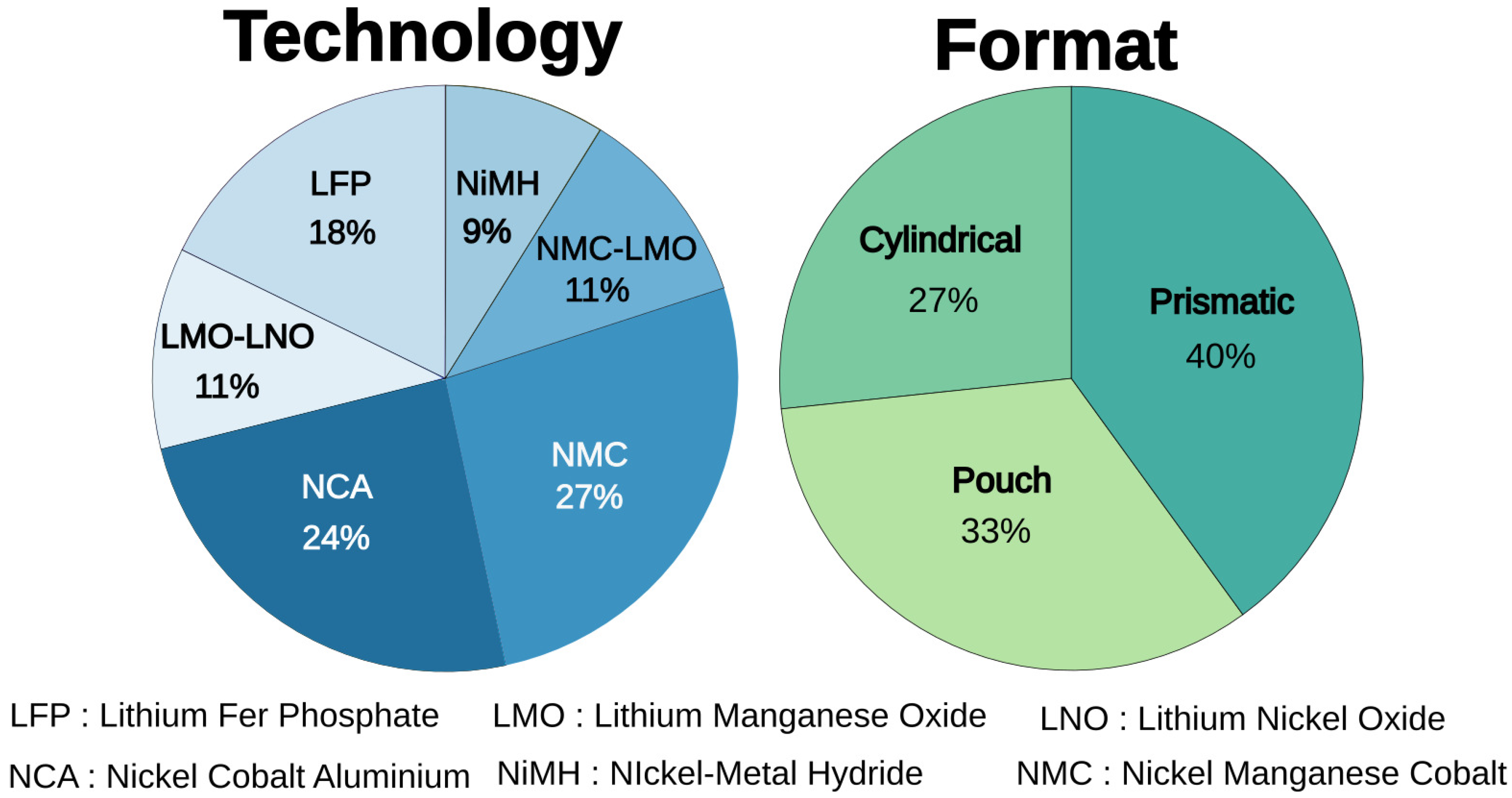

Appendix B. Most Sold Electric Vehicles Worldwide Annually between 2012 and 2022

| Pack Energy | Module Energy | Cell Energy | Max AC Power | Max DC Power | Vehicles sold | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Year | OEM | Model | (kWh) | (kWh) | (Wh) | (kW) | (kW) | Chemistry | Cell format | (in Thousands) |

| Tesla | Model Y | 57 | 15 | 566 | 11 | 170 | LFP | Prismatic | 771 | |

| Tesla | Model 3 | 51.9 | 12.9 | 17 | 11 | 170 | NCA | Cylindrical | 476 | |

| 2022 | Wuling | HongGuang Mini EV | 9.3 | 424 | 1.6 | - | LFP | Prismatic | 424 | |

| BYD | Song | 59.1 | 271 | 6.6 | 50 | LFP | Prismatic | 410 | ||

| BYD | Qin | 53.1 | 646 | 6.6 | 50 | LFP | Prismatic | 205 | ||

| Tesla | Model 3 | 51.9 | 12.9 | 17 | 11 | 170 | NCA | Cylindrical | 500 | |

| Wuling | HongGuang Mini EV | 9.3 | 424 | 1.6 | - | LFP | Prismatic | 424 | ||

| 2021 | Tesla | Model Y | 57 | 15 | 566 | 11 | 170 | LFP | Prismatic | 411 |

| VW | ID.4 | 52 | 5.8 | 271 | 7.2 | 110 | NMC | Cylindrical | 411 | |

| BYD | Qin | 53.1 | 646 | 6.6 | 50 | LFP | Prismatic | 65.1 | ||

| Tesla | Model 3 | 51.9 | 12.9 | 17.4 | 11 | 250 | NCA | Cylindrical | 365.2 | |

| Wuling | HongGuang Mini EV | 9.3 | 424 | 1.6 | - | LFP | Prismatic | 119.2 | ||

| 2020 | Renault | ZOE | 52 | 4.3 | 270.8 | 22 | 50 | NMC | Pouch | 100.4 |

| Tesla | Model Y | 74.5 | 18.6 | 16,9 | 11 | 120 | NCA | Cylindrical | 79.7 | |

| Hyundai | Kona | 64 | 12.8 | 218 | 7.2 | 77 | NMC | Pouch | 65.1 | |

| Tesla | Model 3 | 51.9 | 12.9 | 17.4 | 11 | 250 | NCA | Cylindrical | 300.1 | |

| BAIC | EU-Series EB | 54 | 7 | 60 | NMC | Prismatic | 111.0 | |||

| 2019 | Nissan | Leaf | 40 | 1.7 | 208 | 6.6 | 100 | NMC | Pouch | 69.9 |

| SAIC-GM | Baojun E100/E200 EV | 24 | 2 | - | LFP | Prismatic | 60.1 | |||

| BYD | e5 450 EV S | 60.5 | 4.6 | 360 | 7 | 60 | LFP | Prismatic | 58.0 | |

| Tesla | Model 3 | 51.9 | 12.9 | 17.4 | 11 | 250 | NCA | Cylindrical | 145.9 | |

| BAIC | EC180 | 20.3 | LFP | Prismatic | 90.6 | |||||

| 2018 | Nissan | Leaf | 40 | 1.7 | 208 | 6.6 | 100 | NMC | Pouch | 87.1 |

| JAC | iEV | 23 | 6 | - | LFP | Cylindrical | 55.6 | |||

| Tesla | Model S | 74 | 4.6 | 10.4 | 11 | 200 | NCA | Cylindrical | 50.0 | |

| BAIC | EC180 | 20.3 | 7 | - | LFP | Prismatic | 78.1 | |||

| Tesla | Model S | 74 | 4.6 | 10.4 | 11 | 200 | NCA | Cylindrical | 54.7 | |

| 2017 | Toyota | Prius PHEV | 4.4 | 4.4 | 79 | 2.3 | - | Ni-MH | Prismatic | 50.8 |

| Nissan | Leaf | 40 | 1.7 | 208 | 7 | 50 | NMC | Pouch | 47.2 | |

| Tesla | Model X | 80.5 | 5 | 11.3 | 16.5 | 150 | NCA | Cylindrical | 46.5 | |

| Tesla | Model S | 74 | 4.6 | 10.4 | 11 | 200 | NCA | Cylindrical | 50.9 | |

| Nissan | Leaf | 30 | 0.5 | 125 | 7 | 50 | LMO-LNO | Pouch | 43.5 | |

| 2016 | BYD | Tang PHEV | 18.5 | 86 | - | LFP | Prismatic | 31.4 | ||

| Chevrolet | Volt | 16 | 1.8 | 55 | 3.7 | - | NMC-LMO | Pouch | 28.3 | |

| Mitsubishi | Outlander PHEV | 12 | 2.4 | 150 | 3.7 | - | NMC | Prismatic | 27.8 | |

| Tesla | Model S | 74 | 4.6 | 10.4 | 11 | 200 | NCA | Cylindrical | 50.4 | |

| Nissan | Leaf | 30 | 0.5 | 125 | 7 | 50 | LMO-LNO | Pouch | 43.9 | |

| 2015 | Mitsubishi | Outlander PHEV | 12 | 2.4 | 150 | 3.7 | - | NMC | Prismatic | 43.3 |

| BYD | Qin | 13 | 1.3 | 7 | - | LFP | Prismatic | 31.9 | ||

| BMW | I3 | 21.6 | 2.7 | 225 | 3.7 | 50 | NMC | Prismatic | 24.1 | |

| Nissan | Leaf | 24.4 | 0.5 | 125 | 7 | 50 | LMO-LNO | Pouch | 60.6 | |

| Mitsubishi | Outlander PHEV | 12 | 2.4 | 150 | 3.7 | - | NMC | Prismatic | 31.2 | |

| 2014 | Tesla | Model S | 74 | 4.6 | 10.4 | 11 | 200 | NCA | Cylindrical | 30.4 |

| Chevrolet | Volt | 16 | 1.8 | 55 | 3.7 | - | NMC-LMO | Pouch | 20.0 | |

| Toyota | Prius PHEV | 4.4 | 4.4 | 79 | 2.3 | - | Ni-MH | Prismatic | 19.2 | |

| Nissan | Leaf | 24.4 | 0.5 | 125 | 7 | 50 | LMO-LNO | Pouch | 47.8 | |

| Chevrolet | Volt | 16 | 1.8 | 55 | 3.7 | - | NMC-LMO | Pouch | 28.2 | |

| 2013 | Toyota | Prius PHEV | 4.4 | 4.4 | 79 | 2.3 | - | Ni-MH | Prismatic | 23.1 |

| Tesla | Model S | 74 | 4.6 | 10.4 | 11 | 200 | NCA | Cylindrical | 22.2 | |

| Mitsubishi | Outlander PHEV | 12 | 2.4 | 150 | 3.7 | - | NMC | Prismatic | 18.4 | |

| Chevrolet | Volt | 16 | 1.8 | 55 | 3.7 | - | NMC-LMO | Pouch | 29.6 | |

| Toyota | Prius PHEV | 4.4 | 4.4 | 79 | 2.3 | - | Ni-MH | Prismatic | 27.1 | |

| 2012 | Nissan | Leaf | 24.4 | 0.5 | 125 | 7 | 50 | LMO-LNO | Pouch | 26.9 |

| Renault | Twizy | 7 | 1 | 125 | 3.7 | - | LMO-NMC | Pouch | 9.0 | |

| Mitsubishi | I-Miev | 16 | 1.6 | 182 | 3.7 | 50 | NMC | Prismatic | 7.9 |

References

- Lu, Y.; Khan, Z.A.; Alvarez-Alvarado, M.S.; Zhang, Y.; Huang, Z.; Imran, M. A critical review of sustainable energy policies for the promotion of renewable energy sources. Sustainability 2020, 12, 5078. [Google Scholar] [CrossRef]

- Xue, C.; Zhou, H.; Wu, Q.; Wu, X.; Xu, X. Impact of incentive policies and other socio-economic factors on electric vehicle market share: A panel data analysis from the 20 countries. Sustainability 2021, 13, 2928. [Google Scholar] [CrossRef]

- Armand, M.; Axmann, P.; Bresser, D.; Copley, M.; Edström, K.; Ekberg, C.; Guyomard, D.; Lestriez, B.; Novák, P.; Petranikova, M.; et al. Lithium-ion batteries–Current state of the art and anticipated developments. Journal of Power Sources 2020, 479, 228708. [Google Scholar] [CrossRef]

- Sun, X.; Hao, H.; Zhao, F.; Liu, Z. Tracing global lithium flow: A trade-linked material flow analysis. Resources, Conservation and Recycling 2017, 124, 50–61. [Google Scholar] [CrossRef]

- Etxandi-Santolaya, M.; Casals, L.C.; Montes, T.; Corchero, C. Are electric vehicle batteries being underused? A review of current practices and sources of circularity. J. Environ. Manage. 2023, 338, 117814. [Google Scholar] [CrossRef] [PubMed]

- commission, E. Closing the loop - An EU action plan for the Circular Economy. https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52015DC0614&from=ES, accessed on 2024/01/13.

- Grimaud, G. Conception des scénarios de recyclage pilotée par l’évaluation des performances des procédés. PhD thesis, Paris, ENSAM, 2019.

- Abbas, A.; Rizoug, N.; Trigui, R.; Babin, A.; Redondo-Iglesias, E.; Pelissier, S. Thermal modeling of batteries for EV energy management. In Proceedings of the IEEE VPPC; IEEE, 2022; pp. 1–6. [CrossRef]

- Madaoui, S.; Vinassa, J.M.; Sabatier, J.; Guillemard, F. An Electrothermal Model of an NMC Lithium-Ion Prismatic Battery Cell for Temperature Distribution Assessment. Batteries 2023, 9, 478. [Google Scholar] [CrossRef]

- Houbbadi, A.; Redondo-Iglesias, E.; Trigui, R.; Pelissier, S.; Bouton, T. Optimal Charging Strategy to Minimize Electricity Cost and Prolong Battery Life of Electric Bus Fleet. In Proceedings of the IEEE VPPC; 2019; pp. 1–6. [CrossRef]

- Mathieu, R.; Briat, O.; Gyan, P.; Vinassa, J.M. Fast charging for electric vehicles applications: Numerical optimization of a multi-stage charging protocol for lithium-ion battery and impact on cycle life. Journal of energy storage 2021, 40, 102756. [Google Scholar] [CrossRef]

- Jin, S.; Huang, X.; Sui, X.; Wang, S.; Teodorescu, R.; Stroe, D.I. Overview of methods for battery lifetime extension. In Proceedings of the 2021 23rd European Conference on Power Electronics and Applications (EPE’21 ECCE Europe). IEEE, 2021, pp. 1–8. [CrossRef]

- EC. REGULATION (EU) 2023/1542 OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 12 July 2023 concerning batteries and waste batteries, amending Directive 2008/98/EC and Regulation (EU) 2019/1020 and repealing Directive 2006/66/EC., 2023.

- Martinez-Laserna, E.; Gandiaga, I.; Sarasketa-Zabala, E.; Badeda, J.; Stroe, D.I.; Swierczynski, M.; Goikoetxea, A. Battery second life: Hype, hope or reality? A critical review of the state of the art. Renewable and Sustainable Energy Reviews 2018, 93, 701–718. [Google Scholar] [CrossRef]

- Group, R. Groupe Renault creates the first european factory dedicated to the circular economy of mobility in Flins. https://media.renaultgroup.com/groupe-renault-creates-the-first-european-factory-dedicated-to-the-circular-economy-of-mobility-in-flins/?lang=eng, accessed on 2024/01/13.

- Mercedes-Benz. Business segments. https://www.mercedes-benz.com/en/mercedes-benz-energy/business-segments/, accessed on 2024/01/13.

- Hesse, H.C.; Martins, R.; Musilek, P.; Naumann, M.; Truong, C.N.; Jossen, A. Economic optimization of component sizing for residential battery storage systems. Energies 2017, 10, 835. [Google Scholar] [CrossRef]

- Fallahifar, R.; Kalantar, M. Optimal planning of lithium ion battery energy storage for microgrid applications: Considering capacity degradation. Journal of Energy Storage 2023, 57, 106103. [Google Scholar] [CrossRef]

- Helbig, C.; Bradshaw, A.M.; Wietschel, L.; Thorenz, A.; Tuma, A. Supply risks associated with lithium-ion battery materials. Journal of Cleaner Production 2018, 172, 274–286. [Google Scholar] [CrossRef]

- ADEME. Automobiles: données 2019. Technical report, ADEME, 2019.

- ADEME. Automobiles: données 2020. Technical report, ADEME, 2022.

- Dong, Q.; Liang, S.; Li, J.; Kim, H.C.; Shen, W.; Wallington, T.J. Cost, Energy, and Carbon Footprint Benefits of Second-Life Electric Vehicle Battery Use. iScience 2023. [Google Scholar] [CrossRef] [PubMed]

- Scholz, T.; Pautzke, F.; Schmuelling, B. Experimental Analysis of a Lithium-Ion Battery Pack after Long Service Life in a Conventional Electric Vehicle Considering Second-Life Applications. In Proceedings of the ESREL; 2023. [CrossRef]

- Zhao, Y.; Pohl, O.; Bhatt, A.I.; Collis, G.E.; Mahon, P.J.; Rüther, T.; Hollenkamp, A.F. A review on battery market trends, second-life reuse, and recycling. Sustainable Chemistry 2021, 2, 167–205. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, Y.; Luo, F.; Mu, Y. Operational planning of centralized charging stations utilizing second-life battery energy storage systems. IEEE Transactions on Sustainable Energy 2020, 12, 387–399. [Google Scholar] [CrossRef]

- Leonori, S.; Rizzoni, G.; Mascioli, F.M.F.; Rizzi, A. Intelligent energy flow management of a nanogrid fast charging station equipped with second life batteries. International Journal of Electrical Power & Energy Systems 2021, 127, 106602. [Google Scholar] [CrossRef]

- Janota, L.; Králík, T.; Knápek, J. Second life batteries used in energy storage for frequency containment reserve service. Energies 2020, 13, 6396. [Google Scholar] [CrossRef]

- White, C.; Thompson, B.; Swan, L.G. Repurposed electric vehicle battery performance in second-life electricity grid frequency regulation service. Journal of Energy Storage 2020, 28, 101278. [Google Scholar] [CrossRef]

- Lacap, J.; Park, J.W.; Beslow, L. Development and demonstration of microgrid system utilizing second-life electric vehicle batteries. Journal of Energy Storage 2021, 41, 102837. [Google Scholar] [CrossRef]

- Antunes, E.D.G.; López, A.G.; Lacressonnière, F.; Roboam, X.; Sareni, B. Life cycle assessment of a lithium ion battery: comparison between first and second life batteries environmental impacts in microgrid applications. In Proceedings of the SGE; L2EP, 2023.

- Colarullo, L.; Thakur, J. Second-life EV batteries for stationary storage applications in Local Energy Communities. Renewable and Sustainable Energy Reviews 2022, 169, 112913. [Google Scholar] [CrossRef]

- Thakur, J.; de Almeida, C.M.L.; Baskar, A.G. Electric vehicle batteries for a circular economy: Second life batteries as residential stationary storage. Journal of Cleaner Production 2022, 375, 134066. [Google Scholar] [CrossRef]

- Mathews, I.; Xu, B.; He, W.; Barreto, V.; Buonassisi, T.; Peters, I.M. Technoeconomic model of second-life batteries for utility-scale solar considering calendar and cycle aging. Applied Energy 2020, 269, 115127. [Google Scholar] [CrossRef]

- Steckel, T.; Kendall, A.; Ambrose, H. Applying levelized cost of storage methodology to utility-scale second-life lithium-ion battery energy storage systems. Applied Energy 2021, 300, 117309. [Google Scholar] [CrossRef]

- Börner, M.F.; Frieges, M.H.; Späth, B.; Spütz, K.; Heimes, H.H.; Sauer, D.U.; Li, W. Challenges of second-life concepts for retired electric vehicle batteries. Cell Reports Physical Science 2022, 3. [Google Scholar] [CrossRef]

- Lander, L.; Tagnon, C.; Nguyen-Tien, V.; Kendrick, E.; Elliott, R.J.; Abbott, A.P.; Edge, J.S.; Offer, G.J. Breaking it down: A techno-economic assessment of the impact of battery pack design on disassembly costs. Applied Energy 2023, 331, 120437. [Google Scholar] [CrossRef]

- Tepe, B.; Jablonski, S.; Hesse, H.; Jossen, A. Lithium-ion battery utilization in various modes of e-transportation. eTransportation 2023, 18, 100274. [Google Scholar] [CrossRef]

- RTE. Energy Pathways to 2050. Technical report, RTE, 2022.

- Beckers, C.; Hoedemaekers, E.; Dagkilic, A. al. Round-Trip Energy Efficiency and Energy-Efficiency Fade Estimation for Battery Passport. In Proceedings of the IEEE VPPC; 2023. [CrossRef]

- Walden, J.; Steinbrecher, A.; Marinkovic, M. Digital product passports as enabler of the circular economy. hemie Ingenieur Technik 2021, 93, 1717–1727. [Google Scholar] [CrossRef]

- Clark, S.; Bleken, F.L.; Stier, S.; Flores, E.; Andersen, C.W.; Marcinek, M.; Szczesna-Chrzan, A.; Gaberscek, M.; Palacin, M.R.; Uhrin, M.; et al. Toward a unified description of battery data. Advanced Energy Materials 2022, 12, 2102702. [Google Scholar] [CrossRef]

- Hassini, M.; Redondo-Iglesias, E.; Venet, P. Lithium–Ion Battery Data: From Production to Prediction. Batteries 2023, 9, 385. [Google Scholar] [CrossRef]

- Berger, K.; Schöggl, J.P.; Baumgartner, R.J. Digital battery passports to enable circular and sustainable value chains: Conceptualization and use cases. Journal of Cleaner Production 2022, 353, 131492. [Google Scholar] [CrossRef]

- Berger, K.; Baumgartner, R.J.; Weinzerl, M.; Bachler, J.; Preston, K.; Schöggl, J.P. Data requirements and availabilities for a digital battery passport–A value chain actor perspective. Cleaner Production Letters 2023, 4, 100032. [Google Scholar] [CrossRef]

- Adisorn, T.; Tholen, L.; Götz, T. Towards a digital product passport fit for contributing to a circular economy. Energies 2021, 14, 2289. [Google Scholar] [CrossRef]

- Uusitalo, T.; Karhu, M.; Majaniemi, S.; Kivikytö-Reponen, P.; Hanski, J.; Vatanen, S. Digital Product Passports in Circular Economy: Case Battery Passport. In EcoDesign for Sustainable Products, Services and Social Systems I; Springer, 2024; pp. 175–186. [CrossRef]

- Montes, T.; Etxandi-Santolaya, M.; Eichman, J.; Ferreira, V.J.; Trilla, L.; Corchero, C. Procedure for Assessing the Suitability of Battery Second Life Applications after EV First Life. Batteries 2022, 8. [Google Scholar] [CrossRef]

- Michelini, E.; Höschele, P.; Ratz, F.; Stadlbauer, M.; Rom, W.; Ellersdorfer, C.; Moser, J. Potential and Most Promising Second-Life Applications for Automotive Lithium-Ion Batteries Considering Technical, Economic and Legal Aspects. Energies 2023, 16, 2830. [Google Scholar] [CrossRef]

- Popp, A.; Fechtner, H.; Schmuelling, B.; Scholz, T.; Kremzow-Tennie, S.; Pautzke, F. Challenges in the Real-World Evaluation of Traction Batteries at the End of their First Life. In Proceedings of the ESREL; 2023. [CrossRef]

- Diao, W.; Kulkarni, C.; Pecht, M. Development of an informative lithium-ion battery datasheet. Energies 2021, 14, 5434. [Google Scholar] [CrossRef]

- PushEV. Samsung SDI 94Ah battery cell full specifications. https://pushevs.com/2018/04/05/samsung-sdi-94-ah-battery-cell-full-specifications/, accessed on 2024/01/13.

- Redondo-Iglesias, E.; Hassini, M.; Venet, P.; Pelissier, S. DATTES: Data analysis tools for tests on energy storage. SoftwareX 2023, 24, 101584. [Google Scholar] [CrossRef]

- Baghdadi, I.; Briat, O.; Gyan, P.; Vinassa, J.M. State of health assessment for lithium batteries based on voltage–time relaxation measure. Electrochimica Acta 2016, 194, 461–472. [Google Scholar] [CrossRef]

- Haber, M.; Azaïs, P.; Genies, S.; Raccurt, O. Stress factor identification and Risk Probabilistic Number (RPN) analysis of Li-ion batteries based on worldwide electric vehicle usage. Applied Energy 2023, 343, 121250. [Google Scholar] [CrossRef]

- USDOE. PNGV battery test manual. Technical report, USDOE, 1997. [CrossRef]

- Xiong, R.; He, H.; Sun, F.; Liu, X.; Liu, Z. Model-based state of charge and peak power capability joint estimation of lithium-ion battery in plug-in hybrid electric vehicles. Journal of Power Sources 2013, 229, 159–169. [Google Scholar] [CrossRef]

- Sun, F.; Xiong, R.; He, H. Estimation of state-of-charge and state-of-power capability of lithium-ion battery considering varying health conditions. Journal of Power Sources 2014, 259, 166–176. [Google Scholar] [CrossRef]

- Redondo-Iglesias, E.; Venet, P.; Pelissier, S. Efficiency degradation model of lithium-ion batteries for electric vehicles. IEEE Transactions on Industry Applications 2018, 55, 1932–1940. [Google Scholar] [CrossRef]

- Omariba, Z.B.; Zhang, L.; Sun, D. Review of battery cell balancing methodologies for optimizing battery pack performance in electric vehicles. IEEE Access 2019, 7, 129335–129352. [Google Scholar] [CrossRef]

- Yang, J.; Strickland, D.; Abedi-Varnosfaderani, M. Comparison of Different Battery Balancing Methods for use with Second Life Batteries. In Proceedings of the ICRERA; 2020; pp. 112–117. [CrossRef]

- Schuster, S.F.; Brand, M.J.; Berg, P.; Gleissenberger, M.; Jossen, A. Lithium-ion cell-to-cell variation during battery electric vehicle operation. Journal of Power Sources 2015, 297, 242–251. [Google Scholar] [CrossRef]

- Jiang, Y.; Jiang, J.; Zhang, C.; Zhang, W.; Gao, Y.; Guo, Q. Recognition of battery aging variations for LiFePO4 batteries in 2nd use applications combining incremental capacity analysis and statistical approaches. Journal of Power Sources 2017, 360, 180–188. [Google Scholar] [CrossRef]

- Xu, X.; Mi, J.; Fan, M.; Yang, K.; Wang, H.; Liu, J.; Yan, H. Study on the performance evaluation and echelon utilization of retired LiFePO4 power battery for smart grid. Journal of Cleaner Production 2019, 213, 1080–1086. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Z.; Kang, Y.; Zhang, C.; Duan, B. A quick screening approach based on fuzzy C-means algorithm for the second usage of retired lithium-ion batteries. IEEE Transactions on Transportation Electrification 2020, 7, 474–484. [Google Scholar] [CrossRef]

- Zhou, Z.; Duan, B.; Kang, Y.; Shang, Y.; Cui, N.; Chang, L.; Zhang, C. An efficient screening method for retired lithium-ion batteries based on support vector machine. Journal of Cleaner Production 2020, 267, 121882. [Google Scholar] [CrossRef]

- Braco, E.; San Martín, I.; Berrueta, A.; Sanchis, P.; Ursúa, A. Experimental assessment of first-and second-life electric vehicle batteries: Performance, capacity dispersion, and aging. IEEE Transactions on Industry Applications 2021, 57, 4107–4117. [Google Scholar] [CrossRef]

- Baumann, M.; Wildfeuer, L.; Rohr, S.; Lienkamp, M. Parameter variations within Li-Ion battery packs–Theoretical investigations and experimental quantification. Journal of Energy Storage 2018, 18, 295–307. [Google Scholar] [CrossRef]

- Koppelaar, R.H.; Pamidi, S.; Hajósi, E.; Herreras, L.; Leroy, P.; Jung, H.Y.; Concheso, A.; Daniel, R.; Francisco, F.B.; Parrado, C.; et al. A Digital Product Passport for Critical Raw Materials Reuse and Recycling. Sustainability 2023, 15, 1405. [Google Scholar] [CrossRef]

- Weng, A.; Dufek, E.; Stefanopoulou, A. Battery passports for promoting electric vehicle resale and repurposing. Joule 2023, 7, 837–842. [Google Scholar] [CrossRef]

- Gu, X.; Bai, H.; Cui, X.; Zhu, J.; Zhuang, W.; Li, Z.; Hu, X.; Song, Z. Challenges and opportunities for second-life batteries: Key technologies and economy. Renewable and Sustainable Energy Reviews 2024, 192, 114191. [Google Scholar] [CrossRef]

- Zorn, M.; Ionescu, C.; Klohs, D.; Zähl, K.; Kisseler, N.; Daldrup, A.; Hams, S.; Zheng, Y.; Offermanns, C.; Flamme, S.; et al. An approach for automated disassembly of lithium-ion battery packs and high-quality recycling using computer vision, labeling, and material characterization. Recycling 2022, 7, 48. [Google Scholar] [CrossRef]

- Naseri, F.; Gil, S.; Barbu, C.; Cetkin, E.; Yarimca, G.; Jensen, A.; Larsen, P.; Gomes, C. Digital twin of electric vehicle battery systems: Comprehensive review of the use cases, requirements, and platforms. Renewable and Sustainable Energy Reviews 2023, 179, 113280. [Google Scholar] [CrossRef]

- Schmid, A.U.; Kurka, M.; Birke, K.P. Reproducibility of Li-ion cell reassembling processes and their influence on coin cell aging. Journal of Energy Storage 2019, 24, 100732. [Google Scholar] [CrossRef]

- SDI, S. Safety data sheet. Technical report, SAMSUNG SDI, 2016.

- BMW. The BMW i3 rescue guideline. Technical report, BMW, 2016.

- Mandrile, F.; Pastorelli, M.; Musumeci, S.; Urkiri, I.A.; Remirez, A. Second Life Management from Battery Storage System of Electric Waterborne Transport Applications: Perspectives and Solutions. IEEE Access 2023. [Google Scholar] [CrossRef]

- Phophongviwat, T.; Polmai, S.; Maneeinn, C.; Hongesombut, K.; Sivalertporn, K. Technical Assessment of Reusing Retired Electric Vehicle Lithium-Ion Batteries in Thailand. World Electric Vehicle Journal 2023, 14, 161. [Google Scholar] [CrossRef]

- Chirumalla, K.; Kulkov, I.; Vu, F.; Rahic, M. Second life use of Li-ion batteries in the heavy-duty vehicle industry: Feasibilities of remanufacturing, repurposing, and reusing approaches. Sustainable Production and Consumption 2023, 42, 351–366. [Google Scholar] [CrossRef]

- Hassini, M.; Redondo-Iglesias, E.; Venet, P. Second-Life Batteries Modeling for Performance Tracking in a Mobile Charging Station. World Electric Vehicle Journal 2023, 14, 94. [Google Scholar] [CrossRef]

- Contò, C.; Bianchi, N. E-Bike Motor Drive: A Review of Configurations and Capabilities. Energies 2022, 16, 160. [Google Scholar] [CrossRef]

- Paw, Y.C.; Ang, E.Y.M. Battery cycle life assessment for a lift+ cruise electric vertical takeoff and landing transporter drone. Journal of Energy Storage 2023, 66, 107493. [Google Scholar] [CrossRef]

- Arrinda, M.; Oyarbide, M.; Macicior, H.; Muxika, E.; Popp, H.; Jahn, M.; Ganev, B.; Cendoya, I. Application dependent end-of-life threshold definition methodology for batteries in electric vehicles. Batteries 2021, 7, 12. [Google Scholar] [CrossRef]

- Le Duigou, A.; Guan, Y.; Amalric, Y. On the competitiveness of electric driving in France: Impact of driving patterns. Renewable and Sustainable Energy Reviews 2014, 37, 348–359. [Google Scholar] [CrossRef]

- Plötz, P.; Jakobsson, N.; Sprei, F. On the distribution of individual daily driving distances. Transportation research part B: methodological 2017, 101, 213–227. [Google Scholar] [CrossRef]

- Chowdhury, N.R.; Smith, A.J.; Frenander, K.; Mikheenkova, A.; Lindström, R.W.; Thiringer, T. Influence of state of charge window on the degradation of Tesla lithium-ion battery cells. Journal of Energy Storage 2024, 76, 110001. [Google Scholar] [CrossRef]

- Saxena, S.; Le Floch, C.; MacDonald, J.; Moura, S. Quantifying EV battery end-of-life through analysis of travel needs with vehicle powertrain models. J. Power Sources 2015, 282, 265–276. [Google Scholar] [CrossRef]

- Greenbank, S.; Howey, D. Automated feature extraction and selection for data-driven models of rapid battery capacity fade and end of life. IEEE Transactions on Industrial Informatics 2021, 18, 2965–2973. [Google Scholar] [CrossRef]

- Quinard, H.; Redondo-Iglesias, E.; Pelissier, S.; Venet, P. Fast electrical characterizations of high-energy second life lithium-ion batteries for embedded and stationary applications. Batteries 2019, 5, 33. [Google Scholar] [CrossRef]

- Xiong, W.; Mo, Y.; Yan, C. Online state-of-health estimation for second-use lithium-ion batteries based on weighted least squares support vector machine. IEEE Access 2020, 9, 1870–1881. [Google Scholar] [CrossRef]

- Liu, C.; Wen, X.; Zhong, J.; Liu, W.; Chen, J.; Zhang, J.; Wang, Z.; Liao, Q. Characterization of aging mechanisms and state of health for second-life 21700 ternary lithium-ion battery. Journal of Energy Storage 2022, 55, 105511. [Google Scholar] [CrossRef]

- Zhao, D.; Zhou, Z.; Zhang, P.; Zhang, Y.; Feng, Z.; Yang, Y.; Cao, Y. Health condition assessment of satellite li-ion battery pack considering battery inconsistency and pack performance indicators. Journal of Energy Storage 2023, 60, 106604. [Google Scholar] [CrossRef]

- EV-Volumes. The electric vehicle world sales database. https://www.ev-volumes.com/, accessed on 2024/01/13.

| Stationary storage application | Reference |

|---|---|

| Fixed charging station | [25,26] |

| Grid frequency regulation | [27,28] |

| Micro grid | [29,30] |

| Residential Storage | [31,32] |

| Utility-scale storage | [33,34] |

| Step | Test | Estimated Duration (h) |

|---|---|---|

| 1 | Capacity test | 18 |

| 2 | Impedance test | 8 |

| 3 | Low current test | 42 |

| Characteristics | Values |

|---|---|

| Format | Prismatic |

| Rated capacity [Ah] | 94 |

| Positive electrode material | NMC111 |

| Negative electrode material | Graphite |

| Rated voltage [V] | 3.68 |

| Maximal voltage [V] | 4.15 |

| Minimal voltage [V] | 2.7 |

| Specific energy [Wh/kg] | 165 |

| Size L×W×H [mm] | 173×125×45 |

| Weight [kg] | 2.1 |

| Mean value |

Median value |

Standard deviation |

Worst cell |

Relative dispersion |

|

|---|---|---|---|---|---|

| Q (Ah) | 91.8 | 92.4 | 2.6 | 84.2 | 2.8 |

| E (Wh) | 267.5 | 269.9 | 5.9 | 254.4 | 2.2 |

| R(t) () | 1.30 | 1.11 | 0.57 | 2.73 | 43.3 |

| (%) | 90.7 | 92.2 | 3.4 | 84.0 | 3.7 |

| General information | |||

|---|---|---|---|

| Information | Value | Source | |

|

Annexe VI |

Name and brand of battery | BMW i3 SAMSUNG 94 Ah | 2.1 Visual inspection |

| Battery identification number | 6127 762506706 | 2.1 Visual inspection | |

| Batch or serial number | 170410 00728 | 2.1 Visual inspection | |

| Place of manufacture | Germany | 2.1 Visual inspection | |

| Date of manufacture | 04/2017 | 2.1 Visual inspection | |

| Weight | 28 kg | 2.1 Visual inspection | |

| Rated capacity | 94 Ah | [51] | |

| Date of manufacture of the battery | 05/2017 | 2.1 Visual inspection | |

| Chemistry | NMC111/C | [73] | |

| Hazardous substances present in the battery | Cobalt, Manganese, Nickel, Carbon, Polyvinylidene fluoride, Aluminium, Copper |

[74] | |

| Usable extinguishing agent | Water | [75] | |

| Critical raw materials present in the battery | Lithium, Cobalt, Copper, Nickel, Manganese, Graphite |

[74] | |

| Other | Size | 410x300x150 mm | 2.1 Visual inspection |

| Volume | 18.4 L | 2.1 Visual inspection | |

| Configuration | 12s1p | 2.1 Visual inspection | |

| Temperature range | [-40; 60 °C] | [51] | |

| Voltage range | [32.4; 49.8 V] | [51] | |

| Rated voltage | 44.2 V | [51] | |

| Date end of first life | 07/2021 | Seller | |

| Energy and capacity related information | |||

|

Annexes IV and VII |

Rated capacity | 94 Ah | [51] |

| Remaining capacity | 91.8 | 2.3 Capacity and energy | |

| Capacity lost | 2.3 % | 2.3 Capacity and energy | |

| Other | Rated energy | 4.1 kWh | [51] |

| Remaining energy | 3.6 kWh | 2.3 Capacity and energy | |

| Rated energy densities | 146 Wh/kg; 222 Wh/L | [51] | |

| Measured energy densities | 114 Wh/kg; 174 Wh/L | 2.3 Capacity and energy | |

| Energy/capacity of the worst cell | 254.4 Wh/84.2 Ah | 2.3 Capacity and energy | |

| Dispersion of energy/capacity | 2.2 %/2.8 % | 2.3 Capacity and energy | |

| Power related information | |||

|

Annexes IV and VII |

Ohmic resistance (SoC 50 %, 10 s, 1C) | 15.69 | 2.4 Resistance and power |

| Rated power (SoC 50 %, 10 s, 1C) | 42 kW | [51] | |

| Measured power output (SoC 50 %, 10 s, 1C) | 38.6 kW | 2.4 Resistance and power | |

| Overall power loss | 8 % | 2.4 Resistance and power | |

| Charging power at SoC 80 % | 50.6 kW | 2.4 Resistance and power | |

| Discharging power at SoC 80 % | 12.7 kW | 2.4 Resistance and power | |

| Charging power at SoC 20 % | 31.5 kW | 2.4 Resistance and power | |

| Discharging power at SoC 20 % | 32.5 W | 2.4 Resistance and power | |

| Other | Power/resistance of the worst cell | 1488 W/2.7 | 2.4 Resistance and power |

| Dispersion of rated power | 24.4 % | 2.4 Resistance and power | |

| Dispersion of rated resistance | 43.3 % | 2.4 Resistance and power | |

| Efficiency related information | |||

|

Annexes IV and VII |

Round trip efficiency | 90.7 % | 2.5 Efficiency and energy losses |

| Energy round trip fade | 9 % | 2.5 Efficiency and energy losses | |

| Cooling need | 144 Wh | 2.5 Efficiency and energy losses | |

| Evolution of self-discharging rate | 3.3 %/200 days | [51] | |

| Mobile application | Reference |

|---|---|

| Boat | [76] |

| Electric golf cart and motorcycle | [77] |

| Heavy-duty | [78] |

| Mobile charging station | [79] |

| Energy | Discharge power | Charge power | Efficiency | |

|---|---|---|---|---|

| Beginning of life | 4.1 kWh | 42 kW | 42 kW | 95 % |

| Measure | 3.6 kWh | 38.6 kW | 28.1 kW | 91 % |

| End of life | 2.5 kWh | 1.85 kW | 1.85 kW | 50 % |

| State of Health | 44 % | 91 % | 65 % | 84 % |

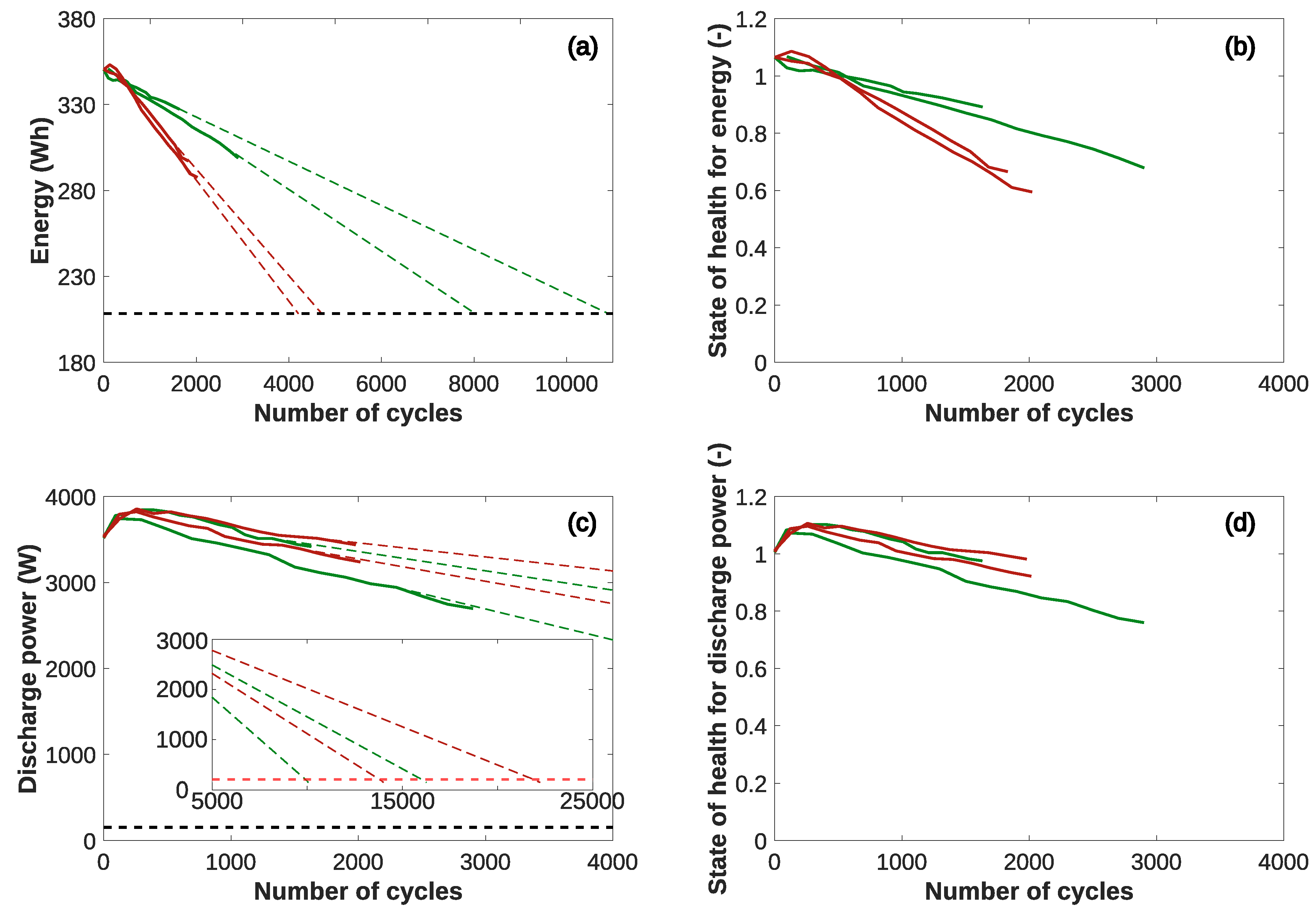

| Energy 25 °C/45 °C | Power 25 °C/45 °C | |

|---|---|---|

| Cell 1 | 8,026/4,710 | 10,062/14,010 |

| Cell 2 | 10,901/4,205 | 16,268/22,235 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).