Submitted:

26 January 2024

Posted:

29 January 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

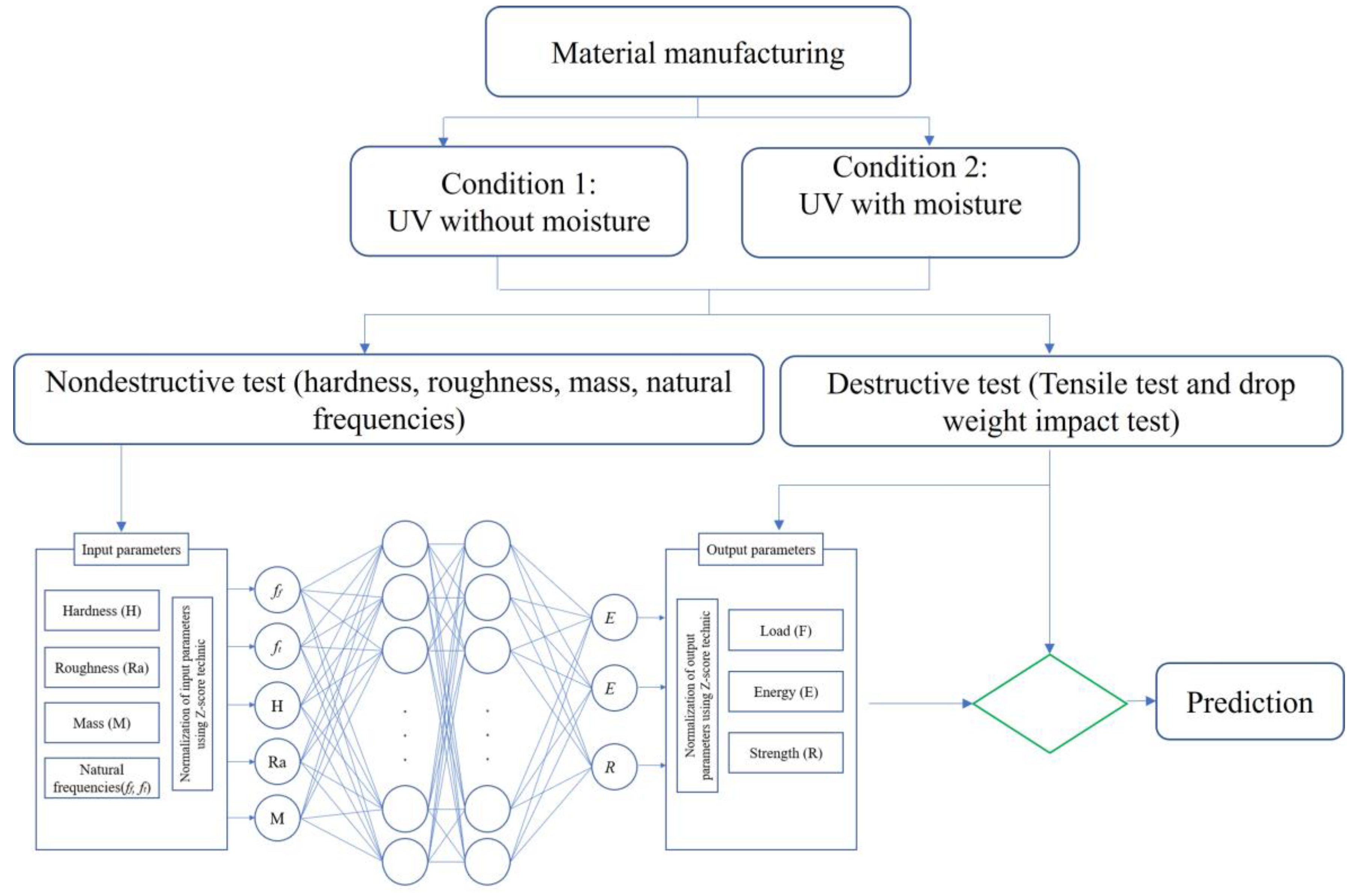

2. Methodology

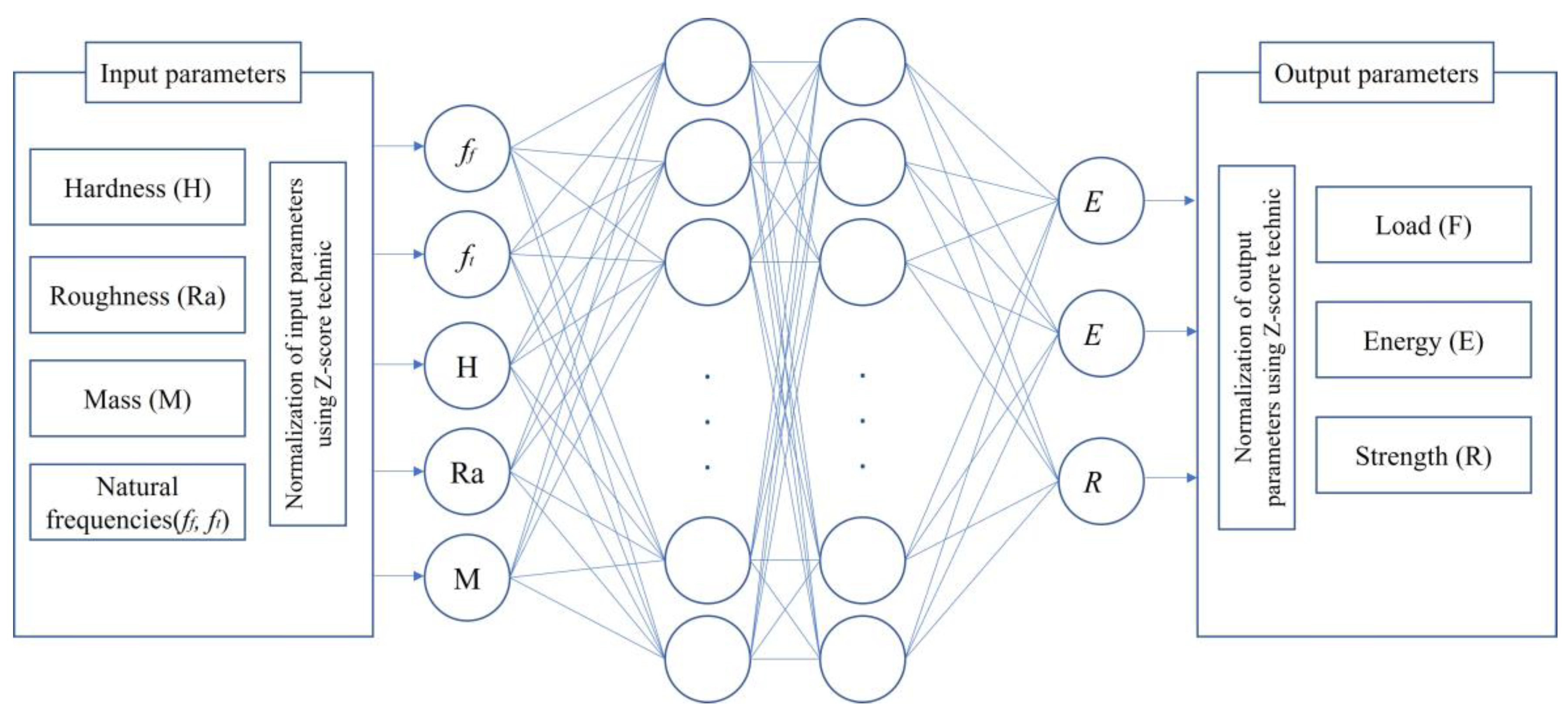

Artificial neural network

3. Experimentation

3.1. Materials and manufacturing

3.2. Aging conditions

- -

- Condition 1 (UV without moisture): The samples were subjected to UV aging using UVA-340 fluorescent lamps emitting irradiance at a wavelength of 340 nm. Aging was performed using a QUV/SE aging apparatus (Q-Lab Co., USA). Over a period of two months, the samples were exposed to 8 h of UV radiation each day at an irradiance of 1.55 W/m2, and the temperature was maintained at 60 °C.

- -

- Condition 2 (UV with moisture): The samples were subjected to the same conditions as Condition 1 for two months. However, after each UV exposure at 60 °C, the samples were subjected to 4 h of water condensation at 50 °C.

3.3. Experimental setup and procedure

3.3.1. Mass Measurement:

3.3.2. Roughness Measurement:

3.3.3. IET (Impulse excitation technic):

3.3.4. Hardness Test:

3.3.5. Tensile test

3.3.6. Drop-Weight Impact Test:

4. Results and discussion

4.1. Experimental results

4.1.1. Mass

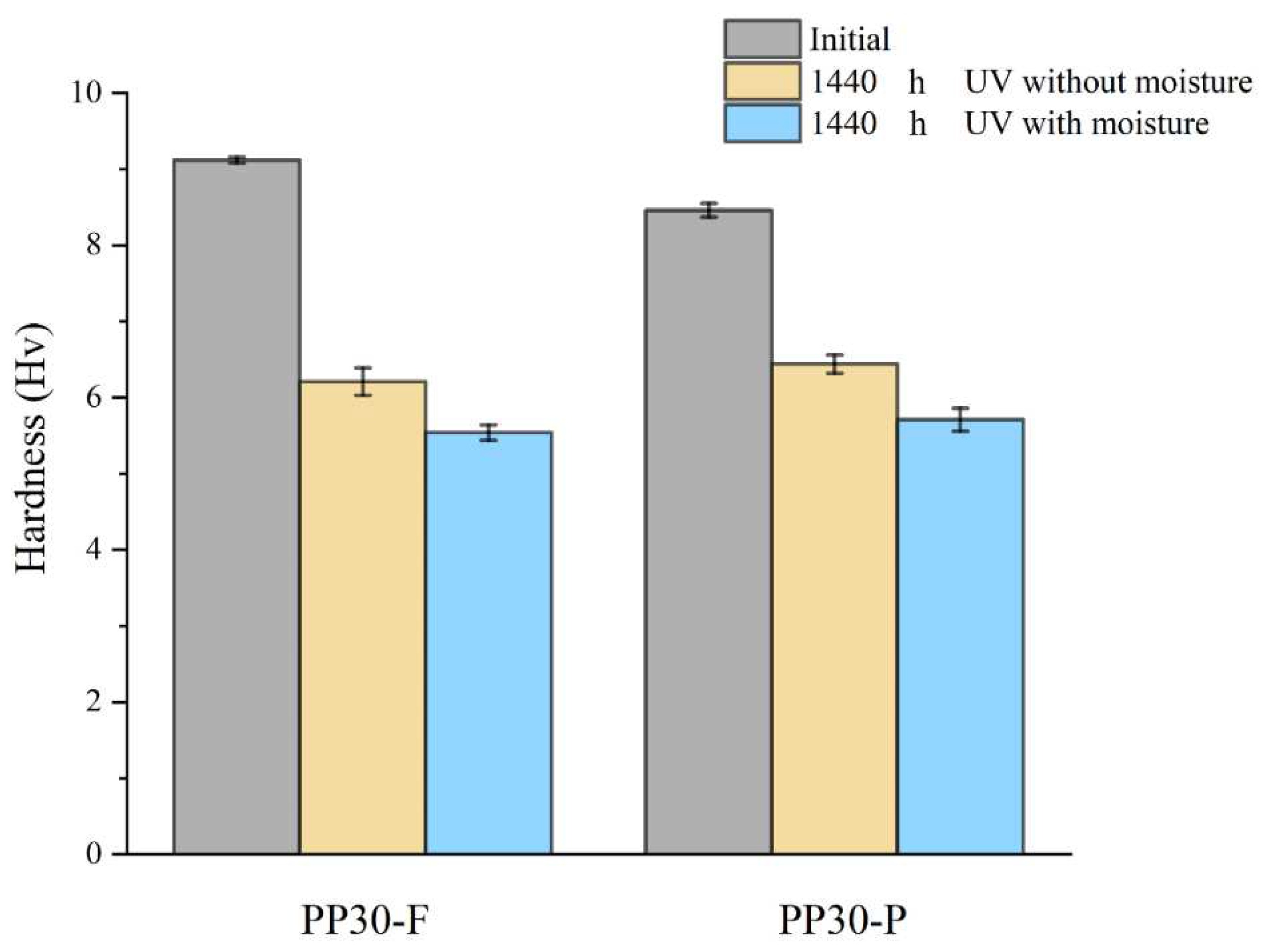

4.1.2. Hardness

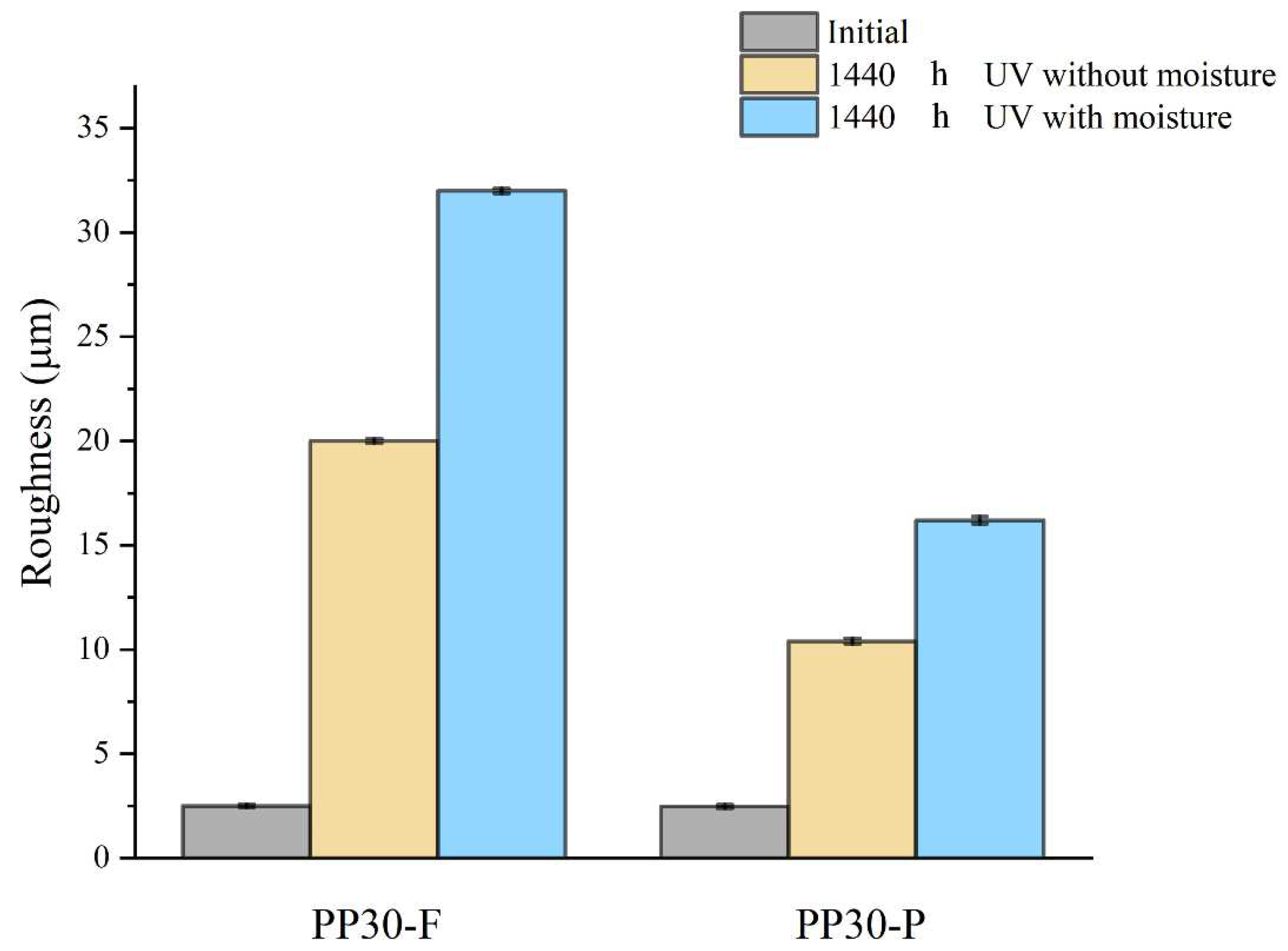

4.1.3. Roughness

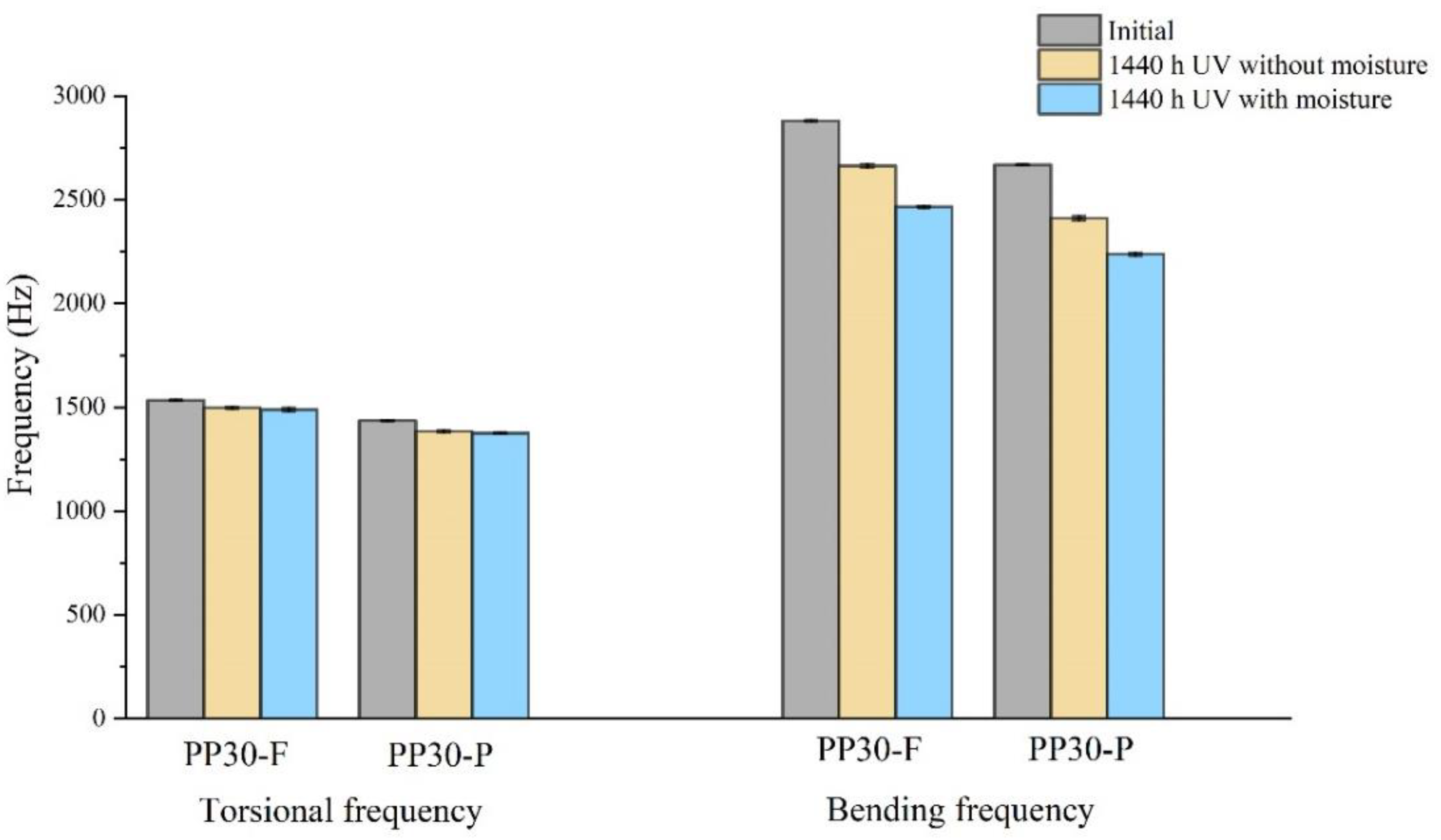

4.1.4. Natural frequencies

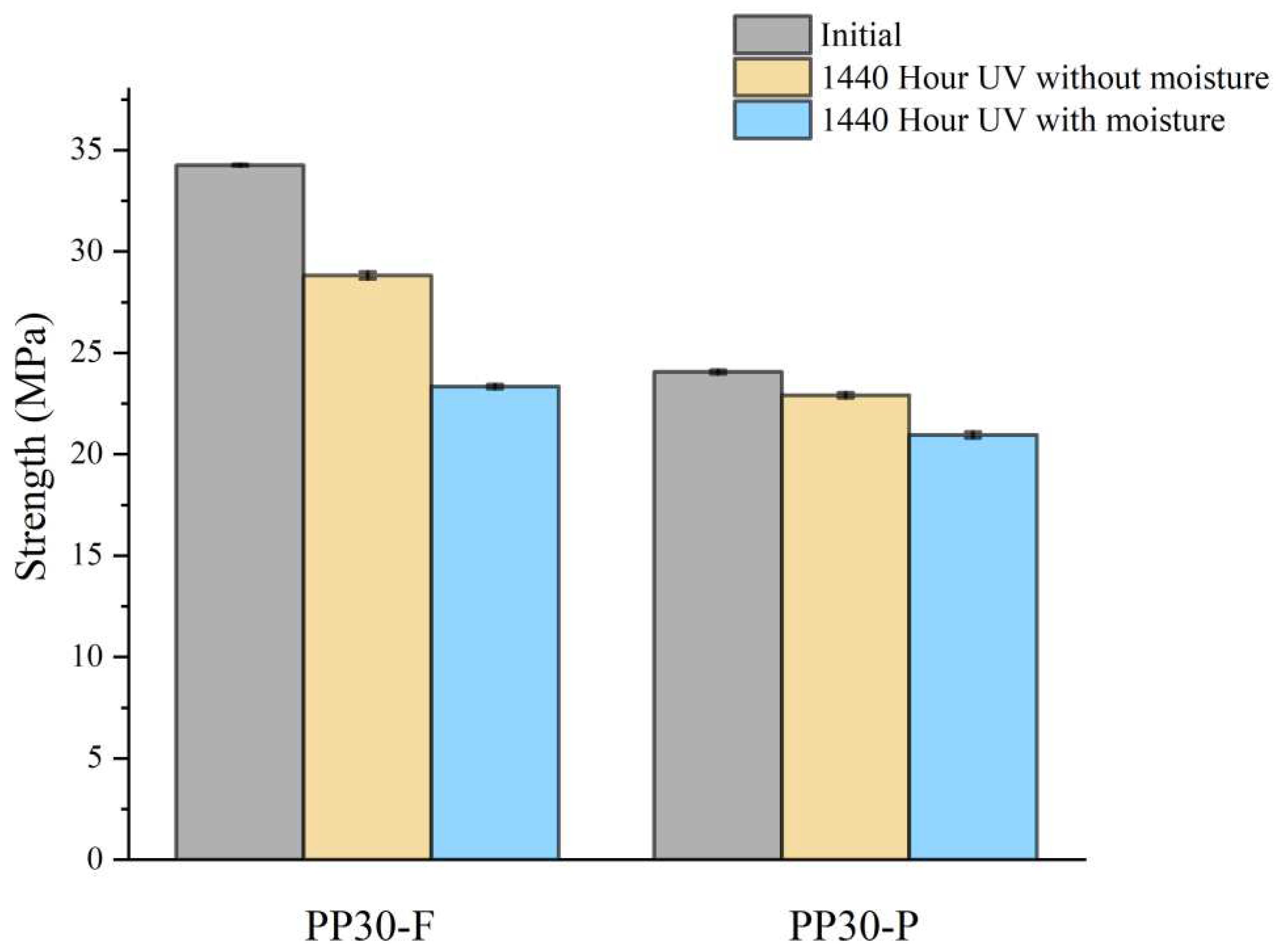

4.1.5. Tensile test

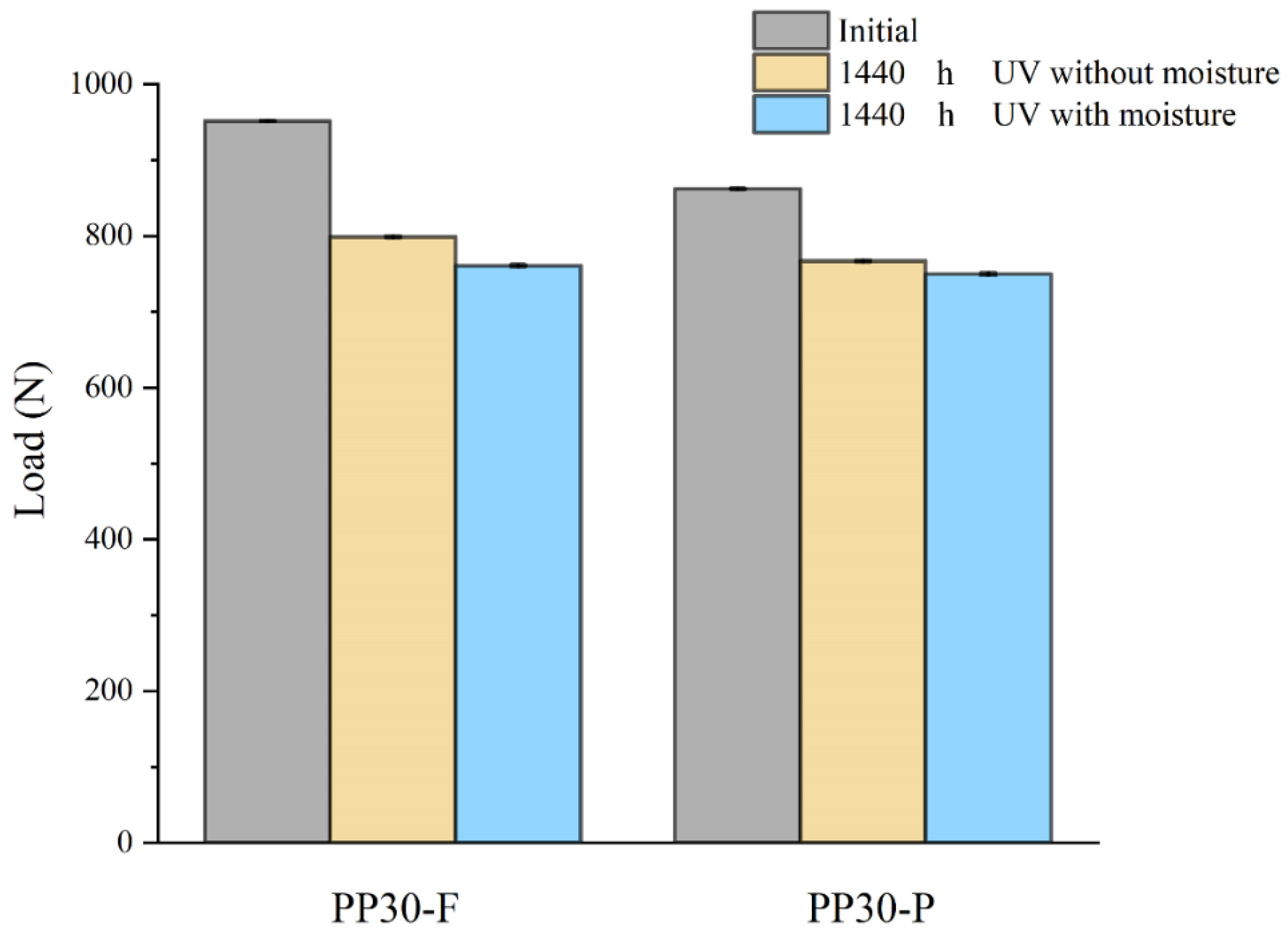

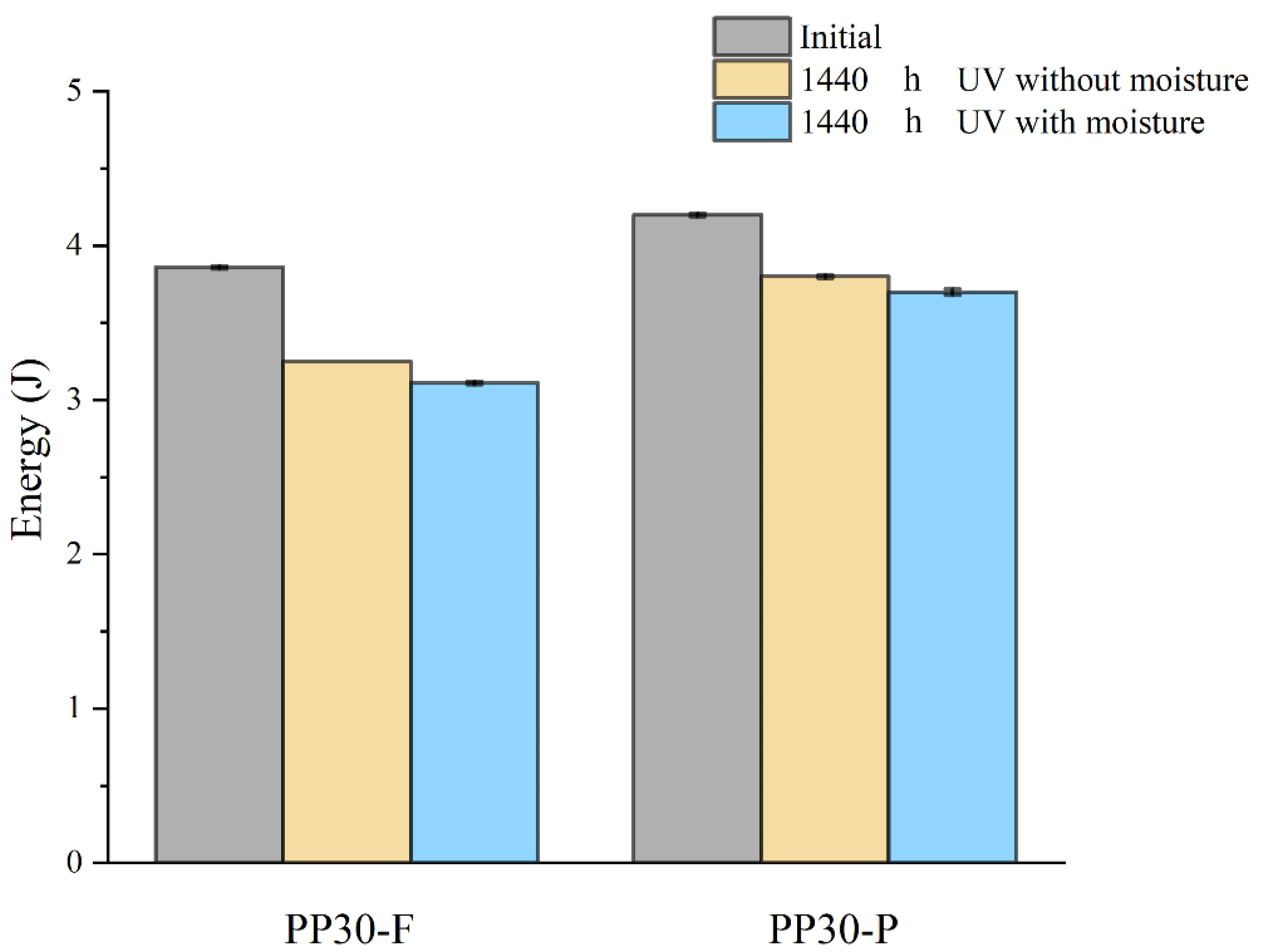

4.1.6. Low-velocity impact properties

4.2. ANN approach

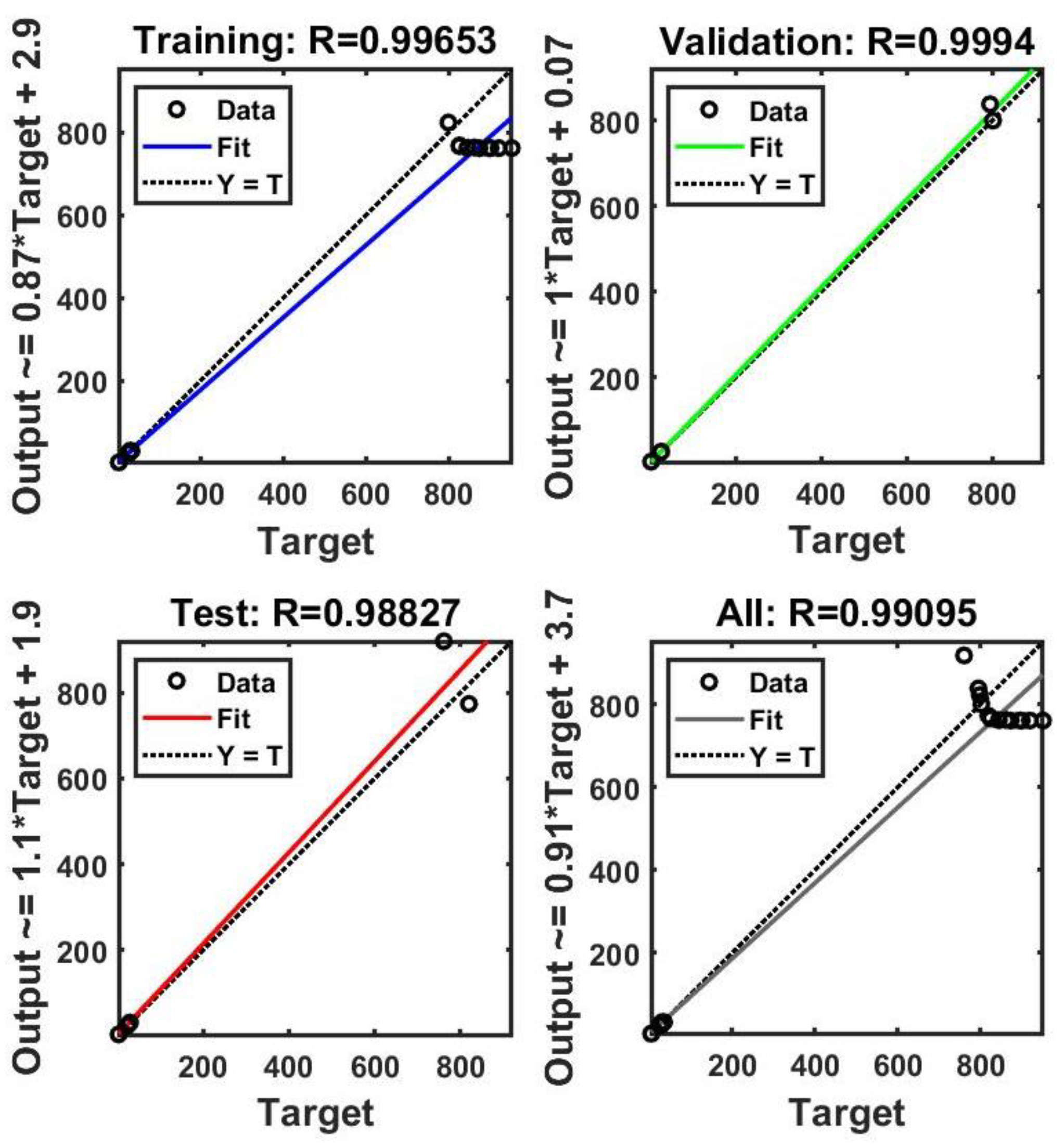

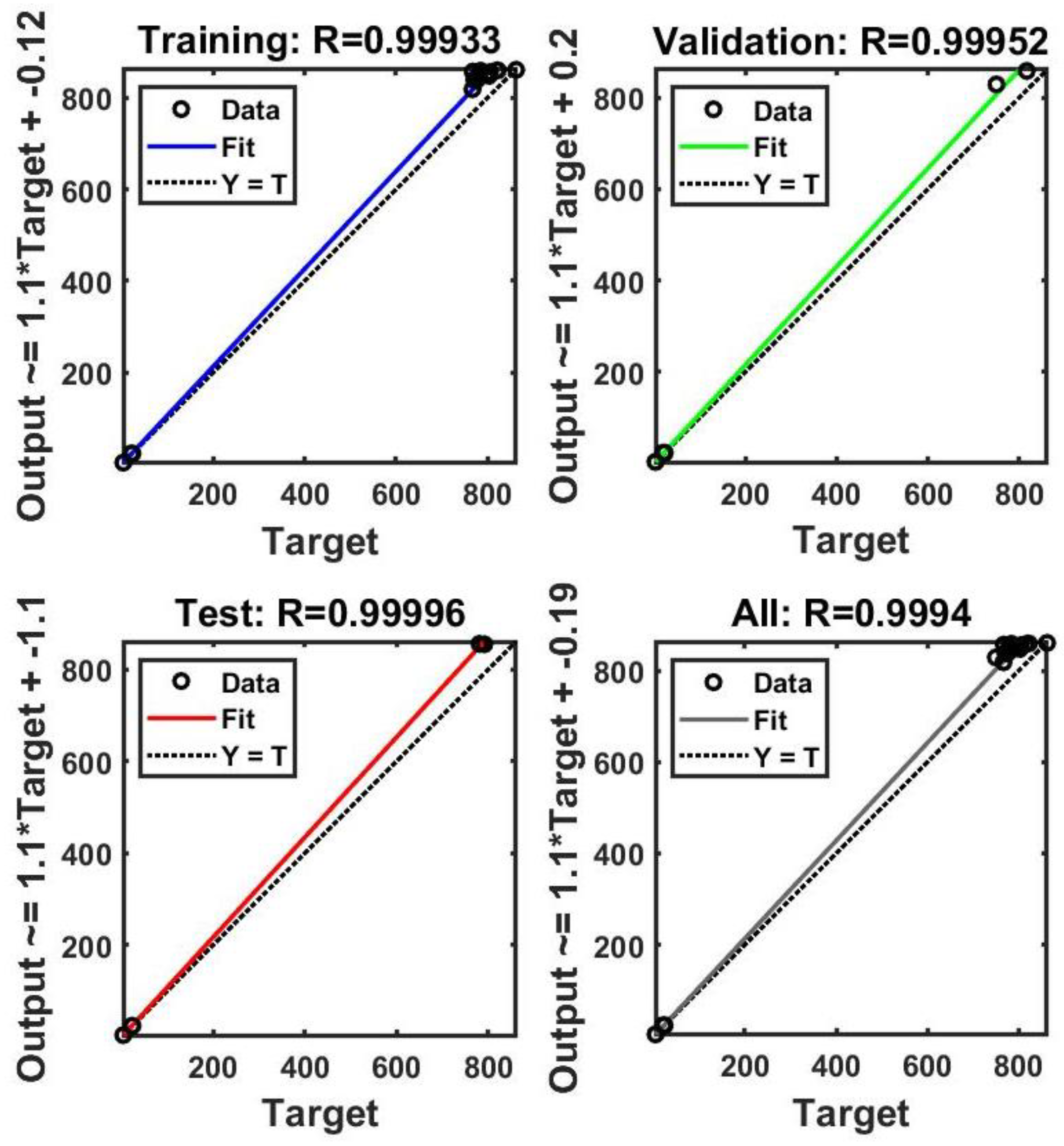

4.2.1. ANN model validation

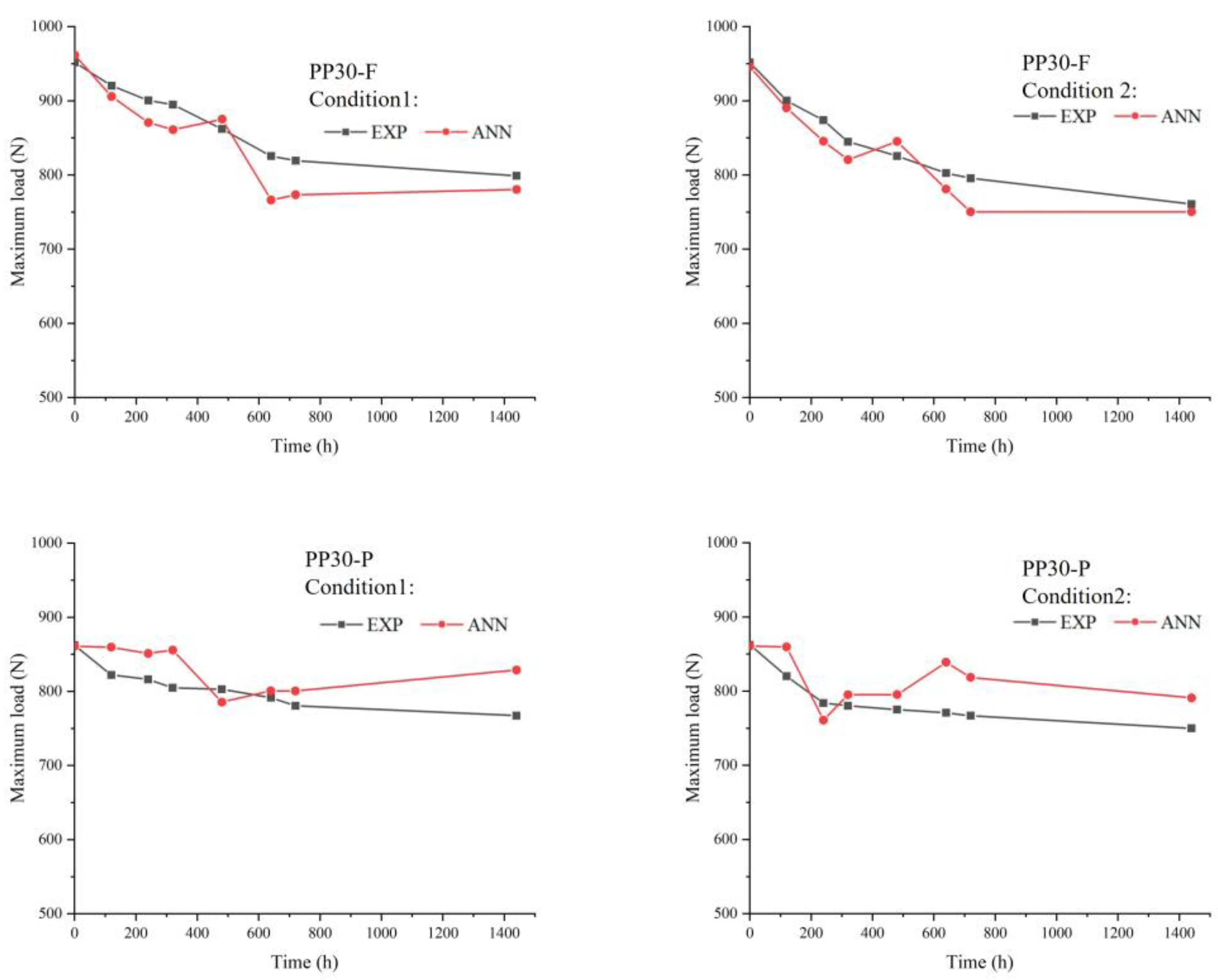

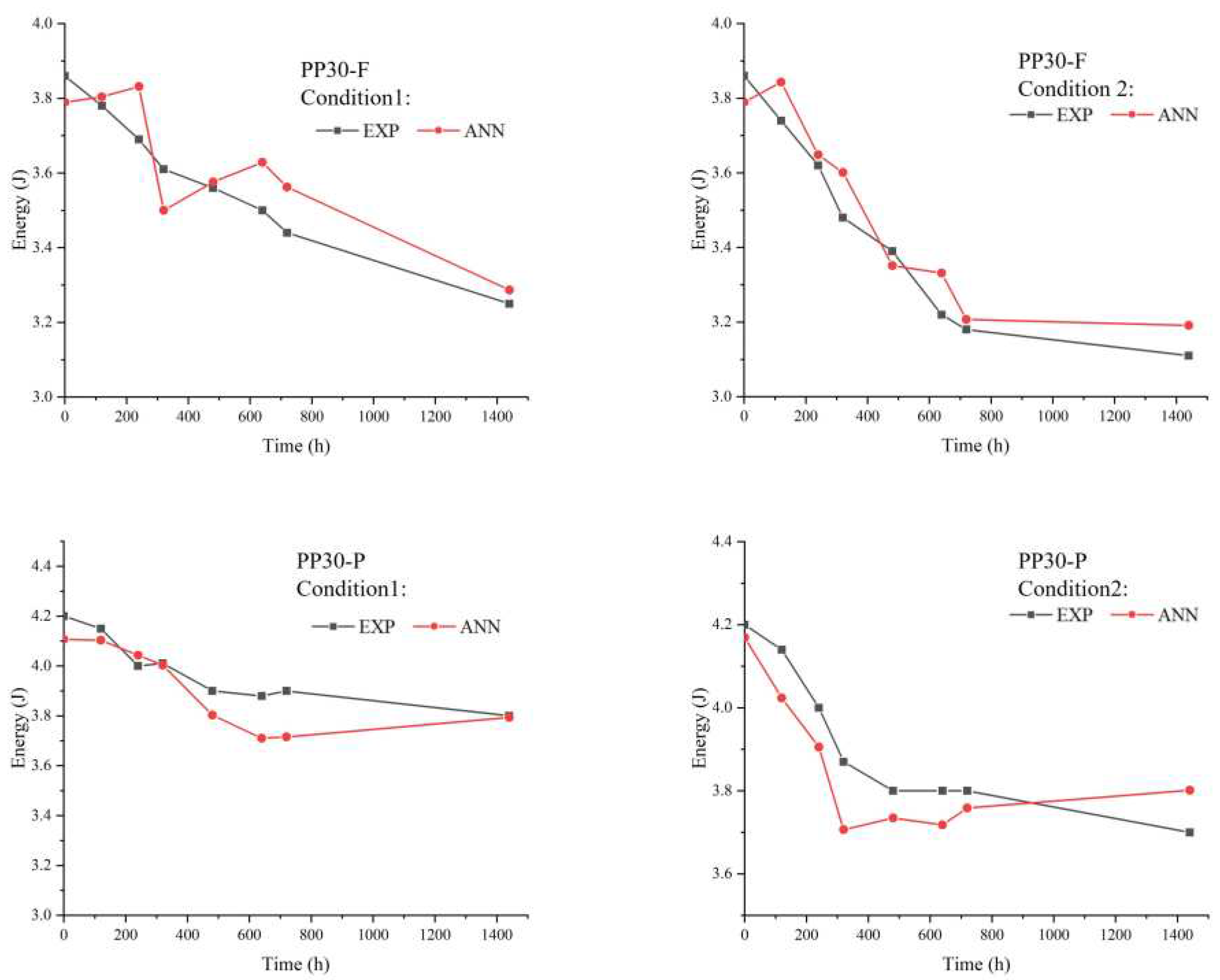

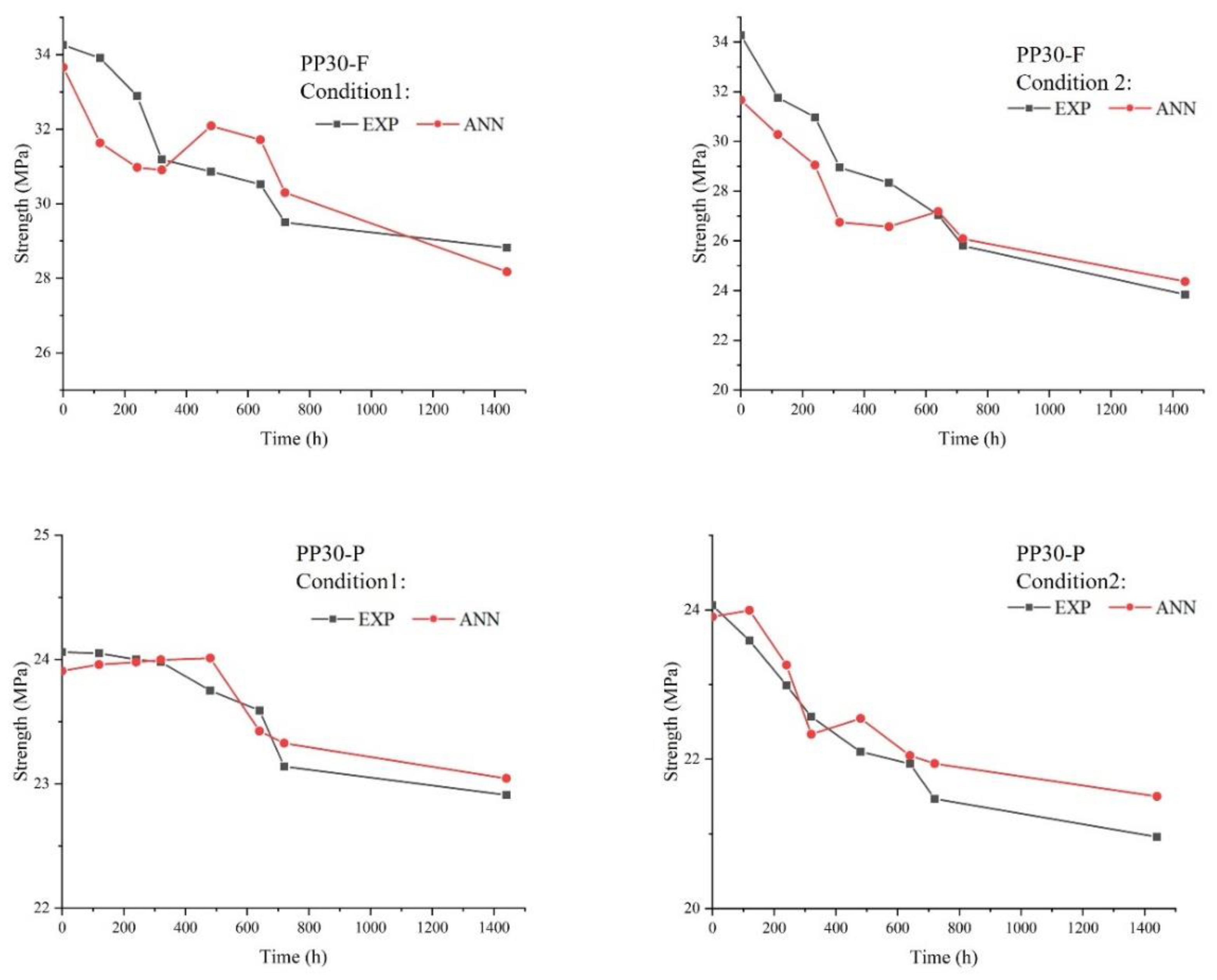

4.2.2. ANN prediction

5. Conclusion

Appendix 1

| Test | Method | Machine | Properties |

|---|---|---|---|

| Physical properties | |||

| Mass measurement | Measuring tape | Electronic scale Accuracy 10–3 g |

M (kg) |

| Roughness measurement | Laser surface scan | 3D laser confocal microscope (Keyence, Canada) | Ra (mm) |

| IET | ASTM E-1876-09 | IMCE machine Signal-processing software: Resonant Frequency and Damping Analyzer (RFDA) |

f (Hz) |

| Mechanical properties | |||

| Hardness test | ASTM E329 | 810-124: HM-100 Economical manual type | H (HRC) |

| Drop-weight impact test | ASTM D-5628 | Instron machine Model CEAST 9350, 22-kN load cell initial impact energy of 5 J, mass of impactor: 5.4 kg |

F (kg⋅m⋅s–2), E (J) |

Appendix 2

References

- Pickering KL, Efendy MGA, Le TM. A review of recent developments in natural fibre composites and their mechanical performance. Composites Part A: Applied Science and Manufacturing 2016, 83, 98–112. [CrossRef]

- Blais P, Toubal L. Single-Gear-Tooth Bending Fatigue of HDPE reinforced with short natural fiber. International Journal of Fatigue 2020, 141. [CrossRef]

- Tanguy M, Bourmaud A, Beaugrand J, Gaudry T, Baley C. Polypropylene reinforcement with flax or jute fibre; Influence of microstructure and constituents properties on the performance of composite. Composites Part B: Engineering 2018, 139, 64–74. [CrossRef]

- Nurazzi NM, Asyraf MRM, Khalina A, Abdullah N, Aisyah HA, Rafiqah SA, et al. A review on natural fiber reinforced polymer composite for bullet proof and ballistic applications. Polymers 2021, 13, 1–42. [CrossRef]

- Lau K tak, Hung P yan, Zhu MH, Hui D. Properties of natural fibre composites for structural engineering applications. Composites Part B: Engineering 2018, 136, 222–33. [CrossRef]

- Koffi A, Koffi D, Toubal L. Mechanical properties and drop-weight impact performance of injection-molded HDPE/birch fiber composites. Polymer Testing 2021, 93, 106956. [CrossRef]

- Nasri K, Toubal L, Koffi D. Composites Part C : Open Access Influence of UV irradiation on mechanical properties and drop-weight impact performance of polypropylene biocomposites reinforced with short flax and pine fibers 2022, 9. [CrossRef]

- Nasri K, Loranger É, Toubal L. Effect of cellulose and lignin content on the mechanical properties and drop-weight impact damage of injection-molded polypropylene-flax and -pine fiber composites. Journal of Composite Materials 2023, 57, 3347–64. [CrossRef]

- Kallakas H, Ayansola GS, Tumanov T, Goljandin D, Poltimäe T, Krumme A, et al. Influence of Birch False Heartwood on the physical and mechanical properties of wood-plastic composites. BioResources 2019, 14, 3554–66. [CrossRef]

- Mejri M, Toubal L, Cuillière JC, François V. Hygrothermal aging effects on mechanical and fatigue behaviors of a short- natural-fiber-reinforced composite. International Journal of Fatigue 2018, 108, 96–108. [CrossRef]

- Sodoke FK, Toubal L, Laperrière L. Hygrothermal effects on fatigue behavior of quasi-isotropic flax/epoxy composites using principal component analysis. Journal of Materials Science 2016, 51, 10793–805. [CrossRef]

- Matuana LM, Jin S, Stark NM. Ultraviolet weathering of HDPE/wood-flour composites coextruded with a clear HDPE cap layer. Polymer Degradation and Stability 2011, 96, 97–106. [CrossRef]

- Nagaraja S, Bindiganavile Anand P, Mahadeva Naik RN, Gunashekaran S. Effect of aging on the biopolymer composites: Mechanisms, modes and characterization. Polymer Composites 2022, 1–11. [CrossRef]

- Fabiyi JS, McDonald AG, Wolcott MP, Griffiths PR. Wood plastic composites weathering: Visual appearance and chemical changes. Polymer Degradation and Stability 2008, 93, 1405–14. [CrossRef]

- Thirmizir MZA, Ishak ZAM, Taib RM, Rahim S, Jani SM. Natural Weathering of Kenaf Bast Fibre-Filled Poly(Butylene Succinate) Composites: Effect of Fibre Loading and Compatibiliser Addition. Journal of Polymers and the Environment 2011, 19, 263–73. [CrossRef]

- Belec L, Nguyen TH, Nguyen DL, Chailan JF. Comparative effects of humid tropical weathering and artificial ageing on a model composite properties from nano- to macro-scale. Composites Part A: Applied Science and Manufacturing 2015, 68, 235–41. [CrossRef]

- Soccalingame L, Perrin D, Bénézet JC, Bergeret A. Reprocessing of UV-weathered wood flour reinforced polypropylene composites: Study of a natural outdoor exposure. Polymer Degradation and Stability 2016, 133, 389–98. [CrossRef]

- Badji C, Beigbeder J, Garay H, Bergeret A, Bénézet JC, Desauziers V. Exterior and under glass natural weathering of hemp fibers reinforced polypropylene biocomposites: Impact on mechanical, chemical, microstructural and visual aspect properties. vol. 148. Elsevier Ltd; 2018. [CrossRef]

- Badji C, Beigbeder J, Garay H, Bergeret A, Bénézet JC, Desauziers V. Correlation between artificial and natural weathering of hemp fibers reinforced polypropylene biocomposites. Polymer Degradation and Stability 2018, 148, 117–31. [CrossRef]

- Peng Y, Liu R, Cao J, Chen Y. Effects of UV weathering on surface properties of polypropylene composites reinforced with wood flour, lignin, and cellulose. Applied Surface Science 2014, 317, 385–92. [CrossRef]

- Stark NM, Matuana LM. Ultraviolet weathering of photostabilized wood-flour-filled high-density polyethylene composites. Journal of Applied Polymer Science 2003, 90, 2609–17. [CrossRef]

- Azwa ZN, Yousif BF, Manalo AC, Karunasena W. A review on the degradability of polymeric composites based on natural fibres. Materials and Design 2013, 47, 424–42. [CrossRef]

- Andrew JJ, Dhakal HN. Sustainable biobased composites for advanced applications: recent trends and future opportunities – A critical review. Composites Part C: Open Access 2022, 7, 100220. [CrossRef]

- Zhang Z, Friedrich K. Artificial neural networks applied to polymer composites: A review. Composites Science and Technology 2003, 63, 2029–44. [CrossRef]

- Stamopoulos AG, Tserpes KI, Dentsoras AJ. Quality assessment of porous CFRP specimens using X-ray Computed Tomography data and Artificial Neural Networks. Composite Structures 2018, 192, 327–35. [CrossRef]

- Yang B, Fu K, Lee J, Li Y. Artificial Neural Network (ANN)-Based Residual Strength Prediction of Carbon Fibre Reinforced Composites (CFRCs) After Impact. Applied Composite Materials 2021, 28, 809–33. [CrossRef]

- Fan HT, Wang H. Predicting the Open-Hole Tensile Strength of Composite Plates Based on Probabilistic Neural Network. Applied Composite Materials 2014, 21, 827–40. [CrossRef]

- Altabey WA, Noori M. Fatigue life prediction for carbon fibre/epoxy laminate composites under spectrum loading using two different neural network architectures. International Journal of Sustainable Materials and Structural Systems 2017, 3, 53. [CrossRef]

- Khan MA, Aslam F, Javed MF, Alabduljabbar H, Deifalla AF. New prediction models for the compressive strength and dry-thermal conductivity of bio-composites using novel machine learning algorithms. Journal of Cleaner Production 2022, 350, 131364. [CrossRef]

| Mat | Condition | Time (h) | M (g) | H | Ra | ft | fb | F | E | R |

| (HRC) | (mm) | (Hz) | (Hz) | (N) | (J) | (MPa) | ||||

| PP30-F | UV without moisture | 0 | 9.706 (0.01) | 9.12 (0.12) |

2.5 (0.01) |

1534 (3.45) |

2880 (9.51) |

951.72 (1.12) |

3.86 (0.01) |

34.26 (0.01) |

| 120 | 9.706 (0.02) |

8.87 (0.15) |

2.8 (0.02) |

1530 (10.12) |

2887 (9.29) |

920.17 (1.18) |

3.78 (0.02) |

33.91 (0.03) |

||

| 240 | 9.702 (0.01) |

8.14 (0.21) |

3.4 (0.02) |

1531 (3.77) |

2886 (4.37) |

900.51 (1.28) |

3.69 (0.02) |

32.89 (0.02) |

||

| 320 | 9.701 (0.02) |

7.92 (0.18) |

6.6 (0.02) |

1518 (7.48) |

2815 (6.29) |

894.74 (2.32) |

3.61 (0.02) |

31.19 (0.05) |

||

| 480 | 9.548 (0.04) |

7.82 (0.09) |

7.8 (0.01) |

1502 (3.45) |

2755 (7.48) |

861.93 (1.78) |

3.56 (0.03) |

30.86 (0.03) |

||

| 640 | 9.341 (0.02) |

7.48 (0.19) |

9.4 (0.03) |

1504 (6.48) |

2743 (5.59) |

825.46 (1.81) |

3.50 (0.03) |

30.52 (0.01) |

||

| 720 | 9.137 (0.01) |

7.25 (0.21) |

13 (0.02) |

1499 (8.55) |

2733 (7.88) |

819.36 (1.89) |

3.44 (0.03) |

29.5 (0.01) |

||

| 1440 | 9.012 (0.01) |

6.21 (0.22) |

19.86 (0.02) |

1498 (6.84) |

2663 (6.79) |

798.84 (2.22) |

3.25 (0.02) |

28.82 (0.06) |

||

| UV with moisture | 120 | 9.704 (0.01) |

6.91 (0.15) |

4.1 (0.02) |

1532 (8.87) |

2856 (7.59) |

900.14 (1.56) |

3.74 (0.01) |

31.76 (0.04) |

|

| 240 | 9.698 (0.02) |

6.74 (0.18) |

6.4 (0.01) |

1530 (7.13) |

2764 (8.49) |

873.82 (4.27) |

3.62 (0.01) |

30.97 (0.01) |

||

| 320 | 9.645 (0.04) |

6.51 (0.19) |

11.6 (0.03) |

1501 (9.44) |

2667 (8.71) |

844.84 (3.48) |

3.48 (0.01) |

28.95 (0.01) |

||

| 480 | 9.412 (0.02) |

6.45 (0.21) |

12.5 (0.01) |

1500 (3.19) |

2565 (4.14) |

825.51 (1.12) |

3.39 (0.02) |

28.34 (0.03) |

||

| 640 | 9.104 (0.04) |

6.22 (0.11) |

18 (0.01) |

1495 (8.42) |

2529 (8.46) |

802.52 (1.29) |

3.22 (0.02) |

27.04 (0.02) |

||

| 720 | 9.016 (0.02) |

6.01 (0.17) |

26 (0.02) |

1493 (8.42) |

2486 (8.46) |

795.59 (3.82) |

3.18 (0.02) |

25.8 (0.05) |

||

| 1440 | 8.802 (0.03) |

5.54 (0.14) |

32.41 (0.02) |

1490 (9.43) |

2466 (7.68) |

760.82 (2.32) |

3.11 (0.02) |

23.84 (0.03) |

||

| PP30-P | UV without moisture | 0 | 9.892 (0.03) |

8.72 (0.18) |

2.47 (0.03) |

1436 (7.12) |

2668 (6.41) |

862.3 (3.72) |

4.2 (0.01) |

24.06 (0.02) |

| 120 | 9.870 (0.03) |

8.45 (0.19) |

3.00 (0.03) |

1415 (9.28) |

2610 (9.11) |

822.15 (2.32) |

4.15 (0.01) |

24.05 (0.04) |

||

| 240 | 9.841 (0.02) |

8.11 (0.27) |

4.47 (0.03) |

1416 (6.66) |

2630 (9.34) |

816.2 (4.32) |

4 (0.02) |

24.04 (0.03) |

||

| 320 | 9.832 (0.01) |

7.85 (0.24) |

5.56 (0.02) |

1403 (9.65) |

2560 (9.40) |

804.74 (2.32) |

4.01 (0.02) |

24.031 (0.05) |

||

| 480 | 9.800 (0.02) |

7.64 (0.19) |

6.71 (0.02) |

1388 (8.41) |

2501 (3.54) |

802.9 (2.42) |

3.9 (0.01) |

24.01 (0.01) |

||

| 640 | 9.394 (0.04) |

7.45 (0.21) |

7.91 (0.02) |

1389 (8.37) |

2490 (8.41) |

791.44 (3.42) |

3.88 (0.02) |

24.04 (0.02) |

||

| 720 | 9.234 (0.02) |

7.12 (0.17) |

8.41 (0.01) |

1385 (9.35) |

2480 (8.19) |

780.6 (1.77) |

3.9 (0.03) |

23.14 (0.03) |

||

| 1440 | 9.108 (0.03) |

6.44 (0.19) |

10.02 (0.01) |

1384 (7.19) |

2411 (8.38) |

767.2 (2.82) |

3.8 (0.02) |

22.91 (0.04) |

||

| UV with moisture | 120 | 9.801 (0.02) |

8.24 (0.22) |

3.13 (0.03) |

1417 (8.48) |

2600 (10.21) |

820.18 (1.68) |

4.14 (0.01) |

23.59 (0.02) |

|

| 240 | 9.851 (0.01) |

7.81 (0.27) |

3.27 (0.03) |

1415 (6.61) |

2510 (4.68) |

783.9 (3.91) |

4 (0.01) |

22.99 (0.05) |

||

| 320 | 9.762 (0.02) |

7.57 (0.29) |

4.15 (0.03) |

1387 (6.39) |

2415 (5.79) |

780.21 (3.10) |

3.87 (0.01) |

22.57 (0.02) |

||

| 480 | 9.571 (0.04) |

6.94 (0.21) |

5.16 (0.03) |

1386 (7.55) |

2315 (9.12) |

775,00 (1.88) |

3.8 (0.02) |

22.1 (0.03) |

||

| 640 | 9.115 (0.02) |

6.64 (0.12) |

10.4 (0.02) |

1381 (8.49) |

2280 (9.11) |

770.74 (2.94) |

3.80 (0.01) |

21.94 (0.06) |

||

| 720 | 9.104 (0.02) |

6.21 (0.28) |

12.5 (0.02) |

1379 (7.22) |

2238 (4.51) |

766.8 (1.11) |

3.8 (0.01) |

21.47 (0.04) |

||

| 1440 | 9.011 (0.03) |

5.71 (0.21) |

16.73 (0.01) |

1376 (6.75) |

2238 (7.64) |

749.9 (1.22) |

3.7 (0.03) |

20.96 (0.03) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).