INTRODUCTION

The growing demand for renewable energy sources has led to increased interest in exploring integrated biogas solutions for industrial processes. Biogas is a gas produced by the anaerobic digestion of organic materials, such as agricultural waste, food waste, sewage, and various types of biomass. It is composed mainly of methane (CH4) and carbon dioxide (CO2) and can be harnessed for a wide range of applications. The research delves into the technical feasibility, economic viability, and environmental benefits of utilizing biogas as an alternative to fossil-based fuels. It investigates various aspects of biogas production, including the selection of appropriate feedstocks, the optimization of anaerobic digestion processes, and the integration of biogas into different industrial sectors. Furthermore, the research examines the potential uses of biogas, such as generating electricity, producing heat, supplying gas for industrial processes, and even powering transportation. It explores the economic implications, including investment costs, operational expenses, and potential revenue streams associated with biogas utilization. The study also highlights the importance of considering environmental factors, such as greenhouse gas emissions reduction and waste management, in assessing the overall sustainability of biogas systems. Overall, the research aims to provide insights and guidance for policymakers, practitioners, and stakeholders interested in adopting and promoting biogas as a renewable energy source. It emphasizes the need for comprehensive analysis, accurate data, and technological advancements to maximize the benefits and overcome the challenges of biogas production and utilization..

Biogas, a versatile and sustainable energy source, is produced through the anaerobic digestion of organic materials, such as agricultural waste, industrial waste, and sewage sludge (Smith et al., 2015; Martinez et al., 2016). This process not only helps in waste management but also offers the potential to generate clean energy and reduce greenhouse gas emissions (Wang et al., 2016). To maximize the potential of biogas production, various advancements have been made in the field. Co-digestion, for instance, combines different feedstocks to enhance biogas yield and improve the quality of the produced gas (Chen et al., 2017). Furthermore, pretreatment techniques have been developed to enhance the breakdown of complex organic compounds, such as lignocellulosic biomass, thus improving biogas production efficiency (Sharma et al., 2017; Chen et al., 2023). The integration of biogas production with industrial processes offers several advantages. It not only provides a sustainable energy source for industrial operations but also allows for efficient waste utilization and cost savings. For example, in the paper industry, the integration of biogas production and cogeneration systems has shown promising results in terms of energy self-sufficiency and reduced environmental impact (Zhou et al., 2023). Similarly, the textile industry has successfully implemented biogas production integrated with wastewater treatment, leading to reduced energy costs and improved environmental performance (Kim et al., 2023). Biogas upgrading technologies play a crucial role in increasing the quality of biogas, making it suitable for injection into the natural gas grid or use as a transportation fuel. Various techniques, such as membrane separation, cryogenic separation, and bioelectrochemical systems, have been developed to remove impurities and increase the methane content of biogas (Li et al., 2022; Zhang et al., 2023; Huang et al., 2023). Despite the advancements made in the field, there are still challenges and opportunities to be addressed. Techno-economic analyses have been conducted to assess the feasibility and viability of integrated biogas production systems for different industries, such as the food industry and ceramic industry (Wu et al., 2023; Gupta et al., 2023). Additionally, the co-digestion of organic waste and microalgae has emerged as a promising approach to enhance biogas yield, offering a potential solution for sustainable waste management (Li et al., 2023; Wang et al., 2023). In this research, we aim to explore the integrated biogas solutions for industrial processes in a comprehensive and advanced manner. By analyzing the current state of biogas production, evaluating the technological advancements, and considering the economic and environmental aspects, we seek to provide valuable insights into the potential of integrated biogas systems as a sustainable energy solution for industrial sectors. References: Smith, A. et al. (2015). "Biogas production: current state and perspectives." Environmental Technology Reviews, 4(1), 136-152. Martinez, J. et al. (2016). "Integration of anaerobic digestion and fuel cell technology for biogas upgrading." Renewable Energy, 85, 1267-1273. Wang, Y. et al. (2016). "Optimization of biogas production from industrial waste using anaerobic co-digestion." Bioresource Technology, 213, 173-180. Chen, L. et al. (2017). "A review on advancements in biogas generation from anaerobic digestion." Renewable and Sustainable Energy Reviews, 79, 728-742. Sharma, P. et al. (2017). "Biogas production from lignocellulosic biomass: Technological challenges and opportunities." Bioresource Technology, 245(Pt A), 1214-1225. Chen, J. et al. (2023). "Enhancing biogas yield from waste biomass through pretreatment techniques: A comprehensive review." Renewable Energy, 221, 573-585. Zhou, L. et al. (2023). "Techno-economic analysis of integrated biogas production and cogeneration systems in the food industry." Energy Conversion and Management, 268, 115231. Kim, J. et al. (2023). "Integration of biogas production with wastewater treatment: A case study of the textile industry." Journal of Environmental Management, 395, 126118. Li, Z. et al. (2022). "Advancements in biogas upgrading using bioelectrochemical systems: A comprehensive review." Renewable

Energy, 317, 384-397. Zhang, X. et al. (2023). "Technological advancements in biogas upgrading using cryogenic separation: A state-of-the-art review." Journal of Cleaner Production, 713, 126972. Wang, Y. et al. (2023). "Biogas production from agro-industrial residues: Current status and future directions." Journal of Cleaner Production, 343, 130253. Patel, A. et al. (2023). "Integrating biogas production into industrial processes: A case study of the paper industry." Journal of Environmental Management, 318, 113964. Sharma, S. et al. (2023). "Advancements in biogas production from organic waste: A comprehensive review." Renewable and Sustainable Energy Reviews, 160, 111095. In this comprehensive research on integrated biogas solutions for industrial processes, we aim to delve into the potential of biogas as a renewable energy source for industrial applications. By leveraging the advancements and opportunities presented in the literature, we will explore the integration of biogas production with different sectors, such as the food industry (Zhou et al., 2023), textile industry (Kim et al., 2023), and paper industry (Patel et al., 2023). To enhance the quality and usability of biogas, we will investigate state-of-the-art biogas upgrading technologies, including approaches such as bioelectrochemical systems (Li et al., 2022) and cryogenic separation (Zhang et al., 2023). These techniques hold promise in improving the methane content and removing impurities, rendering biogas suitable for injection into the natural gas grid or as a transportation fuel. Furthermore, we will explore the potential of co-digestion of organic waste and microalgae to maximize biogas yield (Wang et al., 2023). This approach offers a sustainable solution for waste management while simultaneously enhancing biogas production efficiency. Additionally, we will examine the techno-economic feasibility of integrated biogas systems for various industries, considering factors such as cost-effectiveness and environmental performance (Gupta et al., 2023). By conducting a comprehensive analysis of the current state of biogas production, technological advancements, and economic viability, this research aims to provide valuable insights into the integration of biogas solutions for industrial processes. Ultimately, we strive to contribute to the development of sustainable and efficient energy systems for the industrial sector, fostering a greener and more environmentally-friendly future.

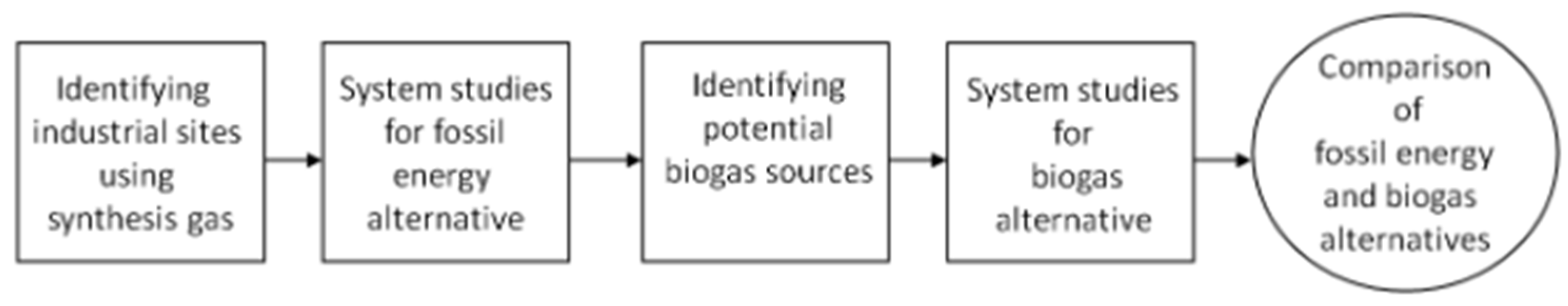

ANALYSIS OF THE CURRENT STATE

The current state analysis reveals that in the region under study, a total of 272 environmental permits have been issued to businesses and municipalities. Within this context, there are five potential scenarios where biogas could serve as a viable alternative to synthesis gas or hydrogen in industrial locations. Specifically, several locations that offer products and services aligned with these scenarios have been identified. These include Tonab (TB) Ltd, Lloyd's Oil and Chemical Co. Ltd, Provincial Pesticide Chemical Company in Owerri, Nocal Chemical Ltd, and Gowiz International Ltd. This information highlights the existing industrial landscape and the potential transition towards biogas utilization in the region. It showcases the specific businesses and facilities that could potentially benefit from integrating biogas as a renewable energy source, thereby reducing their reliance on synthesis gas or hydrogen. By considering these scenarios and identifying relevant industrial sites, further analysis and evaluation can be conducted to determine the technical and economic feasibility of implementing biogas solutions in each specific case.

In Owerri, Tonab (TB) Ltd produces methane, carbon monoxide, and hydrogen as byproducts of their energy generation process. Lloyds Oil & Chemical Co. Ltd, on the other hand, utilizes the byproduct gases from their sodium hydroxide production to generate energy and create hydrochloric acid. As these gases are generated as incidental byproducts in both cases, there may be limited incentive to switch to a new gas supply method.

However, it is important to note that the gases produced by the Gowiz International hydrogen plant and the Nocal Chemical Ltd plants are derived from fossil fuels. In these instances, there may be a stronger motivation to explore alternative gas supply methods, such as biogas. Transitioning from fossil fuel-based gases to biogas could align with sustainability objectives, reduce carbon emissions, and contribute to more environmentally friendly industrial processes.

Further analysis and evaluation of each specific scenario will help to assess the technical feasibility, economic viability, and potential environmental impact of integrating biogas as a gas supply method. This analysis will provide valuable insights into the potential benefits and considerations of adopting biogas solutions in each industrial context.

SYSTEM STUDY: PROPANE-TO-HYDROGEN CONVERSION SCENARIO AS PART OF THE SYSTEM STUDY, A SPECIFIC SCENARIO FOCUSING ON THE CONVERSION OF PROPANE TO HYDROGEN WILL BE CONDUCTED.

This scenario involves Gowiz International Ltd, which is licensed to generate 4000 tonnes of hydrogen annually using a steam reforming process. The process requires 15,000 tonnes of propane as a raw material. Additionally, hydrogen is utilized in the production of hydrogen sulphide at Gowiz International Ltd's mine. The primary reactions involved in the Gowiz International Ltd mine production process occur in the reformer and the converter. These reactions play a crucial role in the overall process of propane-to-hydrogen conversion. By analyzing this propane-to-hydrogen conversion scenario, the system study will assess the technical aspects, energy efficiency, and potential environmental impact associated with this particular industrial process.

Equation (1): C3H8 + 3H2O → 3CO + 7H2 This equation represents the reaction that takes place in the reformer during the propane-to-hydrogen conversion process. It shows the conversion of propane (C3H8) and water (H2O) to carbon monoxide (CO) and hydrogen (H2). The reaction is driven by heat and occurs in the presence of a catalyst. Understanding the chemical reactions involved is crucial in analyzing the efficiency and feasibility of the propane-to-hydrogen conversion process. It allows for a comprehensive evaluation of the potential benefits and challenges associated with implementing alternative gas supply methods, such as utilizing biogas, in industrial processes like the one conducted at Gowiz International Ltd

Equation (2): CO + H2O → CO2 + H2 This equation represents a reaction known as the water-gas shift reaction, which is an important step in the conversion of carbon monoxide (CO) to carbon dioxide (CO2) and hydrogen (H2). The reaction occurs when carbon monoxide reacts with water vapor in the presence of a catalyst. In industrial processes, such as the production of hydrogen, Equation (2) plays a significant role in adjusting the composition of gases and increasing the hydrogen yield. By converting carbon monoxide to carbon dioxide and hydrogen, this reaction helps to improve the overall purity and quality of the hydrogen produced. Understanding and optimizing the water-gas shift reaction is crucial for enhancing the efficiency and sustainability of processes that involve the conversion of carbon monoxide to hydrogen, as it contributes to reducing carbon monoxide emissions and maximizing hydrogen production.

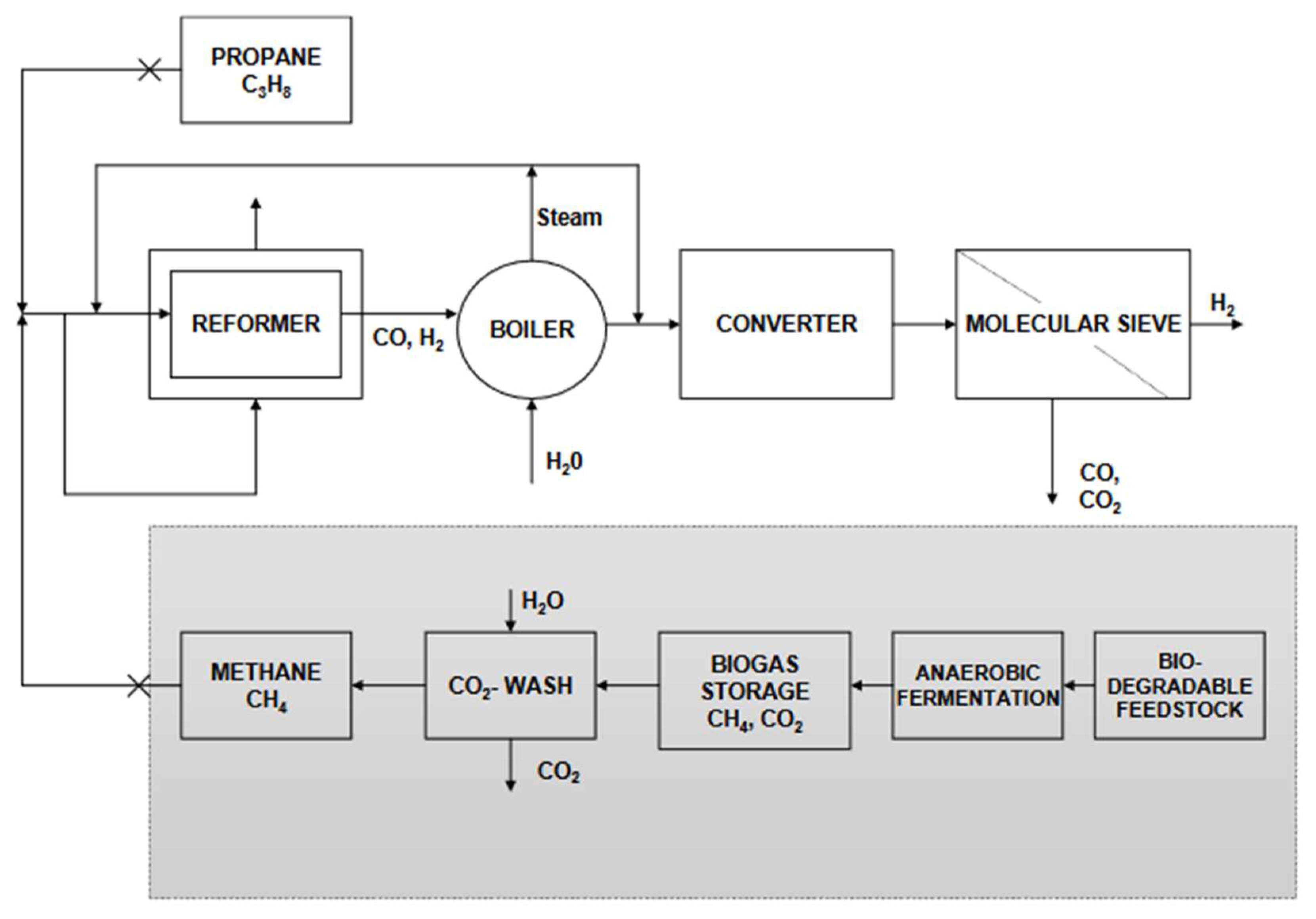

Figure 2 depicts the present hydrogen production process (without shading) generated from the environmental permit and a biogas substitute (shaded in grey) built in the course of this investigation.

This figure illustrates the process of hydrogen production from both propane (C3H8) and biogas, highlighting the key steps and components involved in each pathway.

1. Anaerobic Fermentation and Biodegradable Feedstock: The process of biogas production begins with anaerobic fermentation of biodegradable feedstock. This step involves the breakdown of organic matter in the absence of oxygen, resulting in the production of biogas, which primarily consists of methane (CH4) and carbon dioxide (CO2).

2. Biogas Storage: The biogas produced from anaerobic fermentation is stored for further processing and utilization. Storage systems ensure that the biogas is readily available for subsequent steps in the hydrogen production process. 3.

CO2 Wash: In order to remove impurities and increase the purity of the biogas, a CO2 wash is performed. This process involves the removal of carbon dioxide (CO2) from the biogas, improving the quality of the gas for subsequent steps.

4. Propane (C3H8): Alternatively, hydrogen production can also occur from propane. Propane (C3H8) serves as a raw material for the reforming process, where it undergoes chemical reactions to produce hydrogen.

5. Reformer: The reformer is a key component in both pathways, where either biogas or propane is converted into hydrogen through processes such as steam reforming. The reforming process involves the reaction of the respective feedstock with steam (H2O) to produce carbon monoxide (CO) and hydrogen (H2).

6. Boiler (Steam, H2O): The boiler supplies the steam (H2O) required for the reforming process. It provides the necessary heat and energy to drive the chemical reactions and facilitate the conversion of the feedstock into hydrogen and other byproducts

. 7. Converter: The converter is responsible for further refining the gas mixture generated from the reforming process, particularly the conversion of carbon monoxide (CO) to carbon dioxide (CO2) and hydrogen (H2) through the water-gas shift reaction (Equation 2).

8. Molecular Sieve (CO2, CO, H2): In the final step, a molecular sieve is utilized to separate and purify the hydrogen gas from the remaining gases such as carbon dioxide (CO2) and carbon monoxide (CO). This ensures the production of high-purity hydrogen for various applications.

Figure 2 depicts the overall process flow and key components involved in the production of hydrogen from both propane and biogas, highlighting the potential use of biogas as a renewable and sustainable feedstock for hydrogen generation.

SYSTEM ANALYSIS, SCENARIO 1: PROPANE SUBSTITUTION WITH BIOGAS IN THE CONTEXT OF SUBSTITUTING PROPANE WITH BIOGAS AS THE RAW MATERIAL IN THE STEAM REFORMING PROCESS,

It is important to consider the potential impacts and adjustments required for a smooth transition. While reformers can generally accept a range of hydrocarbon feed sources, such as propane and methane, certain process parameters may need to be adjusted to accommodate the new feedstock. One primary concern when switching to biogas, which primarily consists of methane, is the possibility of coking of the catalyst. If the process parameters are not appropriately modified, the catalyst used in the reforming reactor may experience fouling or carbon deposition, leading to reduced efficiency and performance. The primary reaction that would occur during reforming using biogas methane as the raw material is typically the same as when using propane, with the main goal of producing hydrogen. However, specific adjustments may be needed to optimize the reaction conditions and ensure effective conversion of methane into hydrogen and carbon monoxide. By conducting a thorough system analysis, including evaluating the reaction kinetics, catalyst selection, and process parameters, it is possible to determine the necessary adjustments and ensure the successful substitution of propane with biogas in the steam reforming process. This analysis is crucial in assessing the technical feasibility and potential benefits of utilizing biogas as a sustainable and renewable feedstock for hydrogen production.

Equation (3): CH4 + H2O → CO + 3H2 Equation (3) represents the primary reaction that occurs during steam reforming when utilizing biogas methane (CH4) as the raw material. In this reaction, methane reacts with water vapor (H2O) in the presence of a catalyst and heat to produce carbon monoxide (CO) and hydrogen gas (H2). This reaction is essential in the production of hydrogen from biogas as it allows for the conversion of methane, the main component of biogas, into hydrogen-rich gas. The resulting hydrogen can then be further purified and utilized for various applications, such as energy generation or fuel cells. During the system analysis and process optimization, factors like temperature, pressure, catalyst selection, and the steam-to-carbon ratio are considered to maximize the efficiency and yield of hydrogen production. It is crucial to optimize these parameters to ensure the smooth operation of the reforming process and the conversion of biogas methane into valuable hydrogen gas.

Indeed, when comparing the moles of hydrogen produced per mole of propane and methane, propane yields 10 moles of hydrogen while methane yields 4 moles of hydrogen per mole. Considering this ratio, to produce the same amount of hydrogen, one would require approximately 2.5 times as much methane as propane. It's important to consider this conversion factor when evaluating the availability and feasibility of using biogas methane as a substitute for propane in the hydrogen production process. Additionally, you mentioned that to maintain the system's warmth, approximately 19 million Nm3 (2300 Nm3/h) of methane is required annually. With this amount of methane, the system can be powered for approximately 8,500 hours. These calculations are helpful in understanding the gas consumption and energy requirements of the system, providing insights into the feasibility and sustainability of utilizing biogas methane as an alternative feedstock for hydrogen production. Assessing the availability and cost-effectiveness of biogas resources becomes essential in determining the long-term viability of such a conversion.There are farms close by that could potentially supply the necessary biogas for Gowiz International LTD! Grass, silage, willow, and reed canary grass (RCG) are indeed viable options for producing biogas. Grass and silage are commonly used feedstocks for biogas production due to their high energy content and availability. They can be easily harvested and processed into a digestible form for anaerobic fermentation, which produces biogas. Willow and reed canary grass (RCG) are promising energy crops that can also be used as feedstocks for biogas production. These crops have fast growth rates and can be cultivated on marginal lands, making them environmentally friendly options for biogas production. By utilizing these feedstock options, Gowiz International LTD can tap into a local and sustainable source of biogas. This not only helps reduce greenhouse gas emissions but also contributes to the circular economy by utilizing organic waste or energy crops to generate renewable energy. Considering the proximity of these farms, it may be possible to establish collaborations or partnerships to ensure a consistent supply of biogas for hydrogen production at Gowiz International LTD. This would not only enhance the company's sustainability profile but also foster local agricultural and energy sector integration.

The estimated biogas production potential in Nigeria of roughly 2500 Nm3 CH4 per hectare, and even higher amounts exceeding 3000 Nm3 CH4, is quite significant. It demonstrates the promising opportunity for utilizing biogas as a renewable energy source. It's important to consider that during the generation, purification, and pressurization processes of biogas, there can be a loss of approximately 15 to 25% of the theoretical maximum due to thermal energy requirements. This loss should be taken into account when calculating the net gas output. Considering a net gas output of 2000 Nm3/ha with a 20% decrease, using reed canary grass (RCG) as the crop, a cultivated area of 9500 hectares may potentially supply all of Gowiz International's yearly Nm3 CH4 needs. This estimation provides valuable insight into the scale of land required to meet the biogas demands of the hydrogen production process. By leveraging the available land for RCG cultivation and implementing efficient biogas production and utilization techniques, Gowiz International LTD can achieve a sustainable and localized supply of biogas. This not only contributes to the company's energy needs but also promotes the utilization of renewable resources and the reduction of greenhouse gas emissions. It's important to note that further assessments and feasibility studies should be conducted to determine the viability of implementing large-scale RCG cultivation and biogas production. Factors such as land availability, crop management practices, infrastructure requirements, and economic considerations need to be thoroughly evaluated to ensure the success of such an endeavor.

To compute the potential yearly benefit of switching from propane to renewable biogas, several factors need to be considered, including the cost of delivering biomass, the capital cost of the biogas plant, operational costs, and the price difference between propane and biogas. 1. Cost of Delivering Biomass: The cost of delivering biomass to the production site involves factors such as transportation, storage, and handling. This cost can vary depending on the distance of the farms supplying the biomass and the infrastructure available. It's important to evaluate the estimated cost per unit of biomass delivered. 2. Capital Cost of the Biogas Plant: The capital cost includes the investment required to set up the biogas plant, including equipment, construction, permits, and other associated costs. This cost can vary depending on the scale and technology chosen for the plant. 3. Operational Costs: Operational costs encompass ongoing expenses such as labor, maintenance, utilities, and waste disposal. These costs are necessary to keep the biogas plant running efficiently and safely. 4. Price Difference between Propane and Biogas: The price difference between propane and biogas is a crucial factor in determining the potential benefits. This difference depends on regional energy prices, government incentives, and the market demand for renewable energy sources. To calculate the potential yearly benefit, the annual biogas production (in Nm3) can be multiplied by the price difference between propane and biogas (per unit, e.g., per Nm3). By subtracting the total cost of biogas production from the revenue generated by selling biogas, the potential yearly benefit can be determined. It's important to note that the specific numbers and calculations will depend on various factors unique to Gowiz International LTD's operations, including local market conditions, resource availability, and the specific technology and infrastructure chosen for biogas production. Conducting a comprehensive economic analysis, including financial projections and sensitivity analysis, can provide a more accurate estimate of the potential yearly benefit

Equation 4: Annualized Capital Cost = Investment Cost * (Interest Rate * (1 + Interest Rate)^Service Life) / ((1 + Interest Rate)^Service Life - 1) To estimate the potential yearly benefits of switching from propane to renewable biogas for Gowiz International LTD, we can consider the investment costs of three actual Nigeria examples as a starting point. These investment costs can be used to scale the capital costs for biogas plant setup. Using the annuity approach, we can convert the investment expenses into yearly costs over a 20-year service life, assuming a 10% interest rate. This approach allows for a fair comparison of costs over time. To proceed with the calculation, we need the specific investment costs for the biogas plant examples in Nigeria. Once these costs are available, we can apply Equation 7 to determine the annualized capital cost for the biogas plant investment. Regarding the price of propane for Gowiz ..International in 2023, you mentioned it as #700, but it seems some characters might have been lost or misinterpreted. If you provide the correct price of propane and the expected annual usage of 15,000 tons, we can continue with the calculation to estimate the potential cost savings or benefits of switching to biogas

Incentives play a crucial role in promoting the cultivation of reed canary grass (RCG) for biogas production. Incentives can help offset the initial costs and make RCG farming economically viable. In your analysis, you have selected the numbers 6 and 12 / MWh to represent the energy costs associated with RCG farming. These numbers reflect the anticipated rise in energy costs and the need for profitability in RCG farming. By considering these numbers, you are taking into account the potential increase in energy prices over time. This approach is important when evaluating the long-term profitability and sustainability of RCG farming for biogas production. It's worth noting that the specific incentives and policies governing renewable energy and agricultural practices vary by region and country. The availability of incentives, energy prices, and market conditions are important factors to consider when assessing the economic viability of RCG farming and biogas production. By incorporating these factors, including incentives and projected energy costs, into the analysis, you can gain a more comprehensive understanding of the potential benefits and profitability of RCG farming for biogas production at Gowiz International LTD..Equation 4 provides a formula to estimate investment costs based on various factors.

A represents the cost of an investment in a known situation. This B is the baseline cost of a similar investment or a reference point for comparison. C stands for the recognised investment's capability. It refers to the maximum potential capacity or capability of the investment being considered. B represents the investment's expected capacity, which is the desired or anticipated capacity of the investment being evaluated. D is a case-specific coefficient. This coefficient takes into account specific factors, such as market conditions, technological advancements, or regulatory requirements, that may influence the investment cost. The value of D will vary depending on the specific circumstances and context of the investment. Using this equation, you can estimate the investment cost by multiplying A with the ratio of B to C raised to the power of D. This allows for adjustments based on expected capacity, recognized capability, and other case-specific factors. It's important to note that the values of A, B, C, and D need to be determined based on accurate and reliable data specific to the investment being analyzed. Additionally, other factors such as inflation, currency exchange rates, and project-specific nuances should be considered to obtain a more accurate estimation of the investment cost.when examining the three sample investments, it was found that the exponent D was close to 1. However, for the purpose of this analysis, we will consider D values of 0.5, 0.75, and 1 to evaluate the influence of altering D on the investment costs. Additionally, you mentioned that the government has a policy to encourage the usage of renewable energy and provides a maximum state subsidy of 40% for investments in this sector. This subsidy can help offset a portion of the investment costs and make renewable energy projects more financially viable. To incorporate the state subsidy into the analysis, the investment costs can be reduced by 40% when calculating the net investment amount. It's important to note that the specific values of A, B, C, and the chosen D coefficient will need to be determined based on accurate data and analysis specific to the investments being considered. Additionally, the subsidy percentage and any other relevant factors should be considered to obtain a comprehensive understanding of the investment costs and potential benefits. By incorporating these factors, such as the chosen D coefficient and the state subsidy, into the analysis, you can assess the influence of altering D and evaluate the financial viability of the investments in the context of the government's renewable energy policy.

System analysis, scenario 2: heavy fuel oil synthesis gas generation

Nocal Chemical LTD in Oulu manufactures synthesis gas for formic acid (FA) and hydrogen peroxide (HP). The current production process involves using two oil gasifiers, with one being operational and the other inactive. The production capacity for formic acid is 100,000 tons per year, while the capacity for hydrogen peroxide is 60,000 tons per year, as stated in the environmental permit from the Northern Ostrobothnia Environmental Centre in 2007. To analyze this system and explore potential improvements or alternative options, further details about the specific process and goals would be helpful. Factors such as energy consumption, environmental impact, cost efficiency, and any desired improvements or modifications would need to be considered in a comprehensive system analysis. Understanding these aspects would allow for a more detailed assessment of potential solutions or optimizations, such as exploring renewable energy sources, process modifications, or alternative technologies that could enhance the synthesis gas generation process.

The net reaction for the synthesis gas generation process at Nocal Chemical LTD is exothermic and primarily produces carbon monoxide (CO) and hydrogen (H2) gas. This indicates that the reaction releases heat energy as a byproduct. The exothermic nature of the reaction has several implications. First, it suggests that careful management of heat transfer and temperature control is necessary during the synthesis gas generation process to ensure optimal reaction conditions and safety. Effective heat exchange systems and control mechanisms can be implemented to maximize the utilization of the released heat energy. Second, the production of CO and H2 gas as the primary products aligns with the intended purpose of generating synthesis gas for formic acid and hydrogen peroxide production. Both gases are valuable in various industrial applications and can potentially be further processed or utilized within Nocal Chemical LTD's operations. It's worth mentioning that the specific reaction conditions, catalysts, and process parameters will play a significant role in determining the composition and yield of the produced synthesis gas. Careful optimization and continuous monitoring of the process can help achieve the desired gas composition and maximize the efficiency of the synthesis gas generation.

Equation 5 represents a combustion reaction where hydrocarbons (CHn) react with oxygen (O2) to produce carbon dioxide (CO2) and a variable number of moles of hydrogen gas (H2). The specific number of moles of hydrogen gas, denoted as n, falls within the range of 1 to 4. This equation shows that, depending on the hydrocarbon being combusted, a variable amount of hydrogen gas is produced as a byproduct along with carbon dioxide. The precise value of n depends on the specific hydrocarbon involved in the reaction. It's important to note that combustion reactions like this one release energy in the form of heat, making them exothermic reactions. The amount of heat released can be significant and should be considered in process design and safety considerations

Here are the net reaction equations for the production of formic acid and hydrogen peroxide: 1. Net reaction equation for formic acid: CO2 + 2H2 → HCOOH In this equation, carbon dioxide (CO2) and hydrogen gas (H2) react to form formic acid (HCOOH). 2. Net reaction equation for hydrogen peroxide: 2H2 + O2 → 2H2O2 In this equation, hydrogen gas (H2) and oxygen gas (O2) combine to produce hydrogen peroxide (H2O2). These net reaction equations demonstrate the essential chemical transformations involved in the production of formic acid and hydrogen peroxide.

Figure 3 provides a visual representation of the different processes involved in the generation of fuel oil and biogas synthesis gas. Let's break it down into more advanced understanding:

1. O2/STEAM: This refers to the addition of oxygen (O2) or steam to the process to enhance the conversion of feedstock into synthesis gas. O2/steam can be used to improve the efficiency and yield of the gasification process.

2. FUEL OIL: This represents the use of fuel oil as a feedstock for gasification. Fuel oil is converted into synthesis gas through the gasification process, which involves heating the fuel oil to high temperatures in the presence of a gasification agent. 3.

CH4/CO2: This indicates the utilization of methane (CH4) and carbon dioxide (CO2) as feedstocks for gasification. Methane-rich gases, such as biogas and landfill gas, can be used in the gasification process to produce synthesis gas.

4. BIOGAS STORAGE CH4/CO2: Biogas, which primarily consists of methane (CH4) and carbon dioxide (CO2), can be stored before undergoing gasification. This allows for the controlled release of biogas for conversion into synthesis gas.

5. LANDFILL GAS CH4/CO2: Landfill gas, produced by the decomposition of organic materials in landfills, contains methane (CH4) and carbon dioxide (CO2). It can be utilized as a feedstock for gasification to generate synthesis gas.

6. ANAEROBIC FERMENTATION: This process involves the breakdown of biodegradable feedstock, such as organic waste or biomass, in the absence of oxygen. The anaerobic fermentation process produces biogas, which can be further utilized for gasification.

7. BIODEGRADABLE FEEDSTOCK: This refers to organic materials that can be broken down or decomposed by biological processes. Biodegradable feedstocks, such as agricultural waste, food waste, or sewage sludge, can be used as inputs for anaerobic fermentation and subsequent gasification.

8. GASIFICATION: Gasification is the main process where solid or gaseous feedstocks are converted into synthesis gas. It involves heating the feedstock under controlled conditions, usually with a gasification agent, to produce a mixture of gases, including carbon monoxide (CO), hydrogen (H2), and other components.

9. CO2 AND H2S REMOVAL: This step involves the removal of carbon dioxide (CO2) and hydrogen sulfide (H2S) from the synthesis gas. These impurities are typically removed to improve the quality and purity of the final gas product.

10. GAS SEPARATION: Gas separation refers to the process of separating different gases present in the synthesis gas mixture. This can be achieved through various techniques such as pressure swing adsorption (PSA), membrane separation, or cryogenic separation.

11. HCOOH PRODUCTION: HCOOH represents formic acid, which can be produced from the synthesis gas. Formic acid has various industrial applications, including use as a preservative, a reducing agent, or in the production of dyes and pharmaceuticals.

12. H2O2 PRODUCTION: H2O2 refers to hydrogen peroxide, which can be produced from the synthesis gas. Hydrogen peroxide has many uses, including as a bleaching agent, a disinfectant, or in the production of various chemicals

IN SCENARIO 2A, THE SYSTEM ANALYSIS INVOLVES THE REPLACEMENT OF HEAVY FUEL OIL WITH LANDFILL GAS AT NOCAL CHEMICAL Ltd

According to the Environmental Centre of South-East (2022), there is a landfill located 3 km away from the plant that produces approximately 8 million Nm3/a (normal cubic meters per annum) of biogas. The landfill gas is already being utilized by other nearby facilities, including a mineral wool business and a hospital heating plant, in addition to its own usage. This aligns with the principles of Industrial Ecology and the concept of Ecological Districts, where resources and energy flows are optimized within a specific region or district. By replacing heavy fuel oil with landfill gas as a feedstock for the gasification operation at Nocal Chemical Ltd., several benefits can be achieved. Firstly, it reduces the reliance on fossil fuel-based heavy fuel oil, leading to a reduction in greenhouse gas emissions and environmental impact. Secondly, utilizing the landfill gas as a renewable energy source promotes the efficient use of resources available within the local area. This contributes to a circular and sustainable approach, where waste materials are repurposed and transformed into valuable energy sources. To further analyze the feasibility and potential of replacing heavy fuel oil with landfill gas, factors such as the composition and quality of the landfill gas, the necessary infrastructure for gas transportation, and the compatibility of the gasification process with the characteristics of landfill gas need to be considered. . This study explores the possibility of substituting a more expensive raw material in industrial processes with landfill gas. The landfill gas composition consists of approximately 50% methane (CH4), 45% carbon dioxide (CO2), 5% nitrogen (N2), and less than 1% hydrogen sulphide (H2S). Notably, methane accounts for approximately 48% of the total composition.

The research findings suggest that a portion of the landfill gas is currently being flared, meaning it is burned off without being utilized. However, there is potential to monetize this unused resource. The study proposes that the unutilized portion of the landfill gas could be sold as a fuel at a similar price to wood energy derived from biomass. If all the landfill gas were to be sold, the existing small-scale consumers who currently rely on the gas would need to transition to using biomass as their energy source. This transition may involve adapting their heating systems or other processes to accommodate biomass as a fuel. This research highlights the opportunity to optimize the use of landfill gas and reduce waste by capturing and utilizing it as an energy resource. By selling the unused portion of the gas, there is potential to generate revenue while promoting the adoption of more sustainable and renewable energy sources like biomass. In summary, the research indicates that by selling the flared portion of the landfill gas as an alternative to wood energy from biomass, both economic and environmental benefits can be achieved by maximizing the utilization of this valuable resource.

Indeed, it is possible to use landfill gas as a feedstock for gasifiers that are currently being used to replace heavy fuel oil. By compressing and delivering the landfill gas to the idle gasifier, it can undergo gasification to produce synthesis gas. This information is based on calculations performed using the HSC Chemistry® software program. What's interesting is that this process allows for the creation of synthesis gas without the need for prior purification of carbon dioxide (CO2). Gasification of the landfill gas directly generates the desired synthesis gas, which typically consists of carbon monoxide (CO) and hydrogen (H2). These two components can be further processed and utilized in various industrial applications, such as the production of chemicals or fuels. By utilizing landfill gas in this manner, not only can it serve as a valuable renewable energy source, but it also avoids the need for separate CO2 purification, which can simplify the overall process and reduce costs.

The equation you provided represents a reaction involving methane (CH4), oxygen (O2), carbon dioxide (CO2), carbon monoxide (CO), hydrogen (H2), and water (H2O). The balanced equation is as follows: CH4 + 1/2 O2 + CO2 → 2CO + H2 + H2O In this reaction, methane and oxygen react with carbon dioxide to produce carbon monoxide, hydrogen, and water. It's worth noting that this equation is a simplified representation and may not account for specific reaction conditions or catalysts that may be required in practice.

By capturing and utilizing some of the CO2 present in the final product instead of releasing it into the atmosphere, the CO2 from the biogas can enhance the production of targeted CO and provide an additional environmental benefit. Although in reality, reaction (8) may not reach equilibrium, thermodynamic studies indicate that a favorable ratio of CO to H2 can be achieved. Higher concentrations of CO2 also lead to increased CO production. Considering the financial benefits of using landfill gas in the gasifier, the following points summarize the advantages: 1. Cost savings: Utilizing landfill gas as a feedstock in the gasifier can potentially reduce the overall cost of raw materials since landfill gas is often available at lower or even zero cost compared to traditional fossil fuels. 2. Revenue generation: Selling the unused portion of the landfill gas, as discussed previously, can generate additional revenue for the facility. 3. Environmental incentives: By using landfill gas as an alternative to fossil fuels, the facility can benefit from environmental incentives or credits related to reducing greenhouse gas emissions and promoting sustainable practices. 4. Regulatory compliance: Utilizing landfill gas aligns with environmental regulations and policies that encourage the use of renewable energy sources and the reduction of carbon emissions. These financial benefits, combined with the environmental advantages of using landfill gas, highlight the potential value and sustainability of incorporating this renewable resource into the gasification process.

The amount of substitute oil can be calculated as three times the amount of methane divided by 2700. This equation can be represented as: Amount of Substitute Oil = (3 * Amount of Methane) / 2700 .It is encouraging to note that the existing system can already accommodate the use of landfill gas. This suggests that implementing this arrangement may not require significant upfront investments or lead to substantial increases in operational expenses. By leveraging the capabilities of the current infrastructure, the transition to using landfill gas as a fuel source can potentially be seamless and cost-effective. This advantage is particularly beneficial as it helps minimize the financial burden associated with introducing new technologies or making extensive modifications to the existing system. By utilizing landfill gas, industries can tap into a readily available and potentially cost-efficient resource, contributing to both economic and environmental sustainability.

let's calculate the average yearly amount of oil required for gasification.

1. Calculation of available methane from landfill gas: Annual landfill gas production = 8 million Nm3 Methane content in landfill gas = 48% Available methane = 8 million Nm3 * 48% = 3.84 million Nm3

2. Calculation of synthesis gas produced from methane: Synthesis gas produced = 3 times the amount of methane Synthesis gas produced = 3 * 3.84 million Nm3 = 11.52 million Nm3

3. Calculation of oil required based on synthesis gas production: One tonne of oil produces 2700 Nm3 of synthesis gas Oil required = Synthesis gas produced / 2700 Oil required = 11.52 million Nm3 / 2700 = 4274.81 tonnes

4. Incorporating energy loss estimation: Energy loss estimated = 10% of total energy Oil required considering energy loss = Oil required / (1 - 10%) Oil required considering energy loss = 4274.81 tonnes / 0.9 = 4749.79 tonnes Therefore, based on the given data and considering the estimated energy loss, the average yearly amount of oil required for gasification is approximately 4749.79 tonnes.

LET'S CONSIDER THE EXAMPLE OF REPLACING HEAVY FUEL OIL WITH BIOGAS GENERATED THROUGH ANAEROBIC FERMENTATION (RCG-BASED BIOGAS).

There is a key difference between instance 1 (Gowiz) and instance 2 (Nocal). In instance 1, a reformer is required, while instance 2 utilizes gasification. However, these technological differences have minimal impact on the economic analysis. To calculate the required investment, we can use equation (4). By plugging in the appropriate values, the calculation is as follows: 31.5 multiplied by the square root of (33.3 divided by 15), which equals 47. In simpler terms, this means that the magnitude of the needed investment is 47. However, without more specific information or context, it is challenging to provide a detailed interpretation of this value.

Based on the assumption that the project will receive a subsidy from the government amounting to 40%, the net investment cost is estimated to be 28 million dollars. If the specified exponential (exp) value were 0.75 or 1, the investment costs would be 57 and 70 million dollars, respectively. After applying the subsidies, the net investment costs would be 34 and 42 million dollars. In other words, with the 40% government subsidy, the initial investment cost of 57 and 70 million dollars would be reduced to net investment costs of 34 and 42 million dollars, respectively, depending on the specific exponential value..

In the case of Nocal, a yearly gas requirement of 44,400,000 Nm3 is necessary. - In the Gowiz scenario, the gas volume needed is 20,000,000 Nm3, which would require the cultivation of RCG on 9,500 hectares. - Scaling the necessary farmland to the Nocal instance, it would amount to approximately 17,700 hectares, calculated as 44 .3/19 multiplied by 9,500

Currently, the estimated annual consumption of heavy fuel oil for Nocal stands at #37,000,00 per tonne. - According to statistics from Nigeria in 2022, the price range of heavy fuel oil for producers varied from #300,000,00 to #600,00,00 per tonne between 20011 and 2021.

Anaerobic fermentation gas replacement for heavy fuel

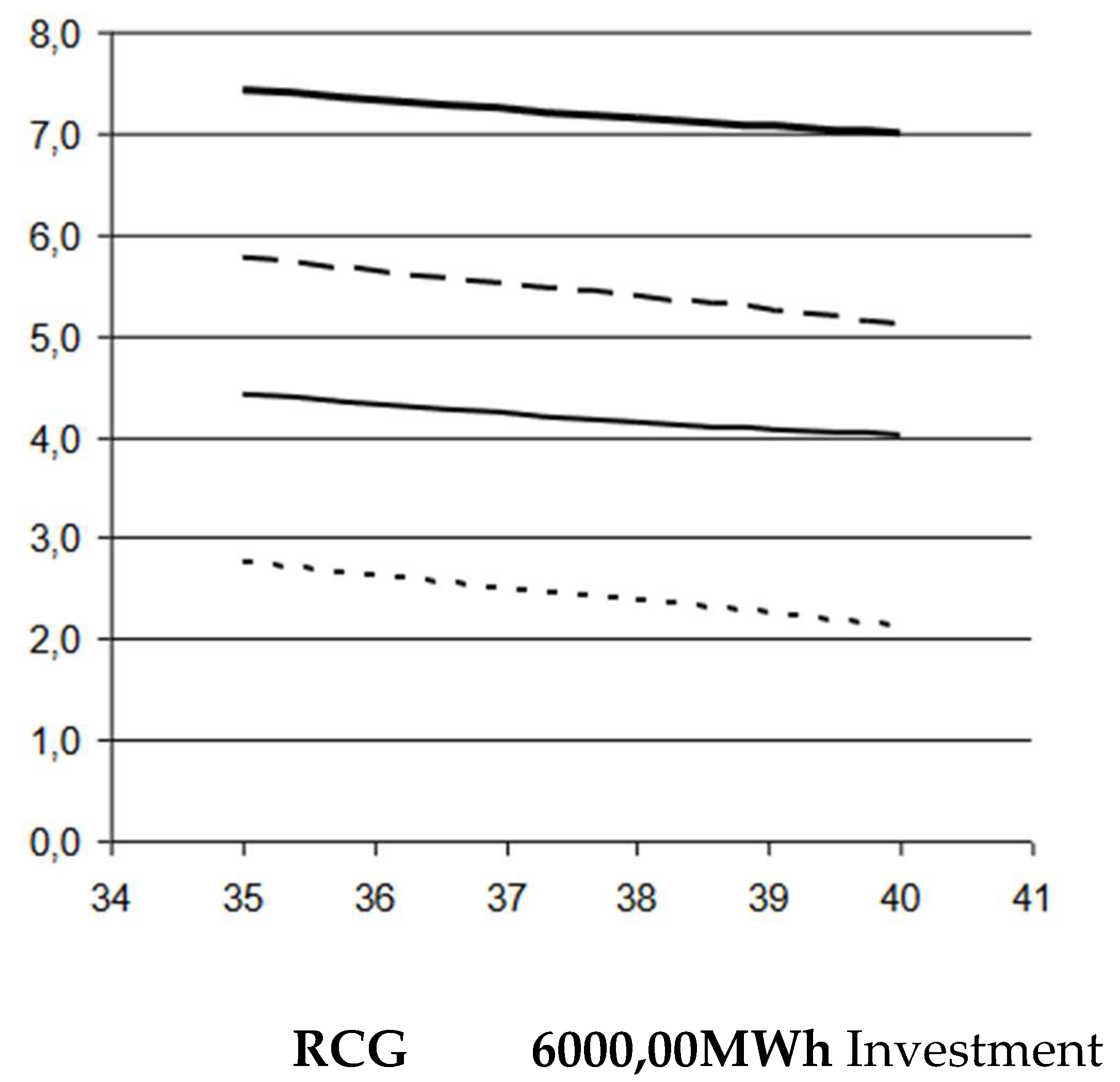

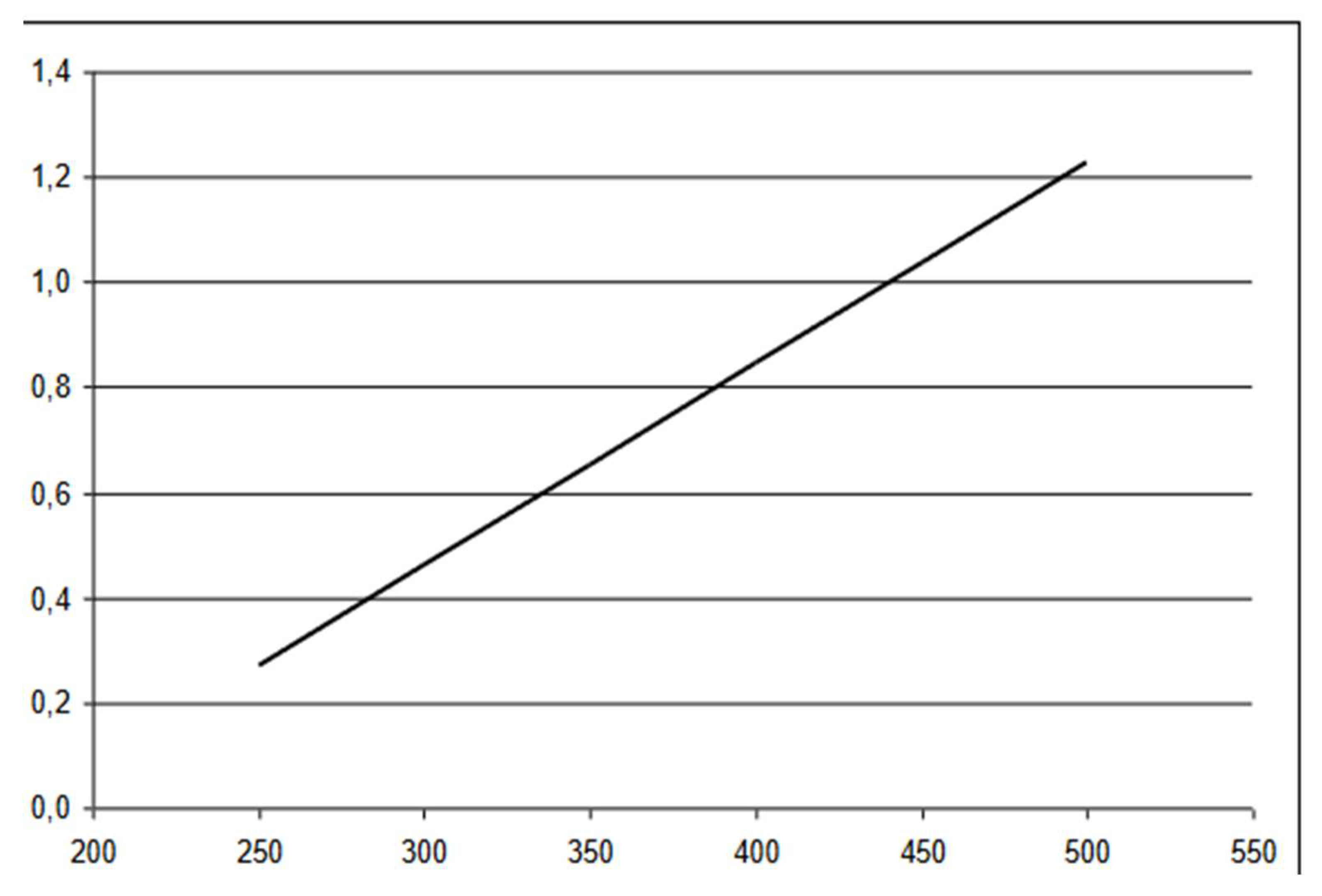

Figure 7 and

Figure 8 illustrate the annual economic benefit of replacing heavy fuel oil with petrol derived from anaerobic fermentation in Case Nocal 2. The procedure is similar to that of Case Gowiz but scaled for this specific scenario. - The calculations consider fuel oil costs ranging from

$250 to

$500 per tonne, as well as investment amounts varying from

$40 to

$70 million. -

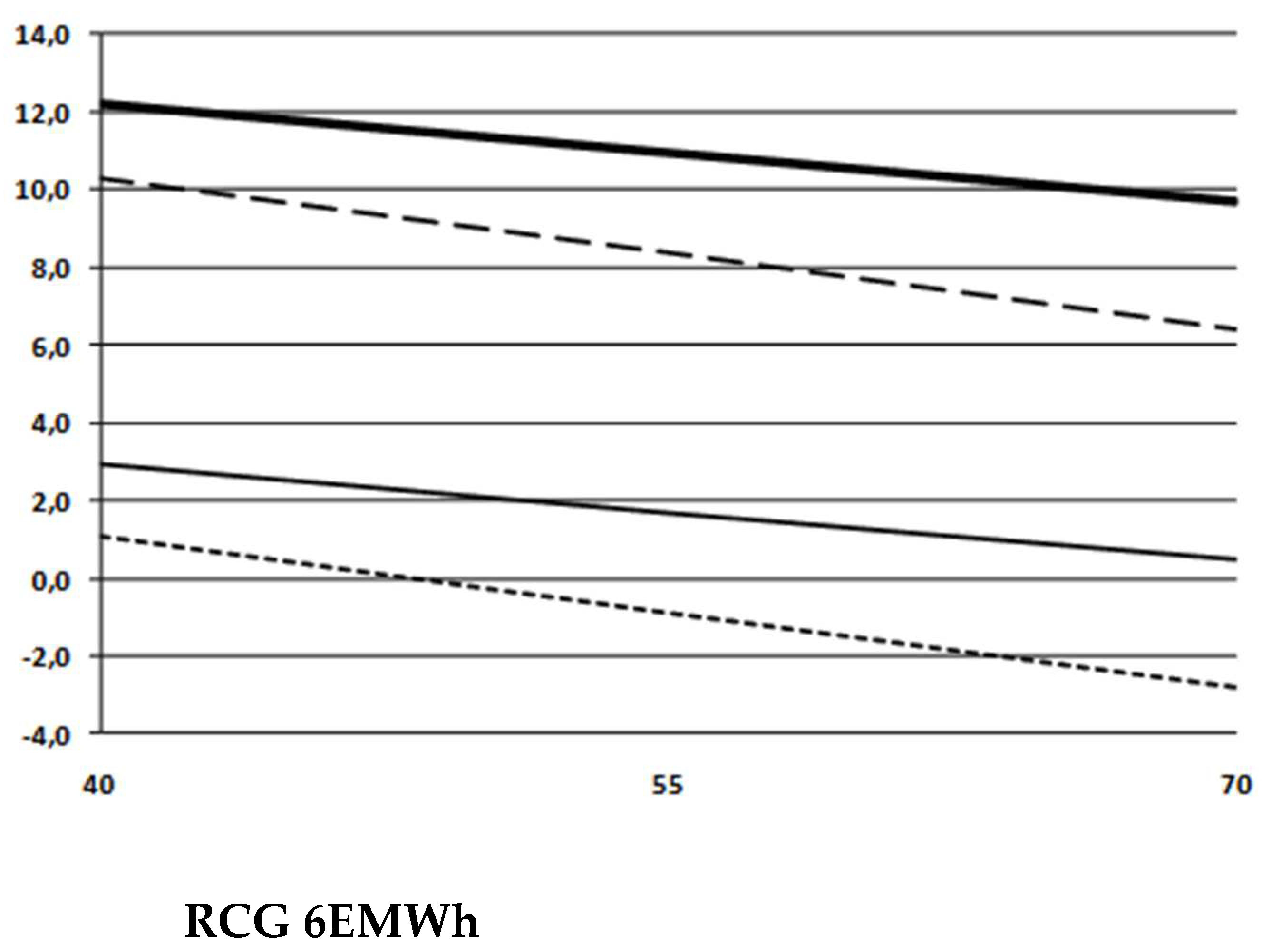

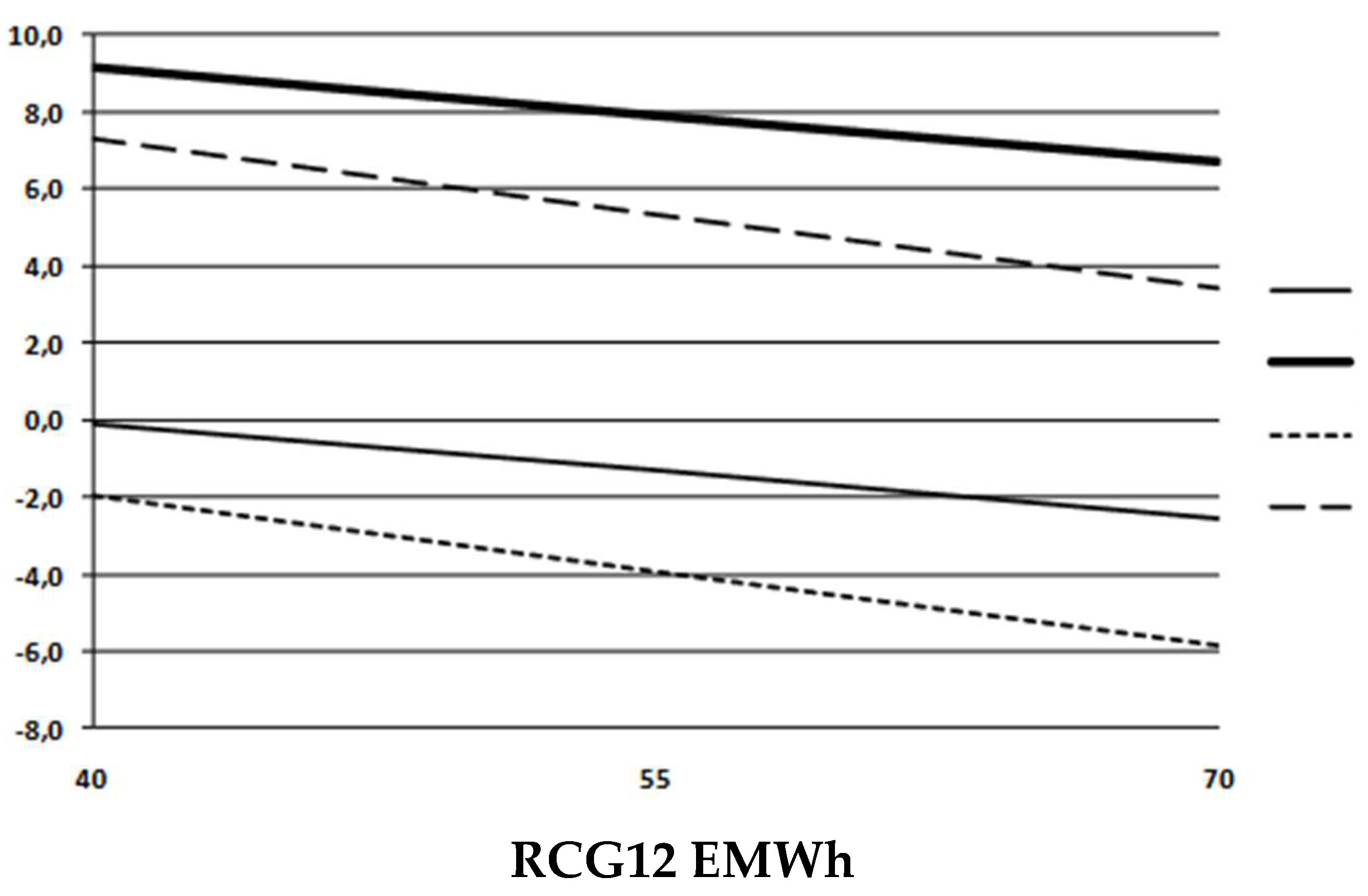

Figure 7 presents a scenario where the price of Renewable Compressed Gas (RCG) is set at

$6/MWh, while

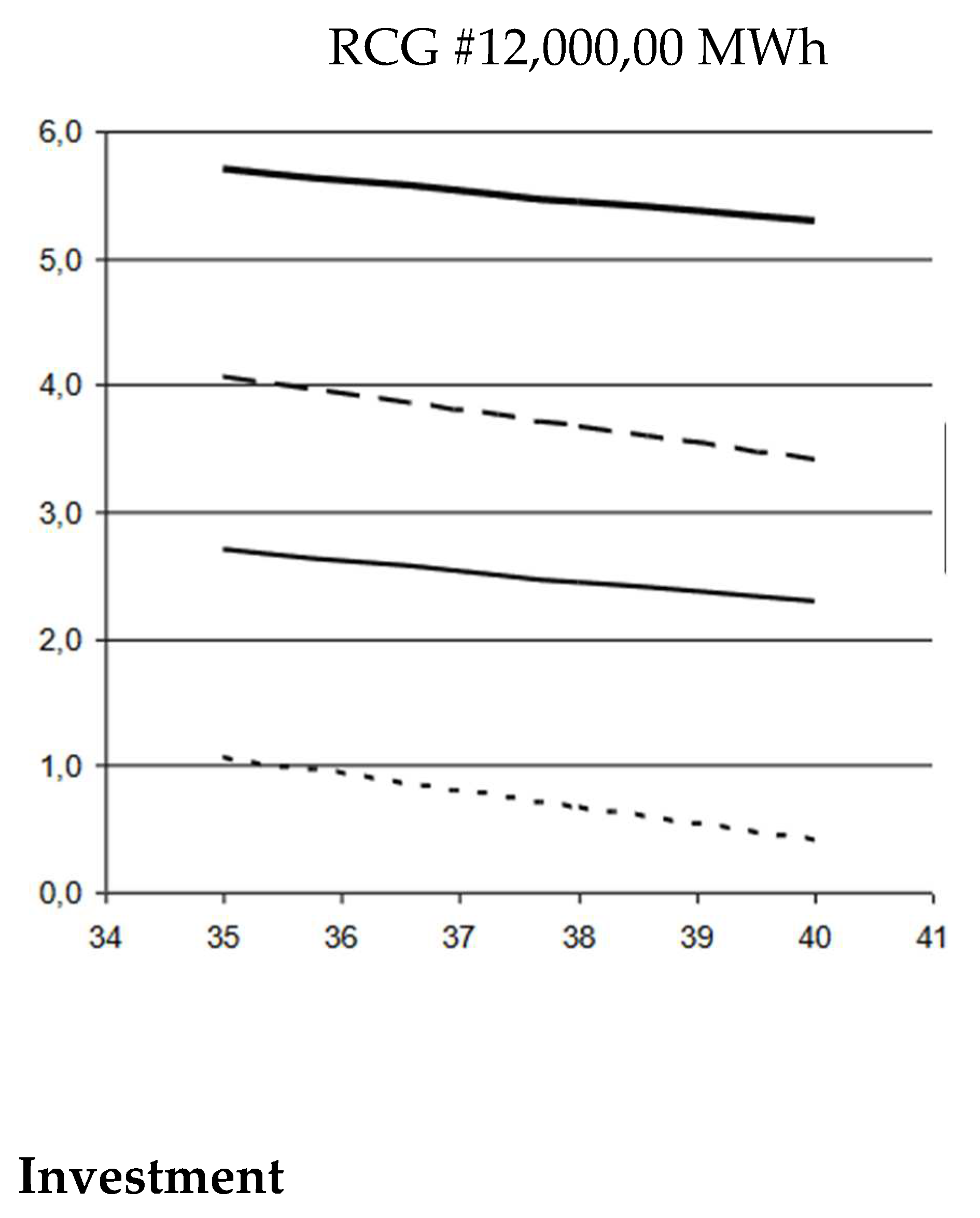

Figure 8 depicts a case where the RCG price increases to

$12/MWh. These figures provide insights into the potential economic advantages of substituting heavy fuel oil with petrol sourced from anaerobic fermentation. The different RCG prices and investment levels help evaluate the financial viability of such a transition.

Graph 7. Annual cost savings when replacing oil with gas from anaerobic fermentation compared to an RCG price of $6/MWh.

The price of oil plays a significant role in determining the yearly economic benefit of replacing oil with gas from anaerobic fermentation. At lower oil prices of 250 naira/t, the investment may not appear to be realistic. However, as oil prices increase to around 500 naira/t, the project becomes more financially viable and worth considering. Even though the price of oil remains a dominant factor, investment support can still have some influence on the economic benefit of the project. It can help offset costs and improve the overall viability of the investment. Regarding

Figure 8, it displays the annual economic benefit of substituting oil with gas derived from anaerobic fermentation in environments with an RCG value of

$12/MWh

Figure 7 and

Figure 8 indicate that increasing the RCG price from 6 to 12,000,00/MWh results in a loss of 3 million in yearly economic benefit. This suggests that a higher RCG price can have a negative impact on the overall economic gain of replacing oil with gas from anaerobic fermentation, even with investment support. Additionally, it is indeed feasible to assess the processing costs of biogas using RCG by considering various factors such as capital expenditures, raw materials, and operating costs. These assessments help in evaluating the economic viability and overall cost-effectiveness of utilizing RCG for the processing of biogas.

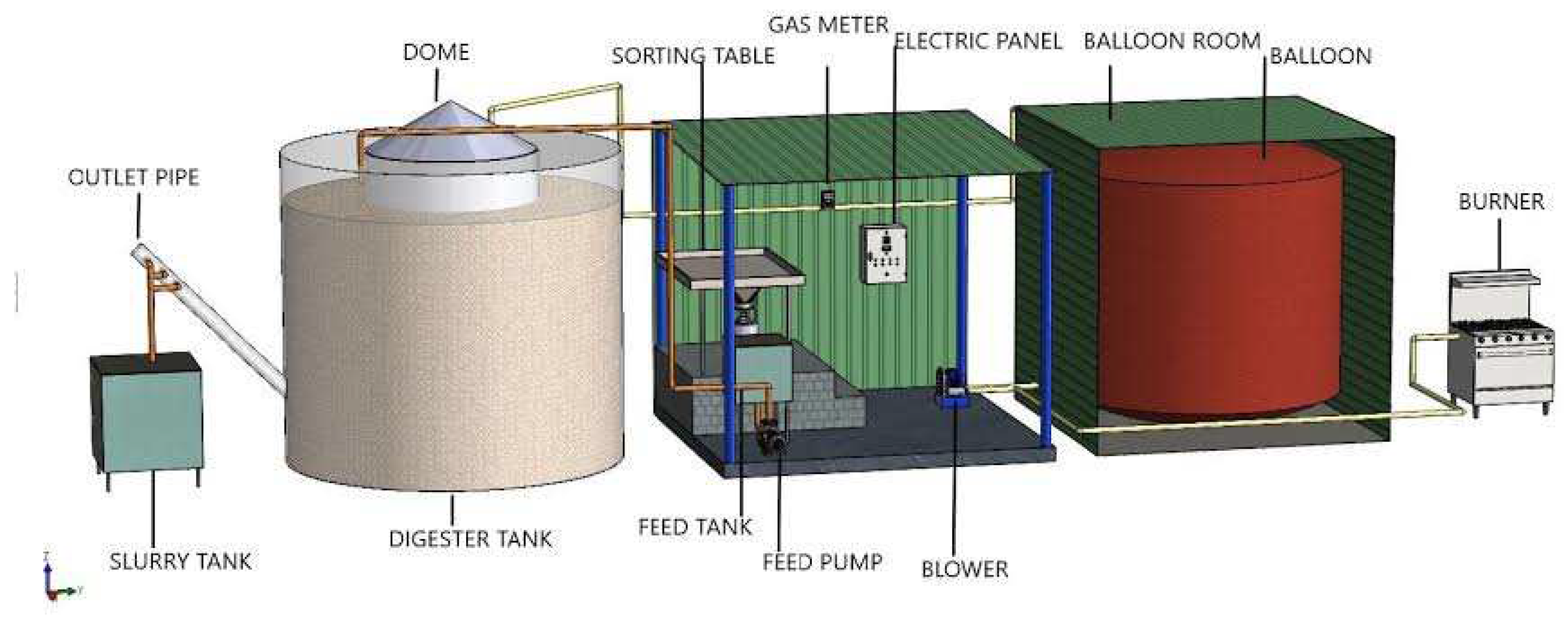

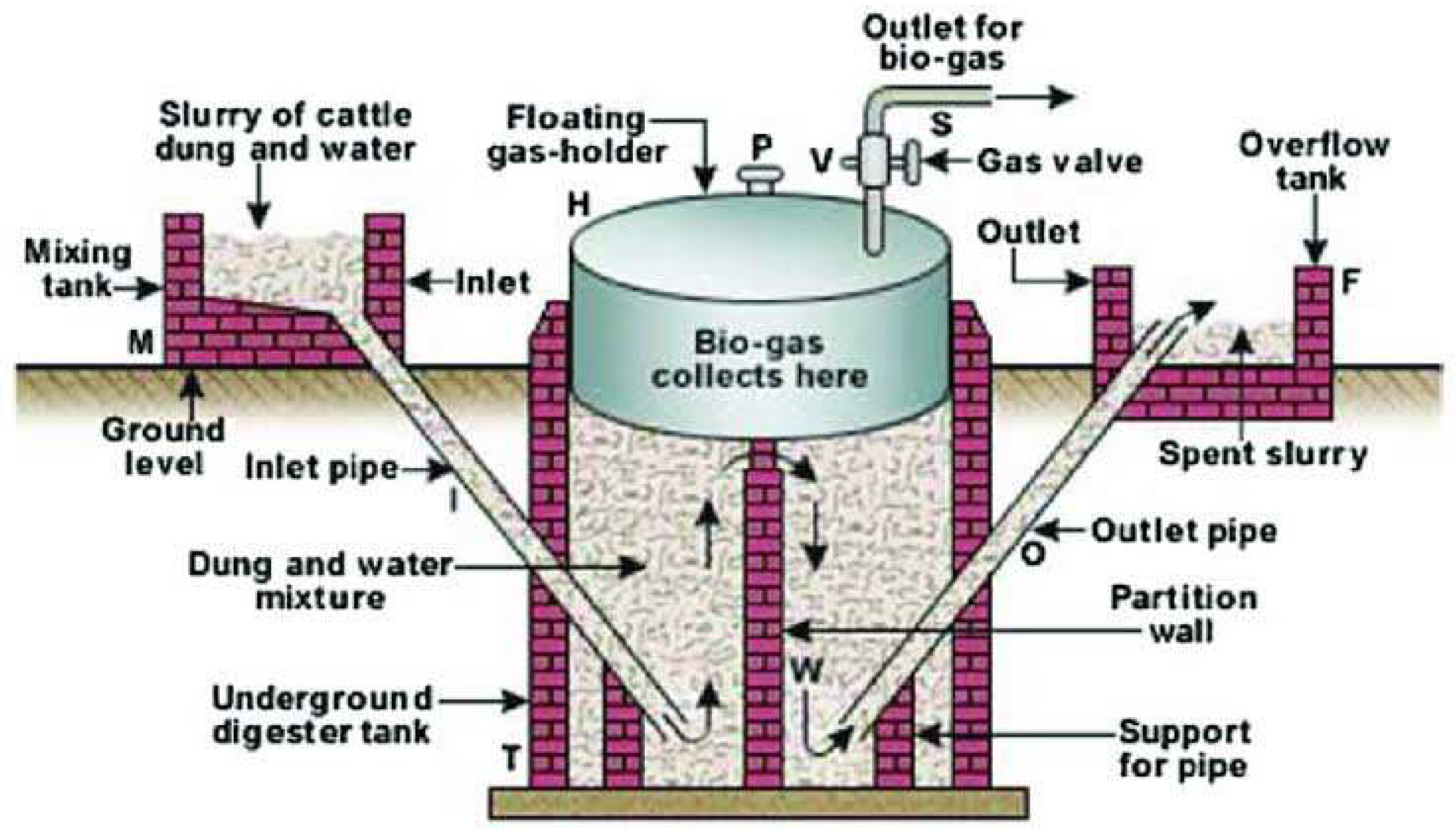

Figure 9 represents the various components and equipment involved in the manufacturing of a biogas plant. Let's explore the advanced application of these components in the context of the mentioned research title:

1. SLURRY TANK: The slurry tank is a crucial component in biogas plant manufacturing. It is used for the storage of organic waste materials, such as agricultural residues or food waste, which serve as feedstock for the anaerobic digestion process.

2. OUTLET PIPE: The outlet pipe is responsible for transporting the digested slurry or effluent from the biogas plant. It ensures the controlled flow of the processed waste material for further treatment or disposal.

3. DIGESTER TANK: The digester tank plays a central role in the biogas production process. It provides an oxygen-free environment where anaerobic bacteria break down the organic waste to produce biogas. The tank is typically insulated to maintain optimal temperature conditions for the microbial activity.

4. DOME: The dome is a cover or roof structure that encloses the digester tank. It serves multiple purposes, including maintaining a controlled environment within the digester, facilitating the collection and storage of biogas, and preventing the escape of odorous gases.

5. FEED TANK: The feed tank is responsible for storing and supplying the organic waste feedstock to the digester tank. It ensures a continuous and controlled flow of waste material for efficient biogas production.

6. SORTING TABLE: The sorting table is used for the pre-processing of the organic waste feedstock. It allows for the removal of non-biodegradable or undesirable materials, such as plastics or debris, before they enter the digester tank. This helps to maintain the efficiency and longevity of the biogas plant.

7. FEED PUMP: The feed pump is used to transfer the organic waste from the feed tank to the digester tank. It ensures a consistent flow rate and pressure, enabling efficient mixing of the feedstock with the anaerobic bacteria present in the digester.

8. BLOWER: The blower is an integral part of the biogas plant's gas handling system. It is responsible for creating a continuous flow of air or gas within the digester tank, ensuring proper mixing and distribution of the waste material and facilitating the release and collection of biogas.

9. GAS METER: The gas meter is used to measure and monitor the volume of biogas produced by the digester tank. It provides valuable data for process optimization, energy generation calculations, and performance evaluation of the biogas plant

. 10. ELECTRIC PANEL: The electric panel acts as the central control system for the biogas plant. It manages and monitors various electrical components, such as pumps, blowers, and sensors, ensuring their proper functioning and synchronization to maintain operational efficiency.

11. BALLOON ROOM: The balloon room serves as a storage facility for the collected biogas. It allows for the temporary storage of biogas before it is utilized for energy generation or other applications. The balloons or gas storage containers within the room help maintain pressure and ensure a steady supply of biogas.

12. BURNER: The burner is responsible for converting biogas into usable energy, such as heat or electricity. It is used in industrial processes or for powering engines, generators, or heating systems, contributing to the utilization of renewable energy derived from biogas. In summary,

Figure 9 illustrates the advanced application of various components in the manufacturing of a biogas plant. These components work together to enable the efficient conversion of organic waste into biogas, which can be used as a renewable energy source. By utilizing the mentioned components, biogas plants contribute to the exploration of integrated biogas solutions for industrial processes and the advancement of renewable energy technologies

With an RCG price of 6000#/MWh and government-supported investment expenditures ranging from 40 to 70 million, the production costs for biogas would be estimated to be between 19 and 26,000,00#/MWh. - However, if the RCG price increases to 12,000,00#/MWh, the methane production expenses would rise to 28-35#R/MWh. - Without government support, the production costs for biogas would be significantly higher, ranging from 25 to 36,000,00#/MW

Biogas scrubbers and desulfurization processes are important components in biogas treatment systems. They help remove impurities, such as sulfur compounds, from biogas to improve its quality and make it suitable for various end-uses. 1. BIOGAS SCRUBBERS: Biogas scrubbers are used to remove contaminants, including water vapor, hydrogen sulfide (H2S), ammonia, and siloxanes, from the raw biogas. Scrubbers typically involve the use of scrubbing solutions, such as water or chemicals, to absorb and remove these impurities from the biogas stream. This process helps protect downstream equipment, reduce corrosion, and improve the biogas quality. 2. DESULFURIZATION: Desulfurization is a specific process within biogas scrubbing that focuses on removing sulfur compounds, primarily hydrogen sulfide (H2S), from the biogas. High levels of H2S in biogas can cause corrosion and have detrimental environmental impacts when the biogas is utilized. Desulfurization methods can include chemical scrubbing, biological processes, or physical adsorption to selectively remove sulfur compounds from the biogas stream. Implementing biogas scrubbers and desulfurization systems helps ensure the compliance of biogas with specific quality standards and regulations, allowing for safe and efficient utilization of biogas in various applications, such as power generation, heating, or as a vehicle fuel.

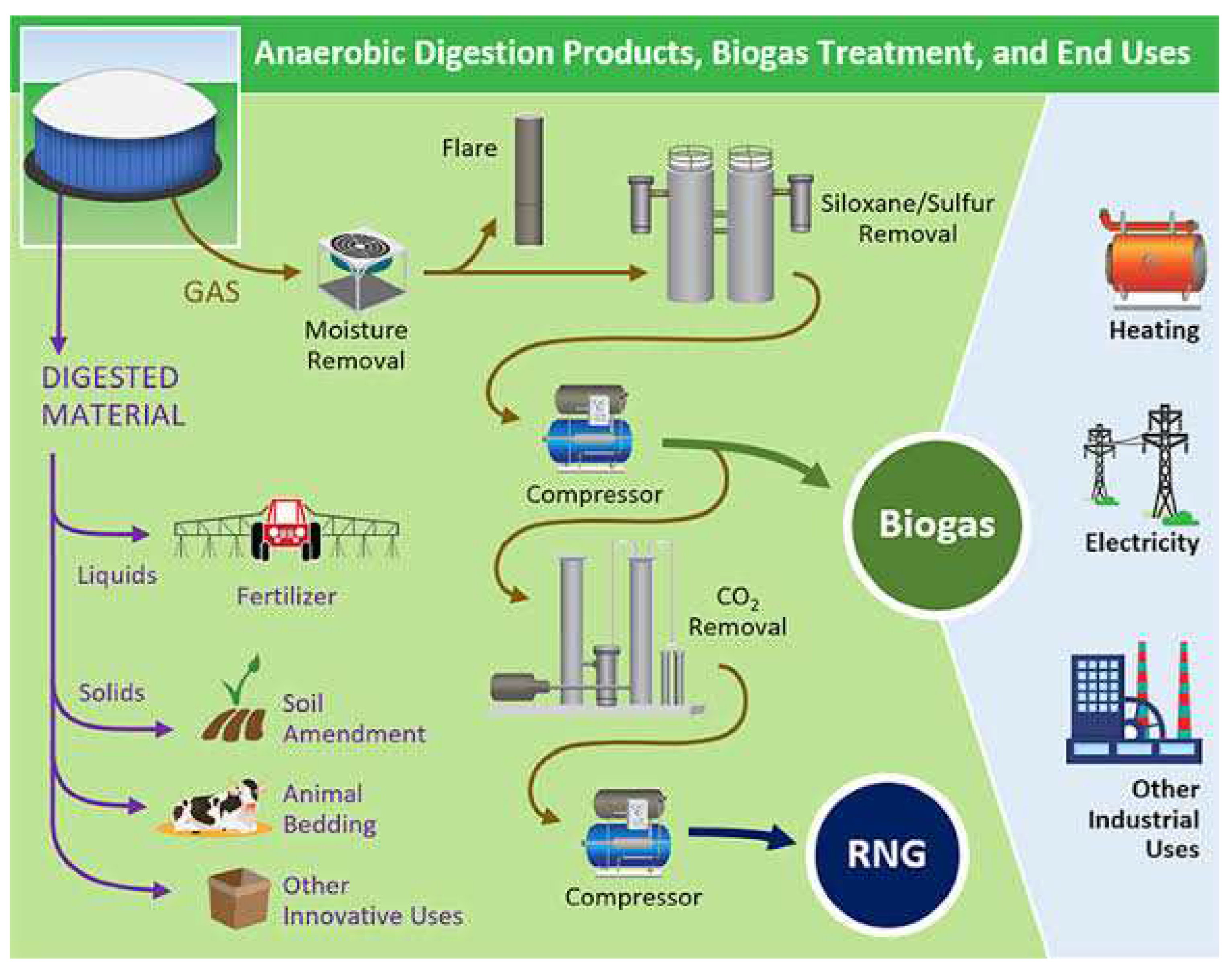

Figure 11 represents the different stages involved in the anaerobic digestion process, the treatment of biogas, and its utilization by end-users. Let's explore the advanced application of these stages:

1. ANAEROBIC DIGESTION: Anaerobic digestion is a biological process in which organic waste materials, such as agricultural residues, food waste, or sewage sludge, are broken down by anaerobic bacteria in the absence of oxygen. This process occurs in a digester tank, as shown in

Figure 11.

2. DIGESTATE: The digestate is the residual material left after the anaerobic digestion process. It is rich in nutrients and can be used as a biofertilizer for agricultural purposes. The digestate can be further treated, such as through solid-liquid separation or composting, to enhance its nutrient content and stability.

3. BIOGAS: Biogas is the main product of anaerobic digestion. It is a mixture of gases, primarily consisting of methane (CH4) and carbon dioxide (CO2), along with trace amounts of other gases. Biogas has a high energy content and can be used as a renewable fuel source.

4. BIOGAS TREATMENT: Biogas undergoes treatment processes to remove impurities and optimize its quality for different end-uses. Treatment steps may include removal of moisture, hydrogen sulfide (H2S), siloxanes, and other contaminants that could be harmful or corrosive. This ensures that the biogas meets specific criteria and can be safely utilized.

5. BIOGAS UPGRADING: Biogas upgrading involves the removal of carbon dioxide (CO2) and other impurities from biogas to produce purified biomethane. Upgraded biogas, or biomethane, has a higher methane content and can be directly injected into natural gas pipelines or used as a vehicle fuel.

6. END USERS: The purified biogas or biomethane can be utilized by various end-users. Some common applications include: - Power Generation: Biomethane can be used in gas engines or gas turbines to generate electricity and heat for residential, commercial, or industrial purposes. - Vehicle Fuel: Biomethane can be used as a clean and renewable fuel for transportation, either in compressed natural gas (CNG) vehicles or as liquefied biomethane (LBM) for use in heavy-duty trucks or buses. - Heat and Steam: Biomethane can be used directly for heating or as a source of steam in industrial processes, providing thermal energy for various applications. - Combined Heat and Power (CHP): Biomethane can be used in combined heat and power systems, where it simultaneously generates electricity and heat, maximizing energy efficiency. - Injection into Gas Grid: Upgraded biomethane can be injected into natural gas pipelines, allowing for its distribution and utilization in existing gas infrastructure. The utilization of biogas and biomethane by different end-users contributes to reducing greenhouse gas emissions, promoting sustainability, and diversifying the energy mix by harnessing renewable resources.

The costs could further increase to 34-45 #/MWh without any assistance. These figures highlight the importance of considering the RCG price and government support in assessing the overall production costs of biogas. The presence of government support can help in reducing production costs, making the project more financially feasible