Submitted:

22 January 2024

Posted:

23 January 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

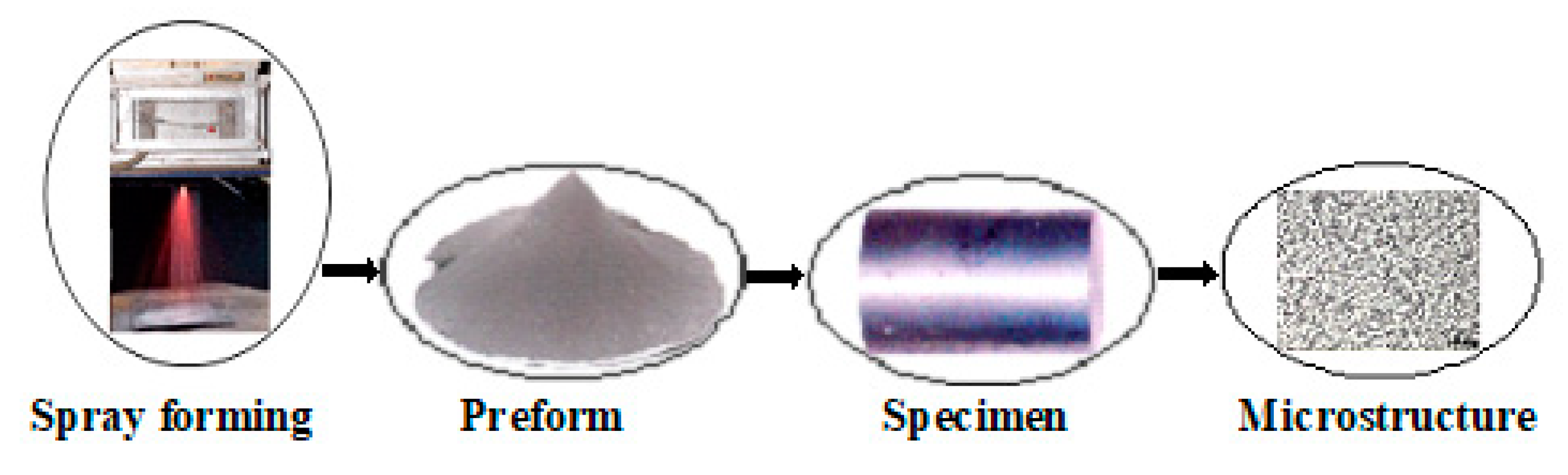

2. Materials and Methods

3. Results and Discussion

3.1. Porosity measurement

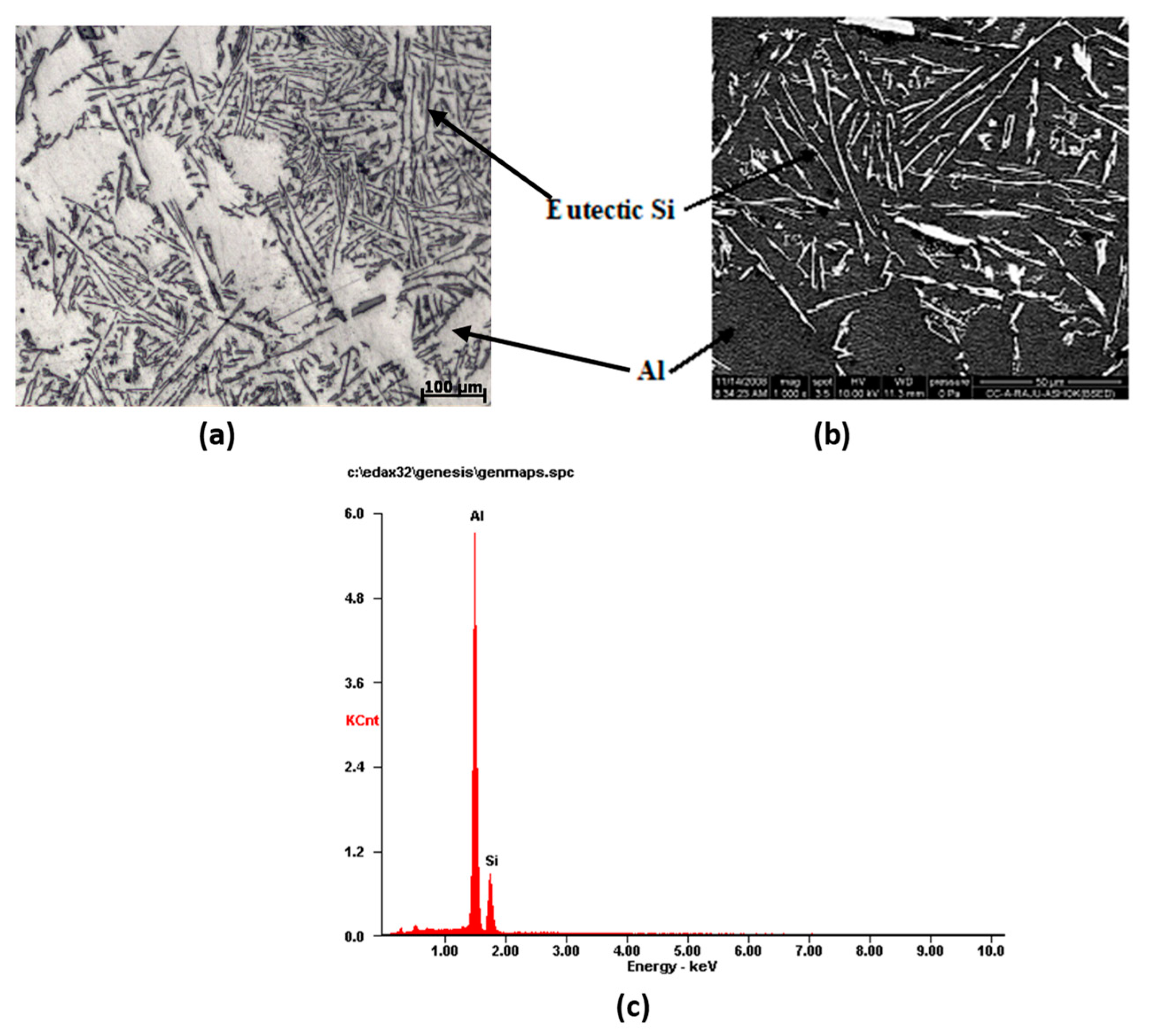

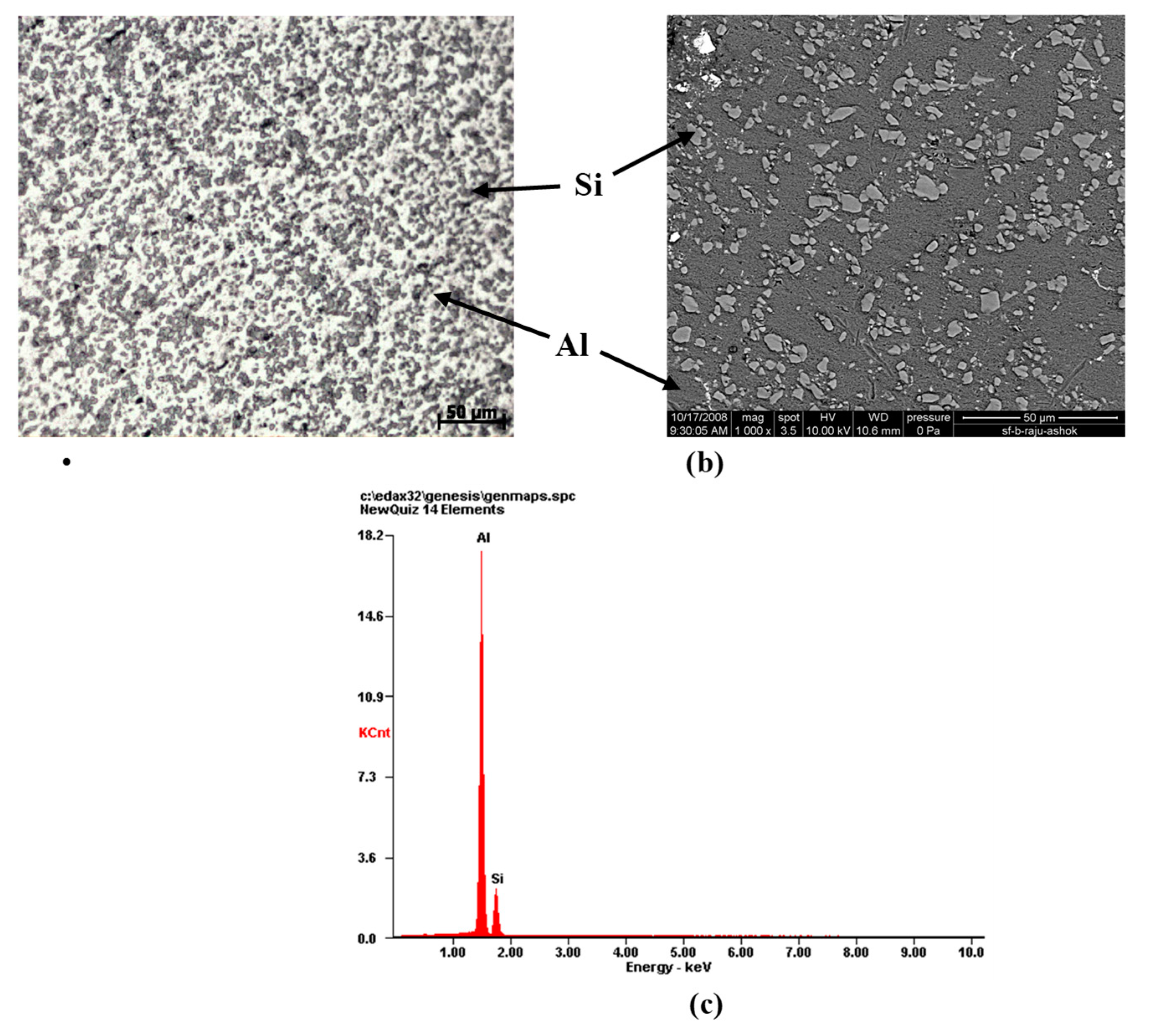

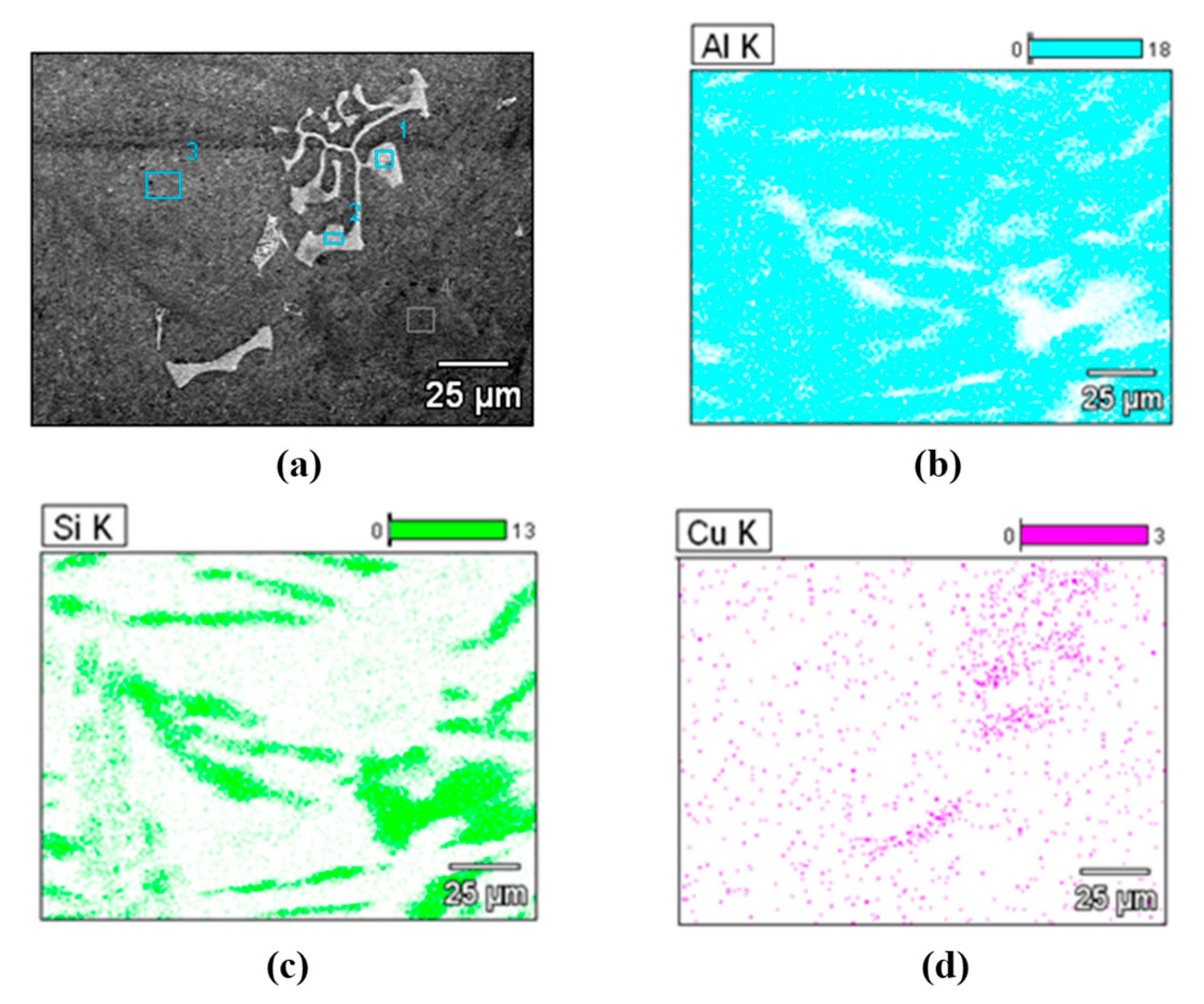

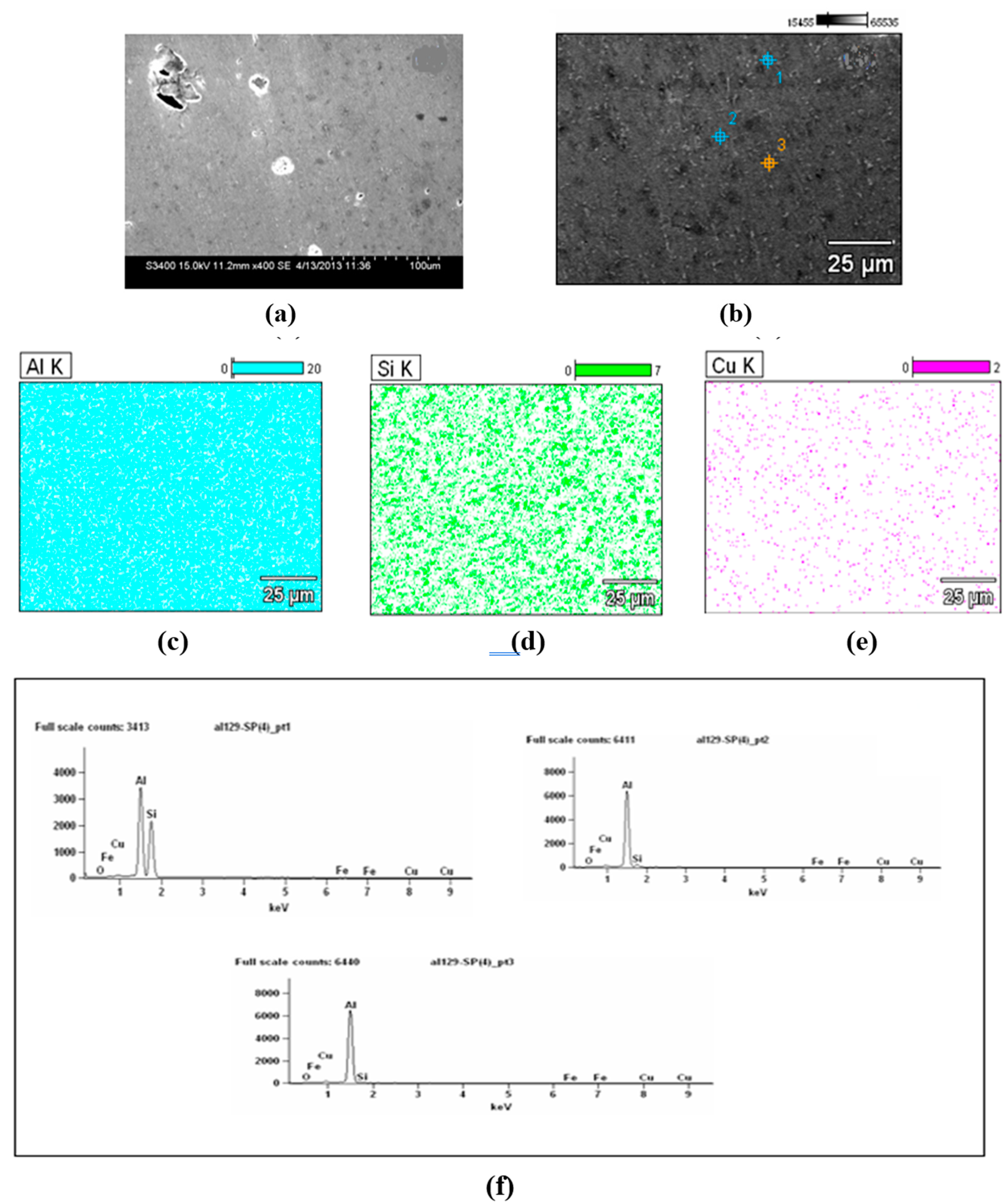

3.2. Microstructural features of Al-Si alloys

3.3. Hardness

3.4. Wear characteristics

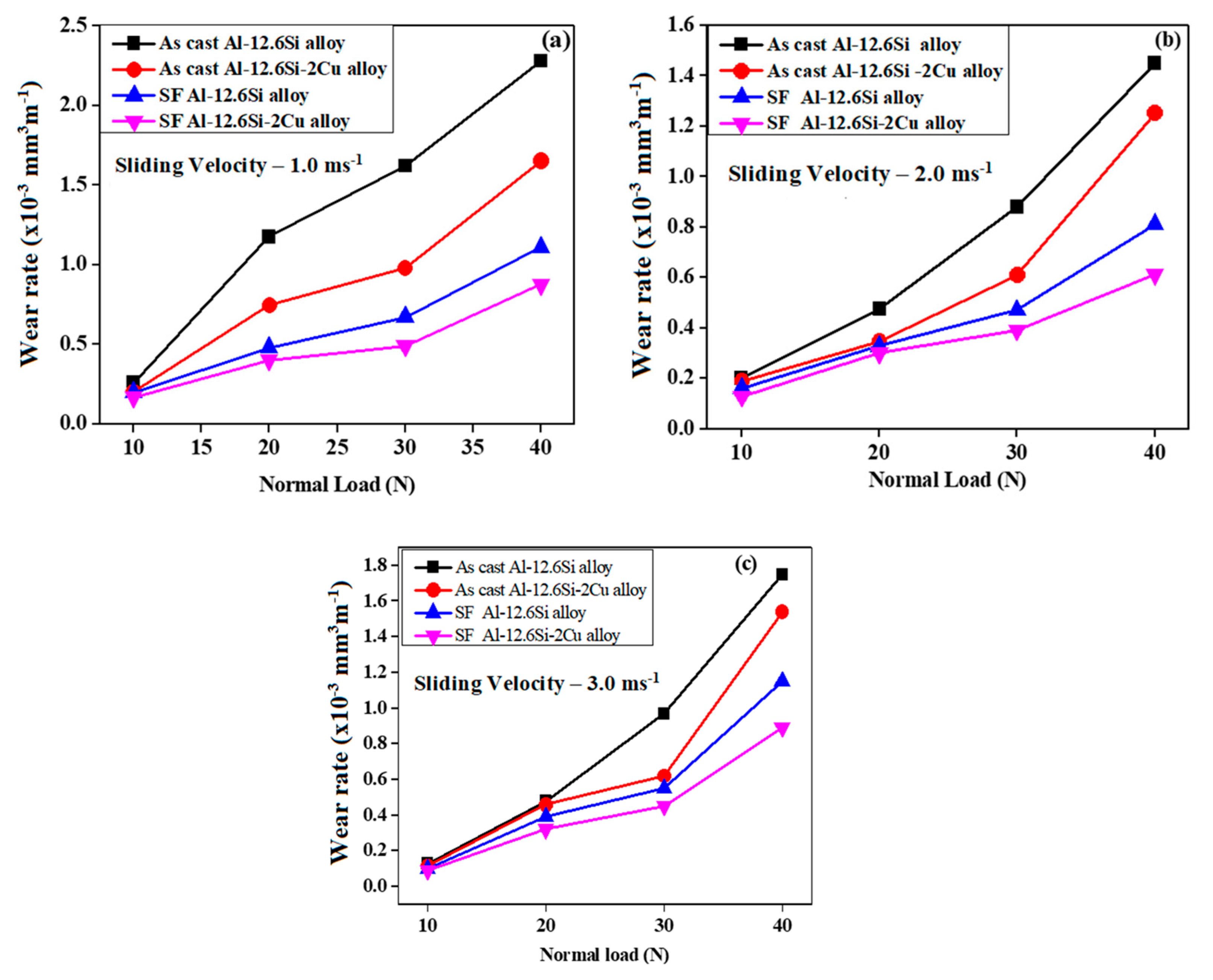

3.4.1. Variation of wear rate with load at constant sliding velocity

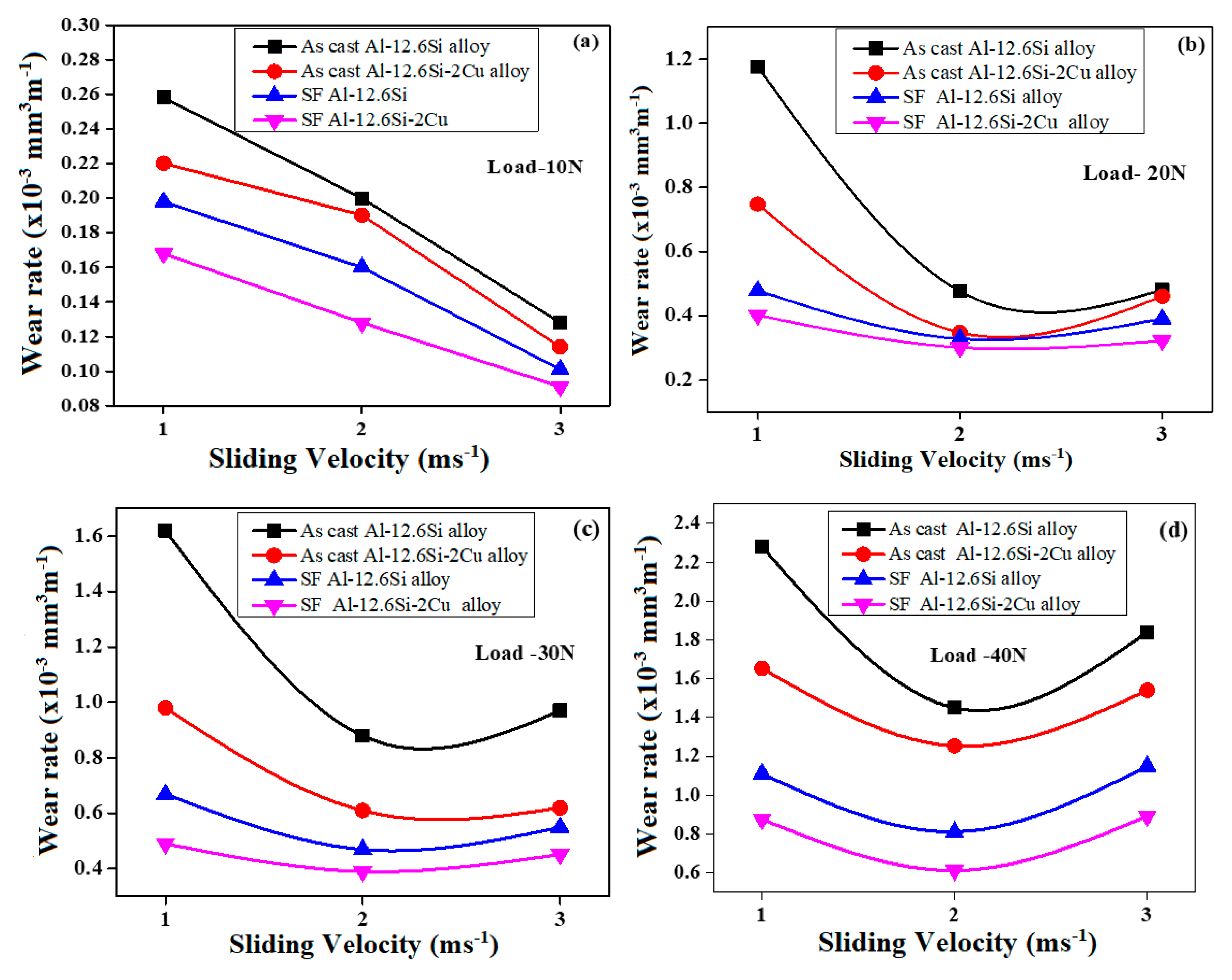

3.4.2. Variation of wear rate with sliding velocity at constant applied load

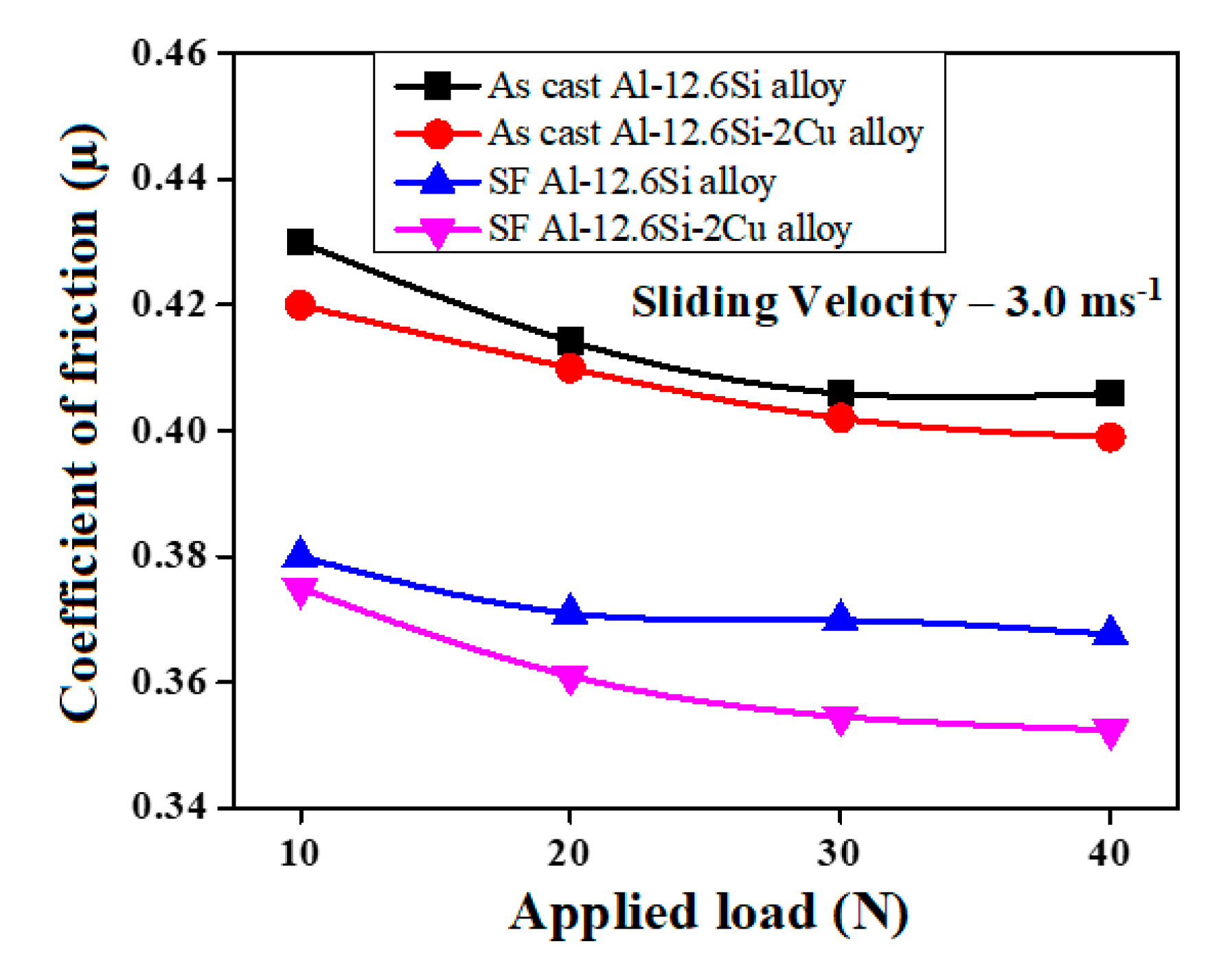

3.4.3. Variation of friction coefficient with load at constant sliding velocity

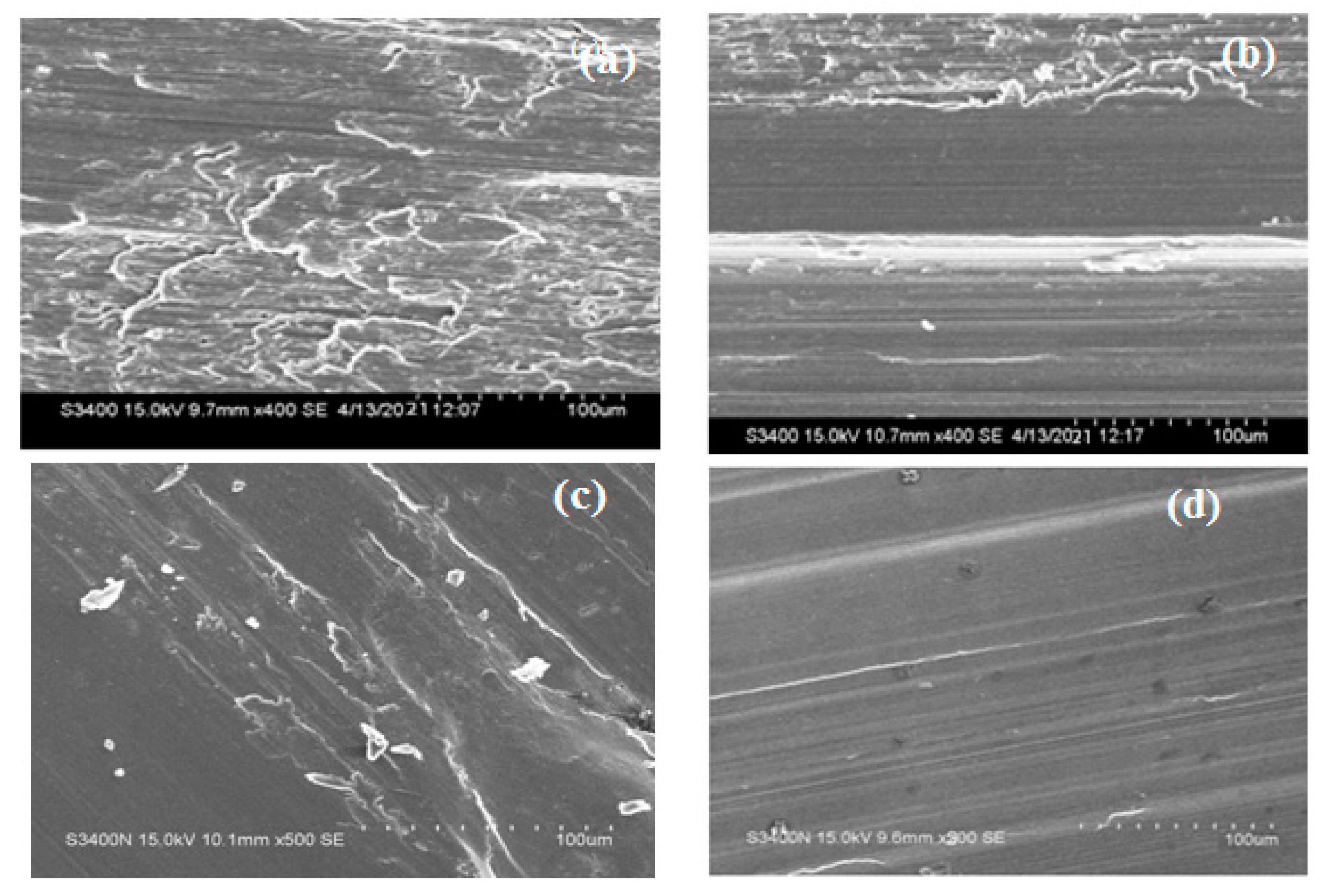

3.5. Topographical features of worn surfaces

4. Conclusions

- The microstructure of SF1 consists of eutectic Si particles ranging from 4 to 7 µm are uniformly distributed in the Al-matrix. The SF2 alloy exhibited a uniform distribution of eutectic Si, Al2Cu and Al-Si-Cu intermetallic phases in the equiaxed Al-matrix.

- The SF2 alloy exhibits superior WR than the AC alloys under varying load and sliding velocity conditions. Specifically, at a 40 N load, the WR of the SF2 alloy is 62%, 47%, and 23% higher than the AC1, AC2, and SF1 alloys, respectively, when sliding at 1 m/s. Similarly, when sliding at 3 m/s, the WR of the SF2 alloy is 52%, 42%, and 21% higher than the AC1, AC2, and SF1 alloys, respectively.

- The primary wear mechanism for the AC alloys under dry sliding conditions, involved abrasion, adhesion and SF alloys involved oxidation and abrasion. The increased load resulted in more wear due to the increased depth of penetration. However, at 40N for all sliding velocities, the AC alloys exhibited considerably higher wear loss throughout the sliding distance compared to SF alloys. This was attributed to the softening of the wearing pin at the high load, which accelerated both abrasive and adhesive wear at 3.0m/s sliding velocity.

- The SF2 alloy exhibited a lower WRt compared to the SF1 alloy at all applied loads and sliding velocities. This improvement was attributed to fine and uniform distribution of Si and intermetallic and increased solid solubility. This section may be divided by subheadings. It should provide a concise and precise description of the experimental results, their interpretation, as well as the experimental conclusions that can be drawn.

Author Contributions

Funding

Acknowledgements

Conflicts of Interest

Acronyms

References

- M.A. Awotunde, A.O. Adegbenjo, B.A. Obadele, et al., J Mater Res Technol. 8, 2432 (2019). [CrossRef]

- A.M. Ali, M.Z. Omar, H. Hashim et al., Rev Adv Mater Sci. 60, 801 (2021). [CrossRef]

- B. Abbasipour , B. Niroumand, S.M. M. Vaghefi et al., Tribological behavior of A356−CNT nanocomposites fabricated by various casting techniques, T Nonferr Metal Soc. 29, 1993–2004 (2019). [CrossRef]

- X. Zhuo, Q. Zhang, H. Liu et al., Journal of Alloys and Compounds. 899, 163321 (2022). [CrossRef]

- Y. Wu, C. Liu, H. Liao et al., J Alloys Compd. 856, 158072 (2021). [CrossRef]

- S. Liu, X. Zhang, H.L. Peng et al., J Mater Res Technol. 9, 4644 (2020). [CrossRef]

- A.A. Rahman, M.S. Salleh, I.S. Othman et al., J Adv Manuf Technol. 14, 1 (2020). Available online: https://jamt.utem.edu.my/jamt/article/view/6029.

- Gencaga Purcek, Onur Saray and Oktay Kul, Met. Mater. Int. 16, 145 (2010). [CrossRef]

- A.R. Riahi, and A.T. Alpas, Mat Sci Eng A. 44, 326 (2006). [CrossRef]

- M. Elmadagli, T. Perry and A.T. Alpas, Wear. 262, 79 (2007). [CrossRef]

- Parveen Kumar and M. F. Wani, Jurnal Tribologi.15, 21 (2017). Available online: https://www.jurnaltribologi.mytribos.org/v15/JT-15-21-49.pdf.

- Gang Liu, Guodong Li, Anhui Cai and Zhaoke Chen, Materials & Design. 32, 121 (2011). [CrossRef]

- F. Alshmri, H.V. Atkinson, Sarah V Hainsworth and C. Haidon, Wear. 313 (2014). [CrossRef]

- Luis Antonio de Souza Baptista, Kessia Gomes Paradelaa, Ivaldo Leão Ferreira, Amauri Garcia and Alexandre Furtado Ferreira, Mater. Res. Technol. 8, 1515 (2019). [CrossRef]

- Yan Zheng, Wenlong Xiao, Sujing Ge, Weitao Zhao, Shuji Hanada and Chaoli Ma, Journal of Alloys and Compounds. 649, 291 (2019). [CrossRef]

- Giulio Timelli, Alberto Fabrizi, Simone Vezzù and Alessandro De Mori, Metals. 10, 1 (2020).

- Muzaffer Zeren, Erdem Karakulak and Serap Gümüş, Influence of Cu addition on microstructure and hardness of near-eutectic Al-Si-xCu-alloys, Transactions, 21, 1698-1702 (2011). [CrossRef]

- Wen-Chi Chen, Chih-Ting Wu, Hui-Yun Bor, and Sheng-Long Lee, Journal of Materials Engineering and Performance. 22, 3854 (2013). [CrossRef]

- M.T. Mahmoud and R.I.M. Essam, Materials. 9, 442 (2016). [CrossRef]

- Eunkyung Lee and Brajendra Mishra, Effect of Solidification Cooling Rate on Mechanical Properties and Microstructure of Al-Si-Mn-Mg Alloy, Materials Transactions. 58, 1624-1627 (2017). [CrossRef]

- S.G. Patrick, Solidification in Spray Forming, Metallurgical and Materials Transactions A, 38, 1520-1529 (2017). [CrossRef]

- M.G. Dayanand, K. Raju, V.C. Srivastava and G. B. Rudrakshi, Top of FormBottom of FormMaterials & Design., 51, 383 (2013). [CrossRef]

- K. Raju, Effect of processing techniques on the microstructure & wear characteristics of Al-Si alloys, Ph. D. Thesis, IIT(BHU) (2009).

- Haichao Li, Fuyang Cao, Shu Guo, Yandong Jia et. al., J Alloys and Compounds. 719, 89 (2017). [CrossRef]

- W.D. Cai and W.J. Lavernia, Mat. Sci. Eng. A, 8, 226-228 (1997).

- E.J. Lavernia, N.J. Grant and T. Ando, Rapidly solidified materials (Eds) (Lee PW, Carbonara RS, Ohio, 1986) pp 29 ISBN-13: 978-0871702241.

- W.S. Gwidon, Wear – Materials, Mechanisms and Practice, (John Wiley & Sons Ltd, The Atrium, Southern Gate, Chichester, West Sussex PO19 8SQ, England, 2006), ISBN-13: 978-0-470-01628-2 (HB).

- Leyu Lin, Yuxiao Zhao, Chi Hua and Alois K. Schlarb, Tribol Lett, 69, 68 (2021). [CrossRef]

- A.G. James, Metal Transfer and Wear, Front. Mech. Eng., 2020. [CrossRef]

- Cyrus Bidmeshki, Vahid Abouei, Hassan Saghafian et al., Journal of Materials Research and Technology, 5, 250 (2016). [CrossRef]

| Alloy | Si | Fe | Mn | Mg | Cu | Ni | Al |

|---|---|---|---|---|---|---|---|

| Al-12.6Si (AC1) | 12.6 | 0.3 | 0.06 | 0.24 | 0.04 | --- | Bal. |

| Al-12.6Si-2Cu (AC2) | 12.6 | 0.4 | 0.02 | 0.14 | 2.06 | -- | Bal. |

| Variable | Value |

|---|---|

| Melt Superheat | 150°C |

| Melt rate | 2.8 kg/min kg/min |

| Gas pressure | 0.55 MPa |

| Diameter of nozzle | 4.0 mm |

| Deposition distance | 400 mm |

| Particulars | SF1 alloy | SF2 alloy |

|---|---|---|

| Theoretical density (gm/cc) | 2.65 | 2.78 |

| Density before hot pressing (gm/cc) | 2.17 | 2.33 |

| Density after hot pressing (gm/cc) | 2.46 | 2.64 |

| % porosity before hot pressing | 18% | 16% |

| % porosity after hot pressing | 7% | 5% |

| EDX spots | Phase | Al-K | Fe-K | Si-K | Cu-K |

|---|---|---|---|---|---|

| Spot 1 | Q-Al74Si9Cu10 | 65.88 | 0.89 | 8.02 | 26.43 |

| Spot 2 | θ-Al2Cu | 67.23 | 0.30 | 1.97 | 30.50 |

| Spot 3 | α-Al | 97.81 | 0.41 | 0.24 | 0.00 |

| EDX spots | Phase | Al-K | Si-K | Fe-K | Cu-K |

|---|---|---|---|---|---|

| Pt1 - Eutectic Si | Al48Si51 | 45.72 | 50.13 | 0.89 | 1.57 |

| Pt2 - Q-phase | Al93Si6Cu1.9 | 89.02 | 6.99 | 0.30 | 2.09 |

| Pt3 - α(Al) | Al92Si1 | 92.89 | 1.27 | 0.41 | 3.62 |

| Alloy | Hardness (Hv) |

|---|---|

| AC1 | 43±4.1 |

| AC2 | 48±3.2 |

| SF1 | 67±5.1 |

| SF2 | 73± 4.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).