1. Introduction

When casting large forging ingots of mild steel, it is important to select effective thermal insulation backfill materials. The quality of a quiet steel ingot is mainly determined during the casting stage and during the formation of the head part of the casting.

The shape of the shrinkage cavity and the choice of effective heat-insulating backfill play important roles; these factors are subject to requirements not only to ensure macro- and microstructural homogeneity of the metal with a high yield but also to ensure environmental safety at the preparation and use stages in metallurgical processing.

The general requirements for heat-insulating materials include high heat-insulating ability, no metal contamination when insulating ingots in melds, and good environmental performance. Not all materials used for thermal insulation meet these requirements. For example, asbestos causes carcinogenic diseases due to significant dust emissions during use.

An increase in yield is achieved by casting ingots cast with the insulation of the profitable part with weakly exothermic mixtures. There are known developments to create mixtures based on hot, oxidizing and inert fillers. Most of these mixtures are characterized by a significant level of heat release but a low heat utilization coefficient of exothermic reactions due to the production of cinder with excessively high thermal conductivity during combustion. This causes an increase in heat loss from the profitable part of the ingot and the head trim.

An increase in the efficiency of exothermic mixtures is achieved by combining sufficiently high thermal properties and retaining the generated heat, which is ensured by obtaining a highly porous, non-destructive, lightweight, highly porous cinder.

The effectiveness of their use depends not only on the thermophysical properties in their pure form but also on the nature of the interaction with the metal, the properties of the resulting cinder, the duration of combustion, etc.

2. Literature review

When heat-insulating boards are used, the heat loss structure from the head part of the ingot changes, and the heat removal through the side surface in the upper part of the ingots decreases. Moreover, the relative amount of heat removed from the metal surface of the ingot increases, which can reduce the effect of using heat-insulating boards. Therefore, the transition to casting ingots with heat-insulating boards requires the use of more effective insulation from the metal mirror than casting ingots with profitable extensions lined with alum inosilicate refractories. The experience of individual plants shows that the difference in the size of the head trim when transferring the insulation of the head part of the ingot from one heat-insulating backfill material to another can reach 3-5% [

1,

2,

3,

4].

The general requirements for heat-insulating materials are as follows: high heat-insulating ability, no metal contamination when insulating ingots in melds, and good environmental performance. Not all materials used for thermal insulation meet these requirements. For example, asbestos, which is a group of natural aqueous minerals of the silicate class with a fine-fibre structure, causes carcinogenic diseases; when a perlite-graphite mixture is used, significant dust emission is observed.

The authors [

5,

6] noted that an increase in yield is achieved, in particular, by rolling ingots cast with insulation of the profitable part with exothermic mixtures. There are known developments to create mixtures based on hot, oxidizing and inert fillers [

5,

6,

7,

8]. Most of these mixtures are characterized by a significant level of heat release but a low heat utilization coefficient of exothermic reactions due to the production of cinder with excessively high thermal conductivity during combustion. This causes an increase in heat loss from the profitable part of the ingot and the head trim.

An increase in the efficiency of exothermic mixtures is achieved when the thermal properties are combined with the ability to retain the generated heat, which is ensured by obtaining a highly porous, lightweight powdered cinder [

8,

9].

There is no doubt that when heat is supplied to the profit metal of the ingot during solidification, the shrinkage cavity can be localized, and the volume of metal in the profit is brought to the theoretical limit. This is evidenced by the experience of using an electric arc and electro slag heating of ingots, which are currently used only on a limited scale in the production of special alloys or high-alloy steels [

12,

13].

When smelting steel ingots over a wide range, the only possible method of heating the metal at

The third group included slow-burning mixtures (with a combustion time of 3-10 minutes) containing 10-15% aluminium powder, 5-15% sodium nitrate, and 20% scale as the active components and fireclay powder, fluoride spars or silicate blocks as the inert component. With additional thermal insulation of the surface of the profit with a heat-insulating mixture, the efficiency of casting ingots weighing 1-3 tons was significantly greater than that of the other ingots, and a satisfactory macrostructure was provided at the 10% level. However, when mixing the 1st and 2nd groups was used, a satisfactory macrostructure was provided at the horizons, corresponding to the 12-14% level from the top of the ingot rolls.

The use of effective mixtures containing nitrate leads to unacceptable pollution of the atmosphere of the casting bay with nitrogen oxides, and this process is possible only in workshops in which ventilation ensures the removal of harmful emissions [

15].

Mixtures with silicone are very expensive, and their use can only be used for the production of special and alloy steels. In addition, they are explosive and can be manufactured only in specially built workshops designed to be explosion-proof. [

15,

16,

17,

18]. It is also very difficult to obtain silicone powder due to its explosiveness. Another disadvantage of the mixtures noted in [

11,

12,

13,

14,

15,

16,

17,

18,

19], which reduce their manufacturability, is that as a result of their combustion, heat-conducting combustion products are formed, which require the additional introduction of a heat-insulating layer of materials.

This drawback was eliminated during the development of similar mixtures by the Institute of Ferrous Metallurgy [

9,

10]. After combustion of these mixtures, a fairly strong cinder with a porous and fine-grained structure is formed. However, these mixtures are multicomponent and contain more explosive and expensive substances; thus, further improvement of these mixtures is needed.

The Dnepropetrovsk Mining Institute was used in combination with the subsequent pipe-rolling plant. K. Liebnecht [

14] developed a technology for manufacturing a one-component heat-insulating coating, which is used when casting steel using the siphon method. This coating is a product of processing ash from thermal power plants and contains 19.4-35.6% SiO2, 6.6-7.5% Fe2O3, 1.5-1.8% CaO, 8.2-15.1% Al2O3, and 1.8-2.0% K2O and is characterized by a uniform granulomeres composition.

However, the preparation of multicomponent exothermic mixtures requires special equipment, which, as a rule, is carried out in the departments of slag-forming mixtures, melds increasing the cost of mild and low-alloy steels.

The choice of compositions of exothermic backfills is still made by the “trial and error” method, which is due to the lack of a sufficiently substantiated scientific analysis of the influence of such important characteristics.

When choosing one or another type of backfill for insulating a metal mirror, it is necessary to keep in mind that all the cooling conditions for the head part of the ingots must be considered; i.e., a comprehensive steel casting technology must be developed to provide a solution to the problem.

Table 1.

Values of the thermal conductivity coefficients of the materials used for insulating metal surfaces.

Table 1.

Values of the thermal conductivity coefficients of the materials used for insulating metal surfaces.

| № |

Material |

Thermal conductivity coefficient, W/m .0С(K) |

| 100 0С (373 К) |

800 0С (1073 К) |

| 1 |

Asbestos |

0,11 |

0,30 |

| 2 |

Perlite |

0,10 |

0,32 |

| 3 |

Perlite-graphite (1:1 ratio) |

0,11 |

0,32 |

| 4 |

Vermiculite |

0,12 |

0,42 |

| 5 |

Expanded clay |

0,08 |

0,87 |

| 6 |

Blast furnace slag |

0,10 |

0,92 |

| 7 |

Kaolin slabs |

0,17 |

0,27 |

| 8 |

Ash from thermal power plant |

0,12 |

0,34 |

| 9 |

Aluminum production waste before filling |

12,27 |

30,13 |

| 10 |

Cinder from aluminum production waste |

0,12 |

0,23 |

The choice of rational parameters for the head part of the ingot cannot be considered one-sidedly only from the point of view of saving metal for the head trim without considering the thermal processes occurring throughout the entire ingot. This is explained by the fact that the profitable part of the bullion performs the following functions:

- Successively solidifying the ingot and influencing the development of shrinkage voids and internal cracks;

- affects the distribution and intensity of the movement of convective flows and the location of zonal segregation in the ingot;

- retains superheated volumes of steel and forms a reservoir for the floating of liquids and nonmetallic inclusions from the ingot.

To accomplish these tasks, it is necessary to select rational profit parameters and organize a heating system in which the metal in the system remains overheated until the ingot completely solidifies.

Many studies have traditionally been devoted to studying the internal structure of ingots, including mild steel [

19,

20,

21,

22]. In this case, the study of the structure of the head part of the ingot is of great interest since this structure most determines the yield of usable metal during shaping processes. Of the information available in the technical literature on this issue, the most relevant are those related to large ingots cast into a melds with a widening downwards since the technology of casting steel into melds with profitable extensions is everywhere being replaced by either continuous casting of steel or casting into melds with thermal insulation slabs.

The location and configuration of the shrinkage cavity in the upper half of the ingot were determined, all else being equal (the mass of the ingot, its transverse dimensions, steel composition, etc.) by the cooling intensity of the ingot and especially its head, which in turn was determined by the efficiency of the insulation of the metal surface and side surfaces.

The use of exothermic mixtures to heat the head part of ingots [

6,

7,

8,

9,

10,

11,

12] is even more effective for bringing the shrinkage cavity upwards, especially if the duration of combustion of the mixture corresponds to the time required to remove overheating of the metal in the entire volume of the ingot above the crystallization temperature.

Analysis of a larger number of literary sources [

17,

18,

19,

20,

21,

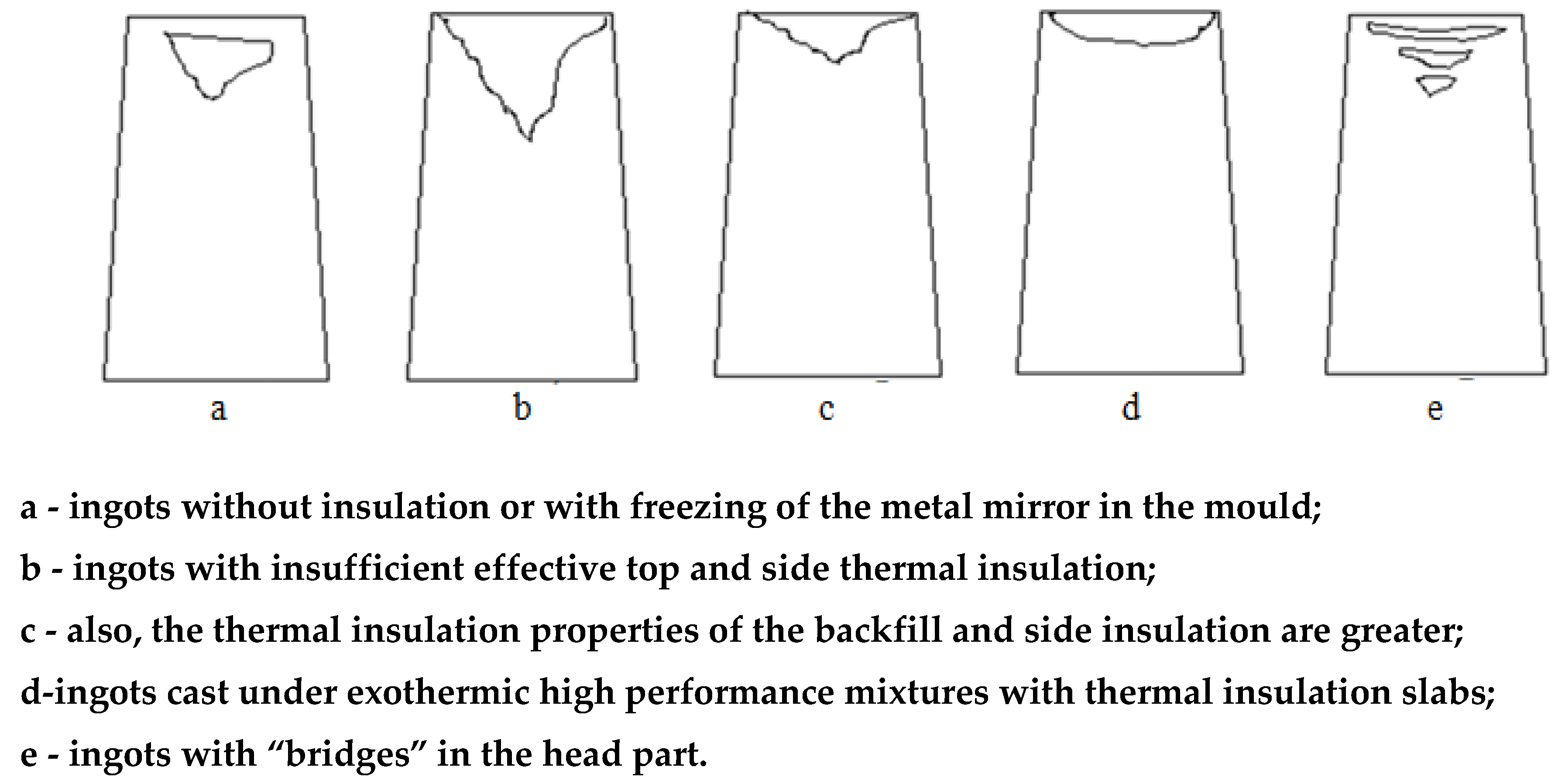

22] allows us to classify all types of mild steel ingots as follows (

Figure 1, a-d):

Type I (

Figure 1, a) is characterized by the presence of a thick solid “bridge”. These ingots are obtained when the metal surface freezes immediately after the mild is filled or when the insulation is insufficiently effective. The walls of the shrinkage cavity, as a rule, are not oxidized; however, welding it when rolling even into thin profiles is not guaranteed due to the large transverse dimensions. As a rule, when rolling such ingots, an increased head cut is observed.

Type II (

Figure 1, b): The shrinkage cavity is open and deeply embedded in the body of the ingot. This structure is observed in ingots cast with insufficiently high thermal insulation of the mirror and insufficiently good thermal insulation of the side faces of the meld. When they are rolled, an increased head cut is observed.

The type (

Figure 1, c) is intermediate between the previous type and type IV.

Type IV (

Figure 1, d) is the best ingot structure from the standpoint of quality and yield of usable metal during rolling. It is formed using highly effective thermal insulation materials for insulating the side surface and exothermic backfill. When rolling, minimal head trimming is observed.

Type V (

Figure 1, e) - ingots with 2-4 “bridges” in the head of the ingot, dividing the shrinkage cavity into parts. The formation of bridges is explained by insufficient effective insulation of the metal surface. “Bridges” can be solid, but they also exhibit fistulas and ruptures, which can lead to oxidation of the internal cavity of the shrinkage cavity and increased trimming during rolling.

If the uppermost bridge consists of dense metal without fistulas, cracks or tears, then this contributes to the welding of the shrinkage cavity during hot plastic deformation because the shell itself appears to be divided into parts. If the “bridges” have gaps or discontinuities through which atmospheric oxygen can enter the volume of the shrinkage cavity, then such ingots, when rolled, behave similarly to ingots with an open shrinkage cavity. The reason for the formation of “bridges” is the insufficient effective insulation of the mirror and the side surface of the ingot.

The temperature of the liquid core in the head part of the ingot is in the crystallization range “liquidus – solidus”, i.e., in the temperature range at which the liquid metal loses its fluidity. As the metal level decreases under the layer of heat-insulating backfill and cools, a hard crust periodically forms, which can bend in the central part, tear off along the periphery, etc. Rapid crystallization from the side surface helps to obtain stronger “bridges.” Typically, the conditions of the ingots are such that 1 to 4 bridges are fixed in the head. Therefore, one of the main criteria for evaluating ingots with bridges in the head part is the quality of the “bridges” themselves. For reliable, guaranteed welding of a shrinkage cavity separated by bridges, it is necessary to have strong, defect-free “bridges” (especially the top one), which prevent atmospheric air from entering the volume of the shrinkage cavity.

Somewhat separate from the problem of casting ingots with “bridges,” but still close to it, there is the problem of producing ingots with a welded shrinkage cavity. The methods for producing such ingots can be different, but an important general requirement is reliable isolation of the shrinkage cavity from the atmosphere.

In [

19,

24], two types of welded shrinkage cavities were obtained-one by the usual turning of the ingot with a still liquid core and the other by dispersing the cavity offset relative to the ingot axis-sometimes by laying the ingot on the side surface after casting. The technology for producing ingots with inversion has been known for a long time; it is used to produce ingots with a closed shell and, during rolling, a welded shell. Filling metal with water is also used for the same purpose. The use of bottle melds for casting mild steels also yielded similar results. In the latter case, the shrinkage cavity is divided into two parts-one open, in which the cinder from the heat insulator accumulates, and the other closed, with small transverse dimensions, which are welded during rolling. Metal from the upper, open shell goes into the head trim, while the yield increases.

3. Research methodology

Steel is poured from above through a collector nozzle with a diameter of 80 mm at a temperature of 1540-1550 °C into melds of type I6H with heat-insulating liners (ingot weight 16.9 tons).

Thermal insulating material was applied to the head surface of the metal in the meld after the meld was filled. Carbon-containing material in the form of coal flotation waste (CFL) was used as a thermal insulation material. The chemical and fractional compositions are given in

Table 2 and

Table 3.

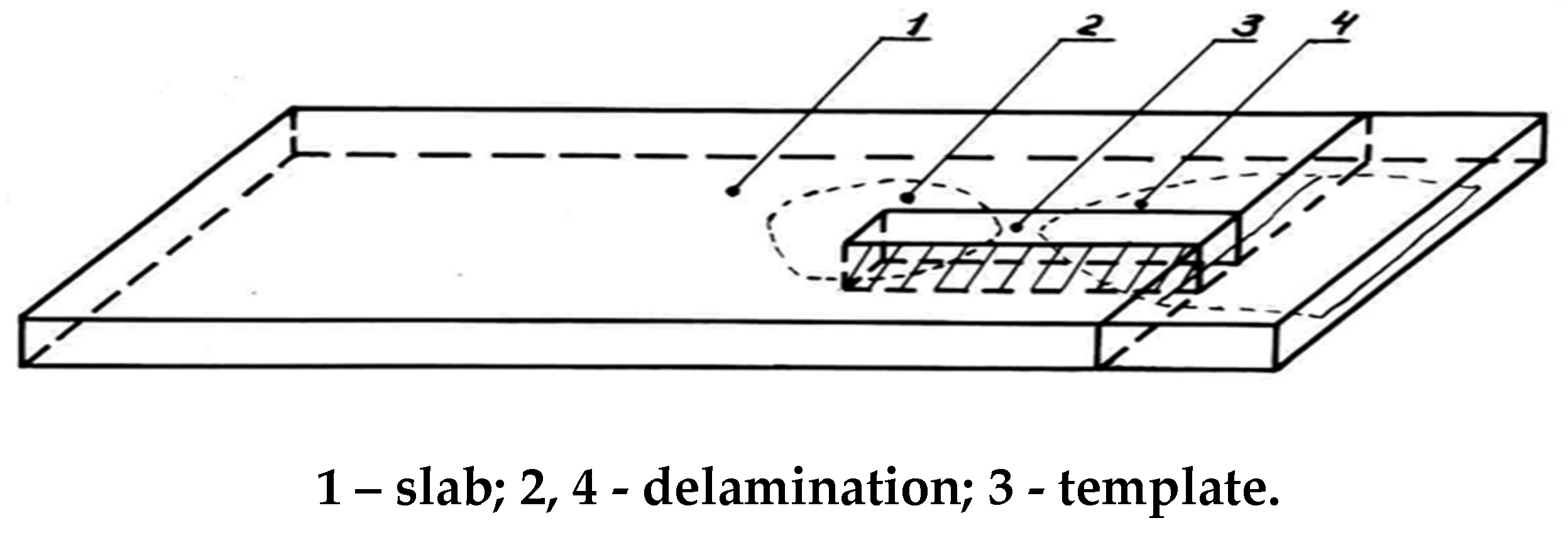

When rolling on a slab, head trimming on the experimental melts occurs at a level of 10-11% from the beginning of rolling and, if necessary, until shrinkage defects are completely removed. The heat-insulating properties of various mixtures of known and proposed options for insulating a metal mirror are assessed by the depth of the shrinkage cavity, i.e., according to the length of suitable slabs. The macrostructure and chemical heterogeneity of the metal are studied on transverse templates taken from the head part of the ingot and slab.

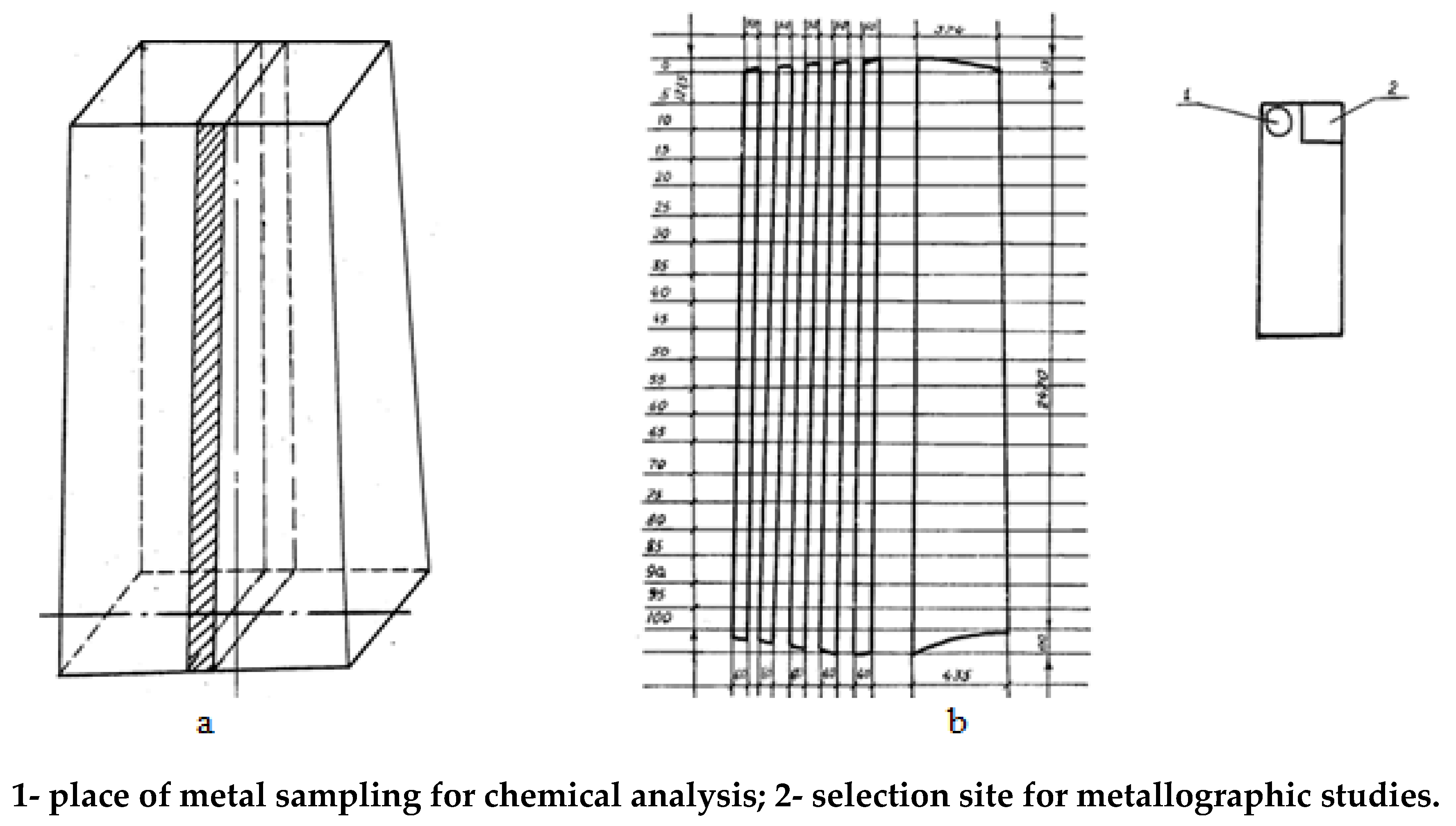

To study chemical heterogeneity and contamination with nonmetallic inclusions, characteristic ingots of mild steel were isolated and deposited in the composition preparation workshop. After cooling, oxygen cutters cut the slabs parallel to the wide edge 120-150 mm above the axial plane (

Figure 2,a); then, in the machine shop, they were planed to the axial plane and ground to remove the sulfuret imprint.

To study chemical heterogeneity and contamination with nonmetallic inclusions, metal samples were taken according to the scheme (

Figure 2, b). Chips were collected for chemical analysis using a drill with a diameter of 12 mm. The contents of the elements [C], [Mn], [Si], [S], [P], [AL], and [N] were determined by chemical methods.

Metal contamination with nonmetallic inclusions was determined by electrolytic deposition and the LT metallographic method.

When rolling on a slab, head trimming on the experimental melts occurs at a level of 10-11% from the beginning of rolling and, if necessary, until shrinkage defects are completely removed. The heat-insulating properties of various mixtures of known and proposed options for insulating a metal mirror are assessed by the depth of the shrinkage cavity, i.e., according to the length of suitable slabs. The macrostructure and chemical heterogeneity of the metal are studied on transverse templates taken from the head part of the slabs.

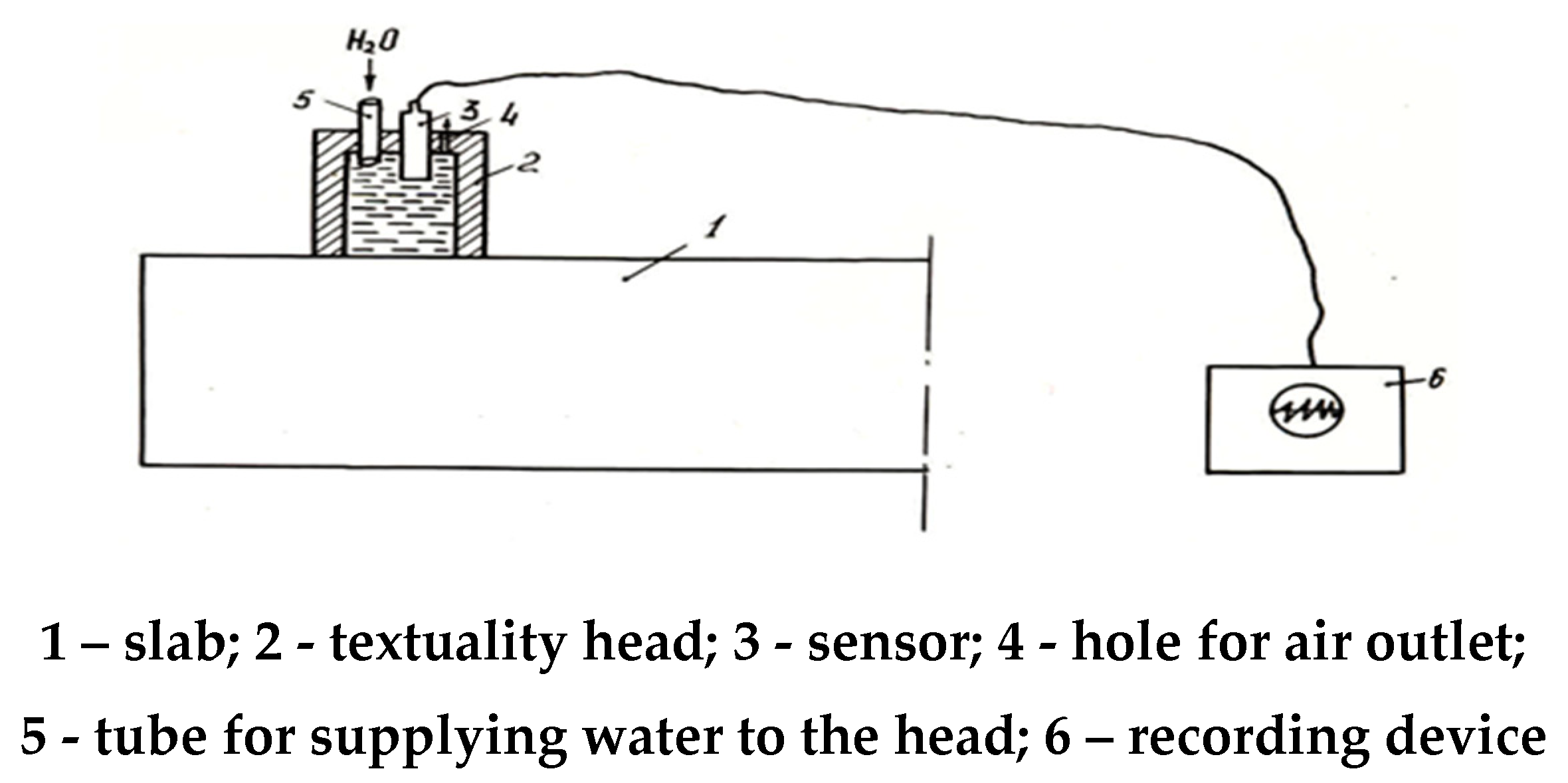

Metal testing for delamination in slabs was carried out using an ultrasonic method with a UDM-1 M flaw detector at a frequency of 1.8 MHz with a straight probe. The installation diagram for ultrasonic testing of the slabs is shown in

Figure 3.

Before ultrasonic testing, the surface of the slab was cleaned of scale. The contact of the metal with the probe was carried out with both technical petroleum jelly and water. The depth of occurrence and the boundaries of the distribution of discontinuities in the slabs were measured using the depth gauge scale of a flaw detector previously calibrated on reference samples.

To study the microstructure and contamination of steel with nonmetallic inclusions, metal samples were taken along the boundaries of the shrinkage looseness defect according to the scheme (

Figure 3). Thin sections were cut from the selected samples to determine the nonmetallic inclusions and chemical composition.

Figure 3.

Installation diagram for ultrasonic testing of slabs and sheets.

Figure 3.

Installation diagram for ultrasonic testing of slabs and sheets.

Figure 3.

Scheme for sampling from defective areas.

Figure 3.

Scheme for sampling from defective areas.

4. Research results

Coal flotation wastes themselves have high heat-insulating properties since, mineralogically; they consist of an organic part (carbonaceous substances) and mineral impurities (clay minerals, carbonates, sulphates, etc.). The main clay component is kaolinite. Inorganic substances are represented mainly by the clayey-hydro mica complex, the share of which is 55-65%. The density varies widely from 1400 to 1800 kg/m2, the bulk density by dry weight is 0.65-0.85 kg/m3, and the calorific value is 2500-4200 kcal/kg.

When developing an industrial technology for casting mild and low-alloy steels using man-made waste from metallurgical production, coal flotation waste (CFW), as heat-insulating fills, it was necessary to establish the conditions for obtaining a closed shrinkage cavity in the head part of the ingot.

According to the proposed method, coal flotation waste is applied to a hardened metal mirror with a layer of 20-40 mm. The optimal holding time before applying it to the head surface has been established to be 10-30 s, which makes it possible to increase the temperature state of the metal-backfill system and reduce the period of heating of the flotation waste to the ignition temperature.

Insulation of the head part of a mild steel ingot using the developed method eliminates carburization of the metal and makes it possible to effectively use the heat of a weakly exothermic combustion reaction for thermal insulation of the metal surface. Carbon-containing material, which is used as coal flotation waste, is applied to the hardened head surface of the ingot, which prevents carburization of the metal and makes it possible to obtain an ingot with a closed shrinkage cavity (

Figure 4.b). When carbon from coal flotation waste burns for a longer time (more than 1.5 hours), the high temperature of the head of the ingot and, as a consequence, the metal in a liquid state under the solidified “bridge” are maintained. A gas cavity formed between the solidified “bridge” and the liquid metal, preventing heat removal in the vertical direction. In addition, the closed shrinkage cavity prevents metal splashes from occurring during the transportation and processing of ingots and during their placement in heating devices.

The research results showed that slight cooling before adding OFU promoted the formation of a dense gas-tight bridge. The gas cavity between the solidified bridge and the liquid metal prevents heat removal like in double window frames; the high temperature of the head surface of the ingot is maintained, and as a result, a large proportion of the metal is in a liquid state under the solidified bridge.

As studies have shown, when an OFC is added to a metal mirror, earlier than 10 s after casting the ingots, the formation of an open shrinkage cavity is observed, and as a consequence, carburization of the metal occurs in the sub gross part of the ingot. In addition, oxidation of the inner surface of the shrinkage cavity occurs during the heating of the ingots in the furnace, which ultimately leads to increased head trimming (

Table 4, examples 1-3).

Checking the influence of the carbon insulation backfill on the degree of carburization of the head part of the ingot with metal sampling along the length of the roll at 4%, 6%, and 10% from the top and at two points along the width (edge and centre) showed that when insulating the head surface of the ingot, in the steel screenings of coke and OFU, there is a slight increase in the carbon concentration, which is typical only for the area up to 4% of the length of the roll, but this change does not affect the quality since it goes with the head trim. Therefore, the type of insulating backfill has no effect on the degree of carbon segregation. This was confirmed by the distribution of carbon along the length and width of the cold-rolled strips (

Table 4).

When OFF is applied to the metal mirror after 30 s after the head part of the ingot is filled, the flammable components of the flotation waste slowly ignite, which worsens the thermal performance and leads to a decrease in yield in the first stage (

Table 5, examples 7-9).

Data from experimental melts showed that the use of the proposed method allows not only the carburization of the metal but also the improvement of the structure of the head part of the ingots and, as a result, the increase in the yield of slabs (examples 4-6).

Table 4.

Changes in the carbon content of cold-rolled rolled products with respect to the length and width of strips obtained from ingots insulated with OFU and dusted asbestos.

Table 4.

Changes in the carbon content of cold-rolled rolled products with respect to the length and width of strips obtained from ingots insulated with OFU and dusted asbestos.

View

thermal insulation backfill

|

Carbon content in the ladle

sample, %

|

Location

selection

by length

stripes

|

Carbon content, % |

| edge |

stripes middle

stripes

|

| Coal flotation waste |

0,03 |

beginning |

0,034 |

0,030 |

| middle |

0,033 |

0,025 |

| end |

0,028 |

0,030 |

| 0,04 |

beginning |

0,037 |

0,040 |

| middle |

0,027 |

0,032 |

| end |

0,34 |

- |

| 0,05 |

beginning |

0,046 |

0,040 |

| middle |

0,047 |

0,046 |

| end |

0,044 |

0,040 |

| Asbestos |

0,03 |

beginning |

0,039 |

0,038 |

| middle |

0,038 |

0,038 |

| end |

0,044 |

0,036 |

| 0,04 |

beginning |

0,034 |

0,031 |

| middle |

0,036 |

0,037 |

| end |

0,026 |

0,031 |

| 0,05 |

beginning |

0,050 |

0,049 |

| middle |

0,056 |

0,050 |

| end |

0,050 |

0,050 |

Table 5.

Metallic logical indicators.

Table 5.

Metallic logical indicators.

| Insulation method |

Type of insulating backfill |

Exposure

before insulation, s

|

Type of shrinkage cavity |

Average length of roll, m |

Consumption coefficient, t/t |

Naugler-living

metal

|

| Proposed |

flotation waste |

|

|

|

|

|

| 1 |

0 |

open |

8,9 |

1,236 |

occurs |

| 2 |

3 |

open |

9,0 |

1,201 |

occurs |

| 3 |

7 |

open |

9,1 |

1,198 |

does not occur |

| 4 |

10 |

closed |

9,3 |

1,176 |

does not occur |

| 5 |

20 |

closed |

9,35 |

1,175 |

does not occur |

| 6 |

30 |

closed |

9,38 |

1,171 |

does not occur |

| 7 |

40 |

closed |

9,2 |

1,189 |

does not occur |

| 8 |

50 |

closed |

9,15 |

1,191 |

does not occur |

| 9 |

60 |

closed |

8,95 |

1,197 |

does not occur |

| 10 |

elimination

coke

|

10 |

open |

8,86 |

1,223 |

occurs |

| 11 |

30 |

closed |

9,35 |

1,175 |

does not occur |

| 12 |

90 |

closed |

9,30 |

1,179 |

does not occur |

| Famous |

asbestos |

0 |

open |

8,89 |

1,201 |

does not occur |

When applying coal flotation waste to an already hardened metal mirror, the following positive processes occur: During the holding process, flotation waste is heated to a temperature at which the combustion reaction of active carbon and hydrogen begins due to atmospheric oxygen, releasing heat and gaseous reaction products, i.e., carbon dioxide and water vapour, to obtain a solid residue in the form of ash. The presence of particles of different sizes in the waste and the presence of an inert filler in the form of ash contribute to the dispersal of combustion over time. Moreover, the combustion process lasts 30-50 minutes. Moreover, in the process of releasing volatiles contained in flotation waste and gaseous reaction products of carbon and hydrogen, the backfill layer is loosened with the formation of a porous cinder during aging, which has a volume 2-2.5 times greater than that of the original layer of flotation waste and good thermal insulation properties. This helps to reduce the rate of heat removal from the head of the crystallizing ingot.

According to actual data, the porosity of the cinder ranges from 60 - 75%. The entire volume of the cinder has a high thermal resistance, which leads to an increase in the amount of heat transferred to the head of the ingot. The main heat flow is directed to the profitable (head) part of the ingot, which slows its crystallization. During the crystallization process, liquid metal is supplied to the axial zone of the ingot, located below the profit. This helps to reduce the volume of the shrinkage cavity, which is the source of layer formation during the rolling process.

The research results showed that the maximum yield, minimum waste and dust removal are achieved when coal flotation waste is applied at a flow rate of 1.5-2.0 kg/t, which corresponds to a layer thickness of 20-40 mm. When the thickness of the layer of carbon-containing material is less than 20 mm, the combustion duration decreases, the heating efficiency of the head of the ingot decreases, and when the layer thickness is more than 40 mm, there is an overconsumption of material without improving the quality characteristics of the metal in the first stage.

The novelty of this method lies in the use of heat insulation and exothermic properties of flotation waste to insulate the head part of the ingot, which solves the problem of recycling production waste and prevents contamination of land allocated for the storage of liquid waste sludge from coke and coal preparation production.

In addition, when using the proposed method with coal flotation waste as a weakly exothermic heat-insulating backfill, no harmful emissions are observed in the atmosphere. Research has shown that the dust content on casting balconies is less than 4 mg/m3 (1.5-2.5 mg/m3); i.e., in ecological terms, these areas have significantly better characteristics (

Table 5). The moment at which the insulating fill is introduced into the meld to insulate the head surface of the ingot also affects the environmental performance of the casting process. An environmental assessment of the use of carbon-containing backfill showed that the highest intensity of pollutant release is observed when the material is applied to a liquid “mirror” of metal. Thus, the concentrations of sulfuric dioxide and carbon monoxide in the air of the pourers in the working area increase to 24.1-29.8 and 30-60 mg/m3, respectively (

Table 5).

Table 5.

Environmental assessment of various modes of applying insulating backfill to a metal “mirror”.

Table 5.

Environmental assessment of various modes of applying insulating backfill to a metal “mirror”.

| Ingredient, mg/m3 |

Asbestos |

Coal flotation waste |

| 0 -10 s |

10 – 30 s |

| Sulfur dioxide |

3,2 |

29,4 |

6,6 |

| Ammonia |

0 |

7,3 |

3,6 |

| Carbon monoxide |

0 |

30,3 |

15,3 |

| Dust |

401,7 |

15,3 |

14,62 |

| Nitrogen dioxide |

0 |

0 |

0 |

| Phenol |

0 |

0,010 |

0,16 |

| Benzene |

0 |

0 |

0 |

| Aluminium |

0 |

0 |

0 |

The positive aspect of the method using flotation waste as a weakly exothermic heat-insulating material in the form of a monocomposition eliminates the need for preliminary preparation-classification by size classes and mixing of components—rather than when using known exothermic mixtures.

The main defects identified in the macrostructure, axial looseness and nonmetallic inclusions, do not exceed 1 point, and carbon segregation is practically absent; i.e., carbon segregation can be considered natural without the influence of insulating backfill.

5. Discussion of the research results

When the shrinkage cavity is closed, when part of the metal is consumed to form a “bridge,” one can expect its deeper penetration into the body of the ingot. However, in practice, this is not observed because when the shrinkage cavity is closed, the surface area of the profit through which heat is lost is constant; when the shrinkage cavity is open, this surface increases as the level of metal in the profit decreases due to the hardened layers of metal at the walls of the profitable extension. When a closed shrinkage cavity is formed, its solidification angle decreases (the angle formed by the intersection of the tangents to the outer surface of the profit and the side surface of the cavity of the shell), which is accompanied by a decrease in the depth of the shrinkage cavity.

This circumstance in which the shrinkage cavity formed under the “bridge” becomes a heat insulator led to the conclusion about the need to accelerate the formation of the “bridge”.

The results of the study (

Table 6) show that heat loss through the surface of the profit with a closed shrinkage cavity decreases by half, and the penetration depth of the shrinkage cavity decreases from 360 to 260 mm.

The quality of the 10 SP steels was studied after the head slabs were rolled onto a 12 mm thick hot-rolled sheet using samples taken at horizons of 12, 14, 16, and 18% (

Table 7, 8).

When the head of the ingot is insulated to obtain a closed shrinkage cavity, the profitable part of the ingot is more dense and less contaminated with nonmetallic inclusions. This is explained by the formation of a closed shrinkage cavity, which is clearly visible on the macrostructure of the ingot insulated with coal flotation waste (CFW) (

Table 8).

Conclusion

Analysis of the technical literature and the results of our research show that to reduce the level of head trimming and increase the yield of forging ingots, it is not necessary to achieve complete removal of shrinkage looseness into the profitable part, which is achieved by using high-temperature insulating fills. Satisfactory results are achieved by using weakly exothermic insulating backfill materials based on industrial waste (coal flotation waste, coke screenings and aluminium shaving screenings) to obtain a closed shrinkage looseness with a dense “bridge”, which helps reduce production costs and air dust during casting and solves the problem of recycling production waste.

Analysis of the macrostructure of cast metal has shown that additional heat supply through the metal mirror is possible by using weakly exothermic backfills in the form of coal flotation waste and coke screenings, which not only reduce the volume of liquid metal while ensuring the required reserve of metal density but also affect the location and size of secondary shrinkage defects.

When burning coal flotation waste carbon, the high temperature of the head of the ingot is maintained for a longer time (more than 1.5 hours). A gas cavity formed between the solidified “bridge” and the liquid metal, preventing heat removal in the vertical direction. In addition, a closed shrinkage cavity prevents metal splashes during the transportation and processing of ingots, which makes it possible to reduce the duration of holding the ingot in the mould and reduce the time before it is seated in the heating device, i.e., increase its heat content and thereby reduce fuel or electricity consumption for subsequent heating before pressure treatment (forging, rolling).

To eliminate carburization of the metal and ensure a dense “bridge” in the head part of the ingot, a method has been developed for introducing a heat-insulating backfill onto the “mirror” of the metal, i.e., cooling for 10-30 seconds, to form a durable, no melting “bridge”, which additionally plays the role of a heat shield.

A new mechanism, cause and technological factor influencing the shape and depth of penetration of the internal “shrinkage looseness” hidden in the body of the ingot have been established, and casting methods and technology for insulating mild steel ingots using man-made waste from metallurgical production have been developed to help reduce delamination.

The studied patterns of the formation of a closed shrinkage cavity with a dense “bridge” in the head part of a quiet steel ingot made it possible to develop and implement a technology for casting large forging ingots of sufficiently high quality using weakly exothermic heat-insulating materials based on metallurgical waste (coke screenings, coal flotation waste) at JSC "ArcelorMittal Temirtau".

A weakly exothermic one-component heat-insulating mixture has been developed based on waste from metallurgical production (carbon-containing sludge from coal preparation), which combines the properties of fairly high thermal properties and good heat-insulating properties due to the production of highly porous, lightweight powdered cinder.

References

- Efimov V. S., Eldarkhanov A. S. Technologies of modern metallurgy. Moscow: New technologies. 2004. 784 p.

- Wray R.W., Hawkin A.L. Optimization of Steel Product. Yield. London, 1967.- p. 15-27.

- Ghosh A., Chatterjee A. Smelting of iron and steel: theory and practice. New Delhi: PHI Learning, 2008. RUR 494.

- Efimov, M.V., Panov, V.V., Kolomoec, A.N., Lobanov, A.I., Pashynskyi, V.V., Snizko, O.A., & Ryabtsev, A.D. 2012. Investigation of non-metallic inclusions in large-mass ingots, produced by PJSC “Energomashspetsstal”. . In: Proceeding of the 5th International Congress on the Science and Technology of Steelmaking 2012 “ICS 2012”, Dresden. , p. 152.

- Jürgen, A. 2012. Perspectives on ingot casting and forging industry in Europe and Worldwide. . In: Proceedings of the 1st International Conference on Ingot Casting, Rolling and Forging ICRF, Aachen, Germany. , pp. 3-7.

- Exothermic insulation mixture for the production of stainless steel ingots May 2023Chernye MetallyFollow journal. DOI: 10.17580/chm.2023.05.03 O. LeushinI. O. LeushinA. N. GrachevL. I. LeushinaA. D. Ryabtsev. [CrossRef]

- Zhang S. Influence of casting parameters on shrinkage porosity of a 19 ton steel ingot/S. Zhang, Y. Bao, M. Wang // La Metallurgia Italiana, 2016. - No. 1. - rr. 37-44.7.

- Leushin I. O. et al. Exothermic mixture for thermal insulation of the head part of the ingot during casting of steels and alloys. RF Patent No. 2773977. Applied: 03/02/2022. Published: 06/14/2022. Bulletin No. 17.

- Pat. EP 2009/1782780 A4. Method for producing an exothermic mixture, exothermic mixture, exothermic composition and exothermic product. IPC: A61F7/08, C09K5/16, 2009.

- Vorobyov N.I. and others. RF Patent, No. 2284876. Exothermic mixture for heating the head of the ingot during casting of steels and alloys. Applied: 03/21/2005. Published: 10/10/2006. Bulletin No. 28.

- PINDOR, J., KURKA, V., KOSŇOVSKÁ, J., ŠTEFANIŠINOVÁ, Š., SOCHA, L., PYSZKO, R. Effect of Cooling of the Ingot on its Macrostructural and Chemical Heterogeneity. Hutnické listy, 70 (2017) 3, 47–57. ISSN 0018-8069.

- Large ESR forging ingots and their quality in production. P. Bettoni, U. Biebricher, H. Franz, A. Lissignoli, A. Paderni, H. Scholz Forgiatura La Metallurgia Italiana - n. 10/2014 ESR.

- Electroslag technology of production of large forging ingots. Medovar, L.B.; Saenko, V.Ya.; Stovpchenko, A.P.; Tsykulenko, A.K.; Shevchenko, N.T.; Zhuravel, V.M.; Advances in Electrometallurgy Jul 1, 2010. Words: 3025.

- 28 Vakumenko S.P., Gulyaev B.B., Verkhovtsev E.V. / Reducing steel ingot waste. - M.: Metallurgy. - 1967. - 217 p.

- 9. Bächle K., Müller D., Lagemann J. Entwicklung eines verfahrens und prüfstandes zur qualitätsprüfung exothermer speiser. Giesserei. 2020. No. 4. pp. 32-37.

- Exothermic insulation mixture for the production of stainless steel ingots May 2023Chernye MetallyFollow journal. DOI: 10.17580/chm.2023.05.03 O. LeushinI. O. LeushinA. N. GrachevL. I. LeushinaA. D. Ryabtsev. [CrossRef]

- J. Wangqi, Formation of Hot-Top Segregation in Steel Ingot and Effect of Steel Composition, Metallurgical Transactions B. 20B (1989) 723-730. DOI: 10.1007/bf02655930. [CrossRef]

- 18 Kushiir Yu.B., Mnushkin I.I., Poyurovsky A.I./ Casting steel under a layer of one-component heat-insulating coating//Steel.- 1991.- No. 2.- p. 38.

- V.V. Nazaratin, O.A. Kobelev, M.V. Efimov et al. Analysis of technologies for manufacturing hollow ingots and prospects for their improvement. Metallurg, 56 (2013) 9–10. DOI: 10.1007/s11015-013-9634-z Google Scholar. [CrossRef]

- D.V. Rutsky, N.A. Zyuban, Development of defective zones and structure of cast metal in elongated two-piece ingots of chromium-nickel-molybdenum steel, Bulletin of Cast Iron and Steel of the CIS. 10 (2015), 14–18. DOI: 10.17580/cisisr.2015.01.03 Google Scholar. [CrossRef]

- M.V. Kolodkin, S.I. Zhuliev, V.S. Oak et al. Selection of a rational casting scheme for a forging ingot for the manufacture of hollow forgings // Electrometallurgy. 8 (2009) 26-29. DOI: 10.1134/s0036029510060169 Google Scholar. [CrossRef]

- [12] V.A. Shamrey, S.I. Zhulyev, New shape of a forging-grade ingot to produce hollow forgings, Metallurgist. 11 (207) 54 – 57. Google Scholar. [CrossRef]

- V.A. Shamrey, S.I. Zhuliev, New form of forging ingot for the production of hollow forgings, Metallurgist. 11 (2007) 54 – 57. Google Scholar.

- Zyuban N.A., Rutsky D.V., Gamanyuk S.B., Kirilichev M.V. Study of the structural features of cast metal ingots of various geometries used to produce round steel//Ferrous metals. 2019. No. 5 (1049). pp. 6-13. EDN:RNVCCE.

- The influence of profit insulation technology on the crystallization process and yield/ Galkin A.N., Rutsky D.V., Zyuban N.A., Gamanyuk S.B.//Science and production of the Urals. - 2012. - No. 8. - pp. 51-53. EDN: SCBBMZ.

- Dudko D.A., Krutikov R.G., Prokhorenko K.K. Comprehensive improvement of the quality of steel ingots. - Kyiv: Technology. - 1968. - 180 p.

- TSYMBAL V.P., etc. Exothermic material for insulation of the head part of a mild steel ingot Patent of the Russian Federation. RU 2007258 Application number: 4863335/02 Registration date: 09/03/1990. Publication date: 02/15/1994.

- Innovative patent of the Republic of Kazakhstan No. 21567. Method for insulating the head part of a mild steel ingot. – Ibraeva O.T., Ibraev I.K., Isagulov A.Z. – Application No. 2007/1318.1 dated 11/01/2007, Industrial Social Bulletin.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).