Submitted:

12 December 2023

Posted:

12 December 2023

Read the latest preprint version here

Abstract

Keywords:

0. About the Thesis

1. INTRODUCTION

2. ELEMENTS AND COMMUNICATION OF ELECTRIC VEHICLES

2.1. The general structure of the electric vehicle.

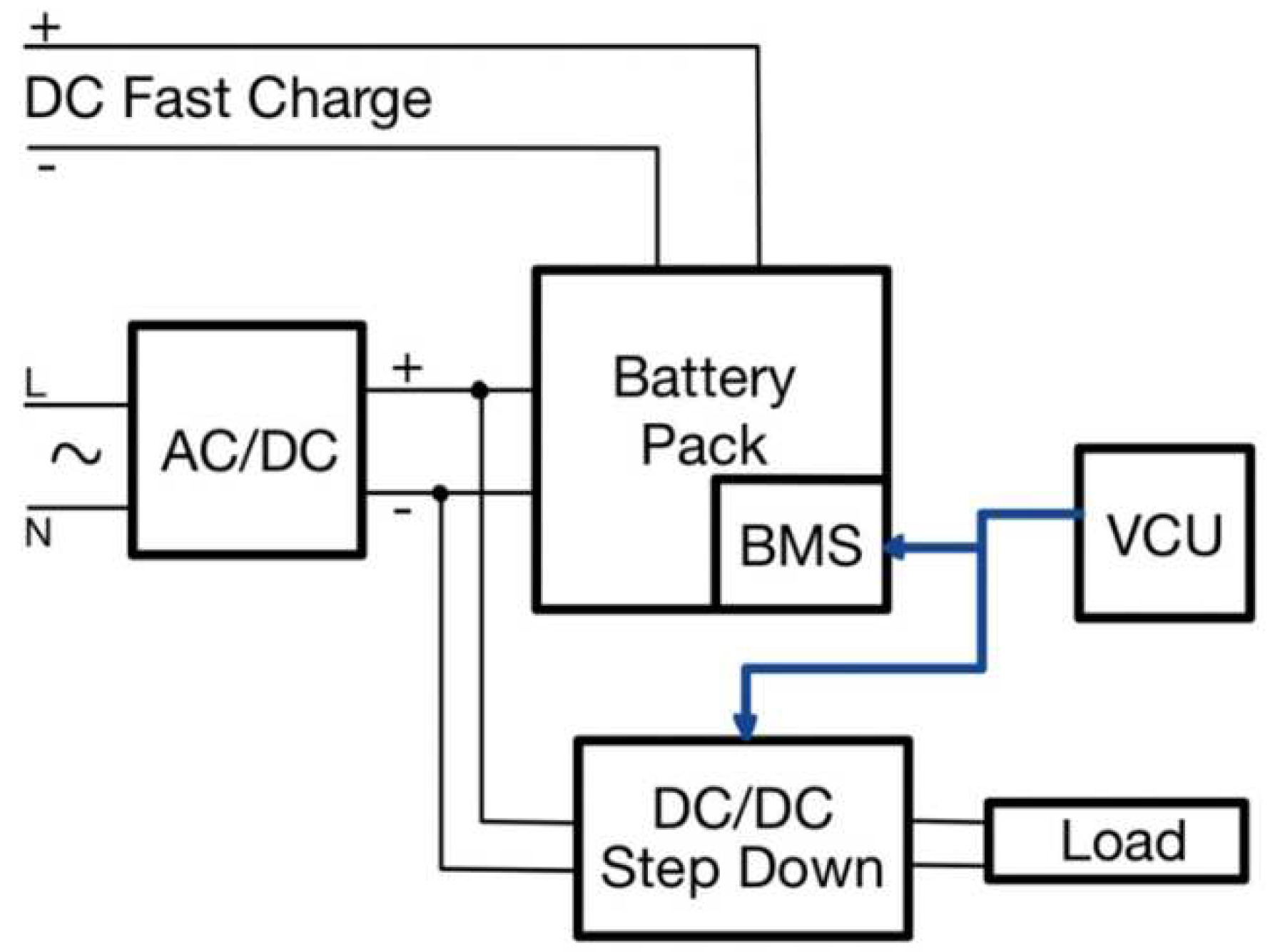

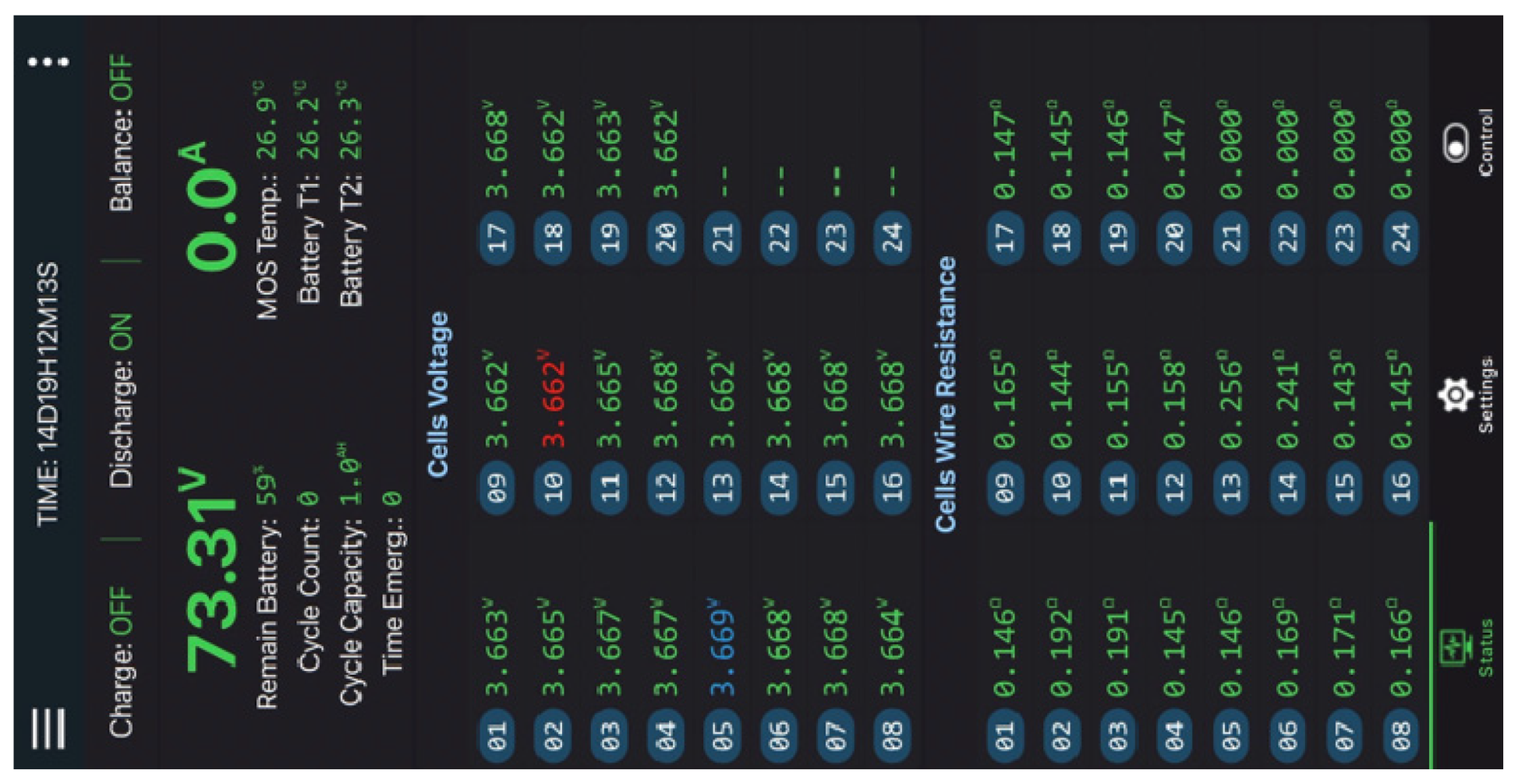

2.2. 72 V 25 Ah Battery Pack and balance with BMS.

2.3. Energy control system in electric vehicles.

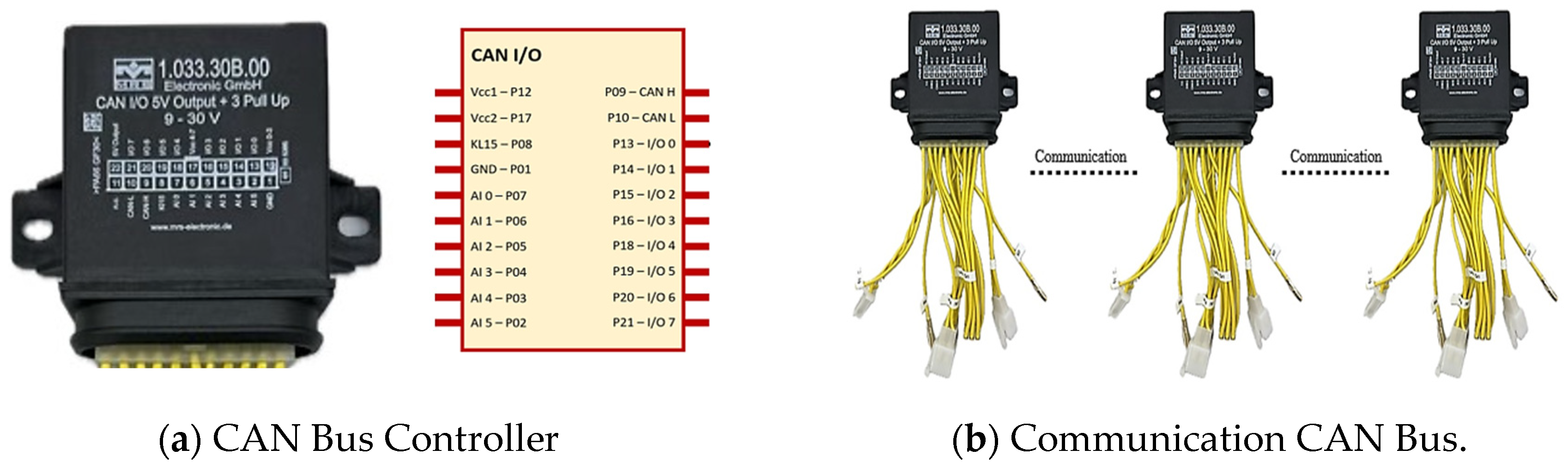

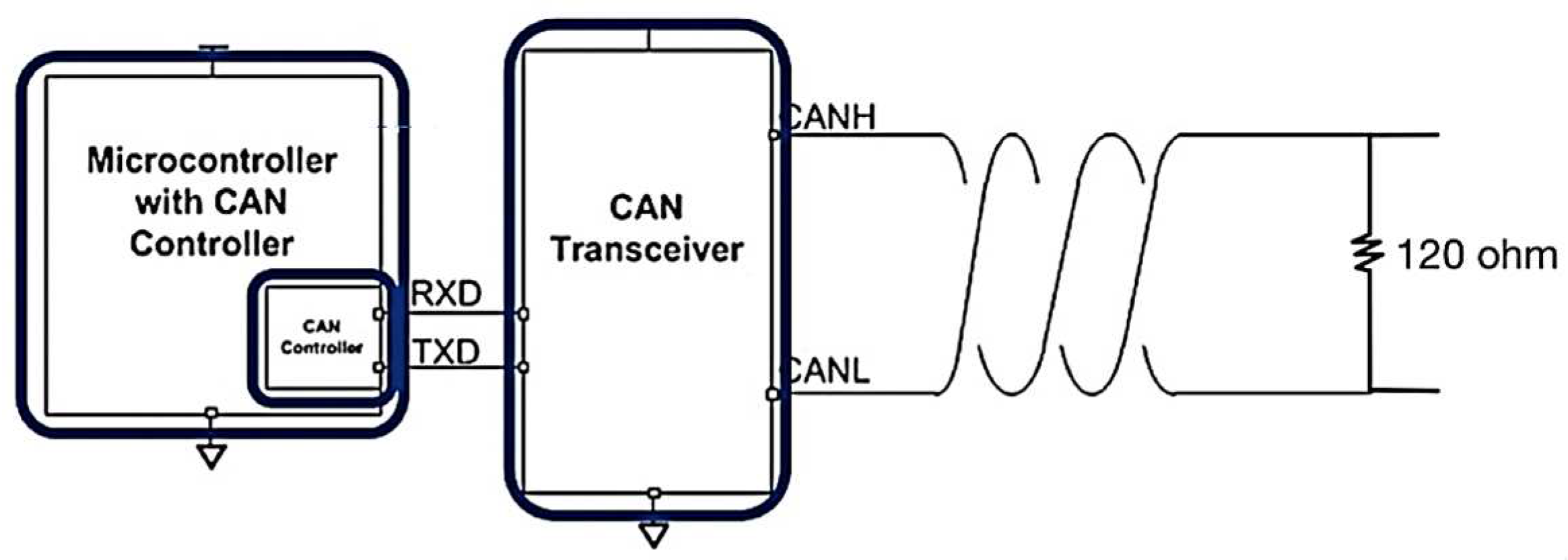

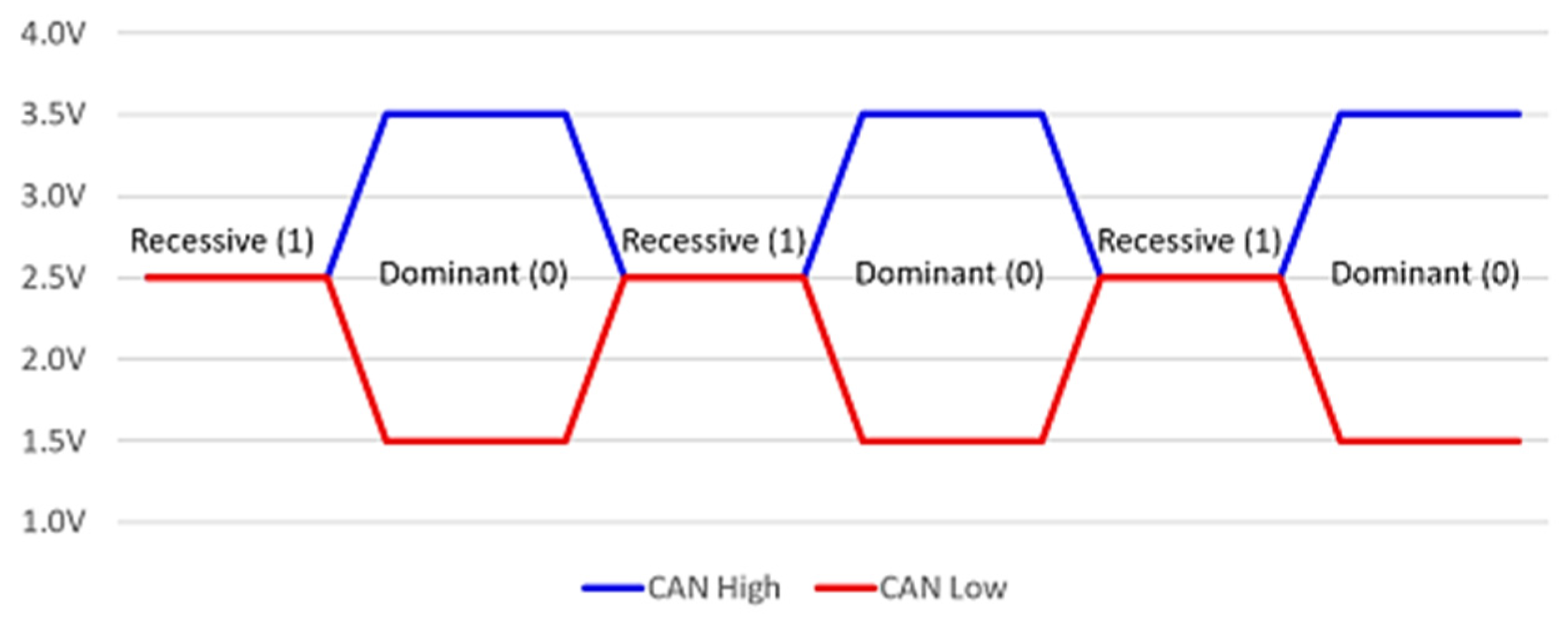

2.4. CAN Bus Controller.

3. RESEARCH AND METHODOLOGY

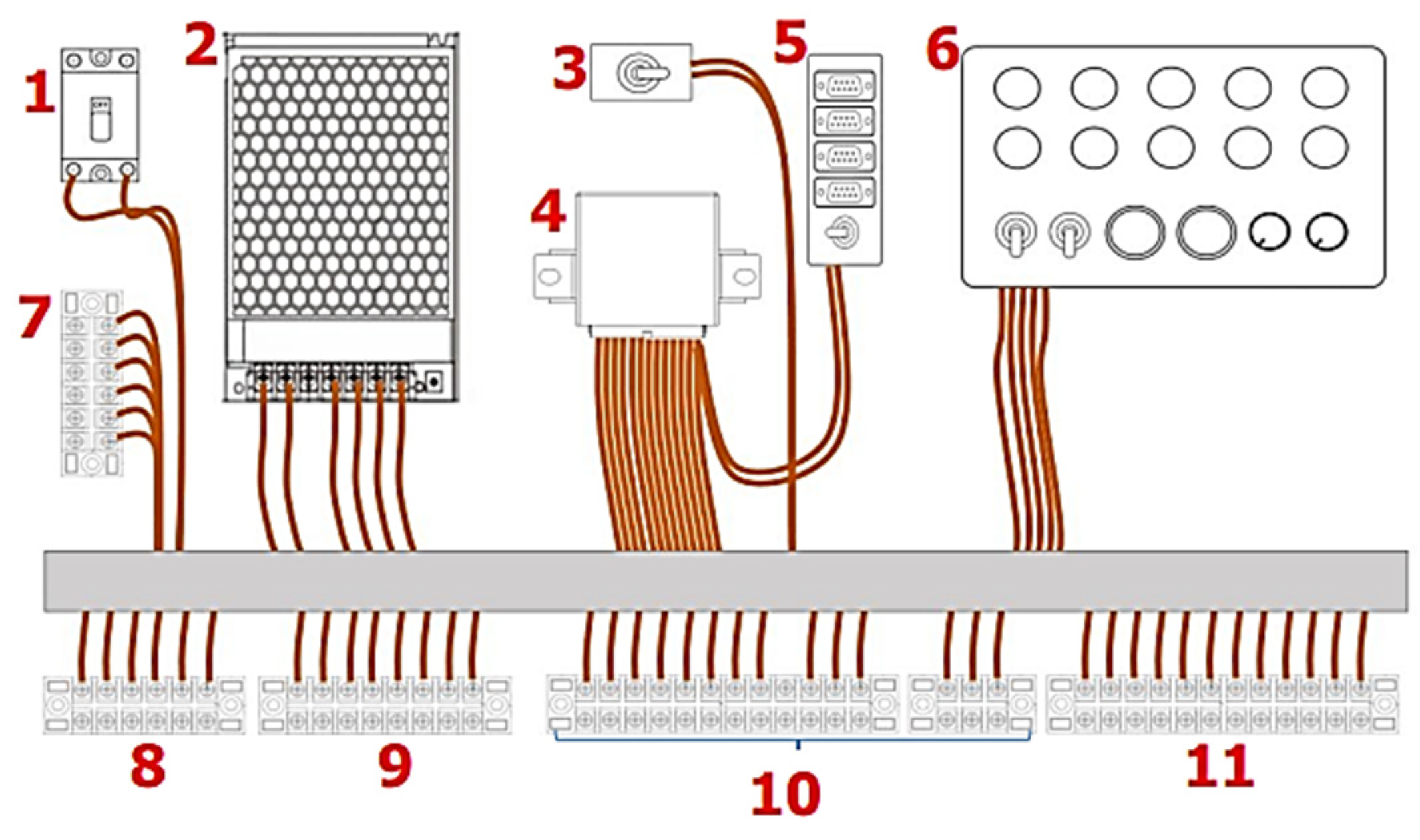

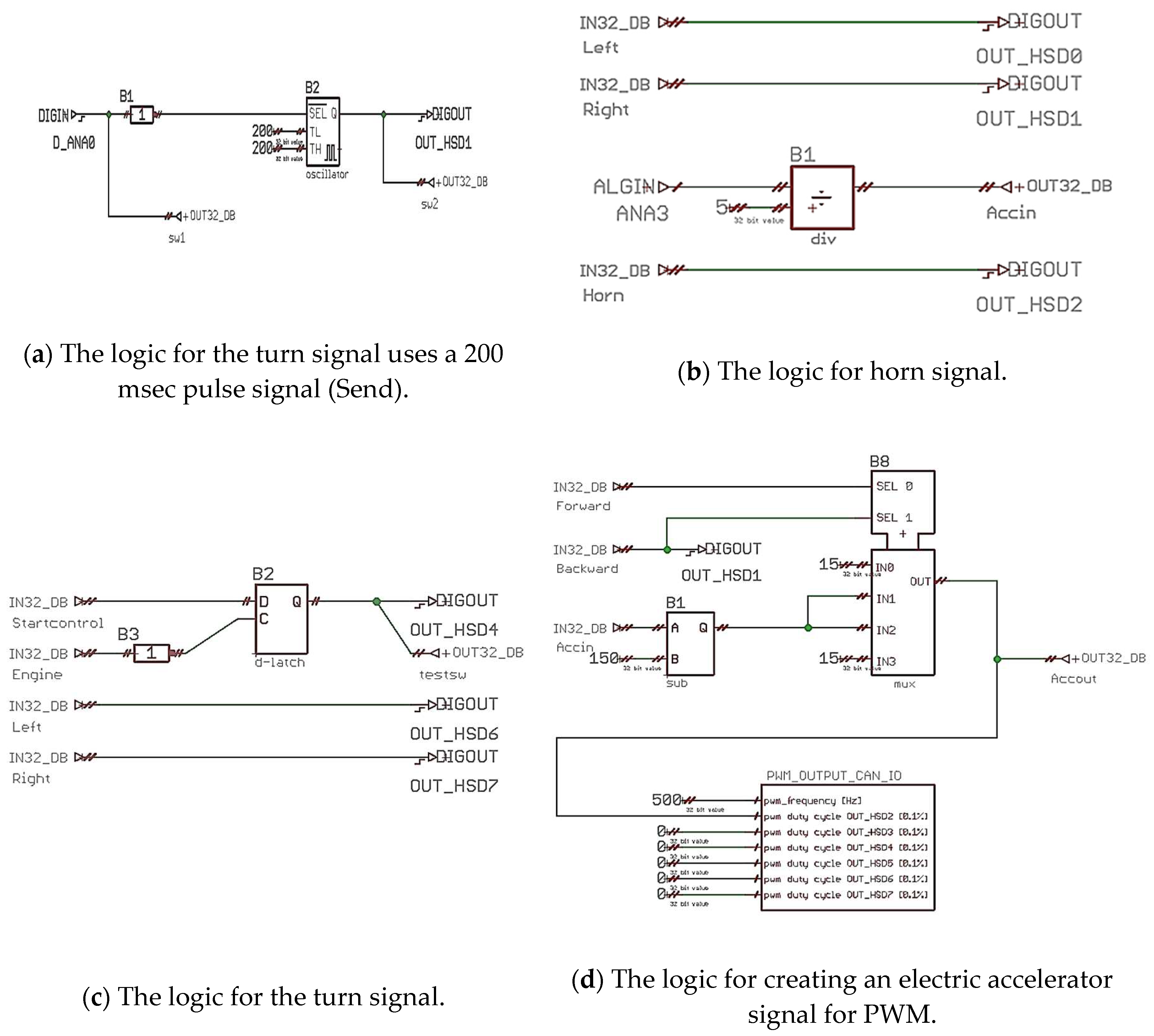

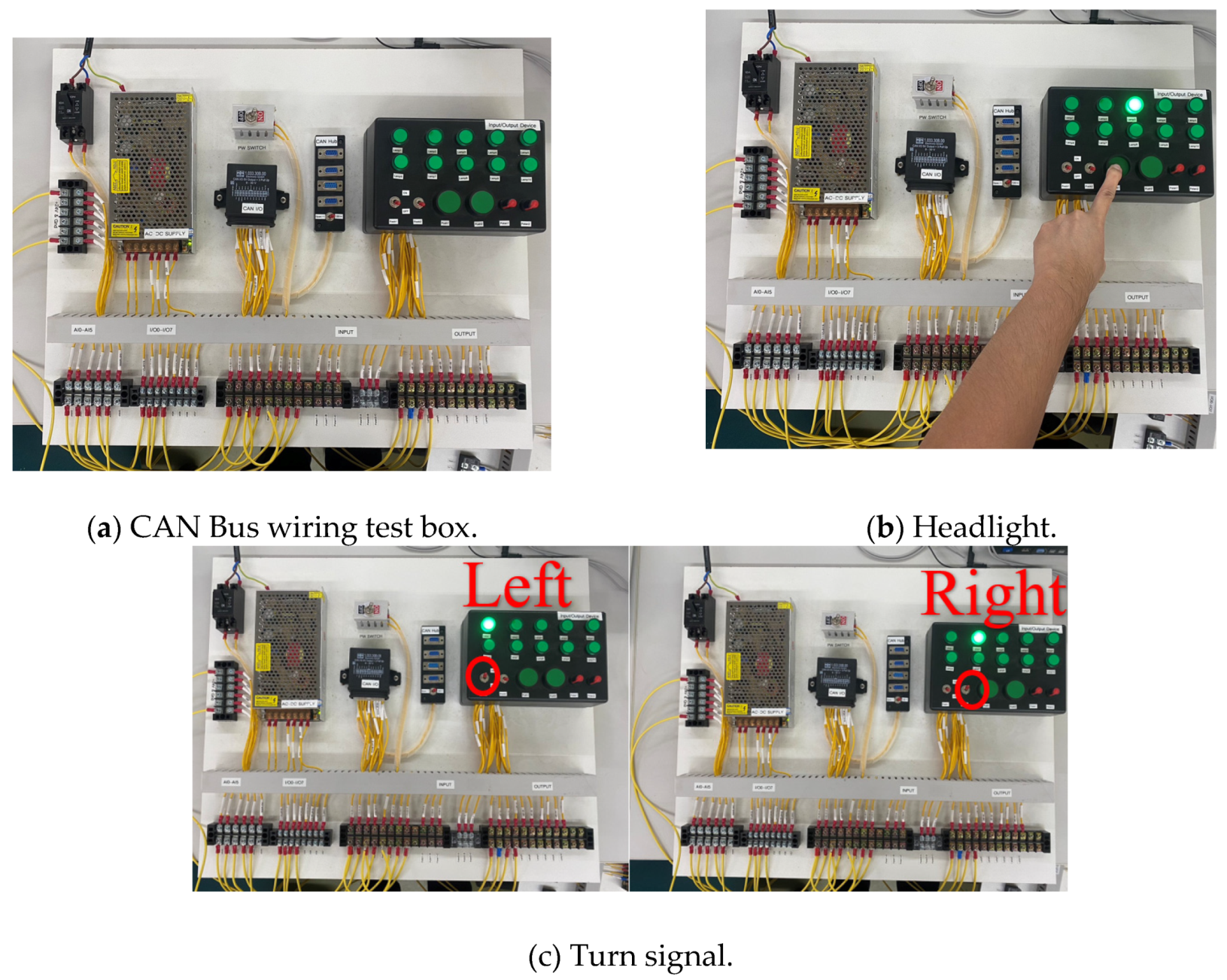

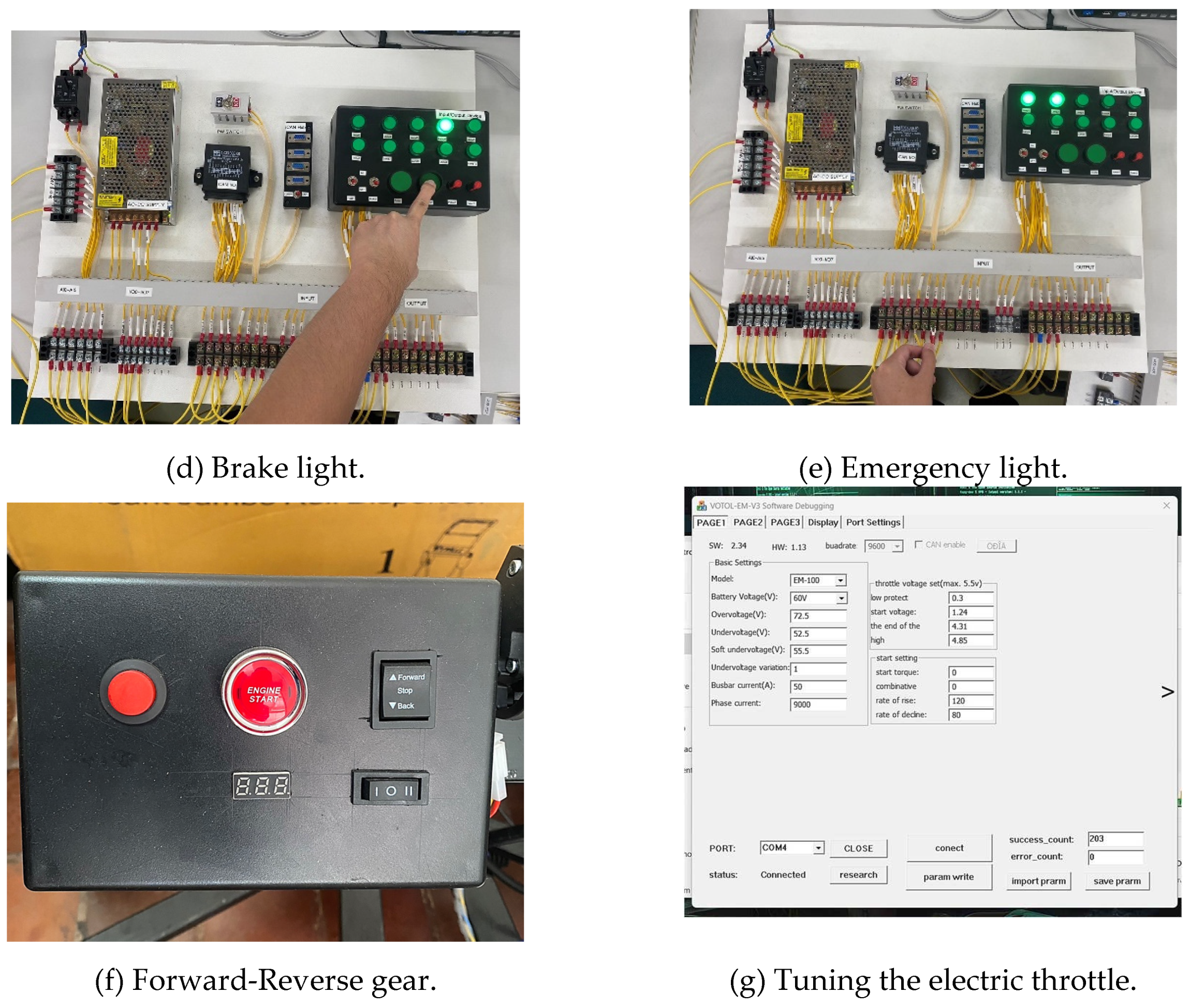

3.1. CAN Bus test box.

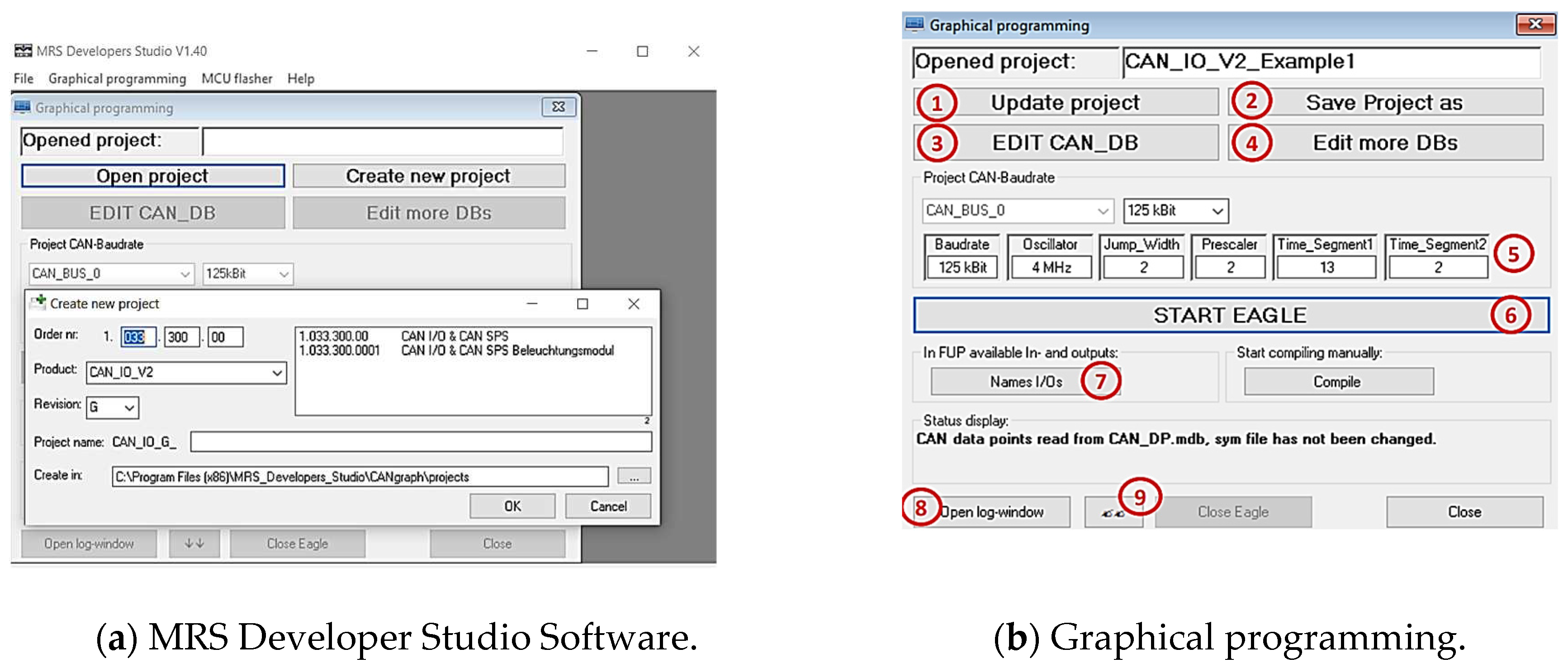

3.2. MRS Developers Studio.

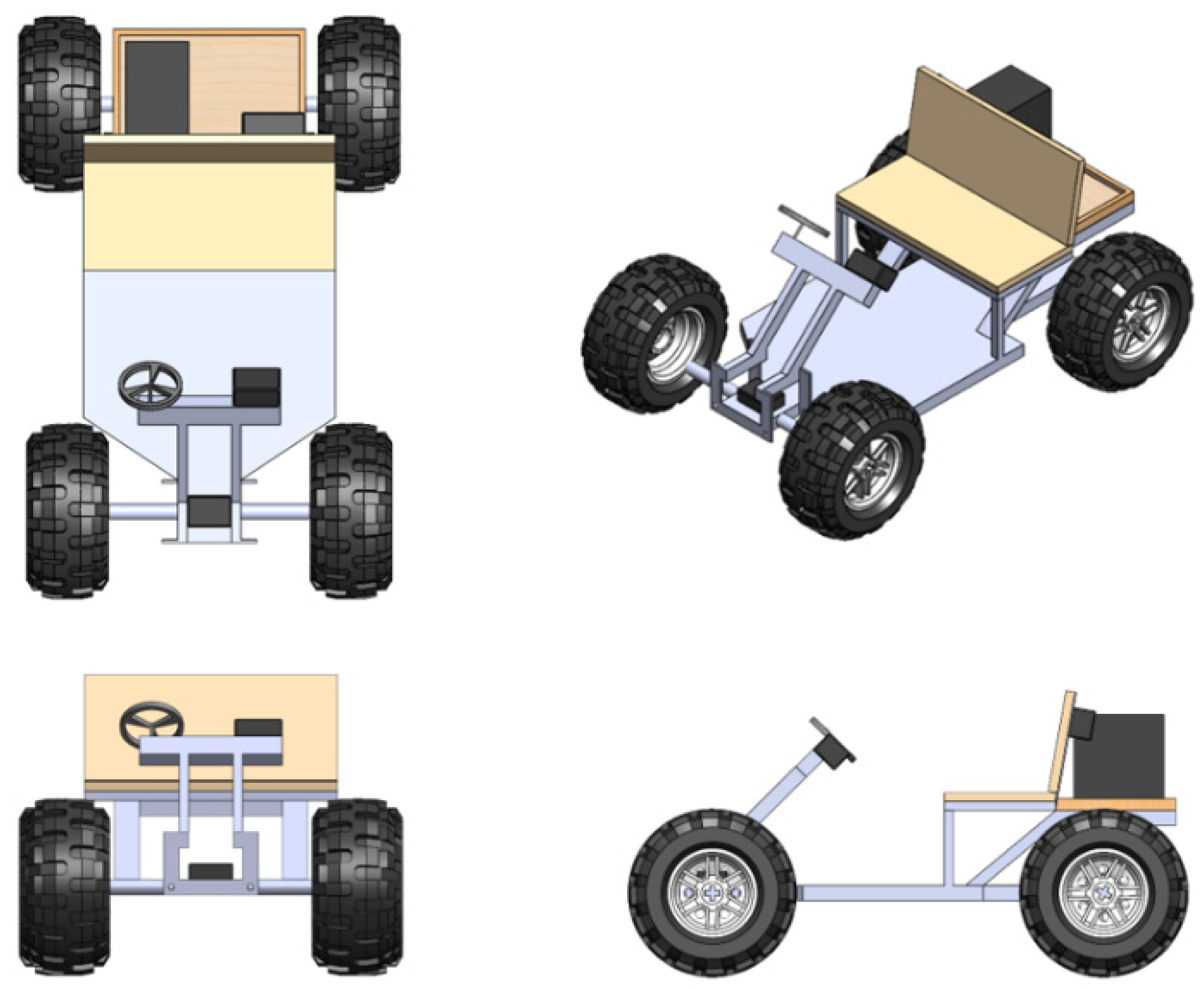

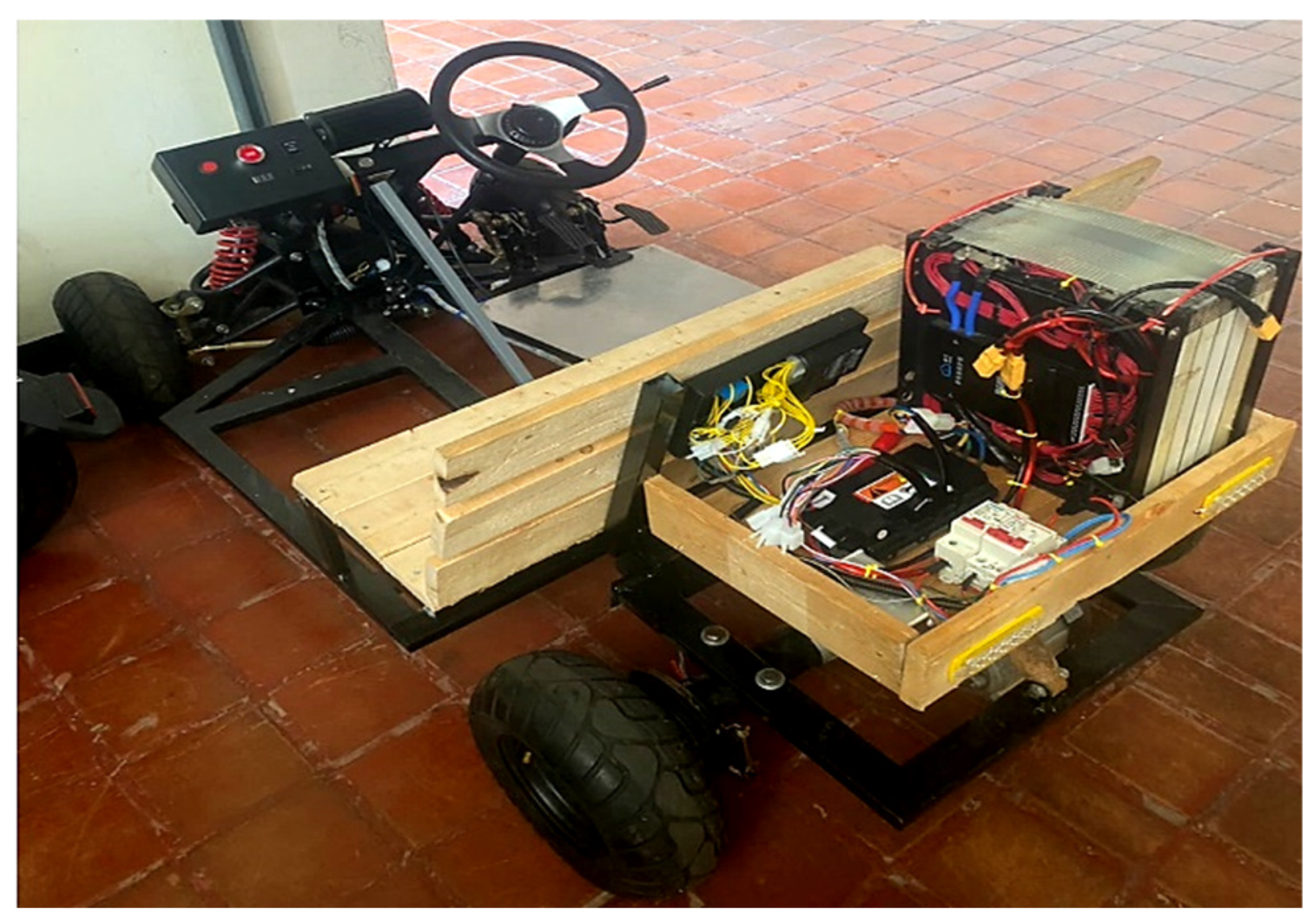

3.3. The Construction of Mechanical Structures.

4. RESULT

3.4. The Cost of electricity per battery charge.

- The electrical energy of the battery can be found from equation (2)

- The unit of electrical energy usage can be found from equation (3)

- Calculating the cost of electricity in Thailand can be found from equation (4)

5. CONCLUSION

Acknowledgments

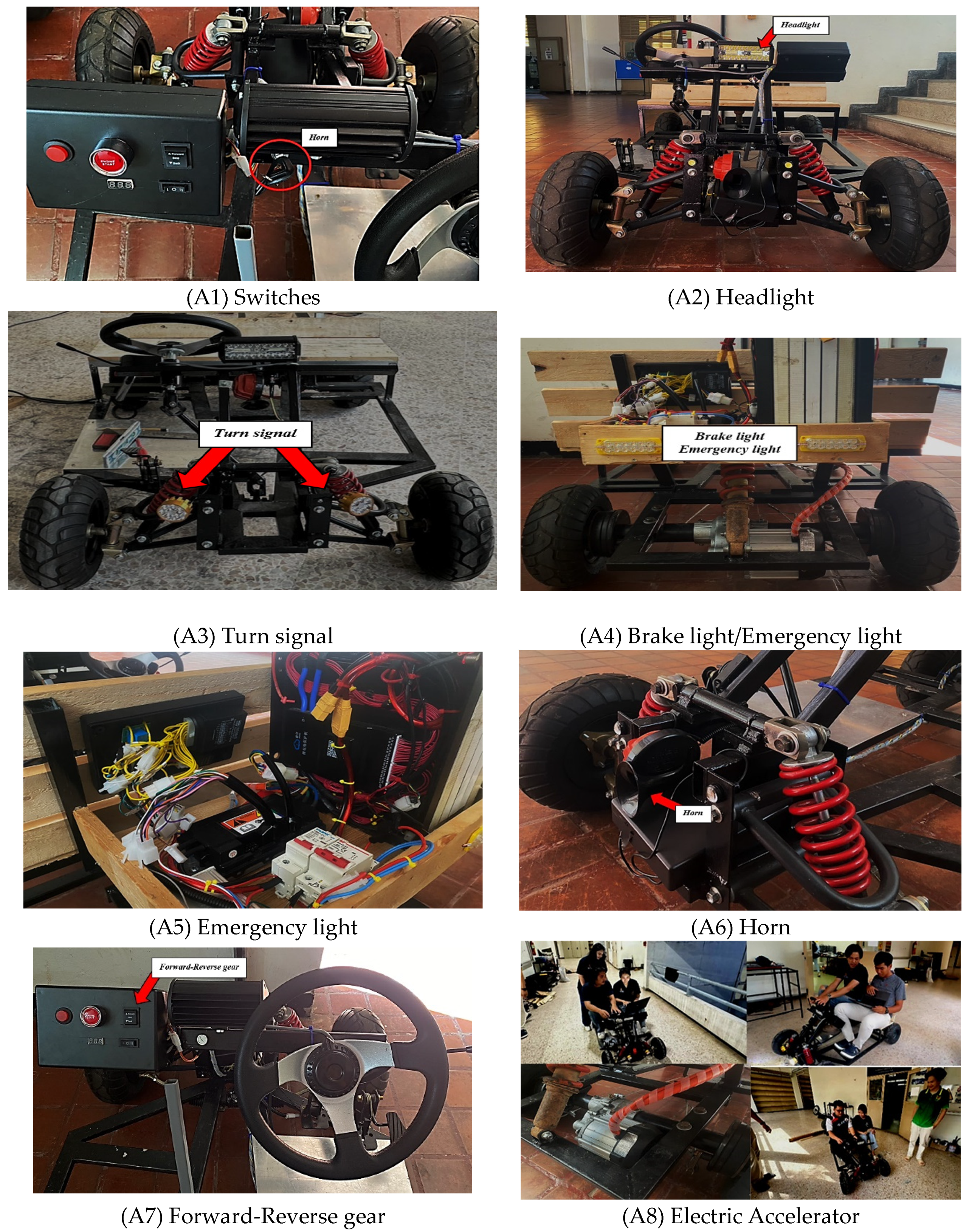

Appendix A: Testing the communication status in actual use

References

- Y. Yuan, "Research on Electric Vehicle Driverless Test System Based on Computer Big Data Technology," 2023 IEEE 2nd International Conference on Electrical Engineering, Big Data and Algorithms (EEBDA), Changchun, China, 2023, pp. 1018-1022. [CrossRef]

- M. MARINOV, J. PETROV, O. STANCHEV and P. ANDREEV, "Studying the Performance Characteristics of the Electric Vehicle," 2019 16th Conference on Electrical Machines, Drives and Power Systems (ELMA), Varna, Bulgaria, 2019, pp. 1-5. [CrossRef]

- B. Zhu et al., "The Design of Automatic Testing Platform on Electric Vehicle Off-Board Charger Interoperability," 2018 5th International Conference on Information Science and Control Engineering (ICISCE), Zhengzhou, China, 2018, pp. 1276-1279. [CrossRef]

- P. Pedret, G. Bayona, J. Webb, C. Moure and S. Boltshauser, "Control systems for high performance electric cars," 2013 World Electric Vehicle Symposium and Exhibition (EVS27), Barcelona, Spain, 2013, pp. 1-7. [CrossRef]

- Z. Wang and D. Yin, "Design and Implementation of Vehicle Control System for Pure Electric Vehicle Based on AUTOSAR Standard," 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 2019, pp. 1-5. [CrossRef]

- J. Valera, L. Huaman, L. Pasapera, E. Prada, L. Soto and L. Agapito, "Design of an autonomous electric single-seat vehicle based on environment recognition algorithms," 2019 IEEE Sciences and Humanities International Research Conference (SHIRCON), Lima, Peru, 2019, pp. 1-4. [CrossRef]

- S. Ledinger, D. Reihs, D. Stahleder and F. Lehfuss, "Test Device for Electric Vehicle Grid Integration," 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC / I&CPS Europe), Palermo, Italy, 2018, pp. 1-5. [CrossRef]

- V. Totev and V. Gueorgiev, "Batteries of Electric Vehicles," 2021 13th Electrical Engineering Faculty Conference (BulEF), Varna, Bulgaria, 2021, pp. 1-6. [CrossRef]

- R. Hou, L. Zhai, T. Sun, Y. Hou and G. Hu, "Steering Stability Control of a Four In-Wheel Motor Drive Electric Vehicle on a Road with Varying Adhesion Coefficient," in IEEE Access, vol. 7, pp. 32617-32627. [CrossRef]

- W. Cao, Z. Zhu, J. Nan, Q. Yang, G. Gu and H. He, "An Improved Motion Control with Cyber-Physical Uncertainty Tolerance for Distributed Drive Electric Vehicle," in IEEE Access, vol. 10, pp. 770-778. [CrossRef]

- E. Siriboonpanit, K. Sasiwimonrit, J. Saelao and N. Patcharaprakiti, "An Air Force Cooling of Lithium–ion Battery Thermal Management System for Heat Eliminating in Modified Electric Vehicle," 2022 International Electrical Engineering Congress (iEECON), Khon Kaen, Thailand, 2022, pp. 1-4. [CrossRef]

- J. Ouyang, D. Xiang and J. Li, "State-of-function evaluation for lithium-ion power battery pack based on fuzzy logic control algorithm," 2020 IEEE 9th Joint International Information Technology and Artificial Intelligence Conference (ITAIC), Chongqing, China, 2020, pp. 822-826. [CrossRef]

- Wang Dafang, Nan Jinrui and Sun Fengchun, "The application of CAN communication in distributed control system of electric city bus," 2008 IEEE Vehicle Power and Propulsion Conference, Harbin, China, 2008, pp. 1-4. [CrossRef]

- Li Ran, Wu Junfeng, Wang Haiying and Li Gechen, "Design method of CAN BUS network communication structure for electric vehicle," International Forum on Strategic Technology 2010, Ulsan, Korea (South), 2010, pp. 326-329. [CrossRef]

- Jinrui Nan, Li Zai, Zhifu Wang and Jun Wang, "Bus Communication and Control Protocol Using the Electric Passenger Car Control System," 2006 6th World Congress on Intelligent Control and Automation, Dalian, 2006, pp. 8288-8291. [CrossRef]

- Z. Wei, B. Li, R. Zhang and X. Cheng, "Contract-Based Charging Protocol for Electric Vehicles With Vehicular Fog Computing: An Integrated Charging and Computing Perspective," in IEEE Internet of Things Journal, vol. 10, no. 9, pp. 7667-7680, 1 May1, 2023. [CrossRef]

- H. Liu, X. Liang, L. Fang, B. Zhang and J. -W. Zhao, "A Secure and Efficient Authentication Protocol Based on Identity Based Aggregate Signature for Electric Vehicle," 2014 International Conference on Wireless Communication and Sensor Network, Wuhan, China, 2014, pp. 353-357. [CrossRef]

- A. Wicaksono and A. S. Prihatmanto, "Optimal control system design for electric vehicle," 2015 4th International Conference on Interactive Digital Media (ICIDM), Bandung, Indonesia, 2015, pp. 1-6. [CrossRef]

- J. Ni, J. Hu and C. Xiang, "Control-Configured-Vehicle Design and Implementation on an X-by-Wire Electric Vehicle," in IEEE Transactions on Vehicular Technology, vol. 67, no. 5, pp. 3755-3766, May 2018. [CrossRef]

- L. Krčmář, J. Břoušek and T. Petr, "Design of Rear Wheel Steering System of an Experimental Electric Vehicle," 2019 International Conference on Electrical Drives & Power Electronics (EDPE), The High Tatras, Slovakia, 2019, pp. 207-210. [CrossRef]

- M. Evzelman, M. M. Ur Rehman, K. Hathaway, R. Zane, D. Costinett and D. Maksimovic, "Active Balancing System for Electric Vehicles with Incorporated Low-Voltage Bus," in IEEE Transactions on Power Electronics, vol. 31, no. 11, pp. 7887-7895. [CrossRef]

- X. Zeng, H. Jing, B. Kuang, F. Chen, W. An and S. Zhao, "Speed Control of Four-Wheel Independently Actuated Vehicle based on MPC Algorithm," 2019 3rd Conference on Vehicle Control and Intelligence (CVCI), Hefei, China, 2019, pp. 1-6. [CrossRef]

- C. Tang, M. Ataei and A. Khajepour, "A Reconfigurable Integrated Control for Narrow Tilting Vehicles," in IEEE Transactions on Vehicular Technology, vol. 68, no. 1, pp. 234-244. [CrossRef]

- H. Xiong, Z. Tan, R. Zhang and S. He, "A New Dual Axle Drive Optimization Control Strategy for Electric Vehicles Using Vehicle-to-Infrastructure Communications," in IEEE Transactions on Industrial Informatics, vol. 16, no. 4, pp. 2574-2582, April 2020. [CrossRef]

- H. Kobayashi, M. Kohriyama, M. Nagata and S. Ohashi, "Study of Deceleration Control using the Power Regenerative Brake to Improve the Ride Comfort in the Electric Vehicle," 2020 23rd International Conference on Electrical Machines and Systems (ICEMS), Hamamatsu, Japan, 2020, pp. 2046-2049. [CrossRef]

- L. Suo and J. Sun, "Design and development of ternary logic sinusoidal pulse width modulated rectifier for electric vehicle charging-discharging device," 2019 IEEE 2nd International Conference on Automation, Electronics and Electrical Engineering (AUTEEE), Shenyang, China, 2019, pp. 418-423. [CrossRef]

- A. -M. Căilean and M. Dimian, "Current Challenges for Visible Light Communications Usage in Vehicle Applications: A Survey," in IEEE Communications Surveys & Tutorials, vol. 19, no. 4, pp. 2681-2703, Fourthquarter 2017. [CrossRef]

- W. Wang, Z. Han, M. Alazab, T. R. Gadekallu, X. Zhou and C. Su, "Ultra Super-Fast Authentication Protocol for Electric Vehicle Charging Using Extended Chaotic Maps," in IEEE Transactions on Industry Applications, vol. 58, no. 5, pp. 5616-5623, Sept.-Oct. 2022. [CrossRef]

- Z. Garofalaki, D. Kosmanos, S. Moschoyiannis, D. Kallergis and C. Douligeris, "Electric Vehicle Charging: A Survey on the Security Issues and Challenges of the Open Charge Point Protocol (OCPP)," in IEEE Communications Surveys & Tutorials, vol. 24, no. 3, pp. 1504-1533, thirdquarter 2022. [CrossRef]

- Song Xuehua, Lu Min, Wu Hesheng, Wang Hong and Liu Fei, "The solution of hybrid electric vehicle information system by modbus protocol," 2011 International Conference on Electric Information and Control Engineering, Wuhan, 2011, pp. 891-894. [CrossRef]

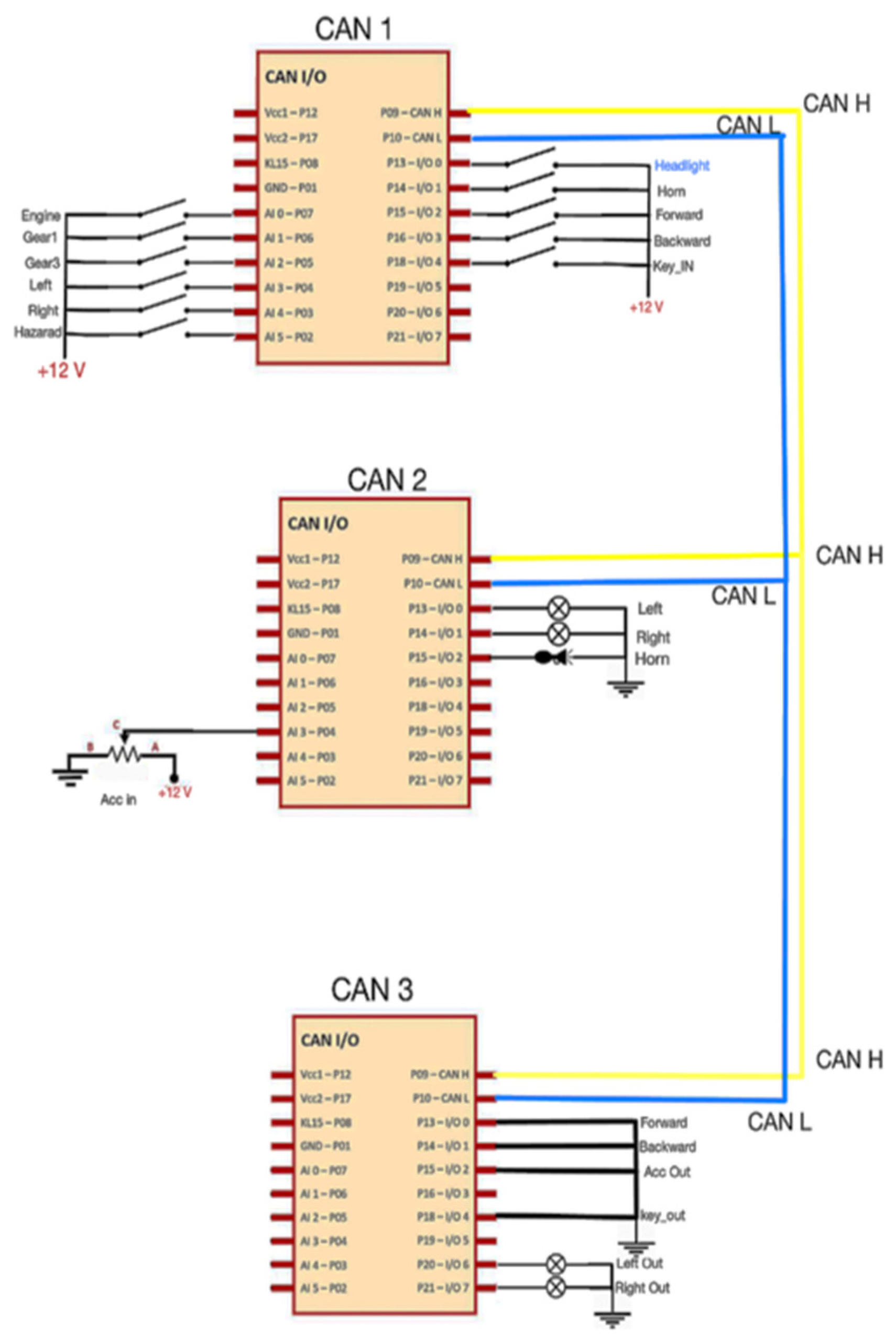

| Materials and Equipment | Units |

|---|---|

| Push Button Start | 1 |

| Electric car headlights | 1 |

| Klaxon (Horn) | 1 |

| Front turn signal | 2 |

| Back turn signal | 2 |

| CAN connector line | 2 |

| CAN Controller Box | 3 |

| DC to DC Step down (72V to 12V) | 1 |

| Battery Pack 72 V (Li-ion: NMC) | 1 |

| Motor DC 1500W 60V | 1 |

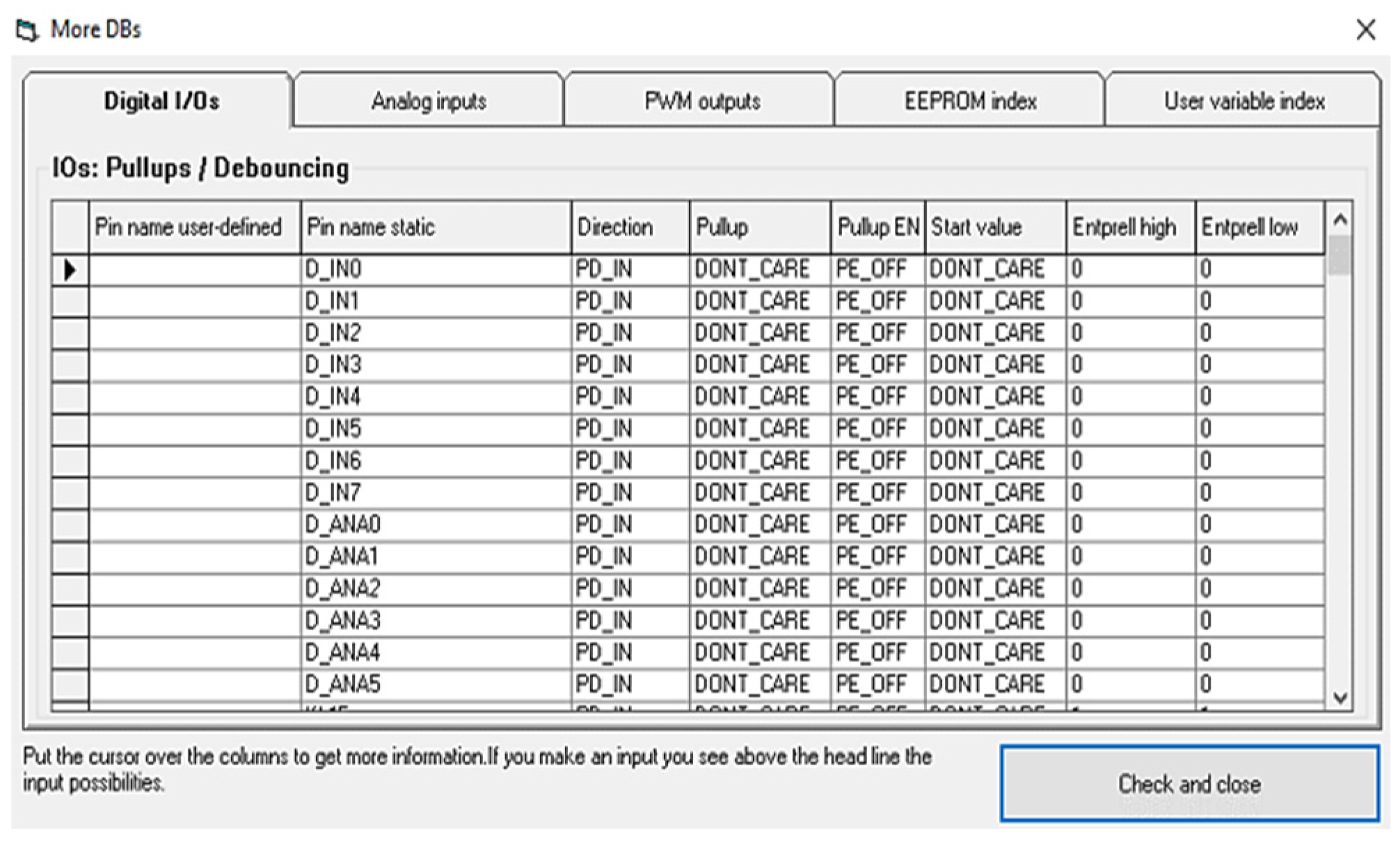

| Number | Materials and Equipment |

|---|---|

| 1 | Circuit Breaker |

| 2 | AC/DC switching |

| 3 | Power Switch |

| 4 | CAN I/O |

| 5 | The CAN hub |

| 6 | Input/output Device |

| 7 | +24V and Gnd. Terminal |

| 8 | Analog Inputs Terminal of CAN I/O |

| 9 | Input/output Terminal of CAN I/O |

| 10 | Input Terminal of input/output device |

| 11 | Output Terminal of input/output device |

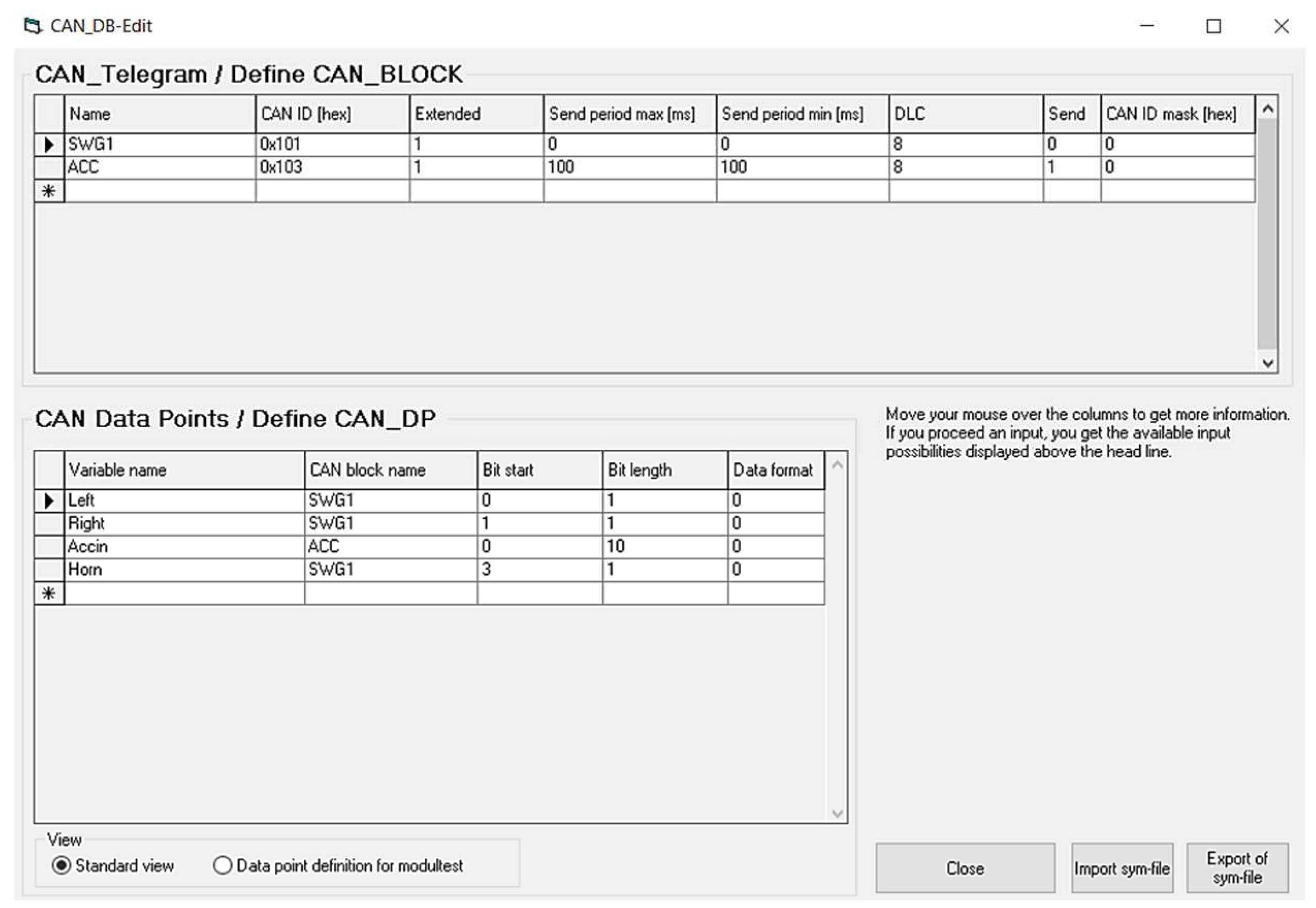

| Header | Description |

|---|---|

| Name | Name of the CAN-Block |

| CAN ID [hex] | CAN-Identifier from CAN-Block in [hex] |

| Extended | 0 is 11 bits identifier, 1 is 29 bits identifier |

| Send period max | Time of send period max |

| Send period min | Time of send period min |

| Data length | Length of the CAN frame data in byte |

| Send | 0 is CAN-Block received the CAN bus1 is CAN-Block send to the CAN bus |

| CAN ID mask | When you want to listen to variable CAN ID information. (EX: 0x10F, 0x100, ...) |

| Header | Description |

|---|---|

| Variable name | Name of the data point |

| CAN block name | Definition of linked CAN-block (Write down in which CAN-block the variable is to be found) |

| Bit start | 0 ... 63, start position of the data into the CAN frame data area |

| Bit length | Length of the information in bits |

|

Testing CAN Bus communication |

Testing (Counts) | ||

| 1 | 100 | 1000 | |

| Switches | ✓ | ✓ | ✓ |

| Headlights | ✓ | ✓ | ✓ |

| Turn signal | ✓ | ✓ | ✓ |

| Brake light | ✓ | ✓ | ✓ |

| Emergency light | ✓ | ✓ | ✓ |

| Horn | ✓ | ✓ | ✓ |

| Forward-Reverse gear | ✓ | ✓ | ✓ |

| Electric Accelerator | ✓ | ✓ | ✓ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).