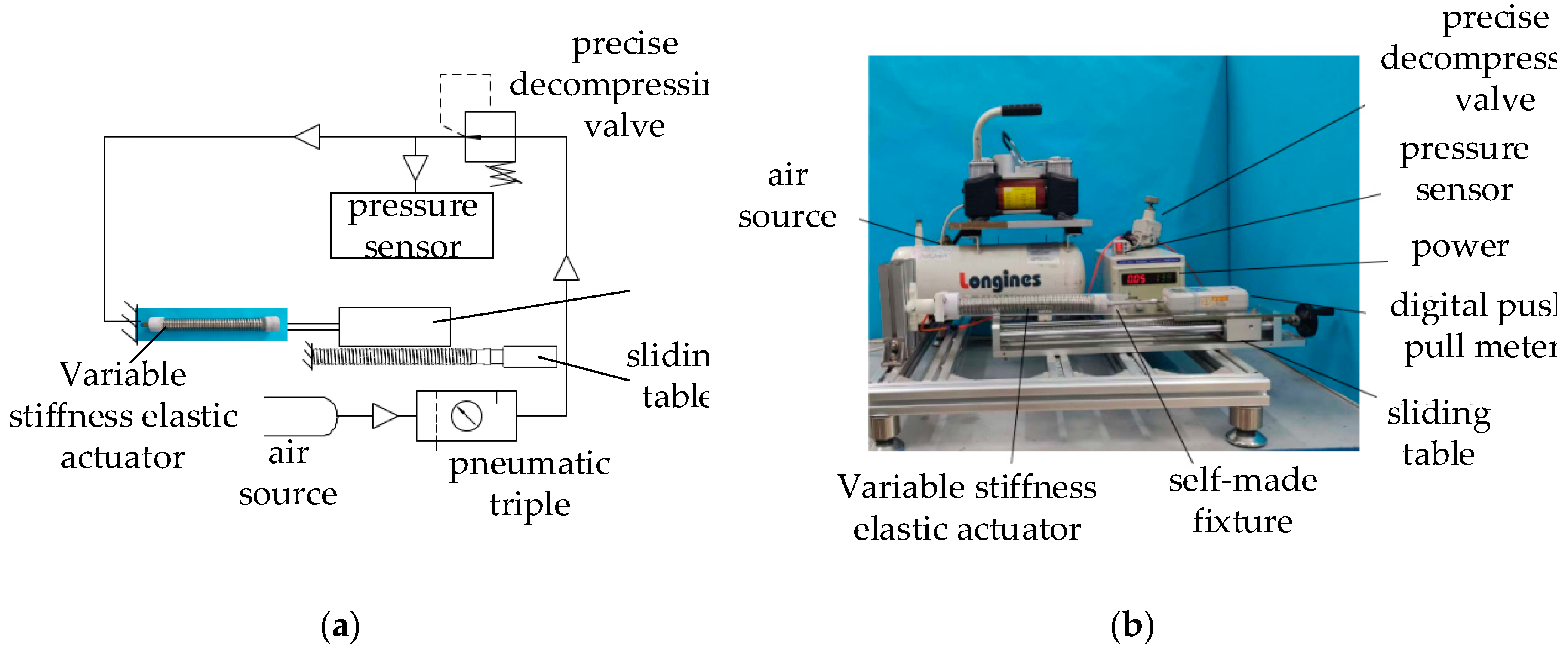

The variable-stiffness elastic actuator is applied to the flexible arm as a driving device and realize the variable-stiffness function of the flexible arm at the same time. During the movement of the flexible arm, the actuator mainly bears axial force and lateral force. Therefore, the anti-tensile, anti-compressive and lateral stiffness are mainly studied.

3.1. Anti-tensile stiffness at any position of variable-stiffness elastic actuator

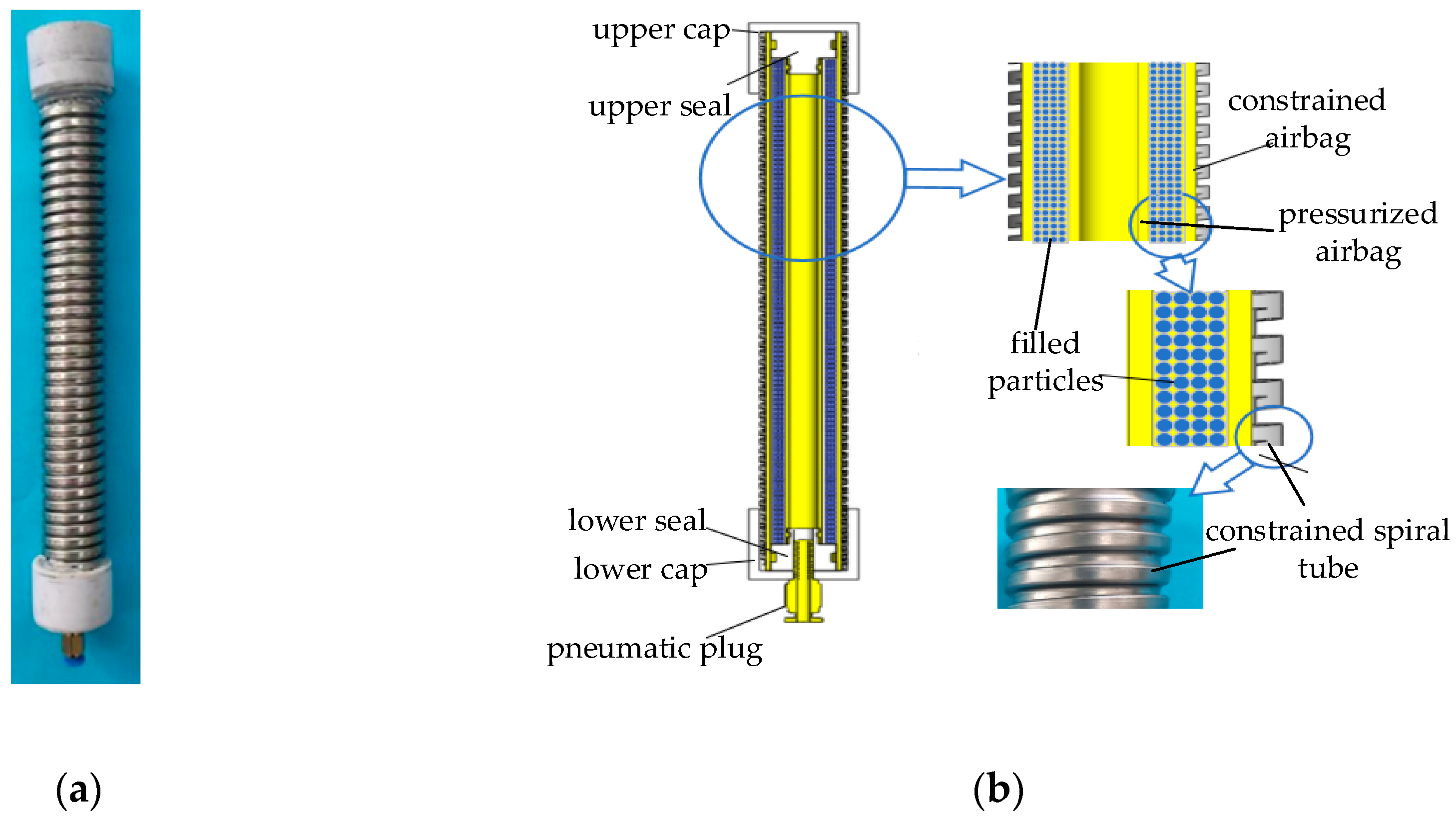

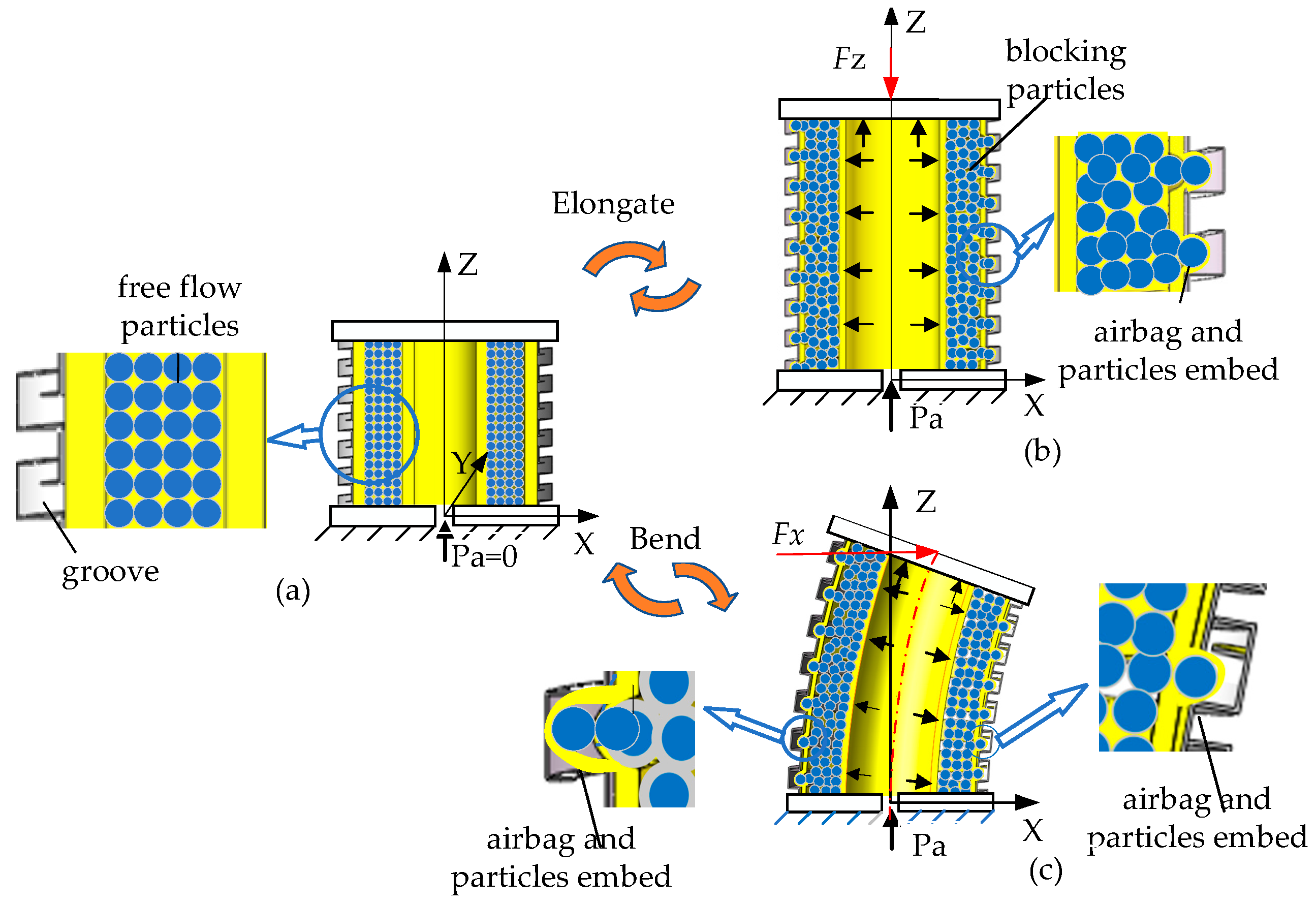

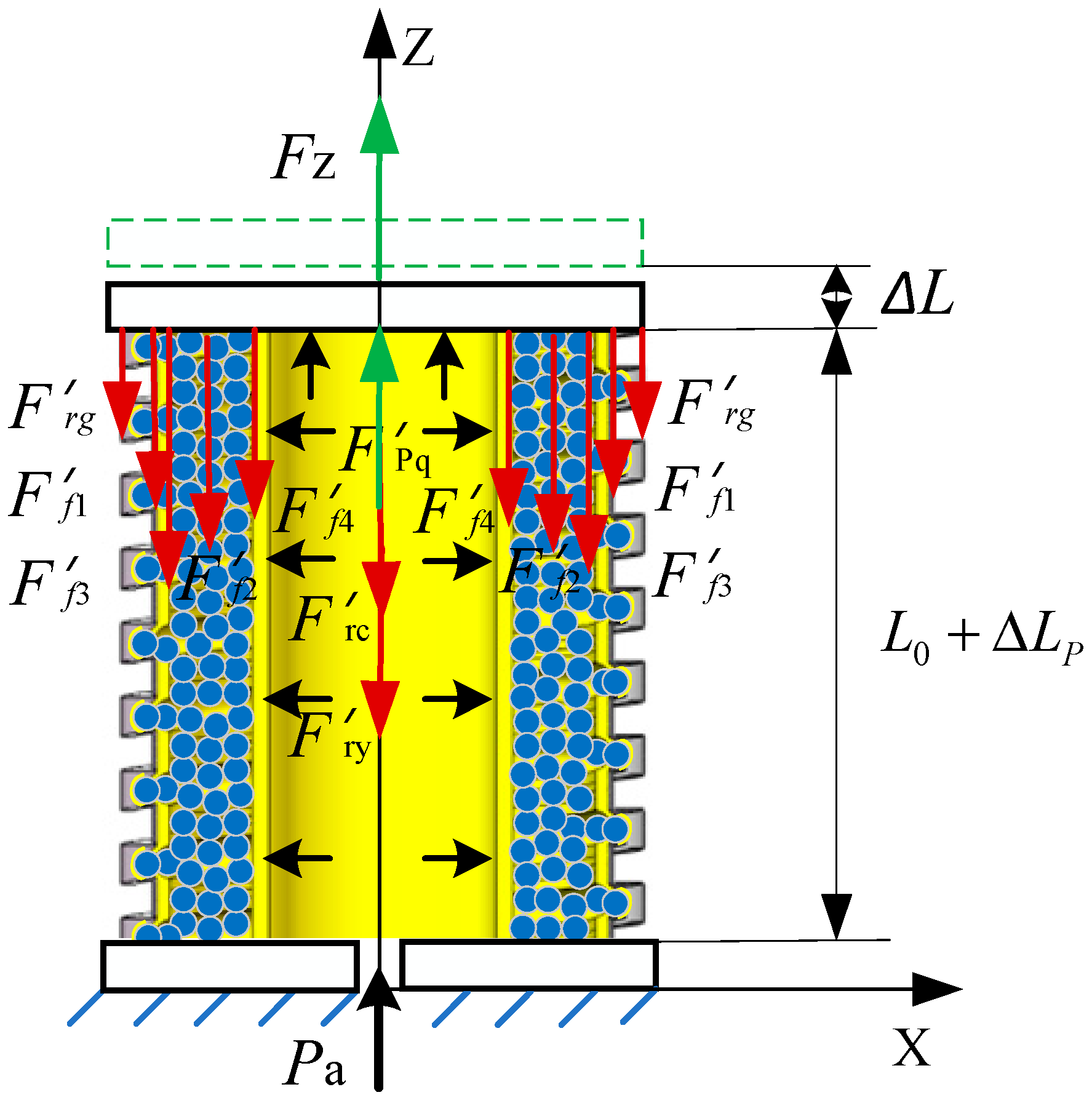

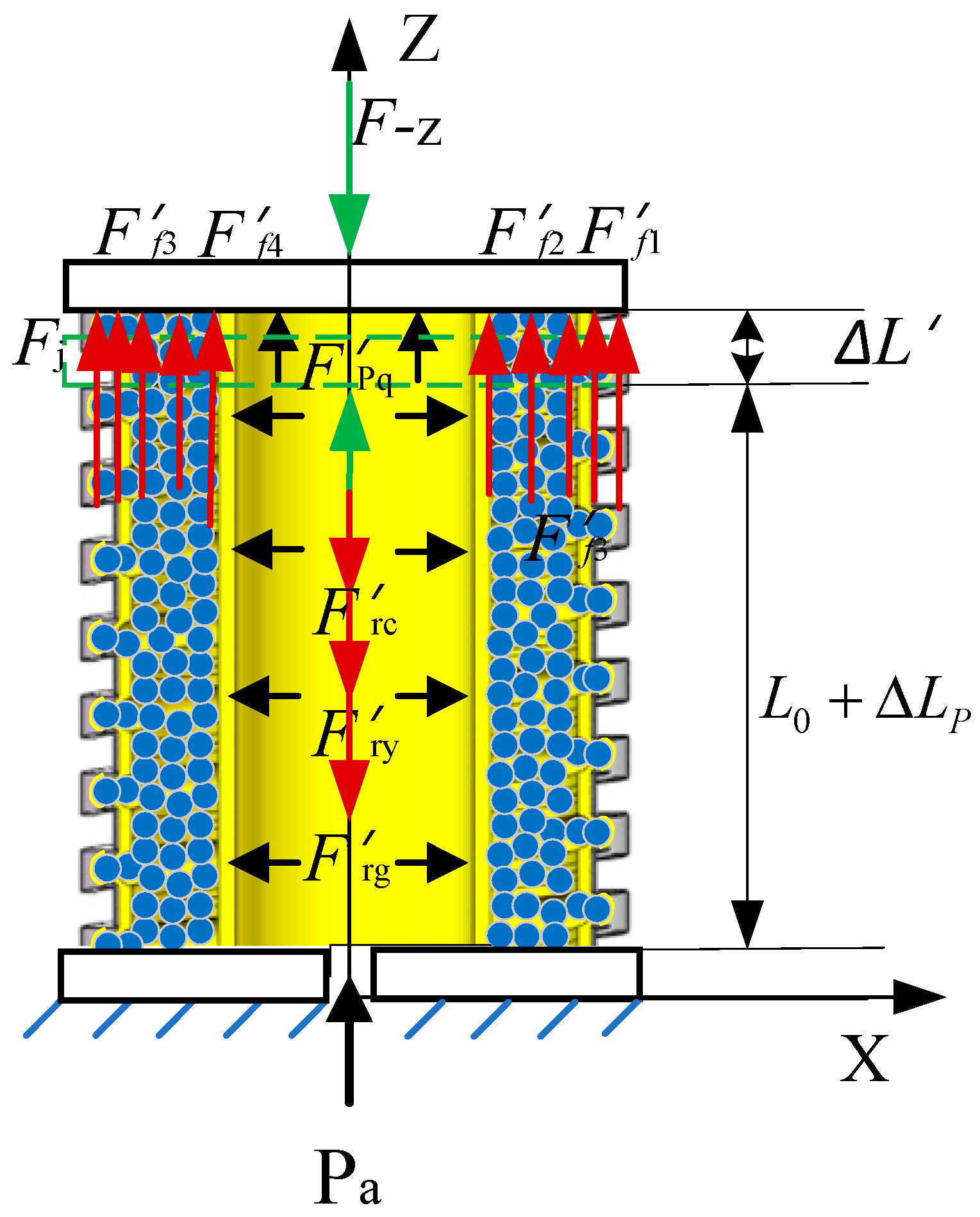

As illustrated in

Figure 3, the actuator undergo axial elongation

due to applied air pressure. In this state, a axial force

Fz is applied at the center of the upper-end cover, causing the actuator to elongate and deform As a result, the center point of the upper-end cover moves

along the axis direction. The internal friction contributing to the impedance moment mainly includes frictional interactions in various regions: between the constrained airbag and the spiral tube, among the filling particles and the constrained airbag, and finally, between the filling particles and pressurized airbag. The constrained airbag , pressurized airbag and spiral tube generate deformation impedance force.

The static equilibrium equation of the variable-stiffness elastic actuator is as follows:

In the formula, is the driving force, is the friction impedance forces between the constrained airbag and the constrained spiral tube, between the filling particles, between the filling particles and the constrained airbag, and between the filling particles and the pressurized airbag, is the axial deformation impedance force of constrained airbag, pressurized airbag and constrained spiral tube.

The driving force is given by:

where

represents the air pressure applied to the pressurized airbag,

denotes the cross-sectional area of the cavity after the pressurized airbag has deformed.

Both the constrained and pressurized airbags are fabricated from silicon-fluorine rubber—a highly elastic and incompressible material—ensuring that the annular volume remains constant after deformation. The constrained spiral tube is made of a rigid material, so its internal cross-sectional area remains unchanged before and after deformation. Consequently, any volume change in the inner cavity of the constrained spiral tube directly reflects the volume change in the inner cavity of the pressurized airbag.

where

represents the cross-sectional area of the inner wall of the spiral tube.

denotes the initial effective length of the variable-stiffness elastic actuator.

symbolizes the initial cross-sectional area of the cavity in the pressurized airbag.

where

stands for the diameter of the inner wall of the spiral tube.

where

represents the initial diameter of the inner wall of the pressurized airbag.

The effective working area of the pressurized airbag is defined by the cross-sectional area of its cavity.

Substituting Equation (6) into Equation (2), the driving force is

- 2.

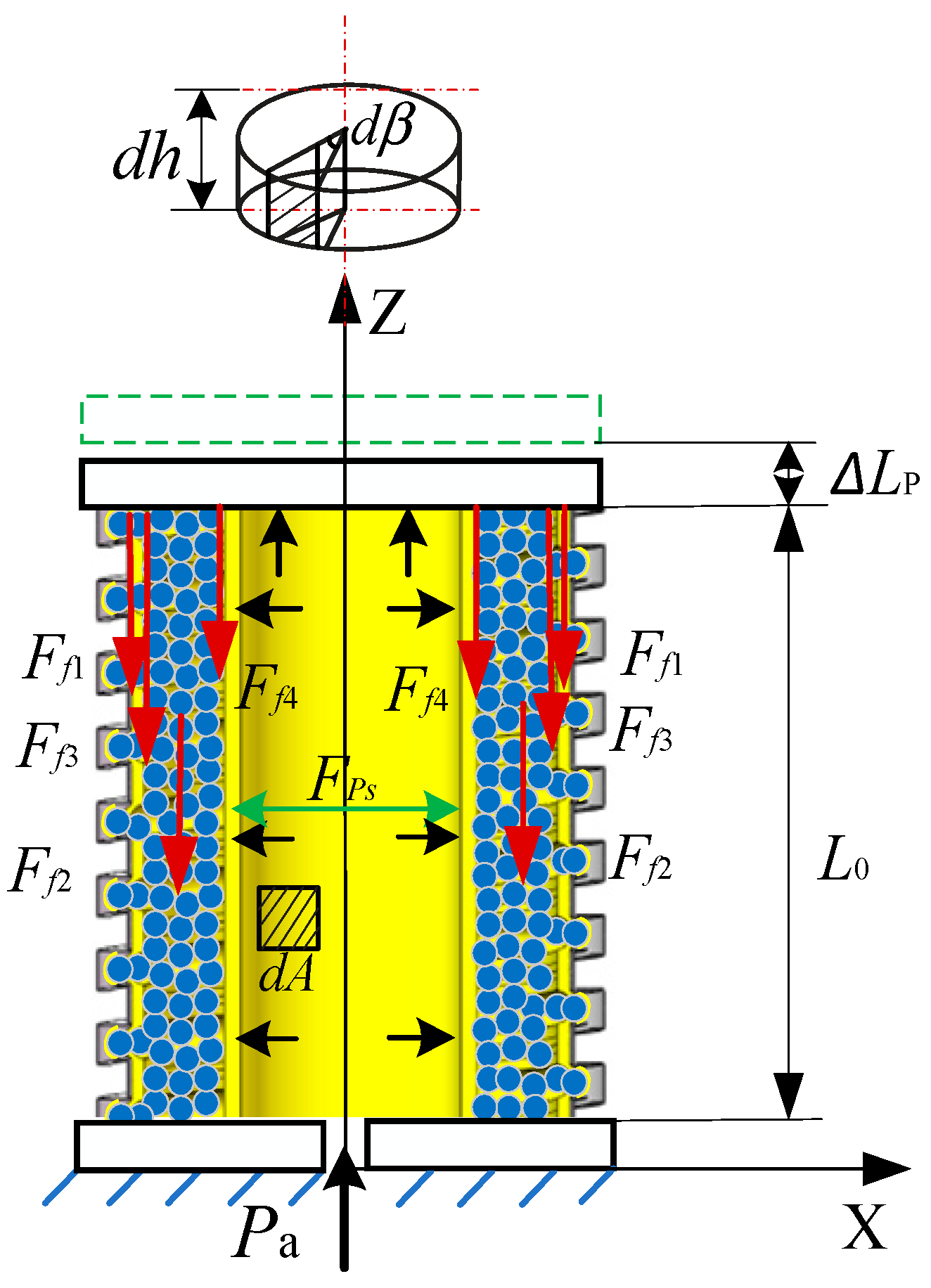

Friction impedance Force

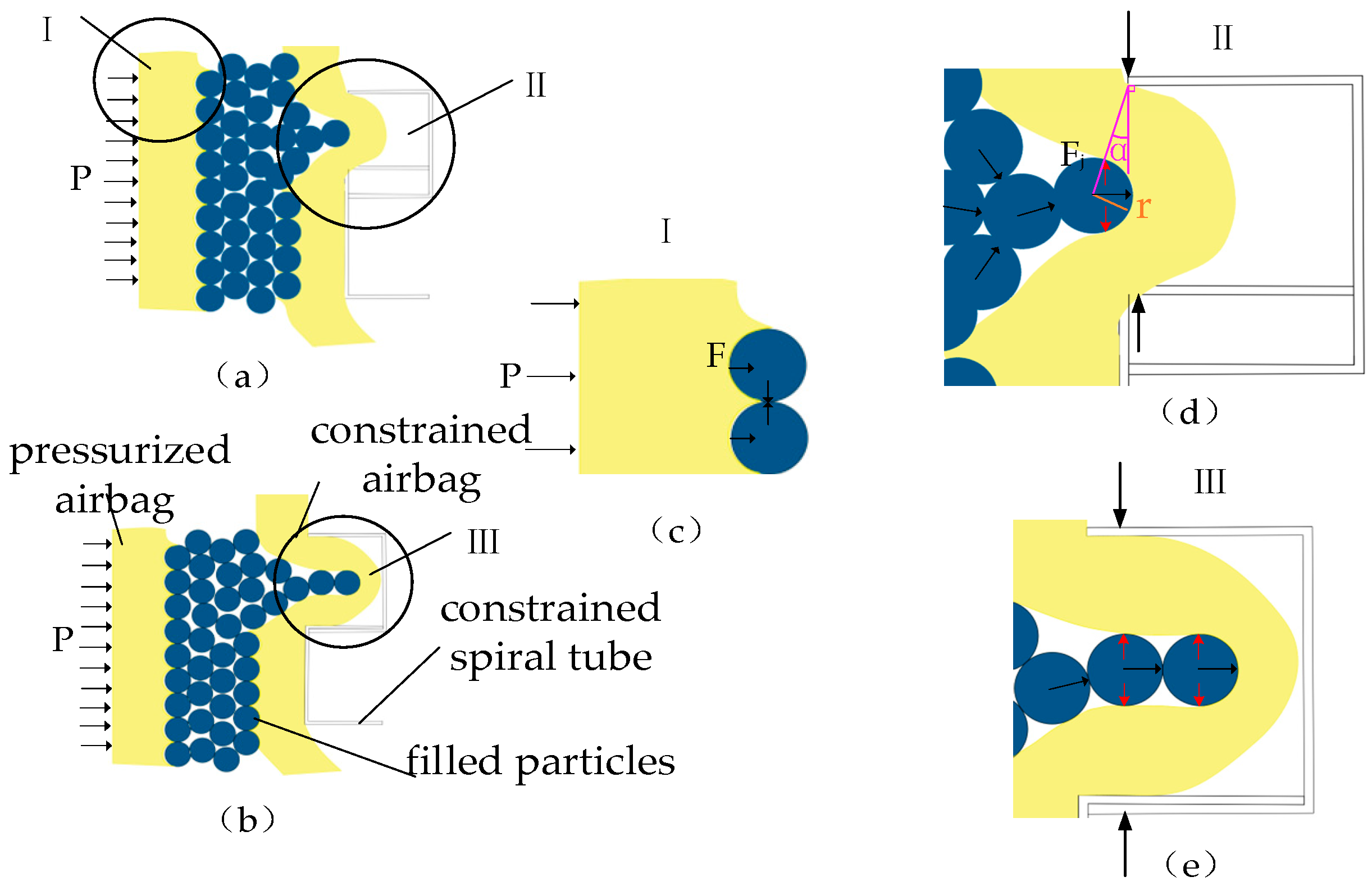

As the actuator expands under pressure, a positive pressure is generated on the inner wall surface of the pressurized airbag, generating a friction impedance force among the actuator's components. (

Figure 4).

Where, is the pressure on the micro-unit inner wall surface of the pressurized airbag, represents the area of the micro-unit side after the airbag is pressurized and deformed. represents the annular angle of the micro-unit on the inner wall surface. denotes the height of the micro-unit on the inner wall surface.

The friction force between the constrained airbag and the spiral tube is:

Where is the friction coefficient between the constrained airbag and spiral tube,

The axial friction force among the filling particles is

Where, signifies the friction coefficient between the particles, denotes the particle correction coefficient,

The friction force among the constrained airbag and particles is

Where, is the friction coefficient between particles and constrained airbag.

The friction between particles and pressurized airbag is

Where, is the friction coefficient between particles and pressurized airbag.

- 3.

Deformation impedance force

The variable-stiffness elastic actuator moves ∆L axial elongation under the action of external force

Fz. According to the principle of elastic deformation [

18], the axial deformation impedance force of the constrained airbag is

where

denotes the elastic modulus of the airbag,

stands for the annular cross-sectional area after deformation of the constrained airbag

The annular volume remains unchanged before and after the deformation of the pressurized airbag.

Where, is the initial diameter of the outer wall of the constrained airbag, is the initial diameter of the inner wall of the constrained airbag.

The axial deformation impedance force of the constrained airbag under the action of air pressure Pa and external force Fz is obtained by combining Equations (13) and (14).

The axial deformation impedance force of the pressurized airbag is

Where, stands for the annular cross-sectional area after deformation of the airbag, denotes the initial outer diameter of pressurized airbag, is the initial diameter of the inner wall of pressurized airbag.

The impedance force generated of the constrained spiral tube is smaller than the above force and can be ignored. Therefore, the axial elongation of the variable-stiffness elastic actuator under the action of

Fz is

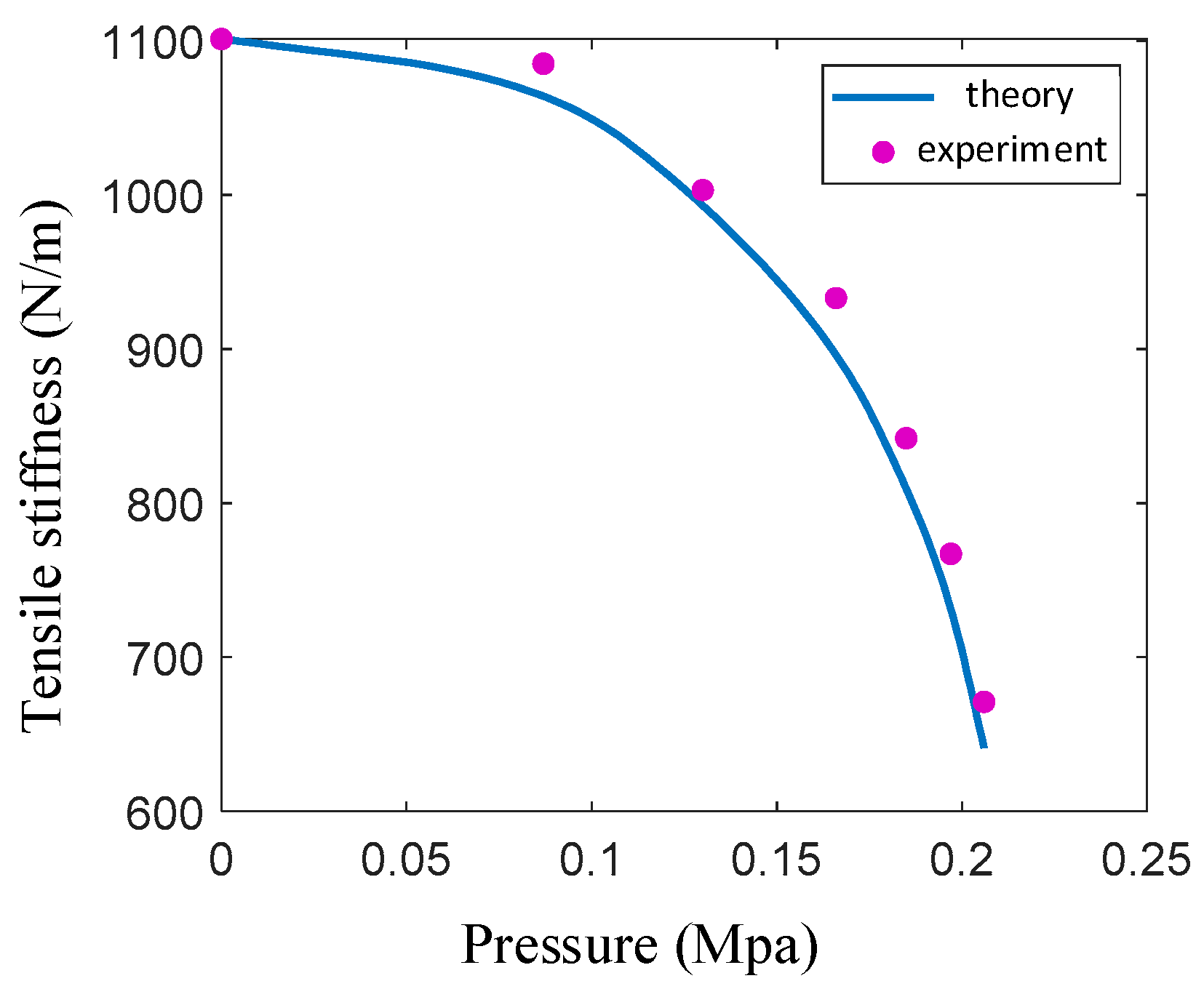

The anti-tensile stiffness of the variable-stiffness elastic actuator is

When , the anti-tensile stiffness is calculated according to Equation (18). When , the variable-stiffness elastic actuator reaches the maximum elongation, and the anti-tensile stiffness depends on the anti-tensile strength of constrained spiral tube.

3.2. Anti-compressive stiffness at any position of variable-stiffness elastic actuator

As illustrated in

Figure 5, the actuator undergo axial elongation

due to applied air pressure. In this state, a axial force

F-z is applied at the center of the upper-end cover, causing the actuator to elongate and deform As a result, the center point of the upper-end cover moves

along the axis direction. At this time, the internal friction contributing to the impedance moment mainly includes frictional interactions in various regions: between the constrained airbag and the spiral tube, among the filling particles and the constrained airbag, and finally, between the filling particles and pressurized airbag. The constrained airbag , pressurized airbag and spiral tube generate deformation impedance force. The wedge impedance force

Fj is generated by filling particles and constrained airbag in the spiral groove.

According to the static equilibrium equation,

The variable-stiffness elastic actuator is compressed under the action of external force, and the air pressure value remains unchanged. Therefore, when the elongation changes to

, the cross-sectional area of the inner cavity changes. According to Equation (7),

- 2.

Friction impedance force

The friction force between constrained airbag and spiral tube is constrained to be

The axial friction force among the filling particles is

The friction force among particles and constrained airbag is equal to

The friction between particles and pressurized airbag is

- 3.

Deformation impedance force

According to the Equation (15), the deformation impedance of constrained airbag is obtained as

According to the Equation (16), the deformation impedance of pressurized airbag is

- 4.

Wedge impedance moment

The magnitude of the wedge resistance force is influenced by the volume of the filler particles and the depth to which the constrained airbag is embedded in groove. When the embedded depth of the filled particles is less than the radius of the particles (

Figure 6a), the force model can be analyzed using wedge clamping mechanisms, as depicted in

Figure 6d. When the filling particles are completely embedded in the groove (

Figure 6b), the force model is as shown in

Figure 6e. Essentially, the force magnitude depends on the anti-compressive strength of the embedded particles and the constrained airbag within the groove.

The force exerted by the pressurized airbag on unit filling particles, when their embedding depth is less than the particle radius, is presented in

Figure 6c and defined as:

where

F denotes the pressure applied to a unit of particles by the pressurized airbag,r represents the radius of the unit filled particle.

For simplicity, we assume a uniform interaction force among the filling particles and designated this uniform force as F. These particles, along with the constrained airbag, are embedded in the groove of the spiral tube, functioning as a wedge clamping mechanism (

Figure 6d). The corresponding wedge resistance force is:

where

denotes the friction angle,

represents the wedge lift angle, associated with the inlet pressure or particle embedding depth.

Therefore, the relationship between the elongation and the external force is

Where, Nk is the total number of particles embedded in the groove.

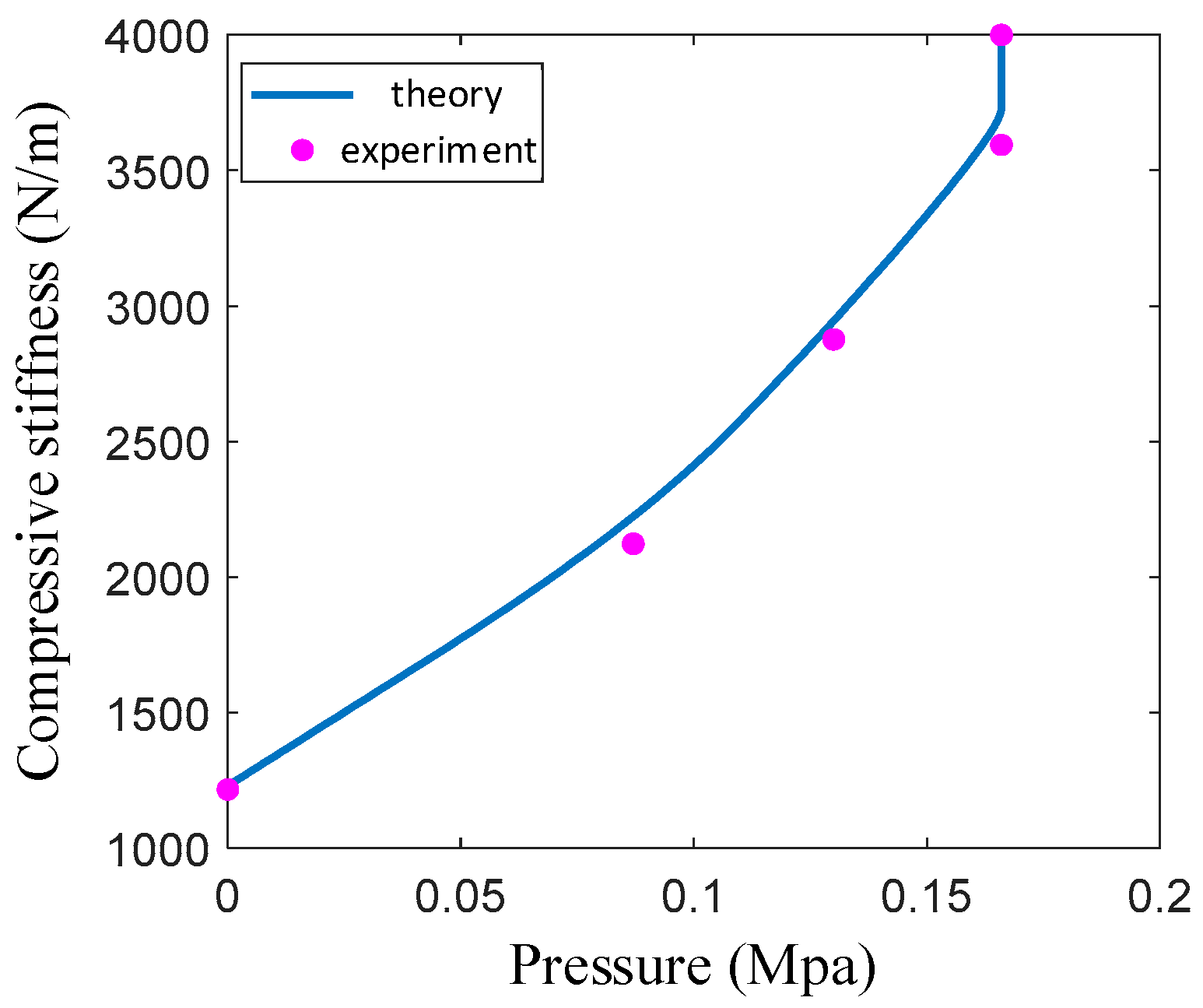

When the embedded groove depth of the filling particles is less than the particle radius, the anti-compressive stiffness of the variable-stiffness elastic actuator is

When , the anti-compressive stiffness of the variable-stiffness elastic actuator is calculated according to Equation (31). When , The filling particles are completely embedded in the groove of the spiral tube, and the anti-compressive stiffness depends on the anti-compressive strength of filling particles and constrained airbag in the embedded groove.

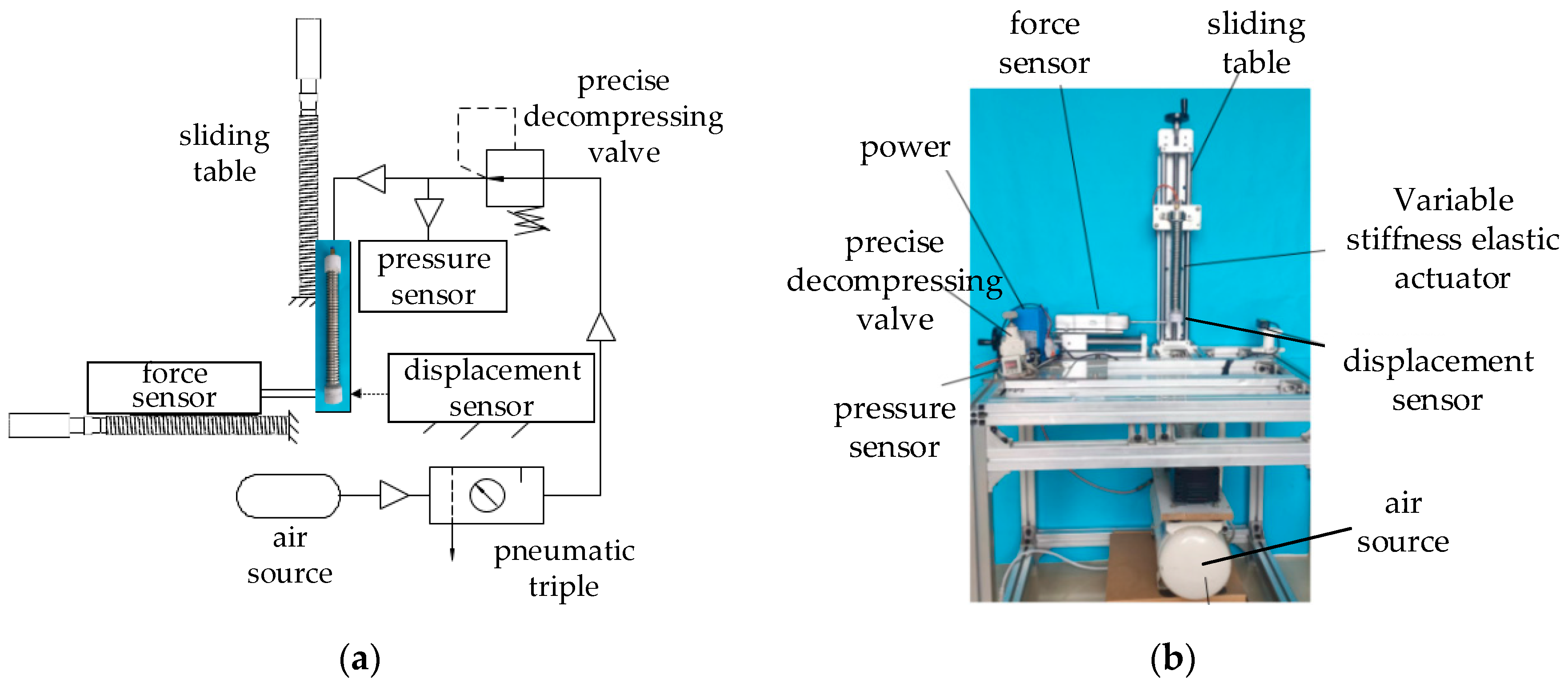

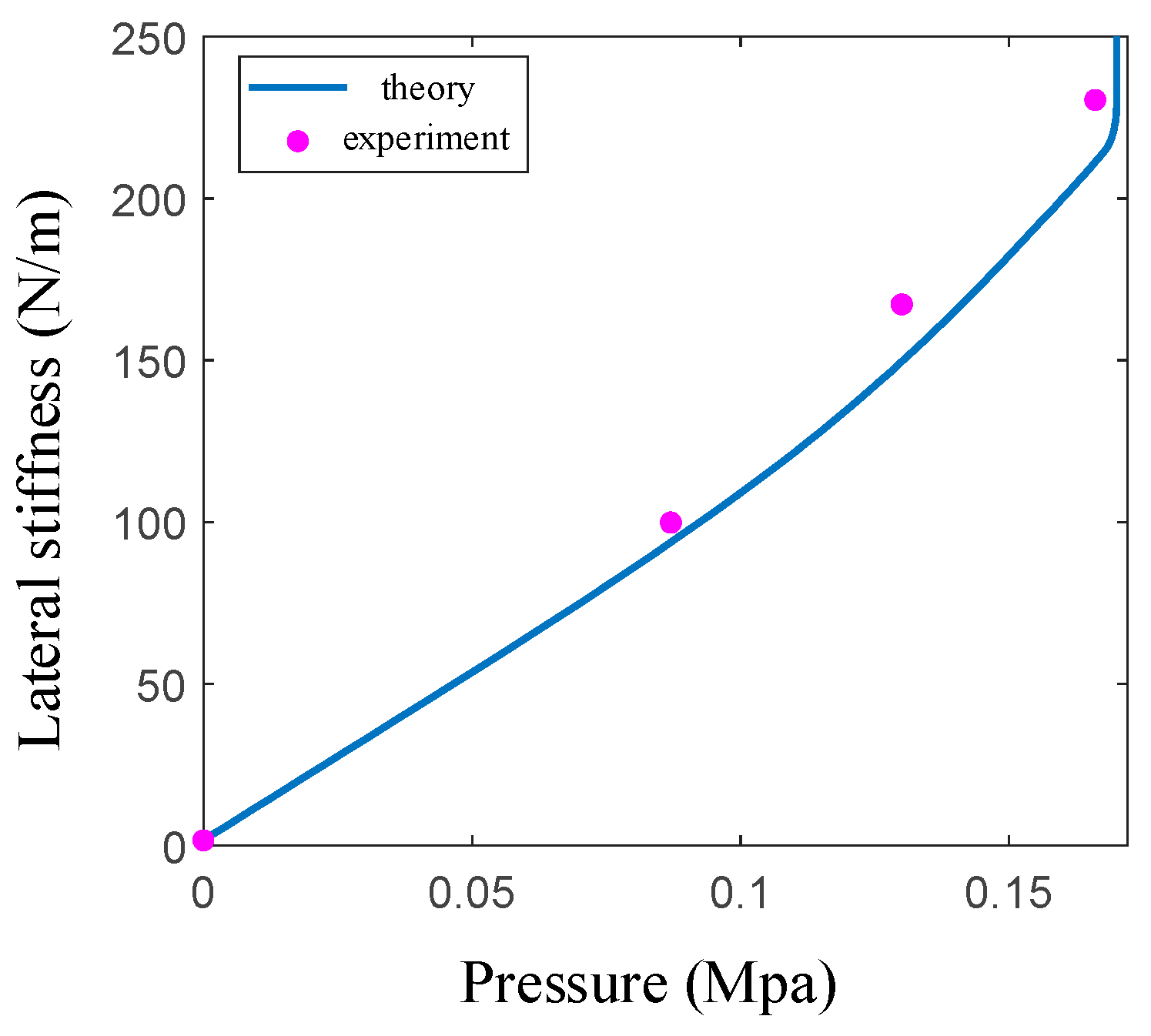

3.3. Lateral stiffness at any position of variable-stiffness elastic actuator

The lateral stiffness of a flexible robot is generally considered to be weak. Therefore, when integrating a variable-stiffness actuator into such a robot, the focus predominantly shifts to studying the lateral stiffness.

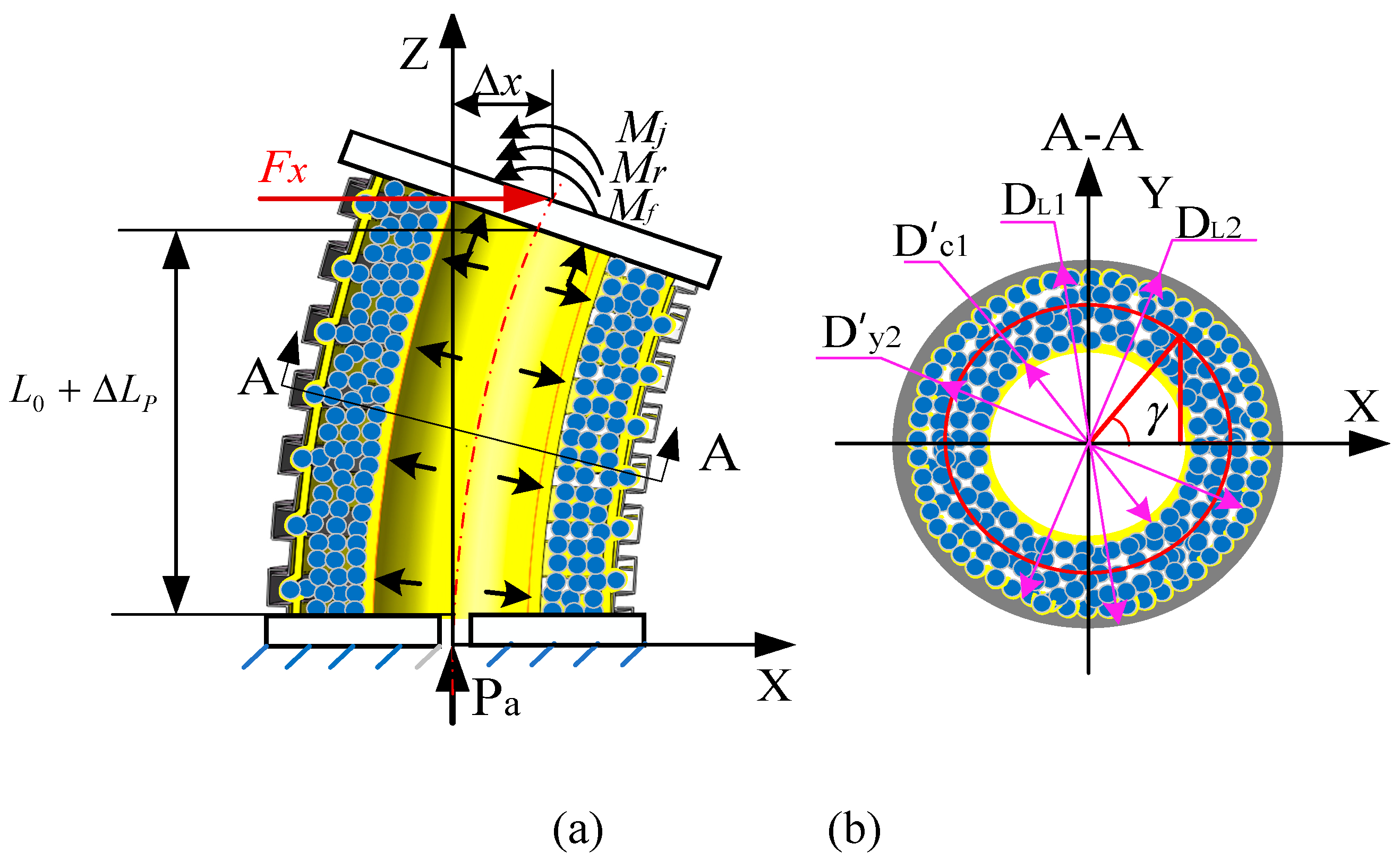

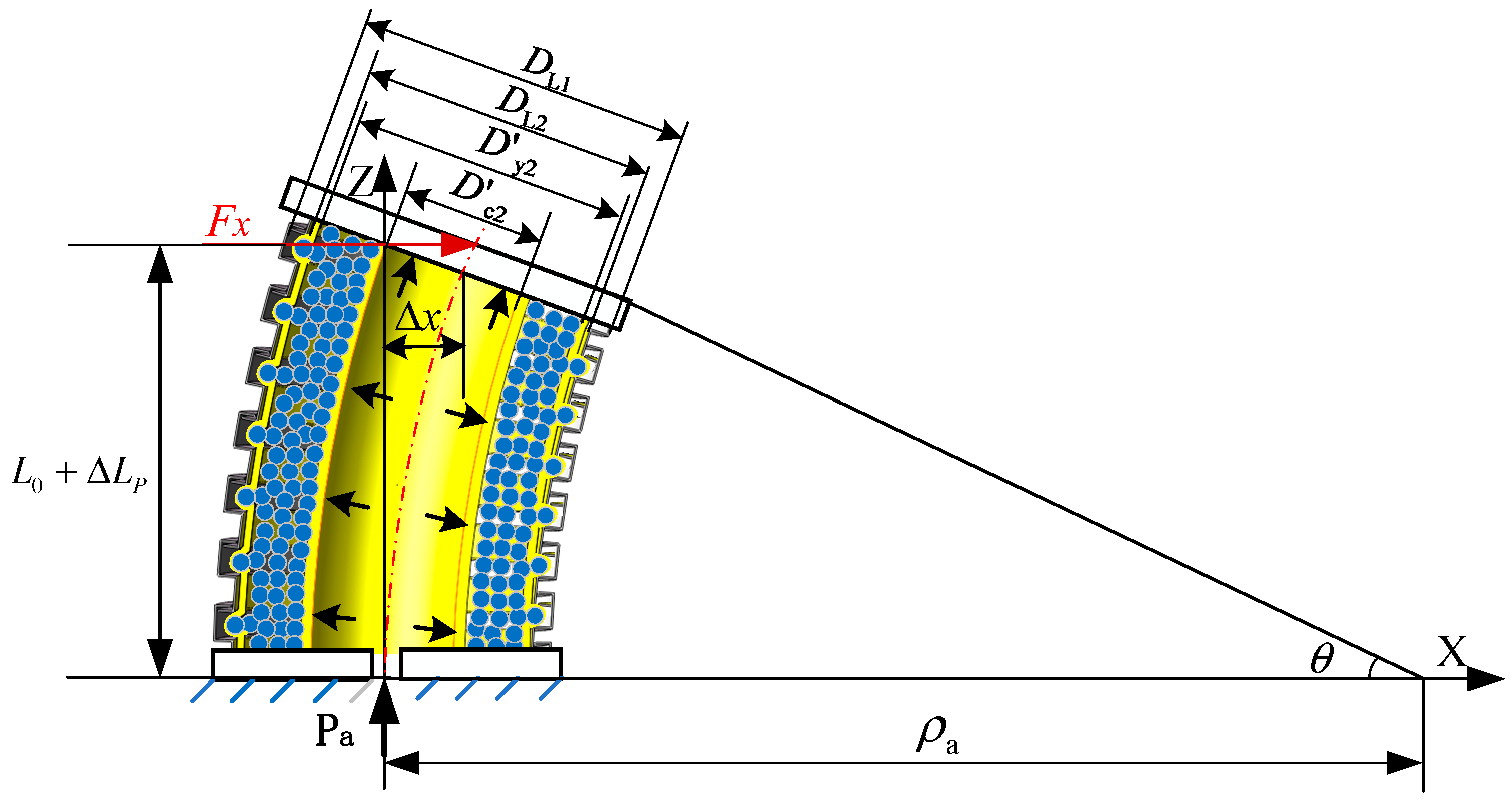

Figure 7a illustrates the bending model of the variable-stiffness elastic actuator, which undergo axial elongation due to applied air pressure. In this state, a lateral force

Fx is applied at the center of the upper-end cover, causing the actuator to bend and deform As a result, the center point of the upper-end cover moves

in the direction of

Fx. When subjected to this external load

Fx, the variable-stiffness elastic actuator behaves akin to a cantilever beam: it elongates on its left side and compresses on the right. This deformation produces a friction resistance moment at the upper-end cover of the actuator. The various components—constrained airbags, pressurized airbags, and spiral tubes—contribute to deformation resistance moments. Additionally, a wedge resistance moment forms on the compressed side of the spiral tube. It is worth noting that while the driving force has an effect on the local lateral stiffness of the actuator, it does not significantly influence the overall lateral stiffness.

According to the moment balance equation of the upper cover:

Where, is the impedance moment due to the external force Fx, is friction-induced resistance moment, is the deformation impedance moment, is the wedge impedance moment.

The driving moment generated by the external load

Fx is

- 2.

Friction impedance moment

Considering the bending geometry of the actuator shown in

Figure 8, the end-face rotation angle is

The bending radius of curvature is

When the actuator is subjected to the external force

Fx, the left side of the pressurized airbag elongates, while the right side compresses. The inner wall diameter remains unchanged. The elongated length on the left side of the inner wall of the pressurized airbag is:

The length on the right side of the pressurized airbag is

The force arms of the friction impedance moment are different due to the different diameters of the constrained airbag, pressurized airbag and constrained spiral tube. And each friction force is different in the circumferential range, as shown in

Figure 7b.

Where,

is the outer wall diameter of the pressurized airbag after deformation,

,

is the inner wall diameter of the constrained airbag after deformation,

.

- 3.

Deformation impedance moment

The deformation of the annular section of constrained airbag and pressurized airbag is stable because of the radial constraint of constrained spiral tube. Under the action of external force, the actuator behaves according to the plane-bending model of an elastic beam. According to the Euler-Bernoulli beam theory, the axial deformation impedance moment generated by constrained airbag is [

19].

The axial deformation impedance moment generated by pressurized airbag under the action of external force is

Therefore, the relationship between the bending angle and the external force is

The lateral stiffness of the variable-stiffness elastic actuator is

When , the lateral stiffness is calculated according to Eq.(44). When , the impedance moment of the wedge depends on the anti-compressive strength of the filling particles and constrained airbag in the right embedded groove.