Submitted:

07 November 2023

Posted:

08 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Research Methods

2.1. Population Type and Sample

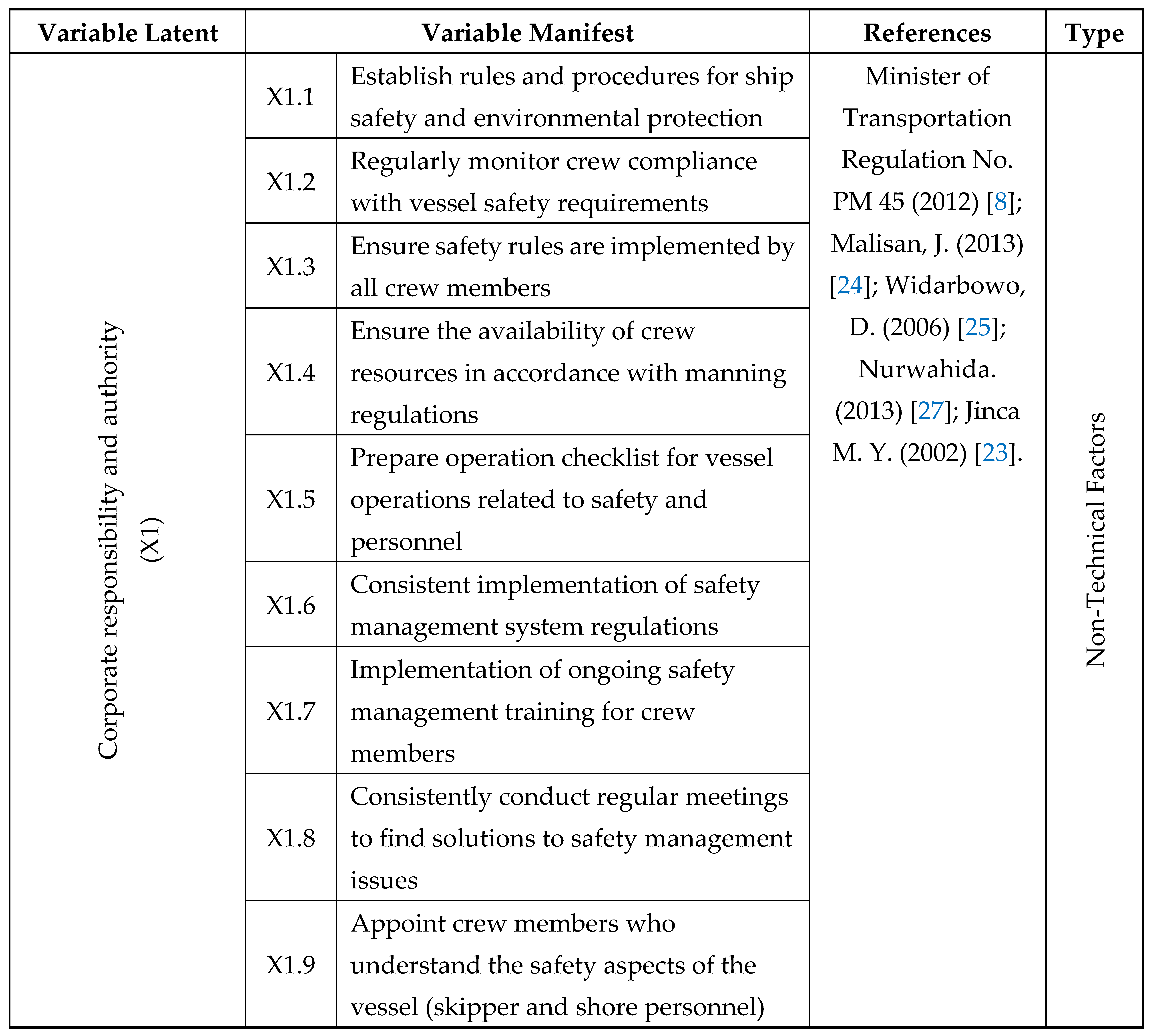

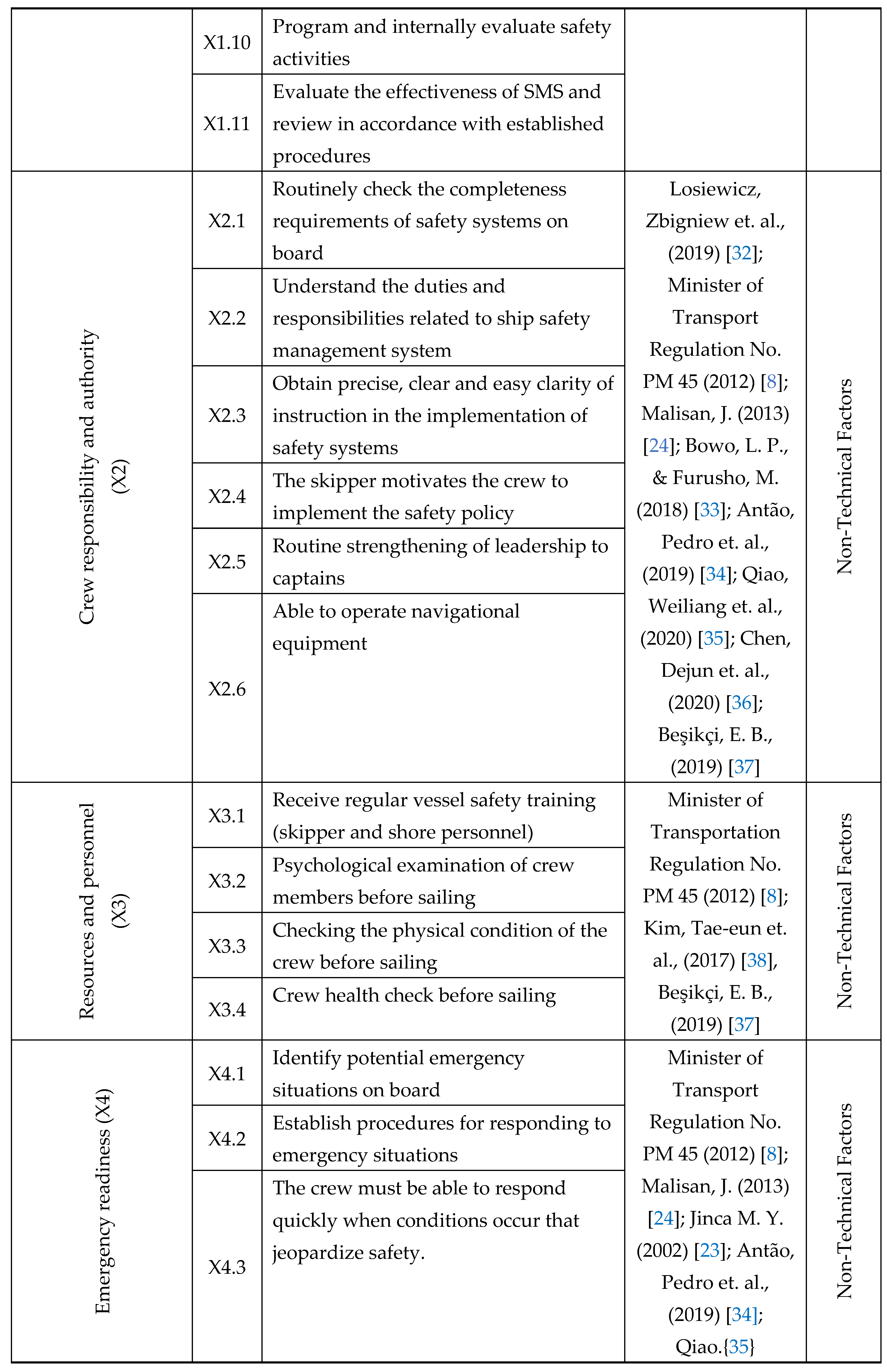

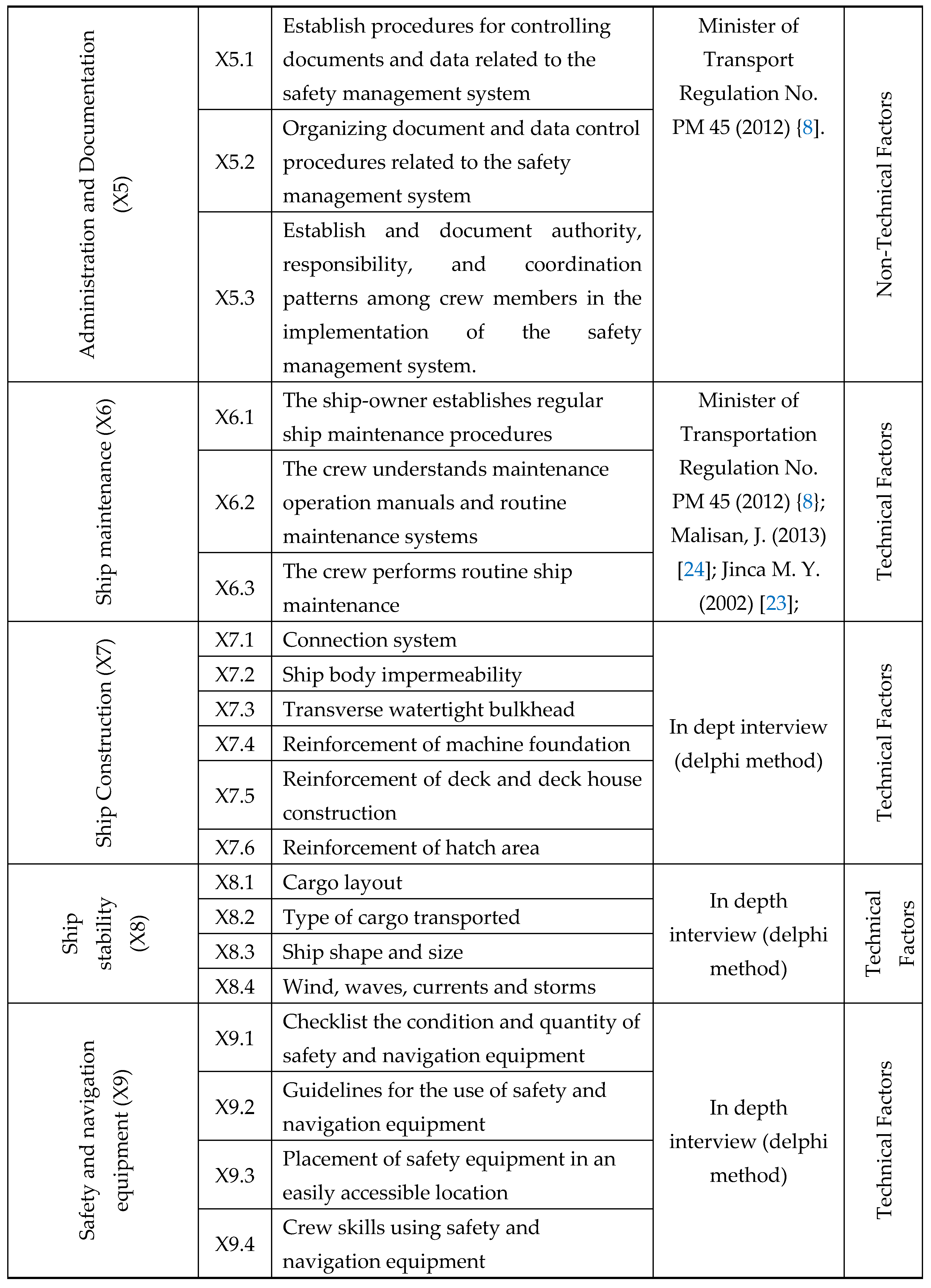

2.2. Research Variables

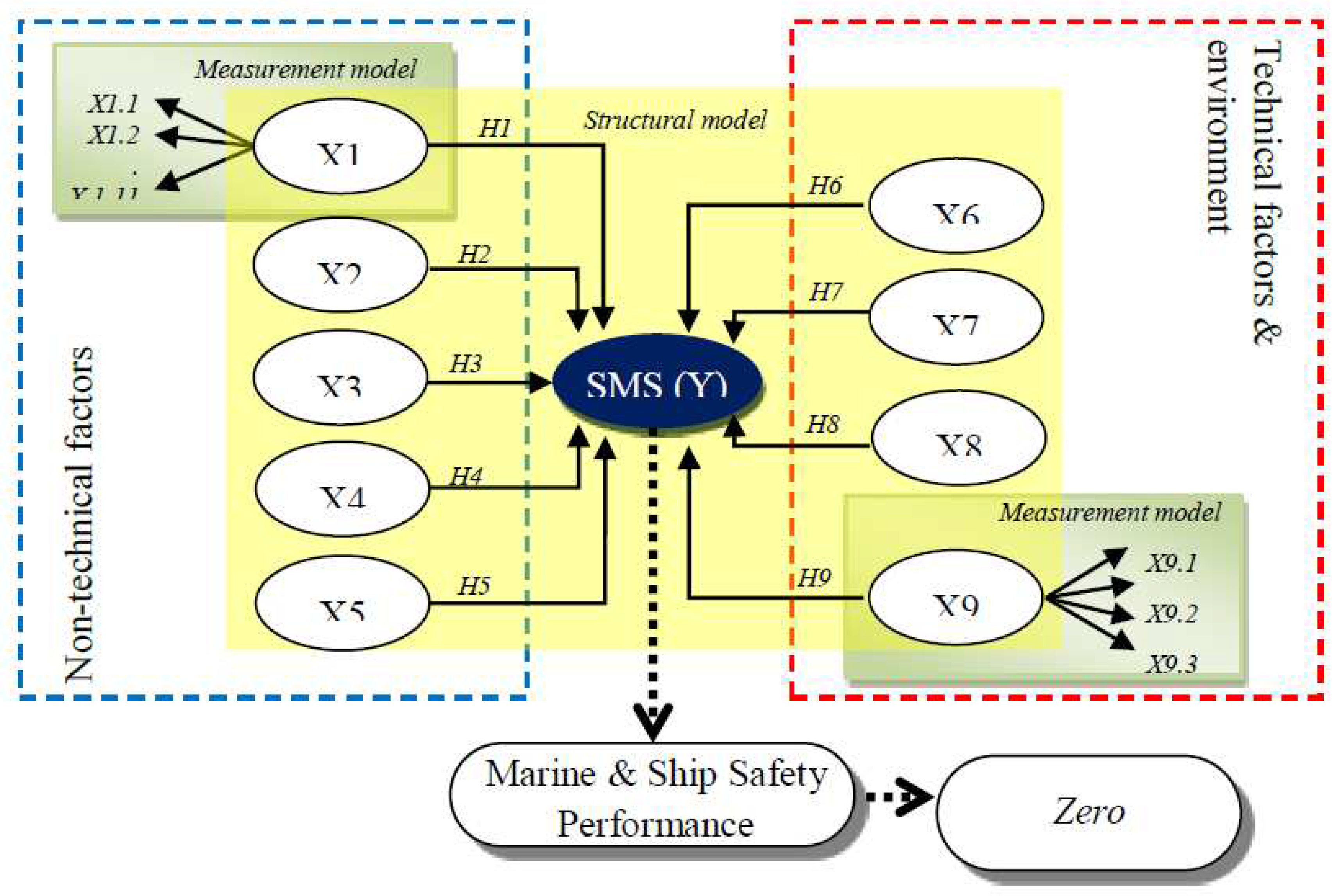

2.3. Conceptual Framework and Hypothesis

3. Results and Discussion

3.1. Statistical Test of Data and Measurement Model

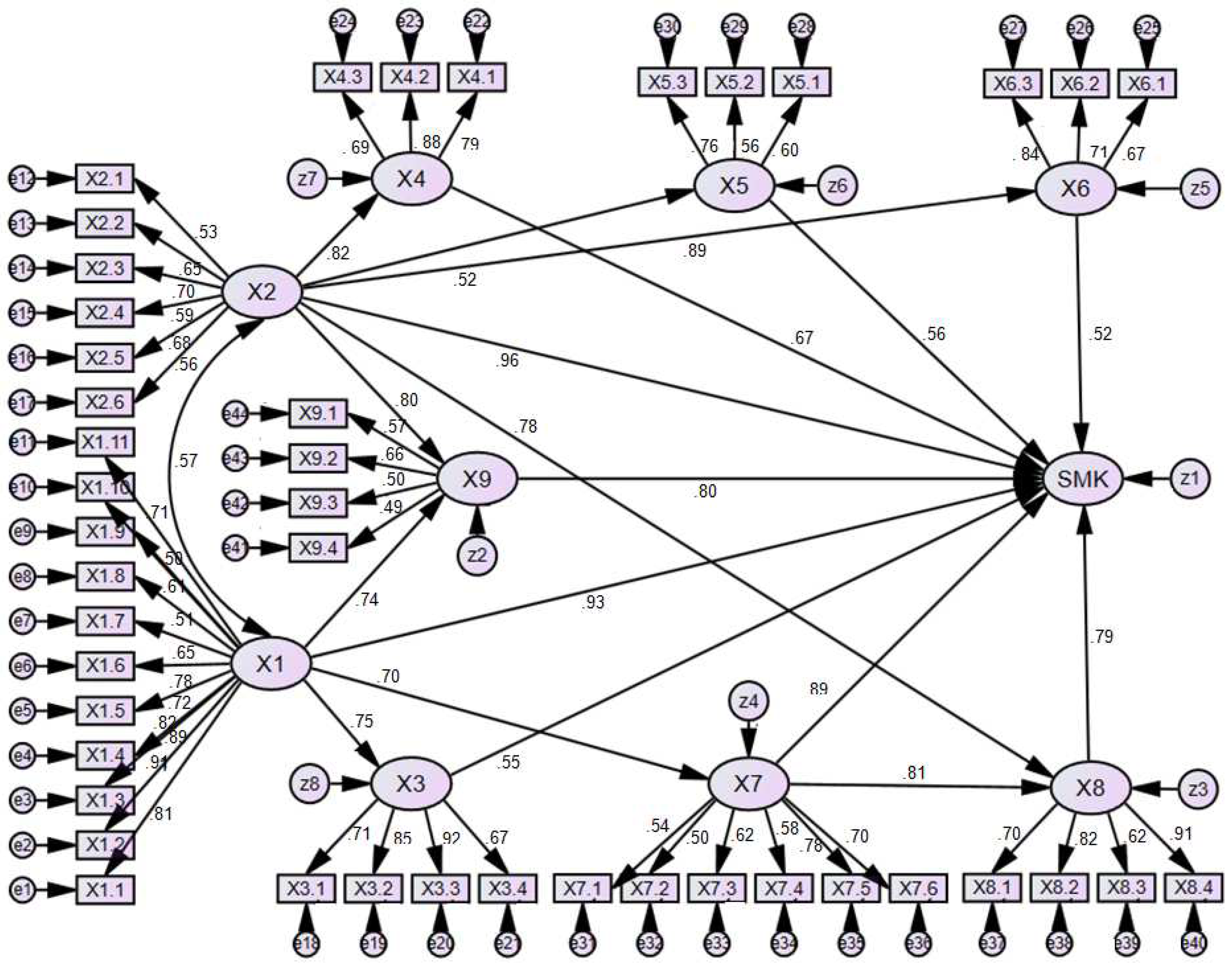

3.2. Structural Model Analysis

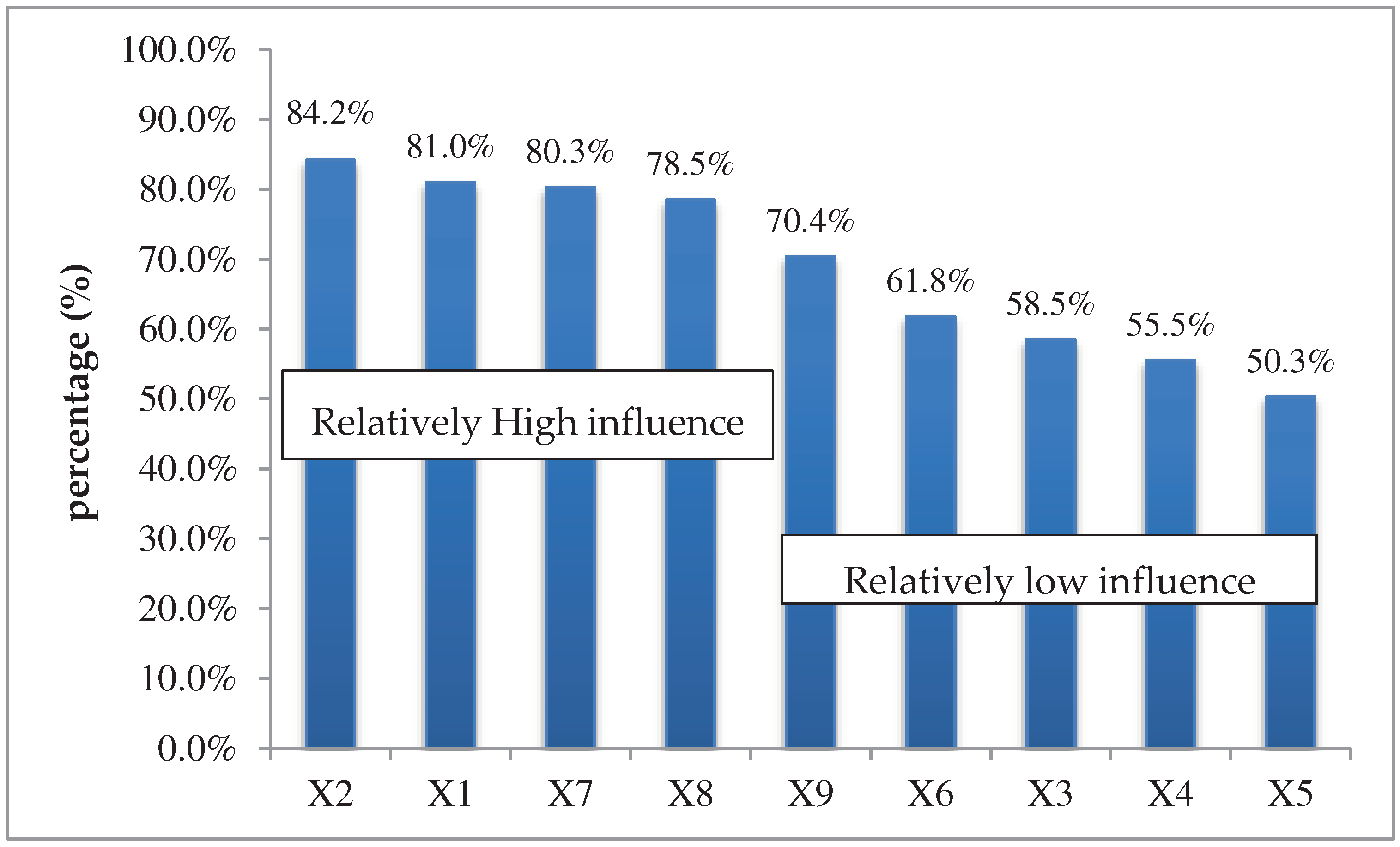

3.3. Model Interpretation

3.4. Implications of Non-Technical and Technical Aspects of SMS Implementation

4. Conclusion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix 1 Overall measurement model convergent validation results

| Latent and manifest variables | FL | SE | CR | AVE | CA |

| Corporate responsibility and authority (X1) | 0.91 | 0.69 | 0.77 | ||

| X1.1 | 0.67 | 0.033 | |||

| X1.2 | 0.76 | 0.021 | |||

| X1.3 | 0.82 | 0.024 | |||

| X1.4 | 0.65 | 0.019 | |||

| X1.5 | 0.85 | 0.042 | |||

| X1.6 | 0.66 | 0.040 | |||

| X1.7 | 0.84 | 0.032 | |||

| X1.8 | 0.70 | 0.081 | |||

| X1.9 | 0.67 | 0.022 | |||

| X1.10 | 0.72 | 0.041 | |||

| X1.11 | 0.78 | 0.039 | |||

| Crew responsibilities and authority (X2) | 0.89 | 0.65 | 0.81 | ||

| X2.1 | 0.81 | 0.018 | |||

| X2.2 | 0.89 | 0.021 | |||

| X2.3 | 0.91 | 0.023 | |||

| X2.4 | 0.71 | 0.041 | |||

| X2.5 | 0.83 | 0.025 | |||

| X2.6 | 0.74 | 0.038 | |||

| Resources and personnel (X3) | 0.85 | 0.75 | 0.73 | ||

| X3.1 | 0.69 | 0.051 | |||

| X3.2 | 0.89 | 0.049 | |||

| X3.3 | 0.74 | 0.043 | |||

| X3.4 | 0.65 | 0.030 | |||

| Emergency readiness (X4) | 0.84 | 0.77 | 0.79 | ||

| X4.1 | 0.82 | 0.017 | |||

| X4.2 | 0.77 | 0.029 | |||

| X4.3 | 0.67 | 0.024 | |||

| Administration and Documentation (X5) | 0.79 | 0.68 | 0.74 | ||

| X5.1 | 0.61 | 0.043 | |||

| X5.2 | 0.72 | 0.053 | |||

| X5.3 | 0.76 | 0.033 | |||

| Ship maintenance (X6) | 0.81 | 0.64 | 0.75 | ||

| X6.1 | 0.68 | 0.041 | |||

| X6.2 | 0.77 | 0.047 | |||

| X6.3 | 0.79 | 0.028 | |||

| Ship Construction (X7) | 0.70 | 0.61 | 0.82 | ||

| X7.1 | 0.81 | 0.021 | |||

| X7.2 | 0.59 | 0.037 | |||

| X7.3 | 0.63 | 0.035 | |||

| X7.4 | 0.73 | 0.019 | |||

| X7.5 | 0.80 | 0.023 | |||

| X7.6 | 0.65 | 0.042 | |||

| Ship stability (X8) | 0.69 | 0.70 | 0.86 | ||

| X8.1 | 0.91 | 0.022 | |||

| X8.2 | 0.77 | 0.049 | |||

| X8.3 | 0.82 | 0.037 | |||

| X8.4 | 0.67 | 0.029 | |||

| Safety and navigation equipment (X9) | 0.73 | 0.64 | 0.82 | ||

| X9.1 | 0.78 | 0.021 | |||

| X9.2 | 0.89 | 0.047 | |||

| X9.3 | 0.76 | 0.046 | |||

| X9.4 | 0.66 | 0.033 | |||

| Description: FL = factor loading; SE = standard error; CR= Construct reability; AVE= Average variance extracted; CA = Cronbach’s alpha. | |||||

References

- Jinca, M.Y, & Humang, W.P, (2023) Transport planning and development of islands. Nas Media Pustaka.

- Minister of Transportation Regulation No. KM 65 Year 2009 on Indonesian-flagged Non Convention Vessel Standard.

- Dominguez-Péry, C., Vuddaraju, L. N. R., Corbett-Etchevers, I., & Tassabehji, R. (2021). Reducing maritime accidents in ships by tackling human error: a bibliometric review and research agenda. Journal of Shipping and Trade, 6, 1-32. [CrossRef]

- Zhang, Y., Zhan, Y., & Tan, Q. (2009). Studies on human factors in marine engine accident. In 2009 Second International Symposium on Knowledge Acquisition and Modeling (Vol. 1, pp. 134-137). IEEE.

- Theotokas, I. (2018). Management of shipping companies. Routledge.

- Håvold, J. I. (2005). Safety-culture in a Norwegian shipping company. Journal of safety research, 36(5), 441-458. [CrossRef]

- Bertram, V. (2011). Practical ship hydrodynamics. Elsevier.

- Minister of Transport Regulation No. PM 45 Year 2012 on Ship Safety Management.

- Humang, W. P., Hadiwardoyo, S. P & Nahry. (2019). Factors influencing the integration of freight distribution networks in the Indonesian archipelago: A structural equation modeling approach. Advances in Science, Technology and Engineering Systems, 4(3), 278-286. [CrossRef]

- Papaioannou, D., & Martinez, L. M. (2015). The role of accessibility and connectivity in mode choice. A structural equation modeling approach. Transportation Research Procedia, 10, 831-839. [CrossRef]

- Mokarami, H., Alizadeh, S. S., Pordanjani, T. R., & Varmazyar, S. (2019). The relationship between organizational safety culture and unsafe behaviors, and accidents among public transport bus drivers using structural equation modeling. Transportation research part F: traffic psychology and behaviour, 65, 46-55. [CrossRef]

- Rahman, F., & Rahman, M. M. (2023). Analyzing service quality of domestic airlines in an emerging country-Bangladesh by structural equation models. Journal of Air Transport Management, 107, 102346. [CrossRef]

- Chao, S. L., Yu, M. M., & Sun, Y. H. (2023). Ascertaining the effects of service quality on customer loyalty in the context of ocean freight forwarders: An integration of structural equation modeling and network data envelopment analysis. Research in Transportation Business & Management, 100955. [CrossRef]

- Lei, P. W., & Wu, Q. (2007). Introduction to structural equation modeling: Issues and practical considerations. Educational Measurement: issues and practice, 26(3), 33-43. [CrossRef]

- Ofori, E. K., Aram, S. A., Saalidong, B. M., Gyimah, J., Niyonzima, P., Mintah, C., & Ahakwa, I. (2023). Exploring new antecedent metrics for safety performance in Ghana’s oil and gas industry using partial least squares structural equation modelling (PLS-SEM). Resources Policy, 81, 103368. [CrossRef]

- Machfudiyanto, R. A., Latief, Y., Suraji, A., & Soeharso, S. Y. (2018). Improvement of policies and institutional in developing safety culture in the construction industry to improve the maturity level, safety performance and project performance in Indonesia. International Journal of Civil Engineering and Technology, 9(10), 1022-1032.

- Ghozali, I. "Structural equation models: concepts and applications with the Amos 16.0 programme". Diponegoro University Publishing Agency. 2013.

- Hair, J. F., Jr., Hult, G. T. M., Ringle, C. M., Sarstedt, M., Danks, N. P., & Ray, S. (2021). Partial least squares structural equation modeling (PLS-SEM) using R: A workbook. Springer Nature Switzerland AG.

- Hair, J. F., Black, W. C., Babin, B. J., & Anderson, R. E. (2014). Multivariate data analysis (7th ed.). Edinburgh Gate: Harlow: Pearson Education Limited. P: Gate: Harlow.

- Fornell, C., & Larcker, D. F. (1981). Evaluating structural equation models with unobservable variables and measurement error. Journal of Marketing Research, 18(1), 39–50. [CrossRef]

- Yoon, S., & Lee, T. (2022). Factors Influencing Military Nurses' Reporting of Patient Safety Events in South Korea: A Structural Equation Modeling Approach. Asian Nursing Research, 16(3), 162-169. [CrossRef]

- Bae, B. R. (2017). Structural equation modeling with Amos 24. Seoul: Chenngram Books, 76-309.

- Jinca M., Y. (2002). Sea Transport of Pinisi Motorised Sailboats, Makassar: Hasanuddin University Research Institute. Makassar.

- Malisan, J., Jinca, M. Y., Herman, P., & Abrar, S. (2013). Traditional shipping transport safety case study: Phinisi fleet (A study on stability, strength and human resources). International Refereed Journal of Engineering and Science (IRJES). 2319-1821.

- Widarbowo, D. (2006). Competency Analysis of People's Shipping Ship Crew Officers. Hasanuddin University, Makassar.

- Humang, W. P. (2021). Demand Model and Role of Stakeholders to Increase General Cargo Load of People's Shipping Transport. Transportation Research Journal, 33(1), 47-56.

- Nurwahida. (2013). Perceptions of Decision Making towards the Implementation of Safety management Standards for People's Shipping Vessels. Postgraduate UNHAS.

- Tajudin. 2009. Review of Shipping Court Decision and Criminal Liability in Ship Accidents in Relation to Law No. 8 Year 1981 on Criminal Procedure Code. Padjadjaran University. Bandung.

- Humang, W.P., Aspar, W.A.N., Upahita, D.P., Muharam, A., Bowo, P. B., & Puriningsih, F.S. (2023). Competitiveness of Traditional Shipping in Sea Transportation Systems Based on Transport Costs: Evidence from Indonesia. International journal of sustainable development and planning, 18 (2), 627-634. 1828. [Google Scholar] [CrossRef]

- Magfiroh, L. I. (2022). Conversion of general cargo pinisi ship into liveaboard tourism pinisi ship with manggarai cultural concept. Thesis. Surabaya State Shipbuilding Polytechnic.

- Santoso, D. B. B, (2007). Technical analysis of Pinisi ship conversion as tourism ship in Ambon-Kep. Banda shipping area. Thesis. Ten November Institute of Technology.

- Łosiewicz, Z., Nikończuk, P., & Pielka, D. (2019). Application of artificial intelligence in the process of supporting the ship owner’s decision in the management of ship machinery crew in the aspect of shipping safety. Procedia Computer Science, 159, 2197-2205. [CrossRef]

- Bowo, L. P., Furusho, M., & Mutmainnah, W. (2020). A New HEART–4M Method for Human Error Assessment in Maritime Collision Accidents. Transactions of Navigation, 5(2), 39-46.

- Antão, P., & Soares, C. G. (2019). Analysis of the influence of human errors on the occurrence of coastal ship accidents in different wave conditions using Bayesian Belief Networks. Accident Analysis & Prevention, 133, 105262. [CrossRef]

- Qiao, W., Liu, Y., Ma, X., & Liu, Y. (2020). A methodology to evaluate human factors contributed to maritime accident by mapping fuzzy FT into ANN based on HFACS. Ocean Engineering, 197, 106892.

- Chen, D., Pei, Y., & Xia, Q. (2020). Research on human factors cause chain of ship accidents based on multidimensional association rules. Ocean Engineering, 218, 107717. [CrossRef]

- Beşikçi, E. B. (2019). Strategic leadership styles on maritime safety. Ocean Engineering, 185, 1-11. [CrossRef]

- Kim, T. E., & Gausdal, A. H. (2017). Leading for safety: A weighted safety leadership model in shipping. Reliability Engineering & System Safety, 165, 458-466. [CrossRef]

- Das, T., Apu, N., Hoque, M. S., Hadiuzzaman, M., & Xu, W. (2017). Parameters affecting the overall performance of bus network system at different operating conditions: a structural equation approach. Transportation research procedia, 25, 5059-5071. [CrossRef]

| Characteristics | n | % | |

| Jobs - Academics - National SAR Agency (Basarnas) - Indonesian Classification Bureau (ICB) - Ditkapel Ministry of Transport - Shipping Court - Marine inspector - Entrepreneur/ship owner - Syahbandar |

30 44 7 6 12 29 78 59 |

11.3 16.6 2.6 2.3 4.5 10.9 29.4 22.3 |

| Test Criteria | Standardized cut-off criteria | GOF test results | Description | |

|---|---|---|---|---|

| Sig-Probability | ≥ 0,05 | 0.083 | Good fit | |

| RMSEA | ≤ 0,08 | 0.047 | Good fit | |

| GFI | ≥ 0,90 | 1.484 | Good fit | |

| AGFI | ≥ 0,90 | 0.915 | Good fit | |

| CMIN/DF | ≤ 2,00 | 1.720 | Good fit | |

| TLI | ≥ 0,95 | 0.945 | Marginal fit | |

| CFI | ≥ 0,95 | 0.921 | Marginal fit |

| Variables | Estimate | S.E | C.R | Description | Influence rating |

| X1 → X9 | 0.590 | 0.187 | 7.452 | significant | - |

| X1 → X3 | 0.506 | 0.023 | 8.704 | significant | - |

| X1 → X7 | 0.691 | 0.095 | 10.450 | significant | - |

| X2 → X4 | 0.703 | 0.150 | 8.054 | significant | - |

| X2 → X5 | 0.609 | 0.034 | 8.334 | significant | - |

| X2 → X6 | 0.534 | 0.090 | 3.903 | significant | - |

| X2 → X8 | 0.804 | 0.056 | 6.034 | significant | - |

| X2 → X9 | 0.690 | 0.056 | 12.434 | significant | - |

| X1 → SMS | 0.810 | 0.138 | 10.034 | significant | 2 |

| X2 → SMS | 0.842 | 0.084 | 6.430 | significant | 1 |

| X3 → SMS | 0.585 | 0.041 | 4.899 | significant | 7 |

| X4 → SMS | 0.555 | 0.039 | 6.346 | significant | 8 |

| X5 → SMS | 0.503 | 0.040 | 13.441 | significant | 9 |

| X6 → SMS | 0.618 | 0.042 | 14.434 | significant | 6 |

| X7 → SMS | 0.803 | 0.023 | 8.233 | significant | 3 |

| X8 → SMS | 0.785 | 0.076 | 7.034 | significant | 4 |

| X9 → SMS | 0.704 | 0.092 | 8.438 | significant | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).