Submitted:

06 November 2023

Posted:

07 November 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

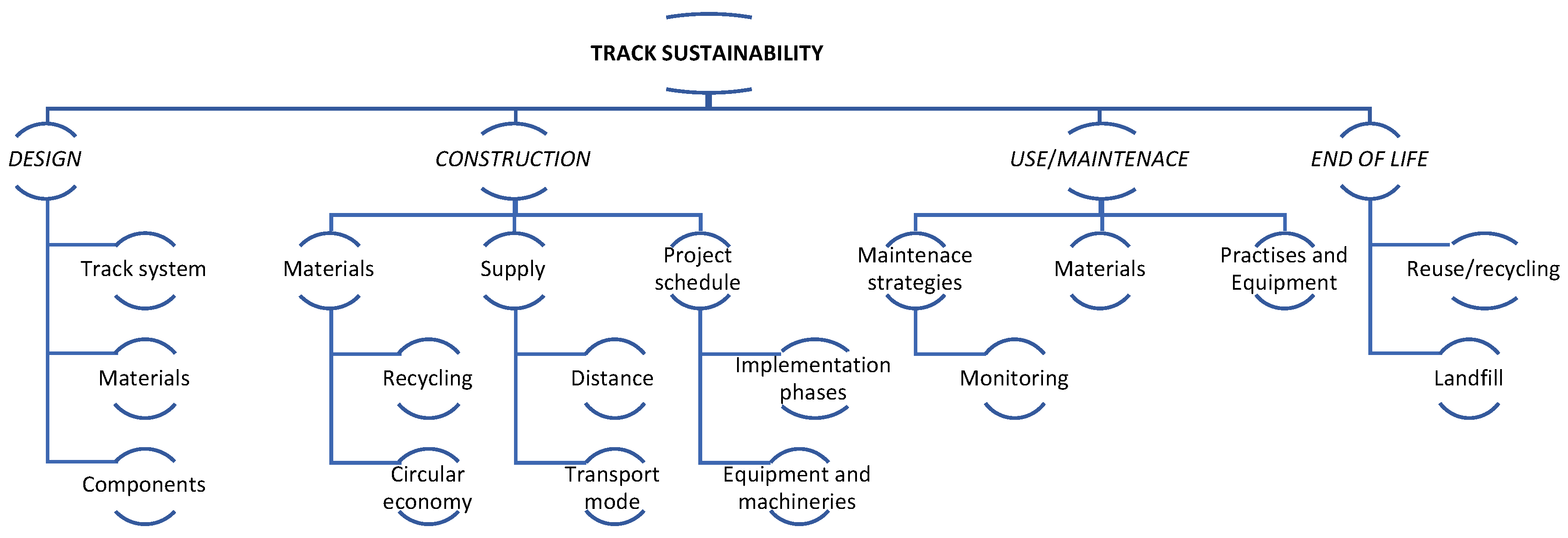

2. Methods

3. Results

3.1. Sustainable Track Materials for Construction and Maintenance

- Allows the resistance of sleepers against vertical, longitudinal, and lateral displacements, thus providing stable support for travelling trains.

- Transfers train forces to the subgrade according to its bearing capacity thus reducing compressive stresses on the subgrade.

- Keeps track geometry in the vertical and lateral directions.

- Provides elasticity to the railway track for getting proper reading comfort.

- Provides effective drainage to the track and absorption of noise and vibration.

- Steel slag as rail ballast exhibits interesting technical properties such as higher modulus of elasticity and lower vertical stress, lower permanent deformation under high train loads. These observations imply that the use of steel slag ballast (SSB) can potentially reduce the track maintenance costs owing to lower settlement and breakage, enhance the lateral resistance due to its higher density, and provide better riding comfort because of higher resilient modulus [22,31].

- Steel slag and crushed rocks: the mixture of crushed rocks with steel slag by 50% (or lower) allow to create a material that meets the standard for special class ballast in terms of abrasion resistance and improves the shear strength of the slag-rock ballast compared to pure steel slag ballast layer [32].

- Crumb Rubber (from end of life of tyre): low percentage of this material (10%) brings significant improvements to the ballast behavior in terms of settlement and deterioration, mechanical properties, capacity to dissipate energy and contributes to extend the service life of the railway track [21,33].

- Asphalt: the use of asphalt in ballast layer improves the ballast layer stiffness, by bonding the discrete ballast into a form of track between slab track and ballasted track. The asphalt can be recycled and decomposed after heating, making it easier to maintain and repair.

- Polyethylene fibres: studies demonstrate that when narrow fibres were used, the fibre-reinforced ballast significantly reduced the settlement because fibres in granular materials reduces the lateral expansion of the mixture (smaller principal strains) and mobilizes a higher stress ratio [34].

- Polyurethane, cement and geopolymer: these binders act like the asphalt; differences deal with costs, working principle and installation. Geopolymer is a promising material for low carbon footprint but suffer of the problem of thermal expansion and contraction. Glued ballast layer is subjected to rapid degradation due to the fouling in the ballast layer [35].

- Bitumen stabilised ballast (BSB): it represents an innovative solution designed to increase ballast service life and reduce overall maintenance burdens. This technology, which can be used for new track-beds as well as to reinforce existing ones, consists of the use of bitumen emulsion (BE) poured or sprayed at ambient temperature onto the ballast. The main advantage resulting from the use of BSB is related to long term analysis (between 40 and 60 years) [36].

- Geogrid: several studies and experiments have shown how the inclusion of geogrid in te ballast increases the service life of the track improving the strength properties and particularly the resilient modulus of the railway ballast. Geogrid also reduces the extent of dynamic amplification factor (DAF) [37,38].

3.2. Maintenance Strategies: Environment-Related Effects

- Maintenance policy: preventive, corrective, and improvement policy

- Maintenance operation: activities and equipment

- Degree of maintenance: prefect, imperfect, minimal

- Decision making level: strategical, tactical, operational

- Maintenance planning: action intervention and prioritization, intervention timing, inspection interval planning

- Maintenance scheduling: possession time of the track for maintenance, maintenance sequencing, vehicle routing, and crew scheduling.

3.3. Tools for Monitoring the State of the Track

- RSMV, Rolling Stiffness Measuring Vehicle, a technique used in Sweden that is based on measurements of track stiffness. It is used to identify areas where action is needed.

- FWD, Falling Weight Deflectometer, used in the United Kingdom. The data obtained after the test is carried out allow the elastic modulus of the lower zone of the track to be calculated.

- GPR, Ground- Penetrating Radar, a tool that allows fast, non-destructive inspection to estimate the integrity of the railway substructure. It provides continuous measurements of the thicknesses and layers of ballast, sub-ballast and subgrade. The measurements are sensitive to water content and material density. It is also capable of distinguishing dirty ballast from clean ballast.

-

Archimedes train, which is the most important diagnostic tool in Italy. This tool has made it possible to:

- Make measurements that were not possible before its introduction (2003)

- Carry out line monitoring without its interruption

- Increase the frequency of visiting operations

- Carry out different measurements simultaneously

- Increase the maximum diagnostic speed from 160 to 200 KM/h.

- ETR500Y2 train Dia.man.te (an acronym for Diagnostics, Maintenance and Technology). This tool is used to periodically monitor the condition of infrastructure and track, contact lines, signaling equipment, and telecommunications facilities.

- Fiber optic sensors: in the last two decades, a significant number of innovative sensing technologies based on fiber optic sensors (FOS) have been utilized for structural health monitoring (SHM) due to their inherent distinctive advantages, such as small size, light weight, immunity to electromagnetic interference (EMI) and corrosion, and embedding capability. Fiber optic-based monitoring systems use quasi-distributed and continuously distributed sensing techniques for real time measurement and long-term assessment of structural properties. This allows for early-stage damage detection and characterization, leading to timely remediation and prevention of catastrophic failure.

- Force Sensing Resistors (FSR) or piezoelectric sheets, work by measuring the voltage changes due to variations in the stress levels to which they are subjected.

3.4. Sustainablity Assessment Methods

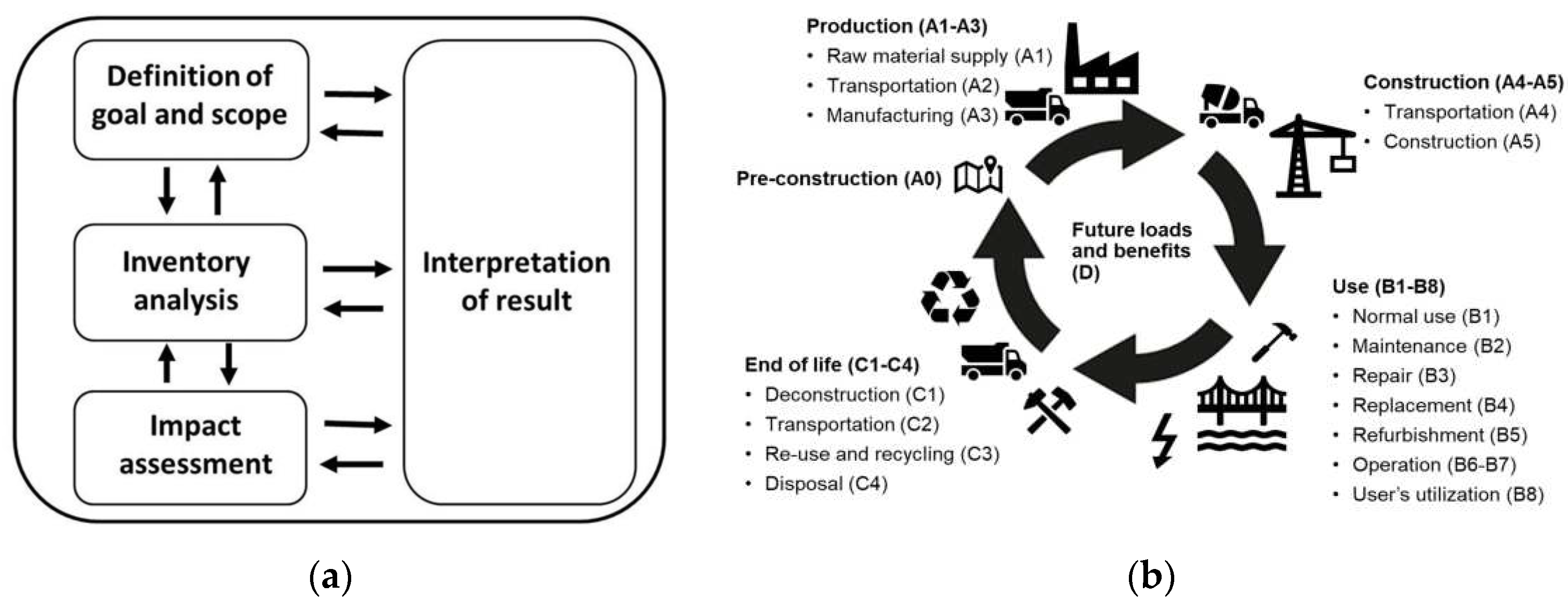

3.4.1. Life Cycle Assessment

- Determine the length of the period of analysis.

- Estimate the maintenance frequency.

- Include the effects of climate change on infrastructure performance.

3.4.2. Circularity Metrics

4. Challenges and Future Perspectives of the Research

- As for materials, different alternative materials, most of them coming from the recycling/reuse in a circular economy perspective, have been proved to be able for the use in the track components. Many questions merit to be tackled in the sustainability assessment of different alternatives: availability and supply distance, circularity index, impacts of the recycling processes, quantitative assessment of environmental benefits.

- Concerning the maintenance strategies and their effects on the environment, regular inspections and preventative repairs are essential to address the challenges of rail track sustainable maintenance. New technologies enable more accurate and frequent monitoring of track conditions. Drones and specialized camera systems can survey large sections of the railroad to spot potential issues proactively. Machine learning is a valid approach to automatically analyze track imagery and data to identify maintenance needs. Future research path is related to the setting-up of track degradation models to formulate appropriate and specific evaluations on the maintenance needs also considering new materials.

- The assessment of environmental performance by means the application of LCA needs to be more extended in railway sector and addressed towards the quantification of the environmental benefits arising from the use of innovative materials and construction and maintenance techniques. In a view of a wide application of the principle of circular economy in design and maintenance of the track, the setting-up of appropriate circularity metrics is a crucial aspect.

Funding

Acknowledgments

Conflicts of Interest

References

- Brundtland, G.; Khalid, M.; Agnelli, S.; Al-Athel, S.; Chidzero, B.; Fadika, L.; Singh, M. 1987. Our Common Future (\’Brundt- land Report\’). Oxford University Press, Oxford.

- European Commission. Adapting Infrastructures to climate change. 2013.

- Ritchie, H. Cars, planes, trains: where do CO2 emissions from transport come from?”. Published online at OurWorldInData.org. Retrieved from: ‘https://ourworldindata.org/co2-emissions-from-transport’ [Online Resource], 2020.

- Lawrence, M.; Bullock, R. The Role of Rail in Decarbonizing Transport in Developing Countries. Mobility and Transport Connectivity Series. © Washington, DC: World Bank. 2022. http://hdl.handle.net/10986/38214 License: CC BY-NC 3.0 IGO.

- Bressi, S.; Santos, J.; Giunta, M.; Pistonesi, L.; Lo Presti, D. A comparative life cycle assessment of asphalt mixtures for railway sub-ballast containing alternative materials. Resources Conservation and Recycling 2018, 137, 76–88. [Google Scholar] [CrossRef]

- Milewicz, J.; Mokrzan, D.; Szymanski, G.M. Environmental Impact Evaluation as a Key Element in Ensuring Sustainable Development of Rail Transport. Sustainability 2023, 15, 13754. [Google Scholar] [CrossRef]

- Da Fonseca-Soares, D.; Galvinicio, J.D.; Eliziário, S.A.; Ramos-Ridao, A.F. A Bibliometric Analysis of the Trends and Characteristics of Railway Research. Sustainability 2022, 14, 13956. [Google Scholar] [CrossRef]

- UIC ARISCC-Adaptation of Railway Infrastructure to Climate Change. Final Report. Nolte, R Berlin, I Z T 2011.

- EEA Adaptation of transport to climate change in Europe: challenges and options across transport modes and stakeholders 2014.

- Baker, C.J.; Chapman, L.; Quinn, A.; Dobney, K. Climate change and the railway industry: a review. Proc IME C J Mech Eng Sci 2010, 224(3), 519–528. [Google Scholar] [CrossRef]

- Nemry, F.; Demirel, F. Impacts of Climate Change on Transport: A Focus on Road and Rail Transport Infrastructures. JRC Working Papers. Directorate growth & innovation and JRC-Seville, Joint Research 2012 Centre. [CrossRef]

- Armstrong J, Preston J, Hood I (2016) Adapting railways to provide resilience and sustainability. Proc Inst Civ Eng Eng Sustain 2016, 169, 1–10. [CrossRef]

- Giunta, M. Sustainability and resilience in the rehabilitation of road infrastructures after an extreme event: an integrated approach. Baltic Journal of Road and Bridge Engineering, 2017, 12(3), 154–160. [CrossRef]

- Climate ADAPT (2019) Operation and construction measures for ensuring climate-resilient railway infrastructure. Available at: https://climate-adapt.eea.europa.eu/ metadata/adaptation-options/operation-and-construction-measures-for-ensuring-climate-resilient-railway-infrastructure.

- Wang, T.; Qu, Z.; Yang, Z.; Nichol, T.; Clarke, G.; Ge, Y-E. Climate change research on transportation systems: Climate risks, adaptation and planning. Transportation Research Part D 2020, 88, 102553. [CrossRef]

- Blackwood, L., Renaud, F.G., Gillespie, S. Nature-based solutions as climate change adaptation measures for rail infrastructure. Nature-Based Solutions 2022, 100013. [CrossRef]

- Praticò, F.G.; Giunta, M. LCC-based appraisal of ballasted and slab tracks: limits and potential. The Baltic Journal of Road and Bridge Engineering 2018, 13(4), 475–499. [Google Scholar] [CrossRef]

- Pons, J.J.; Villalba Sanchis, I.; Insa Franco, R.; Yepes, V. Life cycle assessment of a railway tracks substructures: Comparison of ballast and ballastless rail tracks. Environmental Impact Assessment Review 2020, 85, 106444. [Google Scholar] [CrossRef]

- Krezo, S.; Mirza, O.; Kaewunruen, S.; Sussman, J.M. Evaluation of CO2 emissions from railway resurfacing maintenance activities. Transp Res Part D Transp Environ 2018, 65, 458–465. [Google Scholar] [CrossRef]

- Guo, Y.; Xie, J.; Fan, Z., Markine, V.; Connolly, D.P.; Jing, G. Railway ballast material selection and evaluation: A review. Construction and Building Materials 2022, 344, 128218. [CrossRef]

- Sol-Sanchez M.; Thom, N.H.; Moreno-Navarro, F.; Rubio-Gamez, M.C.; Airey, G.D. A study into the use of crumb rubber in railway ballast, Construction and Building Materials 2015, 75, 19-24. [CrossRef]

- Guimaraes Delgado, B.; Viana da Fonseca, A.; Fortunato, E.; Maia, P. Mechanical behavior of inert steel slag ballast for heavy haul rail track: laboratory evaluation. Transportation Geotechnics 2019, 20, 100243. [Google Scholar] [CrossRef]

- Sahay, J.; Nagpal, O.; Prasad, S. Waste management of steel slag. Steel times international 2000, 24(2), 38. [Google Scholar]

- Jia, W.; Markine, V.L.; Jing, G. Analysis of furnace slag in railway sub-ballast based on experimental tests and DEM simulations, Construction and Building Materials 2021, 288, 123114. [CrossRef]

- Mehran Khoshoei, S.; Mortazavi Bak, H.; Mahdi Abtahi, S.; Mahdi Hejazi, S.; Shahbodagh, B. Experimental Investigation of the Cyclic Behavior of Steel-Slag Ballast Mixed with Tire-Derived Aggregate. Journal of Materials in Civil Engineering 2021 33 (2). [CrossRef]

- Ghanbari, M.; Abbasi, A.M.; Ravanshadnia, M. Production of natural and recycled aggregates: the environmental impacts of energy consumption and CO2 emissions. Journal of Material Cycles and Waste Management 2017, 20 (2) 810-822. [CrossRef]

- Pradhan, S.; Tiwari, B.R.; Kumar, S.; Barai, S.V. Comparative LCA of recycled and natural aggregate concrete using Particle Packing Method and conventional method of design mix. Journal of Cleaner Production 2019, 228, 679–691. [Google Scholar] [CrossRef]

- Nalsund, R. Railway ballast characteristics, selection criterion and performance. PhD Thesis. Norwegian University of Science and Technology, Trondheim, Department of Civil and Transport Engineering, 2014.

- Indraratna, B. 1st Proctor Lecture of ISSMGE: Railroad performance with special reference to ballast and substructure characteristics. Transportation Geotechnics 2016, 7, 74–114. [Google Scholar] [CrossRef]

- Alabbasi, Y.; Hussein, M. Large-scale triaxial and box testing on railroad ballast: a review. SN Applied Sciences 2019, 1(12). [CrossRef]

- Hussain, A.; Hussaini, S.K.K. Use of steel slag as railway ballast: A review. Transportation Geotechnics 2022, 35, 100779. [Google Scholar] [CrossRef]

- Jing, G.; Wang, J.; Wang, H.; Siahkouhi, M. Numerical investigation of the behavior of stone ballast mixed by steel slag in ballasted railway track. Construction and Building Materials, 2020, 262, 120015. [CrossRef]

- Fathali, M.; Nejad, F.M.; Esmaeili, M. Influence of Tire-Derived Aggregates on the Properties of Railway Ballast Material Journal of Materials in Civil Engineering, 2017, 29 (1), 04016177. [CrossRef]

- Ajayi, O.; Le Pen, L.; Zervos, A.; Powrie, V. Feasibility Study of Random Fibre Reinforced Railway Ballast Proceedings of the 23rd European Young Geotechnical Engineers Conference, Barcelona 2014.

- Jing, G.; Qie, L.; Markine, V.L.; Jia, W. Lo Polyurethane reinforced ballasted track: Review, innovation and challenge. Construction and Building Materials 2019, 208(3), 734–74. [Google Scholar] [CrossRef]

- D’Angelo, G.; Bressi, S.; Giunta, M.; Presti, D.; Thom, N. Novel performance-based technique for predicting maintenance strategy of bitumen stabilised ballast. Construction and Building Materials 2018, 161, 1–8. [Google Scholar] [CrossRef]

- Sweta, K.; Khaja, S-; Hussaini, K. Effect of geogrid on deformation response and resilient modulus of railroad ballast under cyclic loading. Construction and Building Materials 2020, 264, 120690. [CrossRef]

- Leonardi, G. Analysis of railway tracks reinforced with geogrids. ARPN Journal of Engineering and Applied Sciences 2021, 16(24), 2722–2728. [Google Scholar]

- Sol-Sanchez, M.; D’Angelo, G. Review of the design and maintenance technologies used to decelerate the deterioration of ballasted railway tracks. Constr Build Mater 2017; 157, 402-415. [CrossRef]

- Banerjee, L.; Chawla, S.; Kumar Dash, S. Application of geocell reinforced coal mine overburden waste as subballast in railway tracks on weak subgrade. Construction and Building Materials 2020, 265, 120774. [Google Scholar] [CrossRef]

- Indraratna, B.; Qi, Y.; Sai Malisetty, R.; Navaratnarajah, S.K.; Fatima Mehmood, F.; Tawk Rail, M. Recycled materials in railroad substructure: an energy perspective. Rail. Eng. Science 2022, 30(3), 304–322. [Google Scholar] [CrossRef]

- https://cordis.europa.eu/project/id/738373 (Accessed on 2023 October 30th).

- Dolci, G.; Rigamonti, L.; Grosso, M. Potential for improving the environmental performance of railway sleepers with an outer shell made of recycled materials. Transportation Research Interdisciplinary Perspectives 2020, 6, 100160. [Google Scholar] [CrossRef]

- Çeçen, F.; Aktas¸, B.; Ozbayrak, A. Decarbonization of the concrete railway sleeper production: bringing the low-dosage pozzolanic cement usage in the sleeper production via novel laminated CFRPU reinforcement technique. Materials Today Sustainability 2023, 23, 100455. [Google Scholar] [CrossRef]

- International Union of Railway. UIC SUSTAINABILITY Circular practices in the railway and ways forward REUSE Project final Report 2021. https://uic.org/IMG/pdf/reuse_project_final_report.pdf.

- Giunta, M.; Praticò, F. G., 2017. Design and maintenance of high-speed rail tracks: A comparison between ballasted and ballast-less solutions based on Life Cycle Cost Analysis. In Proceedings of International Congress on Transport Infrastructure and System, Rome 10-12 April 2017.

- Italferr. LCA Life Cycle Assessment, line guida per la valutazione LCA di infrastrutture ferroviarie, 2019.

- Milford, R.L.; Allwood, J.M. Assessing the CO2 impact of current and future rail track in the UK. Transp Res Part D Transp Environ 2010. [CrossRef]

- Kiani, M.; Parry T, Ceney H. Environmental life-cycle assessment of railway track beds. Proc Inst Civ Eng Eng Sustain 2008. [CrossRef]

- Dépoues, V. Organisational uptake of scientific information about climate change by infrastructure managers: the case of adaptation of the French railway company. Clim Change 2017, 143, 473–486. [Google Scholar] [CrossRef]

- Palin EJ, Thornton HE, Mathison CT, McCarthy RE, Clark RT, Dora J. Future projections of temperature-related climate change impacts on the railway network of Great Britain. Clim Change 2013. [CrossRef]

- Sedghi, M.; Kauppila, O.; Bergquista, B.; Vanhataloa, E.; Kulahcia, M. A taxonomy of railway track maintenance planning and scheduling: A review and research trends. Reliability Engineering and System Safety 2021, 215, 107827. [Google Scholar] [CrossRef]

- ressi, S.; Santos, J; Losa M. Optimization of maintenance strategies for railway track-bed considering probabilistic degradation models and different reliability levels. Reliab Eng Syst Saf 2021, 207, 107359. [CrossRef]

- Soleimanmeigouni, I.; Ahmadi, A.; Kumar, U. Track geometry degradation and maintenance modelling: a review. Proc Inst Mech Eng Part F J Rail Rapid Transit 2018. [Google Scholar] [CrossRef]

- Elkhoury, N.; Hitihamillage, L.; Moridpour, S.; Robert, D. Degradation prediction of rail tracks: a review of the existing literature. Open Transp J 2018, 12(1), 88-104.

- Higgins, A. Scheduling of railway track maintenance activities and crews. J Oper Res Soc 1998. [Google Scholar] [CrossRef]

- Khajehei, H.; Ahmadi, A.; Soleimanmeigouni, I.; Haddadzade, M.; Nissen, A.; Javad Latifi Jebelli, M. Prediction of track geometry degradation using artificial neural network: a case study. International Journal of Rail Transportation 2022, 10:1, 24-43. [CrossRef]

- Jovanovic, S., Guler, H.; Coko, B. 2015. Track degradation analysis in the scope of railway infrastructure maintenance management systems. Gradjevinar 2015, 67 (3), 247-258.

- Bressi, S.; D’Angelo, G.; Santos, J.; Giunta, M. Environmental performance analysis of bitumen stabilized ballast for railway track-bed using life-cycle assessment. Constr Build Mater 2018, 188, 1050–1064. [Google Scholar] [CrossRef]

- Du, C.; Dutta, S.; Kurup, P.; Yu, T.; Wang, X. A review of railway infrastructure monitoring using fiber optic sensors. Sensors and Actuators A 2020, 303, 111728. [Google Scholar] [CrossRef]

- Sol-Sanchez, M.; Castillo-Mingorance, J.M.; Moreno-Navarro, F.; Rubio-Gamez, M.C. Smart rail pads for the continuous monitoring of sensored railway tracks: Sensors analysis. Automation in Construction 2021, 132, 103950 (a). [Google Scholar] [CrossRef]

- Sol-Sanchez, M.; Castillo-Mingorance, J.M.; Moreno-Navarro, F.; Mattinzioli, T.; Rubio-Gamez, M. C. Piezoelectric-sensored sustainable pads for smart railway traffic and track state monitoring: Full-scale laboratory tests., Construction and Building Materials 2021 301, 124324 (b). [CrossRef]

- Antognoli, M.; Marinacci, C.; Ricci, S.; Rizzetto, L. Requirement specifications for track measuring and monitoring systems. Ingegneria Ferroviaria 2020, 11, 841–864. [Google Scholar]

- ISO 14040, 2006a. Environmental Management - Life-Cycle Assessment - Principles and Framework. International Organization for Standardization., Geneva.

- ISO 14044, 2006b. Environmental Management – Life-Cycle Assessment – Requirements and Guidelines. International Organization for Standardization., Geneva.

- ISO 21931-2:2019 Sustainability in buildings and civil engineering works Framework for methods of assessment of the environmental, social and economic performance of construction works as a basis for sustainability assessment. Part 2: Civil engineering works. International Organization for Standardization., Geneva.

- Fathali, M.; Chalabii, J.; Astaraki, F.; Esmaeili, M. A new degradation model for life cycle assessment of railway ballast materials. Construction and Building Materials 2021, 270, 121437. [Google Scholar] [CrossRef]

- Celauro, C.; Cardella, A.; Guerrieri, M. LCA of Different Construction Choices for a Double-Track Railway Line for Sustainability Evaluations. Sustainability 2023, 15, 5066. [Google Scholar] [CrossRef]

- Gulcimen, S.; Aydogan, E.K.; Uzal, N. Life cycle sustainability assessment of a light rail transit system: Integration of environmental, economic, and social impacts. Integr. Environ. Assess. Manag. 2021, 17, 1070–1082. [Google Scholar] [CrossRef] [PubMed]

- Liljenstrom, C.; Bjorklund, A.; Toller, S. Including maintenance in life cycle assessment of road and rail infrastructure-a literature review. The International Journal of Life Cycle Assessment 2022, 27, 316–34. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Moraga, G., Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K., de Meester, S.; Dewulf, J. Circular economy indicators: what do they measure? Resources Conserv. Recycl. 2019, 146, 452–461. [CrossRef]

- Murray, A.; Skene, K.; Haynes, K. The circular economy: an interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics 2017, 140, 369–380. [Google Scholar] [CrossRef]

- Corona, B.; Shen, L.; Reike, D.; Rosales Carreón, J.; Worrell, E. Towards sustainable development through the circular economy—A review and critical assessment on current circularity metrics. Resources, Conservation and Recycling 2019, 151, 104498–2019. [Google Scholar] [CrossRef]

- European Commission. A monitoring framework for the circular economy, Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. 2018.

- Saidani, M., Yannou, B., Leroy, Y., Cluzel, F., Kendall, A., 2018. A taxonomy of circular economy indicators. J. Clean. Prod. 2019, 207, 542–559. [CrossRef]

- De Pascale, A.; Arbolino, R.; Szopik-Depczynska, K.; Limosani, M.; Giuseppe Ioppolo, G. A systematic review for measuring circular economy: The 61 indicators. Journal of Cleaner Production 2021, 281, 124942. [Google Scholar] [CrossRef]

| Topics | Track Component | References |

|---|---|---|

| Materials | Sub-ballast | [5,40,41] |

| Ballast | [20,21,22,23,24,25,26,27,28,29,30,31,32,33,34,35,36,37,38,39] | |

| Sleepers | [42,43,44] | |

| Rail | [45] | |

| Maintenance strategies | All | [46,47,48,49,50,51,52,53,54,55,56,57,58,59] |

| Monitoring | All | [60,61,62,63] |

| Environmental assessment | All | [64,65,66,67,68,69,70,71,72,73,74,75,76,77] |

| Component | Service Life [Years] |

|---|---|

| Rail replacement | 28 |

| Sleepers replacement | 40 |

| Fastenings replacement | 40 |

| Ballast recovery | 30 |

| Tamping/levelling | 1-5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).