Submitted:

30 October 2023

Posted:

31 October 2023

Read the latest preprint version here

Abstract

Keywords:

1. Introduction

2. Horizontal-well cavity leaching test

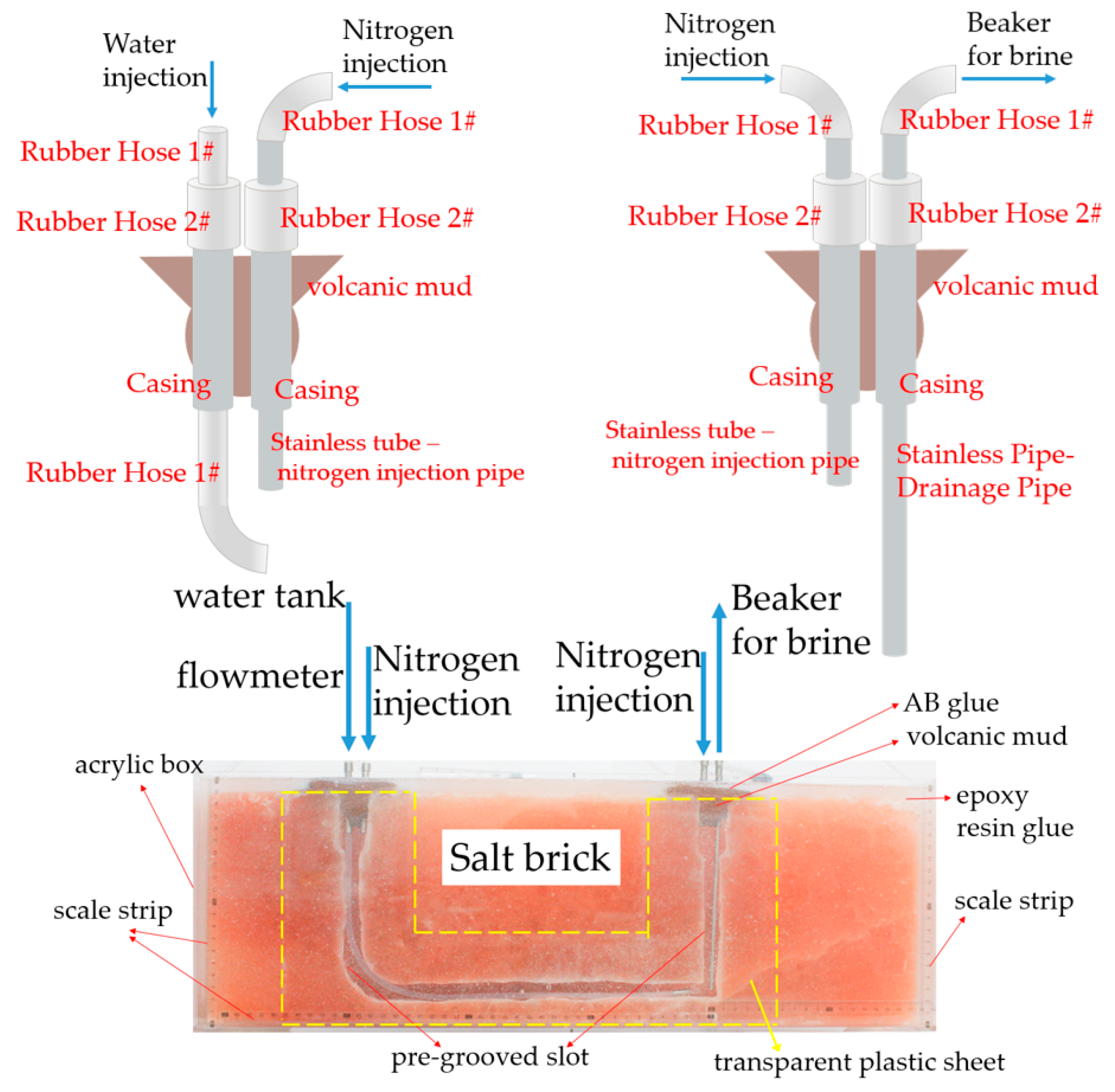

2.1. Construction of leaching test platform

2.2. Experiments design

2.1.1. Test procedure

- Select a salt brick with less impurities and no obvious cracks, clean the surface and absorb the moisture, select a more homogeneous cavity surface, and hand-polish the surface so that the surface flatness can meet the test requirements.

- Put the salt bricks flat, cavity surface upward, marking the slotting position with line in the cavity face. Grooving with drill bit diameter of 6mm drilling machine on slotting position of the cavity face, so that the slot width of the same, about 15mm, the upper slot slightly wider.After the completion of grooving, in the cavity surface of the channel around the uniform coverage of a thin layer of transparent epoxy resin adhesive, and covered with transparent plastic sheet for sealing paste, to prevent the subsequent filling of adhesive gel into the groove. Paste the thin plate need to control the dosage, to avoid the gel into the slot. After slotting and sealing, due to the fluidity of the adhesive, in order to avoid displacement of the adhesive before drying, it is necessary to keep the slotting cavity surface placed horizontally and wait for the epoxy resin adhesive to dry.

- Stand the salt-brick cavity-making surface upright, fix the side-by-side casing and gas pipe with volcanic mud, insert the pipe column into the slotted wellhead at the upper end, and subsequently cover the upper surface of the volcanic mud with a layer of AB glue to further ensure the sealing of the wellhead.

- Put the salt brick into the transparent acrylic box as a whole, the length, width and height of the internal dimensions of the acrylic is 1cm more than the length, width and height of the salt brick, and the thickness of the acrylic plate is 5mm. after putting the salt brick into the salt brick, adjust the position of the salt brick so that it is roughly in the centre, and make the cavity surface parallel to the acrylic box. Pour in the evenly mixed transparent epoxy resin glue from the top and fill the gap between the salt brick and the box to complete the overall sealing, and then paste the scale strip on both sides and below the front of the acrylic box. After the glue solidified, the salt brick is placed on a high load-bearing horizontal tabletop, and rubber hoses are used to connect the water tank, flowmeter, water injection tube in turn, and the end port of the brine tube is placed into a beaker, and the sealing of the connection port is carried out to test the airtightness. After opening the valve of the water tank and adjusting the flow meter to the test flow, the corresponding test can be carried out according to the test design parameters.

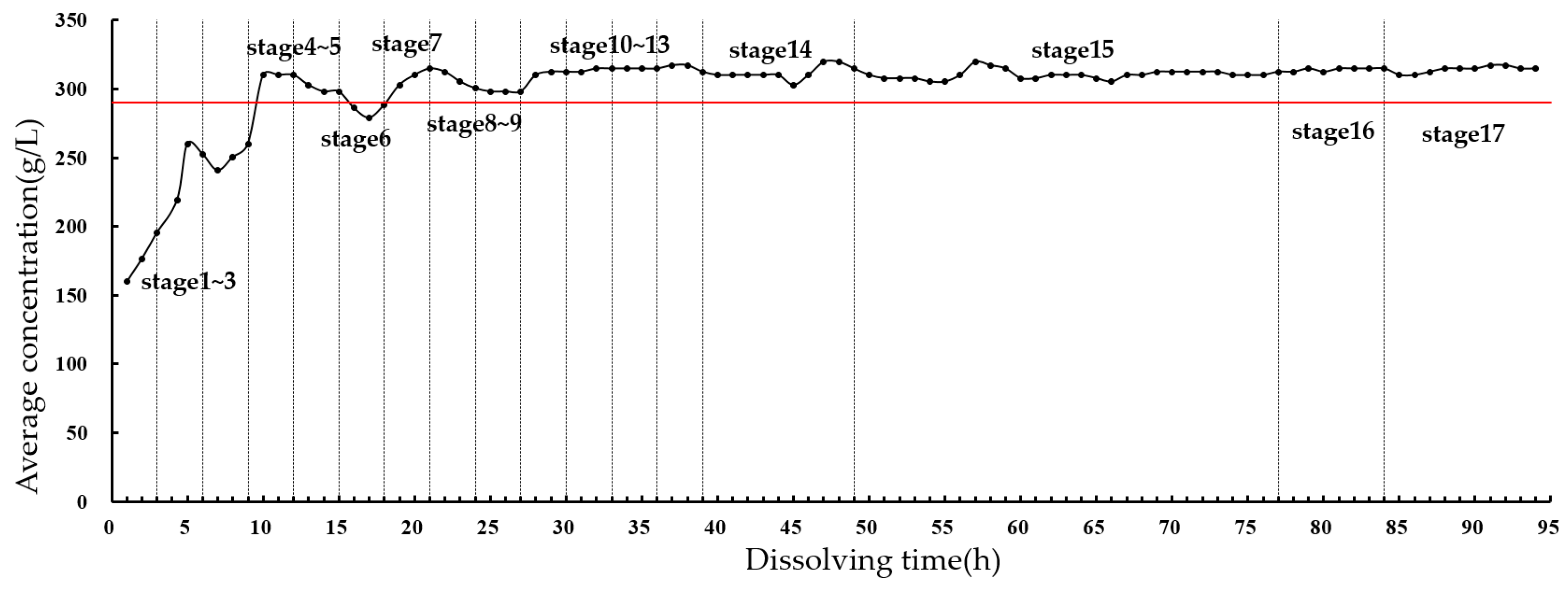

- Measure the concentration and volume of brine at the mouth of the brine discharge every 10 minutes after the test is opened, and record the shape of the cavity at this time with a video camera, and after the concentration is stable, the measurement interval is changed to 30 minutes; after the completion of a certain stage of the cavity-leaching stage is completed, adjust the water injection pipe, the drainage pipe and the position of the liquid level in accordance with the test programme, and then enter into the next cavity-leaching stage.

| Tubes | Inner diameter (mm) | Outer diameter (mm) | Wall thickness (mm) | Tube length (mm) | Notes |

|---|---|---|---|---|---|

| Casing | 5 | 6 | 0.5 | 60 | Fixed with volcanic clay and AB glue at the upper end of the slot on both sides for inserting the injection tube and drainage tube |

| Stainless tube - nitrogen injection pipe | 3.6 | 4 | 0.2 | 130 | Fixed with volcanic mud and AB glue on the upper end of the slot on both sides |

| Stainless Pipe-Drainage Pipe | 3.6 | 4 | 0.2 | 240 | Inserted into the casing at the right straight well end and wrapped with waterproof tape on the outer layer |

| Rubber Hose 1# | 3 | 5 | 1 | - | Water injection tube inserted into the casing in the inclined well, sealing tube at the upper end of the nitrogen injection pipe |

| Rubber Hose 2# | 4 | 6 | 1 | 6 | Wrapped around the outside of the casing to seal the wellhead on both sides |

| Rubber Hose 3# | 4 | 8 | 2 | - | Externally connected to the flow meter and indirectly connected to the tap |

| Rubber Hose 4# | 7 | 9 | 1 | - | Externally connected to the water tap and connected to the rubber hose 4# |

2.2.2. Horizontal-well cavity leaching test with nitrogen cushion in large size salt rock

2.3. Analysis of test results

3. Numerical analysis

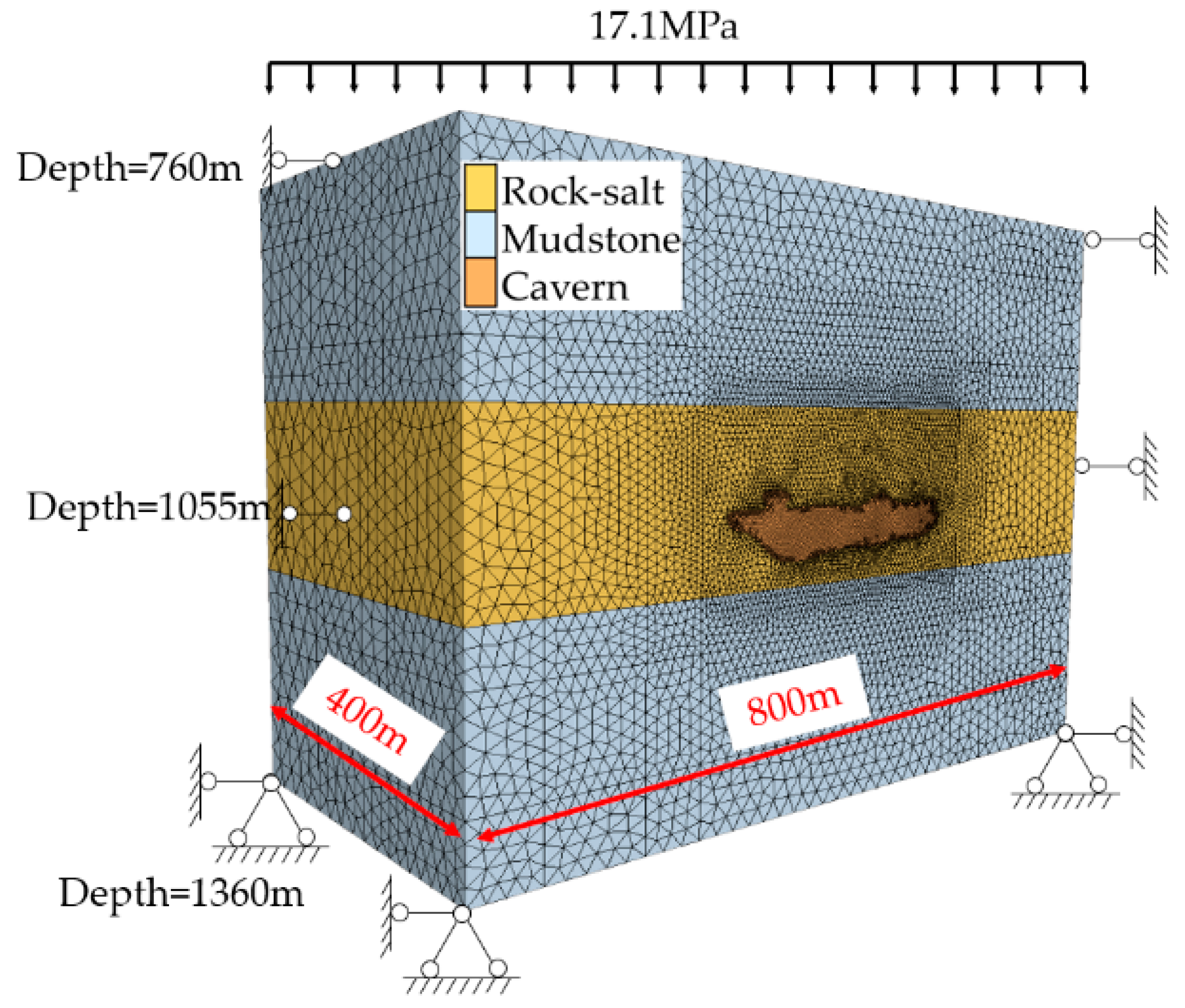

3.1. Numerical modelling

3.2. Analysis of simulation results

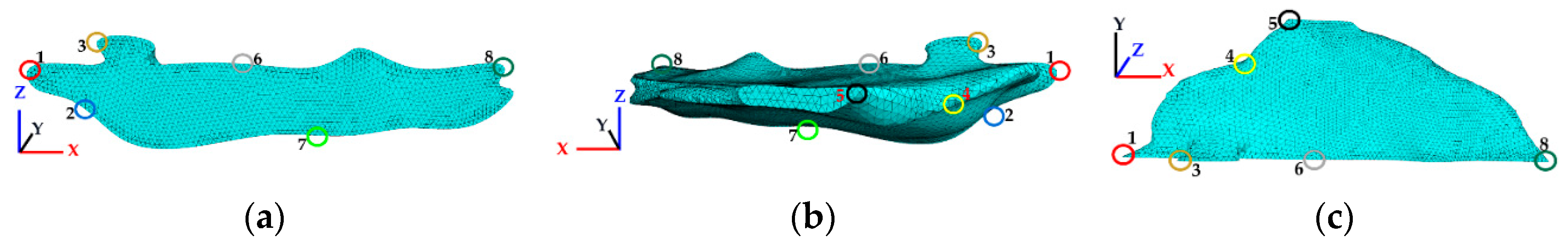

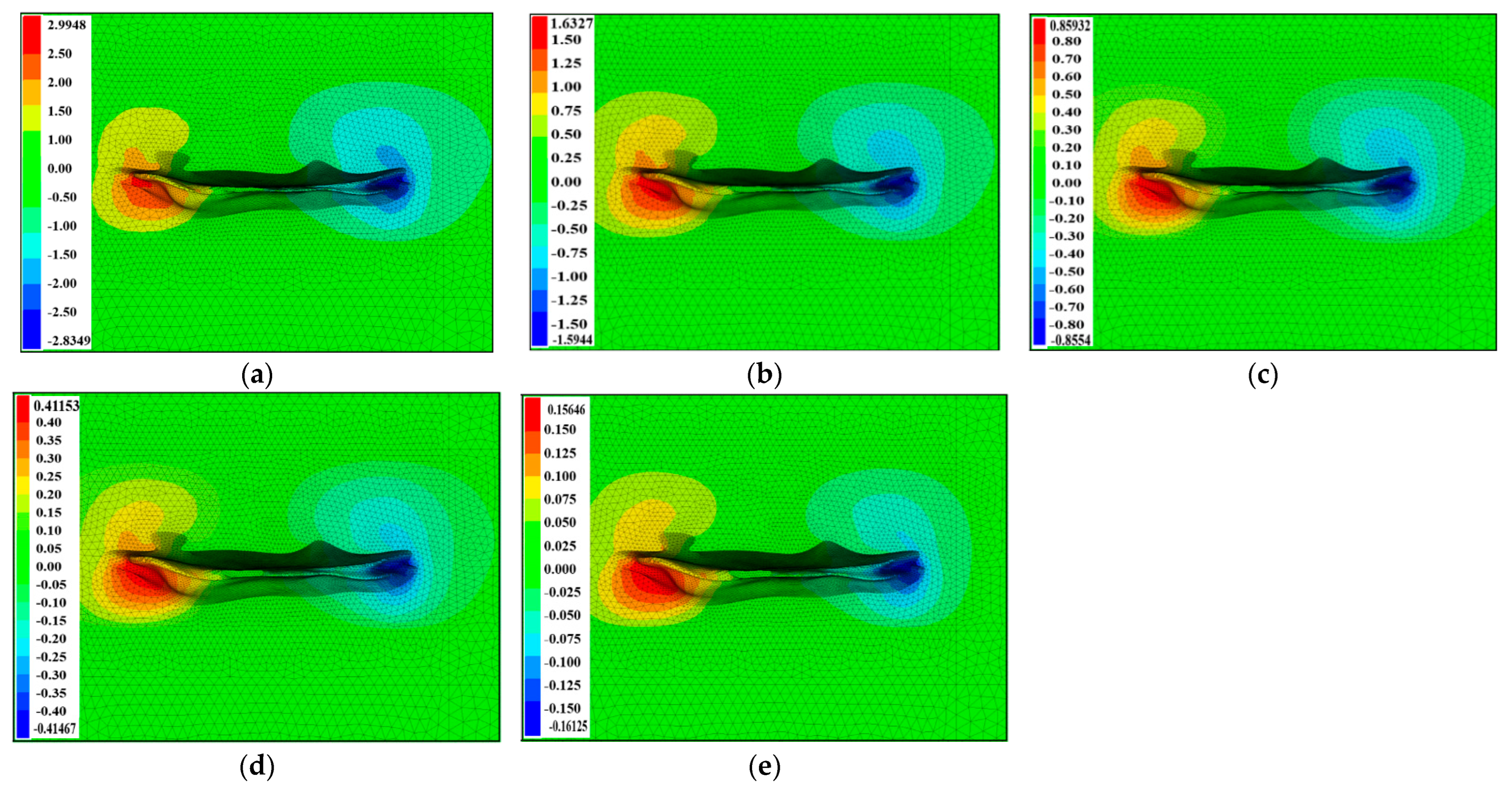

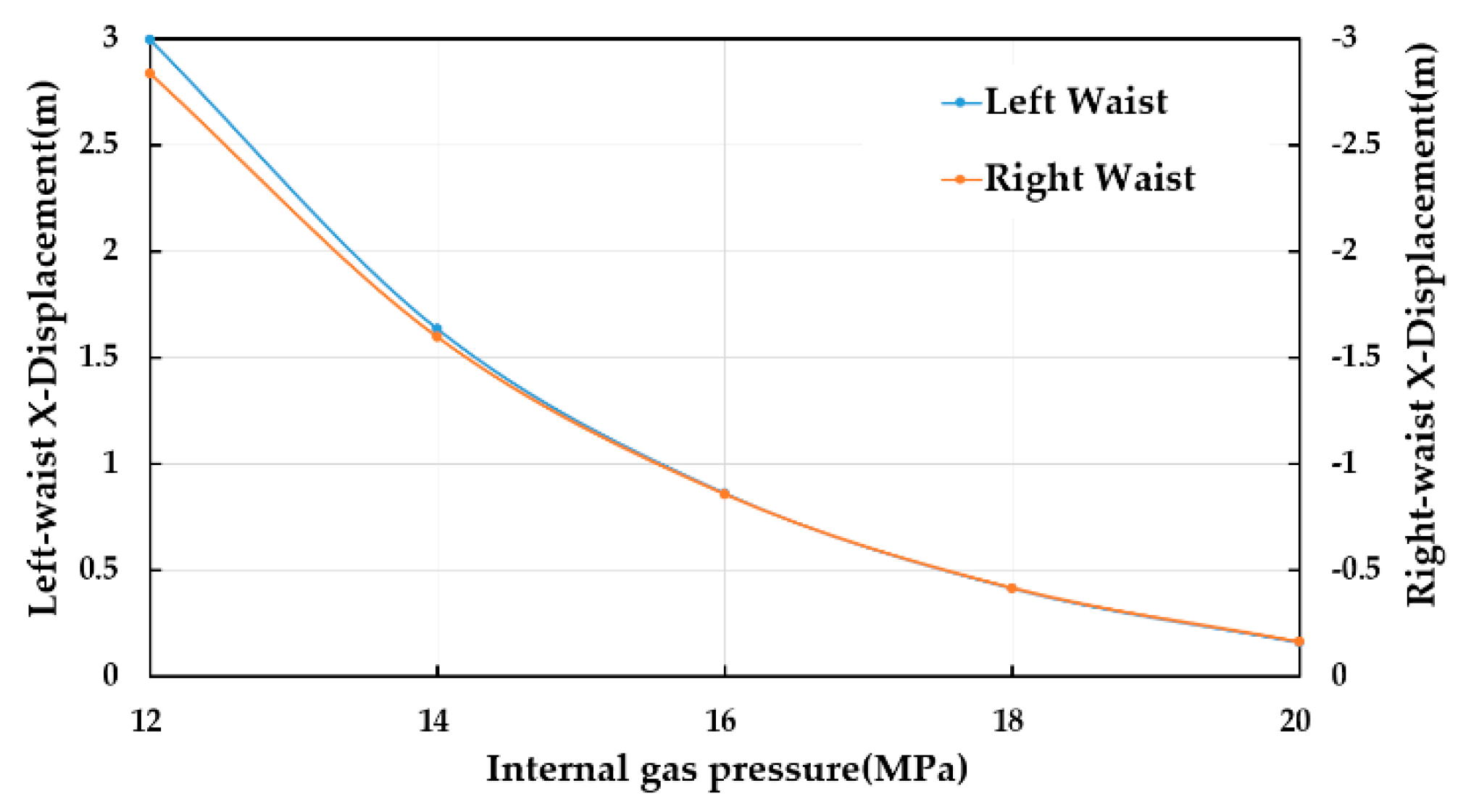

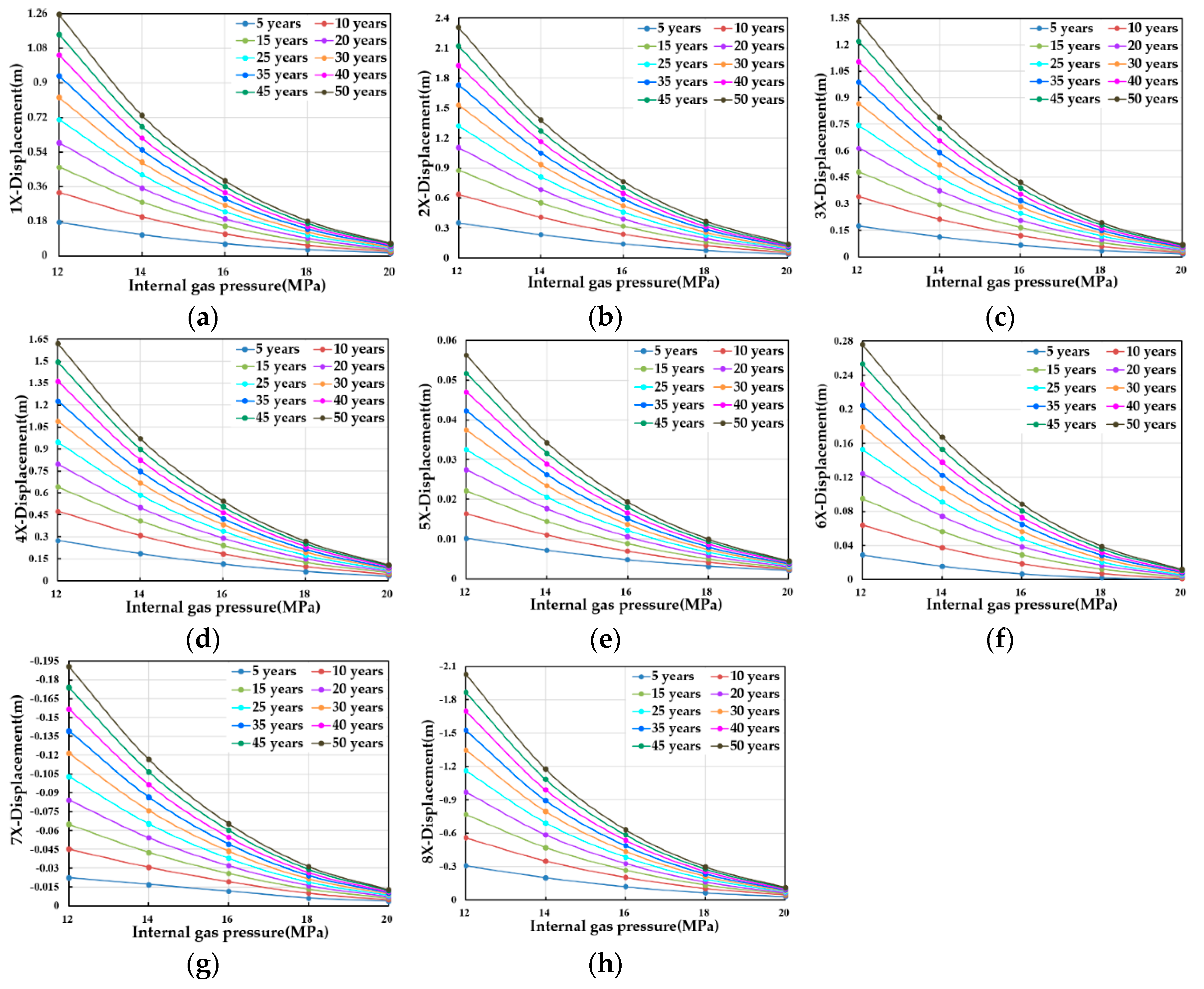

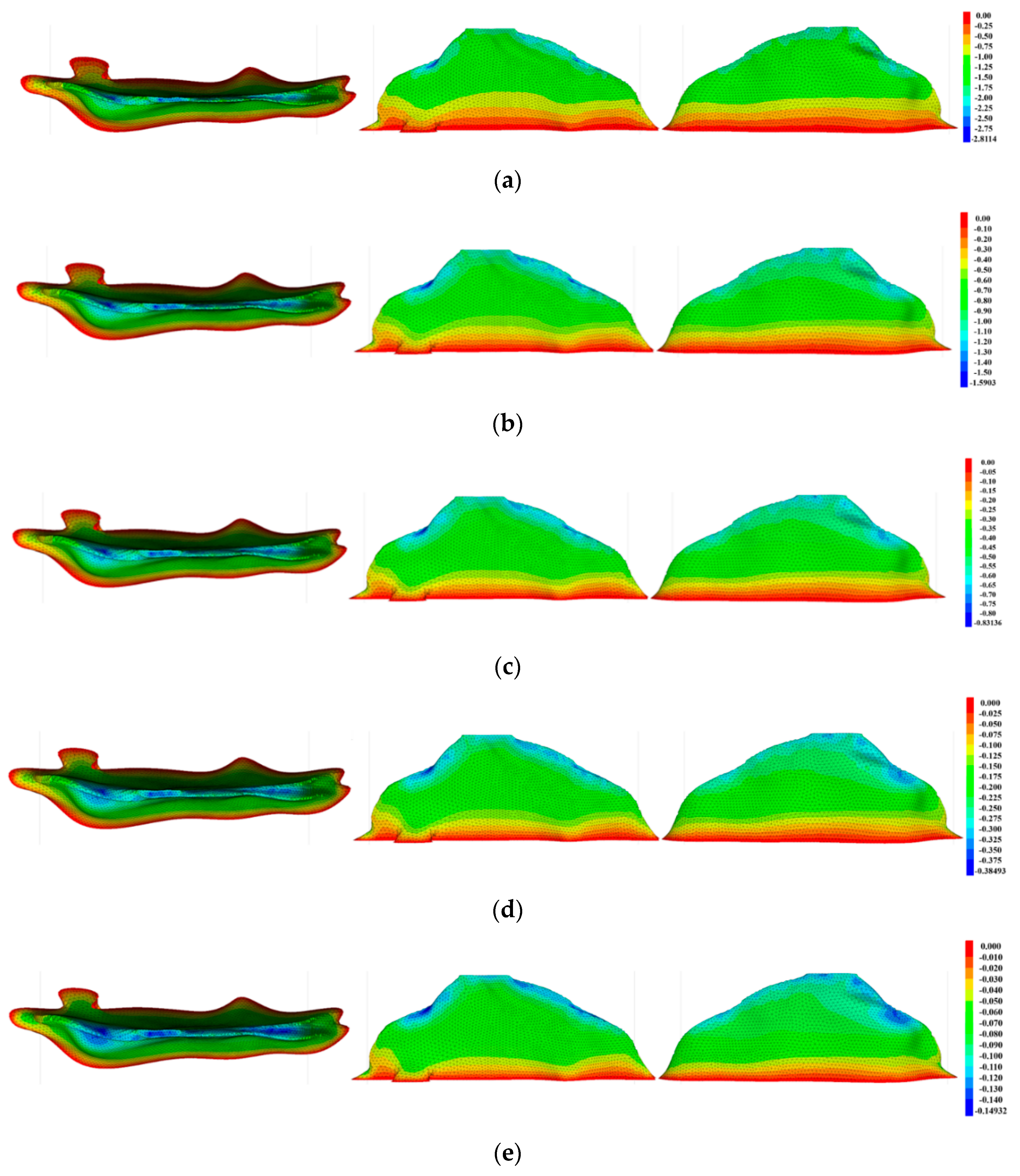

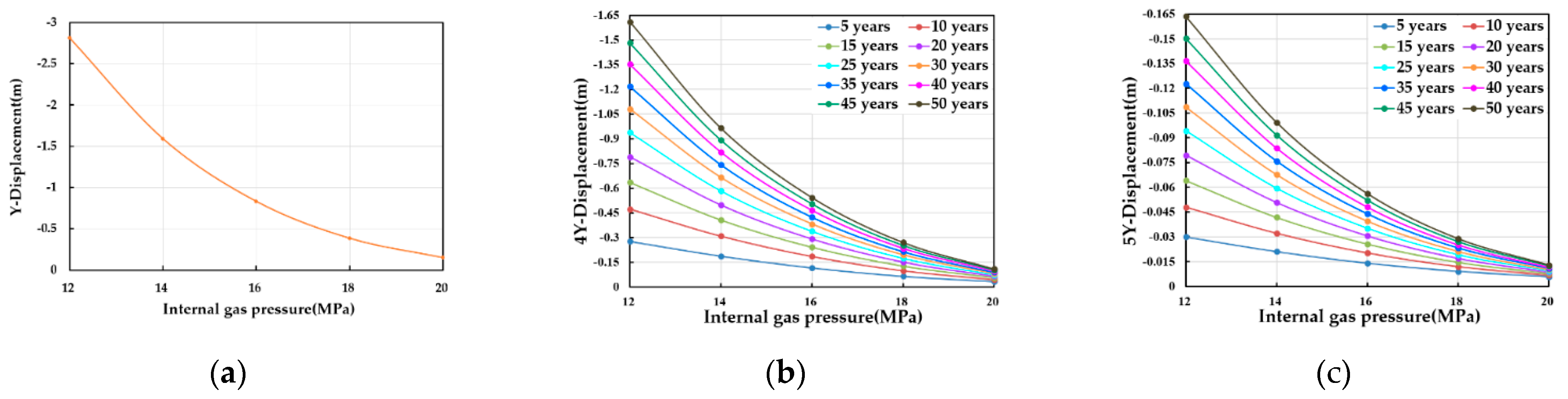

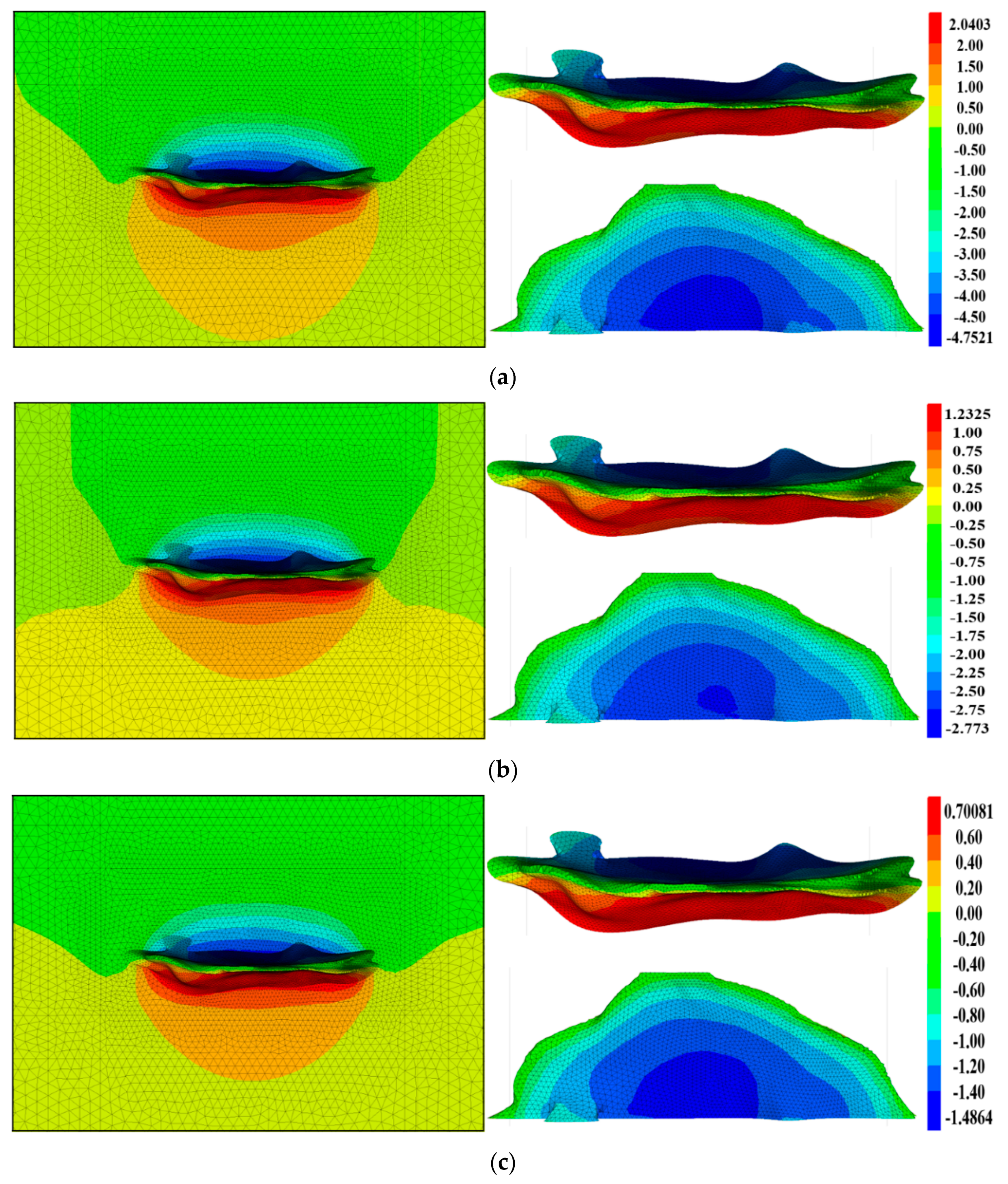

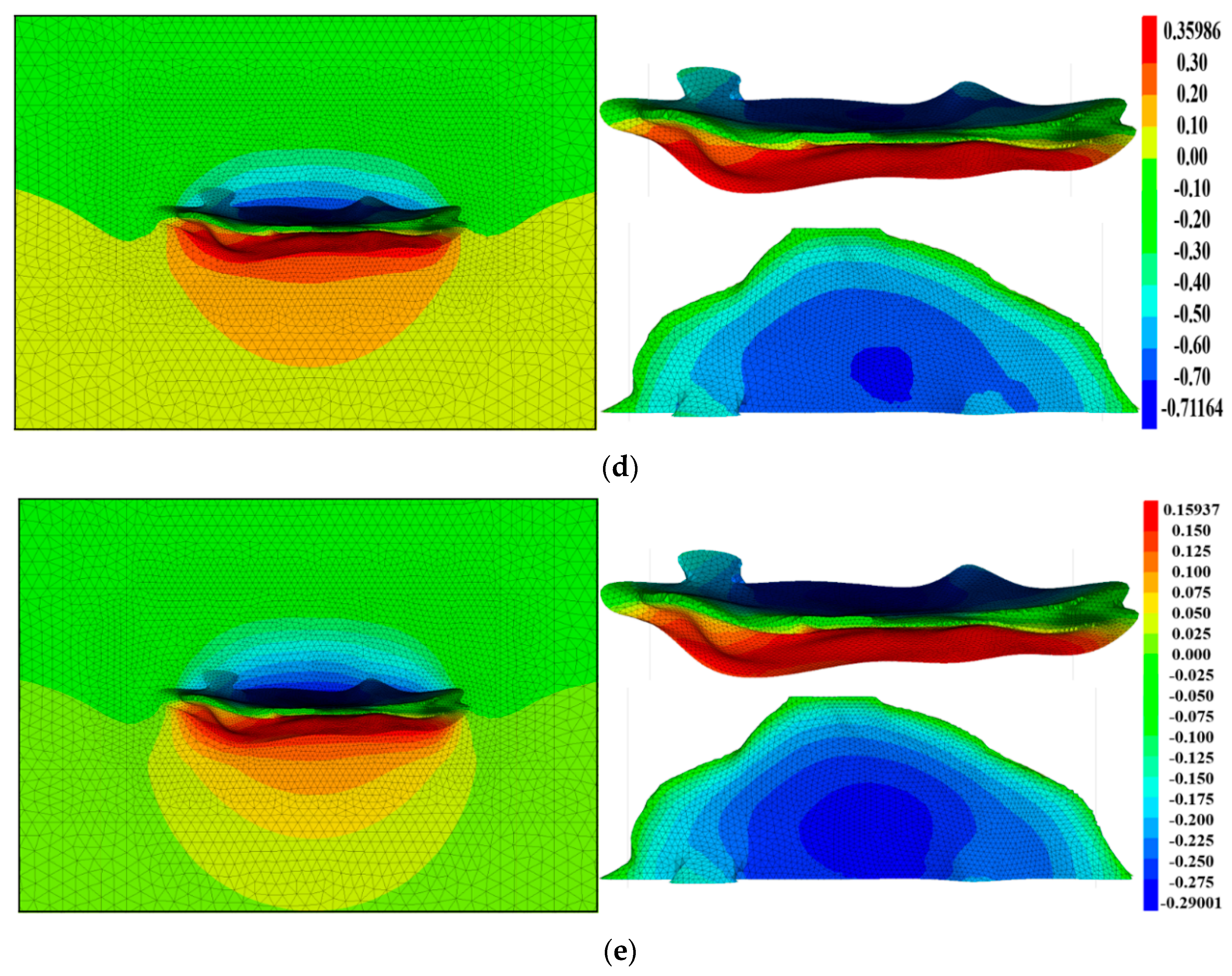

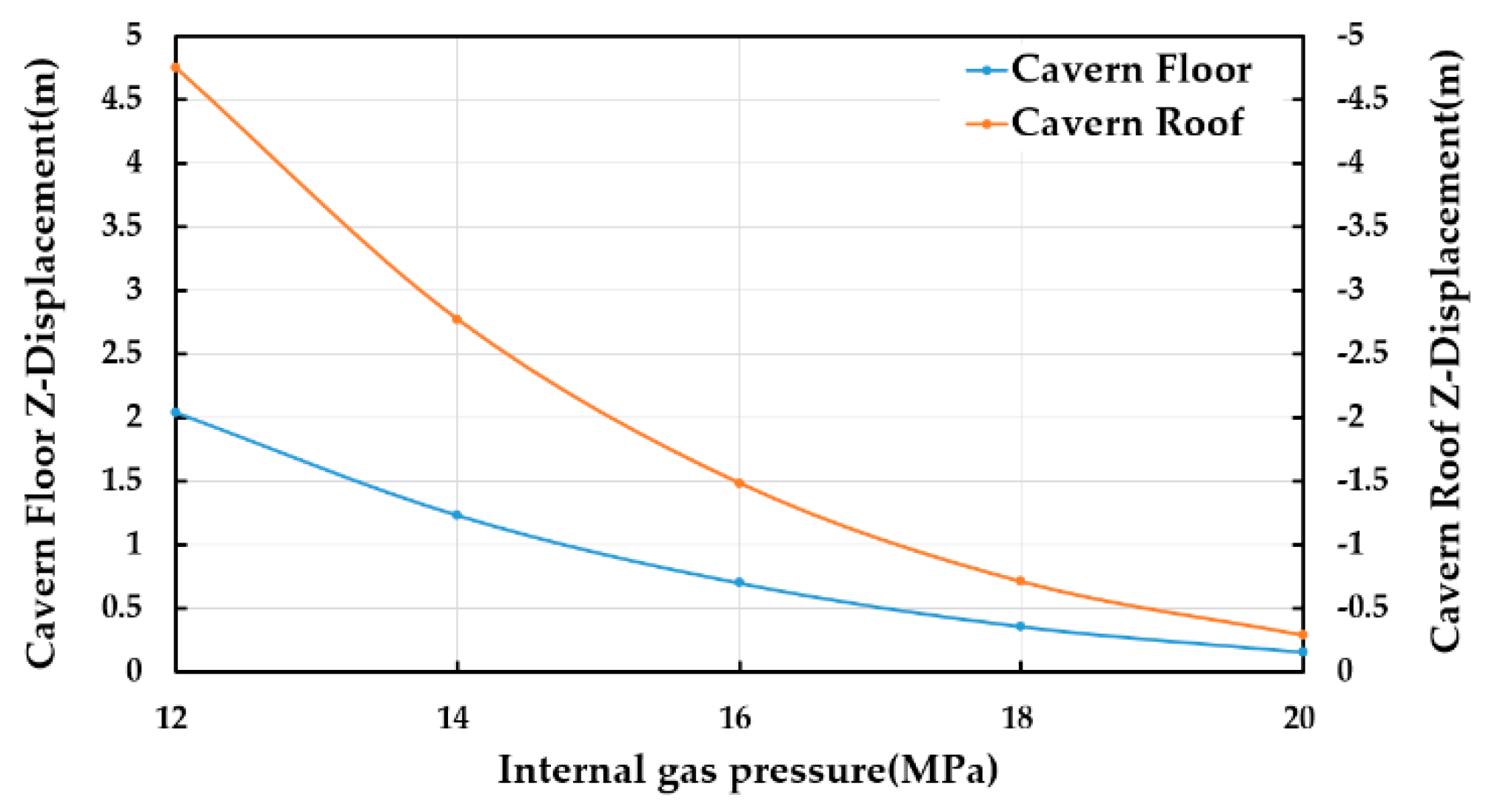

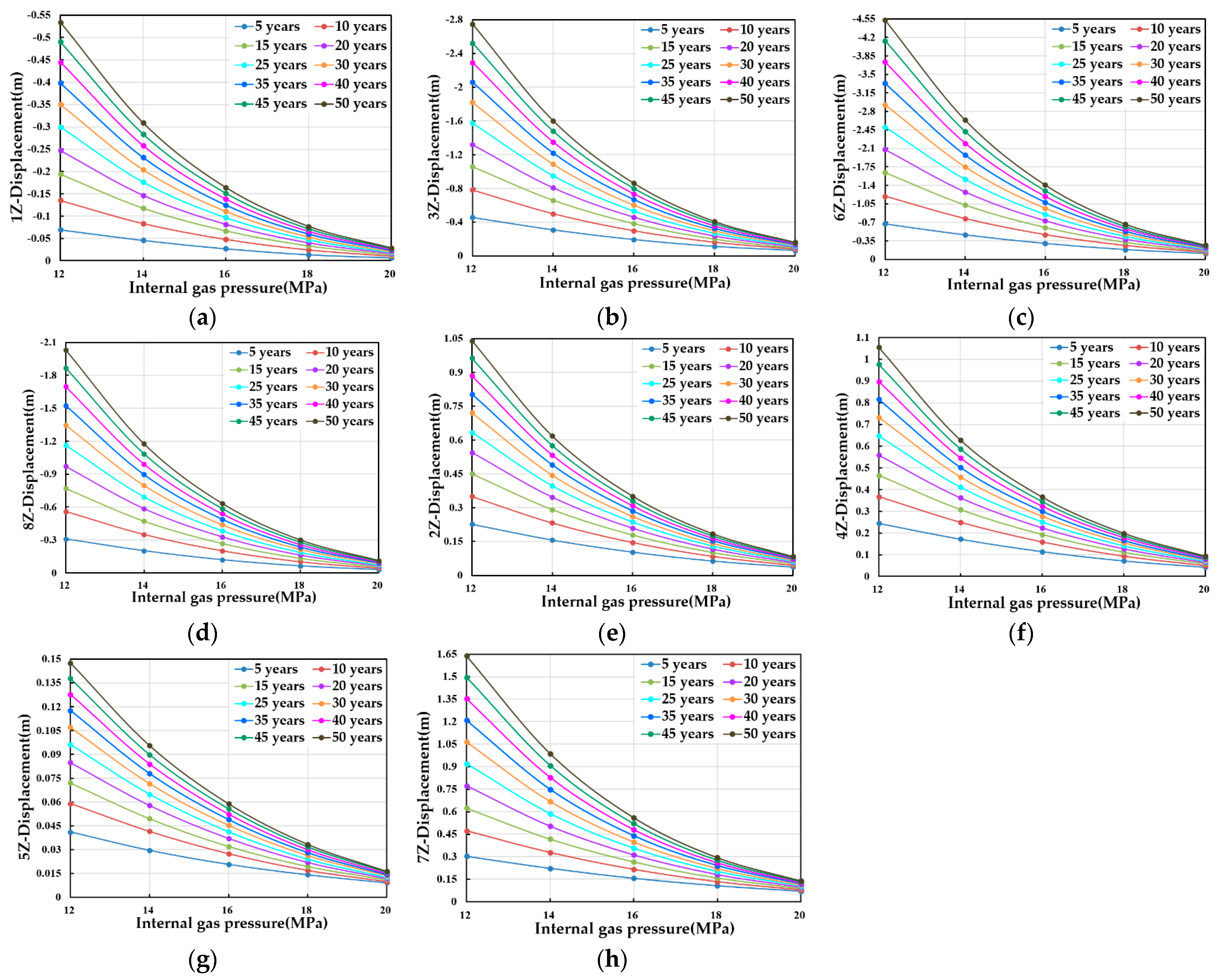

3.2.1. Displacement analysis of Horizontal-well cavity

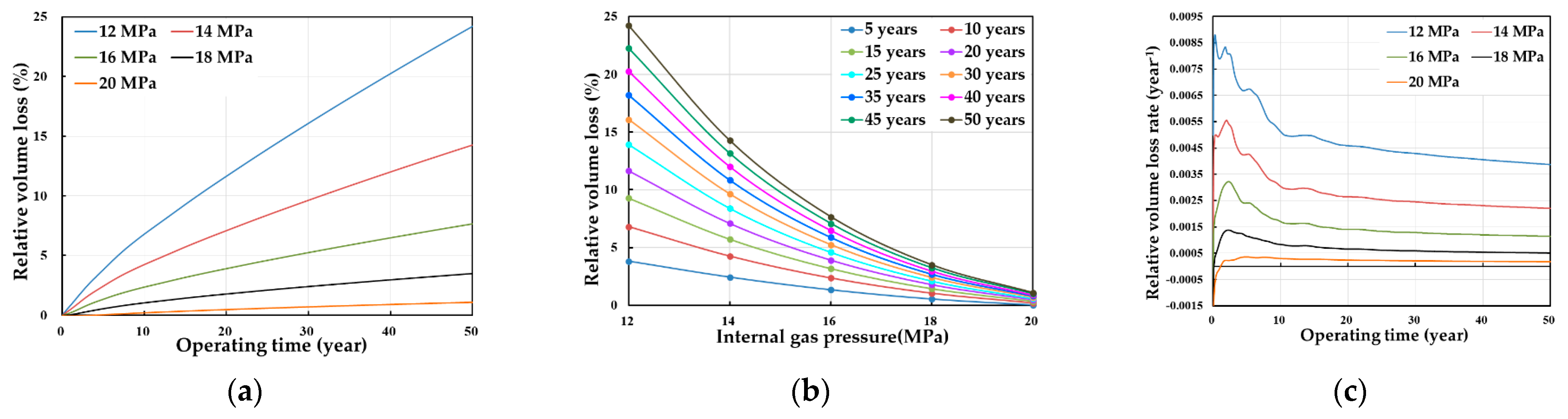

3.2.2. Ralative volume loss of horizontal-well cavity

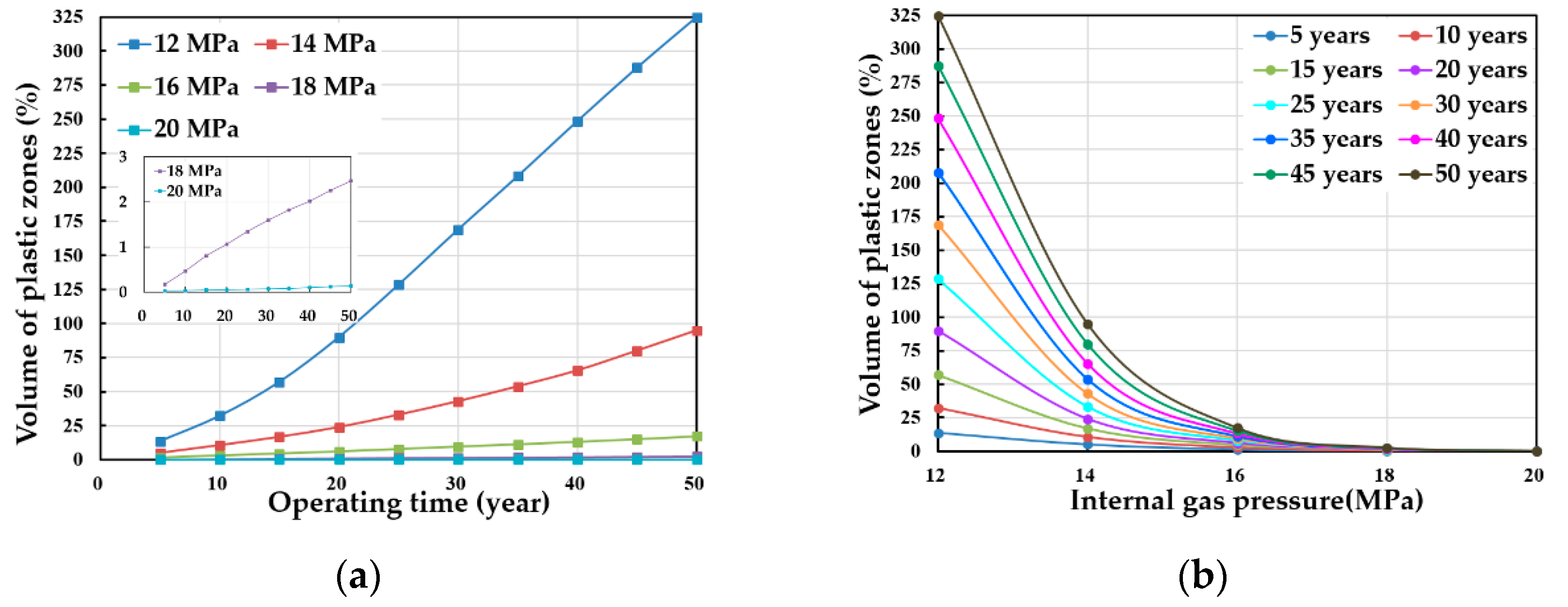

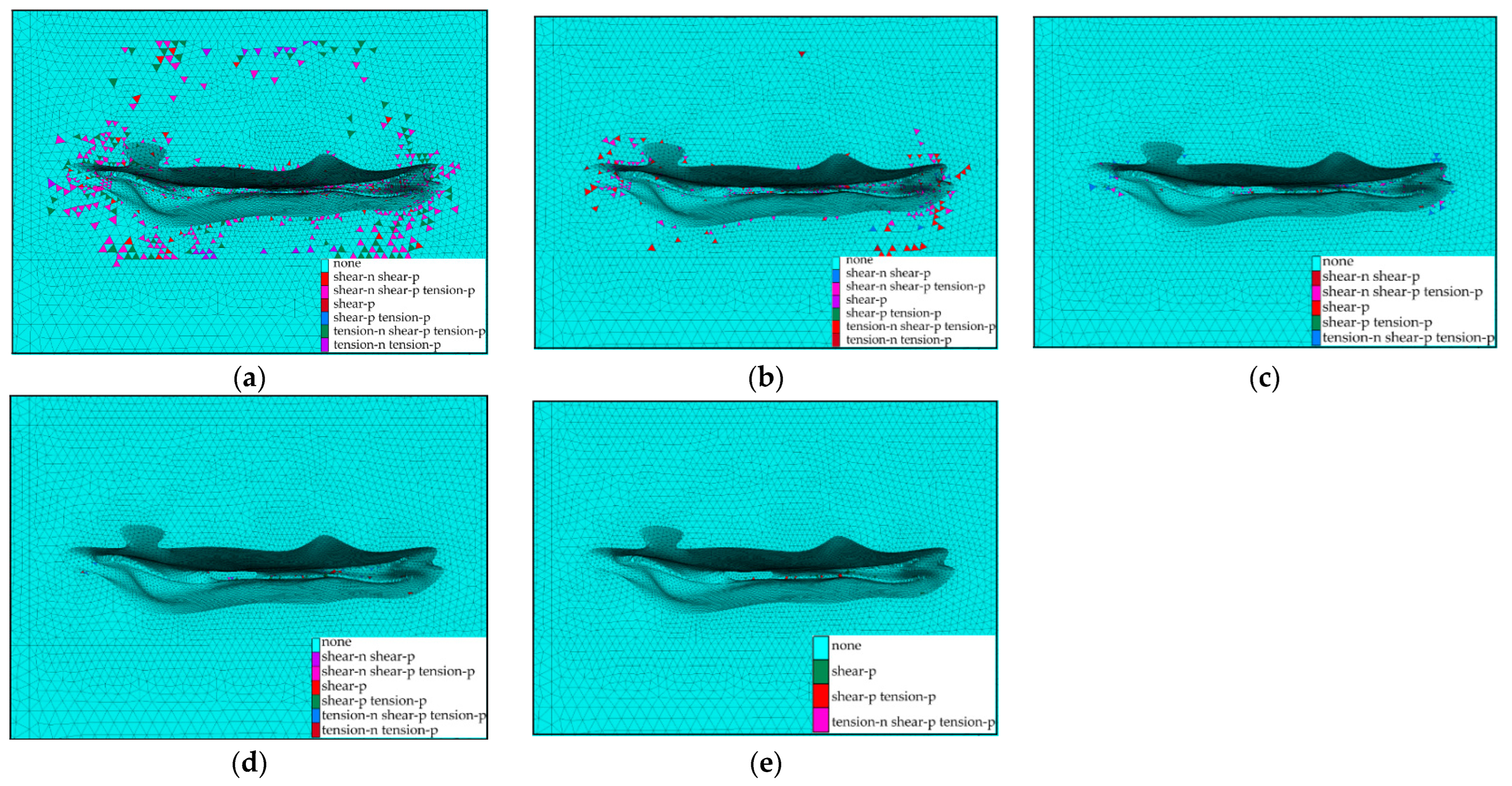

3.2.3. Plastic zone volume of horizontal-well cavity

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Ahmed DS, El-Hiti GA, Yousif E, Hameed AS, Abdalla M. New Eco-Friendly Phosphorus Organic Polymers as Gas Storage Media. Polymers (Basel) 2017, 9, 336. [CrossRef] [PubMed]

- Hadi AG, Jawad K, Yousif E, El-Hiti GA, Alotaibi MH, Ahmed DS. Synthesis of Telmisartan Organotin(IV) Complexes and their use as Carbon Dioxide Capture Media. Molecules 2019, 24, 1631. [CrossRef] [PubMed]

- Xie M, Min J, Fang X, Sun C, Zhang Z. Policy selection based on China’s natural gas security evaluation and comparison. ENERGY 2022, 247, 123460. [CrossRef]

- Li J-M, Dong X-C, Jiang Q-Z, Dong K-Y. Urban natural gas demand and factors analysis in China: Perspectives of price and income elasticities. Pet Sci 2022, 19, 429–40. [CrossRef]

- Capros P, Zazias G, Evangelopoulou S, Kannavou M, Fotiou T, Siskos P, et al. Energy-system modelling of the EU strategy towards climate-neutrality. ENERGY POLICY 2019, 134, 110960. [CrossRef]

- Rodrigues R, Pietzcker R, Fragkos P, Price J, McDowall W, Siskos P, et al. Narrative-driven alternative roads to achieve mid-century CO2 net neutrality in Europe. ENERGY 2022, 239, 121908. [CrossRef]

- Yang C, Wang T, Li Y, Yang H, Li J, Qu D, et al. Feasibility analysis of using abandoned salt caverns for large-scale underground energy storage in China. Appl Energy 2015, 137, 467–81. [CrossRef]

- Zhu K, Zhao Y, Xu X, Hao L. Measuring the natural gas supply security performance of China’s natural gas suppliers: A comprehensive framework using FAHP-Entropy-PROOTHEE method. J Clean Prod 2022, 345, 131093. [CrossRef]

- Wang T, Yan X, Yang H, Yang X, Jiang T, Zhao S. A new shape design method of salt cavern used as underground gas storage. Appl Energy 2013, 104, 50–61. [CrossRef]

- Yang C, Wang T. Advance in deep underground energy storage. Chinese Journal of Rock Mechanics and Engineering 2022, 41, 1729–1759.

- Li Z, Yang Z, Fan J, Fourmeau M, Jiang D, Nelias D. Fatigue Mechanical Properties of Salt Rocks Under High Stress Plateaus: The Interaction Between Creep and Fatigue. Rock Mech Rock Eng 2022, 55, 6627–42. [CrossRef]

- Malyukov, V.P., Shepilev, A.A. Innovative Technologies for Construction of Horizontal and Double-Deck Underground Tanks in Rock Salt. In: Chaplina, T. (eds) Processes in GeoMedia—Volume IV. Springer Geology. Springer, Cham. 2022.

- Zhang B, Lv B, Wu Y, et al. Development and Trend of Salt-Cavern Gas Storage in Domestic and Abroad. China Well and Rock Salt 2021, 52, 21–24.

- Lux K-H. Design of salt caverns for the storage of natural gas, crude oil and compressed air: Geomechanical aspects of construction, operation and abandonment. Geol Soc Lond Spec Publ 2009, 313, 93–128. [CrossRef]

- Chen Y, Wei J. Physical model test of Jintan underground gas storage cavern group. Geomech Eng 2022, 30, 45–9.

- He T, Wang T, Wang D, Xie D, Dong Z, Zhang H, et al. Integrity analysis of wellbores in the bedded salt cavern for energy storage. ENERGY 2023, 263, 125841. [CrossRef]

- Ma H. A Preliminary Study on the Development Current Situation of Salt Cavern Gas Storage in Domestic. China Well and Rock Salt 2021, 52, 12–15.

- Williams JDO, Williamson JP, Parkes D, Evans DJ, Kirk KL, Sunny N, et al. Does the United Kingdom have sufficient geological storage capacity to support a hydrogen economy? Estimating the salt cavern storage potential of bedded halite formations. J Energy Storage 2022, 53, 105109. [CrossRef]

- Lankof L, Urbańczyk K, Tarkowski R. Assessment of the potential for underground hydrogen storage in salt domes. Renew Sustain Energy Rev 2022, 160, 112309. [CrossRef]

- Korzeniowski W, Poborska-Młynarska K, Skrzypkowski K, Zagórski K, Chromik M. Cutting Niches in Rock Salt by Means of a High-Pressure Water Jet in Order to Accelerate the Leaching of Storage Caverns for Hydrogen or Hydrocarbons. Energies 2020, 13, 1911. [CrossRef]

- Shi X, Chen Q, Ma H, Li Y, Wang T, Zhang C. Geomechanical investigation for abandoned salt caverns used for solid waste disposal. Bull Eng Geol Environ 2021, 80, 1205–18. [CrossRef]

- Wang J, Wang N, Xu K, Xia. J. Calculation method for effective cavity volume of salt cavern gas storage. Oil & Gas Storage and Transportation, 2021.

- Yu P, An optimization mass-balance method for calculating the leaching volume of salt-cavern underground gas storage. Petrochemical Industry Application 2020, 39, 4.

- Jiang D, Wang Y, Liu W, Li L, Qiao W, Chen J, et al. Construction simulation of large-spacing-two-well salt cavern with gas cushion and stability evaluation of cavern for gas storage. J Energy Storage 2022, 48, 103932. [CrossRef]

- Jiang D, Li Z, Liu W, Ban F, Chen J, Wang Y, et al. Construction simulating and controlling of the two-well-vertical(TWV) salt caverns with gas cushion. J Nat Gas Sci Eng 2021, 96, 104291. [CrossRef]

- Thoms R, Gehle R. Feasibility of controlled solution mining from horizontal wells. Solut Min Res Inst 1993.

- Li J, Shi X, Zhang S. Construction modeling and parameter optimization of multi-step horizontal energy storage salt caverns. Energy 2020, 203, 117840. [CrossRef]

- Liu W, Zhang Z, Fan J, Jiang D, Daemen JJK. Research on the Stability and Treatments of Natural Gas Storage Caverns With Different Shapes in Bedded Salt Rocks. IEEE Access 2020, 8, 18995–9007. [CrossRef]

- Bérest, P. Cases, causes and classifications of craters above salt caverns. Int J Rock Mech Min Sci 2017, 100, 318–29. [Google Scholar] [CrossRef]

- Tongtao W, Chunhe Y, Jiasong C, et al. Geomechanical investigation of roof failure of China’s first gas storage salt cavern[J]. Engineering Geology 2018, S001379521830200X.

- Li J, Yang C, Shi X, Xu W, Li Y, Daemen JJK. Construction modeling and shape prediction of horizontal salt caverns for gas/oil storage in bedded salt. J Pet Sci Eng 2020, 190, 107058. [CrossRef]

- Yang J, Li H, Yang C, Li Y, Wang T, Shi X, et al. Physical simulation of flow field and construction process of horizontal salt cavern for natural gas storage. J Nat Gas Sci Eng 2020, 82, 103527. [CrossRef]

- Yang J, Weil M, Gu F. Environmental-economic analysis of the secondary use of electric vehicle batteries in the load shifting of communication base stations: A case study in China. J Energy Storage 2022, 55, 105823. [CrossRef]

- Li D, Liu W, Jiang D, Chen J, Fan J, Qiao W. Quantitative investigation on the stability of salt cavity gas storage with multiple interlayers above the cavity roof. J Energy Storage 2021, 44, 103298. [CrossRef]

- Cui K. Roof with Nitrogen Protection Technology of Underground Gas Storage During the Construction of Cavern Dissolution. China Well and Rock Salt 2016, 47, 15-16+23.

- Wang J, An G, Wang W, Jia J, Liu C, Miao S, et al. Solution-mining-under-nitrogen technology for salt-cavern gas storage and field test. Oil & Gas Storage and Transportation 2021, 40, 802–808.

- Li D, Liu W, Li X, Tang H, Xu G, Jiang D, et al. Physical simulation and feasibility evaluation for construction of salt cavern energy storage with recycled light brine under gas cushion. J Energy Storage 2022, 55, 105643. [CrossRef]

- Zhang G, Zhang H, Liu Y, Wang T, Wang Z. Surrounding rock stability of horizontal cavern reconstructed for gas storage. J ENERGY STORAGE 2023, 59, 106534. [CrossRef]

- Malyukov, V. Studies of the Construction of Horizontal Underground Workings-Tanks Under the Impact of Solution on Rock Salt. PMMEEP 2022: Physical and Mathematical Modeling of Earth and Environment Processes—2022, pp 387–393.

- Wan J. Influence of tubing/oil-blanket lifting on construction and geometries of two-well-horizontal salt caverns. Tunnelling and Underground Space Technology 2020, 108.

- Saberian A. A preliminary model horizontal well leaching, SMRI Paper, San Antonio, 1995.

- Wang J, Wang Z, Zeng Q, et al. Simulation of Flow Field of Solution Mining Salt Cavities for Underground Gas Storage. Journal of Energy Resources Technology 2022, 145, 1–19.

- Zhang G, Zhang H, et al. Surrounding rock stability of horizontal cavern reconstructed for gas storage. Journal of Energy Storage 2023, 59, 106534.

- Xing, W., Zhao, J., Hou, Z. et al. Horizontal natural gas caverns in thin-bedded rock salt formations. Environ Earth Sci 2015, 73, 6973–6985. [CrossRef]

- Li, Qingdong & Ning, Zexu & Liu, Jia & Xu, Wenjie & Zhan, Liangtong & Liu, Jiqin & Chen, Yunmin & Shi, Xilin & Chen, Xiangsheng & Li, Jinlong. Stability and economic evaluation of multi-step horizontal salt caverns with different step distances in bedded salt formations. Journal of Energy Storage 2023, 57, 106192.

- Wang J, Wang X, Long-term stability analysis and evaluation of horizontal salt cavern gas storage. Journal of Energy Storage 2023, 66, 107413. [CrossRef]

| Parameters | Dimension(unit) | Parameters | Dimension(unit) |

|---|---|---|---|

| l | L | c | ML-3 |

| t | T | T | Θ |

| ρ | ML-3 | q | L3T-1 |

| ω | ML-2T-1 |

| Parameters | Cavity diameter /m |

Density of salt rock /kg·m-3 | Dissolution rate of the brine/g·cm-2·h-1 | Mining time/h | Brine concentration/g·L-1 | Flow rate/ ml·min-1 |

|---|---|---|---|---|---|---|

| Prototype | 125 | 2176 | 3.68 | - | - | 50 m3/h |

| Model | 0.25 | 2117 | 1.42 | - | - | 10 ml/min |

| Similarity Ratio | 500 | 1 | 2.59 | 1500 | 1 | 83333 |

| Stage | Duration (h) | Flow rate (ml/min) |

Wellhead distance (mm) |

|---|---|---|---|

| 1 | 3 | 3 | 5 |

| 2 | 3 | 6 | 5 |

| 3 | 3 | 9 | 5 |

| 4 | 3 | 3 | 35 |

| 5 | 3 | 6 | 35 |

| 6 | 3 | 9 | 35 |

| 7 | 3 | 3 | 65 |

| 8 | 3 | 6 | 65 |

| 9 | 3 | 9 | 65 |

| 10 | 3 | 3 | 95 |

| 11 | 3 | 3 | 125 |

| 12 | 3 | 6 | 125 |

| 13 | 3 | 9 | 125 |

| 14 | 10 | 12 | 125 |

| 15 | 28 | 12 | 155 |

| 16 | 7 | 12 | 155 |

| 17 | 10 | 15 | 155 |

| Lithology | Modulus of elasticity (GPa) | Poisson’s ratio | Cohesive force (MPa) |

internal friction angle(°) | Tensile strength (MPa) |

|---|---|---|---|---|---|

| mudstone | 10 | 0.27 | 2.5 | 35 | 1.5 |

| Rock salt | 15 | 0.3 | 1.75 | 37.5 | 1.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).