Submitted:

12 September 2023

Posted:

15 September 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Computational Model

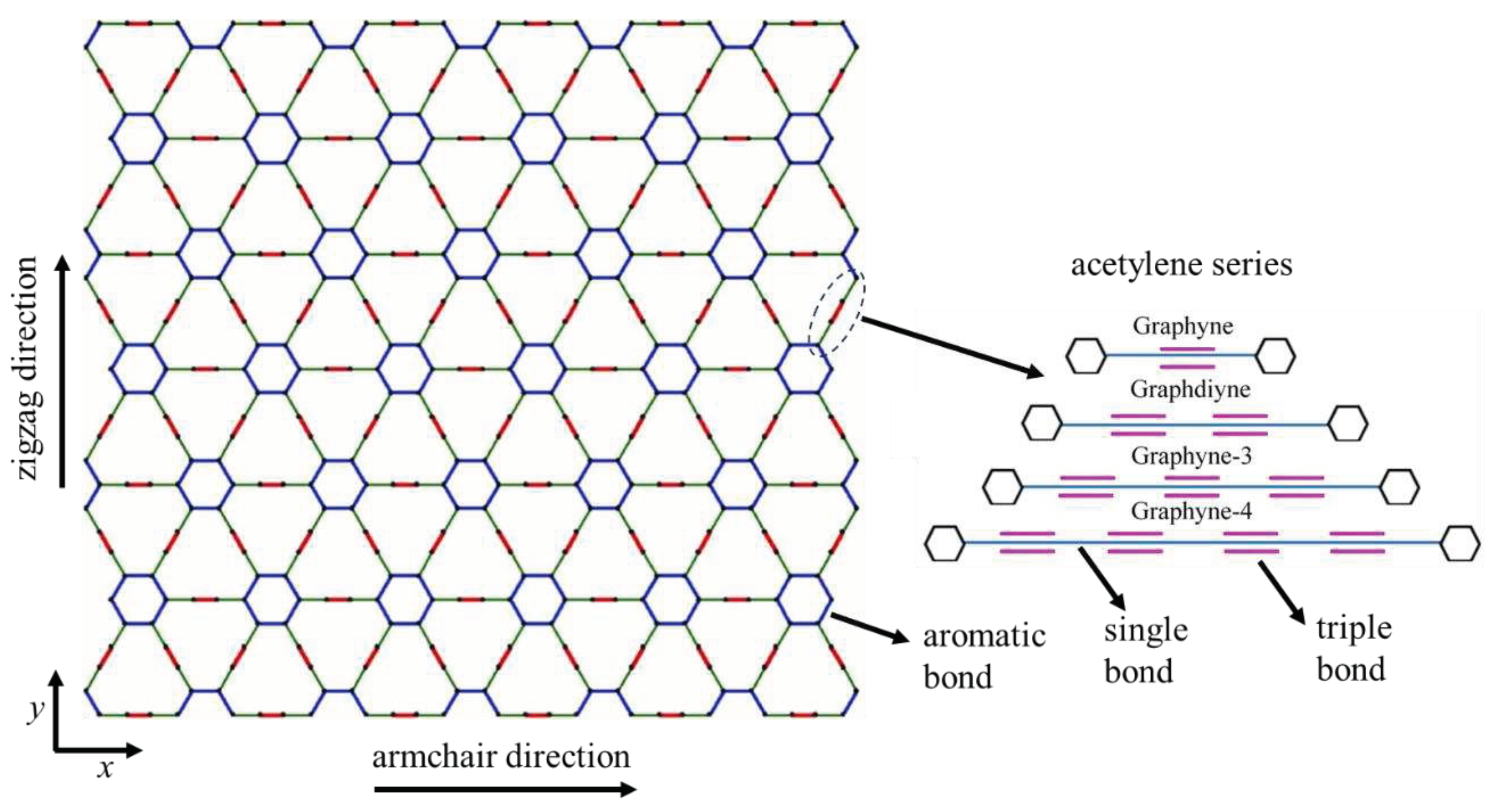

2.1. Geometric Characteristics

2.2. Force Field Description

2.3. Finite Element Model

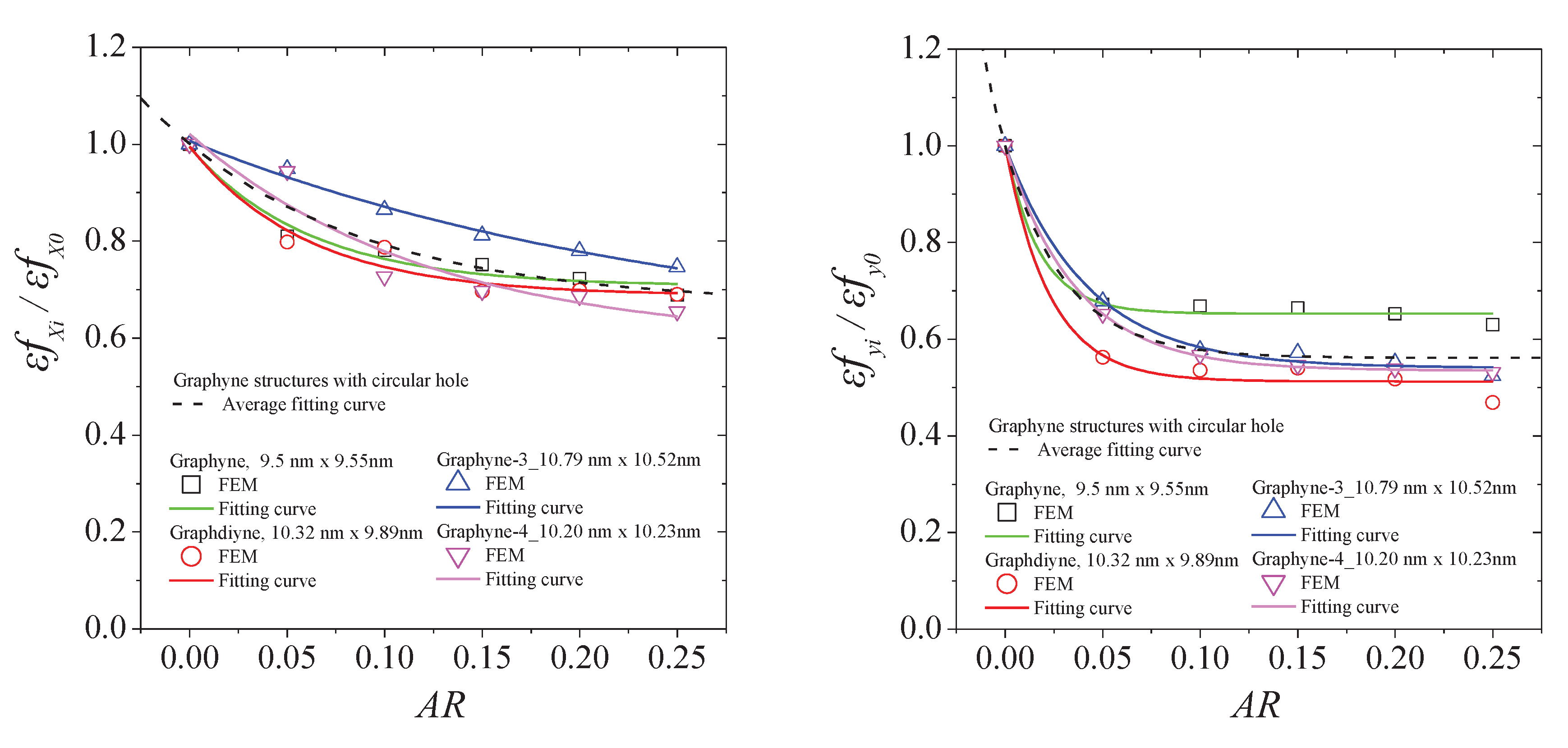

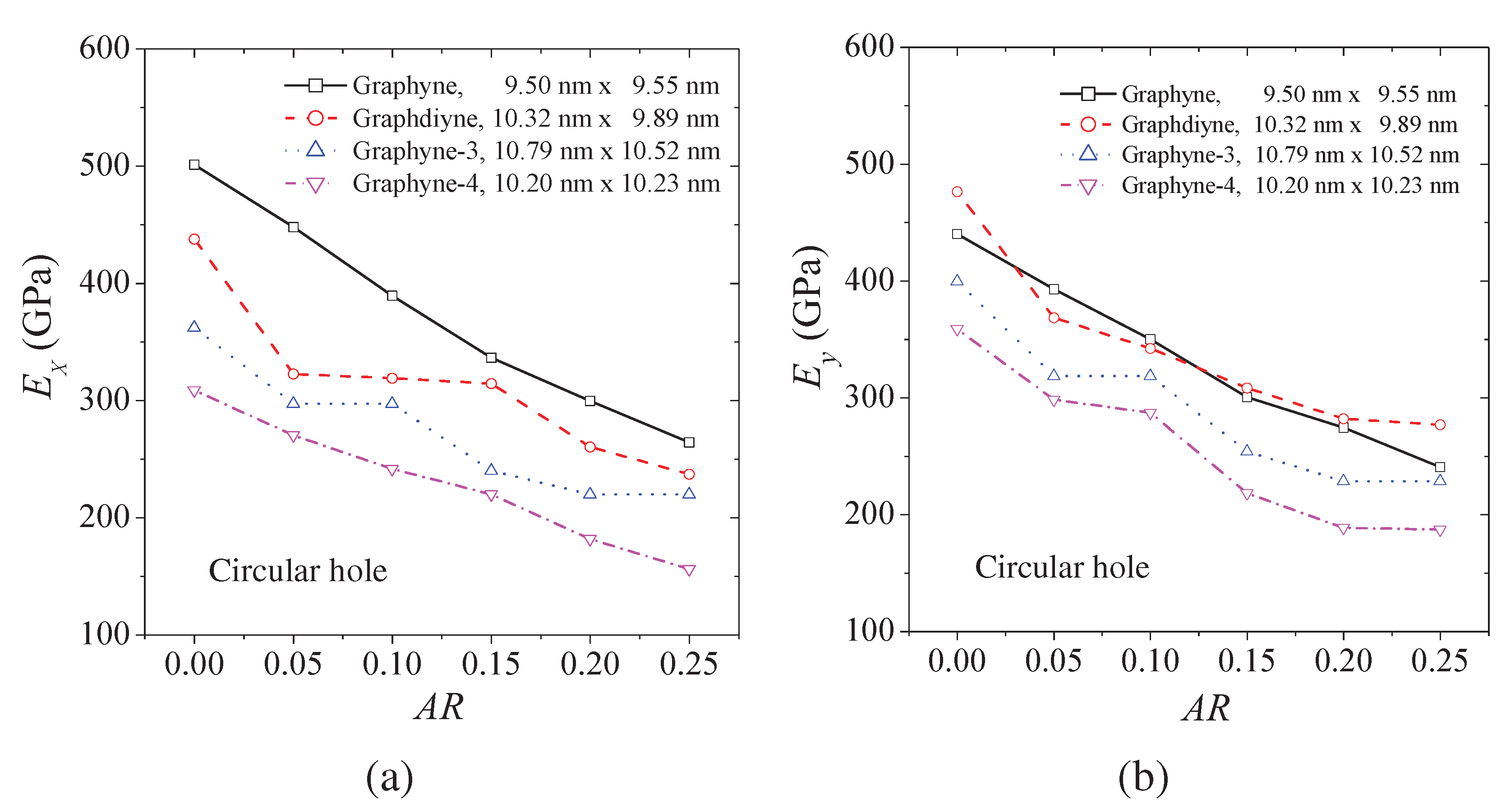

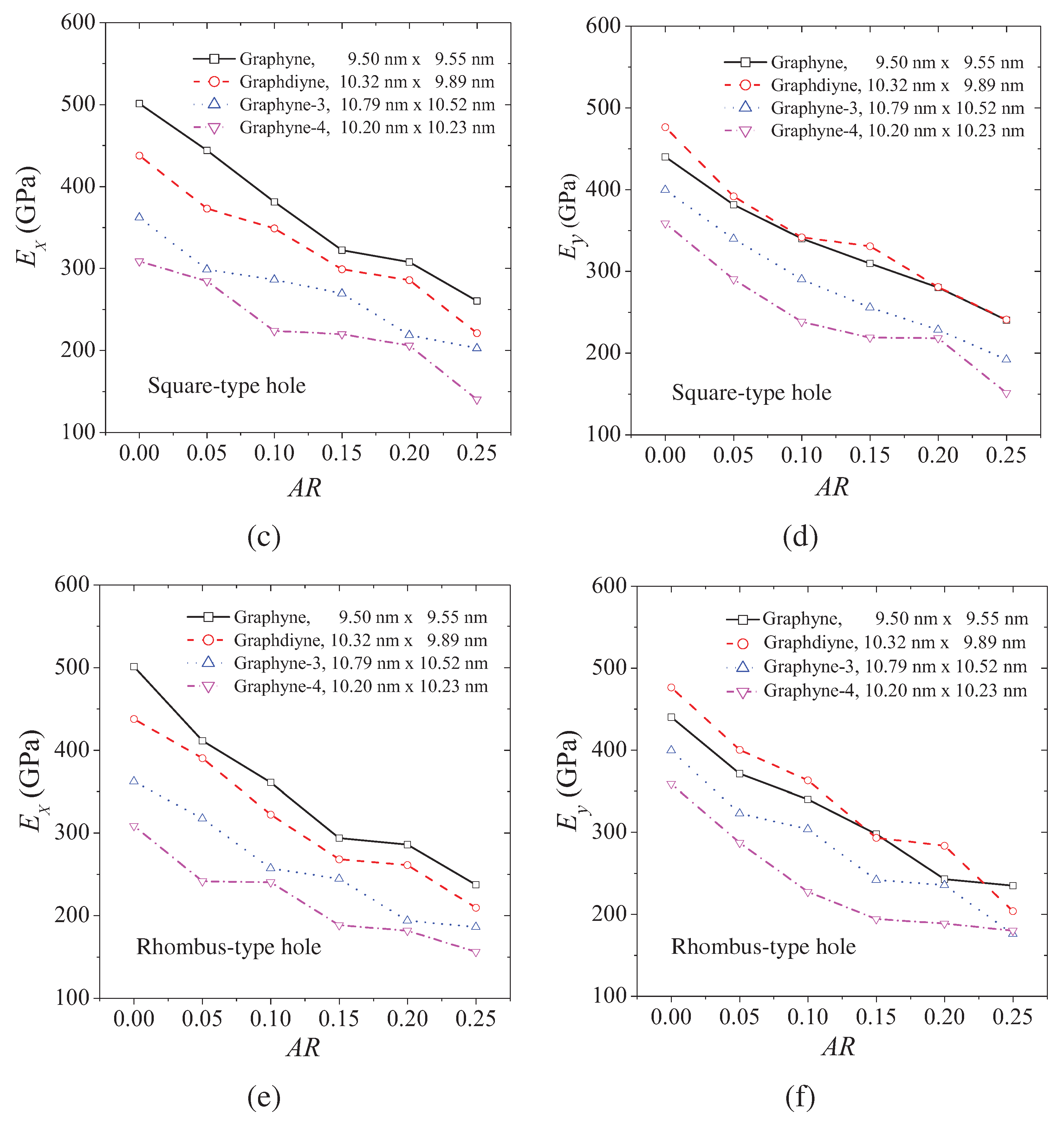

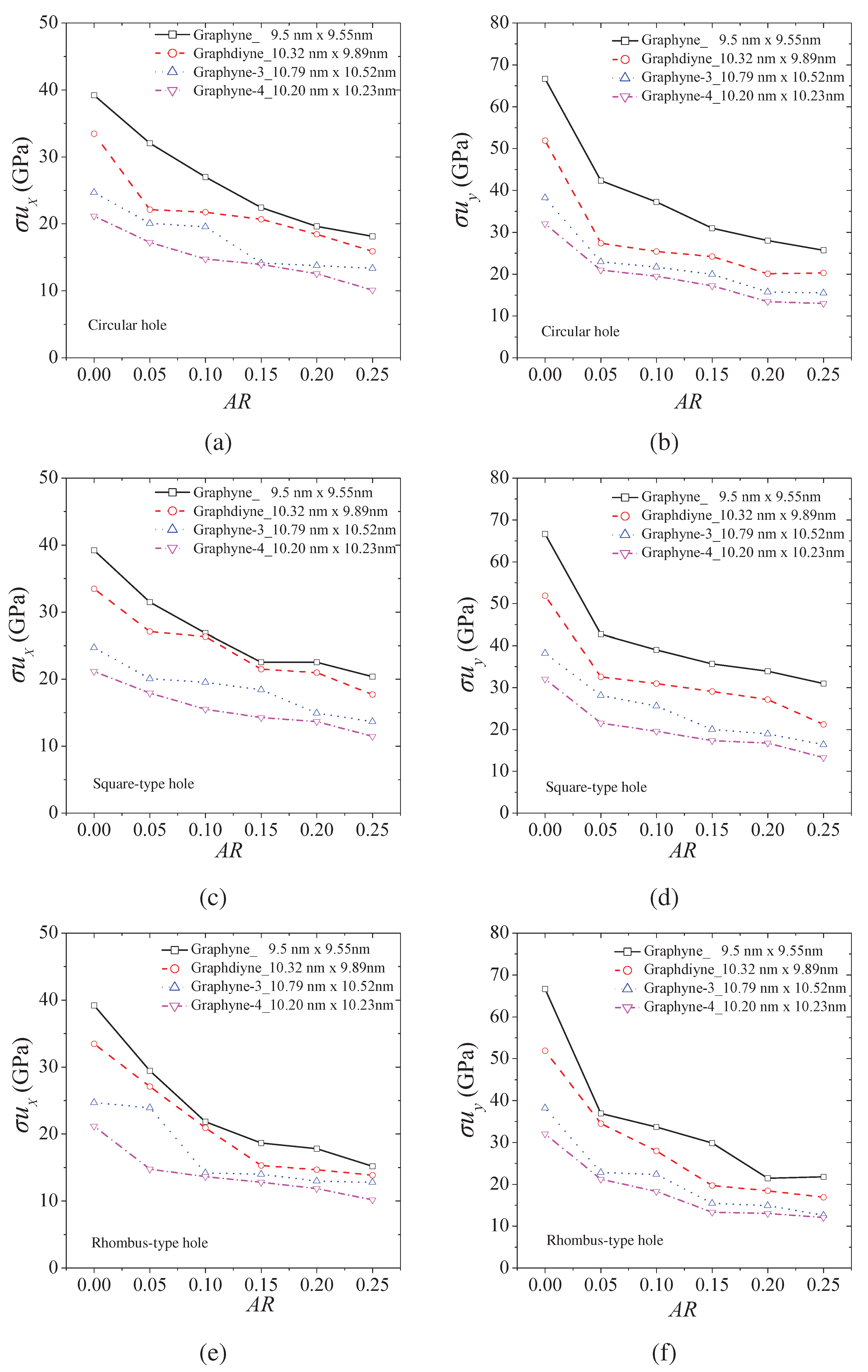

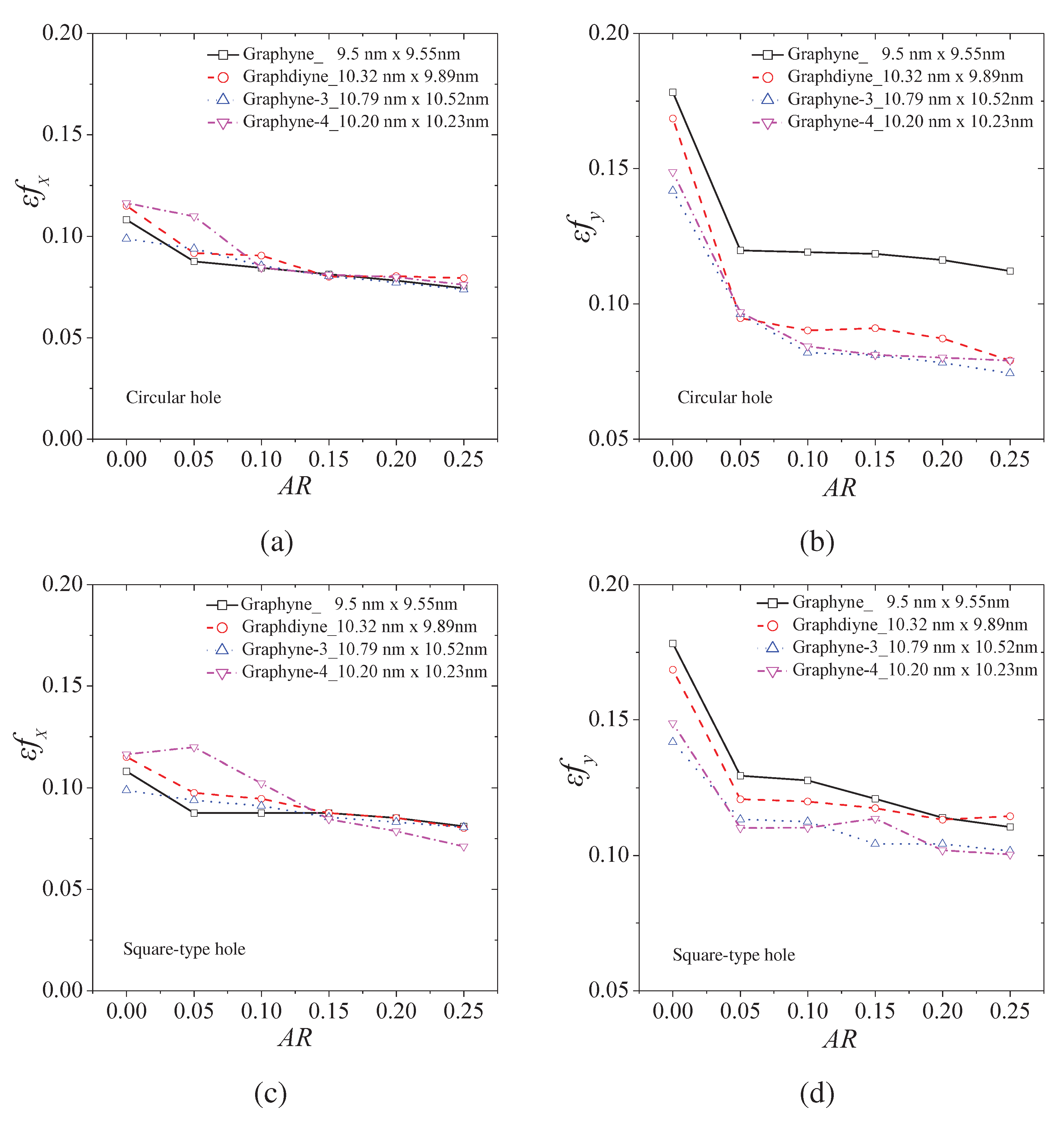

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

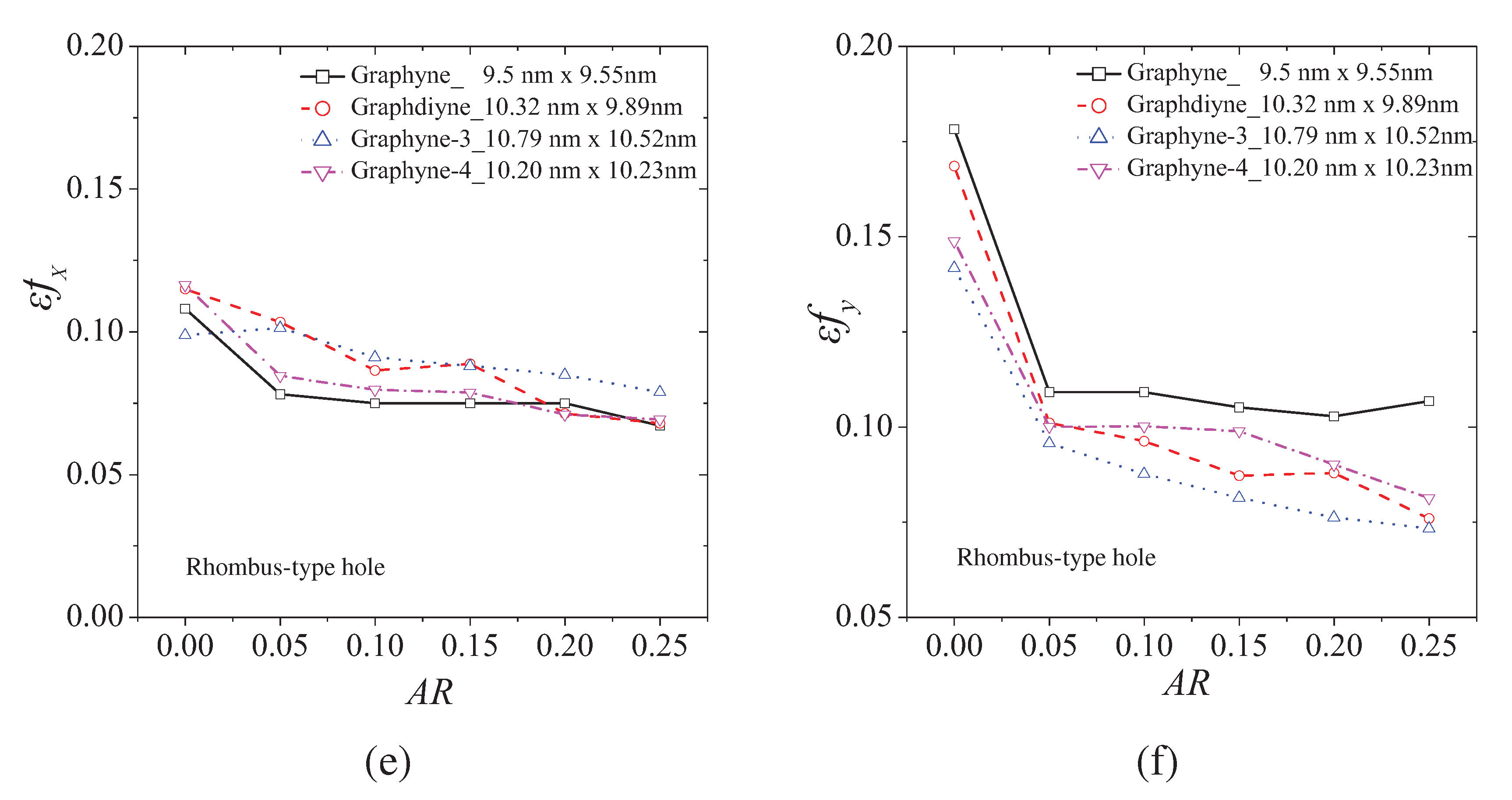

| Ex | Ey | σux | σuy | εfx | εfy | ||

|---|---|---|---|---|---|---|---|

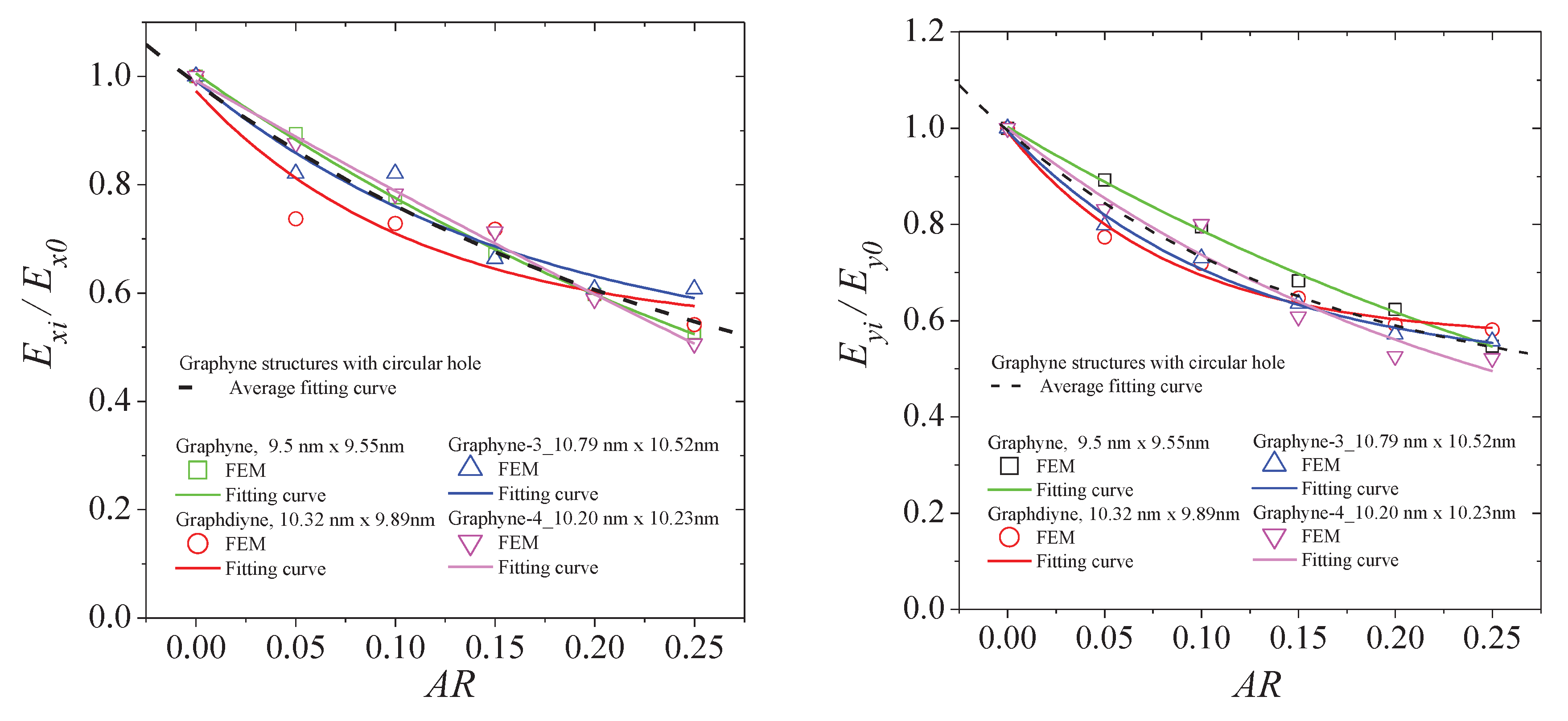

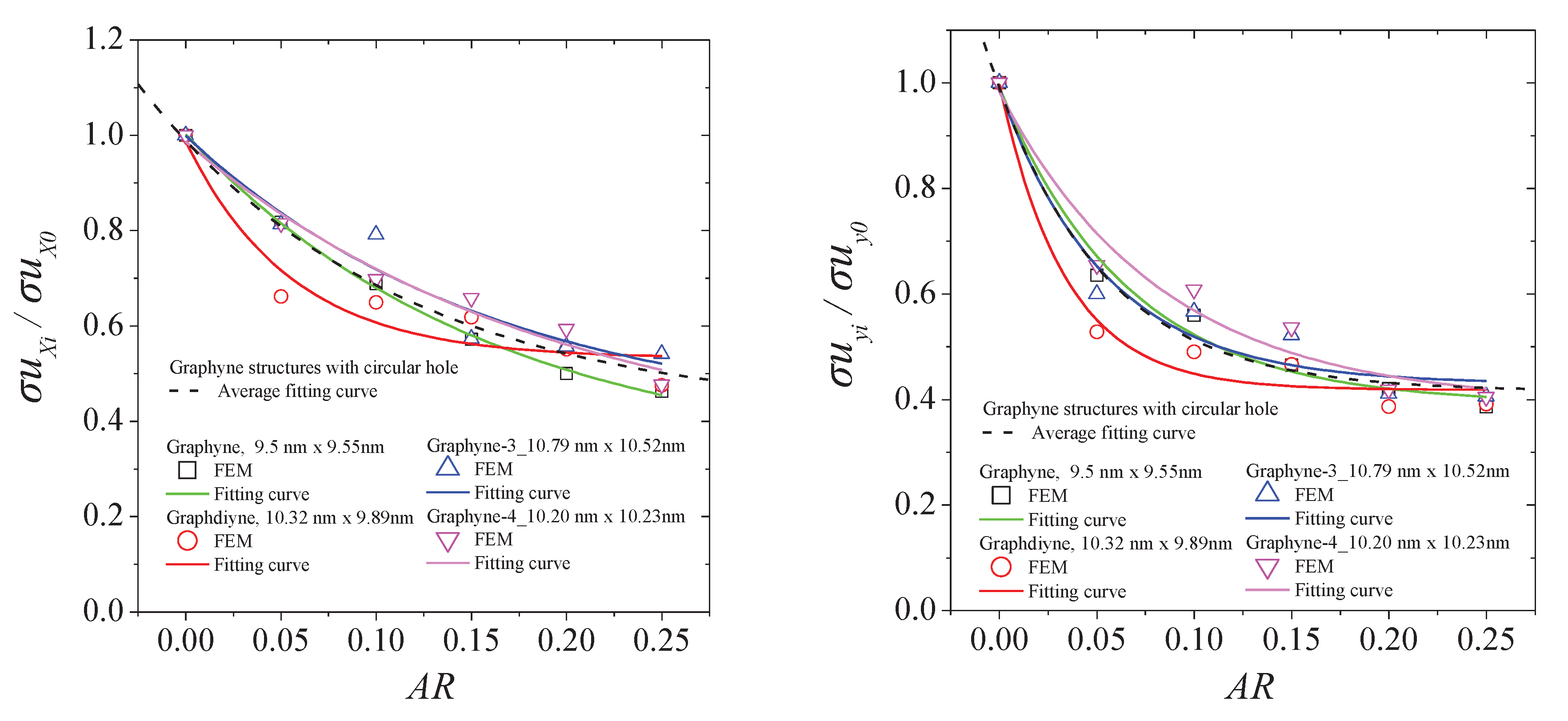

| Circular hole | a | -0.01328 | -0.02175 | 0.31215 | 0.39201 | 0.70679 | 0.65288 |

| b | 1.01861 | 1.02460 | 0.68999 | 0.59942 | 0.28739 | 0.34707 | |

| c | 0.39087 | 0.42385 | 0.15879 | 0.06569 | 0.06158 | 0.01771 | |

| R2 | 0.99000 | 0.99000 | 0.99000 | 0.98000 | 0.95000 | 0.98000 | |

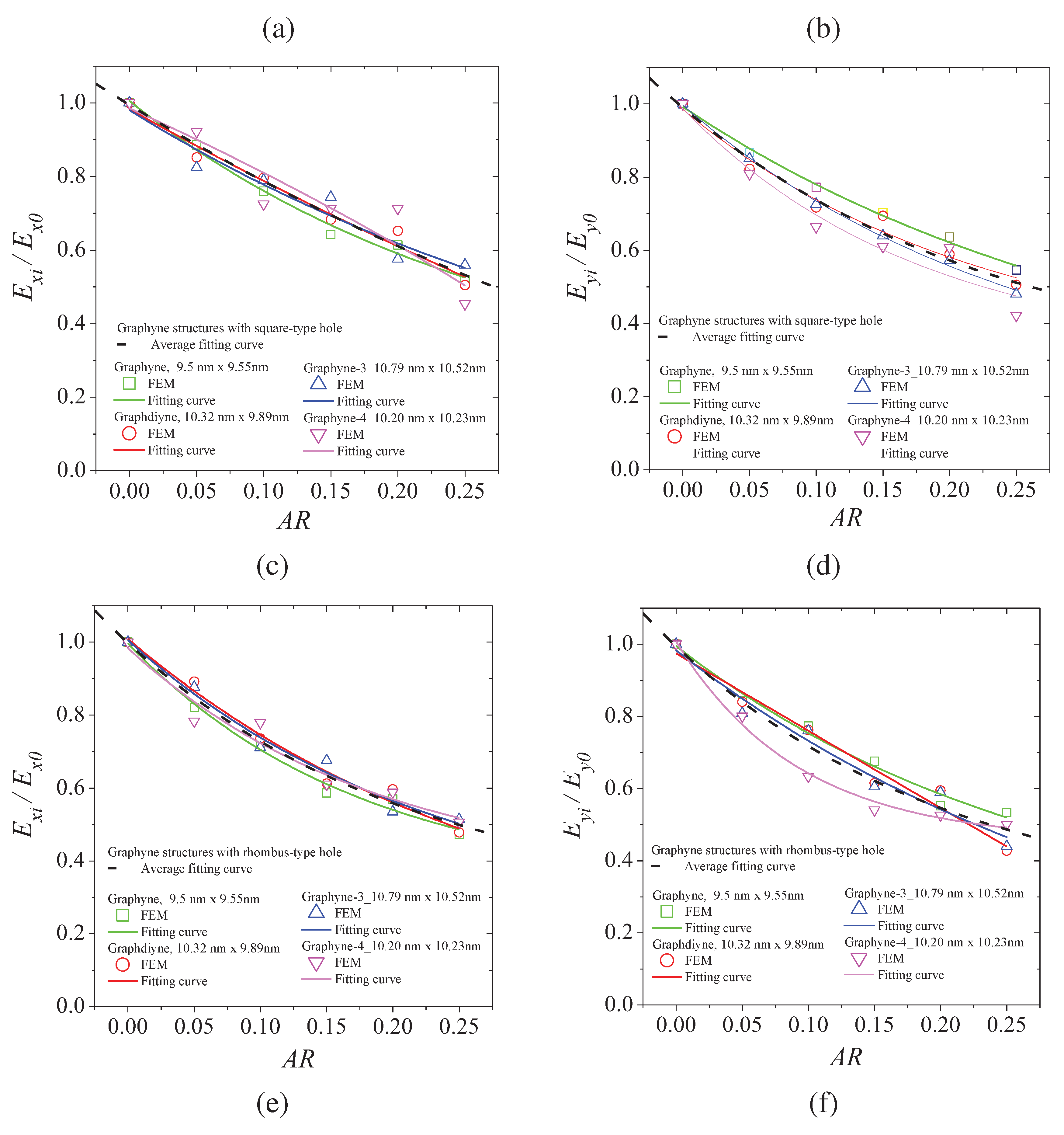

| Square hole | a | 0.19684 | 0.15620 | 0.47900 | 0.49592 | 0.78609 | 0.64616 |

| b | 0.80854 | 0.83635 | 0.52249 | 0.49939 | 0.21336 | 0.34956 | |

| c | 0.27754 | 0.34094 | 0.10267 | 0.04676 | 0.02598 | 0.04227 | |

| R2 | 0.98 | 0.99 | 0.99 | 0.97 | 0.90 | 0.94 | |

| Rhombic hole | a | 0.32312 | 0.18802 | 0.35359 | 0.34209 | 0.67028 | 0.59384 |

| b | 0.6737 | 0.80686 | 0.65038 | 0.64546 | 0.32904 | 0.40612 | |

| c | 0.17649 | 0.28148 | 0.09313 | 0.05726 | 0.02908 | 0.01662 | |

| R2 | 0.98 | 0.97 | 0.99 | 0.94 | 0.93 | 0.99 |

| Ex | Ey | σux | σuy | εfx | εfy | ||

|---|---|---|---|---|---|---|---|

| Circular hole | a | 0.52877 | 0.56265 | 0.53169 | 0.41842 | 0.68781 | 0.51250 |

| b | 0.44434 | 0.43016 | 0.45601 | 0.57879 | 0.30756 | 0.48722 | |

| c | 0.11159 | 0.08445 | 0.05557 | 0.03396 | 0.06053 | 0.02279 | |

| R2 | 0.82000 | 0.98000 | 0.87000 | 0.96000 | 0.94000 | 0.97000 | |

| Square hole | a | -1.22782 | 0.30336 | 0.34185 | 0.48296 | 0.68108 | 0.68787 |

| b | 2.21081 | 0.68163 | 0.64310 | 0.50637 | 0.31021 | 0.31189 | |

| c | 1.08266 | 0.22266 | 0.21818 | 0.05221 | 0.10768 | 0.02238 | |

| R2 | 0.96 | 0.96 | 0.94 | 0.89 | 0.95 | 0.98 | |

| Rhombic hole | a | 0.11455 | 61266 | 0.29567 | 0.28294 | -96147 | 0.50061 |

| b | 0.89455 | -61265 | 0.7189 | 0.71424 | 96148 | 0.49665 | |

| c | 0.28715 | -28643 | 0.12369 | 0.08568 | 58937 | 0.03542 | |

| R2 | 0.97 | 0.95 | 0.97 | 0.99 | 0.9 | 0.96 |

| Ex | Ey | σux | σuy | εfx | εfy | ||

|---|---|---|---|---|---|---|---|

| Circular hole | a | 0.47251 | 0.49490 | 0.39114 | 0.42952 | 0.58107 | 0.54080 |

| b | 0.51969 | 0.49912 | 0.60804 | 0.55934 | 0.42564 | 0.45870 | |

| c | 0.16870 | 0.11669 | 0.16182 | 0.05451 | 0.26025 | 0.04193 | |

| R2 | 0.91 | 0.98 | 0.90 | 0.93 | 0.98 | 0.99 | |

| Square hole | a | 0.01813 | 0.18307 | -0.03830 | 0.36855 | 0.61464 | 0.72907 |

| b | 0.96220 | 0.81386 | 1.01187 | 0.62103 | 0.38556 | 0.26762 | |

| c | 0.42336 | 0.25694 | 0.47241 | 0.11561 | 0.37605 | 0.04605 | |

| R2 | 0.91 | 0.99 | 0.91 | 0.97 | 0.98 | 0.95 | |

| Rhombic hole | a | 0.24141 | -0.0613 | 0.46377 | 0.33207 | 1.38875 | 0.53561 |

| b | 0.76417 | 1.04379 | 0.5563 | 0.65178 | -0.39214 | 0.46029 | |

| c | 0.23271 | 0.36545 | 0.09018 | 0.07463 | -0.62357 | 0.04771 | |

| R2 | 0.97 | 0.96 | 0.9 | 0.93 | 0.98 | 0.98 |

| Ex | Ey | σux | σuy | εfx | εfy | ||

|---|---|---|---|---|---|---|---|

| Circular hole | a | -2.31049 | 0.20093 | 0.32807 | 0.39183 | 0.58986 | 0.53511 |

| b | 3.30293 | 0.79905 | 0.65845 | 0.59124 | 0.43111 | 0.46471 | |

| c | 1.57087 | 0.25039 | 0.19239 | 0.08284 | 0.12130 | 0.03638 | |

| R2 | 0.99000 | 0.93000 | 0.96000 | 0.94000 | 0.87000 | 0.99000 | |

| Square hole | a | 2.34985 | 0.30658 | 0.43378 | 0.45300 | 14.08941 | 0.70433 |

| b | -1.36430 | 0.68101 | 0.56028 | 0.53464 | -13.06307 | 0.29473 | |

| c | -0.82667 | 0.17919 | 0.17312 | 0.07094 | -7.71899 | 0.02722 | |

| R2 | 0.82 | 0.91 | 0.97 | 0.93 | 0.94 | 0.93 | |

| Rhombic hole | a | 0.34482 | 0.45448 | 0.51764 | 0.35273 | 0.62012 | 0.61046 |

| b | 0.63847 | 0.55286 | 0.47121 | 0.64212 | 0.37527 | 0.38635 | |

| c | 0.19142 | 0.09276 | 0.06646 | 0.07679 | 0.04731 | 0.03378 | |

| R2 | 0.92 | 0.99 | 0.93 | 0.98 | 0.94 | 0.88 |

References

- Novoselov, K.S; Geim, A.K.; Morozov, S. v.; Jiang, D.; Zhang, Y.; Dubonos, S. v.; Grigorieva, I. v; . Firsov, A. A; Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat Mater 2007, 6, 183–191. [Google Scholar] [CrossRef]

- Balaban, A.T.; . Rentia, C.C; Ciupitu, E. . Chemical graphs. 6. Estimation of relative stability of several planar and tridimensional lattices for elementary carbon. Revue Roumaine de Chimie. 1968, 13, 231–247. [Google Scholar]

- Narita, N.; Nagai, S.; Suzuki, S.; Nakao, K. Optimized geometries and electronic structures of graphyne and its family. Phys Rev B. 1998, 58, 11009–11014. [Google Scholar] [CrossRef]

- Gong, Y.; Shen, L.; . Kang, Z; Liu, K. ;. Du, Q.; Ye, D.; Zhao, H.; Sun, X.A.; Zhang, J. Progress in energy-related graphyne-based materials: Advanced synthesis, functional mechanisms and applications. J Mater Chem A Mater. 2020, 8, 21408–21433. [Google Scholar] [CrossRef]

- Peng, Q.; Crean, J.; Han, L.; Liu, S.; Wen, X.; De, S.; Dearden, A. New materials graphyne, graphdiyne, graphone, and graphane: Review of properties, synthesis, and application in nanotechnology. Nanotechnol Sci Appl. 2014, 7, 1–29. [Google Scholar] [CrossRef]

- Srinivasu, K.; Ghosh, S.K. Graphyne and Graphdiyne: Promising Materials for Nanoelectronics and Energy Storage Applications. The Journal of Physical Chemistry C 2012, 116, 5951–5956. [Google Scholar] [CrossRef]

- Li, G.; Li, Y.; Liu, H.; Guo, Y. Li, Y.; Zhu, D. Architecture of graphdiyne nanoscale films. Chemical Communications 2010, 46, 3256. [Google Scholar] [CrossRef]

- Ivanovskii, A.L. Graphynes and graphdyines. Progress in Solid State Chemistry 2013, 41, 1–19. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, J.; Li, Z.; Zhao, R.; Tong, L.; Liu, Z.; Zhang, J.; Liu, Z. Raman Spectra and Corresponding Strain Effects in Graphyne and Graphdiyne. The Journal of Physical Chemistry C. 2016, 120, 10605–10613. [Google Scholar] [CrossRef]

- Xiao, K.; Li, J.; Wu, X.; Liu, H.; Huang, C.; Li, Y. Nanoindentation of Thin Graphdiyne Films: Experiments and Molecular Dynamics Simulation. Carbon 2019, 144, 72–80. [Google Scholar] [CrossRef]

- Ghorbani, K.; Rajabpour, A.; Ghadiri, M. Determination of carbon nanotubes size-dependent parameters: Molecular dynamics simulation and nonlocal strain gradient continuum shell model. Mechanics Based Design of Structures and Machines 2021, 49, 103–120. [Google Scholar] [CrossRef]

- Rafiee, R.; Eskandariyun, A. Estimating Young’s modulus of graphene/polymer composites using stochastic multi-scale modeling. Compos B Eng. 2019, 173, 106842. [Google Scholar] [CrossRef]

- Ansari, R.; Ajori, S.; Malakpour, S. Characterization of Elastic Properties of Porous Graphene Using an Ab Initio Study. Journal of Ultrafine Grained and Nanostructured Materials 2016, 49, 97–102. [Google Scholar] [CrossRef]

- Zhang, C.; . Hao, X.-L.; Wang, C.-X.; Wei, N.; Rabczuk, T. Thermal conductivity of graphene nanoribbons under shear deformation: A molecular dynamics simulation. Sci Rep. 2017, 7, 41398. [Google Scholar] [CrossRef] [PubMed]

- Volgin, I. v.; Larin, S. v.; Abad, E.; Lyulin, S. v. Molecular Dynamics Simulations of Fullerene Diffusion in Polymer Melts. Macromolecules 2017, 50, 2207–2218. [Google Scholar] [CrossRef]

- Cruz-Silva, R.; Araki, T.; Hayashi, T.; Terrones, H.; Terrones, M.; Endo, M. Fullerene and nanotube growth: New insights using first principles and molecular dynamics. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences 2016, 374, 20150327. [Google Scholar] [CrossRef]

- Hsu, J.-C.; Chang, R.-P.; Chang, W.-J. Resonance frequency of chiral single-walled carbon nanotubes using Timoshenko beam theory. Phys Lett A. 2008, 372, 2757–2759. [Google Scholar] [CrossRef]

- Li, C.; Chou, T.-W. A structural mechanics approach for the analysis of carbon nanotubes. Int J Solids Struct. 2003, 40, 2487–2499. [Google Scholar] [CrossRef]

- Ansari, R.; Rouhi, S. Atomistic finite element model for axial buckling of single-walled carbon nanotubes. Physica E Low Dimens Syst Nanostruct. 2010, 43, 58–69. [Google Scholar] [CrossRef]

- Georgantzinos, S. K. A New Finite Element for an Efficient Mechanical Analysis of Graphene Structures Using Computer Aided Design/Computer Aided Engineering Techniques. J. Comput. Theor. Nanosci. 2017, 14, 5347–5354. [Google Scholar] [CrossRef]

- Georgantzinos, S.K.; Giannopoulos, G.I.; Anifantis, N.K. Coupled thermomechanical behavior of graphene using the spring-based finite element approach. J Appl Phys. 2016, 120, 014305. [Google Scholar] [CrossRef]

- Georgantzinos, S.K.; Giannopoulos, G.I.; Anifantis, N.K. On the coupling of axial and shear deformations of single-walled carbon nanotubes and graphene: A numerical study. Proceedings of the Institution of Mechanical Engineers Part N: Journal of Nanoengineering and Nanosystems 2010, 224, 163–172. [Google Scholar] [CrossRef]

- Theodosiou, T.C.; Saravanos, D.A. ; Numerical investigation of mechanisms affecting the piezoresistive properties of CNT-doped polymers using multi-scale models. ComposSci Technol. 2010, 70, 1312–1320. [Google Scholar] [CrossRef]

- Ru, C.Q. Elastic buckling of single-walled carbon nanotube ropes under high pressure. Phys Rev B. 2000, 62, 10405–10408. [Google Scholar] [CrossRef]

- Giannopoulos, G.I.; Tsiros, A.P.; Georgantzinos, S.K. Prediction of Elastic Mechanical Behavior and Stability of Single-Walled Carbon Nanotubes Using Bar Elements. Mechanics of Advanced Materials and Structures 2013, 20, 730–741. [Google Scholar] [CrossRef]

- Georgantzinos, S.K.; Giannopoulos, G.I. Thermomechanical buckling of single walled carbon nanotubes by a structural mechanics method. Diam Relat Mater. 2017, 80, 27–37. [Google Scholar] [CrossRef]

- Couto, R.; Silvestre, N. Finite Element Modelling and Mechanical Characterization of Graphyne. J Nanomater. 2016, 2016, 1–15. [Google Scholar] [CrossRef]

- Lee, H.L.; Yang, Y.C.; . Chang, W.J. Atomic-scale finite element method for analyzing the sensitivity of graphyne-based resonators. J Nanomater 2018, 2018. [Google Scholar] [CrossRef]

- Georgantzinos, S.K.; Siampanis, S.G. Size-dependent elastic mechanical properties of γ-graphyne structures: A comprehensive finite element investigation. Mater Des. 2021, 202. [Google Scholar] [CrossRef]

- Georgantzinos, S.K.; Siampanis, S.G.; Baldoukas, A.; . Giannopoulos, G.I. Designing the nonlinear mechanical response of graphyne structures: A finite element structural mechanics approach. Mater Today Commun. 2022, 31. [Google Scholar] [CrossRef]

- Galhofo, D.; Silvestre, N. Computational simulation of γ-graphynes under monotonic and hysteretic loading. Mechanics of Advanced Materials and Structures 2021, 28, 495–505. [Google Scholar] [CrossRef]

- Siampanis, S.G.; . Giannopoulos, G.I; Lagaros, N.D.; Hatziefremidis, A.; Georgantzinos, S.K. Nonlinear Finite Element Analysis of γ-Graphyne Structures under Shearing. Molecules 2022, 27. [Google Scholar] [CrossRef]

- Jiang, D.; Cooper, V.R.; Dai, S. Porous Graphene as the Ultimate Membrane for Gas Separation. Nano Lett. 2009, 9, 4019–4024. [Google Scholar] [CrossRef] [PubMed]

- Cohen-Tanugi, D.; Grossman, J.C. Water Desalination across Nanoporous Graphene. Nano Lett. 2012, 12, 3602–3608. [Google Scholar] [CrossRef]

- Tang, C.; Wang, H.-F.; Huang, J.-Q.; Qian, W.; Wei, F.; Qiao, S.-Z.; Zhang, Q. 3D Hierarchical Porous Graphene-Based Energy Materials: Synthesis, Functionalization, and Application in Energy Storage and Conversion. Electrochemical Energy Reviews 2019, 2, 332–371. [Google Scholar] [CrossRef]

- Tao, Y.; Sui, Z.-Y.; Han, B.-H. Advanced porous graphene materials: From in-plane pore generation to energy storage applications. J Mater Chem A Mater. 2020, 8, 6125–6143. [Google Scholar] [CrossRef]

- Chernozatonskii, L.A.; Demin, V.A.; Bellucci, S. Bilayered graphene/h-BN with folded holes as new nanoelectronic materials: Modeling of structures and electronic properties. Sci Rep. 2016, 6. [Google Scholar] [CrossRef]

- Genoese, A.; Genoese, A.; Salerno, G. In-plane and out-of-plane tensile behaviour of single-layer graphene sheets: A new interatomic potential. Acta Mech. 2020, 231, 2915–2930. [Google Scholar] [CrossRef]

- Muraru, S.; Burns, J.S.; Ionita, M. GOPY: A tool for building 2D graphene-based computational models. SoftwareX 2020, 12. [Google Scholar] [CrossRef]

- Yoon, J.; Kwon, M.H.; Shin, D.H.; Lee, S.W. Mechanical resonance properties of porous graphene membrane; simulation study and proof of concept experiment. Current Applied Physics 2021, 23, 30–35. [Google Scholar] [CrossRef]

- Lee, H.L.; Wang, Y.M.; Yang, Y.C.; Chang, W.J. Young’s modulus of nanoporous γ-graphyne membrane using an atomistic finite element model. Solid State Commun. 2018, 280, 1–5. [Google Scholar] [CrossRef]

- Rodrigues, F.C.; Silvestre, N.; Deus, A.M. Nonlinear mechanical behaviour of γ-graphyne through an atomistic finite element model. Comput. Mater. Sci. 2015, 134, 171–183. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, X. Mechanical properties of graphyne and its family – a molecular dynamics investigation. Comput. Mater. Sci. 2012, 61, 83–88. [Google Scholar] [CrossRef]

- Yue, Q.; Chang, S.; Kang, J.; Qin, S.; Li, J. Mechanical and electronic properties of graphyne and its family under elastic strain: Theoretical predictions. J. Phys. Chem. C. 2013, 117, 14804–14811. [Google Scholar] [CrossRef]

- Wang, Y.; Gu, Y.; Liu, J. A Domain-Decomposition Generalized Finite Difference Method for Stress Analysis in Three-Dimensional Composite Materials. Appl. Math. Lett. 2020, 104, 106226. [Google Scholar] [CrossRef]

- Kabir, H.; Aghdam, M.M. A Robust Bézier Based Solution for Nonlinear Vibration and Post-Buckling of Random Checkerboard Graphene Nano-Platelets Reinforced Composite Beams. Compos. Struct. 2019, 212, 184–198. [Google Scholar] [CrossRef]

- Bert, C.W.; Malik, M. Differential Quadrature: A Powerful New Technique for Analysis of Composite Structures. Compos. Struct. 1997, 39, 179–189. [Google Scholar] [CrossRef]

| Method | Lx×Ly (nm×nm) | Ex (GPa) | Ey (GPa) | σux (GPa) | σuy (GPa) | εfx | εfy | |

|---|---|---|---|---|---|---|---|---|

| Graphyne | FEM (present) | 9.5×9.55 | 501.2 | 440.1 | 39.2 | 66.6 | 0.108 | 0.178 |

| FEM [31] | 10.9×9.8 | 512.6 | 507.8 | 48.6 | 72 | 0.13 | 0.17 | |

| FEM [43] | 9.5×9.55 | 481.6 | 419.0 | - | - | - | - | |

| MD [5] | 10×10 | - | - | 45 | 63.96 | 0.11 | 0.177 | |

| Graph-diyne | FEM (present) | 10.32×9.89 | 439.2 | 476.4 | 33.4 | 51.8 | 0.115 | 0.168 |

| FEM [3] | 10.7 × 10.1 | 360.6 | 383.6 | - | - | - | - | |

| MD [44] | 10×10 | 312.5 | 270.3 | 29.8 | 65.1 | 0.109 | 0.208 | |

| DFT [45] | 7×7 | - | 384.8 | - | - | - | - | |

| Graphyne-3 | FEM (present) | 10.8×10.5 | 364.9 | 399.5 | 24.8 | 38.2 | 0.096 | 0.141 |

| FEM [43] | 11.2 × 10.7 | 288.9 | 307.8 | - | - | - | - | |

| MD [5] | 10×10 | 243.1 | 212.3 | 22.8 | 65.3 | 0.109 | 0.223 | |

| Graphene-4 | FEM (present) | 10.2×10.23 | 310.2 | 345.8 | 21.15 | 32.5 | 0.116 | 0.166 |

| FEM [31] | 10.8×10.5 | 364.9 | 399.5 | 24.8 | 38.2 | 0.096 | 0.141 | |

| FEM [43] | 10.6 ×10.4 | 239.7 | 257.4 | - | - | - | - | |

| MD [44] | 10×10 | 199.5 | 168.3 | 18.4 | 65.3 | 0.108 | 0.224 |

| Ex | Ey | σux | σuy | εfx | εfy | ||

|---|---|---|---|---|---|---|---|

| Circular hole | a | 0.2655 | 0.41855 | 0.41263 | 0.41566 | 0.66951 | 0.56134 |

| b | 0.72223 | 0.57663 | 0.57642 | 0.57436 | 0.33157 | 0.4381 | |

| c | 0.26581 | 0.16479 | 0.13383 | 0.05611 | 0.10066 | 0.03045 | |

| R2 | 0.94 | 0.95 | 0.93 | 0.95 | 0.84 | 0.91 | |

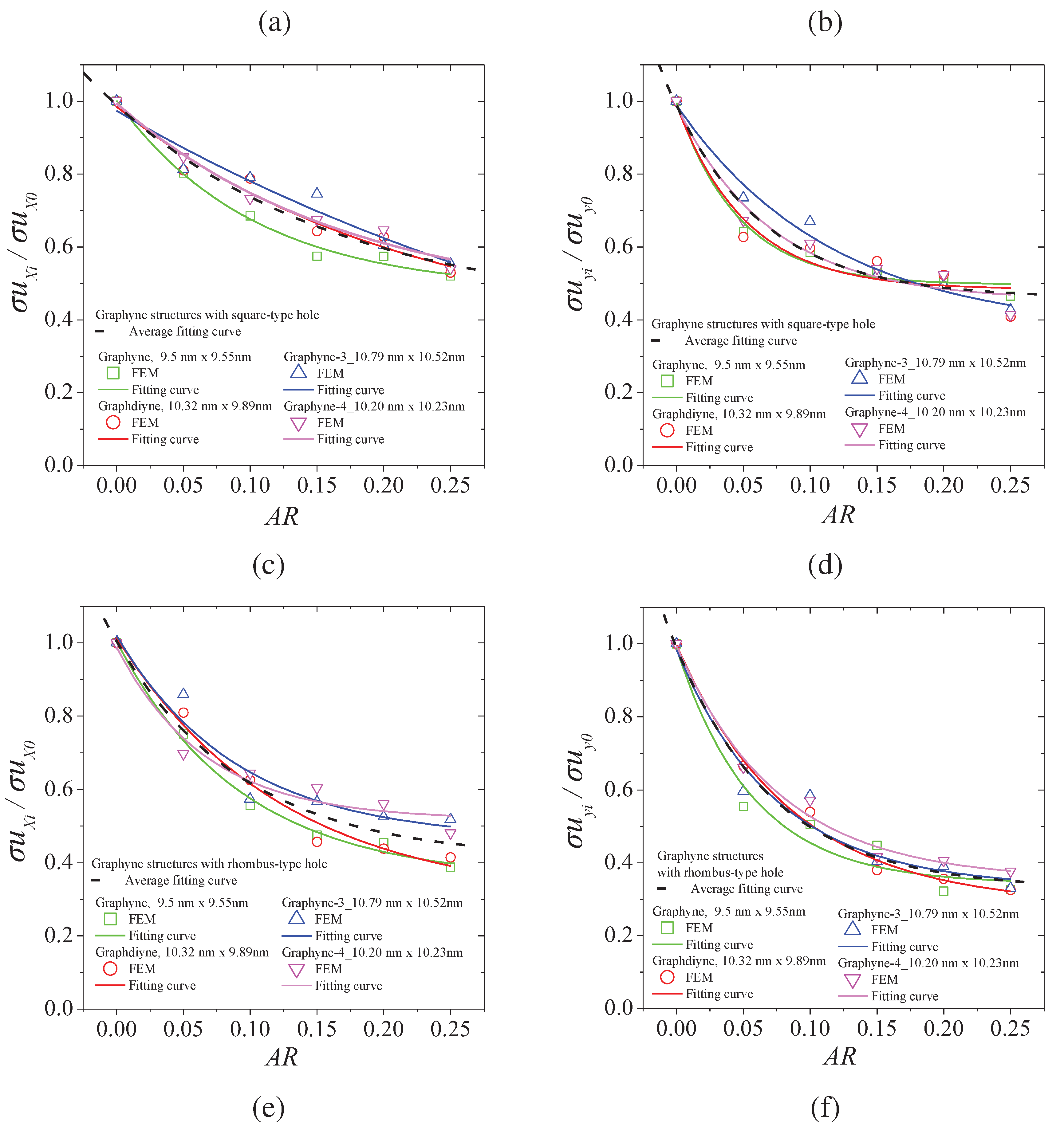

| Square hole | a | -0.40512 | 0.25461 | 0.41804 | 0.45973 | 0.60684 | 0.69359 |

| b | 1.39502 | 0.73541 | 0.57141 | 0.52862 | 0.38811 | 0.30464 | |

| c | 0.62309 | 0.23804 | 0.17159 | 0.06837 | 0.20698 | 0.03318 | |

| R2 | 0.94 | 0.95 | 0.94 | 0.95 | 0.77 | 0.91 | |

| Rhombic hole | a | 0.26796 | 0.26272 | 0.40943 | 0.32775 | 0.64213 | 0.56321 |

| b | 0.73041 | 0.73113 | 0.59529 | 0.66189 | 0.34733 | 0.43487 | |

| c | 0.21701 | 0.21103 | 0.09505 | 0.07381 | 0.10297 | 0.0326 | |

| R2 | 0.97 | 0.95 | 0.94 | 0.97 | 0.78 | 0.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).