Submitted:

11 September 2023

Posted:

13 September 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Thermal calculation model for tubular condensing heat exchanger

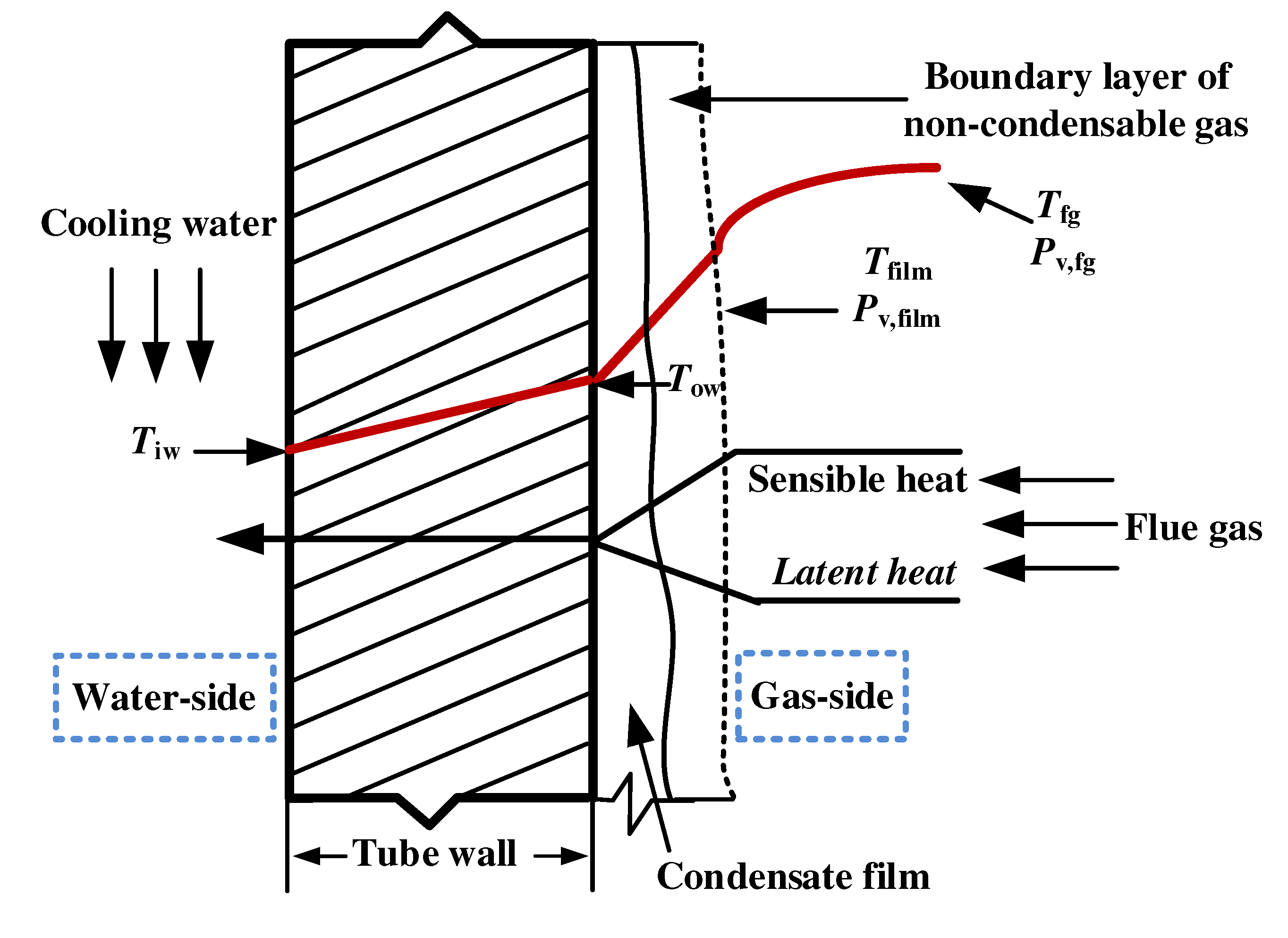

2.1. Principle of thermal calculation

- (1)

- The flow of flue gas in a condensing heat exchanger is one-dimensional, which means that parameters like the temperature of the flue gas and the volume fraction of the water vapor only change in the direction of the gas flow.

- (2)

- The convective heat transfer and convective mass transfer coefficients of the flue gas are evenly distributed on the outer wall of each tube.

- (3)

- The inlet and outlet parameters such as the flue gas temperature, the volume fraction of the water vapor and the cooling water temperature are linearly changed for each transverse tube bundle, allowing for the calculated values of working fluid parameters in each bundle to be obtained through the arithmetic mean of these parameters.

- (4)

- The flow on the flue gas side is single-phase and any effect of liquid condensate on the flow is ignored.

- (5)

- Water vapor in the flue gas only condenses on the tube wall, not in the flue gas stream.

- (6)

- The thickness of condensate film is considered to be zero and the heat and mass transfer resistance of this film is ignored.

- (7)

- Secondary evaporation of the condensate water in the heat exchanger is also neglected.

- (8)

- No chemical reaction occurs in the condensing heat exchanger.

- (1)

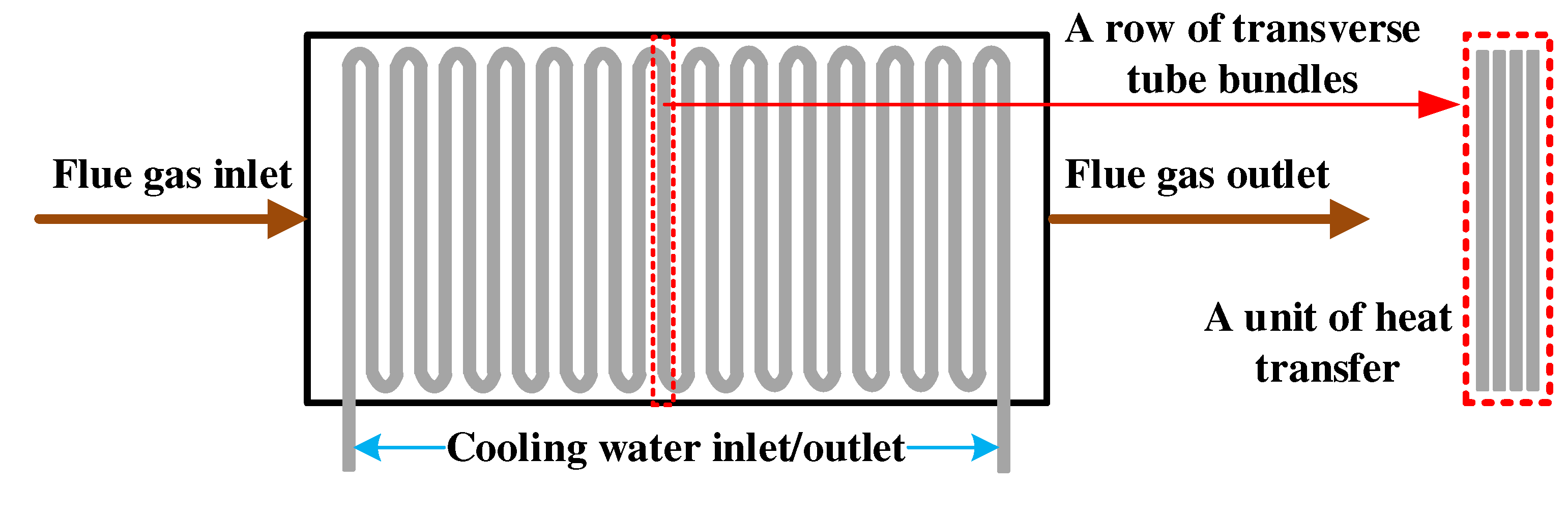

- Firstly, the entire heat exchanger is divided into several tube bundles, with each transverse tube bundle being considered a heat exchanger unit. These units are connected in series to form the complete condensing heat exchanger.

- (2)

- Next, the thermal calculation is conducted on each individual heat exchanger unit. The heat transfer from the flue gas to the cooling water is divided into three processes, including the convective-condensation heat transfer of the flue gas on the outer wall of tube, the heat conduction of the tube wall, and the convective heat release from the inner wall to the cooling water inside the tube. The most complex process is the first one. To solve this, the sensible heat is calculated by the classical heat transfer formula [39]. The temperature difference for sensible heat transfer is equal to the difference between the arithmetic mean temperature of the incoming and outgoing flue gas and the temperature of the outer wall of tube. When the outer wall is under wet conditions, the latent heat transferred from the flue gas to the outer wall of tube is equal to the latent heat of vaporization released. The amount of the condensate water flowrate could be calculated by the classical mass transfer formula [39]. The mass concentration difference of the water vapor for the mass transfer is equal to the difference between the arithmetic mean mass concentration of the incoming and outgoing flue gas and the mass concentration on the outer wall of tube. However, the condensate water flowrate is zero when the outer wall is under dry conditions.

- (3)

- Finally, the thermal calculation is constructed for each heat exchanger unit in turn along the flow direction of the flue gas. The inlet parameters of the working fluid for the present heat exchanger unit are equal to the outlet parameters of the previous one. The iterative algorithm is applied for each heat exchanger unit and then the thermal calculation of the entire condensing heat exchanger could be completed.

2.2. Thermal calculation for each heat transfer unit

2.2.1. Sensible heat transfer

2.2.2. Condensate water flowrate and latent heat transfer

2.2.3. Energy balance on the flue gas side

2.2.4. Energy balance on the water side

2.2.5. Total energy balance

2.2.6. Heat conduction of the tube wall

2.3. Sensible and latent heat transfer efficiencies of fin

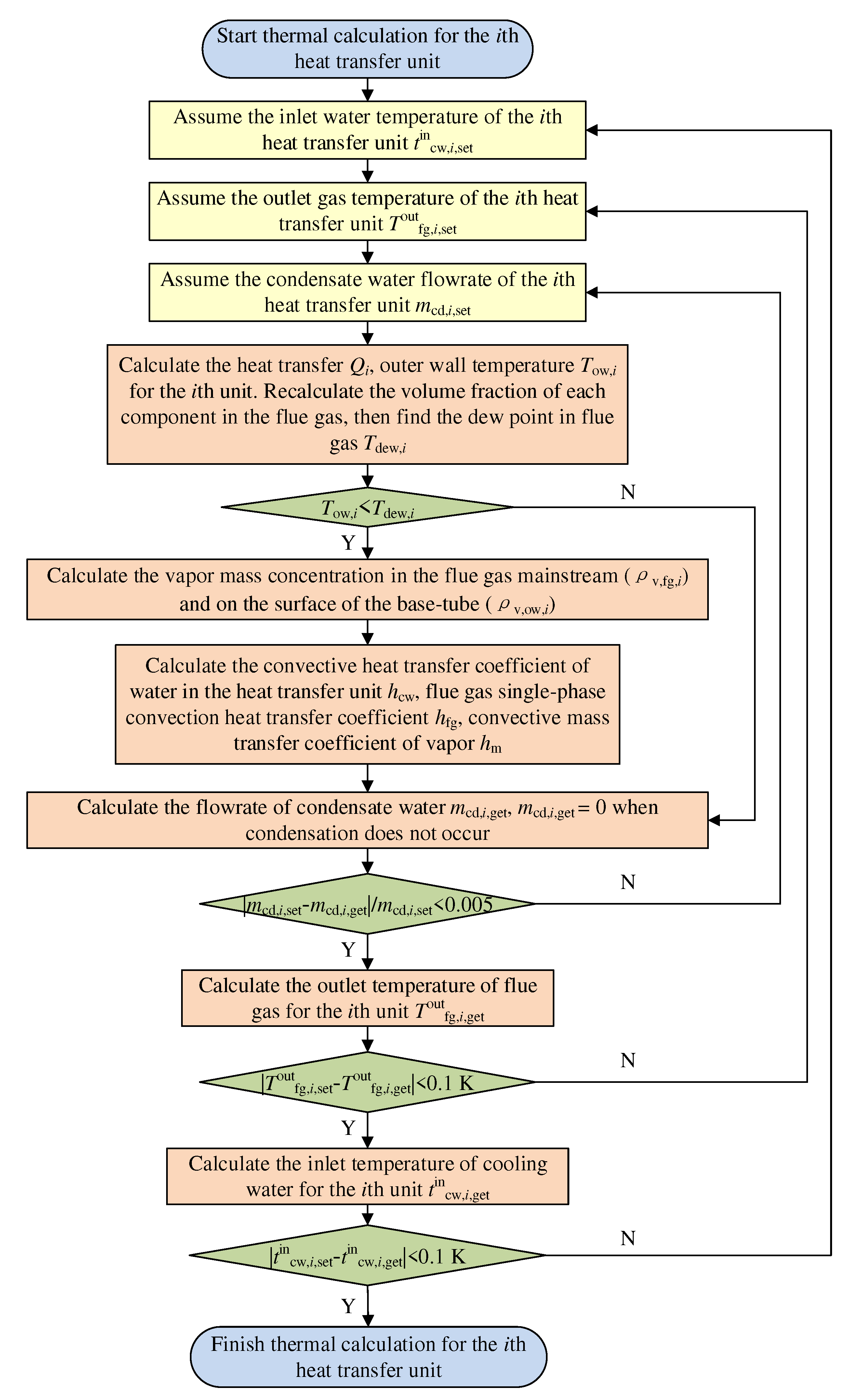

2.4. Process of thermal calculation

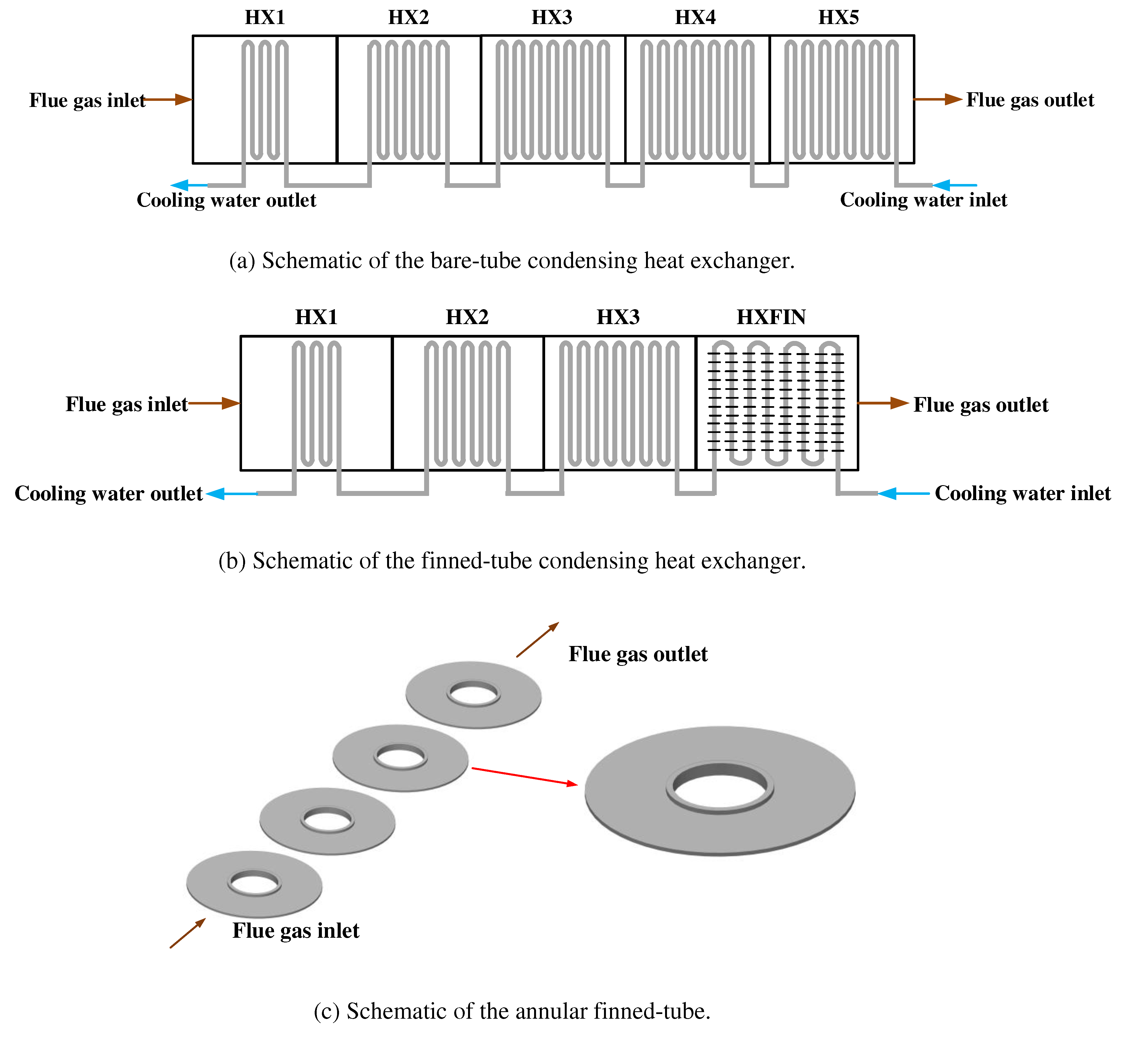

3. Structure of condensing heat exchanger

4. Case study

4.1. Bare-tube condensation model

4.2. Finned-tube condensation model

5. Conclusions

- (1)

- By using the thermal calculation model derived from theoretical analysis, it is possible to not only determine the sensible and latent heat transfer, as well as the condensate water flowrate, but also predict the distributions of the flue gas temperature and the water vapor volume fraction. Additionally, the location where the condensation of the water vapor begins could be determined by monitoring the condensate water flowrate of each sub-heat exchanger.

- (2)

- The sensible and latent heat transfer efficiencies for the annular fin are obtained by fitting the numerical data, with the absolute errors of 0.0365 and 0.0268, respectively.

- (3)

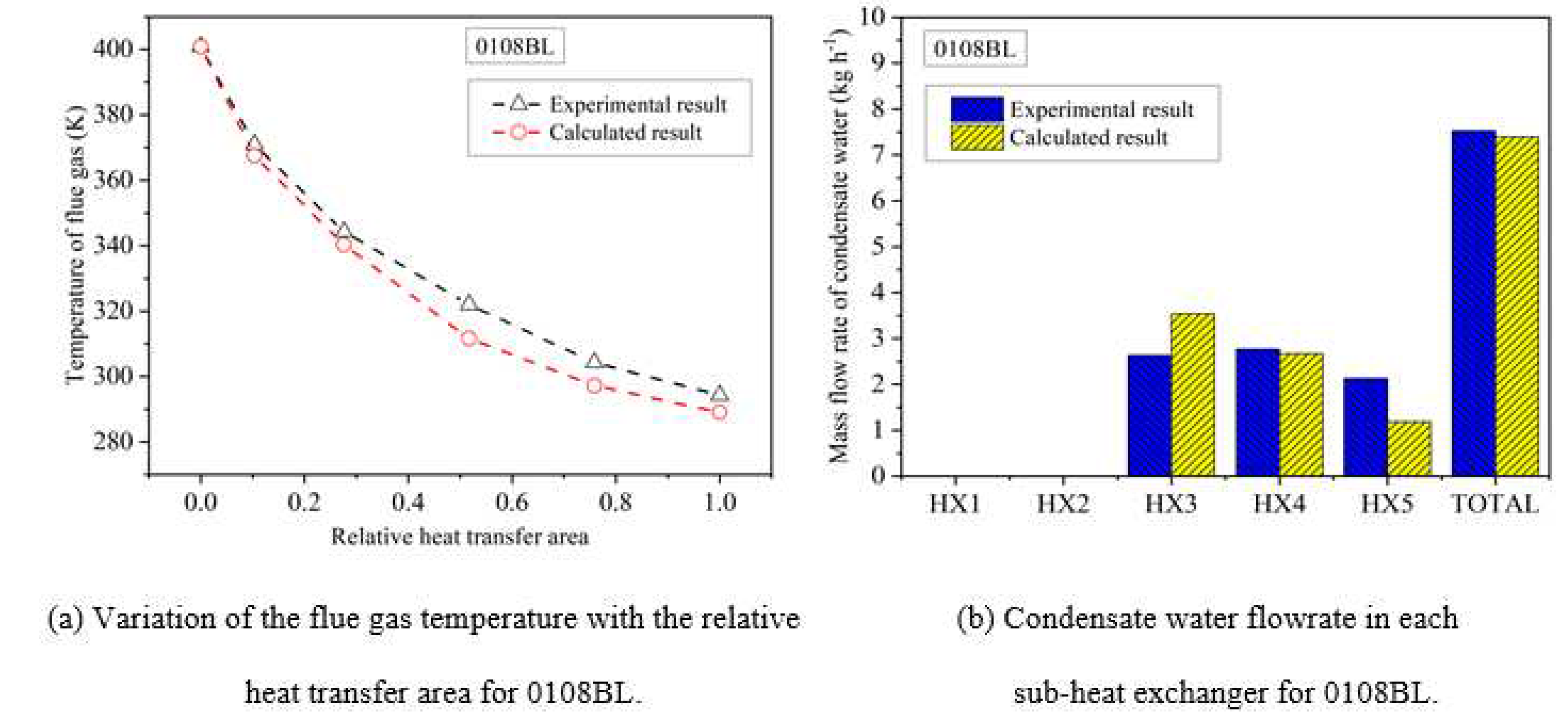

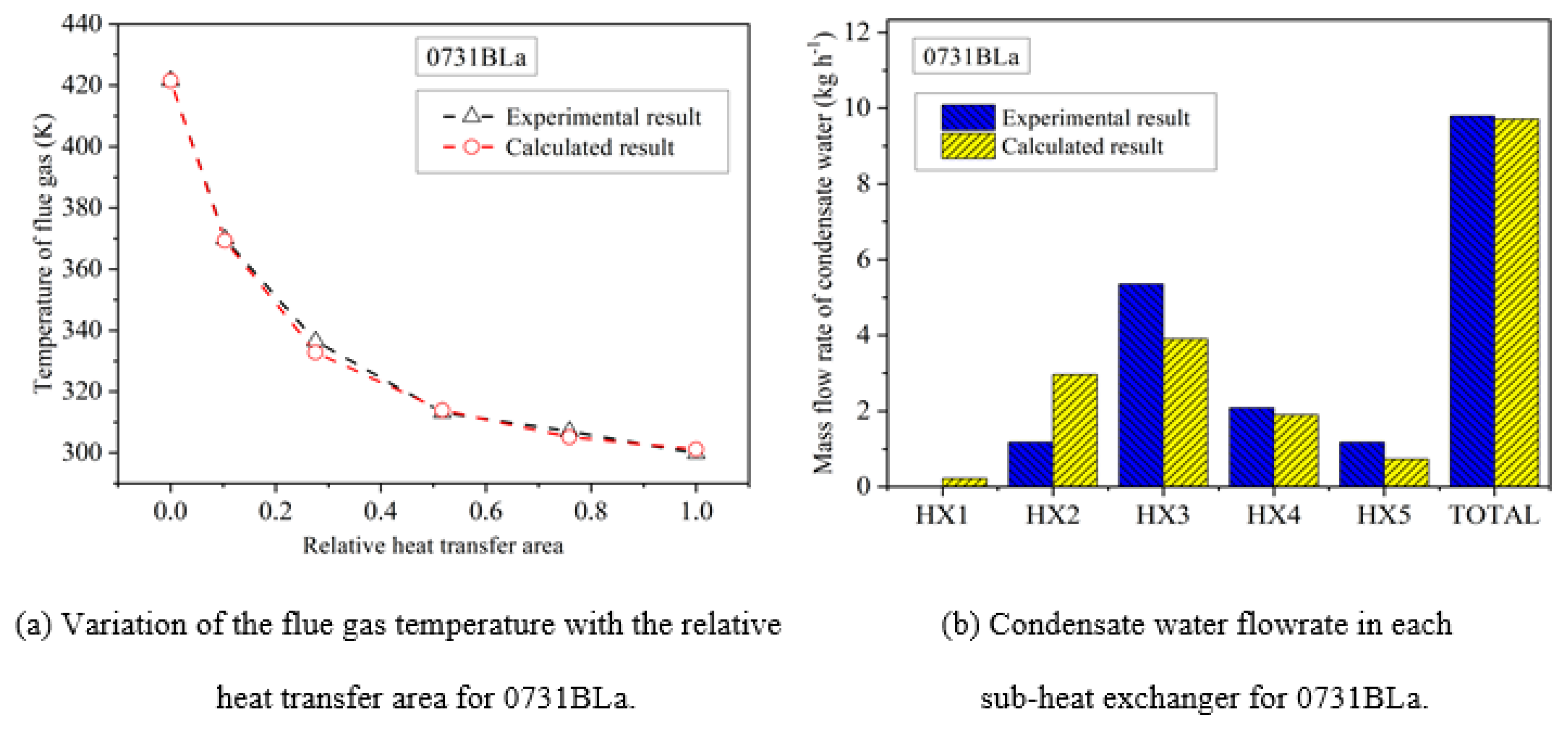

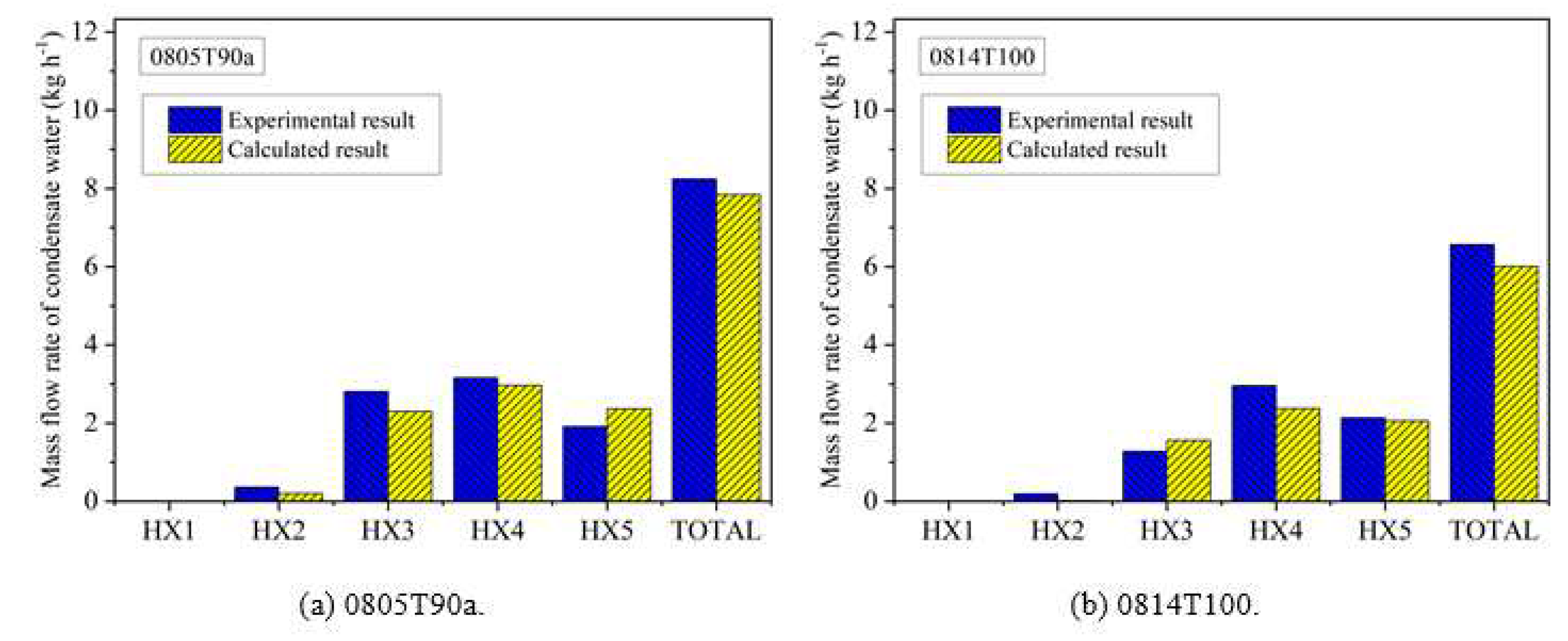

- Under the 0108BL and 0731BLa conditions with bare-tubes, the flue gas temperature decreases by 106.6 and 121.7 K, respectively. The outlet temperature of the flue gas has a deviation of 5.2 and 1.3 K, respectively. The water vapor starts to condense in HX3 under the 0108BL condition, which is later than the 0731BLa condition. The relative error of the condensate water flowrate is within ±5.0% under all 34 bare-tube conditions, with a maximum relative error of 17.4%.

- (4)

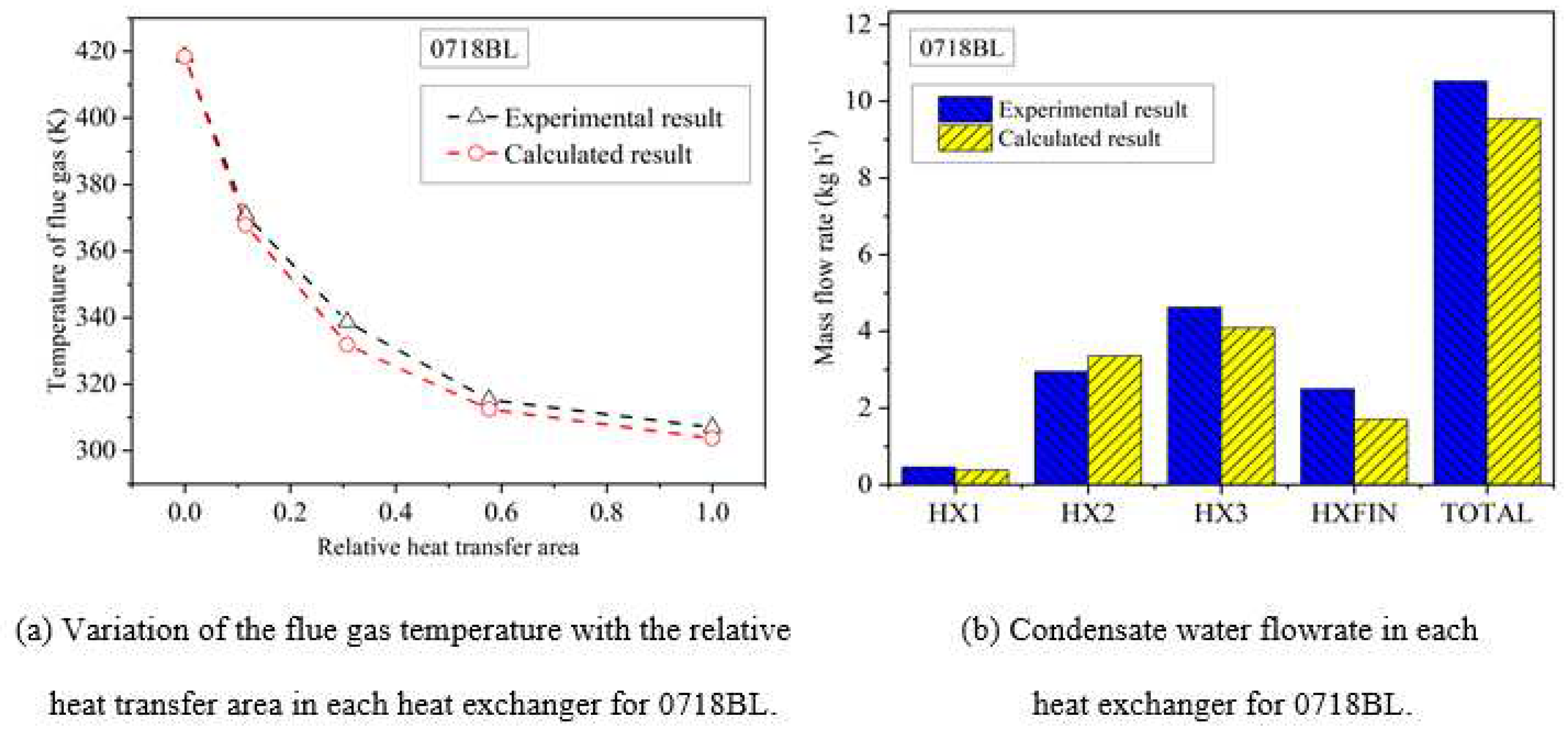

- The flue gas temperature decreases from 418.5 to 307.0 K under the finned-tube condition of 0718BL. In this case, the absolute deviation of the calculated outlet temperature of the flue gas is 3.3 K. The difference between the measured and simulated results of the condensate water flowrate is only 0.99 kg h-1. For the other 30 finned-tube conditions, the relative error of the condensate water flowrate mostly falls within ±10.0%, with the greatest deviation being 19.4%.

Author Contributions

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| Afin | area of fins/m2 |

| Aiw | area of the inner wall of tube/m2 |

| Aow | area of the outer wall of tube /m2 |

| At | area of tubes not occupied by fins/m2 |

| Bp | calculated fuel consumption of the boiler/kg s-1 |

| Cp,cw | constant-pressure specific heat capacity of the cooling water/kJ kg-1 K-1 |

| Dfin | fin outer diameter/m |

| d | tube outer diameter/m |

| Hfg | enthalpy of the flue gas from the combustion of 1 kg fuel/kJ kg-1 |

| hcw | convective heat transfer coefficient of the cooling water/W m-2 K-1 |

| hfg | convective heat transfer coefficient of the flue gas/W m-2 K-1 |

| hfin | fin height/m |

| Km | convective mass transfer coefficient of the flue gas /m s-1 |

| mcd | condensate water flowrate/kg s-1 |

| mcw | cooling water flowrate/kg·s-1 |

| Pfg | flue gas pressure/Pa |

| Pv,fg | partial pressure of the water vapor in the flue gas stream/Pa |

| Pv,film | partial pressure of the water vapor on the surface of the condensate film/Pa |

| Q | total heat release of the flue gas from the combustion of 1 kg fuel/kJ kg-1 |

| Q1 | latent heat release of the flue gas from the combustion of 1 kg fuel/kJ kg-1 |

| Qs | sensible heat release of the flue gas from the combustion of 1 kg fuel/kJ kg-1 |

| qfin | total heat transfer on the fin surface/W |

| qmax | the greatest heat transfer assuming the fin surface temperature is equal to the fin-root temperature/W |

| R | fouling resistance/m2 K W-1 |

| latent heat of vaporization for water vapor/kJ kg-1 | |

| Tdew | water dew point of the flue gas/K |

| Tfg | mean temperature of the flue gas stream/K |

| Tfilm | mean temperature of the condensate film surface/K |

| Tiw | mean temperature of the inner wall of tube/K |

| Tow | mean temperature of the outer wall of tube/K |

| tcw | cooling water temperature/K |

| Greek symbols | |

| δfin | fin thickness/m |

| tube thickness/m | |

| ηfin | fin heat efficiency |

| ηfin,l | latent heat transfer efficiency of fin |

| ηfin,s | sensible heat transfer efficiency of fin |

| λfin | fin thermal conductivity/W m-1 K-1 |

| λt | tube thermal conductivity/W m-1 K-1 |

| ρv,fg | average water vapor mass concentration of the flue gas/kg m-3 |

| ρv,ow | average water vapor mass concentration of the surface of the base-tube/kg m-3 |

| ωv | volume fraction of water vapor |

References

- Vizitiu, R.S.; Burlacu, A.; Abid, C.; Verdes, M.; Balan, M.C.; Branoaea, M. Experimental and Numerical Study of Thermal Performance of an Innovative Waste Heat Recovery System. Applied Sciences-Basel 2021, 11, 11542. [Google Scholar] [CrossRef]

- Blumberg, T.; Morosuk, T.; Tsatsaronis, G. Exergy-based evaluation of methanol production from natural gas with CO2 utilization. Energy 2017, 141, 2528–2539. [Google Scholar] [CrossRef]

- Wang, Z.C.; Wang, Y.M.; Zhang, J.L.; Li, S.; Xu, Y. Numerical Simulation of Heat Transfer Performance of a Dimpled Tubular Heat Exchanger. Applied Sciences-Basel 2022, 12, 12965. [Google Scholar] [CrossRef]

- Ferreira, S.; Nicoletti, V.R. Use of a tubular heat exchanger to achieve complex coacervation in a semi-continuous process: Effects of capsules curing temperature and shear rate. J. Food Eng. 2021, 310, 110698. [Google Scholar] [CrossRef]

- Park, Y.; Park, H.K.; Pusey, A.; Hong, J.; Park, J.; Chung, B.J.; Kim, H. Heat transfer augmentation in two-phase flow heat exchanger using porous microstructures and a hydrophobic coating. Appl. Therm. Eng. 2019, 153, 433–447. [Google Scholar] [CrossRef]

- Kang, J.; Kim, H.; Bak, J.; Lim, S.G.; Yun, B. Condensation of steam mixed with non-condensable gas on vertical heat exchanger tubes in circumstances with free convection. Int. J. Heat Mass Transf. 2021, 169, 120925. [Google Scholar] [CrossRef]

- Wang, J.S.; Duan, Y.F.; Qin, Y.Z.; Guo, Y.J.; Han, X.Q.; Yan, J.J. Experimental study on pressure drop and heat transfer characteristics of wet air with ash particles across circular finned tube bundles. Heat Transf. Eng. 2022, 43, 708–719. [Google Scholar] [CrossRef]

- Kazi, S.R.; Short, M.; Biegler, L.T. Heat exchanger network synthesis with detailed exchanger designs: Part 1. A discretized differential algebraic equation model for shell and tube heat exchanger design. Aiche Journal 2021, 67, 17056. [Google Scholar] [CrossRef]

- Jouhara, H.; Almahmoud, S.; Brough, D.; Guichet, V.; Delpech, B.; Chauhan, A.; Ahmad, L.; Serey, N. Experimental and theoretical investigation of the performance of an air to water multi-pass heat pipe-based heat exchanger. Energy 2021, 219, 119624. [Google Scholar] [CrossRef]

- Gundermann, M.; Raab, F.; Raab, D.; Botsch, T.W. Investigation of the heat transfer coefficient during the condensation of small quantities of water vapour from a mixture with a high proportion of non-condensable gas in a horizontal smooth tube. Int. J. Heat Mass Transf. 2021, 170, 121016. [Google Scholar] [CrossRef]

- Ji, C.; Li, L.; Qi, H. Improving heat transfer and water recovery performance in high-moisture flue gas condensation using silicon carbide membranes. Int. J. Energ. Res. 2021, 45, 10974–10988. [Google Scholar] [CrossRef]

- Osakabe, M.; Ishida, K.; Yagi, K.; Itoh, T.; Ohmasa, K. Condensation heat transfer on tubes in actual flue gas. Heat Transf.-Asian Res. 2001, 30, 139–151. [Google Scholar] [CrossRef]

- Bougriou, C.; Bessaih, R. Prediction and measurement of apparent heat transfer coefficient by condensation in finned-tube heat exchangers. Heat Transf. Eng. 2007, 28, 940–953. [Google Scholar] [CrossRef]

- Lee, J.; Kim, T.J.; Kim, M.H. Experimental study on the heat and mass transfer of Teflon-coated tubes for the latent heat recovery. Heat Transf. Eng. 2005, 26, 28–37. [Google Scholar] [CrossRef]

- Hwang, K.; Song, C.H.; Saito, K.; Kawai, S. Experimental study on titanium heat exchanger used in a gas fired water heater for latent heat recovery. Appl. Therm. Eng. 2010, 30, 2730–2737. [Google Scholar] [CrossRef]

- Poskas, R.; Sirvydas, A.; Kulkovas, V.; Poskas, P.; Jouhara, H.; Miliauskas, G.; Puida, E. Flue Gas Condensation in a Model of the Heat Exchanger: The Effect of the Cooling Water Flow Rate and Its Temperature on Local Heat Transfer. Applied Sciences-Basel 2022, 12, 12650. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Diao, H.M.; Tian, M.; Xie, L.Y.; Ge, M.H.; Wang, Y.L.; Wang, S.X. Condensation characteristics of air–water vapor mixture on the surface of vertical flat plate. Int. J. Heat Mass Transf. 2023, 210, 124185. [Google Scholar] [CrossRef]

- Krempaský, J.; Havlík, J.; Dlouhý, T. Theoretical and experimental study of water vapour condensation with high content of non-condensable gas in a vertical tube. Acta Polytechnica 2022, 62, 352–360. [Google Scholar] [CrossRef]

- Zhu, X.J.; Chen, S.; Shen, S.Q.; Ni, S.Q.; Shi, X.; Qiu, Q.G. Experimental study on the heat and mass transfer characteristics of air-water two-phase flow in an evaporative condenser with a horizontal elliptical tube bundle. Appl. Therm. Eng. 2020, 168, 114825. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, X.Y.; Kong, S. Experimental study on wet gas condensation heat transfer and flow resistance in horizontal intensified tube. Appl. Therm. Eng. 2023, 230, 120742. [Google Scholar] [CrossRef]

- Poredoš, P.; Petelin, N.; Vidrih, B.; Žel, T.; Ma, Q.; Wang, R.; Kitanovski, A. Condensation of water vapor from humid air inside vertical channels formed by flat plates. iSci. 2022, 25, 103565. [Google Scholar] [CrossRef] [PubMed]

- Abeykoon, C. Compact heat exchangers - Design and optimization with CFD. Int. J. Heat Mass Transf. 2020, 146, 118766. [Google Scholar] [CrossRef]

- Claesson, J. Correction of Logarithmic Mean Temperature Difference in a compact brazed plate evaporator assuming heat flux governed flow boiling heat transfer coefficient. Int. J. Refrigeration-Revue Internationale Du Froid 2005, 28, 573–578. [Google Scholar] [CrossRef]

- Wang, C.Y.; Tu, C.J. Effects of non-condensable gas on laminar-film condensation in a vertical tube. Int. J. Heat Mass Transf. 1988, 31, 2339–2345. [Google Scholar] [CrossRef]

- Desrayaud, G.; Lauriat, G. Heat and mass transfer analogy for condensation of humid air in a vertical channel. Heat Mass Transf. 2001, 37, 67–76. [Google Scholar] [CrossRef]

- Wu, X.M.; Che, D.F. A numerical study of high moisture flue gas in tube banks. Numerical Heat Trans. Part a-Applications 2014, 65, 357–377. [Google Scholar] [CrossRef]

- Morales-Fuentes, A.; Jimenez-Zuniga, A.M.; Alfaro-Ayala, J.A.; Loredo-Saenz, Y.A.; Belman-Flores, J.M. Wet-dry thermohydraulic performance comparison on fin-and-tube geometries. Appl. Therm. Eng. 2022, 214, 118881. [Google Scholar] [CrossRef]

- Guo, C.M.; Liu, Q.L.; Zheng, B.; You, Y.W.; Li, Y. Development of model based on condensation area ratio and effect on heat transfer capacity of indirect evaporative cooling. Appl. Therm. Eng. 2020, 164, 114557. [Google Scholar] [CrossRef]

- Alshehri, A.; Andalib, S.; Kavehpour, H.P. Numerical modeling of vapor condensation over a wide range of non-condensable gas concentrations. Int. J. Heat Mass Transf. 2020, 151, 119405. [Google Scholar] [CrossRef]

- Dehbi, A. Correcting for tube curvature effects on condensation in the presence of a noncondensable gas in laminar regimes. Int. J. Heat Mass Transf. 2020, 151, 119384. [Google Scholar] [CrossRef]

- Li, K.; Wang, E.L.; Li, D.L.; Husnain, N.; Fareed, S. Numerical and experimental investigation on water vapor condensation in turbulent flue gas. Appl. Therm. Eng. 2019, 160, 114009. [Google Scholar] [CrossRef]

- Jiang, J.; Liu, F.; Zhang, X.; Wei, H. Model development and simulation on dropwise condensation by coupling absorption theory in the presence of non-condensable gas (NCG). Int. Commun. Heat Mass Transf. 2020, 119, 104936. [Google Scholar] [CrossRef]

- Jeong, K. Condensation of water vapor and sulfuric acid in boiler flue gas. PhD, Lehigh University, Bethlehem, 2009.

- Zhu, Y.; Tso, C.Y.; Ho, T.C.; Leung, M.K.H.; Yao, S.; Qiu, H.H. Heat transfer enhancement on tube surfaces with biphilic nanomorphology. Appl. Therm. Eng. 2020, 180, 115778. [Google Scholar] [CrossRef]

- Hu, W.; Ma, A.; Guan, Y.; Cui, Z.; Zhang, Y.; Wang, J. Experimental study of the air side performance of fin-and-tube heat exchanger with different fin material in dehumidifying conditions. Energies 2021, 14, 7030. [Google Scholar] [CrossRef]

- Niu, D.; Gao, H.T.; Tang, G.H.; Yan, Y.Y. Droplet nucleation and growth in the presence of noncondensable gas: A molecular dynamics study. Langmuir 2021, 37, 9009–9016. [Google Scholar] [CrossRef]

- Kroger, D.G.; Rohsenow, W.M. Condensation heat transfer in presence of a non-condensable gas. Int. J. Heat Mass Transf. 1968, 11, 15–26. [Google Scholar] [CrossRef]

- Ji, D.Y.; Lee, J.W.; Kim, D.; Hwang, W.; Lee, K.Y. Effective reduction of non-condensable gas effects on condensation heat transfer: Surface modification and steam jet injection. Appl. Therm. Eng. 2020, 174, 115264. [Google Scholar] [CrossRef]

- Tao, W.Q. "Heat Transfer", fifth ed.; Higher Education Press: Beijing, 2019. [Google Scholar]

- Ma, Y.Y. "Standard Method for Thermal Calculation of Boiler Units", first ed.; China Water&Power Press: Beijing, 1960. [Google Scholar]

- Sharqawy, M.H.; Moinuddin, A.; Zubair, S.M. Heat and mass transfer from annular fins of different cross-sectional area. Part I. Temperature distribution and fin efficiency. Int. J. Refrigeration 2012, 35, 365–376. [Google Scholar] [CrossRef]

- Moinuddin, A.; Sharqawy, M.H.; Zubair, S.M. Heat and mass transfer from annular fins of different cross sectional area. Part II. Optimal dimensions of fins. Int. J. Refrigeration 2012, 35, 377–385. [Google Scholar] [CrossRef]

- Sharqawy, M.H.; Zubair, S.M. Efficiency and optimization of an annular fin with combined heat and mass transfer – An analytical solution. Int. J. Refrigeration 2007, 30, 751–757. [Google Scholar] [CrossRef]

- Li, J.B. "Study on thermal calculation method of condensing heat exchanger in boilers". Master, Xi'an Jiaotong University, Xi'an, 2016.

- Zhang, W.; Wang, S.L.; Mu, L.B.; Jamshidnia, H.; Zhao, X.D. Investigation of the forced-convection heat-transfer in the boiler flue-gas heat recovery units employing the real-time measured database. Energy 2022, 238, 121715. [Google Scholar] [CrossRef]

- Lin, C.; Wang, D.; Bao, A. Numerical modeling and simulation of condensation heat transfer of a flue gas in a bundle of transport membrane tubes. Int. J. Heat Mass Transf. 2013, 60, 41–50. [Google Scholar] [CrossRef]

- Jeong, K.; Kessen, M.J.; Bilirgen, H.; Levy, E.K. Analytical modeling of water condensation in condensing heat exchanger. Int. J. Heat Mass Transf. 2010, 53, 2361–2368. [Google Scholar] [CrossRef]

| Case No. | Flowrate of inlet flue gas (kg h-1) | Temperature of inlet flue gas (K) | Flowrate of inlet cooling water (kg h-1) | Temperature of inlet cooling water (K) | Inlet moisture fraction (%) |

|---|---|---|---|---|---|

| 0108BL | 199.5 | 400.9 | 332.0 | 282.8 | 7.7 |

| 0731BLa | 152.4 | 421.5 | 372.2 | 298.0 | 13.5 |

| 0718BL | 157.6 | 418.5 | 374.2 | 296.7 | 13.5 |

| Parameters | HX1 | HX2 | HX3 | HX4 | HX5 | HXFIN |

|---|---|---|---|---|---|---|

| Cross-sectional width (mm) | 152.4 | 152.4 | 152.4 | 152.4 | 152.4 | 330.2 |

| Height of inlet cross-section (mm) | 355.6 | 355.6 | 355.6 | 355.6 | 355.6 | 136.53 |

| Height of outlet cross-section (mm) | 381 | 381 | 381 | 381 | 381 | 155.58 |

| Mean cross-section height (mm) | 368.3 | 368.3 | 368.3 | 368.3 | 368.3 | 146.05 |

| Tube’s outer diameter (mm) | 12.7 | 12.7 | 12.7 | 12.7 | 12.7 | 12.7 |

| Tube’s wall thickness (mm) | 0.889 | 0.889 | 0.889 | 0.889 | 0.889 | 1.24 |

| Transverse pitch (mm) | 18.34 | 18.34 | 18.34 | 18.34 | 18.34 | 26.99 |

| Longitudinal pitch (mm) | 50.80 | 50.80 | 50.80 | 50.80 | 50.80 | 101.6 |

| Number of transverse tube rows | 8 | 8 | 8 | 8 | 8 | 5 |

| Number of longitudinal tube rows | 6 | 10 | 14 | 14 | 14 | 8 |

| Type of tube bundle | Bare-tube | Bare-tube | Bare-tube | Bare-tube | Bare-tube | Finned-tube |

| Fin height | — | — | — | — | — | 6.35 |

| Fin thickness | — | — | — | — | — | 0.38 |

| Fin pitch | — | — | — | — | — | 4.55 |

| Layout of tube bundle | In-line | In-line | In-line | In-line | In-line | In-line |

| Case No. | Flowrate of inlet flue gas (kg h-1) | Temperature of inlet flue gas (K) | Flowrate of inlet cooling water (kg h-1) | Temperature of inlet cooling water (K) | Inlet moisture fraction (%) | Experimental measured condensate water flowrate (kg h-1) | Calculated condensate water flowrate (kg h-1) | Relative error (%) |

|---|---|---|---|---|---|---|---|---|

| 0110BL | 200 | 426.5 | 280 | 282.9 | 7.8 | 7.4 | 7.6 | -2.5 |

| 0112BL | 223 | 429.5 | 310 | 282.6 | 8.7 | 9.3 | 9.7 | -4.2 |

| 0116BL | 242 | 440.4 | 315 | 282.2 | 8.6 | 9.9 | 10.2 | -2.8 |

| 0118BL | 227 | 436.8 | 327 | 282.1 | 9.0 | 10.5 | 10.4 | 1.2 |

| 0119BL | 217 | 437.4 | 318 | 281.5 | 9.3 | 10.1 | 10.4 | -3.6 |

| 0302BL | 183 | 437.0 | 328 | 278.5 | 10.3 | 10.4 | 10.5 | -0.8 |

| 0323BL | 185 | 405.5 | 320 | 279.5 | 9.6 | 9.8 | 9.8 | 0.4 |

| 0302T55 | 179 | 415.1 | 571 | 286.5 | 11.4 | 11.0 | 11.0 | 0.0 |

| 0302T75 | 164 | 422.4 | 256 | 297.2 | 10.9 | 7.3 | 7.1 | 2.8 |

| 0302T90 | 162 | 424.0 | 185 | 305.5 | 10.5 | 4.1 | 3.4 | 17.4 |

| 0731BLb | 163 | 424.3 | 372 | 298.4 | 13.2 | 10.1 | 9.9 | 2.1 |

| 0731BLc | 158 | 421.4 | 371 | 298.4 | 13.2 | 9.8 | 9.6 | 2.2 |

| 0801T100 | 161 | 415.8 | 385 | 310.8 | 12.8 | 6.4 | 5.7 | 11.3 |

| 0805T90b | 185 | 410.2 | 662 | 304.4 | 12.3 | 9.3 | 8.9 | 3.4 |

| 0805T90c | 184 | 421.2 | 558 | 305.3 | 13.7 | 10.5 | 10.2 | 3.1 |

| 0805T90d | 183 | 425.9 | 519 | 305.9 | 14.5 | 10.8 | 10.8 | 0.7 |

| 0805T90e | 177 | 424.4 | 369 | 305.0 | 14.0 | 9.3 | 9.2 | 0.7 |

| 0806T90a | 181 | 419.5 | 653 | 304.4 | 13.1 | 10.0 | 9.7 | 3.0 |

| 0813BL | 186 | 423.7 | 363 | 298.5 | 13.0 | 10.8 | 10.5 | 2.9 |

| 0814BLa | 189 | 420.9 | 394 | 297.5 | 12.7 | 10.7 | 10.9 | -1.0 |

| 0814BLb | 192 | 421.0 | 393 | 297.7 | 11.9 | 9.9 | 10.0 | -0.5 |

| 0814BLc | 188 | 419.4 | 378 | 297.5 | 12.6 | 10.5 | 10.6 | -1.2 |

| 0815BL | 188 | 419.0 | 401 | 298.7 | 13.1 | 11.0 | 11.0 | 0.3 |

| 0815T100 | 182 | 415.2 | 404 | 311.1 | 13.2 | 7.3 | 6.5 | 10.6 |

| 0220BL | 253 | 439.3 | 345 | 278.1 | 12.3 | 16.0 | 17.2 | -7.6 |

| 0220T60 | 248 | 440.3 | 444 | 288.8 | 12.0 | 15.4 | 15.3 | 0.7 |

| 0220T70 | 240 | 440.0 | 290 | 294.8 | 10.9 | 10.7 | 9.3 | 13.4 |

| 0221BLa | 251 | 432.9 | 223 | 278.7 | 9.1 | 11.3 | 10.1 | 10.4 |

| 0221BLb | 263 | 440.2 | 440 | 278.0 | 11.2 | 16.3 | 16.7 | -2.8 |

| 0221BLc | 267 | 439.9 | 542 | 277.9 | 12.8 | 20.2 | 20.0 | 1.3 |

| Case No. | Flowrate of inlet flue gas (kg h-1) | Temperature of inlet flue gas (K) | Flowrate of inlet cooling water (kg h-1) | Temperature of inlet cooling water (K) | Inlet moisture fraction (%) | Experimental measured condensate water flowrate (kg h-1) | Calculated condensate water flowrate (kg h-1) | Relative error (%) |

|---|---|---|---|---|---|---|---|---|

| 0518BL | 181 | 388.5 | 283 | 283.1 | 8.3 | 7.0 | 7.2 | -2.7 |

| 0518T50 | 173 | 386.7 | 197 | 284.1 | 8.4 | 6.8 | 6.3 | 7.7 |

| 0518T70 | 176 | 386.3 | 393 | 294.6 | 9.5 | 7.6 | 7.0 | 7.9 |

| 0523BLa | 179 | 386.8 | 295 | 283.3 | 7.7 | 6.0 | 6.5 | -8.4 |

| 0523BLb | 178 | 387.0 | 301 | 283.4 | 8.1 | 6.3 | 6.9 | -9.1 |

| 0523BLc | 173 | 386.1 | 298 | 283.5 | 7.9 | 6.0 | 6.6 | -8.9 |

| 0523T65 | 159 | 383.0 | 555 | 291.5 | 11.0 | 8.8 | 8.6 | 2.5 |

| 0523T80 | 157 | 383.2 | 317 | 300.1 | 7.8 | 3.9 | 3.5 | 10.8 |

| 0523T100 | 155 | 382.7 | 223 | 310.3 | 8.8 | 1.4 | 1.4 | 2.6 |

| 0606BL | 173 | 396.5 | 273 | 284.4 | 9.7 | 8.2 | 8.3 | -1.8 |

| 0606T55 | 167 | 388.7 | 294 | 285.8 | 12.2 | 10.6 | 10.7 | -0.4 |

| 0606T70 | 169 | 389.7 | 447 | 294.4 | 11.9 | 10.0 | 9.7 | 2.9 |

| 0608BL | 157 | 387.3 | 274 | 285.4 | 11.9 | 9.4 | 9.8 | -4.1 |

| 0608T55 | 130 | 385.0 | 275 | 286.2 | 14.7 | 10.4 | 10.7 | -2.9 |

| 0608T80 | 137 | 385.0 | 272 | 301.0 | 12.7 | 7.0 | 6.8 | 2.4 |

| 0627BL456 | 118 | 378.8 | 271 | 287.0 | 15.0 | 9.8 | 9.9 | -1.6 |

| 0628BL456 | 150 | 381.9 | 263 | 286.5 | 12.4 | 10.0 | 9.7 | 2.6 |

| 0629BL45 | 151 | 383.6 | 287 | 287.0 | 9.5 | 5.9 | 6.8 | -16.0 |

| 069BL456 | 148 | 382.8 | 274 | 287.0 | 10.6 | 7.9 | 7.9 | -0.6 |

| 0717BLa | 177 | 407.5 | 352 | 296.2 | 12.0 | 10.1 | 9.0 | 10.8 |

| 0717BLb | 158 | 411.0 | 354 | 296.0 | 12.1 | 9.1 | 8.5 | 7.3 |

| 0717BLc | 135 | 413.0 | 364 | 296.5 | 13.6 | 9.2 | 8.7 | 5.0 |

| 0717BLd | 135 | 414.3 | 373 | 296.0 | 13.8 | 9.4 | 9.0 | 4.0 |

| 0717BLe | 140 | 418.6 | 373 | 296.0 | 11.8 | 7.9 | 7.5 | 5.5 |

| 0717BLf | 148 | 418.9 | 373 | 297.0 | 11.8 | 8.3 | 7.8 | 5.1 |

| 0718T100c | 155 | 416.5 | 369 | 311.0 | 13.6 | 7.1 | 5.7 | 19.4 |

| 0719BL | 154 | 417.4 | 373 | 296.5 | 13.3 | 10.2 | 9.4 | 7.3 |

| 0719T90a | 155 | 420.4 | 604 | 305.3 | 14.2 | 9.6 | 9.0 | 6.2 |

| 0719T90b | 156 | 410.3 | 597 | 305.2 | 13.8 | 9.3 | 8.6 | 7.4 |

| 0719T90c | 138 | 407.3 | 583 | 305.0 | 14.2 | 8.5 | 8.1 | 5.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).