1. Introduction

The translation and rotation of small particles in Newtonian fluids at low Reynolds numbers play important roles in a variety of technological and industrial processes such as centrifugation, sedimentation, aggregation, microfluidics, suspension rheology, and aerosol technology. The analysis of this subject was initiated by Stokes [

1,

2] on the motions of an isolated nonslip spherical particle in a viscous fluid. The phenomena that viscous fluids in creeping flow can frictionally slip at particle surfaces occur for numerous situations such as a colloidal particle with lyophobic surface [

3,

4,

5,

6,

7], an aerosol particle in low-density gas [

8,

9,

10], and a porous particle [

11,

12]. The slip velocity is presumably proportional to the shear stress of the fluid at the particle surface with the proportionality constant

as the slip coefficient [

13,

14,

15].

The hydrodynamic torque exerted on a slip sphere of radius

rotating with angular velocity

in a fluid of viscosity

was obtained by Basset [

13] as

where

signifies a slip length. In the limiting case of the stickiness/slip parameter

, the particle is perfectly slip (like a gas bubble in a liquid) and

. In the other limit

, the particle is nonslip and Eq. (1) becomes the Stokes result. More recently, the creeping-flow rotation of slip particles has been examined for a slightly deformed sphere [

16], an axisymmetric particle such as spheroid [

17,

18,

19], and a circular cylinder [

20].

In many technical applications, slip particles are not isolated. Thus, it is imperative to determine if the attendance of adjoining particles meaningfully affects the particle movement [

21,

22]. Through an exact representation in spherical bipolar coordinates, the axisymmetric slow translation of two slip spherical particles was investigated semi-analytically and numerical results were calculated for the cases of identical spheres with equal magnitude of velocities [

23] and arbitrary spheres with arbitrary velocities [

24]. On the other hand, the translational and rotational motions of two arbitrarily oriented spheres with arbitrary radii and slip coefficients were analyzed using a method of twin multipole expansions [

25]. Subsequently, the creeping flow around two arbitrary slip spheres translating along and rotating about their line of centers was studied by using a boundary collocation method [

26]. It was found from these investigations that the two-sphere interaction effect decreases with increasing slip coefficients of the particles, may be pronounced as the distance between particle surfaces approaches zero, and is greater on the smaller particles than on the larger ones.

For a concentrated suspension, the interaction amongst multiple particles may be important. The objective of this article is to analyze the slow rotation of a chain of coaxial slip spherical particles about the axis. The particles may vary in radius, slip coefficient, and angular velocity, and they are permitted to be unevenly spaced. Through the use of the boundary collocation method, the Stokes equation is solved semi-analytically and the torques exerted on the particles by the fluid are obtained with excellent convergence. For the simple case of rotation of two spherical particles, our collocation solutions for the torques agree well with the asymptotic solutions resulted from the method of twin multipole expansions [

25] and with some numerical calculations [

26].

2. Analysis

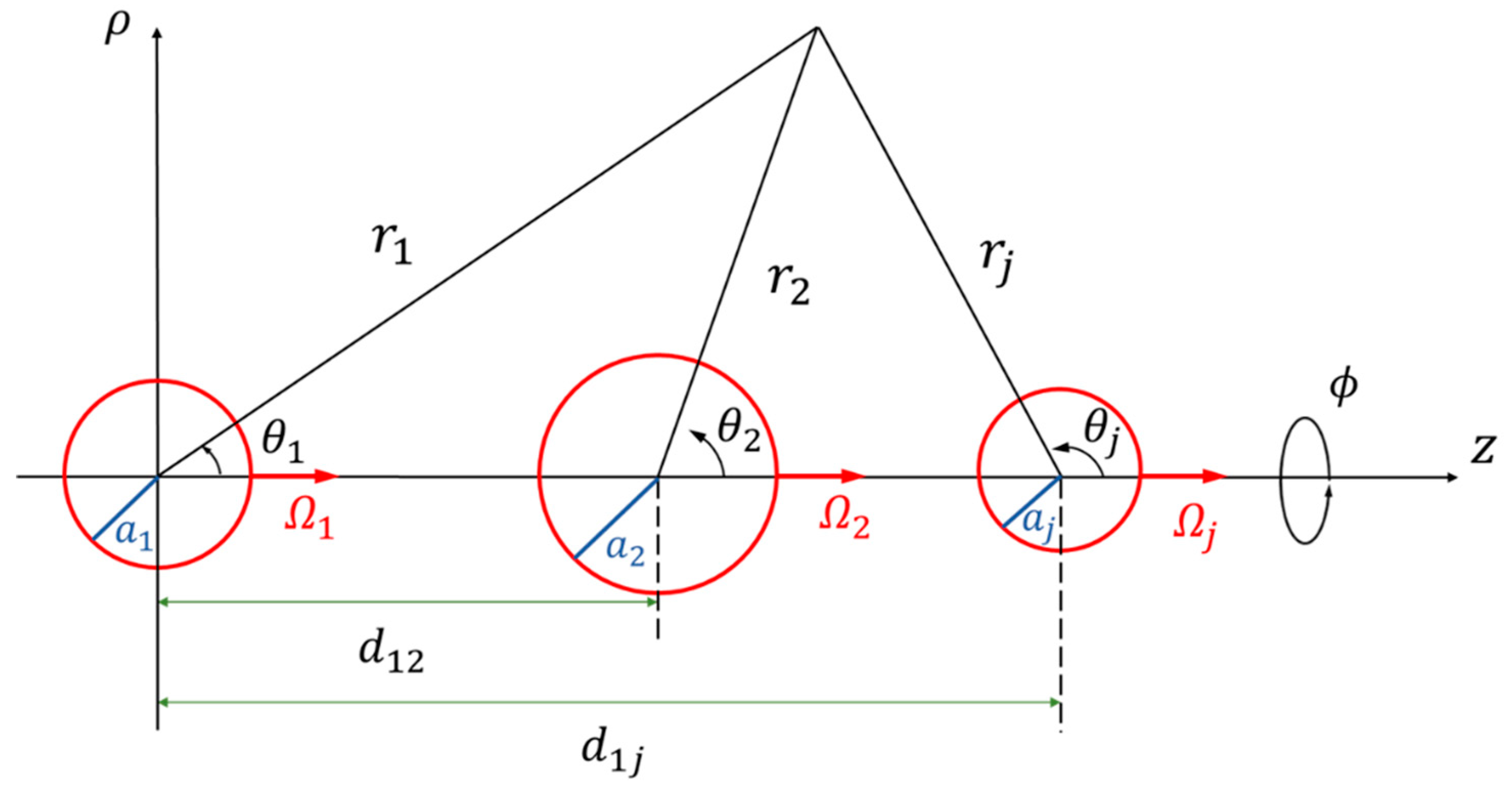

As shown in

Figure 1, we consider the steady slow rotation of a straight chain of

neutrally-buoyant spherical particles in a boundless, quiescent, incompressible Newtonian fluid of viscosity

about the line through their centers (

axis), where the fluid may slip frictionally at the particle surfaces. The spherical coordinates

are measured from the center of particle

(with radius

) for

, 2, …, and

, and the origin of the circular cylindrical coordinates

is set at the center of particle 1. The particles may vary in size, surface slippage, and angular velocity, and they are permitted to be unevenly spaced. The purpose is to obtain the correction to Eq. (1) for the rotational motion of each particle owing to the presence of the other ones.

The Stokes equation governing the creeping flow around the rotating particles is

where

or

is the

(only nontrivial) component of the fluid velocity distribution (with

,

, …, and

), the continuity equation is satisfied, and the dynamic pressure is constant everywhere. In Eq. (2), any coordinate system

can be chosen. Because the slip velocity is proportional to the nontrivial tangential stress locally at each particle surface [

13], the fluid velocity satisfies the boundary conditions

where

is the angular velocity of particle

,

which is the relevant shear stress, and

is the Navier slip coefficient about the particle

.

We can express a sufficiently general solution of the fluid velocity in the form

where

is the associated Legendre function of the first kind of order

and degree 1, and

are the unknown constants to be determined. The boundary condition (4) is satisfied immediately by Eq. (6), in which the solutions in

spherical coordinate systems can be superimposed due to the linearity of Eq. (2). Substituting Eq. (6) into Eq. (3), we obtain

To express Eqs. (6) and (7) in a single coordinate system, one can use the conversion formulas between the coordinates

and

,

where

denotes the distance between the centers of particles

and

(thus

).

The satisfaction of the boundary conditions in Eq. (7) on the particle surfaces requires the solution of the unknown constants

. The collocation technique [

27,

28,

29] permits these boundary conditions to be imposed at

points along the longitudinal arc of each sphere and the infinite series in Eq. (6) is truncated after the

terms, leading to

simultaneous algebraic equations in the truncated form of Eq. (7). For sufficiently large number of

, these equations can be numerically solved to yield the

constants

required in the truncated form of Eq. (6). The details of the adopted boundary collocation arrangement were given in an early article on the translation of a chain of fluid spheres along their line of centers [

30].

The hydrodynamic torque acting on the particle

is the integral of the product of the shear force

exerted on a differential surface element and the lever arm

of that element over the particle surface, resulting in

The previous formula shows that only the lowest-order constants

contribute to the hydrodynamic torques

.

The torque results can be expressed as

with

which is the torque acting on the isolated particle

given by Eq. (1). The torque correction parameters

are functions of the scaled radii, separation distances, and surface slippages of the particles. When the separation distances are infinite, obviously,

equals unity if

and zero if

.

3. Results for Two Particles

In this section, we present the boundary collocation results for the rotation of two slip spheres (

) about their line of centers. Once the unknown constants

and

in Eq. (6) for the fluid velocity are solved from the truncated form of Eq. (7), Eq. (10) can be used to calculate the torque exerted by the fluid on each particle. Numerical results of the four torque correction parameters

,

,

, and

in Eq. (11) are presented in

Table 1 for the case of two identical spheres (

,

,

, and

) with various values of the stickiness/slip parameter

and spacing parameter

. In

Table 2, collocation solutions of the torque correction parameters

,

,

, and

for the axisymmetric rotation of two nonslip spheres (

) with different radii (choosing

equal to 2 and 5) at various values of the spacing parameter

are given. In

Table 3, we list typical collocation results of these torque correction parameters for cases of two slip spheres differing in either size or slippage at various values of the spacing parameter

. All of our results converge to at least five digits after the decimal point.

In

Table 1,

Table 2 and

Table 3, for all values of

,

, and

, the parameters

and

are positive and increase with an increase in

from unity at

, while

and

are negative and whose magnitudes also increase with an increase in

but from zero at

. These results manifest that the particles’ interaction rises with diminishing gap thickness between them. In general, this interaction can be significant as

and its influence is stronger on a smaller or less slippery (stickier) particle than on a larger or more slippery (less sticky) one for any given value of

.

Using a method of twin multipole expansions, Keh and Chen [

25] analytically obtained the following power-series formulas of the torque correction parameters

,

,

, and

for the axial rotation of two spheres with

:

where

Thus, there are two independent torque correction parameters to be determined for

and

. Alternatively, we could determine all four parameters in the range

and

. In the particular case of

(two nonslip spheres), more terms of

are available [

31]:

The asymptotic solutions for the torque correction parameters obtained from the previous formulas are also listed in

Table 1 and

Table 2 for comparison. It is found that our collocation results are in good agreement with these asymptotic solutions as

is small. However, the errors of these asymptotic solutions become significant when

gets close to unity.

Using the reciprocal theorem of Lorentz [

15] for the axisymmetric rotation of any two slip spheres with

, we obtain

The collocation results in

Table 1 and

Table 2 satisfy Eq. (20) and the relations

and

(with

and

being positive and

and

negative), indicating that the rotation of one particle is enhanced (its hydrodynamic torque is reduced) by another nearby particle rotating with a comparable or larger angular velocity in the same direction but is hindered (the resisting torque is augmented) by another particle rotating with an arbitrary angular velocity in the opposite direction.

4. Results for Multiple Particles

We now present the boundary collocation results for the rotation of a chain of three or more slip spheres about their line of centers. From Eq. (11), the general problem requires nine torque correction parameters to represent the hydrodynamic torques on the three-sphere chain. For the sake of brevity, here we only consider the rotation of three coaxial spheres with the same slip coefficient (

) in a symmetric configuration, i.e. the spheres at both ends have equal radii (

) and are equally distant from the central sphere (

). For this symmetric case, it is clear that the torque correction coefficients

In

Table 4, collocation results of the torque correction parameters in Eq. (11) for the axisymmetric rotation of three identical slip spheres (

) with different values of the stickiness parameter

and spacing parameter

are offered. In

Table 5, the numerical results of the torque correction parameters for the rotation of three nonslip spheres (

) for two typical cases of relative particle sizes (

equal to 2 and 1/2) at various values of the spacing parameter

are given. In

Table 6, we list results of the torque correction parameters for the rotation of three slip spheres (with

and

equal to 2 and 1/2) at various values of

. In general, particle interactions increase with decreasing gap thickness between two adjacent particles. When the central particle is greater than the end ones, however, the torque correction parameters

and

are not always monotonical functions of

. Again, Eq. (20) holds in Tables IV and V for the axisymmetric rotation of the three-sphere chain and the effect of particle interactions on the hydrodynamic torques is greater for smaller or less slippery particles than for larger or more slippery ones for a given value of

.

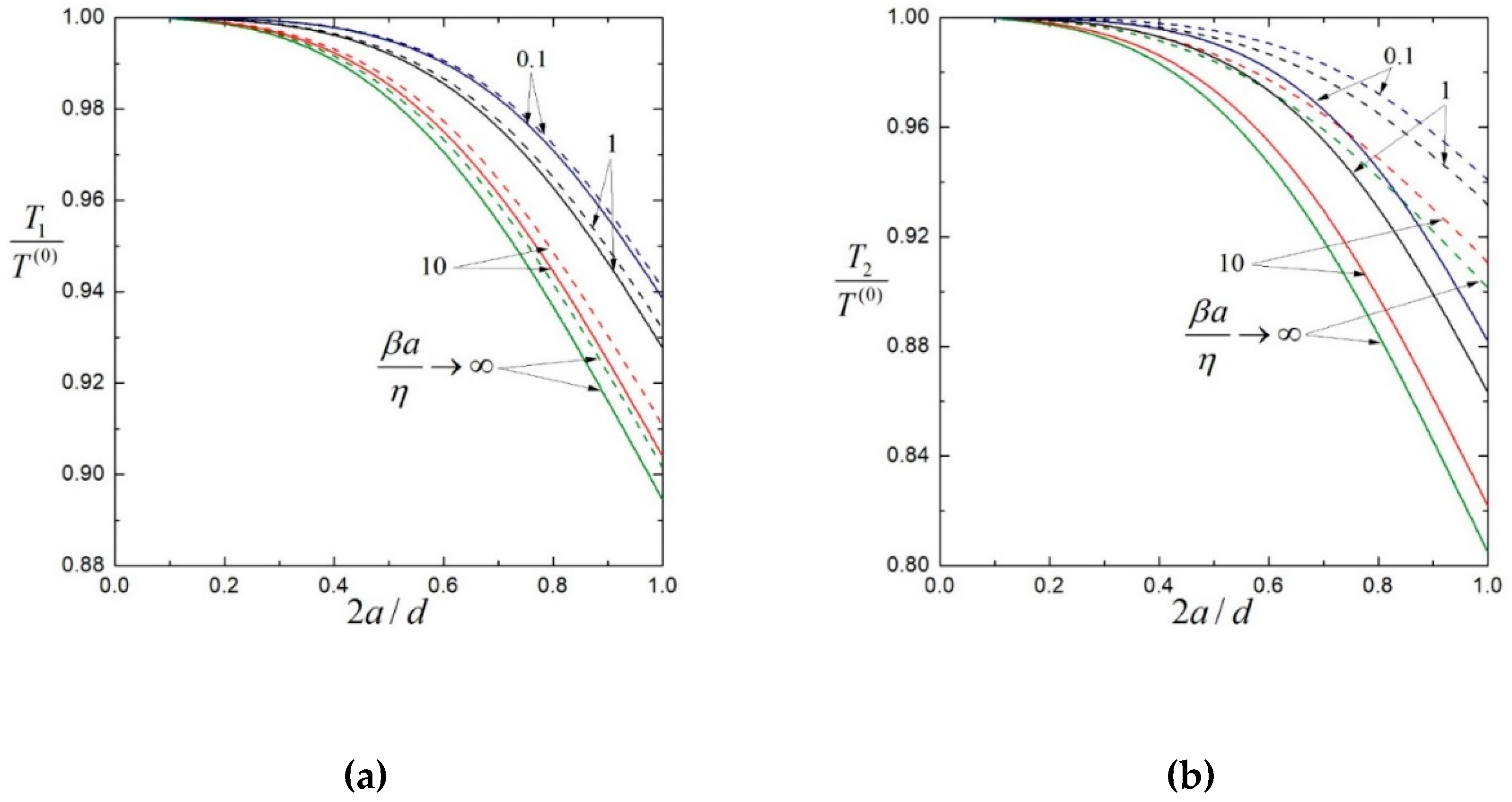

It may be interesting to realize how much the presence of a third particle influences the hydrodynamic torques of its two neighbors. The normalized torques

of three identical spheres (

,

, and

) rotating at equal angular velocities (

) about their line of centers at equal spacings (

) are plotted versus the spacing parameter

by solid curves for various values of the stickiness parameter

in

Figure 2. For comparison, the corresponding results of normalized torques of the first and second particles in the absence of the third one, which agree well with those obtained by Saad [

26], are plotted in the same figure by dashed curves. Clearly, the presence of the third particle reduces the torques of the other two particles. As expected, the reduction in torque is much more pronounced on the center particle than on the end ones. When the particles are in contact with each other (

), the presence of the third particle reduces the torque on the first (end) particle by merely about 0.8% in the case of no-slip particles (

) and about 0.3% in the case of slip particles with

, as shown in

Figure 2a (and

Table 1 and

Table 4). In contrast, as shown in

Figure 2b (and

Table 1 and

Table 4), the torque on the second (center) particle is reduced by 10.7% in the case of no-slip particles and by 7.3% in the case of slip particles with

when the particles touch each other. Note that, due to the configurational symmetry, the torque results presented in

Table 1 and

Figure 2 for two identical slip spheres a distance

apart and rotating at identical angular velocity are the same as those for an isolated slip sphere rotating at equal angular velocity at a distance

from a large planar free surface (with vanishing shear stress) normal to the axis of rotation.

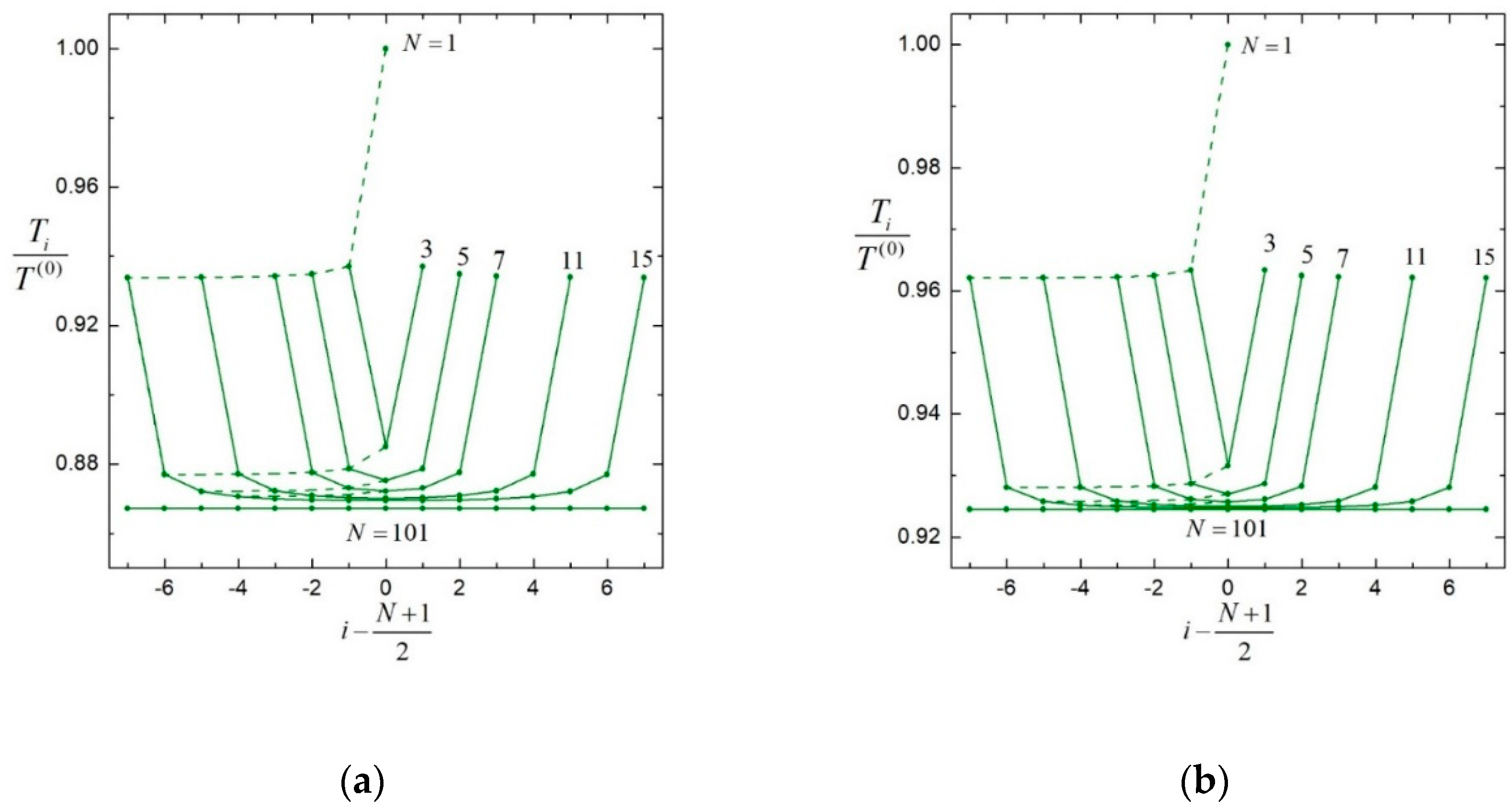

The solution to the problem of chains consisting of different numbers of

(up to 101) identical slip spheres (

,

, and

) with equal spacings (

), rotating about their line of centers with equal angular velocities (

), has also been obtained by the boundary collocation method. Results of the normalized torques

for these chains with

are plotted against the particle number

in

Figure 3. It can be seen that the torques on the central particles decrease with increasing chain length, indicating a shielding effect of the particle chain. When approaching the ends of the chain, the relative torques of neighboring particles change rapidly, demonstrating a strong end effect. As the chain length increases for a relatively long chain, the torques on the central particles change slowly. The torque on each particle will be the same in the limit of an infinite chain. The dashed curves in

Figure 3 represent the change in torque of the

ith particle in the chain as more particles are added to the chain. These curves are leveled out as the chain length is increased, again demonstrating the shielding effect exhibited by particle chains.

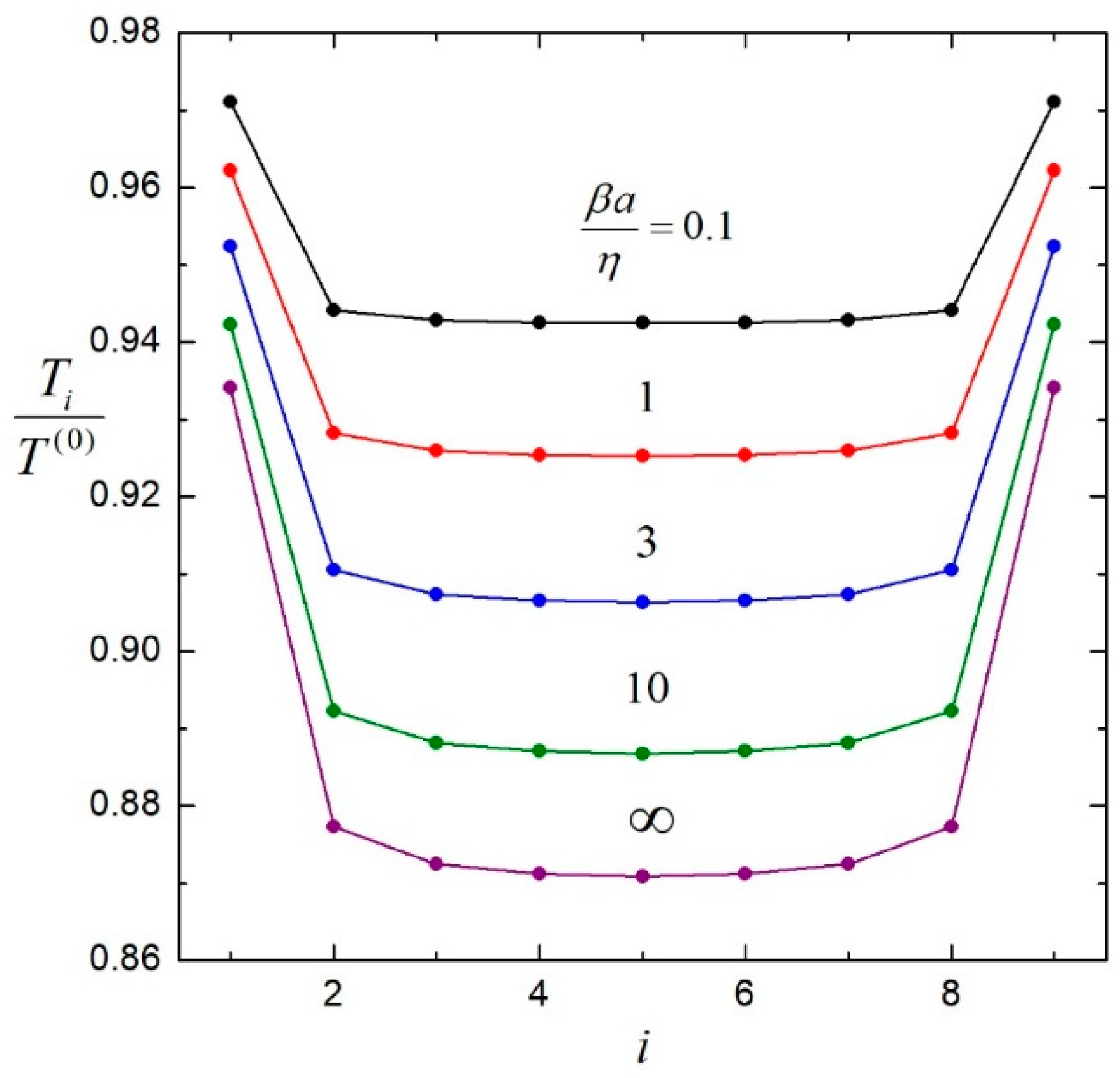

Figure 4 represents a plot of the normalized torques

versus the particle number

for a chain of nine identical and equally spaced slip particles with

rotating with equal angular velocities at different values of the stickiness parameter

. These results show that as

increases, the torque on each particle in the chain decreases. Particle interactions are strictest for no-slip particle chains and weaker for corresponding more slippery particle chains.

To examine the effect of particle spacing, the normalized torques

versus the particle number

are plotted in

Figure 5 for the chain containing nine identical and equally spaced particles rotating at equal angular velocities with

as a parameter. Both the case of no-slip (

) particle chains and a case of partly slip (with

) particle chains are shown. The results in this figure illustrate that end effects decrease with increasing spacing (decreasing

). As expected, the torque of each particle in the chain decreases as the particles get closer together.

5. Concluding Remarks

The slow rotation of a straight chain of multiple slip spheres about their line of centers in a Newtonian fluid is analyzed in this article. The spheres may vary in radius, slip coefficient, and angular velocity, and they are permitted to be unevenly spaced. The boundary collocation method has been employed to obtain the fluid velocity field semi-analytically. The solutions of the hydrodynamic torques exerted on the particles can be obtained even when the number of particles is large and the particles touch one another.

Section 2 presents the linear algebraic collocation formulations for solving the general axisymmetric problem of multi-sphere rotations, and numerical results of the torques for two-sphere, three-sphere, and multi-sphere systems to correct Eq. (1) are given in

Section 3 and

Section 4. The interaction effects among the particles are found to be noteworthy under appropriate conditions.

The results for the resistance problem are presented in previous sections, in which the hydrodynamic torques

experienced by a chain of particles are calculated for specified angular velocities

according to Eqs. (11) and (12). In a mobility problem, on the other hand, the applied torques on the particles are specified and the resultant angular velocities need to be determined. For the axisymmetric rotation of

slip spheres, the angular velocity of particle

can be expressed as

with

which is the angular velocity of particle

subject to an applied torque

in the absence of the other particles, and the mobility parameters

are functions of the scaled radii, separation distances, and surface slippages of the particles. For the case of two particles (

), one can use Eqs. (11), (12), (22), and (23) to obtain

where the corresponding expressions for

and

can be determined from the previous formulas by interchanging subscripts 1 and 2. The mobility parameters

,

,

, and

can thus be calculated from using the torque correction parameters

,

,

, and

obtained in

Section 3 for its resistance problem.

Figure 1.

Geometric sketch for the rotation of a chain of coaxial slip spheres about their axis.

Figure 1.

Geometric sketch for the rotation of a chain of coaxial slip spheres about their axis.

Figure 2.

Normalized torques on three coaxial, identical, equally spaced, slip spheres rotating at equal angular velocities about their axis versus the separation parameter with various values of the stickiness parameter : (a) the first (end) sphere; (b) the second (center) sphere. For comparison, the dashed curves are plotted for the torques when only two spheres are present.

Figure 2.

Normalized torques on three coaxial, identical, equally spaced, slip spheres rotating at equal angular velocities about their axis versus the separation parameter with various values of the stickiness parameter : (a) the first (end) sphere; (b) the second (center) sphere. For comparison, the dashed curves are plotted for the torques when only two spheres are present.

Figure 3.

Normalized torques on coaxial, identical, equally spaced, slip spheres rotating at equal angular velocities about their axis versus the sphere number with : (a) ; (b) .

Figure 3.

Normalized torques on coaxial, identical, equally spaced, slip spheres rotating at equal angular velocities about their axis versus the sphere number with : (a) ; (b) .

Figure 4.

Normalized torques on nine coaxial, identical, equally spaced, slip spheres rotating at equal angular velocities about their axis versus the sphere number with and various values of the stickiness parameter .

Figure 4.

Normalized torques on nine coaxial, identical, equally spaced, slip spheres rotating at equal angular velocities about their axis versus the sphere number with and various values of the stickiness parameter .

Figure 5.

Normalized torques on nine coaxial, identical, equally spaced, no-slip spheres (, solid curves) and slip spheres (with , dashed curves) rotating at equal angular velocities about their axis versus the sphere number with various values of the separation parameter .

Figure 5.

Normalized torques on nine coaxial, identical, equally spaced, no-slip spheres (, solid curves) and slip spheres (with , dashed curves) rotating at equal angular velocities about their axis versus the sphere number with various values of the separation parameter .

Table 1.

The torque correction parameters , , , and for the axisymmetric rotation of two identical spheres (, ). The asymptotic solution is calculated from Eqs. (13)-(19) for comparison.

Table 1.

The torque correction parameters , , , and for the axisymmetric rotation of two identical spheres (, ). The asymptotic solution is calculated from Eqs. (13)-(19) for comparison.

|

|

Collocation solution |

Asymptotic solution |

|

|

|

|

| 1 |

0.2 |

1.00000 |

-0.00033 |

1.00000 |

-0.00025 |

| 0.3 |

1.00000 |

-0.00123 |

1.00000 |

-0.00084 |

| 0.4 |

1.00001 |

-0.00322 |

1.00000 |

-0.00200 |

| 0.5 |

1.00006 |

-0.00691 |

1.00002 |

-0.00391 |

| 0.6 |

1.00023 |

-0.01306 |

1.00005 |

-0.00675 |

| 0.7 |

1.00079 |

-0.02260 |

1.00011 |

-0.01072 |

| 0.8 |

1.00247 |

-0.03676 |

1.00026 |

-0.01600 |

| 0.9 |

1.00738 |

-0.05761 |

1.00052 |

-0.02278 |

| 0.99 |

1.02224 |

-0.08900 |

1.00092 |

-0.06064 |

| 1.0 |

1.02693 |

-0.09567 |

1.00098 |

-0.06250 |

| 10 |

0.2 |

1.00000 |

-0.00079 |

1.00000 |

-0.00077 |

| 0.3 |

1.00001 |

-0.00271 |

1.00001 |

-0.00260 |

| 0.4 |

1.00005 |

-0.00653 |

1.00004 |

-0.00615 |

| 0.5 |

1.00020 |

-0.01295 |

1.00014 |

-0.01202 |

| 0.6 |

1.00068 |

-0.02273 |

1.00043 |

-0.02077 |

| 0.7 |

1.00199 |

-0.03674 |

1.00109 |

-0.03298 |

| 0.8 |

1.00529 |

-0.05612 |

1.00242 |

-0.04923 |

| 0.9 |

1.01351 |

-0.08313 |

1.00491 |

-0.07010 |

| 0.99 |

1.03508 |

-0.12286 |

1.00870 |

-0.01971 |

| 1.0 |

1.04120 |

-0.13103 |

1.00925 |

-0.02031 |

| ∞ |

0.2 |

1.00000 |

-0.00100 |

1.00000 |

-0.00100 |

| 0.3 |

1.00001 |

-0.00338 |

1.00001 |

-0.00338 |

| 0.4 |

1.00007 |

-0.00800 |

1.00007 |

-0.00800 |

| 0.5 |

1.00030 |

-0.01563 |

1.00030 |

-0.01563 |

| 0.6 |

1.00097 |

-0.02704 |

1.00096 |

-0.02703 |

| 0.7 |

1.00273 |

-0.04306 |

1.00268 |

-0.04301 |

| 0.8 |

1.00702 |

-0.06485 |

1.00669 |

-0.06451 |

| 0.9 |

1.01727 |

-0.09494 |

1.01539 |

-0.09280 |

| 0.99 |

1.04336 |

-0.13974 |

1.03082 |

-0.12569 |

| 1.0 |

1.05097 |

-0.14943 |

1.03320 |

-0.12988 |

Table 2.

The torque correction parameters , , , and for the axisymmetric rotation of two no-slip spheres (). The values in parentheses are the asymptotic solution calculated from Eqs. (13)-(19) for comparison.

Table 2.

The torque correction parameters , , , and for the axisymmetric rotation of two no-slip spheres (). The values in parentheses are the asymptotic solution calculated from Eqs. (13)-(19) for comparison.

|

|

g11

|

g12

|

g21

|

g22

|

| 2 |

0.5 |

1.00024 |

-0.00463 |

-0.03705 |

1.00019 |

| (1.00024) |

(-0.00463) |

(-0.03705) |

(1.00019) |

| 0.6 |

1.00086 |

-0.00801 |

-0.06406 |

1.00058 |

| (1.00084) |

(-0.00801) |

(-0.06406) |

(1.00058) |

| 0.7 |

1.00271 |

-0.01275 |

-0.10197 |

1.00153 |

| (1.00250) |

(-0.01273) |

(-0.10187) |

(1.00152) |

| 0.8 |

1.00795 |

-0.01917 |

-0.15335 |

1.00363 |

| (1.00673) |

(-0.01908) |

(-0.15262) |

(1.00358) |

| 0.9 |

1.02335 |

-0.02800 |

-0.22396 |

1.00809 |

| (1.01667) |

(-0.02737) |

(-0.21897) |

(1.00769) |

| 0.99 |

1.06197 |

-0.04126 |

-0.33012 |

1.01787 |

| (1.03560) |

(-0.03691) |

(-0.29532) |

(1.01444) |

| 1.0 |

1.09395 |

-0.04449 |

-0.35606 |

1.02075 |

| (1.03861) |

(-0.03812) |

(-0.30497) |

(1.01544) |

| 5 |

0.5 |

1.00007 |

-0.00058 |

-0.07234 |

1.00004 |

| (1.00007) |

(-0.00058) |

(-0.07234) |

(1.00004) |

| 0.6 |

1.00030 |

-0.00100 |

-0.12504 |

1.00013 |

| (1.00027) |

(-0.00100) |

(-0.12503) |

(1.00013) |

| 0.7 |

1.00110 |

-0.00159 |

-0.19873 |

1.00033 |

| (1.00086) |

(-0.00159) |

(-0.19862) |

(1.00033) |

| 0.8 |

1.00412 |

-0.00238 |

-0.29764 |

1.00074 |

| (1.00247) |

(-0.00237) |

(-0.29679) |

(1.00074) |

| 0.9 |

1.01743 |

-0.00344 |

-0.43050 |

1.00156 |

| (1.00653) |

(-0.00339) |

(-0.42353) |

(1.00152) |

| 0.99 |

1.09830 |

-0.00508 |

-0.63487 |

1.00318 |

| (1.01468) |

(-0.00453) |

(-0.56594) |

(1.00274) |

| 1.0 |

1.14324 |

-0.00556 |

-0.69390 |

1.00368 |

| (1.01601) |

(-0.00467) |

(-0.58361) |

(1.00291) |

Table 3.

The torque correction parameters , , , and for the axisymmetric rotation of two spheres differing in size or slippage.

Table 3.

The torque correction parameters , , , and for the axisymmetric rotation of two spheres differing in size or slippage.

|

|

|

|

|

|

, ,

|

| 0.2 |

1.00000 |

-0.00033 |

-0.00100 |

1.00000 |

| 0.3 |

1.00000 |

-0.00123 |

-0.00338 |

1.00000 |

| 0.4 |

1.00003 |

-0.00322 |

-0.00800 |

1.00003 |

| 0.5 |

1.00014 |

-0.00691 |

-0.01563 |

1.00013 |

| 0.6 |

1.00049 |

-0.01307 |

-0.02702 |

1.00046 |

| 0.7 |

1.00155 |

-0.02263 |

-0.04298 |

1.00140 |

| 0.8 |

1.00449 |

-0.03688 |

-0.06453 |

1.00387 |

| 0.9 |

1.01258 |

-0.05814 |

-0.09382 |

1.01021 |

| 0.99 |

1.03642 |

-0.09147 |

-0.13622 |

1.02710 |

| 1.0 |

1.04514 |

-0.09962 |

-0.14624 |

1.03280 |

|

, ,

|

| 0.2 |

1.00000 |

-0.00016 |

-0.00169 |

1.00000 |

| 0.3 |

1.00000 |

-0.00055 |

-0.00588 |

1.00000 |

| 0.4 |

1.00002 |

-0.00134 |

-0.01438 |

1.00002 |

| 0.5 |

1.00011 |

-0.00271 |

-0.02901 |

1.00009 |

| 0.6 |

1.00042 |

-0.00482 |

-0.05184 |

1.00028 |

| 0.7 |

1.00143 |

-0.00788 |

-0.08532 |

1.00079 |

| 0.8 |

1.00459 |

-0.01216 |

-0.13272 |

1.00201 |

| 0.9 |

1.01496 |

-0.01813 |

-0.20015 |

1.00479 |

| 0.99 |

1.05306 |

-0.02690 |

-0.30147 |

1.01124 |

| 1.0 |

1.06789 |

-0.02888 |

-0.32475 |

1.01311 |

Table 4.

The torque correction parameters for the axisymmetric rotation of three identical slip spheres ( and ) with equal spacings ().

Table 4.

The torque correction parameters for the axisymmetric rotation of three identical slip spheres ( and ) with equal spacings ().

|

|

|

|

|

|

| 1 |

0.2 |

1.00000 |

1.00000 |

-0.00033 |

-0.00004 |

| 0.3 |

1.00000 |

1.00000 |

-0.00123 |

-0.00013 |

| 0.4 |

1.00002 |

1.00001 |

-0.00322 |

-0.00032 |

| 0.5 |

1.00012 |

1.00006 |

-0.00691 |

-0.00063 |

| 0.6 |

1.00046 |

1.00023 |

-0.01305 |

-0.00110 |

| 0.7 |

1.00158 |

1.00080 |

-0.02256 |

-0.00171 |

| 0.8 |

1.00493 |

1.00247 |

-0.03666 |

-0.00244 |

| 0.9 |

1.01473 |

1.00739 |

-0.05740 |

-0.00322 |

| 0.99 |

1.04441 |

1.02225 |

-0.08866 |

-0.00392 |

| 1.0 |

1.05330 |

1.02724 |

-0.09501 |

-0.00399 |

| 10 |

0.2 |

1.00000 |

1.00000 |

-0.00079 |

-0.00010 |

| 0.3 |

1.00002 |

1.00001 |

-0.00271 |

-0.00032 |

| 0.4 |

1.00010 |

1.00005 |

-0.00652 |

-0.00075 |

| 0.5 |

1.00040 |

1.00020 |

-0.01293 |

-0.00142 |

| 0.6 |

1.00136 |

1.00069 |

-0.02267 |

-0.00232 |

| 0.7 |

1.00396 |

1.00200 |

-0.03660 |

-0.00341 |

| 0.8 |

1.01054 |

1.00531 |

-0.05582 |

-0.00461 |

| 0.9 |

1.02693 |

1.01355 |

-0.08259 |

-0.00586 |

| 0.99 |

1.06996 |

1.03511 |

-0.12204 |

-0.00695 |

| 1.0 |

1.08354 |

1.04192 |

-0.13082 |

-0.00707 |

| ∞ |

0.2 |

1.00000 |

1.00000 |

-0.00100 |

-0.00012 |

| 0.3 |

1.00002 |

1.00001 |

-0.00337 |

-0.00041 |

| 0.4 |

1.00014 |

1.00007 |

-0.00799 |

-0.00094 |

| 0.5 |

1.00059 |

1.00030 |

-0.01560 |

-0.00175 |

| 0.6 |

1.00193 |

1.00098 |

-0.02695 |

-0.00282 |

| 0.7 |

1.00545 |

1.00275 |

-0.04286 |

-0.00409 |

| 0.8 |

1.01397 |

1.00705 |

-0.06445 |

-0.00546 |

| 0.9 |

1.03439 |

1.01732 |

-0.09423 |

-0.00687 |

| 0.99 |

1.08644 |

1.04341 |

-0.13864 |

-0.00812 |

| 1.0 |

1.10321 |

1.05182 |

-0.14909 |

-0.00826 |

Table 5.

The torque correction parameters for the axisymmetric rotation of three no-slip spheres () with and .

Table 5.

The torque correction parameters for the axisymmetric rotation of three no-slip spheres () with and .

|

|

|

|

|

|

|

| 1:2:1 |

0.2 |

1.00000 |

1.00000 |

-0.00030 |

-0.00237 |

-0.00004 |

| 0.3 |

1.00002 |

1.00001 |

-0.00100 |

-0.00800 |

-0.00012 |

| 0.4 |

1.00009 |

1.00006 |

-0.00237 |

-0.01896 |

-0.00026 |

| 0.5 |

1.00037 |

1.00024 |

-0.00463 |

-0.03703 |

-0.00045 |

| 0.6 |

1.00116 |

1.00087 |

-0.00800 |

-0.06402 |

-0.00067 |

| 0.7 |

1.00306 |

1.00271 |

-0.01273 |

-0.10188 |

-0.00088 |

| 0.8 |

1.00726 |

1.00795 |

-0.01915 |

-0.15320 |

-0.00103 |

| 0.9 |

1.01616 |

1.02335 |

-0.02797 |

-0.22373 |

-0.00110 |

| 0.99 |

1.03572 |

1.07433 |

-0.04123 |

-0.32982 |

-0.00110 |

| 0.999 |

1.04058 |

1.09059 |

-0.04397 |

-0.35177 |

-0.00110 |

| 1.0 |

1.04136 |

1.09376 |

-0.04445 |

-0.35557 |

-0.00110 |

| 2:1:2 |

0.2 |

1.00000 |

1.00000 |

-0.00237 |

-0.00030 |

-0.00030 |

| 0.3 |

1.00002 |

1.00001 |

-0.00799 |

-0.00100 |

-0.00099 |

| 0.4 |

1.00011 |

1.00005 |

-0.01892 |

-0.00236 |

-0.00233 |

| 0.5 |

1.00049 |

1.00021 |

-0.03685 |

-0.00461 |

-0.00447 |

| 0.6 |

1.00172 |

1.00064 |

-0.06346 |

-0.00793 |

-0.00756 |

| 0.7 |

1.00536 |

1.00169 |

-0.10038 |

-0.01255 |

-0.01165 |

| 0.8 |

1.01568 |

1.00396 |

-0.14971 |

-0.01871 |

-0.01681 |

| 0.9 |

1.04600 |

1.00872 |

-0.21645 |

-0.02706 |

-0.02308 |

| 0.99 |

1.14694 |

1.01894 |

-0.31689 |

-0.03961 |

-0.02980 |

| 0.999 |

1.17932 |

1.02142 |

-0.33813 |

-0.04227 |

-0.03054 |

| 1.0 |

1.18582 |

1.02188 |

-0.34194 |

-0.04274 |

-0.03062 |

Table 6.

The torque correction parameters for the axisymmetric rotation of three slip spheres with , , , and .

Table 6.

The torque correction parameters for the axisymmetric rotation of three slip spheres with , , , and .

|

|

|

|

|

|

|

| 1:2:1 |

0.2 |

1.00000 |

1.00000 |

-0.00006 |

-0.00083 |

-0.00001 |

| 0.3 |

1.00000 |

1.00000 |

-0.00023 |

-0.00322 |

-0.00002 |

| 0.4 |

1.00001 |

1.00001 |

-0.00061 |

-0.00865 |

-0.00006 |

| 0.5 |

1.00006 |

1.00004 |

-0.00133 |

-0.01896 |

-0.00011 |

| 0.6 |

1.00021 |

1.00017 |

-0.00254 |

-0.03657 |

-0.00017 |

| 0.7 |

1.00069 |

1.00067 |

-0.00442 |

-0.06463 |

-0.00024 |

| 0.8 |

1.00202 |

1.00254 |

-0.00720 |

-0.10748 |

-0.00030 |

| 0.9 |

1.00549 |

1.00977 |

-0.01125 |

-0.17256 |

-0.00033 |

| 0.99 |

1.01456 |

1.04047 |

-0.01731 |

-0.27461 |

-0.00030 |

| 0.999 |

1.01694 |

1.05118 |

-0.01849 |

-0.29502 |

-0.00030 |

| 1.0 |

1.01726 |

1.05328 |

-0.01864 |

-0.29841 |

-0.00030 |

| 2:1:2 |

0.2 |

1.00000 |

1.00000 |

-0.00114 |

-0.00009 |

-0.00013 |

| 0.3 |

1.00000 |

1.00000 |

-0.00417 |

-0.00033 |

-0.00046 |

| 0.4 |

1.00002 |

1.00001 |

-0.01070 |

-0.00083 |

-0.00113 |

| 0.5 |

1.00011 |

1.00005 |

-0.02252 |

-0.00174 |

-0.00228 |

| 0.6 |

1.00047 |

1.00017 |

-0.04185 |

-0.00320 |

-0.00406 |

| 0.7 |

1.00175 |

1.00052 |

-0.07142 |

-0.00541 |

-0.00658 |

| 0.8 |

1.00619 |

1.00141 |

-0.11479 |

-0.00855 |

-0.00995 |

| 0.9 |

1.02229 |

1.00358 |

-0.17814 |

-0.01300 |

-0.01428 |

| 0.99 |

1.08748 |

1.00878 |

-0.27514 |

-0.01954 |

-0.01910 |

| 0.999 |

1.10984 |

1.01016 |

-0.29470 |

-0.02083 |

-0.01964 |

| 1.0 |

1.11423 |

1.01033 |

-0.29798 |

-0.02096 |

-0.01970 |