2. Selected literature

According to studies, there are three ways to mitigate supply chain interruption throughout the COVID-19 pandemic using global supply chain ideas prior to the outbreak. The JIT (just-in-time) supply chain comes first. Second, reducing supply chain risk The third factor is supply chain visibility (Busse et al., 2017, pp. 18–40; Jiang, 2022, pp. 141–184; Choi et al., 2023, pp. 1–10)

2.1. Just-in-time (JIT) manufacturing

Recently, business managers and research experts now prefer just-in-case (JTC) manufacturing over the Japanese-invented JIT, which asserts that supplier diversification is essential for cost reduction and price competitiveness (Brakman, 2023, pp. 1–39; Jiang et al., 2022, pp. 141–184). JTC is favored over JIT because JIT relies too heavily on suppliers, who might not have the same resilience and flexibility as procurement organizations (Jiang et al., 2022, p. 142). The caution that was urged became clear as the COVID-19 epidemic affected the world's supply chain network. It is clear that JIT is still feasible for supply chains in unstable periods, despite the fact that many theoretical and empirical studies misunderstood the JIT failure during the pandemic (Choi et al., 2023, pp. 1–10). These false beliefs regarding JIT's impossibility during stressful times, like the epidemic, is refuted by a JIT study conducted by Choi et al. (2023, pp. 1–10). Choi et al. (2023) posed the following queries: Is JIT only practical during times of stability? Is JIT adaptable enough to handle challenging circumstances? The study concluded that JIT implementation is not binary. In order to cushion its manufacturing facilities and those of its tier-1 suppliers from daily supply chain turbulence, Toyota—the pioneer of JIT, for example—used traditional JIT practices to stockpile component materials upstream and finished cars downstream (Choi et al., 2023, p. 6). In order to implement JIT, one must consider other technical aspects. In order to do this, demand and supply must be matched in an uncertain environment, creating a creative supply chain architecture built on swift action aspects (Gligor, 2017, pp. 253-265; Prajogo et al., 2018, pp. 168–180). Furthermore, in the post-pandemic stable supply chain context, Choi et al. (2023) emphasize that an ideal JIT strategy would place a greater emphasis on cost efficiency than responsiveness. Contrarily, the JIT system story has been altered by two factors: the instability of the supply chain and the close proximity of buyers and providers. Two problems are to blame for the supply disruption. First, the epidemic brought about subtle differences in demand. This was as a result of the shift in work-life style—the work-from-home that emerged—which spiked online purchases. In addition, there are the repressed consumers with great savings and economic stimulus from the government. This caused a rush of demand for products that made the unavailability of consumers desired goods Which spiked the lead time of supply chains. (Choi et al., 2023, p. 6) Second, the competition across industries over component parts, labor, and shipping containers is another reason for the shortage of goods during the 2020–2021 period. The buyer-supplier distance is problematic. As noted, in the implementation of traditional JIT, there is the assumption that buyers and suppliers share proximity in location, which shortens transportation time.

Subsequently, it is assumed in the traditional JIT implementation that personnel from various corporate sites work together to solve problems (Choi et al., 2023, p. 6). By implication, this leads to rigid relationship building and a lack of interpersonal interactions among employees. As a result, there is a delay in identifying and correcting problems in the supply chain system due to the rigid construction of connections and the absence of human relationships. Above all, four methods—buffers, JIT segments, visibility, and buyer-seller collaboration—are suggested in order to adapt JIT into robust supply chains (Choi et al., 2023, pp. 6–8). First, buffers need a business to go beyond inventory control. Instead, a company's capacity and capability are included in the buffer. This can be accomplished by using inventory at the subsequent stage of the supply chain, which entails providing finished products and services to end users (Sodhi and Tang, 2021, pp. 74–78). Companies can then employ this production capacity to stock finished goods made from raw resources, which releases products for the next supply chain stage (Choi et al., 2023, p. 7). In order to produce their products domestically or through suppliers who are closer to their target markets, businesses employ their capabilities to do so. Sodhi and Choi (2022) suggest that these buffers can be placed at the edges of supplier segments with a JIT orientation and a push-pull inventory strategy. Second, the JIT segments consider the least amount of demand fluctuation, the manufacturing cycle time that is consistent across the segment's nodes, and the nearness of these nodes, which would consider the short transit times and possible close collaboration made at various levels of the organizations in connections (Sodhi and Choi, 2022). Consequently, a single plant could be present in some of the segments; others might include vendors spread out over multiple tiers. The study claims that utilizing a single buffer to provide support for several JIT segments that are vulnerable to upstream risks improves cost effectiveness (Choi et al., 2023, pp. 7-8). Third, real-time activity visibility for significant upstream suppliers is crucial. Digital technologies like supply chain software, block chains, and artificial intelligence are used to benefit the JIT supply chain in order to achieve this (Holmstrom et al., 2019, pp. 728–734; Sodhi et al., 2022). Due to the long lead time, this is also accomplished by forecasting each JIT segment. JIT's digitalization also makes it possible for the concept to survive in a challenging supply chain environment. Which provides JIT operations with the toolkit to prepare for uncertainties and respond via visibility and collaboration (Wagner and Postel, 2022, pp. 32–37; Hastig and Sodhi, 2020, pp. 935–954). Finally, there are relationships between buyers and sellers across the supply chain (Choi et al., 2023, pp. 7-8). According to the study's hypothesis, the relationships between adversarial-collaborative and trustworthy-untrustworthy matrices give researchers the chance to identify supply chain segments that are vulnerable to adversarial relationships and to design the necessary buffers that would protect the identified adversarial relationships by fostering collaborative relationships between an organization and its vendor partners (Choi et al., 2023, pp. 7-8; Caniels and Gelderman, 2007, pp. 21). Before a chaotic time like the COVID-19 epidemic, Choi et al. (2023, p. 1) offer an investigation of JIT that was conducted regarding the context of disruptions and the associated criticisms against JIT. Revisiting JIT principles in the context of the tumultuous global supply chain was how the study's authors began this endeavor (Choi et al., 2023, p. 1). However, because there is currently little practical evidence to demonstrate the applicability and viability of the JIT principles in a volatile global supply chain, the generality of the JIT concepts in the study is arguable.

2.2. Supply chain risk mitigation

Even more important, is the supply chain risk mitigation. The supply chain mitigation takes into practical account of how some JIT issues disclosed by Choi et al (2023) were handled positively by some companies during the COVID-19 pandemic. The pandemic lockdown caused a significant drop in sales orders, according to a study on supply chain mitigation techniques during COVID-19 in India's make-to-order handloom saree garment sectors. Because of a decline in sales and a decline in consumer purchasing power, the flow of funds within the industry dwindled. The study took into account the following risk variables: Natural disasters are risk number 1. (Heckman et al., 2015, pp. 119–132; Majundar et al., 2020; Vishnu et al., 2019, pp. 548–578) These are natural calamities such as floods and earthquakes. Transport failure is the second risk (Chowbury et al., 2019; Majundar et al., 2020). Employee churn and unavailability are risks number three (Chowbury et al., 2019, pp. 102-113; Handfield et al., 2020, pages 803–821). A pandemic-related industry disruption is risk number four. Failure to share information is risk number five. Financial risk is risk 6. Infrastructure risk is risk number 7. Resource scarcity is risk number eight. The lack of synchronization and alignment is risk number nine. Demand vulnerability is risk number 10. Market nuance is risk number 11. Consequently, seven (7) methods for mitigating risk can be used by businesses affected by pandemics to reduce their exposure to this risk (Dohale et al., 2020). The visibility of the supply chain is improved by Strategy 1, that Indian garment makers have embraced. As a result, supply chain authorities are more likely to have faith in the sector, according to Bonanni and Batemen (2019, pp. 2–8; Kilubi, 2016, pp. 604-629). The second strategy, flexibility, enabled the Indian clothing manufacturers to deploy organizational resources to respond to inescapable market shifts and unanticipated demand swings from consumers. Due to this, the personal protection equipment—PPE—and garment sectors have to change their focus (Kochan and Nowicki, 2018, pp. 842–865; Dubey et al., 2019; Nakano and Lau, 2020, pp. 433–473; Srinivasan and Swink, 2018, pages 1849–1867). Due to a decline in demand, Strategy 3, a delayed strategy, hindered the manufacture of clothing. These subsequently assist Indian businesses in mass producing protective masks and PPE kits to satisfy global demand. Until companies can obtain accurate order information, the best course of action is to bring down production, making purchases, packaging, and distribution (Carbonara and Pellegrino, 2018, pp. 5249–5271; Hult and Craighead, 2010, pp. 435–458; Yang et al., 2004, pp. 468–487; Yang and Yang, 2010, pp. 1901–1912; Dasgupta and Joshi, 2020). Utilizing extra stock and unused capacity as a backup strategy is used by a few firms as a strategy 5 to efficiently manufacture safety masks and personal protective equipment (Dohale, 2020; Nakano and Lau, 2020, pp. 433–473). With strategy 4, they source raw materials from various suppliers both near and far from their facility.

In order to avoid the disruptive losses caused by the pandemic, the Indian garment sector has implemented Strategy 6 of partnership research, working with academics and consultants (Fan and Stevenson, 2018; Nakano and Lau, 2020, pp. 433–473). The creation of a team made up of all departmental managers in these businesses is accomplished using strategy 7, joint planning, and coordination. With the help of this team, various strategies are discussed, identified, and planned to reduce the disruptive effects of risks associated with the supply chain (Kilubi, 2016, pp. 604-629; Nakano and Lau, 2020, pp. 433–472). The results of the study's risk reduction technique were derived from several case studies. Four companies—make-to-order handloom companies (Dohale, 2020)—were the subjects of the case studies. An Indian company called Case A was founded in 1981 and is renowned for its premium goods. In the US, UK, France, Germany, Italy, China, UAE, Australia, Brazil, Singapore, and other countries, the company is present on a global scale. The business has survived a transportation disaster, a pandemic, information sharing, financial risk, resource shortages, demand uncertainty, and market upheaval. To reduce its risks, the organization implemented supply chain risk mitigation tactics such as visibility and transparency, deferral, and collaboration. Second Situation B is an Indian business that was founded in 1988 and exports silk and cotton sarees to over 27 nations. It had to deal with catastrophic events, transportation problems, employee shortages, pandemics, information sharing, resource shortages, poor coordination, unpredictable sales, and market shifts. The organization employed a combination of supply chain visibility, adaptability, postponement, and collaboration to reduce these risks. A clothing company from India is the third instance. The US, UK, Germany, Pakistan, Spain, and other countries all have a firm presence there. Transportation failure, staff insufficient supply, pandemic, financial risk, infrastructural risk, resource scarcity, insufficient coordination, demand fragility, and market shift were supply chain issues that the corporation had to deal with. Visibility and transparency, adaptability, delay, redundancy, and collaboration helped reduce the risks associated with the supply chain. The fourth instance, D, is a business that was founded in 1982 and has operations in over twenty different nations. Transport mishaps, pandemics, resource scarcity, demand vulnerability, and market intricacies are all hazards to a company's supply chain. The organization manages these risks associated with the supply chain through collaboration, flexibility, postponement, visibility, and transparency. The literature was used to gather information about supply chain hazards and risk mitigation techniques. For example, 20 experts from the companies chosen for the case studies also verified their supply chains as well as risk mitigation measures. The study did, however, admit significant shortcomings. First of all, the study's findings are subject to the personal prejudices of the experts who were enlisted to participate in it (Dohale, 2020). The risk abatement variables and the detected risk factor do not, as in typical case studies, have a known cause-and-effect relationship. The study's findings and conclusions cannot be extended due to the study's relatively small sample size of only four case studies (Queiros et al., 2017, p. 378).

2.3. Supply Chain Visibility (SCV)

According to Somapa et al. (2018), SCV refers to how much access relevant stakeholders within a supply chain have to correct and timely information. On operational capabilities, SCV focuses on process visibility (Lee and Rim, 2016, p. 11). Three key aspects of SCV are pertinent to the supply chain. The first are the auto-national traits. The second category is informational traits. The third category is transformational traits (Somapa et al. 2018, pp. 313–329). The independent nature of SCVs makes it possible to collect and distribute communication across the supply chain using information technology. This calls for the capacity to collect and transmit useful data using ICT tools and techniques (Papert et al., 2016, pp. 859–884). A local business and its suppliers can share information thanks to ICT (Somapa et al., 2018, p. 320). SCV adopts and makes use of automated data collection. According to Somapa et al. (2018), automated information capture is the process of collecting data using machine-readable automatic identification and data capture (AIDC) technologies such as bar codes, matrix codes, non-contact magnetic devices, and radio frequency identification systems (RFID). Production planning, shipment, storage, and movement by freight forwarders, inspection and clearance, and inland transit to end consumers all fall under the scope of automated information capture. Since information is integrated and transferred automatically, the supply chain can receive quick and useful feedback as a result (Somapa et al., 2018, p. 321). Due to the fact that both notions can function independently, auto-national characteristics also emphasize the difference between information sharing and SCV (Kim et al., 2011, pp. 667–676). SCV does not take the negative aspects of information technology into account as an information quality concept. It does, however, emphasize the soft aspect of managerial ability, which is crucial for preserving information flow through the correct routes (Somapa et al., p. 323). As a result, the supply chain's strategic goals are more fully realized, and the information is complete to meet the users' specific needs (Somapa et al., p. 323). Individuals can more effectively comprehend how their transformational qualities connect to their business activities by using the operational efficiency that the transformative characteristics of SCV provide (Barratt and Barratt, 2011, pp. The qualities of strategic competency in SCV improve information flow between downstream and upstream SCs.

Consequently, SC members are encouraged to trust one another's knowledge (Narasimhan et al., 2006, p. 23). Actionable information sharing across channels is necessary for multinational corporations to scale through SC disruptions in order to improve supply chain efficiency (Nyaga et al., 2010; Mishra et al., 2018; Routroy et al., 2018). According to empirical research on SCV, sharing information across SC has a good and significant impact on the performance of the supply chain, collaboration, and visibility (Baah et al., 2020, pp. 434–455). A study on the administrative perspectives and objectives of SCV found that data quantity, information sharing, backing from upper management, confidence in inter-organizational collaboration, harmonized SC data, and standardized unified systems of information are the factors that make SCV possible (Agrawal et al., 2022, p. 7; Wei and Wang, 2010, pp. 238–249). These empirical studies do, however, have some drawbacks. Instead of the overall industry, the studies concentrate on a specific area of a given industry. p. 292 in Baah et al., 2020. the lack of research on the long-term effects of SCV on productivity (Wei and Wang, 2010, pp. 238–249).

2.4. Proposed conceptual framework

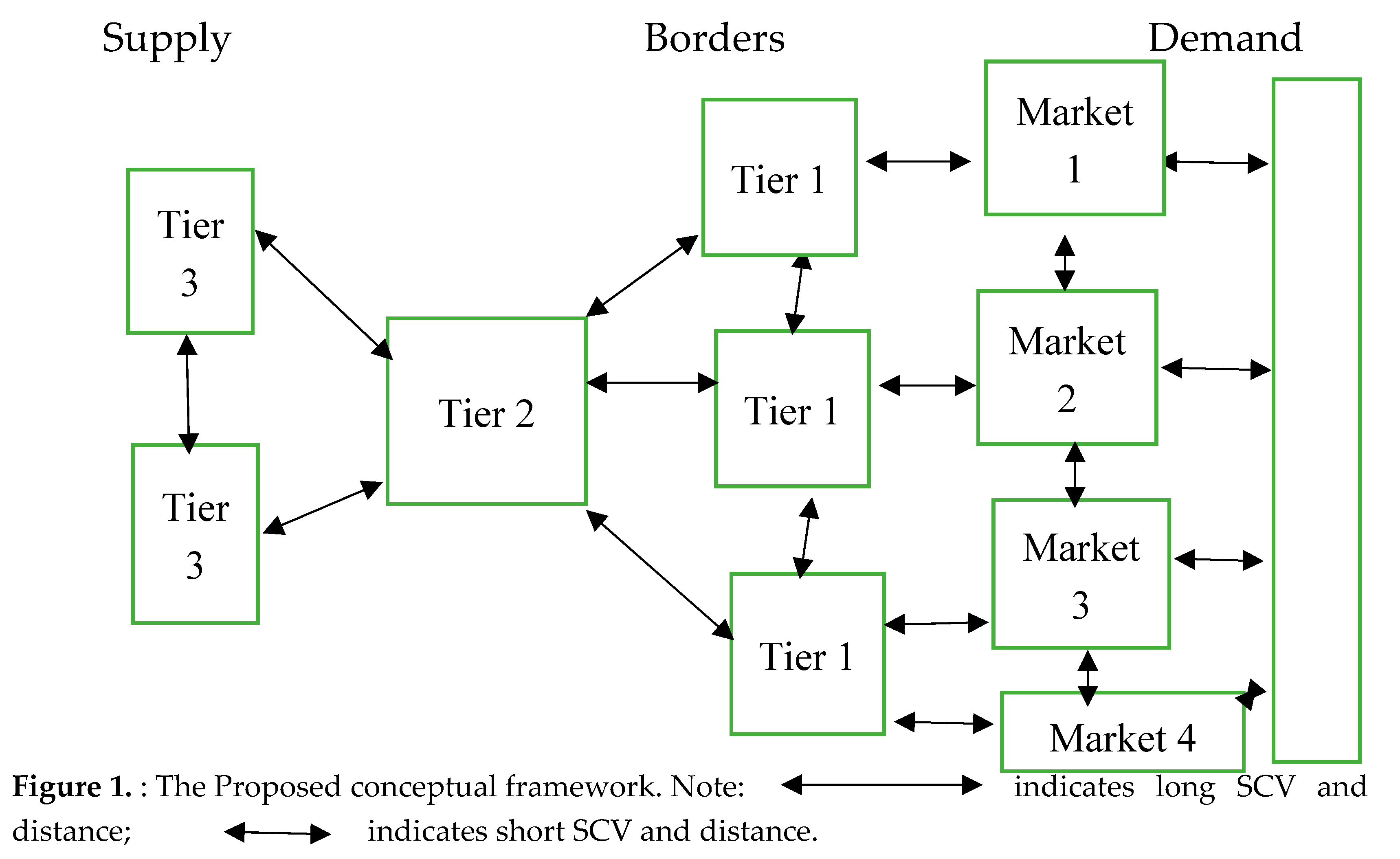

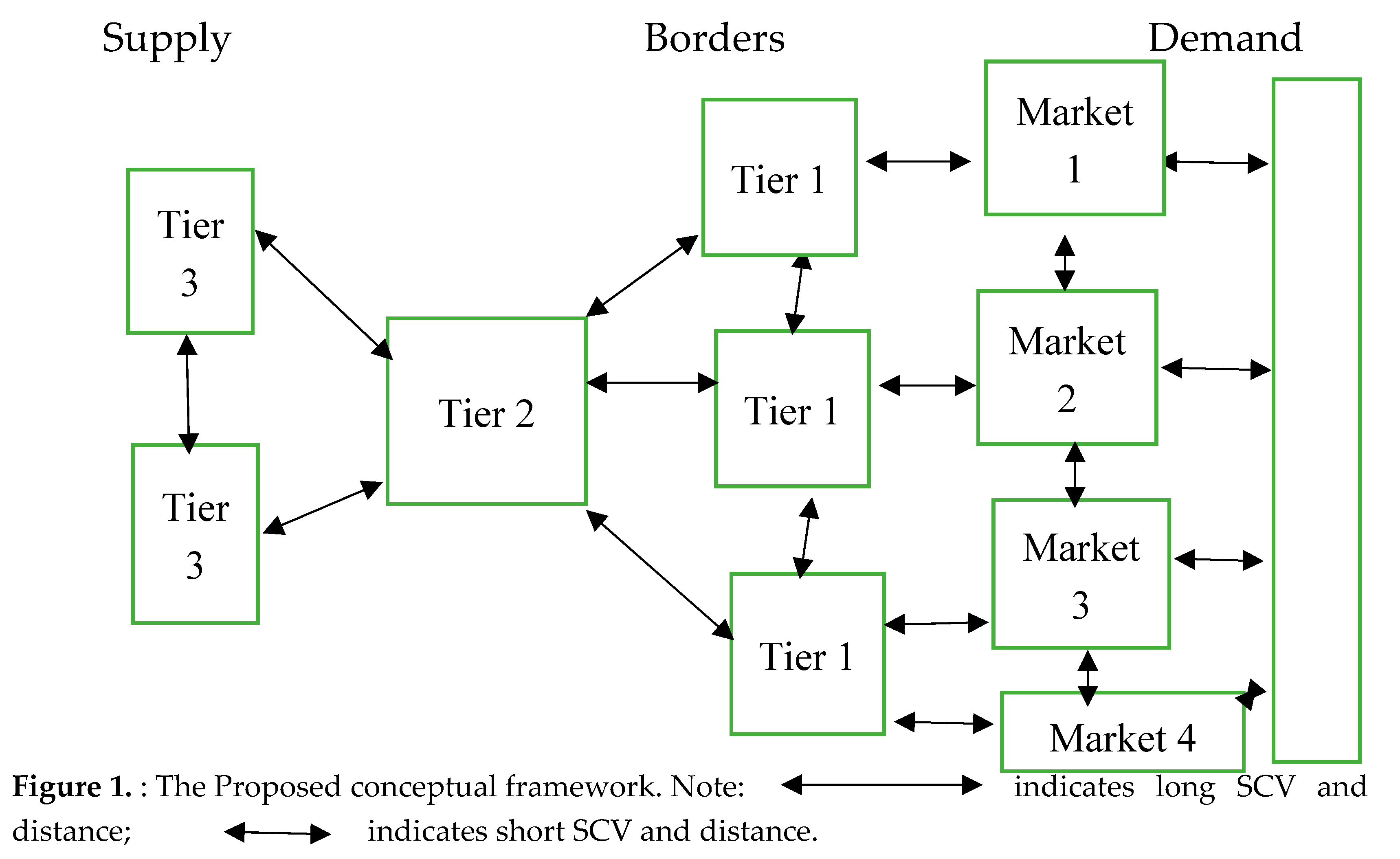

Is there a viable post-COVID-19 GSCM, as suggested in this article? Can GSCs similar to those encountered during the pandemic be prevented by using these GSCM concepts? Reiterating this point, several theoretical as well as empirical studies have misinterpreted the reason why JIT failed during the epidemic because it is believed that JIT is dependent on the management of inventory and cost-efficiency rather than its flexibility to react to shifting supply chain environments. This article's concatenation of studies on JIT, the supply-chain risk mitigation method, and SCV shows that those mentioned strategies are definitely resilient to turbulence. These supply chain management approaches can also be used as a failsafe against future instability. An illustrated conceptual framework provides examples of these conclusions.

It is conceivable to develop a sustainable and resilient GSCM, according to the conceptual framework for sustainable GSCM that has been proposed by the chosen authors of the literature studied in this research. The JIT approach is used first. Figure 1 demonstrates that in order for a company to be sustainable, geographical gaps with suppliers must be closed by aligning with numerous Tier 1 suppliers who are located on the periphery of its targeted markets (Choi et al., 2023). This aids a business in obtaining the appropriate labor from the same defined marketplaces as needed. Additionally, JIT enables the business to, if necessary, employ these Tier 1 items as buffers for unused material availability to generate the capability to quickly invent new products to meet demand. GM's manufacturing of oxygen tanks during the COVID-19 epidemic can be noticed in response to the scarcity in demand. The mass production of nose masks, which were in high demand during the course of the pandemic turmoil, was also carried out by an Indian clothing company using this unique capacity utilization. The openness and openness between all SC channels, from tier 3 to tier 1, help to reduce the hazards related to pre- and post-pandemic SC turbulence (Jiang, 2022, pp. 141–184). Having access to raw materials from multiple sources reduces reliance on one provider. In order to do this, it is necessary to have a number of tier 1 suppliers with stock capacity at the tier 1 level (upstream) as well as a number of tier 1 suppliers with the ability to collaborate with different tier 1 collaborators on data and resource swaps (Choi et al., 2023). The long nodes represent the communication networks that SCV has improved in order to share beneficial knowledge regarding developments in the various targeted marketplaces that would keep strategic partner suppliers informed about market trends and the direction of supply actions. The short loop around the SC network shows tight proximity and communication loops, indicating a close working relationship involving a company and its suppliers.

Furthermore, the SCV is made feasible by cross-departmental cooperation in planning and communication that recognizes and examines trends in consumer demand in the marketplace. Overall, the analysis of the literature has demonstrated that the key to having a supply chain that is failsafe against turbulence is being sensitive to the subtle variations in demand in the market where a company competes. However, there are two flaws on the suggested conceptual framework. The framework does not, first and foremost, apply to or reflect the entire industry. Global manufacturing enterprises can use the framework. Second, the suggested framework does not include any mathematical methods for estimating the lengths of the loops.