1. Introduction

Oilfield wastewater mainly comes from oilfield extraction water, drilling fluid waste fluid, refinery wastewater, etc. After mixing, its composition is very complex, and the main characteristic is that the wastewater contains a large number of oil droplets of different sizes and suspended matter [

1,

2,

3,

4]. Chemical flocculation treatment method can make the oil droplets and suspended matter in the wastewater quickly settle and flocculate, which is one of the main treatment methods for oilfield wastewater [

5,

6]. The organic polymer flocculant cationic polyacrylamide (CPAM) has the characteristics of low additive amount, good turbidity removal and water purification effect, high COD removal efficiency, and has become the most commonly used polymer flocculant in the oilfield wastewater treatment process [

7,

8,

9,

10,

11].

Polyacrylamide solid particles need to be prepared into diluent of a certain concentration for use, which will undergo three stages of wetting, swelling and dissolution during the dilution process [

12]: Wetting is the gradual solventization (hydration) of the surface of the polymer particles; swelling is the hydrated polymer particles surface by the osmotic pressure of the solvent, small water molecules continue to penetrate into the polymer particles, resulting in the gradual swelling of the particles; When the distance between polymer molecules within the swelling polymer particles reaches a certain value, the linear polymer molecular clusters begin to disperse, forming a solution, this process is dissolution. The dilution process of all water-soluble polymer solid particles is the same. The external fine particles will first quickly wet, swell and dissolve, forming a locally highly viscous solution, which makes a large number of solvated water molecules adhere to the outside of the polymer, preventing the internal small particles from further contact with the solvent water molecules, resulting in the external particles of the polymer has been dissolved, while the internal particles have not even come into contact with water molecules. These internal particles are "encapsulated" to make it difficult to reach the water molecules, forming a "fish eye" that is difficult to dissolve. Once the "fish eye" is formed, it will cause the waste of flocculant, or it will block the pipeline and pump head, which will affect the production of the system. In addition, due to the slow dissolution rate of solid particle flocculants, specialized devices are needed to dissolve these flocculants, and the device operates continuously for 24 hours, increasing equipment maintenance costs and energy consumption.

The solubility problem of CPAM solid particles has brought great trouble to the oilfield wastewater treatment process, restricting the improvement and innovation of the oilfield wastewater treatment process. In recent years, researchers have begun to study the preparation technology of liquid cationic polyacrylamide products [

13,

14,

15], but there are still many technical difficulties to be solved in these technologies, such as low effective content, poor storage stability, poor water purification effect, complex preparation process, high production costs, etc. Liquid CPAM products represented by "water-in-oil" emulsions and "water-in-water" emulsions have received extensive attention from many researchers due to their fast dissolution rate [

16,

17,

18,

19,

20], and the advantages and disadvantages of different products are shown in

Table 1.

Franklin[

21] prepared a polyacrylamide water-in-oil microemulsion, which has good stability and is not easy to separation. However, the viscosity of the product is relatively high. When the polymer content is 28.10%, the apparent viscosity of the microemulsion reaches more than 321 mPa·s, and the mobility is too poor to be pumped in practical applications. Liu [

22] prepared a water-in-water cationic polyacrylamide emulsion with a viscosity of 150~500 mPa·s, but the effective content was only about 15%. The preparation of this "water-in-water" emulsion requires strict monomer concentration. In the polymerization process, once the monomer concentration is too high, it is easy to form a gel rather than a stable emulsion. The "water-in-oil" emulsion prepared by Wang has stable performance [

23], no separation after 3 months at room temperature, and the dissolution time is about 10 min. However, the preparation process of "water-in-oil" emulsion is very complicated, and it needs to be synthesized under the conditions of no metal ions and no oxygen, so the production cost is high and the cost performance of the product is relatively low. In short, the preparation technology of these liquid products is still immature, and there are obvious defects, such as low effective content of the solid phase, the effective content is generally not more than 30%, which brings great inconvenience to the transportation and production; poor storage stability, long time placing will be serious degradation; low molecular weight, compared with the solid particles, not only need to greatly increase the dosage of the agent, at the same time, the flocculation and purification performance of the wastewater is also poor, it is difficult to meet the most of the application requirements.

In order to solve the problems of slow dissolution speed and easy formation of "fish-eye" in diluent, this paper researches a kind of solid particles CPAM secondary processing technology, prepares a suspension product with fast dissolution speed, high effective content, good storage stability, and no “ fish-eye ”, and evaluates its flocculation and purification performance in simulated wastewater and oilfield wastewater.

2. Materials and Methods

2.1. Materials and Instrument

Cationic polyacrylamide 4190 (CPAM 4190) was purchased from snfchina Co., Ltd., Taixing, China. 5#White Oil (5#WO) was purchased from Shenzhen Zhongruntong Chemical Co., Ltd., Shenzhen, China. Fumed Silica (F-Silica 5000 mesh) was purchased from Yangshan Yuanfeng Powder Material Co., Ltd., Qingyuan, China. Organic Bentonite (O-Bent) was purchased from CNPC Bohai Drilling Engineering Co., Ltd., Tianjin, China. Polyaluminum chloride (PAC) was purchased from Nanjing Xianglingde Environmental Protection Technology Co., Ltd., Nanjing, China.Sodium dodecyl sulfate (SDS), Sodium dodecyl benzene sulfonate (SDBS), Polysorbate 80 (Tween 80), Sorbitan Tristearate 60 (Span60), Sorbitan Tristearate 80 (Span80), hexadecyl trimethyl ammonium bromide (CTAB), Dodecyl phenol polyoxyethylene ether 10 (OP-10) were purchased from Beijing Yili Fine Chemicals Co., Ltd., Beijing, China. Fumaric acid sludge (FAS) was obtained from Karamay Zhengcheng Co., Ltd., Karamay, China. Except for CPAM 4190, 5#WO, F-Silica, and O-Bent, which were industrial grade, the other reagents were analytical grade.

Six-speed rotary viscometer ZNN-D6 and digital display high-speed mixer GJ-2S were manufactured in Qingdao Tongda Special Instrument Co., Ltd., Qingdao, China. Multi-functional high-speed blender SUS-304 was manufactured in Wuyi Hainan Electric Co., Ltd., Haikou, China. Standard Sample Sieve was manufactured in Beijing Chemical Glass Station Bioanalytical Technology Co., Ltd., Beijing, China. Desktop high-speed centrifuge was manufactured in Changsha Dongwang Experimental Instrument Co., Ltd, Changsha, China. High speed adjustable homogeneous emulsifier FSV-2 was manufactured in Changzhou Jintan Jingda Instrument Manufacturing Co., Ltd, Changzhou, China. Digital display laser turbidity meter SGZ-2 was manufactured in Shanghai Yuefeng Instrument Co., Ltd, Shanghai, China. Optical microscope CX-43 was manufactured in olympus (China) Co., Ltd, Beijing, China.

2.2. Preparation Method of CPAM Suspension

First of all, use the pulverizer to crush the industrial grade CPAM solid particles for 2 min and then pour out, and then pass the crushed CPAM solid particles through a 100-mesh standard sample sieve to get CPAM fine powder to be used.

Then, add a certain amount of organic bentonite in white oil, using a high-speed homogenizer to emulsify and stir for 2 min to be used. According to a certain ratio, the CPAM fine powder is added to the emulsified white oil, while adding a certain amount of fumed silica, stirring and mixing well. Finally, add two kinds of emulsifying and dispersing agents of Span 80 and CTAB, and use the high-speed homogenizer to emulsify and disperse at high speed for 10 min, then the stable CPAM suspension is obtained.

2.3. Performance Evaluation Methods for Suspension

2.3.1. Evaluation Method of Solubility

Non-Newtonian fluid rheological performance test: Take a certain volume of non-Newtonian fluid, fill it into a special measuring cup for viscosity testing, record the readings of the six-speed rotational viscometer at different speeds, and use the following formula to calculate the rheological parameters:

where:

R600 = the reading of the viscometer at 600 r/min (dia);

R300 = the reading of the viscometer at 300 r/min (dia);

AV = apparent viscosity (mPa·s);

PV = plastic viscosity (mPa·s);

YP = yield point (Pa).

Dissolution time test: Under the speed of 200r/min, a certain mass of suspension was slowly added dropwise to the beaker containing deionized water, and the apparent viscosity value of the solution was recorded at intervals until the apparent viscosity value no longer increased, which was the dissolution time for the sample to fully form an aqueous solution.

2.3.2. Evaluation Method of Stability

A certain volume of CPAM suspension was placed in a test tube and the height from the bottom of the test tube to the liquid surface was recorded as L1, and after storing the test tube at room temperature for 1 day, 3 days, and 7 days, the height of the separated supernatant was recorded as L2, and the following formula was used to calculate the storage separation rate of the suspension:

where:

S = storage separation rate (%);

L1 = height of the suspension (cm);

L2 = height of separated supernatant (cm).

A certain mass of CPAM suspension was weighed and recorded as M

1, poured into a centrifuge tube and sealed, placed into a high-speed centrifuge and then centrifuged at 2000 r/min for 30 min, the mass of the centrifuged supernatant was weighed and recorded as M

2, and the following formula was used to calculate the centrifugal separation rate of the suspension:

where:

C = centrifugal separation rate (%);

M1 = height of the suspension (g);

M2 = height of separated supernatant (g).

2.3.3. Evaluation Method of Flocculation and Purification Performance

The simulated wastewater preparation: weighing a certain mass of diatomite, adding a certain volume of tap water, using a high-speed mixer, and mixing well to prepare a simulated wastewater with a turbidity of about 1,000 NTU; The oilfield wastewater was taken from the combined wastewater treatment stations of the Oilfield of PetroChina Daqing, such as La-I-1, Xing-1, and Xing-20.

Wastewater turbidity removal rate test: first calibrate the turbidimeter with 400 NTU standard solution. After the reading of the turbidimeter is stable, take a certain volume of wastewater and put it into the test bottle of the turbidimeter. The original turbidity of the wastewater is recorded as U

1; Add a certain amount of flocculant to the wastewater, stir thoroughly and let it stand for 2 minutes. Take the upper clear liquid and test its turbidity as U

2. Use the following formula to calculate the turbidity removal rate of the flocculant on the wastewater:

where:

T = turbidity removal rate (%);

U1 = turbidity of original wastewater (NTU);

U2 = turbidity after turbidity removal (NTU).

2.3.4. Optical Microscope

The slides and coverslips were first cleaned using ethanol and then dried in an oven at 85°C. Samples of the CPAM suspension were taken with a dropper, a drop was placed on the slide and then the coverslip was covered and the suspension sample was observed using the optical microscope Olympus CX-43 at different magnifications.

3. Results and Discussion

3.1. Influencing Factors of the Suspension

3.1.1. Effect of the Separation Agent

The finer the polymer particles are, the easier it is to agglomerate, in order to prevent the fine CPAM particles in the water to form a "fish-eye", it is necessary to add a separation agent to disperse the CPAM particles. And the F-silica [

24,

25] has the characteristics of small particle size, large specific surface area and strong adsorption, which can be effectively adsorbed on the surface of CPAM particles, making the suspension more stable[

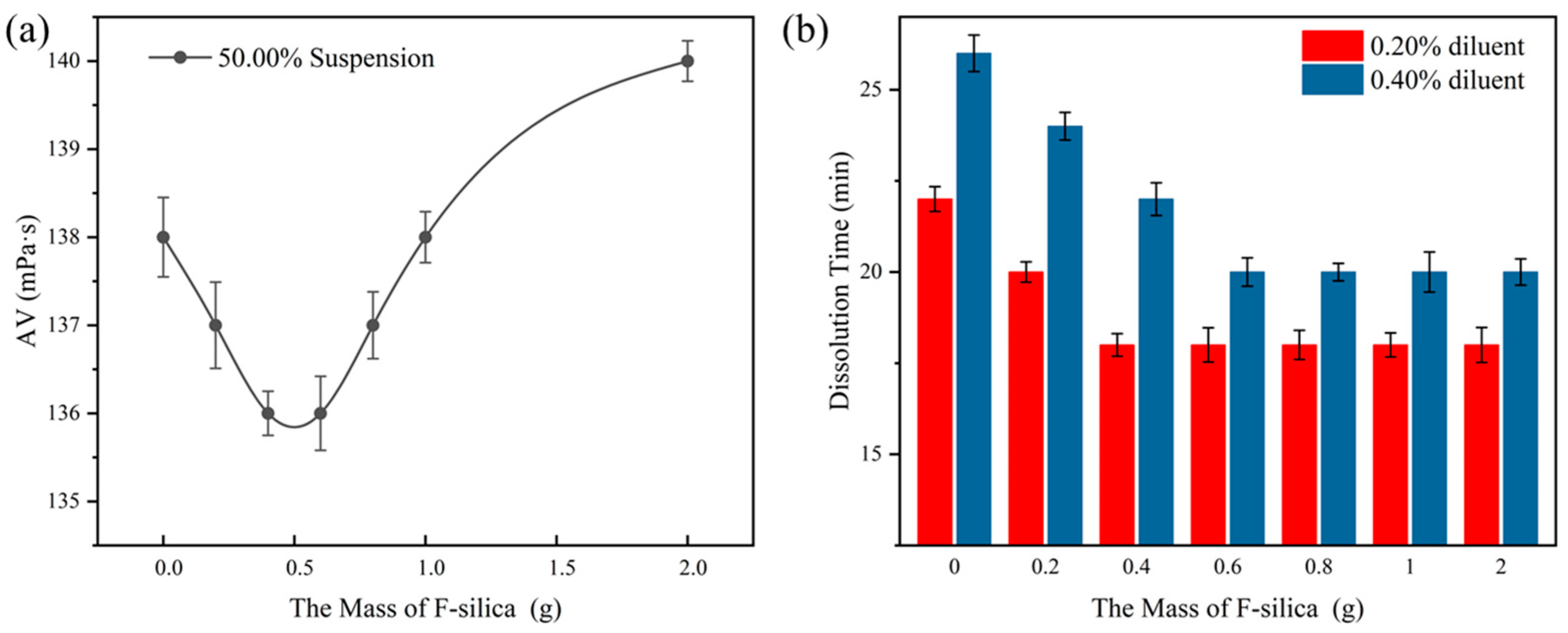

26]. In this study, different masses of F-Silica were added to the suspension to test the apparent viscosity of the suspension and the dissolution time of different concentrations of diluent, and the results are shown in

Figure 1.

As can be seen from

Figure 1a, the apparent viscosity of the suspension showed a trend of decreasing and then increasing with the increase in the mass of F-Silica, and the apparent viscosity of the suspension reached a minimum of 136.00 mPa·s at its addition of 0.40 g/60.00 g. This is due to the fact that with the addition of F-Silica, the overall structure of CPAM particles in the suspension is fluffier and easier to flow, but with the excessive addition of F-Silica, the internal friction between particles increases, which makes it difficult for the particles to slide in the suspension, thus increasing the apparent viscosity of the suspension. As can be seen from

Figure 1b, the addition of F-Silica can indeed reduce the dissolution time of the suspension in water, and the complete dissolution time of the 0.40% concentration diluent is reduced from 26.00 min to 20.00 min, but the addition of F-Silica is more than 0.60 g/30.00 g, and the dissolution time is not further reduced. This is because the presence of F-Silica makes there a barrier between the polymer fine particles, which is not easy to agglomerate in water and is conducive to dissolution; The F-Silica adsorbed on the surface of polymer particles only plays an isolation role, and does not accelerate the diffusion rate of particles in water, so the amount of F-Silica additive selection of 0.40 g / 60.00 g is appropriate.

3.1.2. Effect of the Emulsifying and Dispersing Agent

In this study, WO was used as the solvent of the suspension, but WO could not be dissolved in water, so it was necessary to add surfactants with hydrophilic and non-hydrophilic groups to the suspension, so that WO could be quickly dispersed and dissolved in water, and at the same time to promote the rapid diffusion of polymer fine particles in water. Both the type and amount of surfactant added affects the emulsification and dispersion of WO, in this study, 1.00 g/60.00 g of different types of surfactants were added to the suspension and then the complete dissolution time of the suspension in water was tested and the results are shown in

Figure 2.

As shown in

Figure 2a, it can be seen that the emulsification effect of SDS and SDBS on WO is not well, and it does not emulsify and disperse WO in water, resulting in no improvement in the dissolution time of the suspension; whereas Tween80 and Span60 have some emulsification effect, which can accelerate the dissolution of the suspension to a certain extent; the emulsification effect of Span80, CTAB and OP-10 on WO is Obviously, the dissolution time of the suspension in water was obviously accelerated, and the shortest dissolution time was 18.00 min. Since the use of OP emulsifiers is restricted by relevant regulations due to their harmful effects on the environment [

27], CTAB and Span80 were used as the main and auxiliary emulsifiers for the suspension from the perspective of environmental friendliness.

After Span80/CTAB was added to the suspension at different mass ratios, the dissolution time of the 0.4% diluent was tested and the results are shown in

Figure 2b. It can be seen that when the mass ratio of Span80 : CTAB = 1 : 1, the apparent viscosity of the diluent reaches the maximum value of 11.00 mPa·s in the shortest time, which takes only 16.00 min. This is because under the synergistic effect of Span80 and CTAB, after the suspension is added to water, WO molecules wrapped around the surface of CPAM fine particles are rapidly emulsified and dispersed in water, and the surface of the polymer particles comes into rapid contact with water molecules to achieve rapid dissolution.

3.1.3. Effect of the Rheology Modifier

The density of the WO used in this study is about 0.85 g/cm

3, while the density of the CPAM particles is about 1.32 g/cm

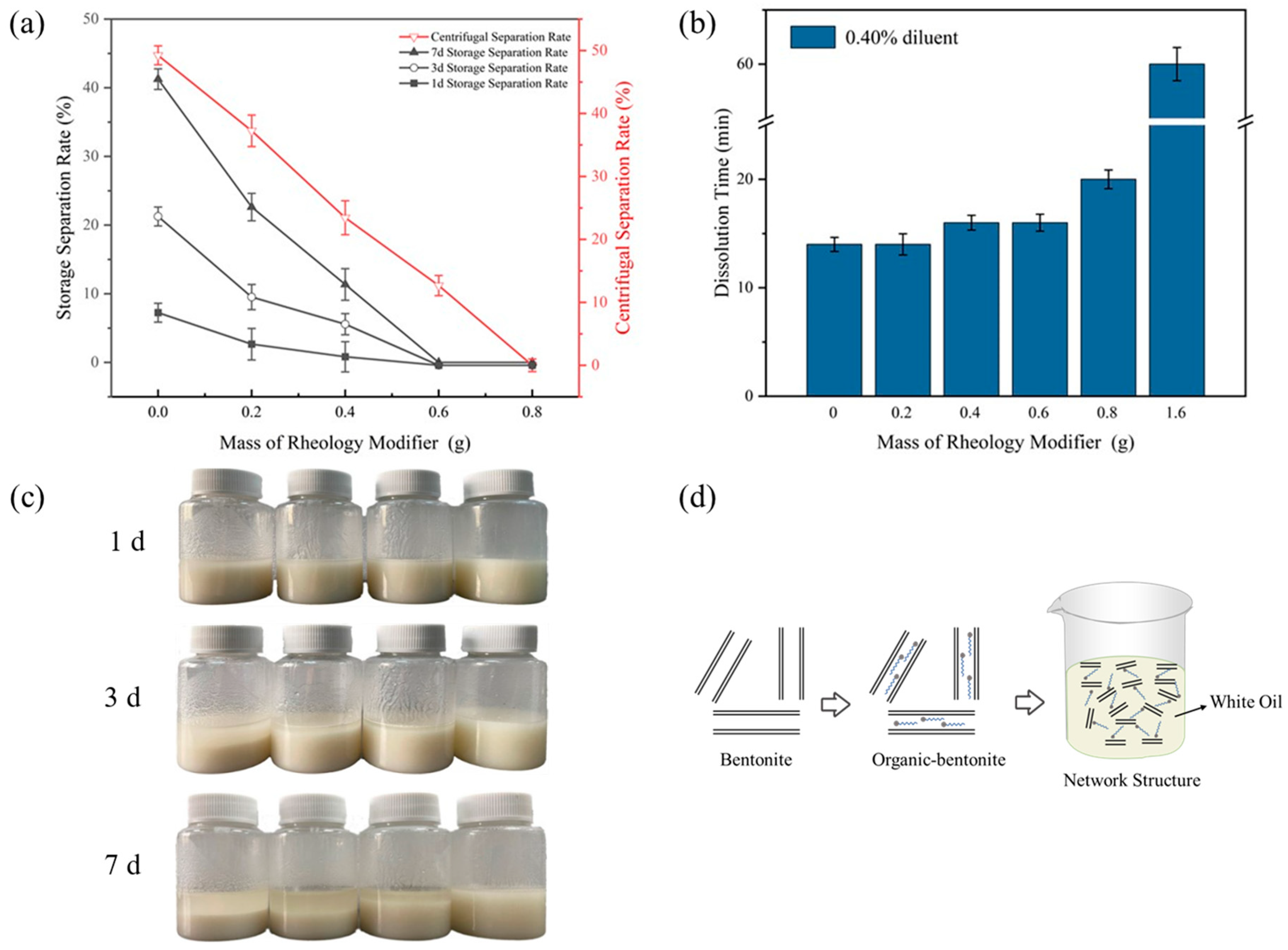

3, and the polymer particles added to the WO will be directly settled, so it is necessary to improve the shearing force of the WO. In the field of oilfield chemical drilling, bentonite is modified into organic bentonite (O-Bent), which can be dispersed and swelled in WO to form a spatial network structure and increase the viscosity and shearing force of oil-based drilling fluids (

Figure 3d), which is used to enhance the cuttings transportation of drilling fluids [

28,

29,

30]. Therefore, in this study, different masses of O-Bent were firstly added to the suspension as a rheology modifier , and then the rheology and separation rate of the suspension were tested, and the experimental results are shown in

Table 2 and

Figure 3.

As can be seen from

Table 2, with the increase in the addition of O-Bent, the viscosity and dynamic shear of the suspension are significantly improved, but when the mass of the rheology modifier is 1.60 g/60.00 g, the suspension becomes gelatinous and difficult to flow, and it is difficult to disperse after adding to the water, which indicates that the addition of the rheology modifier should not be too much. As can be seen from

Figure 3a, when the mass of the rheology modifier was 0.60 g/60.00 g, the suspension was storage for seven days without separation, which indicates that when stored at room temperature, the O-Bent can provide the solvent with enough shear force so that the solvent can suspend the CPAM particles. When the mass of the rheology modifier is 0.80 g/60.00 g, the suspension did not separate when stored at room temperature for 7 days, nor did it separate when centrifuged at 2000 r/min for 30 min, but the apparent viscosity of the suspension is higher, and the diffusion of the suspension is slower after the drop is added to the water, resulting in a longer time for the complete dissolution of the suspension in the water (as shown in

Figure 3b), and the comprehensive consideration of the stability and dissolvability, the mass of rheology modifier is 0.60 g/60.00 g is more appropriate.

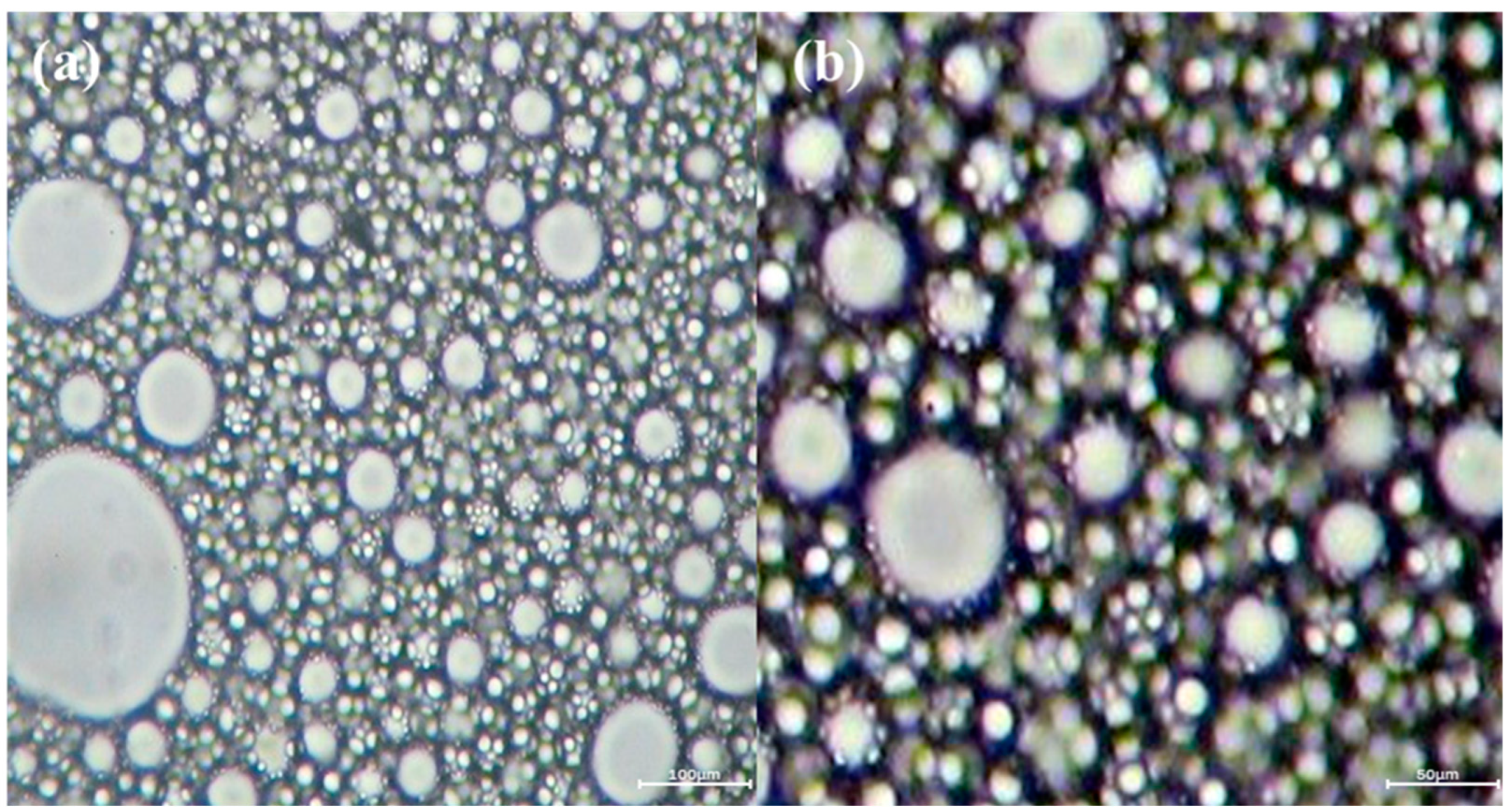

As can be seen from

Figure 4, the size of most polymer particles in the suspension is < 100 μm, and the polymer particles are uniformly distributed in the suspension, with obvious boundaries between the particles, and there is no aggregation of the particles to precipitate, which indicates that the rheology modifier does play a role in improving the shear force, so that the suspension has enough shear force to suspend the polymer particles. In addition, it is obvious that there are many fine particles attached to the surface of the polymer particles, which indicates that the separation agent F-Silica is indeed adsorbed to the surface of the polymer particles, making the polymer particles dispersed from each other.

Considering all the influencing factors, the proportion of each component of the suspension was obtained as shown in

Table 3, and the suspension prepared according to this proportion can have good suspension stability and can be completely dissolved in a short time.

3.2. Comparison of the Products Performance

3.2.1. Comparison of the Dissolution Performance

In this study, the original particles of the CPAM, the fine particles of the CPAM crushed to 100 mesh, and 50% content of the CPAM suspension were prepared into different concentrations of diluent, and the rheology and complete dissolution time of the diluent were tested, and the results are shown in

Table 4.

As can be seen from

Table 4, CPAM fine particles are easy to form "fish eyes" and difficult to dissolve in water no matter how much concentration diluent is prepared; at 0.40% diluent, the AV value began to decline, but the formed "fish eyes" still failed to dissolve completely. While the CPAM original particles start to appear "fish-eye" when the concentration reaches 0.40%, making the dissolution time more than 120.00 min; benefiting from the liquid form of the product, the CPAM suspension can be quickly dispersed in the water, and the CPAM particles have a smaller particle size, so the dissolution time is greatly shortened (0.20% diluent dissolves in 12.00 min). Since the CPAM suspension needs to be mechanically refined during the preparation process, and this process will make part of the molecular chain of the linear polyacrylamide broken, which will lead to a certain degree of viscosity decrease of the diluent. In the preparation of 0.20% CPAM diluent, compared with the original particles, although the apparent viscosity of the suspension decreased by 12.50%, but the dissolution time can be shortened by 83.33%, and does not produce a "fish-eye", the decrease in apparent viscosity is worthwhile.

3.2.2. Comparison of the Flocculation and Water Purification Performance

In this study, we prepared the original CPAM particles into a diluent with a concentration of 0.10%; the CPAM suspension into a diluent with a concentration of 0.20%; and the inorganic flocculant PAC into a diluent with a concentration of 10.00%, and then the prepared diluent was added to the simulated wastewater and the oilfield wastewater according to different dosing amounts, and the turbidity before and after dosing was tested, and then the turbidity removal rate was calculated, as shown in

Figure 5.

As can be seen from

Figure 5a, for the diatomite simulated wastewater, the best turbidity removal effect was achieved at a polymer dosing of 4.00 ppm, and the turbidity removal effects of the CPAM original particles and the CPAM suspension were basically the same, with the optimal turbidity removal rates of 99.60% and 99.50%, respectively; whereas the inorganic flocculant PAC at 140.00 ppm dosage showed the best turbidity removal effect for simulated wastewater and the turbidity removal rate was 98.40% (

Figure 5b), which was lower than the CPAM suspension. For the oilfield wastewater (Xing-1 combined wastewater treatment station), the turbidity removal rate of the CPAM suspension was higher than that of the CPAM original particles under the same polymer dosage, with the optimal turbidity removal rate of the CPAM suspension being 35.60%, and that of the CPAM original particles being 28.40% (

Figure 5c). When the dosage of the CPAM suspension was 1.5 times of the optimal dosage of the CPAM original particles, the turbidity removal rates were basically the same, with 28.40% and 28.20%, respectively. This is due to the addition of cationic surfactants in the suspension, cationic surfactants can assist the polyacrylamide adsorption of suspended particles in the wastewater through electrostatic action, when the more negatively charged suspended particles in the wastewater, the more pronounced this auxiliary flocculation effect [

31]. As shown in

Figure 5d, for the oilfield wastewater from Xing-1 combined wastewater treatment station, the wastewater with the addition of the CPAM suspension was obviously clearer and brighter than that with the addition of the CPAM original particles, and the flocs aggregated out of the wastewater were obviously larger.

3. Conclusions

CPAM suspension prepared from CPAM solid particles, the effective content can reach 50%; No separation in 7 days of storage at room temperature, no separation in 30 min of centrifugation at a speed of 2000 r/min; When diluted in 0.40% aqueous solution, the apparent viscosity was only decreased by 12.5%, but the dissolution time was shortened by 81.40% compared with CPAM solid particles.

The optimum composition ratio of the CPAM suspension was 50.00% CPAM fine powder, 46.87% oil phase solvent, 0.63% isolator, 1.56% emulsifying and dispersing agent, and 0.94% rheology modifier.

The best turbidity removal rate of CPAM suspension for diatomite simulated wastewater is 99.50%, slightly lower than the CPAM solid particles of the best turbidity removal rate of 99.60%, but better than the inorganic flocculant PAC best turbidity removal rate of 98.40%.

The best turbidity removal rate of CPAM suspension for oilfield wastewater is 35.60%, which is better than the best turbidity removal rate of CPAM solid particles 28.40%; when the addition amount of CPAM suspension is 1.5 times of the addition amount of CPAM solid particles, the same turbidity removal and purification effect can be achieved.

Author Contributions

All authors contributed to the conception and design of the study. Material preparation, data collection, and analyses were performed by Z.W., W.L., and S.L. Original draft preparation, Z.W. Review and editing, Z.W. and F.Z. Software, Z.W., Y.Z., and S.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Fundamental Research Funds for the Central Universities, grant numbers No. 2- 9-2019-141 and No. 4-2-2022-002.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available from the authors upon request.

Conflicts of Interest

We declare that this is original research that has not been published previously and has not been under consideration for publishing elsewhere. There is no conflict of interest in the submission of this manuscript, and the manuscript is approved by all authors for publication.

References

- Liu, X.Y. Study on the Synthesis Of NFP Modified Cationic Polyacrylamide and Its Flocculation Performance for Oily Wastewater. Master Thesis, Shaanxi University of Science and Technology, Xian, China, 2020. Available online: https://d.wanfangdata.com.cn/thesis/ChJUaGVzaXNOZXdTMjAyMzAxMTISCFkzNzMyNjI0GghsMjlhd2szbQ%3D%3D (accessed on 16 June 2023).

- Yu, L.; Han, M.; He, F. A review of treating oily wastewater. Arabian Journal of Chemistry 2017, 10, S1913-S1922. [CrossRef]

- Peng, Y.; Liu, Y.; Dai, J.; Cao, L.; Liu, X. A sustainable strategy for remediation of oily sewage: Clean and safe. Separation and Purification Technology 2020, 240, 116592. [CrossRef]

- Jamaly, S.; Giwa, A.; Hasan, S.W. Recent improvements in oily wastewater treatment: Progress, challenges, and future opportunities. Journal of Environmental Sciences 2015, 37, 15-30. [CrossRef]

- Wang, C.; Zhang X.; Ning, P.; Yuan, W.; Bai, J. Research progress and prospect of oil-bearing wastewater treatment technology. Chemical Industry and Engineering Progress 2021, 40, 451-462. [CrossRef]

- Wang, Q. Application of oil-bearing wastewater treatment technology in oilfield. China Petroleum and Chemical Standard and Quality 2023, 43, 193-195. [CrossRef]

- Swerin, A.; Ödherg, L. Flocculation of cellulosic fibre suspensions by a microparticulate retention aid system consisting of cationic polyacrylamide and anionic montmorillonite. Effect of contact time, shear level and electrolyte concentration 1996, 11, 22-29. [CrossRef]

- Lee, K.E.; Morad, N.; Poh, B.T.; Teng, T.T. Comparative study on the effectiveness of hydrophobically modified cationic polyacrylamide groups in the flocculation of kaolin. Desalination 2011, 270, 206-213. [CrossRef]

- Chi, N.; Liu, J.; Lei, M.; Feng L. Preparation of amphiphilic cationic polyacrylamide (CPAM) with cationic microblock structure to enhance printing and dyeing sludge dewatering and condition performance. Environ Sci Pollut Res 2023, 30, 13079–13093. [CrossRef]

- Wang, Y.; He, Y.; Lin, A. Synthesis and optimization of cationic polyacrylamide flocculant PAD. Chinese Journal of Environmental Engineering 2020, 14, 1453-1464. [CrossRef]

- Ji, G.; Xu W. Treatment of oily wastewater by new cationic flocculant. Applied Chemical Industry 2017, 46, 2091-2093,2098. [CrossRef]

- Yan, R.X. Water-soluble polymer; Chemical Industry Press: Beijing, China, 1998; pp. 12–25.

- Aveyard, R.; Binks, B.P.; Clint, J.H. Emulsions stabilised solely by colloidal particles. Advances in Colloid and Interface Science 2003, 100-102, 503-546. [CrossRef]

- Tseng, C.M.; Lu, Y.Y.; El-Aasser, M.S.; Vanderhoff, J.W. Uniform polymer particles by dispersion polymerization in alcohol. Journal of Polymer Science Part A: Polymer Chemistry 1986, 24, 2995-3007. [CrossRef]

- Ahmed, S.F.; Poehlein, G.W. Kinetics of Dispersion Polymerization of Styrene in Ethanol. 1. Model Development. Industrial & Engineering Chemistry Research 1997, 36, 2597-2604. [CrossRef]

- Esquena, J. Water-in-water (W/W) emulsions. Current Opinion in Colloid & Interface Science 2016, 25, 109-119. [CrossRef]

- Fu, Z.B.; Peng, X.H. Preparation conditions for cationic polyacrylamide water-in-water emulsion by dispersion polymerization. Petrochemical Technoloogy 2010, 39, 1140-1145. Available online: https://d.wanfangdata.com.cn/periodical/ChlQZXJpb2RpY2FsQ0hJTmV3UzIwMjMwNDI2Eg1zeWhnMjAxMDEwMDEzGghkNHNpaGh4cw%3D%3D (accessed on 27 March 2023).

- Jahandideh, H.; Ganjeh-Anzabi, P.; Bryant, S.L.; Trifkovic, M. The Significance of Graphene Oxide-Polyacrylamide Interactions on the Stability and Microstructure of Oil-in-Water Emulsions. Langmuir 2018, 34, 12870-12881. [CrossRef]

- Chen, Z.; Zhou, Y.; Chen, C.; Wang, R. Polymerization of cationic polyacrylamide as flocculant with inverse emulsion and its characterization. Journal of Lanzhou University of Technology 2019, 45, 16-21. [CrossRef]

- Yang, B.; Sun, B. Synthesis of cationic polyacrylamide water-in-water emulsion. Contemporary Chemical Industry 2018, 47, 491-493,497. [CrossRef]

- Franklin, E.S.; Ryan, S.T.; Todd, J.O. Water-in-oil polyacrylamide-based microemulsions and related methods. USA Patent US20190169418A1, 6 June 2019. Available online: https://www.freepatentsonline.com/9428630.html (accessed on 16 June 2023).

- Liu, J.; Huang, Z.; Shu, X.; Ren, Q. A preparation method of cationic polyacrylamide water-in-water emulsion. China Patent CN201210536403.9, 3 April 2013. Available online: https://d.wanfangdata.com.cn/patent/ChJQYXRlbnROZXdTMjAyMjEyMDcSEENOMjAxMjEwNTM2NDAzLjkaCHlzcmV2N3Fi (accessed on 16 June 2023).

- Wang, Q.; Qin, X.; Hu, H.; Zhou, T. A fast dissolving water-in-oil cationic polyacrylamide emulsion preparation method. China Patent CN201010133804.0, 5 October 2011. Available online: https://d.wanfangdata.com.cn/patent/ChJQYXRlbnROZXdTMjAyMjEyMDcSEENOMjAxMDEwMTMzODA0LjAaCG44NmpmbnE5 (accessed on 16 June 2023).

- Gun'ko, V.M.; Mironyuk, I.F.; Zarko, V.I.; Voronin, E.F.; Turov, V.V.; Pakhlov, E.M.; Goncharuk, E.V.; Nychiporuk, Y.M.; Vlasova, N.N.; Gorbik, P.P.; et al. Morphology and surface properties of fumed silicas. Journal of Colloid and Interface Science 2005, 289, 427-445. [CrossRef]

- Xiu, H.; Duan, X.; Zhang, T.; Zhao, Y.; Guo, Z.; Wu, C.; Wang, Y. Determination of physical adsorption water of fumed silica and its relationship with surface silanol concentration. Polymer Materials Science and Engineering 2021, 37, 102-108,149. [CrossRef]

- Huang, Y.; Kobayashi, M. Direct Observation of Relaxation of Aqueous Shake-Gel Consisting of Silica Nanoparticles and Polyethylene Oxide. Polymers 2020, 12, 1141. [CrossRef]

-

SY/T 6787-2010; CNPC Enterprise Standard. Technical requirements of environmental protection for water-soluble oilfield chemical. China National Petroleum Corporation: Beijing, China, 2010. (In Chinese).

- Jordan, J.W.; Hook, B.J.; Finlayson, C.M. The Organophilic Bentonites. II. Organic Liquid Gels. The Journal of Physical and Colloid Chemistry 1950, 54, 1196-1208. [CrossRef]

- Li, Z.B. Emulsion and Organic Clay Dispersion Stability in Oil-based Drilling Fluid. Master Thesis, Shandong University, Jinan, China, 2017. [CrossRef]

- Pan, Y. Research on the Modification Mechanism of Organic Clay Used in Oil-based Drilling Fluids. Master Thesis, China University of Petroleum, Qingdao, China, 2014.

- Chang, M.; Ma, X.; Dong, X.; Fan, Y.; Chen, R. The Synergistic Effects of Al3+ and Chitosan on the Solid–Liquid Separation of Coal Wastewater and Their Mechanism of Action. Polymers 2022, 14, 3970. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).